Похожие презентации:

Modern machine tools

1.

Modern machine tools2.

For the manufacture of any metal part,special processing equipment is used.

Without him not to do either in small

factories or in large enterprises.

Depending on the type of production,

various machines and units are selected

that allow you to perform the most

complex manipulations with metal.

3.

Technological machines are a category of technologicalequipment that makes up a whole complex of various units

that allow processing metal parts both at the preparation

stage and at the final stages, such as grinding.

There are 8 main types of machines that are commonly used

in the modern Metalworking industry. Classification of

technological equipment of this type is carried out by the

type of its impact on metal parts and products.

4.

Modern technological and engineering equipment isdesigned to optimize production.

Innovative developments, in particular numerical

software, allow us to achieve this noble goal. The high

value of this invention is that it is possible to minimize

human participation in the metal processing process,

and this significantly reduces the possibility of

marriage.

Time costs are also reduced – the intelligent

technologies that the units are equipped with allow

several times faster production and processing of parts

and finished products.

5.

The financial side of the issue is also an important factor.Modern software-based machines are configured to use

energy efficiently, and they also have significantly less

impact on the environment, which is important for

consumers, especially for owners of large enterprises.

6.

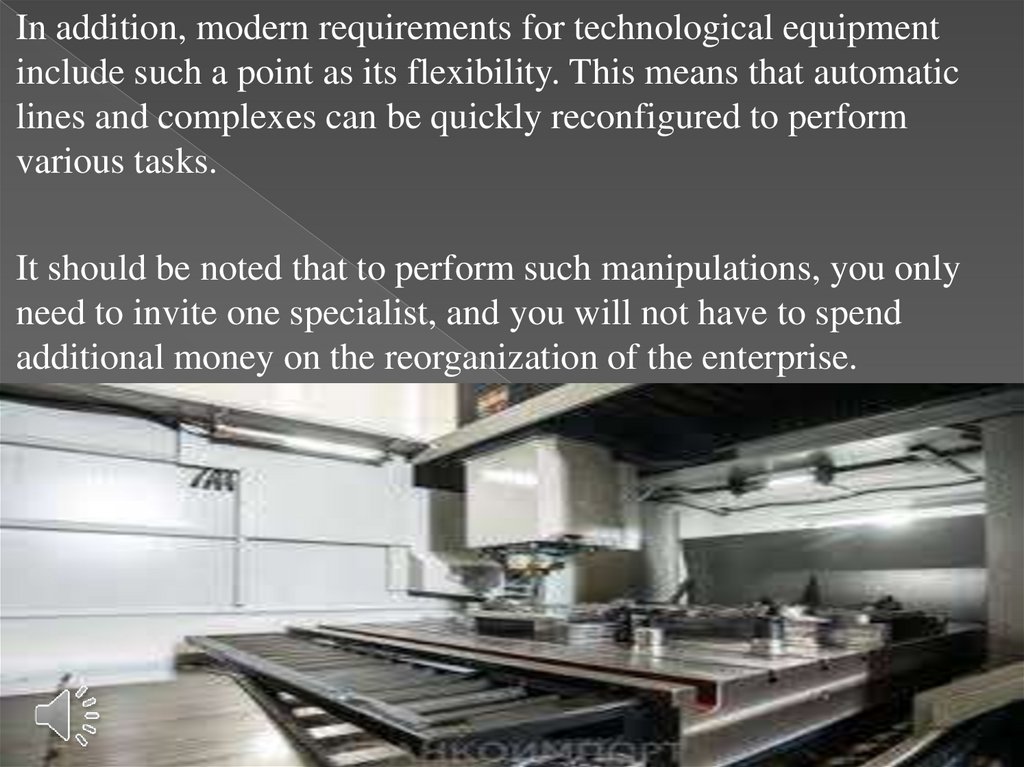

In addition, modern requirements for technological equipmentinclude such a point as its flexibility. This means that automatic

lines and complexes can be quickly reconfigured to perform

various tasks.

It should be noted that to perform such manipulations, you only

need to invite one specialist, and you will not have to spend

additional money on the reorganization of the enterprise.

Английский язык

Английский язык Промышленность

Промышленность