Похожие презентации:

1С:ERP. Company description

1. 1С:ERP

2.

Case study3. Company description

Company which produce tractors:Custom production

Basic configurations

Production on a warehouse

3

4. Scenario

1.When buying complex machinery, there is a concept of "configuration".

• When ordering, you can specify the parameters of the tractor.

• These parameters will affect the cost of the product and the production process.

2.

Order production of a tractor under the client.

• The customer's order for a tractor with certain characteristics.

• Sales officer asks what parameters should be in the tractor and starts this option

configuration in the system. Makes out the order of the client.

• Оn the basis of this order, a production order is created and a tractor is produced

for the customer.

3.

Production to the warehouse.

Release of basic, running machines in advance to the warehouse according to the

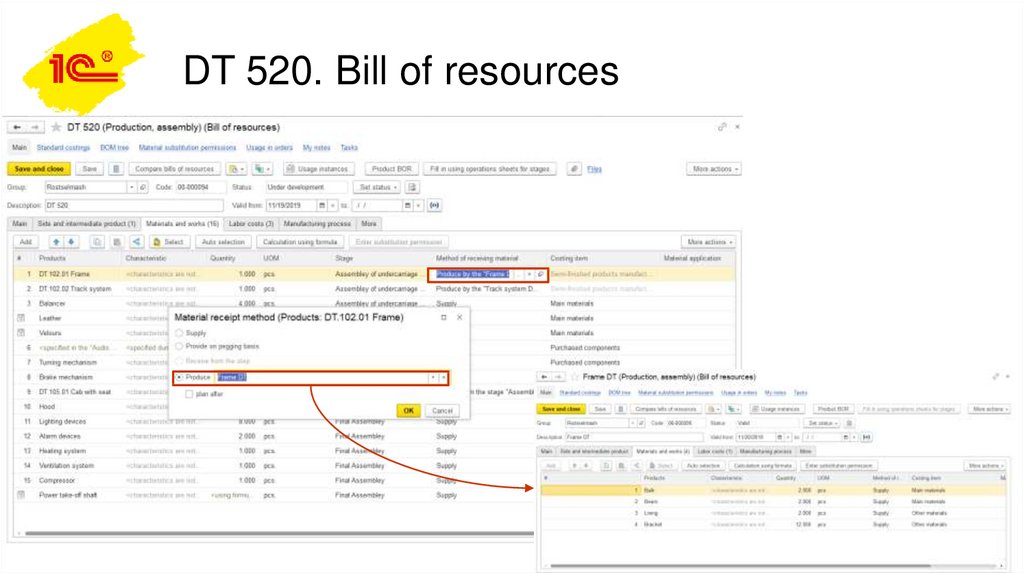

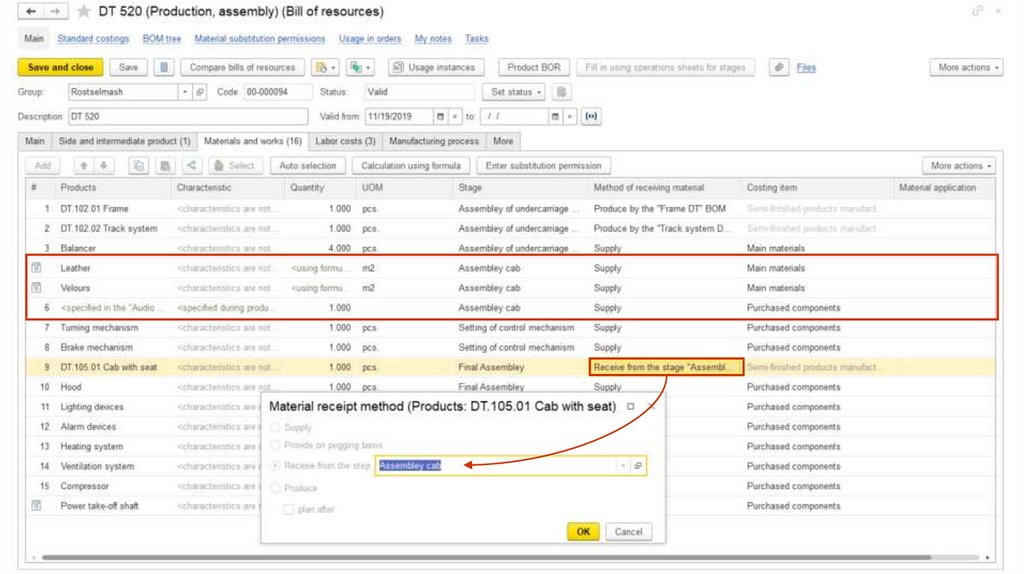

production plan. After receipt of the customer's order, this basic running machine

is equipped to the specific customer and his wishes.

4

5.

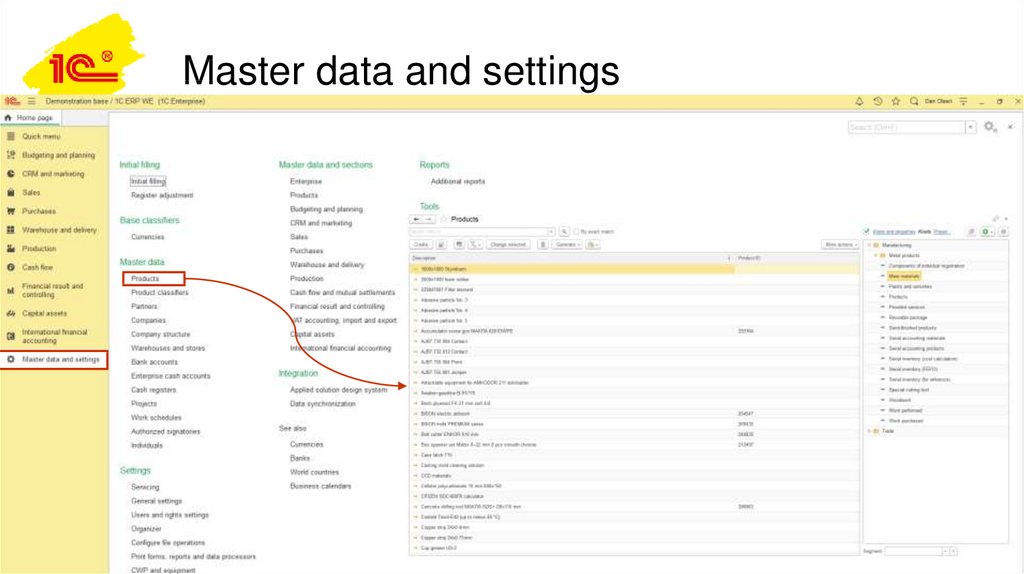

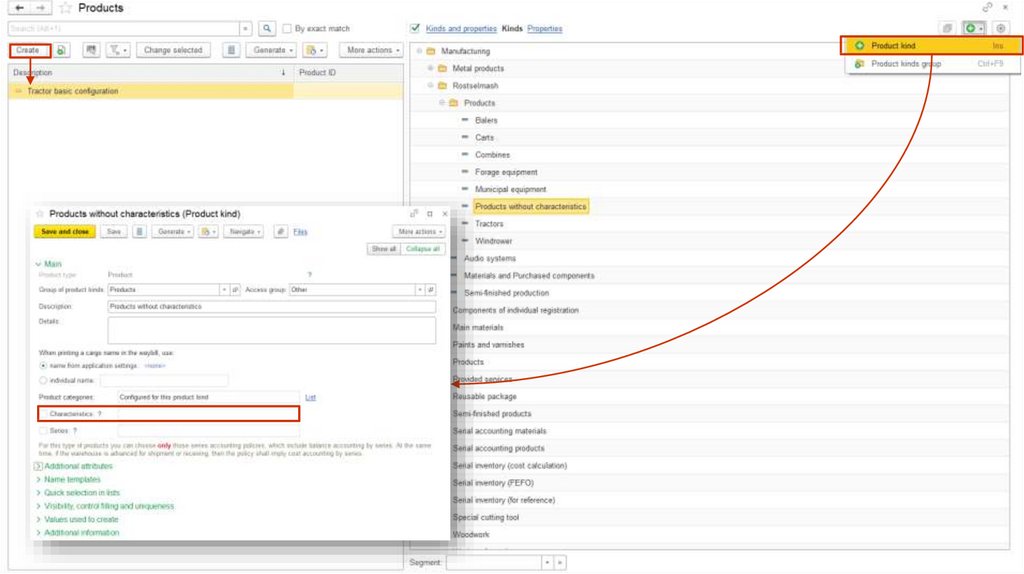

Master data6. Product options

7. Master data and settings

8. Production

9. Production

10. Production

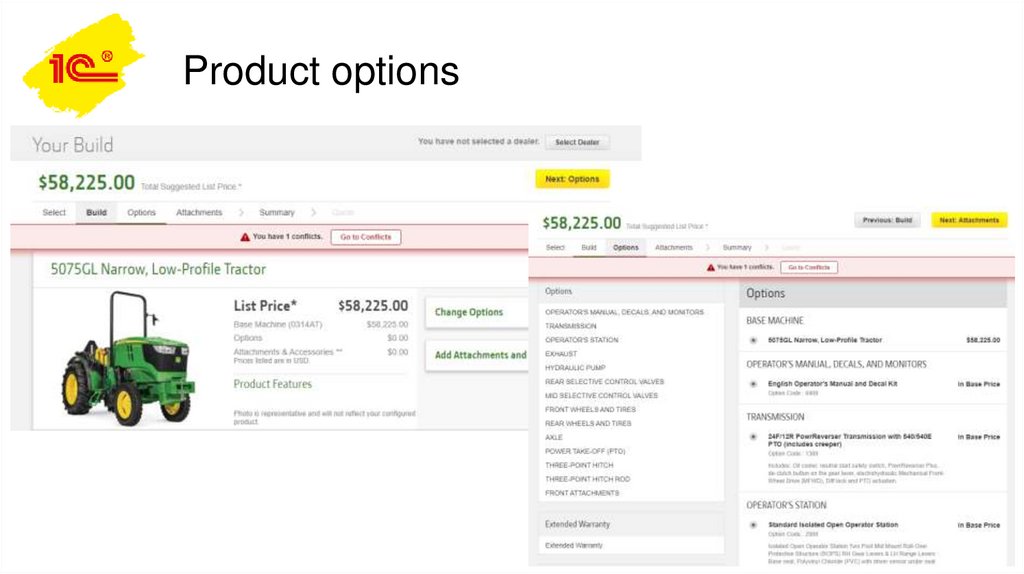

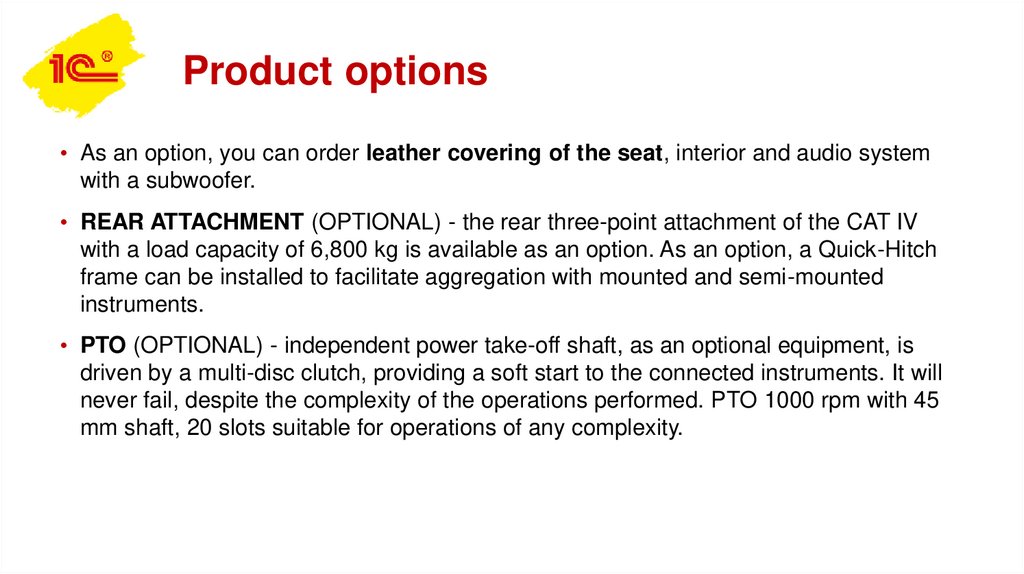

11. Product options

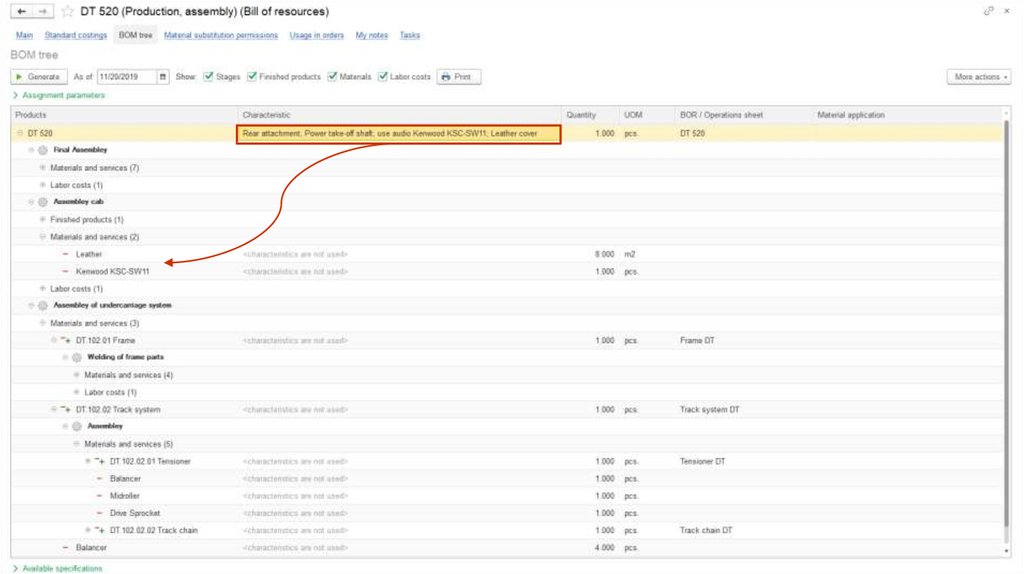

• As an option, you can order leather covering of the seat, interior and audio systemwith a subwoofer.

• REAR ATTACHMENT (OPTIONAL) - the rear three-point attachment of the CAT IV

with a load capacity of 6,800 kg is available as an option. As an option, a Quick-Hitch

frame can be installed to facilitate aggregation with mounted and semi-mounted

instruments.

• PTO (OPTIONAL) - independent power take-off shaft, as an optional equipment, is

driven by a multi-disc clutch, providing a soft start to the connected instruments. It will

never fail, despite the complexity of the operations performed. PTO 1000 rpm with 45

mm shaft, 20 slots suitable for operations of any complexity.

12. Production

13. Production

14. Production

15. Production

16.

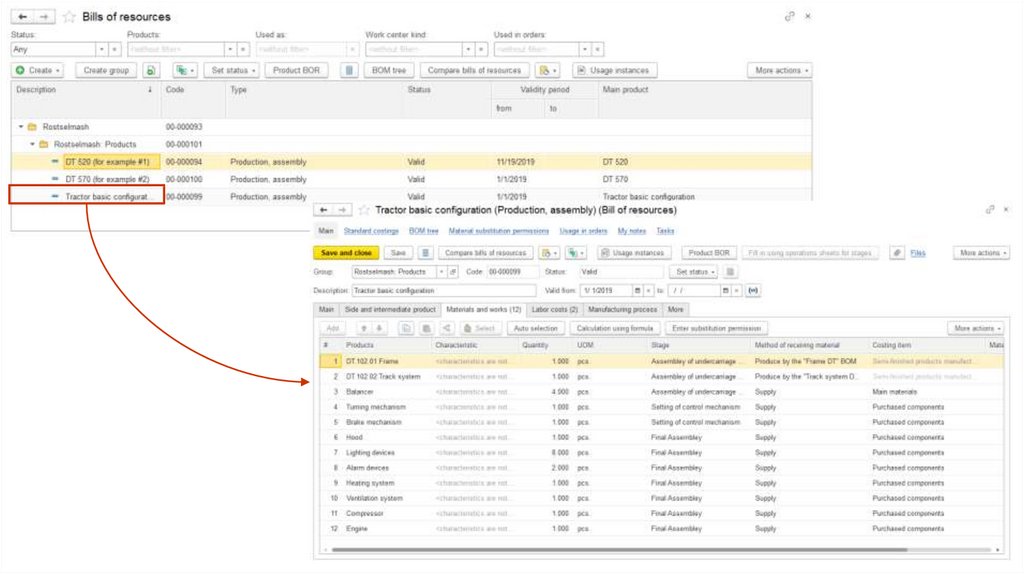

Bill of materials17.

18. Options

19.

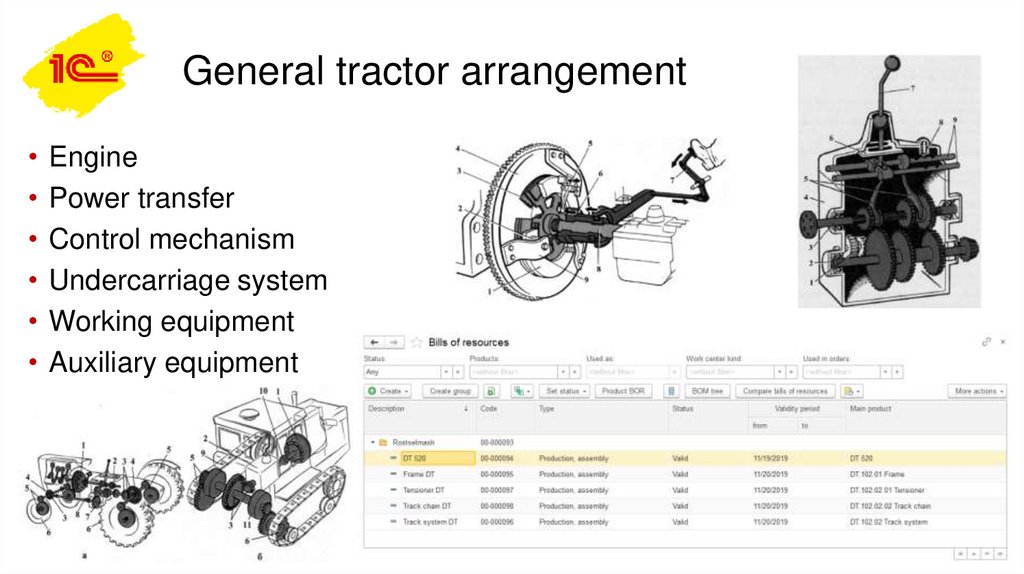

1 out of 10 audio system20. General tractor arrangement

Engine

Power transfer

Control mechanism

Undercarriage system

Working equipment

Auxiliary equipment

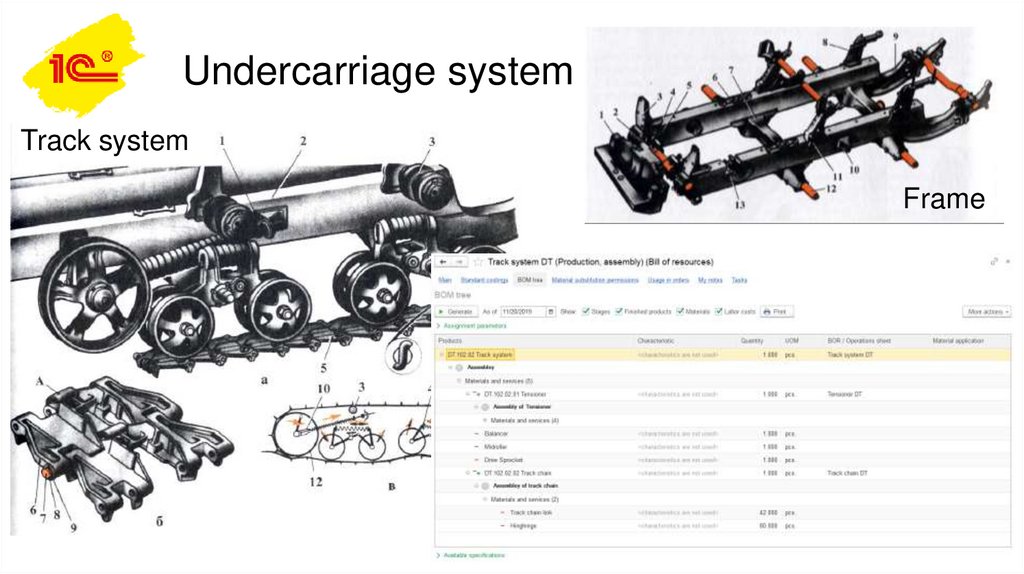

21. Undercarriage system

Track systemFrame

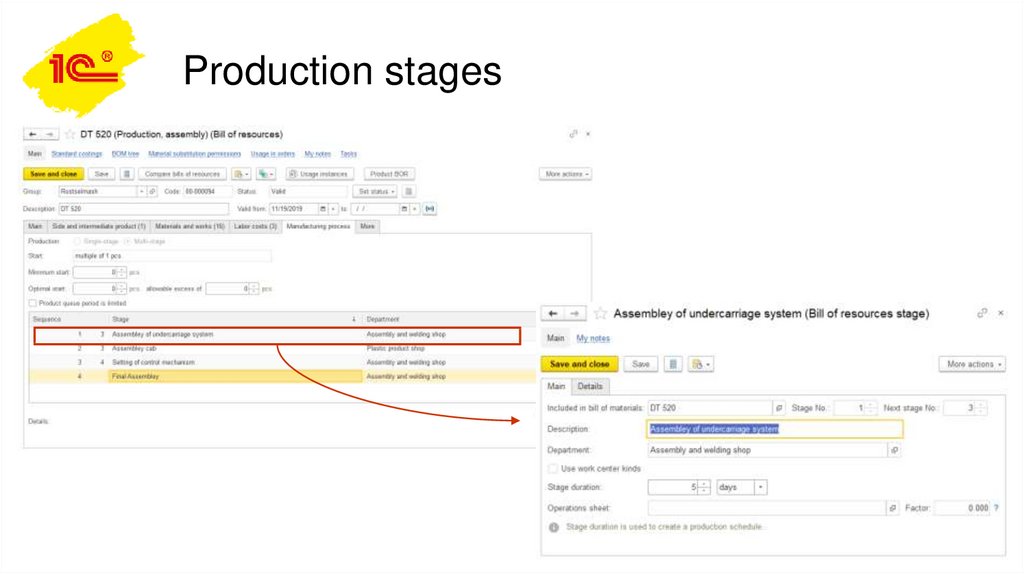

22. Production stages

23. DT 520. Bill of resources

24.

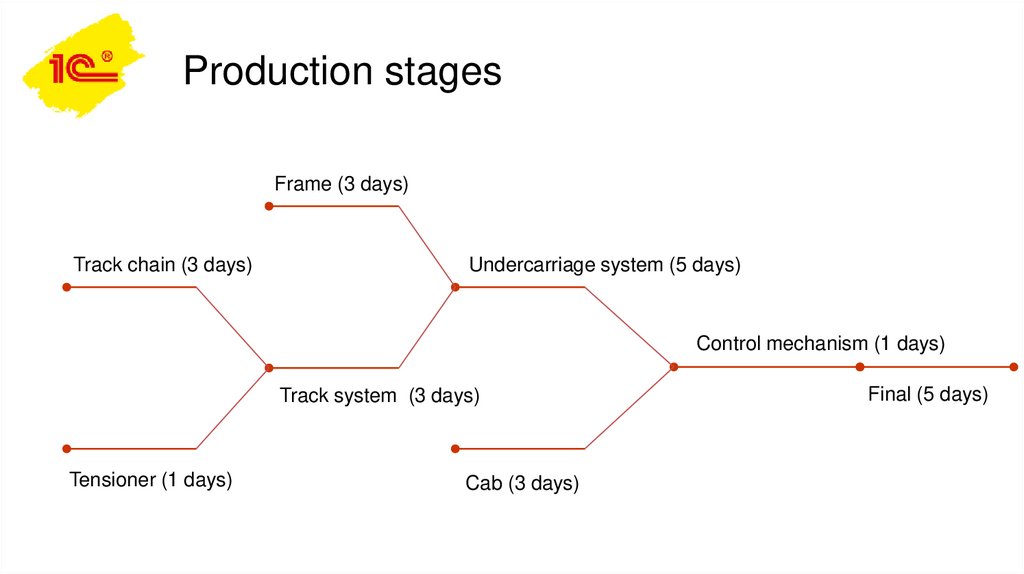

25. Production stages

Frame (3 days)Track chain (3 days)

Undercarriage system (5 days)

Control mechanism (1 days)

Track system (3 days)

Tensioner (1 days)

Cab (3 days)

Final (5 days)

26.

27.

Sales28.

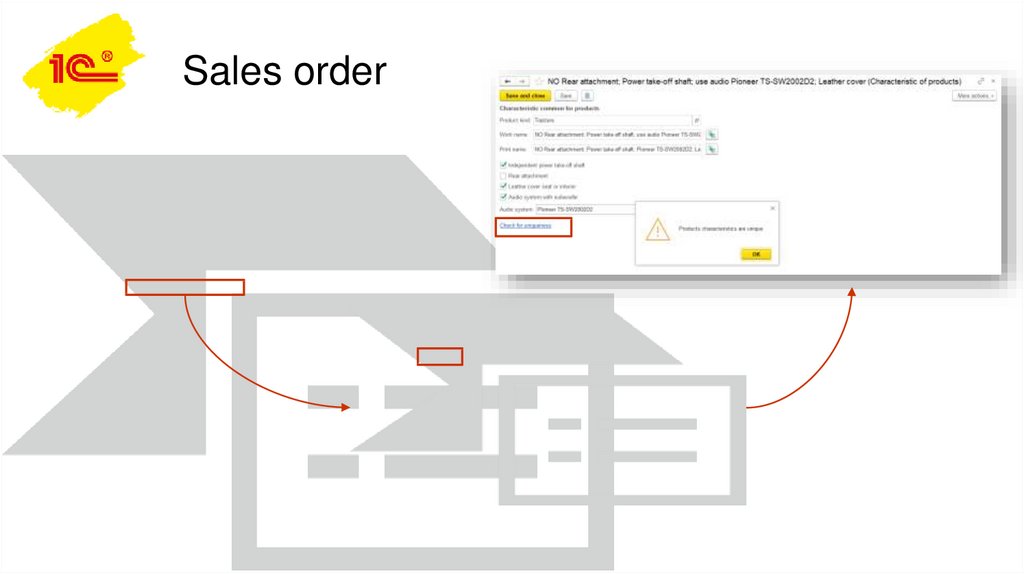

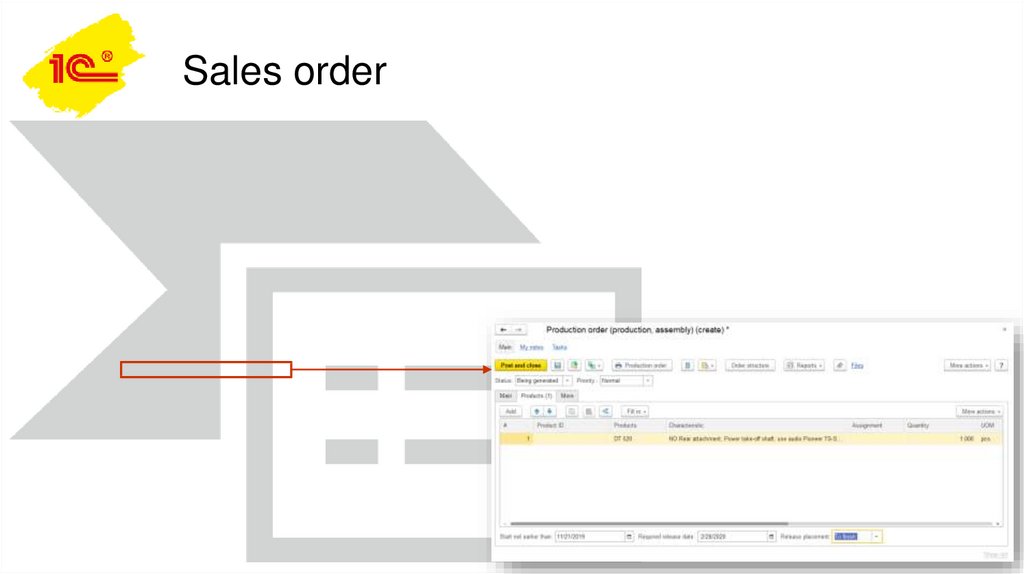

29. Sales order

30. Sales order

31. Sales order

32.

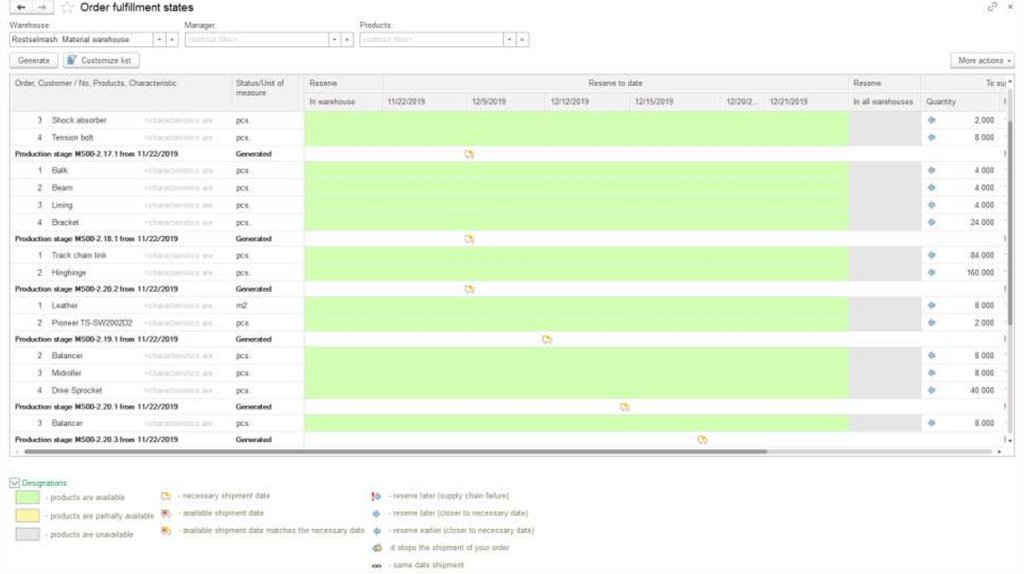

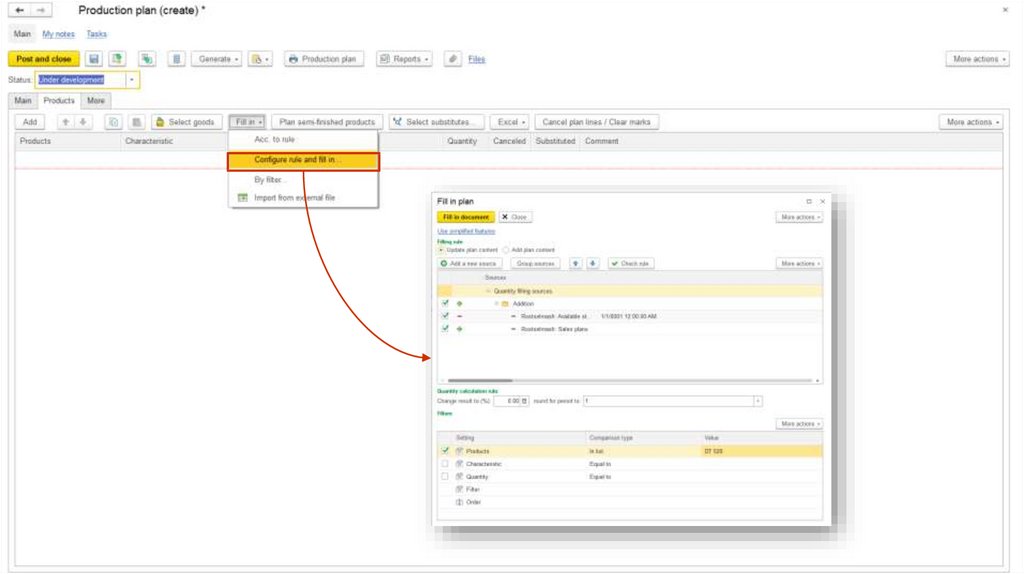

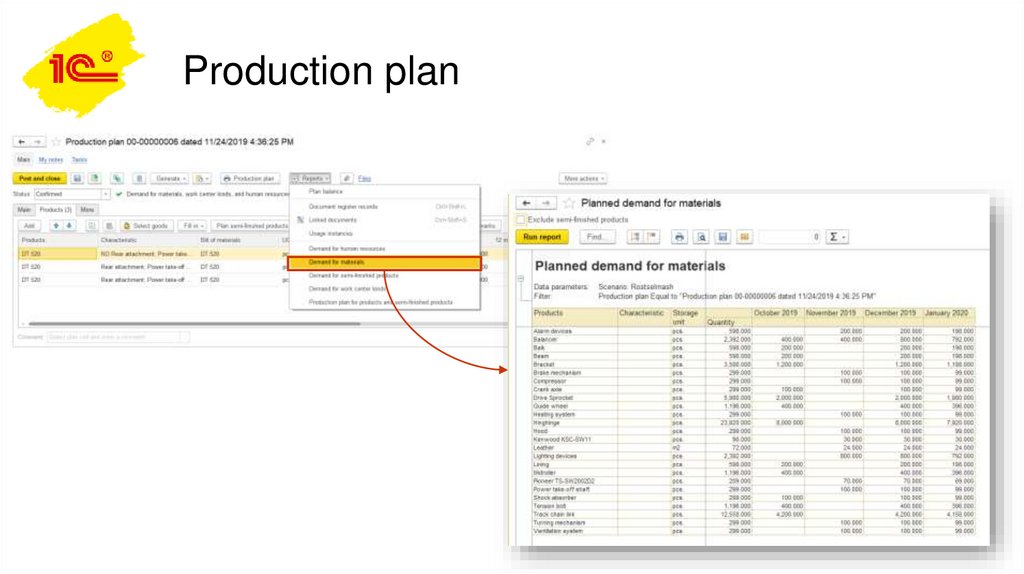

Manufacturing33. Manufacturing

34. Manufacturing

35. Manufacturing

36. Manufacturing

37. Manufacturing

38. Manufacturing

39. Manufacturing

40.

41. Manufacturing

42. Manufacturing

43.

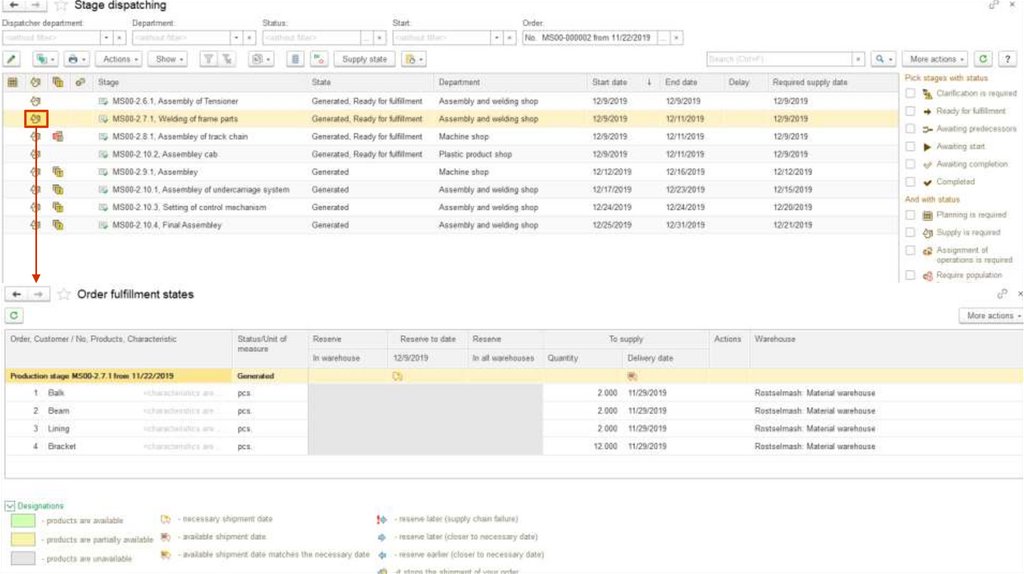

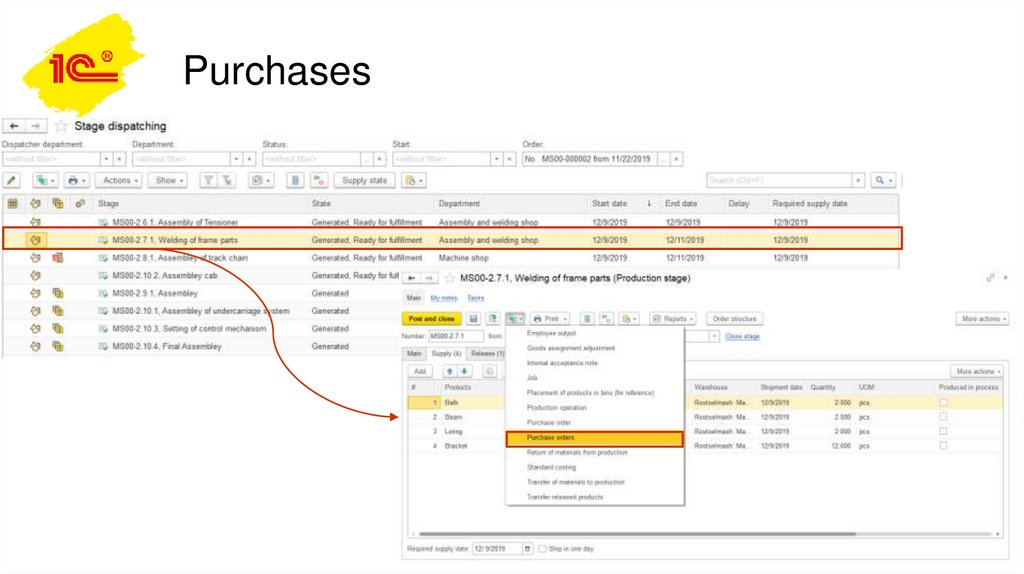

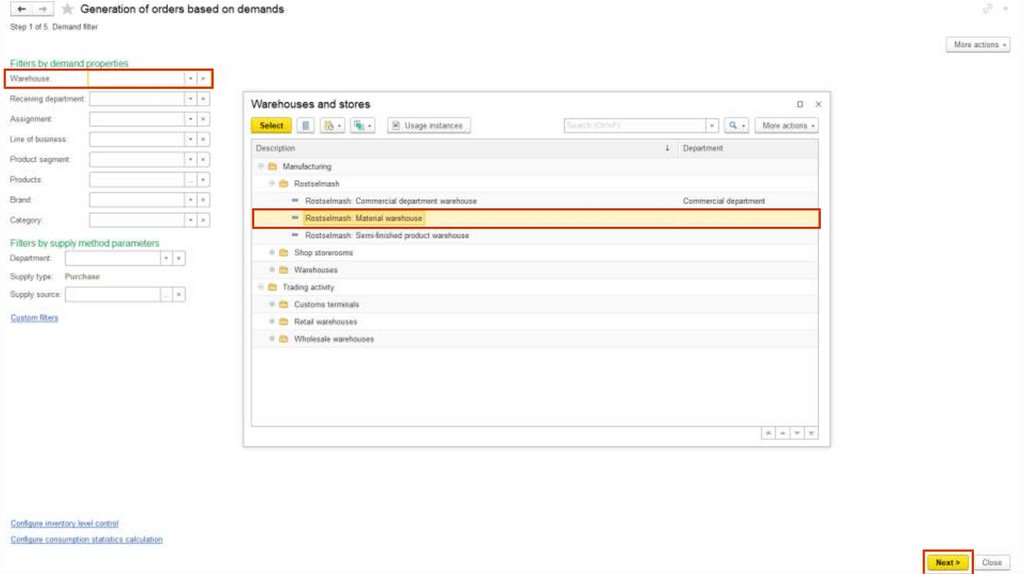

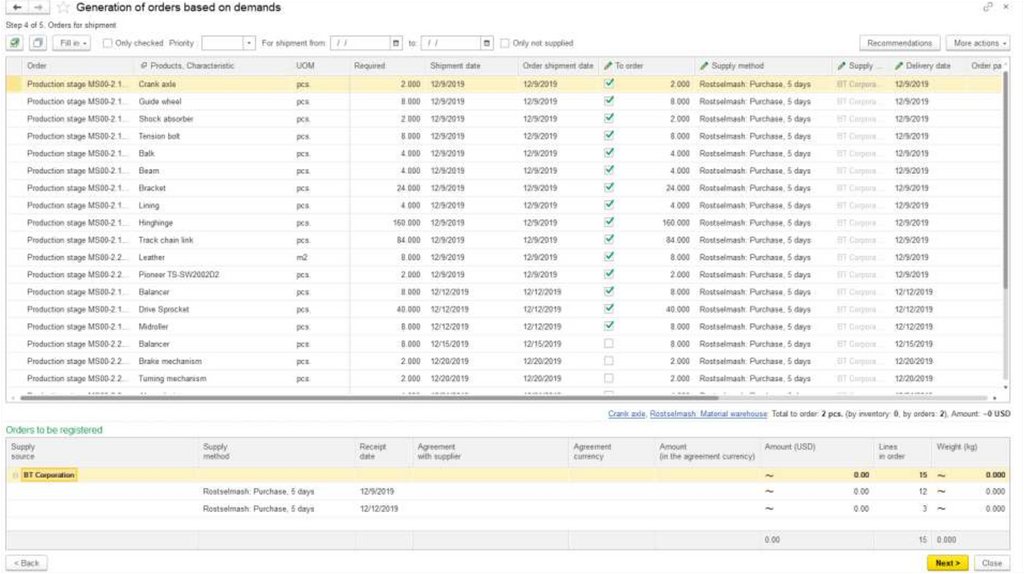

Supply44. Purchases

45. Purchases

4546.

47. Purchases

48. Purchases

4849.

50. Purchases

51.

52.

53.

54. Manufacturing

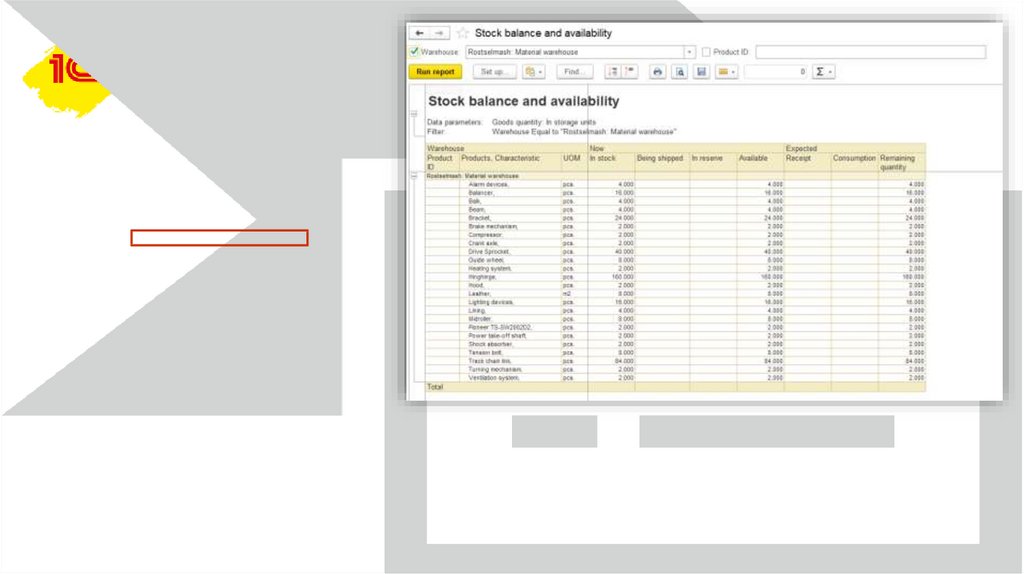

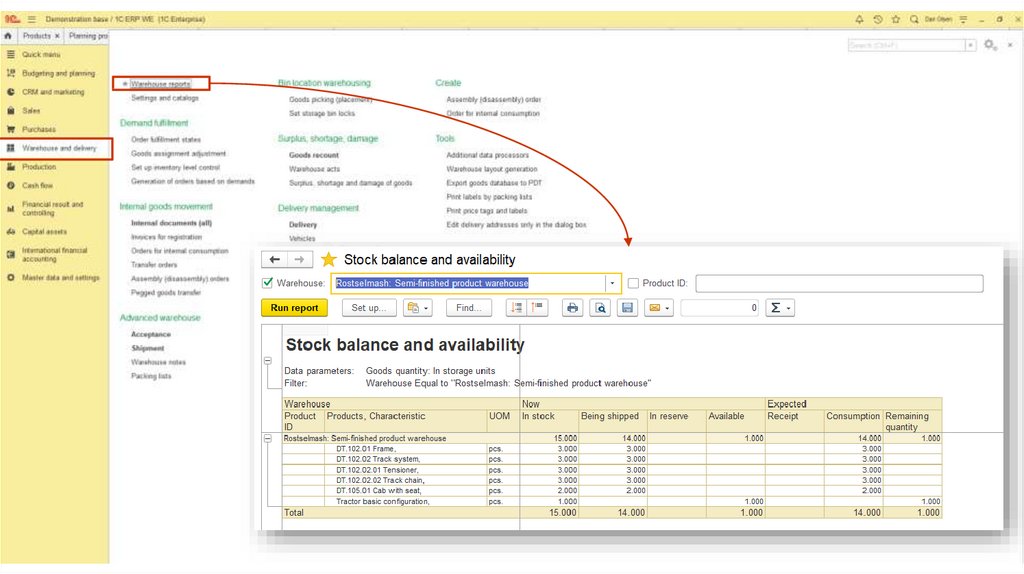

55. Stock

56. Manufacturing

57.

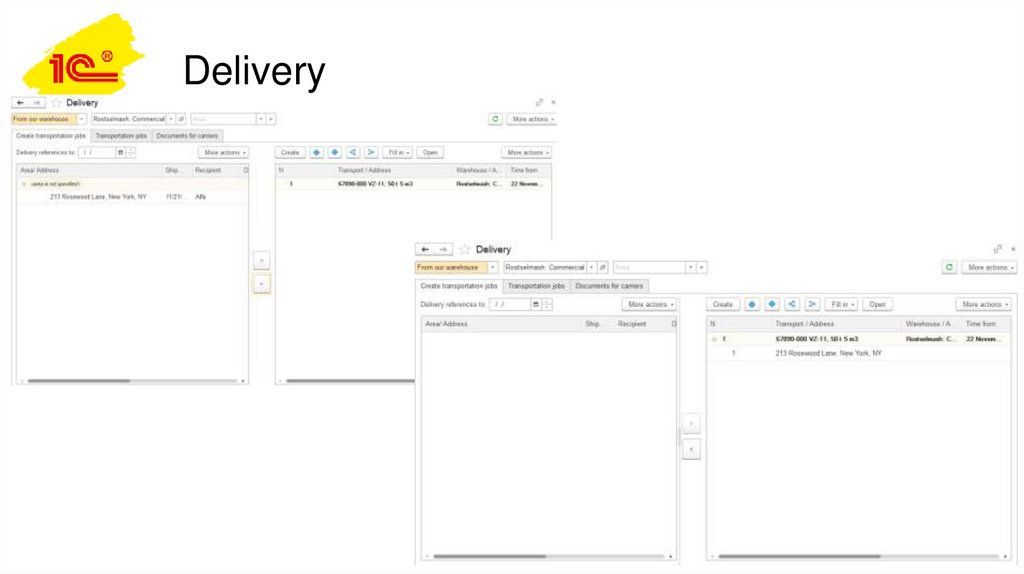

Delivery58. Sales order

59.

60. Delivery

61.

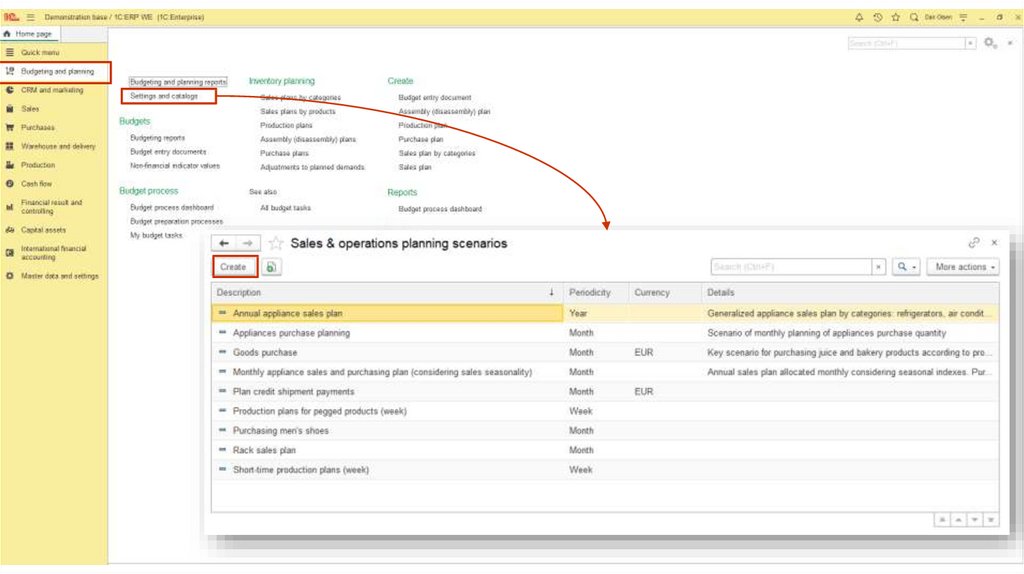

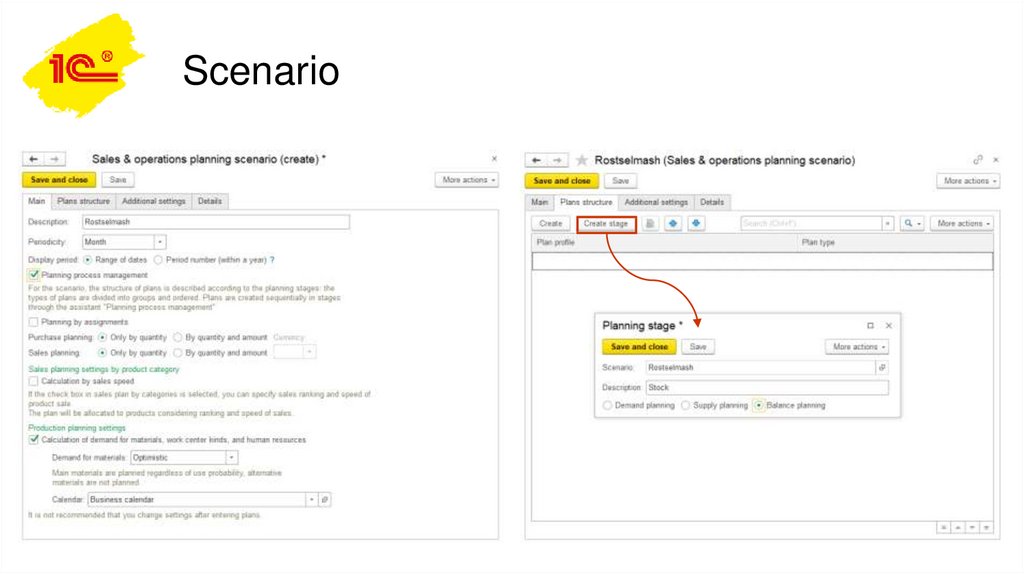

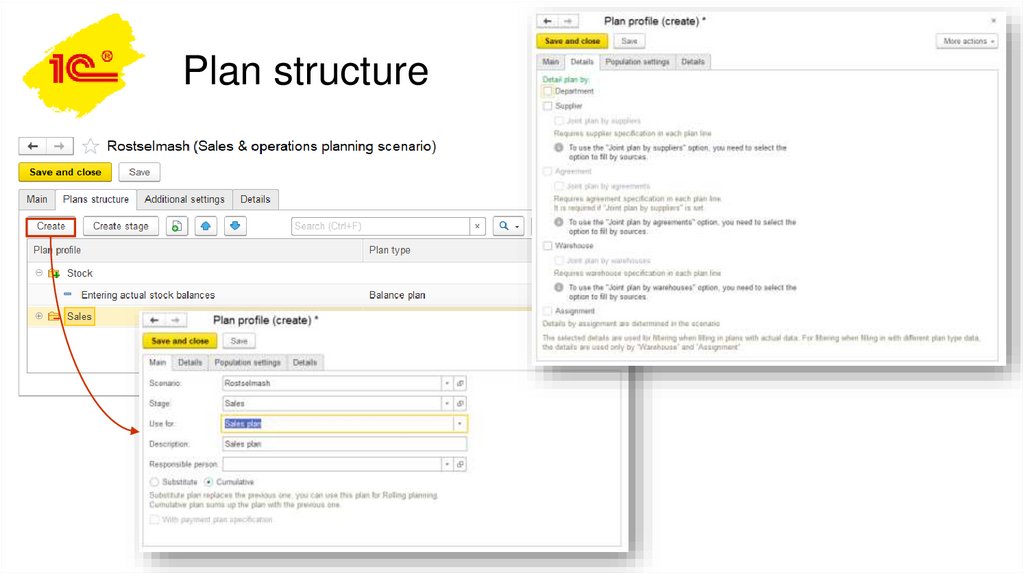

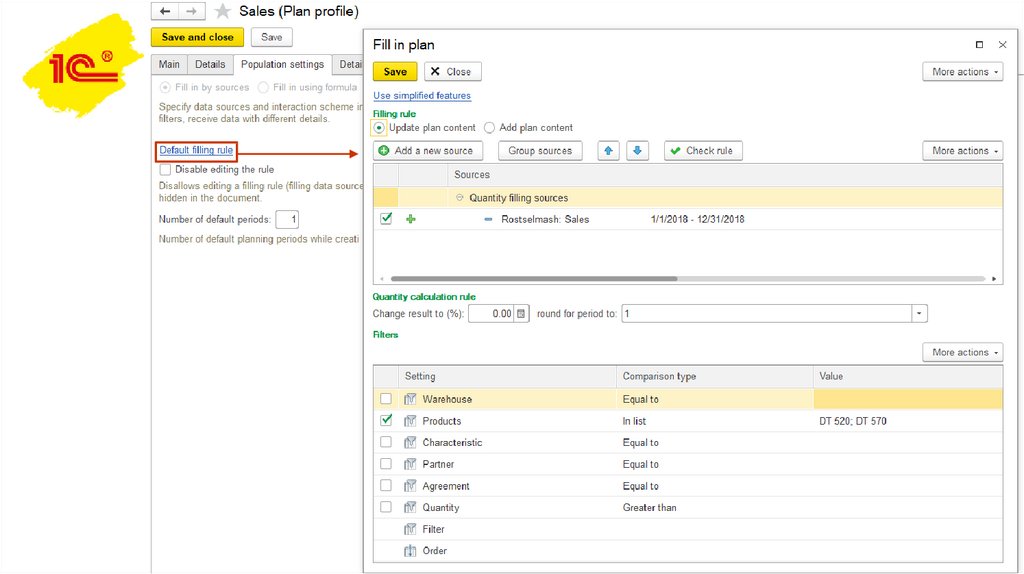

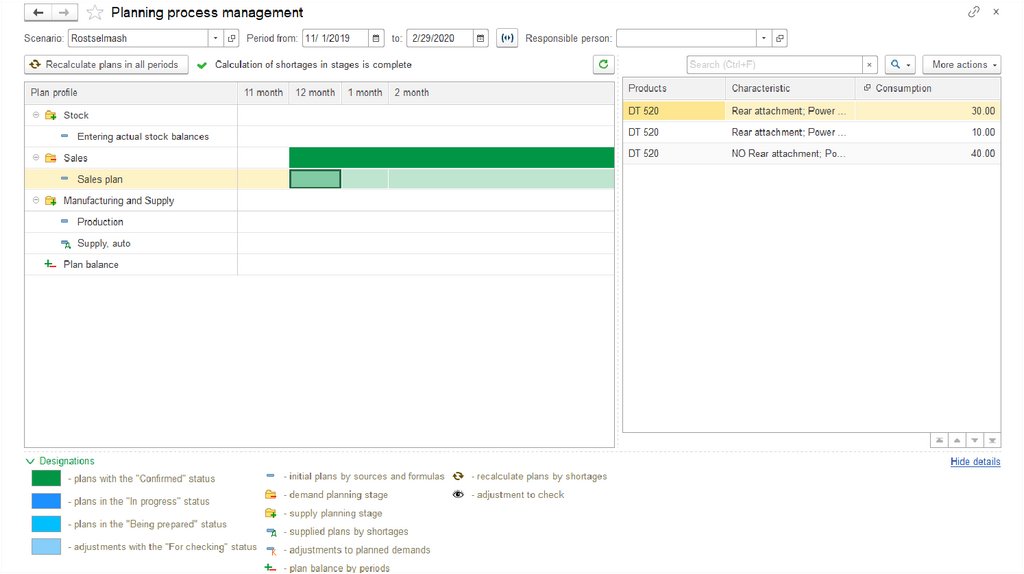

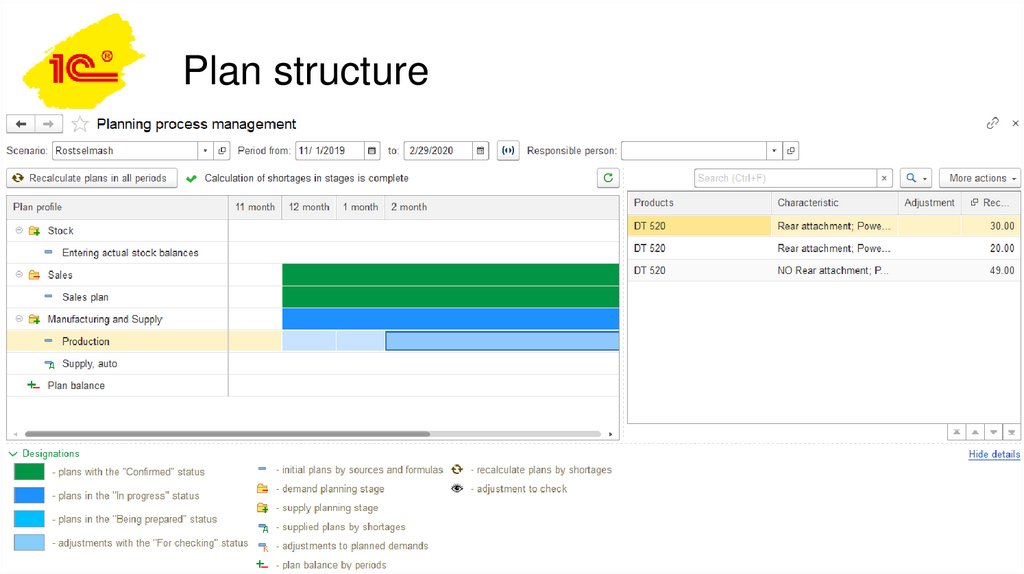

Planning62. Scenario

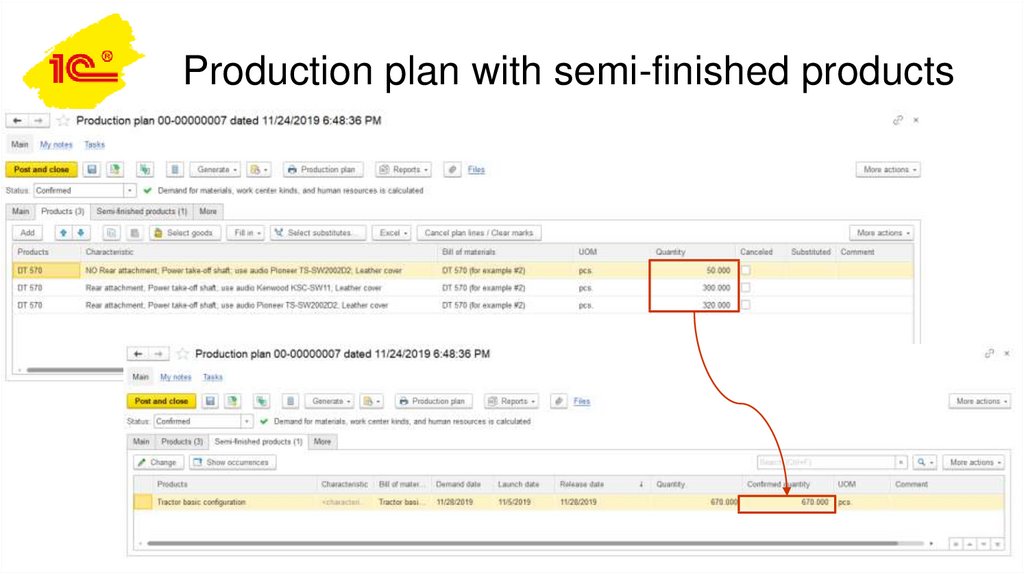

1.Production to the warehouse.

Release of basic, running machines in advance to the warehouse according to the

production plan. After receipt of the customer's order, this basic running machine

is equipped to the specific customer and his wishes.

62

Программирование

Программирование