Похожие презентации:

Bottom mounted freezer type

1.

BOTTOM MOUNTED FREEZER TYPEBASIC MODEL : RL55VE*

MODEL NAME : R

L55VE*/Q*/T*/S*/J*

RL52VE*/S*/W*

RL55TE*/Q*/T*/S*/J*

RL57TE*/Q*/T*/S*/J*

RL52TE*/S*/W*

REFRIGERATOR

RL55VE*/S*/J*

RL52VE*/S*

RL55TE*/S*/J*

RL57TE*/S*/J*

RL52TE*/S*

RL55VQ*

RL55TQ*

RL57TQ*

RL55VT*

RL55TT*

RL57TT*

PRODUCT FEATURE

RL52VW*

RL52TW*

High Efficiency A++, A+

CoolSelect Zone™

7 Inch Touch LCD Display

Handle Lighting

2.

WARNINGIMPORTANT SAFETY NOTICE

The service guide is for service men with adequate backgrounds of

electrical, electronic, and mechanical experience. Any attempt to

repair a major appliance may result in personal injury and property

damage. The manufacturer or dealer cannot be responsible for the

interpretation of this information.

SAMSUNG ELECTRONICS AMERICA, INC.

Technical Service Guide

Copyright ©2009

ll rights reserved. This service guide may not be reproduced in whole or in part in

A

any form without written permission from the SAMSUNG ELECTRONICS Company.

3.

Contents1. PRECAUTIONS (SAFETY WARNINGS)·········································································4

2. PRODUCT SPECIFICATIONS························································································7

3. DISASSEMBLY AND REASSEMBLY············································································14

4. TROUBLE SHOOTING·································································································38

5. PCB DAIGRAM···········································································································162

6. WIRING DIAGRAM·····································································································169

7. CIRCUIT DIAGRAM····································································································175

3

4.

1. PRECAUTIONS (SAFETY WARNINGS)●B

efore attempting a repair of any kind ensure that the appliance is disconnected from the mains electricity

supply.

● Use rated electronic Control equipment.

Make sure to check out ModeL name, Rated voltage, Rated current, Operation Temp, etc.

● Take care not to use excessive force and damage any wiring connectors when disconnecting/reconnecting.

Also ensure that the wiring connectors are placed in their original position and not subject to water

penetration.

●U

pon repair, completely remove dust or other foreign substances from housing, harness, connector, etc.

To prevent fire by tracking, short, etc.

● Check the electronic control system for signs of water damage.

I f there is any kind of trace, take necessary measures such as related component change, insulation

tapping, etc.

● After repair, check out the assembled state of parts.

It should be the same as the original state.

● Check the surrounding conditions.

C

hange the location, if the fridge is located at humid, wet places or the installed state is unstable.

● If needed, ground the fridge.

Especially, if there is a possibility of electric leakage, ground is indispensable.

● Advise the consumer if electrical sockets are overloaded.

●C

heck whether the power cord or the outlet is broken, squeezed, chopped off or heat-deformed.

Replace the power cord/outlet if it is damaged in any way.

● Do not allow consumers to keep food unstable or place bottles in the Freezer Room.

● Do not allow consumers to repair the fridge for themselves.

● Do not allow consumers to keep things except for food.

P

harmaceutical, Chemical substances : These are not possible to be fine-Controlled with a consumer

fridge.

Flammable material (alcohol, benzene, ether, LPG, etc) : possibility of explosion.

4

5.

PRECAUTIONS(SAFETY WARNINGS)Read all instructions before repairing the product and keep to the instructions

in order to prevent danger or property damage.

CAUTION/WARNING SYMBOLS DISPLAYED

Warning

Caution

SYMBOLS

means Prohibition”.

Indicates that a

danger of death

or serious injury

exists.

means Do not disassemble”.

means No contact”.

means The things to

be followed”.

Indicates that a risk

of personal injury

or material damage

exists.

means Power cord should be

unplugged from the consent”

means Earth to prevent Electric

shock”.

Warning & Caution

Pull the power plug out to exchange

the interior lamp of the refrigerator.

● It may cause electric shock.

Use the rated components on the

replacement.

●C

heck the correct model, rated voltage, rated

current, operating temperature and so on.

On repair, make sure that the wires

such as harness are bundled tightly.

●B

undle tightly wires in order not to be

detached by the external force and then not to

be wetted.

comRated

pone

nts

Unplug

On repair, remove completely dust

or other things of housing parts,

harness parts, and check parts.

●C

leaning may prevent the possible fire by

tracking or short.

After repair, check the assembled

state of components.

● I t must be in the same assembled state when

compared with the state before disassembly.

5

Check if there is any trace indicating

the permeation of water.

● I f there is that kind of trace, change the related

components or do the necessary treatment

such as taping using the insulating tape.

6.

PRECAUTIONS(SAFETY WARNINGS)❈ Please let users know following warnings & cautions in detail.

Warning & Caution

Do not allow users to put bottles or

glass in the freezer.

● Freezing of the contents may inflict a wound.

Prohibition

Do not allow users to insert the power

plugs for many products at the same

time.

● May cause abnormal generation of heat or fire.

Prohibition

Do not allow users to store articles on

the product.

Do not allow users to store narrow and Do not allow users to store materials,

lengthy bottles or foods in a small

etc., in the refrigerator.

multi-purpose room.

●T

he products which temperature control should

● I t may hurt you when refrigerator door is opened

and closed resulting in falling stuff down.

Prohibition

not be stored in the refrigerator.

Prohibition

Do not allow users to disassemble,

repair or alter.

Do not allow users to bend the power

cord with excessive force or do not have

the power cord pressed by heavy article.

● I t may cause fire or abnormal operation which

leads to injury.

● May cause fire.

Do not

disassemble

Do not allow users to install the

refrigerator in the wet place or the

place which water splashes.

●O

pening or closing the door may cause things to

●D

eterioration of insulation of electric parts may

fall down, with may inflict a wound.

cause electric shock or fire.

Prohibition

Make sure of the earth.

● I f earthing is not done, it will cause breakdown

and electric shock.

Earth

6

7.

2. PRODUCT SPECIFICATIONS2-1. INTRODUCTION OF MAIN FUNCTION··································································8

2-2. MODEL SPECIFICATION························································································9

2-3. ELECTRIC PARTS SPECIFICATION····································································11

2-4. DIMENSIONS (MM)·······························································································13

7

8.

PRODUCT SPECIFICATIONS2-1) Introduction of main function

SAMSUNG refrigerator has the following characteristics.

Characteristics

Specification

• This products protects the environment by using the R600a refrigerant

and the cyclopentane blowing agent.

Environment-friendly

fridge/freezer using R600a • Properties :ODP(Ozone Depletion Potential):0GWP :Lowest

* GWP(Global Warming Potential)

High -energy efficiency

(A++, A+)

• Optimized power consumption when using R600a and cyclopentane.

• Help to preserve the taste of food and prolong its freshness.

• Use this space to store cheese, meat, poultry, fish or any other foods.

Store specific foods at

various temperature

conditions.

Fridge at the top,

drawer-type freezer

at the bottom

• The highly ergonomic vegetables compartment is placed at waist height

as it is frequently used.

• The drawer -type freezer minimize temperature variations and stores food

cleanly and conveniently.

7 inch LCD Display

or Digital display

• 7 inch LCD provides you various information such

as photo slide show, memo, etc.

• The digital display shows all functions of the

appliance, so that you can easily control them.

Supply of cool water

without door opening

• With the water dispenser,you can obtain chilled water easily

without opening the door. In addition, you can save electricty by

more than 30% reducing the number of times the door is open.

SUPER fast freezing

function

• Food can be stored in fresh conditions by cooling it

quickly via the "Power Freeze" freezing function.

Vacation

• Save on energy consumption by switching off the fridge

and maintaining only the freezer when you take a long

vacation or are away for any reason.

8

9.

PRODUCT SPECIFICATIONS2-2) Model Specification

Item

Specification

Model

Net

Capacity

Gross

Capacity

(ISO 15502)

Net

Dimension

*/XSH,

*/BWT,

Total */HAC

other

countries

Refrigerator

RL57TT*

RL57TQ*

RL57TJ*

RL57TE*

RL57TS*

RL55TT*

RL55TQ*

RL55TJ*

RL55TE*

RL55TS*

RL52TS*

RL55VT*

RL55VQ*

RL55VJ*

RL55VE*

RL55VS*

RL52VS*

RL52VE*

RL52VW*

RL52TE*

RL52TW*

328L

328L

348L

348L

350L

330L

328L

320L

324L

316L

324L

324L

344L

344L

346L

326L

324L

316L

320L

310L

232L

232L

252L

252L

254L

234L

232L

224L

232L

224L

*/XSH,

*/BWT,

Freezer */HAC

other

countries

96L

96L

96L

92L

92L

92L

Total

348L

348L

367L

367L

367L

347L

347L

339L

347L

339L

Refrigerator

237L

237L

256L

256L

256L

236L

236L

228L

236L

228L

73kg

75kg

Freezer

111L

W(mm)

600

D(mm)

646

H(mm)

2000

Rated Voltage and

Frequency

1920

220 ~ 240V / 50Hz

110 ~ 127V / 60HZ : (Only for */PEC)

Motor Rated

Consumption Power

80 ~ 95 W

Electric Heater Rated

Consumption Power

240W ~ 288W

Kind of Refrigerator

INDIRECT COOLING METHOD REFRIGERATOR

Refrigerant /

Refrigerant Amount

R600a / 60g or R134a / 145g

Freezer Performance

Product Weight

4 -STAR

88kg

79kg

75kg

75kg

9

73.5kg

73kg

75kg

10.

PRODUCT SPECIFICATIONSNOTE

This operation instruction covers various

models.

The characteristics of your appliance

may differ slightly from those described

in this manual.

10

11.

Components for FreezerElectric Components

RL55VJ*

RL55TJ*

RL57TJ*

RL52VS*

4-STAR

RL52VE*

RL52TS*

11

DC 12V / 3W(10EA)

LED Type

LED Type

Interior Lamp

Exterior Lamp

Door Switch

-

IS-27210SNC5B

-

AC

DC 12V / 1.2W(4EA)

-

DREP5020LB

-

Reed Switch

DC 12V / 1.2W(4EA)

-

DC 12V / 1.5W(5EA)

DREP5020LB

DC 12V / 1.2W(4EA)

110 ~ 127V/60Hz

220 ~ 240V / 50Hz

DC 12V /

3W(10EA)

-

DREP5020LB

69 ±9℃

4TM445PHBYY-82

61±9℃

IS-27210SNC5B

FREOL α-10 (ESTER)

Temp. OFF

-

RL52TW*

125 ± 5℃

BLDC

Motor

R134a

RL52TE*

MSV162AL1J/E01

RL52VW*

130±5℃

4TM308RFBYY-82

AC 250V / 10A / 77℃ (+0℃ / -5℃)

240W

RL52VE*

RL55TT*

Temp. ON

Rated Voltage

Over-load

Relay

Model

Thermal-Fuse for preventing

overheating of Refrigerator DefrostHeater

Conducting

at F Defros

ID 0.75 x L3500, 5.95kg/㎠

Capillary Tube

Defrost

Heater

Molecular Sieve XH-9

Split Fin Type

BLDC

MSV4A1AL1J/E01

RL52VW*

RL55VE*

Dryer

DREP5020LB

Mineral Oil (10 cst)

MSV4A1AL1B/

E01

R600a

RL55VS*

RL55TS*

RL57TS*

Natural Convection Type

Freezer

Oil Charge

Starting type

RL55VQ*

RL55VT*

RL55TE*

RL57TE*

MSV4A1AL1J/E01

RL55TQ*

RL57TQ*

RL55TT*

RL57TT*

Specification

Condenser

Evaporator

Compressor

Model

Freezing Capacity

Refrigerant

Models

Item

PRODUCT SPECIFICATIONS

2-3) Electric Parts Specification

12.

ItemsSpecification

Model

RL55 / RL52

Refrigerator

Freezer

Model

Defrost Cycle

Defrost Related Components Room Temperature Sensor Components

PRODUCT SPECIFICATIONS

Temperature Selection

ON(°C)

OFF(°C)

-23°C

-24.0

-22.0

-20°C

-19.0

-21.0

-14°C

-13.0

-15.0

Temperature Selection

ON(°C)

OFF(°C)

1°C

2.0

0

3°C

4.0

2.0

7°C

8.0

6.0

THERMISTOR

(Freezer sensor)

502AT

Model

THERMISTOR

(Fridge sensor)

502AT

First Defrost Cycle (Concurrent defrost of F and F)

6hr ±10min

Defrost Cycle(FRE)

6 ~ 53hr (vary according to the conditions used)

Pause time

8 ±1 min

Defrost Sensor

Thermal-Fuse

Model

Thermister(502AT)

SPEC

5.0KΩ at 25 °C

Rated

AC 250V 10A

Operating temperature

77 °C (+0 °C/-5 °C)

12

13.

PRODUCT SPECIFICATIONS2-4) Dimensions (mm)

646

2000 (RL55* / RL57*) or 1920 (RL52*)

50

590

1164.5

600

560

13

14.

3. DISASSEMBLY & REASSEMBLY3-1) PRECAUTION··········································································································· 15

3-2) ASSY DOOR ·············································································································16

REMOVING THE REFRIGERATOR DOOR ······························································16

REMOVING THE FREEZER DOOR ·········································································17

3-3) DOOR SUB PARTS ··································································································18

3-4) REFRIGERATOR COMPARTMENTS ·······································································23

3-5) FREEZER COMPARTMENTS ··················································································28

3-6) MACHINE COMPARTMENTS ··················································································29

3-7) REVERSING THE DOOR SWING ············································································30

3-8) RELAY PROTECTOR O/L ························································································38

14

15.

DISASSEMBLY & REASSEMBLY3-1) PRECAUTION

• Unplug the refrigerator before cleaning and making repairs.

• Do not dissemble or repair the refrigerator by yourself.

- You run risk of causing a fire, malfunction and/or personal injury.

• Remove any foreign matter or dust from the power plug pins.

- Otherwise there is a risk of fire.

• Do not use a cord that shows cracks or abrasion damage along its length or at either end.

• Do not plug several appliances into the same multiple power board. The refrigerator should always

be plugged into its own individual electrical which has a voltage rating that matched the rating plate.

- This provides the best performance and also prevents overloading house wiring circuits, which

could cause a fire hazard from overheated wires.

• Do not install the refrigerator in a damp place or place where it may come in contact with water.

- Deteriorated insulation of electrical parts may cause an electric shock or fire.

• The refrigerator must be grounded.

- You must ground the refrigerator to prevent any power leakages or electric shocks caused by

current leakage from the refrigerator.

• Do not put bottles or glass containers in the freezer.

- When the contents freeze, the glass may break and cause personal injury.

• Do not store volatile or flammable substances in the refrigerator.

- The storage of benzene, thinner, alcohol, ether, LP gas and other such products may cause

explosions.

- NEED TOOL

IMAGE

ITEM

USE

Phillips Head Driver

Use for assembling and

disassembling of screws

Flat Head Driver

Use for assembling and

disassembling

of HomeBar, Dispenser, Deli

Cartessen Box, Main PBA etc...

11mm Wrench

Use for assembling and

disassembling of Hinge

Socket Wrench Ø10mm

Use for assembling and

disassembling of Door Hinge

15

16.

DISASSEMBLY & REASSEMBLY3-2) Assy Door

Removing the Refrigerator Door

PART NAME

FIGURE

DESCRIPTION

1) With the door closed, remove 4 screws on

the top of the refrigerator and disconnect

the wire underneath the Cap Cabi (①),

then take off the Cap Cabi(①).

①

Be careful of injury.

Ensure that the appliance is

disconnected from the electricity

supply before starting this

procedure.

Removig

the

Refrigerator

Door

2) Disconnect the wire and then remove 3

bolts(②) on the top of the refrigerator. And

then disassemble the Fridge door(③) by

carefully lifting the door straight up.

Make sure the Fridge door is

closed firmly. Fridge door is

heavy, be careful not to injure

yourself and not to scratch when

removing the Fridge door.

②

③

16

17.

DISASSEMBLY & REASSEMBLYRemoving the Freezer Door

PART NAME

FIGURE

DESCRIPTION

1) Open the Freezer door and disassemble

the Front Leg Cover(①) by removing 2

screws.

Removig

the

Refrigerator

Door

①

Be careful not to scratch the

cabinet.

②

2) Remove 2 bolts securing the Assy Hinge

Low(②).

Before removing the Assy Hinge

Low, slightly turn the front leg

clockwise for easier disassembling.

2) Take off the Freezer door(③) and the Assy

Hinge Low(②) together.

③

Take care when removing the

door to ensure that it does not fall

on you.

- If you want to reassemble, follow the

instruction in reverse order.

17

18.

DISASSEMBLY & REASSEMBLY3-3) Door Sub parts

PART NAME

FIGURE

DESCRIPTION

- 7 Inch LCD Type

1. Insert a flat-head screwdriver on the slot

as shown, and unlock the tabs.

2. Disconnect the wire connector.

When diassembling, make sure

the unit turned off.

- Trim Kit Type

1. Disassemble the Wire Cap Door by

removing a screw on the top of the Fridge

door.

2. Take out display upper direction.

3. Disconnect the wires.

Removing

the

Refrigerator

Door

When diassembling, make sure

the unit turned off.

- Plate Type

1. Insert a flat-head screwdriver on the

slot as shown, and unlock the tabs.

2. Disconnect the wire connector.

18

19.

DISASSEMBLY & REASSEMBLYPART NAME

FIGURE

DESCRIPTION

1. Remove 2 screws underneath the Fridge

door. And then take off 2 Cap sheets and

remove 2 screws on the Freezer door.

Door Handle

Type A

2. Slightly push down the Fridge handle and

then remove it by pulling it toward to you.

Slightly push up the Freezer handle and

then remove it by pulling it toward to you.

Be careful not to break hook

inside of Door Handles, when you

disassemble them.

1. Remove 2 screws underneath the Fridge

door and then pull the Cover Handle

forward to you.

Be careful not to break hooks

inside of Cover Handle, when you

disassemble it.

COVER HANDLE

Door Handle

Type B

HANDLE EASY

2. Disassemble the Handle Easy, after

removing 3 screws and the Grommet

Handles both side of the Fridge door.

GROMMET

SLIDER HANDLE

3. Remove Slider Handle and the Spring.

SPRING

19

20.

DISASSEMBLY & REASSEMBLYPART NAME

FIGURE

DESCRIPTION

1. Remove 2 screws underneath the Fridge

door and then pull the Cover Handle

forward to you.

COVER HANDLE

HANDLE EASY

2. Disassemble the Handle Easy, after

removing 3 screws and the Grommet

Handles both side of the Fridge door.

GROMMET

Handle

Lighting

(Glass)

Be careful not to break hooks

inside of Cover Handle. When you

disassemble it.

Cover Lamp

3. Disassemble Cover Lamp after removing

2 screws on the Fridge door.

4. Take out the LED lamp.

5. Disconnect the wire.

When diassembling, make sure

the unit turned off.

20

21.

DISASSEMBLY & REASSEMBLYPART NAME

FIGURE

DESCRIPTION

Cover Lamp

1. Disassemble Cover Lamp after removing 2

screws underneath the Fridge door.

2. Take out the LED lamp and then

disconnect the wire.

Handle

Lighting

(Plate Door)

When diassembling, make sure

the unit turned off.

The door gasket is a molded gasket set into

a channel located in the door liner.

1. Open the door.

2. Grasp the gasket and pull in an outward

motion until the molded gasket separates

from the door liner.

Door Gaskets

(Fridge/

Freezer)

Be careful of injury.

The refrigerator has a door magnet

switch located in the upper center for the

refrigerator.

Fridge Door

Magnet S/W

1. U

se a small flat-blade screwdriver to unlock

the locking tab and pull the switch out.

The refrigerator has door reed switches.

Reed switch for the fridge door is located

under the cap cabi. Reed switch for the

freezer door is located underneath the fridge

door.

Fridge/

Freezer

Door Reed

S/W

1. Use a small flat-head screwdriver to unlock

the reed switches and pull the switches

out.

21

22.

DISASSEMBLY & REASSEMBLYPART NAME

FIGURE

DESCRIPTION

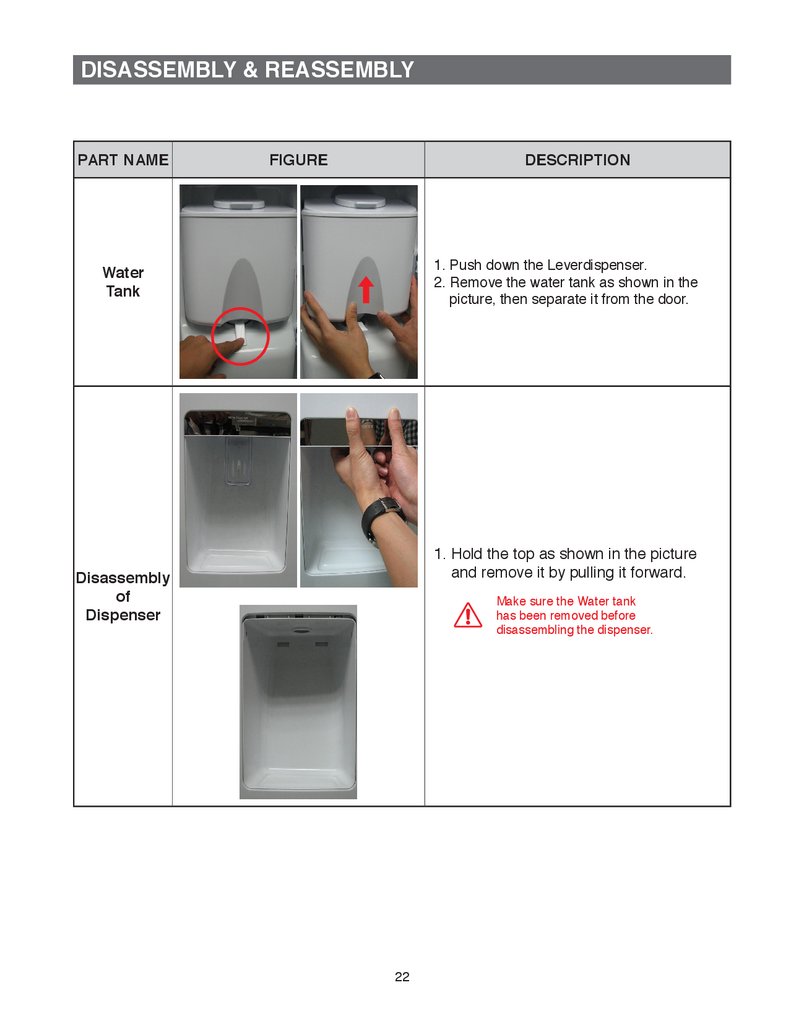

1. Push down the Leverdispenser.

2. Remove the water tank as shown in the

picture, then separate it from the door.

Water

Tank

1. H

old the top as shown in the picture

and remove it by pulling it forward.

Disassembly

of

Dispenser

Make sure the Water tank

has been removed before

disassembling the dispenser.

22

23.

DISASSEMBLY & REASSEMBLY3-4) Refrigerator Compartments

PART NAME

FIGURE

DESCRIPTION

These shelves allow the storage of larger

items and pull out for easy access.

Glass

Shelf

1. Lift it up and pull the shelf out to the front.

Drawers are designed for storage of

fruits,vegetables,and deli items.The drawers

are located in the lower portion of the

refrigerator.

Plastlc

Drawers

In

Refrlgerator

1. Pull out the drawer as far as it goes.

2. Tilt the drawer up and pull it out until it is

removed.

1. Remove 2 screws and pull the CoolSelect

Zone drawer out and then disconnect the 2

wire connectors.

Cool

Select

Zone™

When diassembling, make sure

the unit turned off.

1. Pull the Cooler Zone drawer out.

2. Push the hooks under the Cover Chilled

High to disassemble the Cover Chilled

High.

COOLER

ZONE

23

24.

DISASSEMBLY & REASSEMBLYPART NAME

FIGURE

DESCRIPTION

The refrigerator lights are located in the

Refrigerator.

1. Remove all shelves, plastic drawer and

CoolSelect Zone drawer.

2. Pull out cover lamp after removing 1 screw

as shown.

3. Remove 3 screws as shown and disconnect

the upper and lower wire connectors.

When diassembling, make sure

the unit turned off.

Refrigerator

Light

(Type Ⅰ)

4. Remove tape for cover of wire at the back

side and remove 3 screws at the front side.

24

25.

DISASSEMBLY & REASSEMBLYPART NAME

FIGURE

DESCRIPTION

The Refrigerator lights are located in the

Refrigerator.

1. Disassemble Cover Lamp by pushing

hooks.

2. Take out the LED lamp and then disconnet

the wire.

Refrigerator

Light

(Type Ⅱ)

When diassembling, make sure

the unit turned off.

- Type Ⅰ

The refrigerator thermistor is located inside of

the light cover of the refrigerator.

Refrigerator

Thermistor

- Type Ⅱ

The refrigerator thermistor is located inside

the refrigerator.

25

26.

DISASSEMBLY & REASSEMBLYPART NAME

FIGURE

DESCRIPTION

The CoolSelect Zone™ thermistor is located

inside the back of CoolSelect Zone™

drawer.

The temperature signal is sent to the

microprocessor.

Cool Select

Zone™

Thermistor

Dairy Bin

Door Bin

The door bins allow storage of perishable

items.

Variety

1.Push the bin up and slide it out .

Bottle Bin

Kids

26

27.

DISASSEMBLY & REASSEMBLYPART NAME

FIGURE

DESCRIPTION

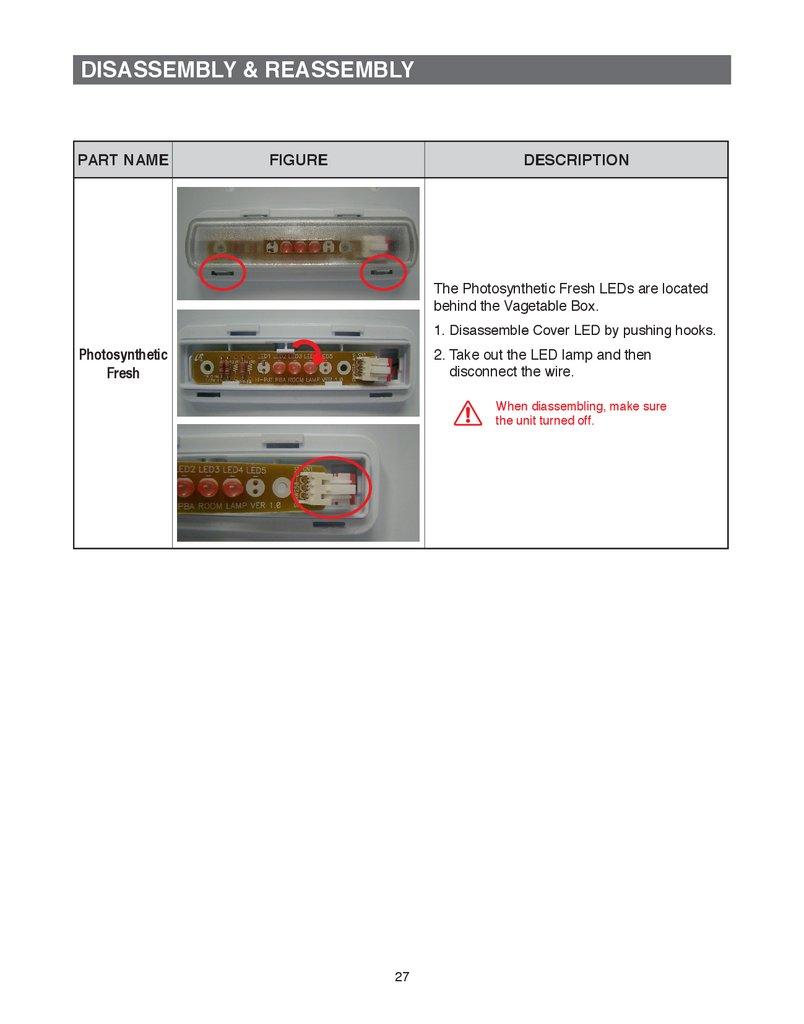

The Photosynthetic Fresh LEDs are located

behind the Vagetable Box.

1. Disassemble Cover LED by pushing hooks.

Photosynthetic

Fresh

2. Take out the LED lamp and then

disconnect the wire.

When diassembling, make sure

the unit turned off.

27

28.

DISASSEMBLY & REASSEMBLY3-5) Freezer Compartments

PART NAME

FIGURE

DESCRIPTION

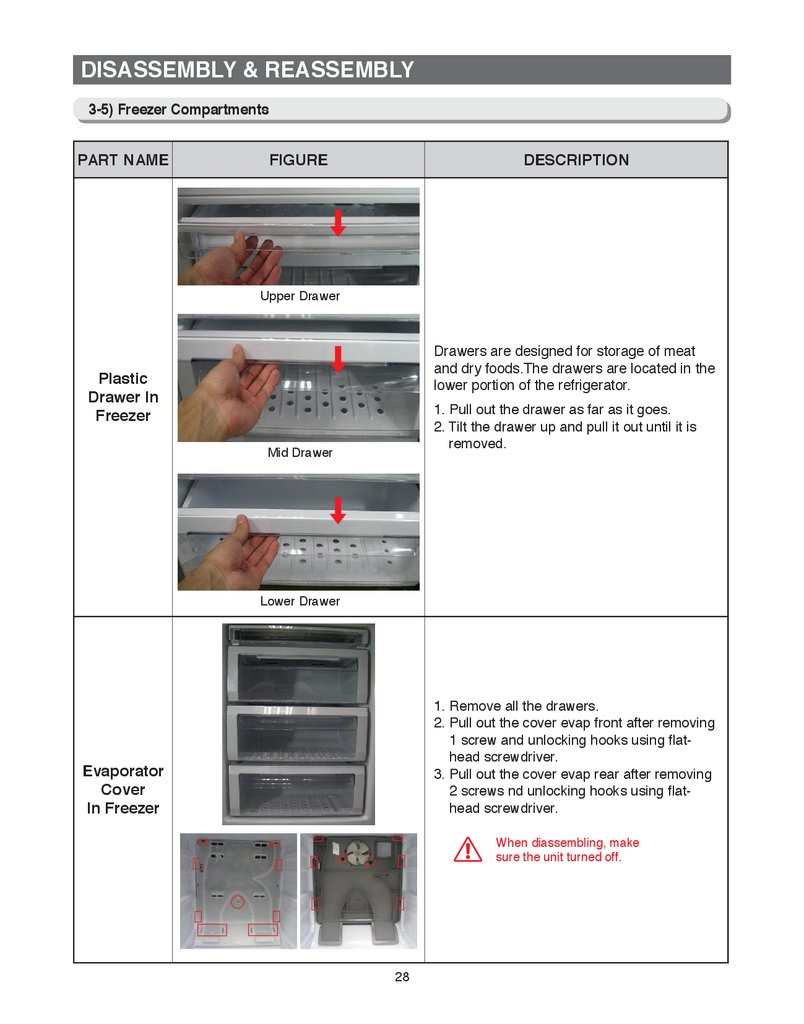

Upper Drawer

Drawers are designed for storage of meat

and dry foods.The drawers are located in the

lower portion of the refrigerator.

Plastic

Drawer In

Freezer

1. Pull out the drawer as far as it goes.

2. Tilt the drawer up and pull it out until it is

removed.

Mid Drawer

Lower Drawer

1. Remove all the drawers.

2. Pull out the cover evap front after removing

1 screw and unlocking hooks using flathead screwdriver.

3. Pull out the cover evap rear after removing

2 screws nd unlocking hooks using flathead screwdriver.

Evaporator

Cover

In Freezer

When diassembling, make

sure the unit turned off.

28

29.

DISASSEMBLY & REASSEMBLYPART NAME

FIGURE

DESCRIPTION

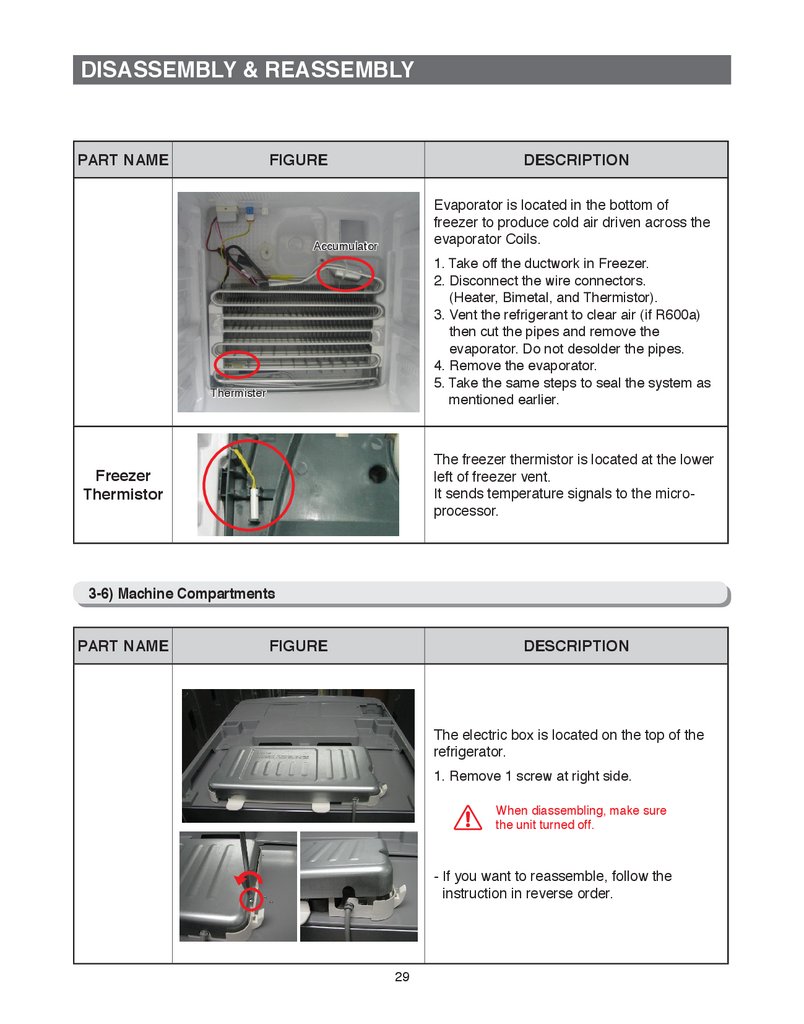

Evaporator is located in the bottom of

freezer to produce cold air driven across the

evaporator Coils.

Accumulator

1. Take off the ductwork in Freezer.

2. Disconnect the wire connectors.

(Heater, Bimetal, and Thermistor).

3. Vent the refrigerant to clear air (if R600a)

then cut the pipes and remove the

evaporator. Do not desolder the pipes.

4. Remove the evaporator.

5. Take the same steps to seal the system as

mentioned earlier.

Thermister

The freezer thermistor is located at the lower

left of freezer vent.

It sends temperature signals to the microprocessor.

Freezer

Thermistor

3-6) Machine Compartments

PART NAME

FIGURE

DESCRIPTION

The electric box is located on the top of the

refrigerator.

1. Remove 1 screw at right side.

When diassembling, make sure

the unit turned off.

- If you want to reassemble, follow the

instruction in reverse order.

29

30.

DISASSEMBLY & REASSEMBLY3-7) Reversing the Door swing

Read these instructions completely and carefully

Warning

• Before reversing the door, first of all, main power should be switched off you should

take out contents and accessories like door guard from the doors.

Be careful not to drop the doors during dissembling or assembling.

1. Handle parts carefully to avoid scratching paint.

2. Set screws down by their related parts to avoid using them in the wrong places.

3. Provide a non-scratching work surface for the doors. (ex:blanket)

4. During door reversing, refrigerator should not be stained with oil.

Not provided

Phillips Head

Driver (+)

PART NAME

Flat Head

Driver (-)

Additional part

10mm Socket

Wrench (for bolts)

11mm Wrench

(for hinge shaft)

FIGURE

3/16” Allen Wrench

(for middle hinge)

Top Left Hinge

Cover (Underneath

the Top Cover)

DESCRIPTION

1. With the door closed, remove 4 screws on

the top of the refrigerator.

2. Disconnect the wire underneath the Cap

Cabi, then take off the Cap Cabi.

Make sure the unit is unplugged

before reversing door.

DISASSEMBLY

OF THE

FRIDGE DOOR

3. Disconnect the wire.

4. Remove 3 bolts on the top of the

refrigerator.

Make sure the Fridge door is

closed firmily.

30

31.

DISASSEMBLY & REASSEMBLYPART NAME

FIGURE

DESCRIPTION

5. Remove the Fridge door from the Hinge

Mid by carefully lifting the door.

DISASSEMBLY

OF THE

FRIDGE DOOR

Fridge door is heavy, be careful

not to injure yourself when

removing the door.

HINGE MID

6. Disassemble the Freezer door by removing

2 bolts, a screw and the Hinge Mid.

Be careful not to drop and scratch

the Freezer Door.

DISASSEMBLY

OF THE

FREEZER

DOOR

COVER LEG

7. Detach the Front Leg Cover after removing

2 screws.

8. Unscrew 2 bolts tightening the Hinge Low

and also unscrew a bolt on the left side by

the front leg where removed the Hinge Low

will be attached.

HINGE LOW

Before removing the Assy Hinge Low,

slightly turn the front legs clockwise for

easier disassembling and reassembling.

ASSEMBLY OF

THE FREEZER

DOOR

AUTO GUIDE

9. Remove the screw on the Auto guide and

remove the Hinge shaft with 11mm wrench.

Attach the Hinge shaft on the left and put

the reversed Auto Guide back.

SHAFT

31

32.

DISASSEMBLY & REASSEMBLYPART NAME

FIGURE

DESCRIPTION

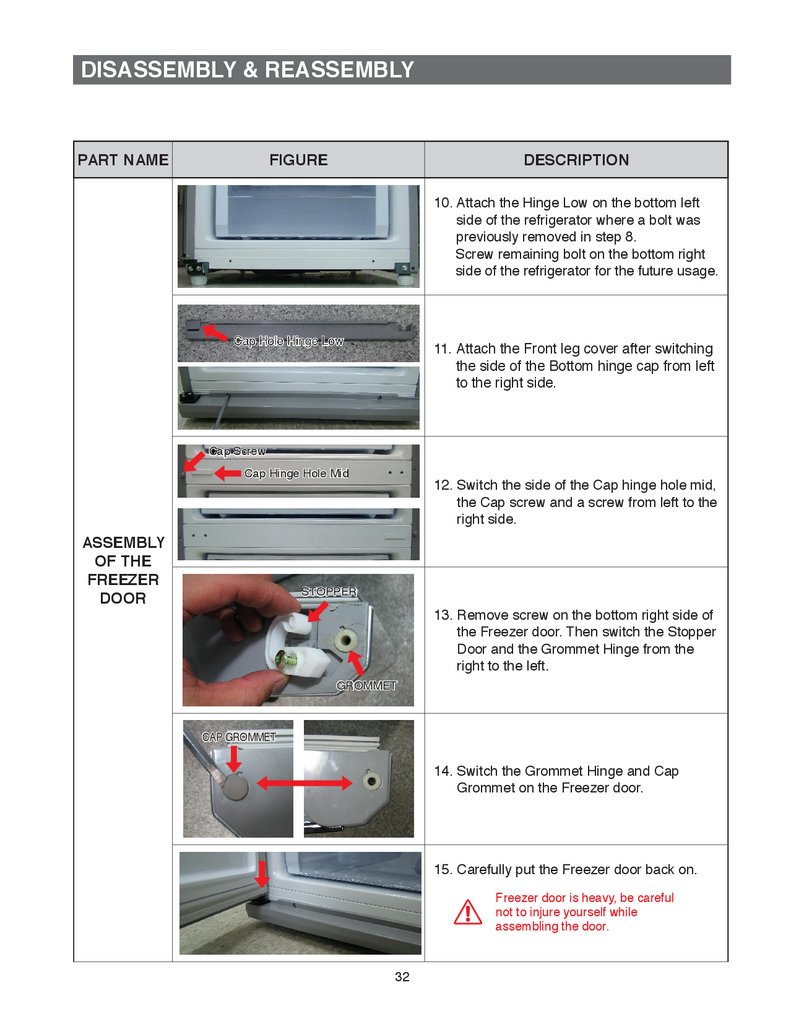

10. Attach the Hinge Low on the bottom left

side of the refrigerator where a bolt was

previously removed in step 8.

Screw remaining bolt on the bottom right

side of the refrigerator for the future usage.

11. A

ttach the Front leg cover after switching

the side of the Bottom hinge cap from left

to the right side.

Cap Screw

Cap Hinge Hole Mid

ASSEMBLY

OF THE

FREEZER

DOOR

12. Switch the side of the Cap hinge hole mid,

the Cap screw and a screw from left to the

right side.

STOPPER

GROMMET

13. Remove screw on the bottom right side of

the Freezer door. Then switch the Stopper

Door and the Grommet Hinge from the

right to the left.

CAP GROMMET

14. Switch the Grommet Hinge and Cap

Grommet on the Freezer door.

15. Carefully put the Freezer door back on.

Freezer door is heavy, be careful

not to injure yourself while

assembling the door.

32

33.

DISASSEMBLY & REASSEMBLYPART NAME

FIGURE

DESCRIPTION

16. Assemble the Hinge Mid with 2 bolts on

the left side.

HINGE MID

ASSEMBLY

OF THE

FREEZER

DOOR

A screw will be remained after

reversing door.

And it does not affect performance

of the refrigerator.

STOPPER

GROMMET

17. Remove screw on the bottom right side of

the Fridge door. Then switch the Stopper

Door and the Grommet Hinge from the

right to the left.

COVER WIRE DOOR

18. Remove the Cover Wire Door on the top

of the Fridge door with flat head driver.

ASSEMBLY

OF THE

FRIDGE

DOOR

ASSY HINGE UPP

19. Take out the Assy Hinge UPP from the

Fridge door.

20. Detach the Cover Wire Hinge R from the

Assy Hinge Upp and disassemble the

Wires.

21. Use 11mm wrench to separate the Hinge

Shaft and then flip the hinge and reattach

the Hinge Shaft.

HINGE SHAFT

33

34.

DISASSEMBLY & REASSEMBLYPART NAME

FIGURE

CAP SPACE

DESCRIPTION

GROMMET

22. Switch the Cap Space Door and the

Grommet Hinge on the Fridge door.

23. After switching wires from right side to the left

reassemble the Assy Hinge Upp by reversing

step 20. and put into the Fridge door. Make

sure to use the Cover Wire Hinge L which can

be found underneath the Cap Cabi. (Make

sure that red tape on the wire is positioned on

the end of the Cover Wire Hinge L as shown.)

ASSEMBLY

OF THE

FREEZER

DOOR

24. Carefully put the Fridge door back on.

25. Tighten 3 bolts to assemble the Assy

Hinge Upp.

26. Connect Wire.

34

35.

DISASSEMBLY & REASSEMBLYPART NAME

FIGURE

DESCRIPTION

27. Assemble the Cover Wire Door on the top

of the Fridge door.

CAP HOLE HINGE

28. Change the position of the Cap Hole

Hinge Upp. Connect wire under the Top

Table.

ASSEMBLY

OF THE

FRIDGE

DOOR

29. Put the Top Table back to its original

position with 4 screws.

30. Detach the Fridge and the Freezer gaskets

then attach them after rotating 180˚.

GASKET

After reversing the door, make

sure Fridge and Freezer gaskets

are properly arranged.

35

36.

DISASSEMBLY & REASSEMBLYPART NAME

FIGURE

DESCRIPTION

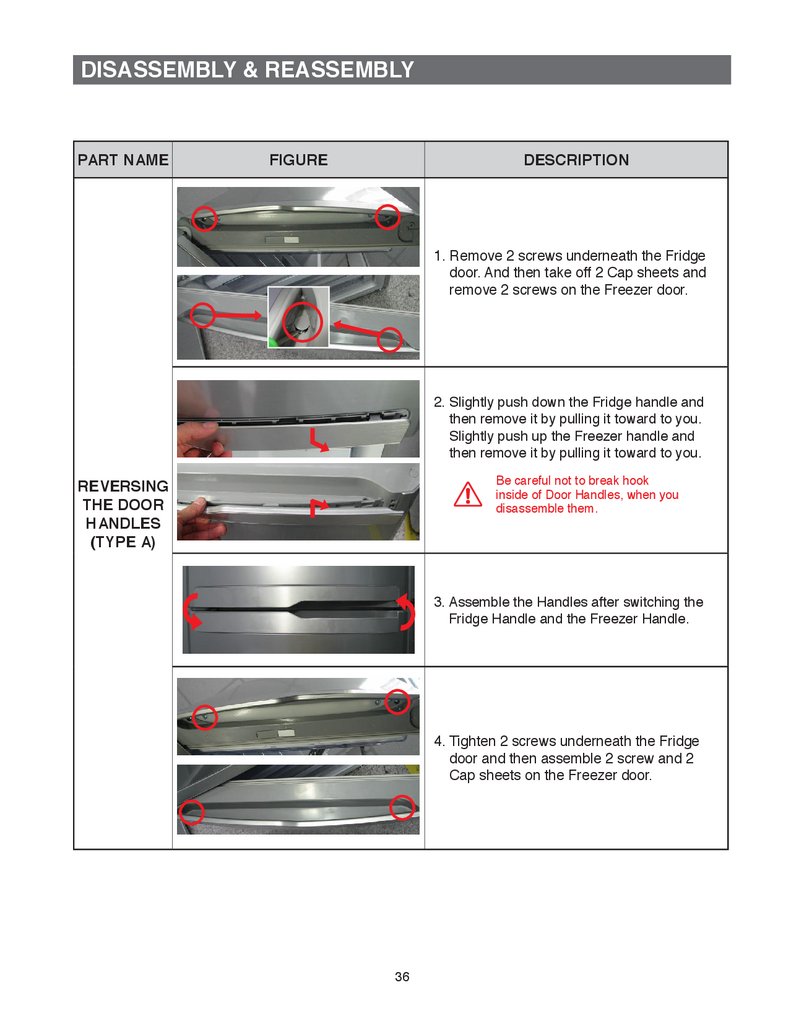

1. Remove 2 screws underneath the Fridge

door. And then take off 2 Cap sheets and

remove 2 screws on the Freezer door.

2. Slightly push down the Fridge handle and

then remove it by pulling it toward to you.

Slightly push up the Freezer handle and

then remove it by pulling it toward to you.

Be careful not to break hook

inside of Door Handles, when you

disassemble them.

REVERSING

THE DOOR

HANDLES

(TYPE A)

3. Assemble the Handles after switching the

Fridge Handle and the Freezer Handle.

4. Tighten 2 screws underneath the Fridge

door and then assemble 2 screw and 2

Cap sheets on the Freezer door.

36

37.

DISASSEMBLY & REASSEMBLYPART NAME

FIGURE

DESCRIPTION

1. Remove 2 screws underneath the Fridge

door and then pull the Cover Handle

forward to you.

Be careful not to break hooks

inside of Cover Handle, when you

disassemble it.

COVER HANDLE

HANDLE EASY

2. Disassemble the Handle Easy, after

removing 3 screws and the Grommet

Handles both side of the Fridge door.

GROMMET

REVERSING

THE DOOR

HANDLES

(TYPE B)

3. Change position of the Slider Handle and

the Spring from left to right side.

SLIDER HANDLE

SPRING

4. Assemble the Handle Easy with Grommet

Handle.

5. Assemble the Cover Handle with 2 screws.

37

38.

DISASSEMBLY & REASSEMBLY3-8) RELAY PROTECTOR O/L

PART NAME

FIGURE

DESCRIPTION

Disengage the housing connector.

(Refer to the picture)

Insert the flat-blade screwdriver into the

slot, and remove the Relay Cover along

the arrow.

Remove the Relay Protector O/L along the

arrow.

RELAY

PROTECTOR

O/L

Disassemble the Relay by pulling the

connector as shown.

Assemble in reverse order and be careful

not to change by checking initial position

assembled in relay.

Be careful not to assemble terminal

without white housing into the side tab

of relay.

(Models with 2pcs housing are

unrelated)

38

39.

4. TROUBLESHOOTING4-1) CHECK-LIST BEFORE TROUBLE-SHOOTING (T, H, E, W)··································· 41

4-1-1) TEST FUNCTION (FORCED OPERATION / FORCED DEFROST) ··············41

4-1-2) SELF-DIAGNOSIS FUNCTION ·····································································43

4-1-3) LOAD STATUS DISPLAY FUNCTION ···························································45

4-1-4) RESTORATION OF PREVIOUS SETTINGS UPON INSTANT POWER OUTAGE ··········47

4-1-5) DEMO MODE FUNCTION FOR STORE DISPLAY ·······································47

4-1-6) OPTION SETTING FUNCTION ·····································································48

4-1-7) OPTION TABLE ·····························································································49

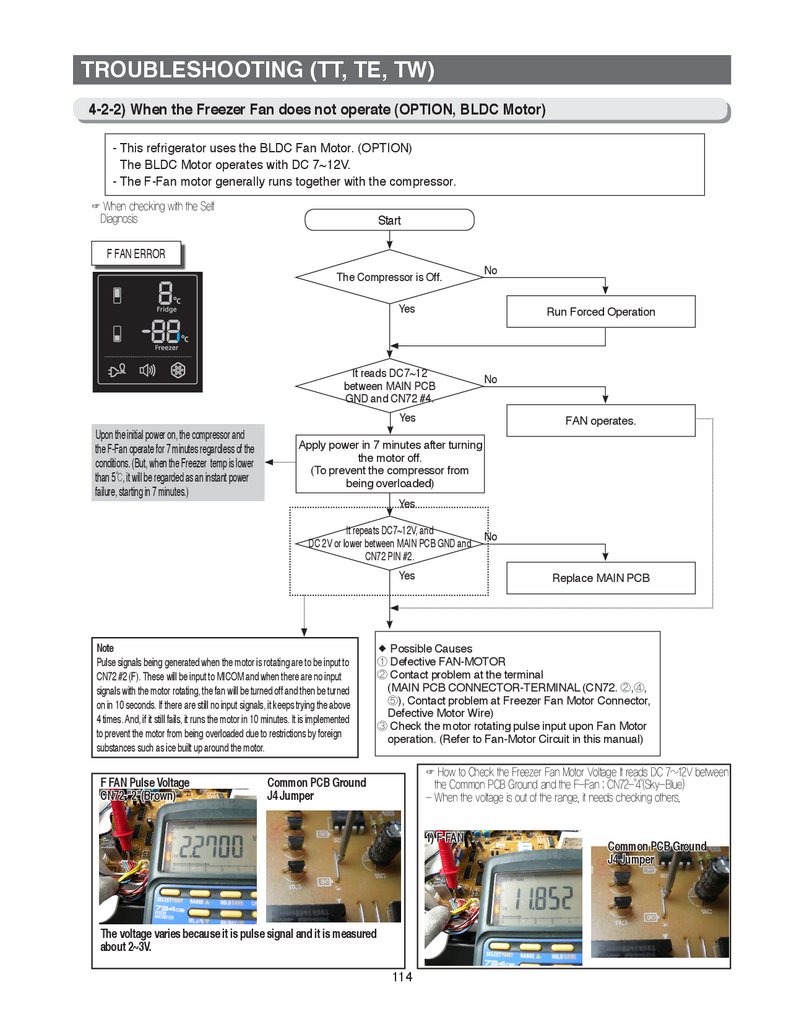

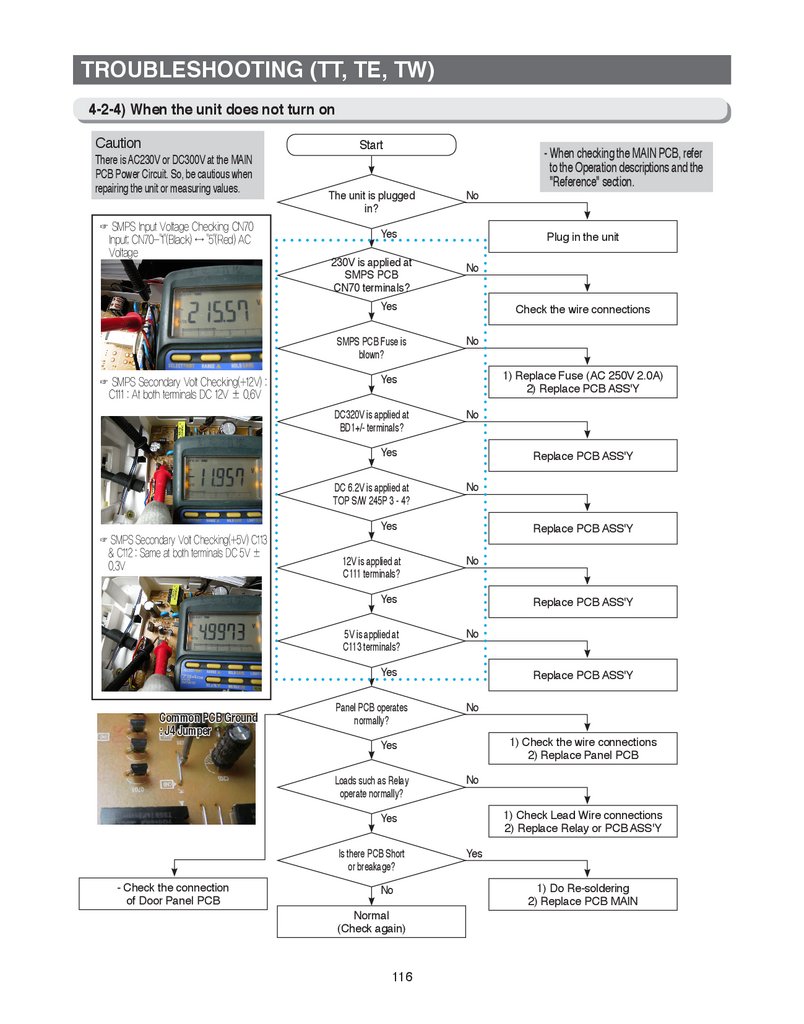

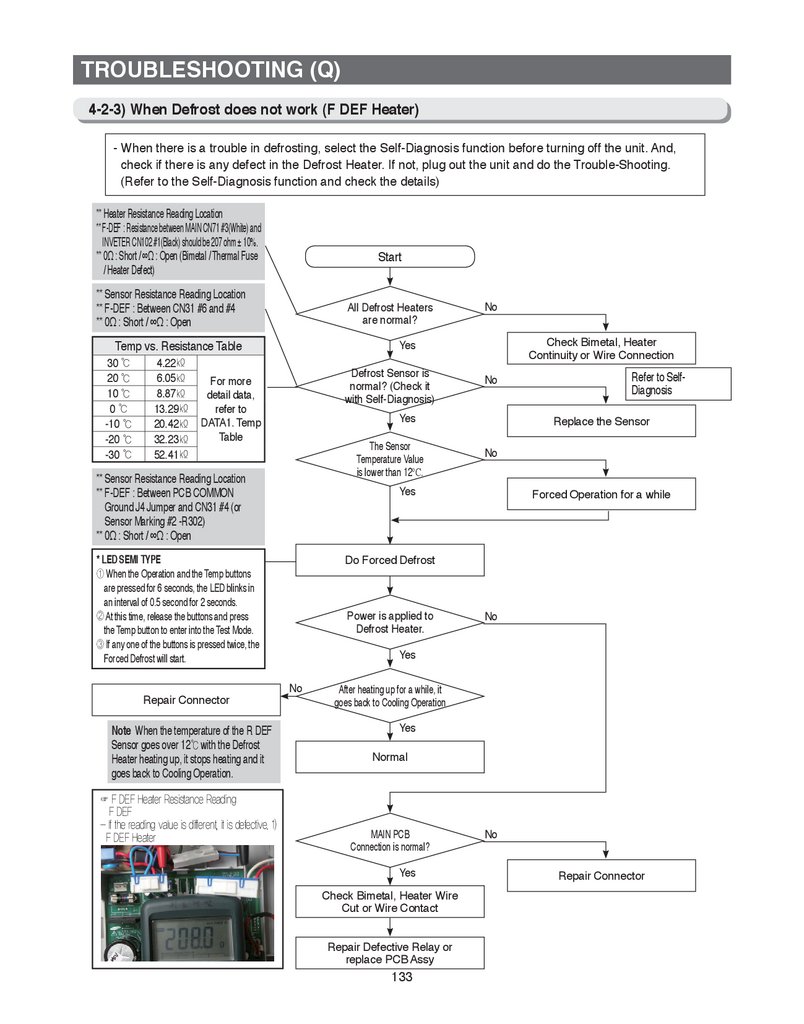

4-1) CHECK-LIST BEFORE TROUBLE-SHOOTING (TT, TE, TW)································· 51

4-1-1) TEST FUNCTION (FORCED OPERATION / FORCED DEFROST) ··············51

4-1-2) SELF-DIAGNOSIS FUNCTION ·····································································53

4-1-3) LOAD STATUS DISPLAY FUNCTION ···························································56

4-1-4) RESTORATION OF PREVIOUS SETTINGS UPON INSTANT POWER OUTAGE ··········58

4-1-5) DEMO MODE FUNCTION FOR STORE DISPLAY ·······································58

4-1-6) OPTION SETTING FUNCTION ·····································································59

4-1-7) OPTION TABLE ·····························································································61

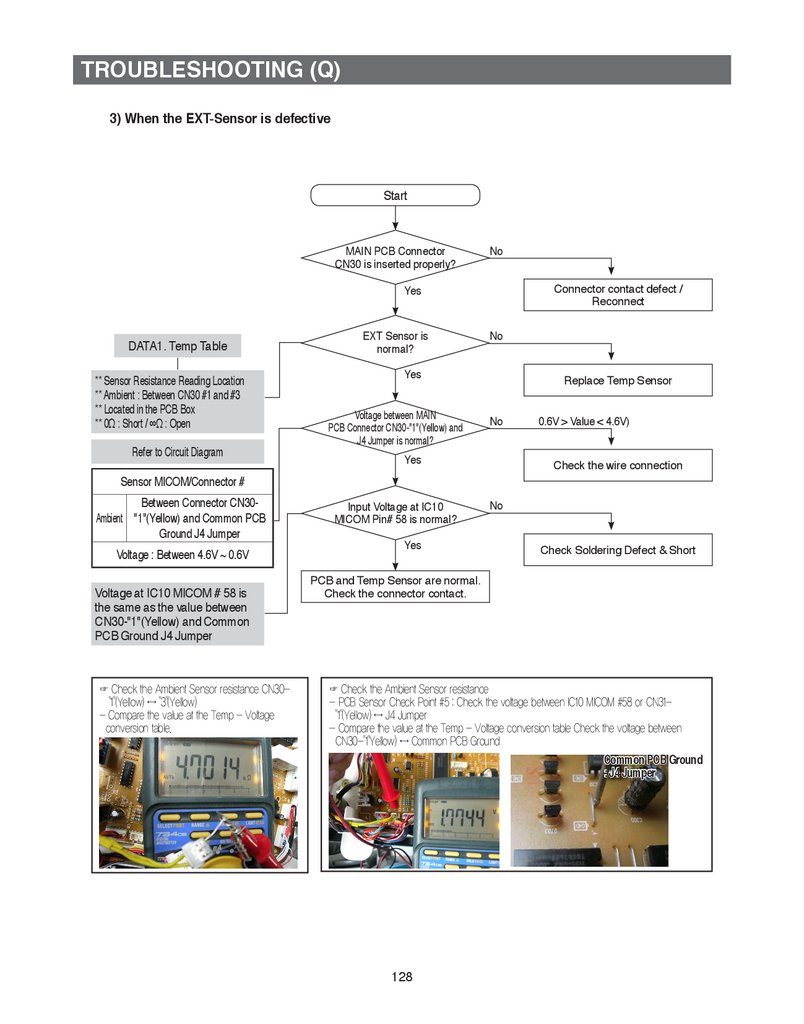

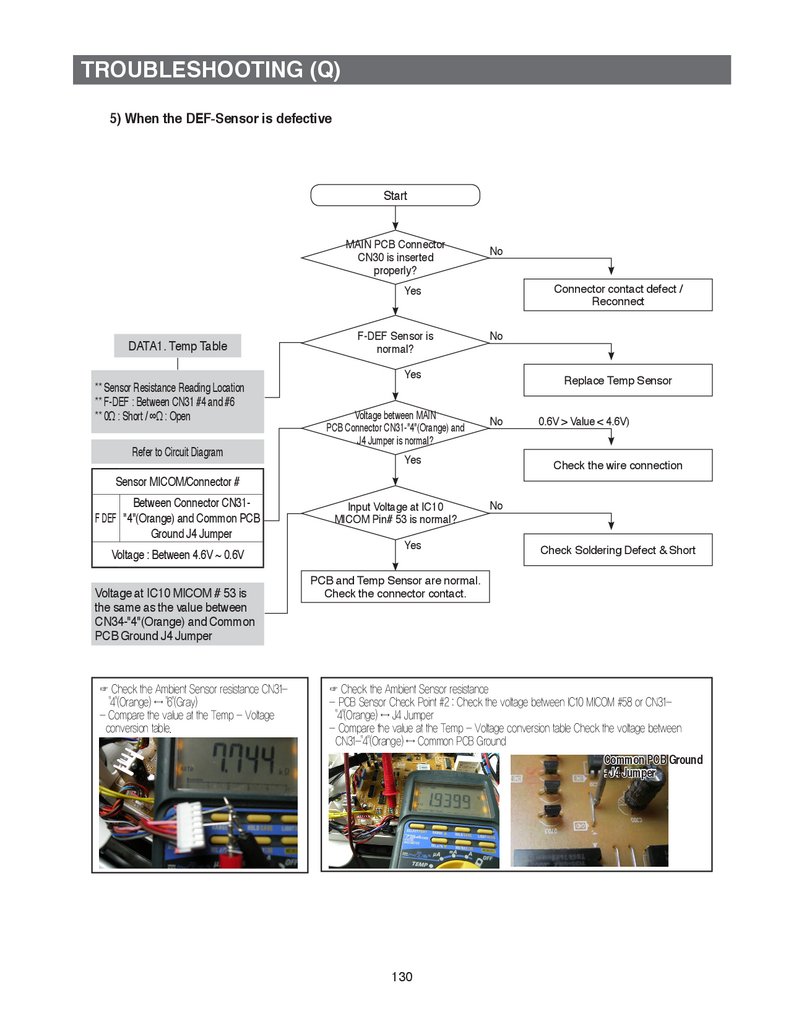

SERVICE FUNCTIONS (Q)······························································································ 64

4-1) CHECK POINTS PRIOR TO FAILURE DIAGNOSTICS··········································· 64

4-1-1) FORCED OPERATIONS ················································································64

4-1-2) COMMUNICATION ERROR DISPLAYS ························································65

4-1-3) SELF-DIAGNOSTICS ····················································································66

4-1-4) LOAD OPERATION CHECK ··········································································68

4-1-5) SHOWROOM MODE ·····················································································69

4-1-6) SET POINT SHIFT ·························································································70

4-1-7) ERROR HISTORY FUNCTION ······································································71

39

40.

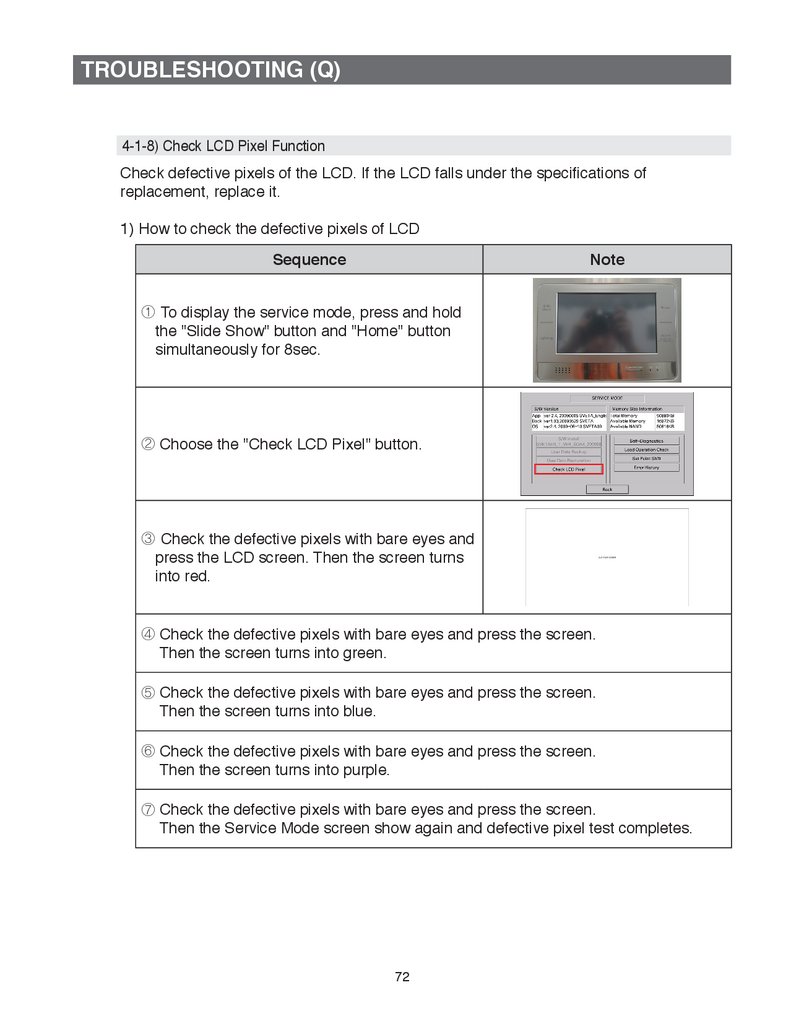

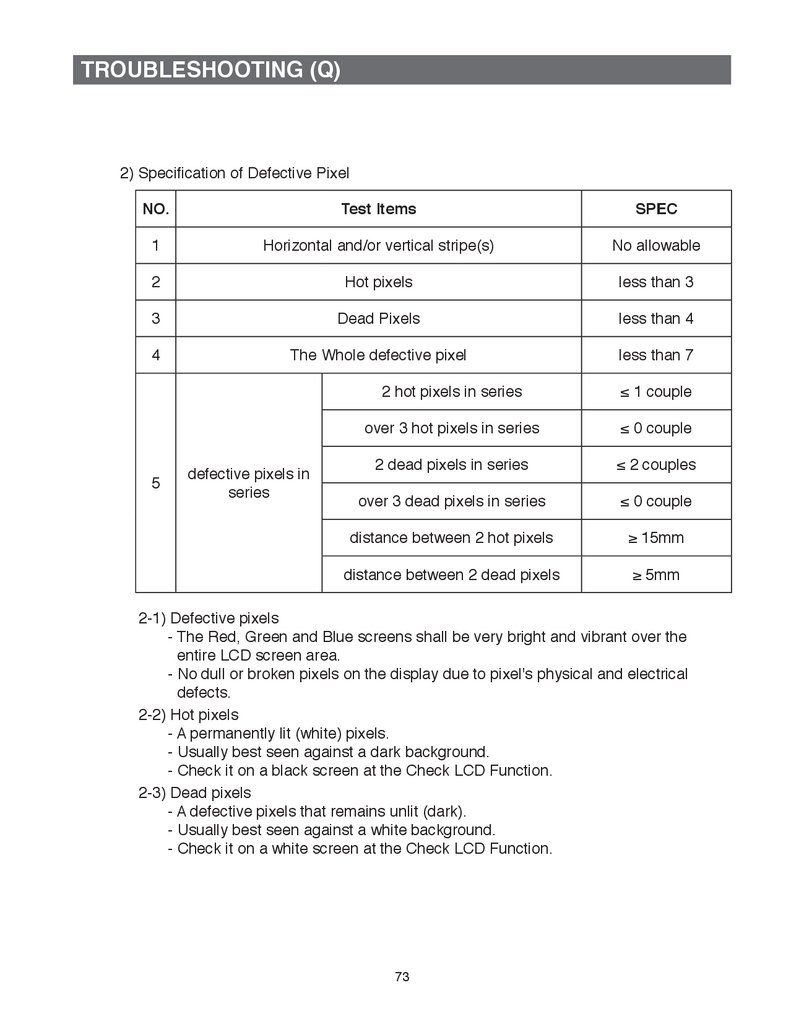

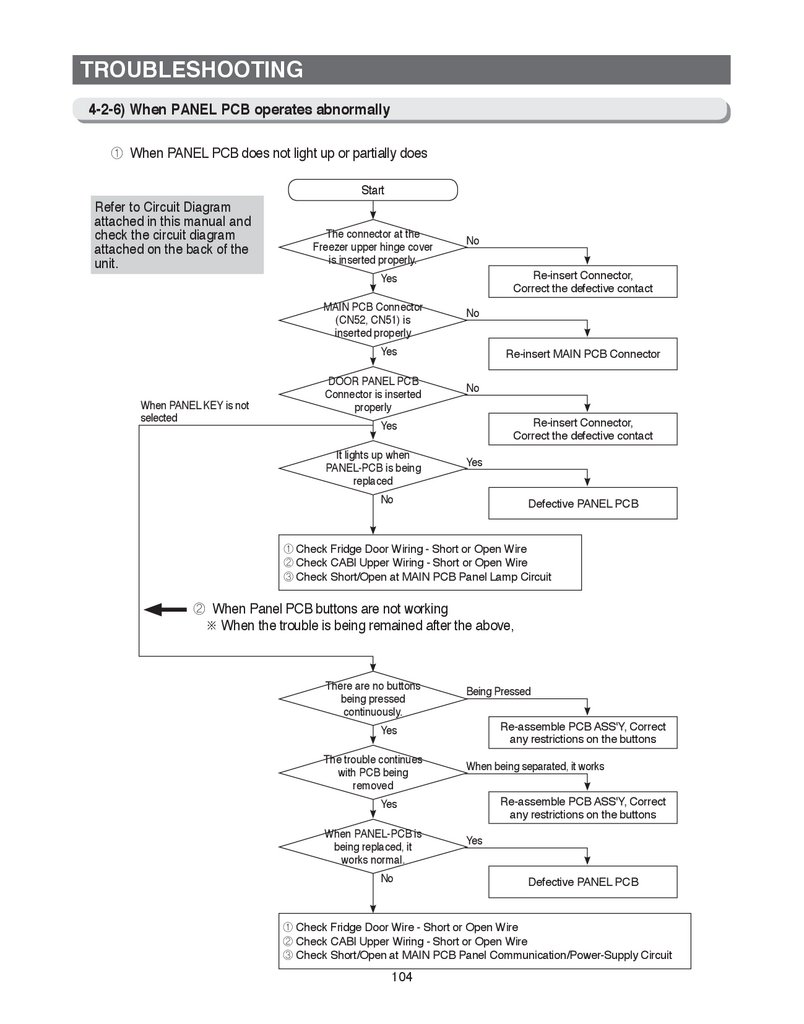

TROUBLESHOOTING4-1-8) CHECK LCD PIXEL FUNCTION (J) ·······························································72

4-1-9) TOUCH POINT CALIBRATION ······································································74

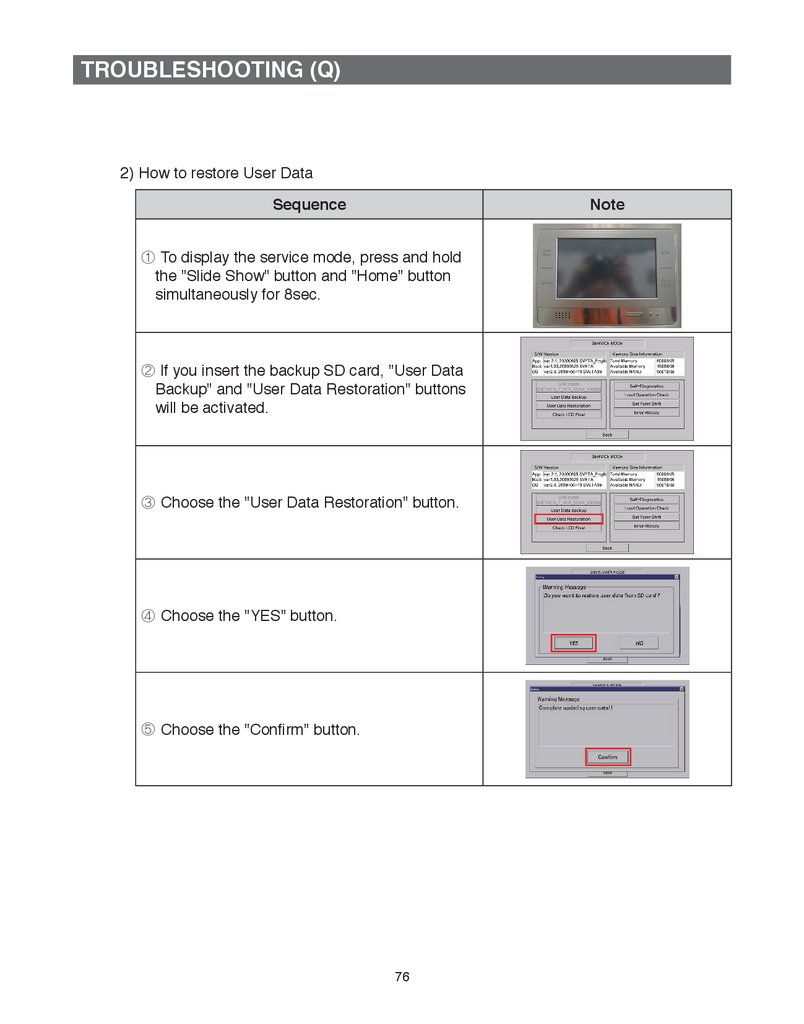

4-1-10) USER DATA BACKUP/RESTORATION FUNCTION ···································75

4-1-11) OS UPGRADE FUNCTION ··········································································77

4-1) CHECK-LIST BEFORE TROUBLE-SHOOTING (VJ, VE, VW)································ 81

4-1-1) TEST FUNCTION (FORCED OPERATION / FORCED DEFROST) ··············81

4-1-2) SELF-DIAGNOSIS FUNCTION ·····································································83

4-1-3) LOAD STATUS DISPLAY FUNCTION ···························································86

4-1-4) RESTORATION OF PREVIOUS SETTINGS UPON INSTANT POWER OUTAGE ··········88

4-1-5) DEMO MODE FUNCTION FOR STORE DISPLAY ·······································88

4-1-6) OPTION SETTING FUNCTION ·····································································89

4-1-7) OPTION TABLE ·····························································································91

40

41.

TROUBLESHOOTING (S)4-1. Check-List before Trouble-Shooting

4-1-1) Test Function (Forced Operation / Forced Defrost)

● When the Cold and the Coldest buttons on the display panel are held down for more than 4

seconds, the entire display panel will blink in an interval of 0.5 second for about 3 seconds.

While the display panel blinks for 3 seconds, take your fingers off the Cold and the Coldest

buttons, and press the Coldest button to go into the Test mode.

At the Test mode, all the display buttons will work as the Test button.

● Each time the Test button is pressed, it will change in the following order.

F

orced Operation → Forced F-Defrost → Cancellation (Normal Operation) It is recommended

that the unit be disconnected and reconnected from the electricity supply to terminate the

operation of the Test function.

1) How to Enter Test Mode

①

②

① When pressing the Cold and the Coldest buttons for 4 seconds simultaneously, the entire

LEDs on the Display Panel will flash on and Off in an interval of 0.5 second for 3 seconds.

② While it is blinking, remove fingers from the two buttons and press the Coldest button to

enter the Test Mode.

③ Remove finger and press any button to enter the Test Mode.

41

42.

TROUBLESHOOTING (S)2) Test Mode Description

1. Forced Operation Function

1-1) When any button is pressed at the Test Mode, the Temp. LED will set to the Coldest indicating

that it is in the Forced Operation.

1-2) When the Forced Operation is selected, the compressor starts without a 7-minute delay in

any operation mode. At this time, when it is in a Defrost mode, it stops defrosting and the

Forced Operation begins. (If the Forced Operation begins as soon as the compressor stops,

it may cause the overload. So, take care when entering into the Forced Operation.)

1-3) When the Forced Operation is selected, the compressor and the F-Fan operate for 24 hours

without stopping and the Fridge compartment will operate according to the set temperature.

1-4) When the unit is shifted to the Forced Operation, the Temp. LED will set to "Coldest"

(Freezer : -25ºC, Fridge : 1ºC).

1-5) To cancel the Forced Operation in the middle of the Test function, turn off the power and

turn it on again, or select the Test Cancellation mode.

2. Forced Defrost Function

2-1) When the Test button is pressed once more at the Forced Operation (Coldest), the Temp.

LED will set to "Colder (medium)". And, the Forced Operation will be cancelled right away

and the Forced F-Defrost will start.

2-2) For this function, the lower 3 LED sections (Cold, Cold/Mid, Mid) will light up.

3. Test Cancellation Mode

3-1) W

hen turning the display panel into the Test mode and pressing the TEST button once more

during the Forced F-Defrost, the Forced F-Defrost will be cancelled and it will go back to the

normal operation. Also, disconnect and reconnect the unit from the electricity supply to exit

the test mode.

42

43.

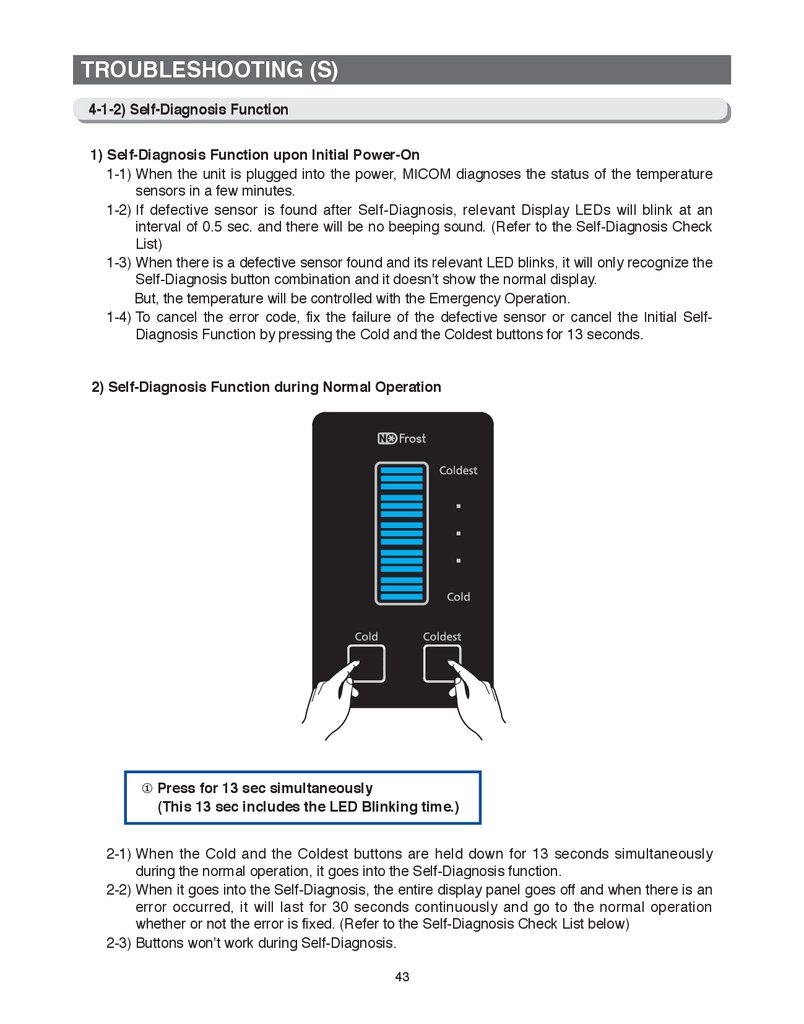

TROUBLESHOOTING (S)4-1-2) Self-Diagnosis Function

1) Self-Diagnosis Function upon Initial Power-On

1-1) When the unit is plugged into the power, MICOM diagnoses the status of the temperature

sensors in a few minutes.

1-2) If defective sensor is found after Self-Diagnosis, relevant Display LEDs will blink at an

interval of 0.5 sec. and there will be no beeping sound. (Refer to the Self-Diagnosis Check

List)

1-3) When there is a defective sensor found and its relevant LED blinks, it will only recognize the

Self-Diagnosis button combination and it doesn't show the normal display.

But, the temperature will be controlled with the Emergency Operation.

1-4) To cancel the error code, fix the failure of the defective sensor or cancel the Initial SelfDiagnosis Function by pressing the Cold and the Coldest buttons for 13 seconds.

2) Self-Diagnosis Function during Normal Operation

① Press for 13 sec simultaneously

(This 13 sec includes the LED Blinking time.)

2-1) When the Cold and the Coldest buttons are held down for 13 seconds simultaneously

during the normal operation, it goes into the Self-Diagnosis function.

2-2) When it goes into the Self-Diagnosis, the entire display panel goes off and when there is an

error occurred, it will last for 30 seconds continuously and go to the normal operation

whether or not the error is fixed. (Refer to the Self-Diagnosis Check List below)

2-3) Buttons won't work during Self-Diagnosis.

43

44.

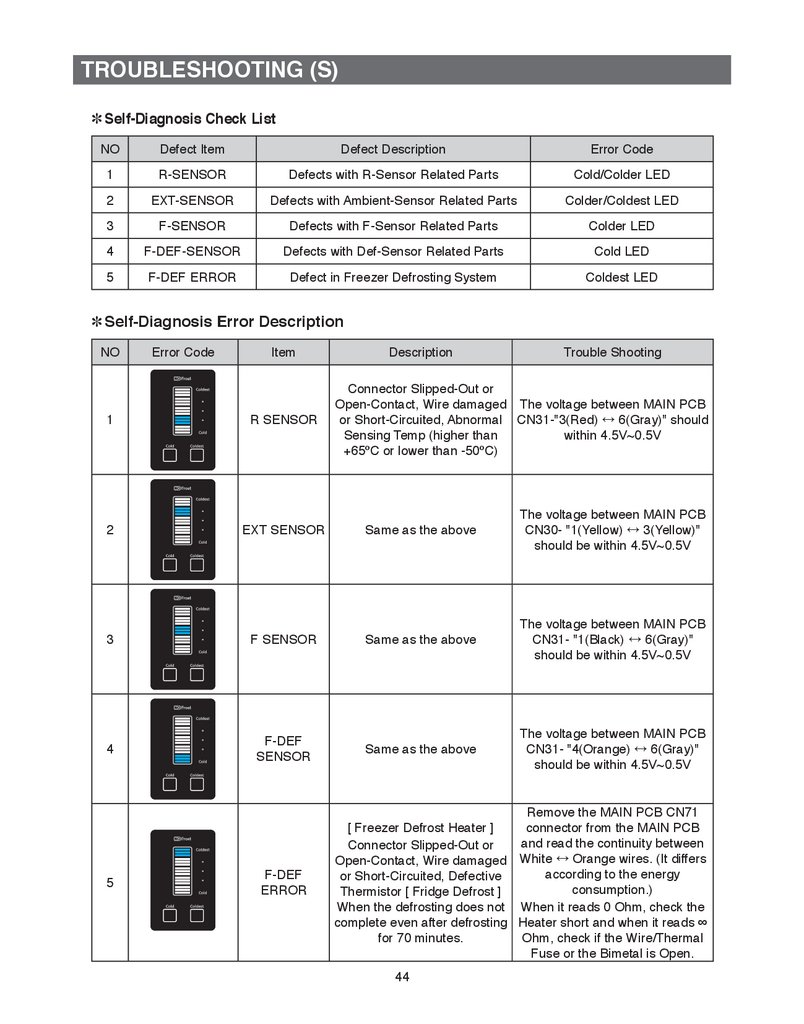

TROUBLESHOOTING (S)✽ Self-Diagnosis Check List

NO

Defect Item

Defect Description

Error Code

1

R-SENSOR

Defects with R-Sensor Related Parts

Cold/Colder LED

2

EXT-SENSOR

Defects with Ambient-Sensor Related Parts

Colder/Coldest LED

3

F-SENSOR

Defects with F-Sensor Related Parts

Colder LED

4

F-DEF-SENSOR

Defects with Def-Sensor Related Parts

Cold LED

5

F-DEF ERROR

Defect in Freezer Defrosting System

Coldest LED

✽ Self-Diagnosis Error Description

NO

Error Code

Item

Description

Trouble Shooting

Connector Slipped-Out or

Open-Contact, Wire damaged The voltage between MAIN PCB

or Short-Circuited, Abnormal CN31-"3(Red) ↔ 6(Gray)" should

Sensing Temp (higher than

within 4.5V~0.5V

+65ºC or lower than -50ºC)

1

R SENSOR

2

EXT SENSOR

Same as the above

The voltage between MAIN PCB

CN30- "1(Yellow) ↔ 3(Yellow)"

should be within 4.5V~0.5V

3

F SENSOR

Same as the above

The voltage between MAIN PCB

CN31- "1(Black) ↔ 6(Gray)"

should be within 4.5V~0.5V

4

F-DEF

SENSOR

Same as the above

The voltage between MAIN PCB

CN31- "4(Orange) ↔ 6(Gray)"

should be within 4.5V~0.5V

5

F-DEF

ERROR

Remove the MAIN PCB CN71

[ Freezer Defrost Heater ]

connector from the MAIN PCB

and read the continuity between

Connector Slipped-Out or

Open-Contact, Wire damaged White ↔ Orange wires. (It differs

according to the energy

or Short-Circuited, Defective

consumption.)

Thermistor [ Fridge Defrost ]

When the defrosting does not When it reads 0 Ohm, check the

complete even after defrosting Heater short and when it reads ∞

for 70 minutes.

Ohm, check if the Wire/Thermal

Fuse or the Bimetal is Open.

44

45.

TROUBLESHOOTING (S)4-1-3) Load Status Display Function

1) At the normal operation, press the Cold + Coldest buttons for 7 seconds.

Then, the "Colder (Cold), Colder (Mid), Colder (Coldest)" LED section will blink in an interval of

0.5 second for 3 seconds.

2) At this time, release the Cold + Coldest buttons and press the Cold button.

Then, it shifts to the Load Display mode.

3) The Load Display function shows what MICOM signals come out from MAIN PCB.

But, it just indicates that there are MICOM signals coming out. It does not necessarily mean that

the related parts (Loads) are operating. In other word, even though it shows a certain load

working, the related part may not operate due to such as a defective PCB relay or the defective

part itself (it needs checking).

4) The Load Display function lasts for 30 seconds and then it goes back to the normal operation.

① When pressing the buttons for 7 seconds simultaneously, the "Colder (Cold), Colder

(Mid), Colder (Coldest)" LED section blinks in an interval of 0.5 second for 3 seconds.

② At this time, release the buttons and press the Cold button.

Then, it will shift to the Load Test Mode.

45

46.

TROUBLESHOOTING (S)✽ Load Mode Check List

NO

Defect Item

①

Overload

②

Low Temperature

③

Normal Operation

⑤

COMP

⑧

Freezer Defrost

Heater

⑩

Fridge Damper Open

Defect Description

Error Code

LED On when the ambient

temperature is over 34ºC

Cold/Colder LED

LED On when the ambient

temperature is lower than 21ºC

Cold LED

Cold/Colder & Cold LEDs are all Off

When the ambient temperature

is between 22ºC~33ºC

Coldest LED

LED On when the COMP

operates

Colder/Coldest LED

LED On when the Freezer

Defrost

Heater is on

When the Fridge Damper is

Open

Colder LED

46

47.

TROUBLESHOOTING (S)4-1-4) Restoration of Previous Settings upon Instant Power Outage

1) If the Display Panel is initialized by the instant power outage, it will cause customer inquiries. To

prevent this, when the power is restored, the previous settings will be restored or reset based on

the inside temperature of the unit.

2) Upon the initial power on, it checks its Freezer temperature. When it is lower than +5ºC, it is to

be considered as an instant power failure and it brings back all its previous operation functions

(Temp. Control LED, Operation Function, etc) related to the panel display.

3) When it is higher than +5ºC, it is to be considered as a long-period power failure and it will initialize

the panel display. [set to "Colder (Mid)"] (Freezer: -19ºC, Fridge: 3ºC : "Colder (Mid) Setting Values)

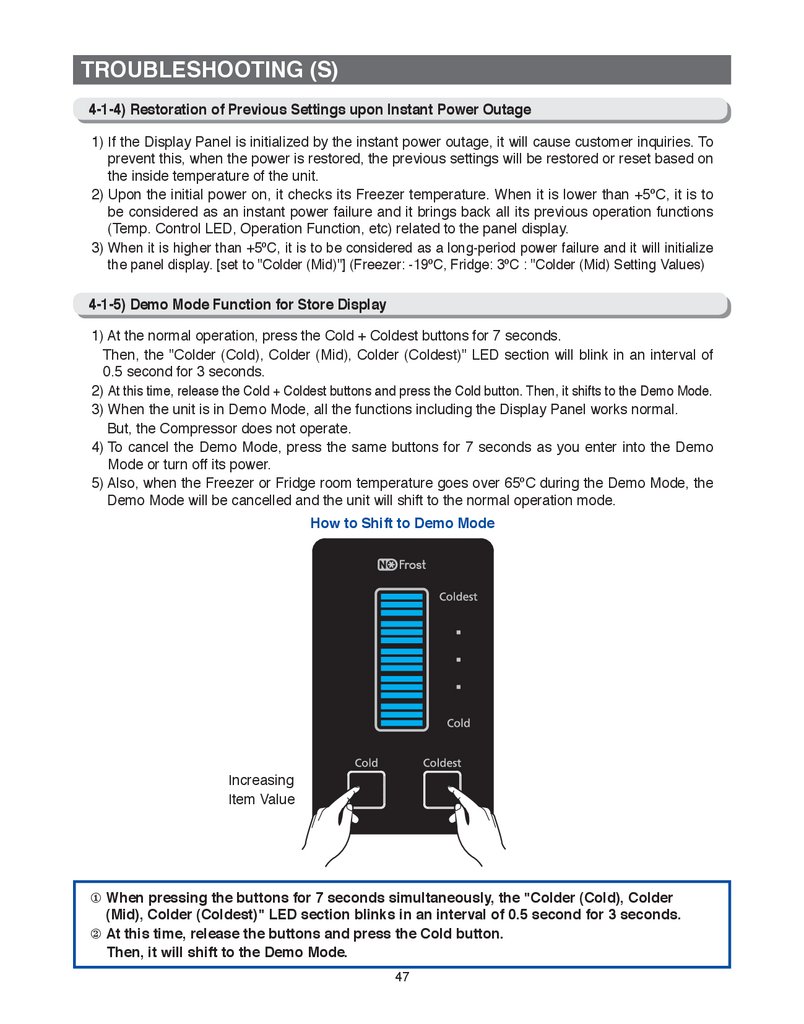

4-1-5) Demo Mode Function for Store Display

1) At the normal operation, press the Cold + Coldest buttons for 7 seconds.

Then, the "Colder (Cold), Colder (Mid), Colder (Coldest)" LED section will blink in an interval of

0.5 second for 3 seconds.

2) At this time, release the Cold + Coldest buttons and press the Cold button. Then, it shifts to the Demo Mode.

3) When the unit is in Demo Mode, all the functions including the Display Panel works normal.

But, the Compressor does not operate.

4) To cancel the Demo Mode, press the same buttons for 7 seconds as you enter into the Demo

Mode or turn off its power.

5) Also, when the Freezer or Fridge room temperature goes over 65ºC during the Demo Mode, the

Demo Mode will be cancelled and the unit will shift to the normal operation mode.

How to Shift to Demo Mode

Increasing

Item Value

① When pressing the buttons for 7 seconds simultaneously, the "Colder (Cold), Colder

(Mid), Colder (Coldest)" LED section blinks in an interval of 0.5 second for 3 seconds.

② At this time, release the buttons and press the Cold button.

Then, it will shift to the Demo Mode.

47

48.

TROUBLESHOOTING (S)4-1-6) Option Setting Function

● Press the the Cold + Coldest buttons on the Display Panel for 4 seconds simultaneously. Then,

the entire Display Panel will blink in an interval of 0.5 second for 3 seconds. While the entire

Display Panel is blinking, it shifts to the Option Mode when the Cold button is pressed.

● When there is no button press for 20 seconds at the Option Setting Mode, it will go back to the normal

display mode. There are two modes in the Option Setting Mode. When the Coldest LED is on, it displays

the Item Number. And, when the Coldest LED is off, it displays the Item Value. At the Item Number Display

Mode, press the Coldest button to shift it to the Item Value Display Mode and keep pressing the Coldest

button until selecting a desired Item Value. At the Item Value Display Mode, press the Cold button to shift it

to the Item Number Display Mode and keep pressing the Cold button until selecting a desired Item Value.

How to Shift to Option Setting Mode

① When pressing the Cold + Coldest buttons for

4 seconds simultaneously, the entire Temp.

LEDs will blink in an interval of 0.5 second for

3 seconds.

② At this time, release the buttons and press the

Cold button.

Option Mode & Button Description

On : Item #

Off : Item Value

Item # or

Item Value

Increasing

Item Value

Setting Item #

Note Basically, when units being shipped out, all the data in the Option function are cleared.

That is, the Default settings are “0”. However, for the purpose of quality improvement during mass production,

the Default values may change. Therefore, be sure to check quality information, such as SVC bulletins.

48

49.

TROUBLESHOOTING (S)4-1-7) Option Table

1) Freezer Temperature Shifting Table

Ex) Freezer Temperature : -1.0ºC Shift

Option Mode & Button Description

On : Item #

Off : Item Value

Item # or

Item Value

Increasing

Item Value

Setting Item #

0 ºC

-0.5 ºC

-1.0 ºC

-1.5 ºC

0.5 ºC

49

1.0 ºC

1.5 ºC

2.0 ºC

50.

TROUBLESHOOTING (S)2) Fridge Temperature Shifting Table

Ex) Fridge Temperature : -1.0ºC Shift

Option Mode & Button Description

On : Item #

Off : Item Value

Item # or

Item Value

Increasing

Item Value

Setting Item #

0 ºC

-0.5 ºC

-1.0 ºC

-1.5 ºC

0.5 ºC

50

1.0 ºC

1.5 ºC

2.0 ºC

51.

TROUBLESHOOTING (TT, TE, TW)4-1. Check-List before Trouble-Shooting

4-1-1) Test Function (Forced Operation / Forced Defrost)

● When the Power Freeze and the Fridge buttons on the display panel are held down for more

than 8 seconds, the Panel Display will be off and it goes into the Test Mode. At the Test mode, all

the display buttons will work as the Test button.

● Each time the Test button is pressed, it will change in the following order.

F

orced Operation → Forced F-Defrost (Fd) → Cancellation (Normal Operation) It is

recommended that the unit unit be disconnected and reconnected from the electricity supply to

in to terminate the operation of the Test function.

1) How to Enter Test Mode

① Press for 8 seconds simultaneously

② When pressing any one of the five buttons, it will go into the Test Mode.

51

52.

TROUBLESHOOTING (TT, TE, TW)2) Test Mode Description

1. Forced Operation Function

1-1) Each time any button is pressed during the Test Mode, the display lamp changes in the

order of “FF 1”, "FF 2" and "FF 3" indicating that it is in the Forced Operation.

At this time, it starts alarming with “Beep” sounds.

1-2) When the Forced Operation is selected, the compressor starts without a 7-minute delay in

any operation mode. At this time, when it is in a Defrost mode, it stops defrosting and the

Forced Operation begins. (If the Forced Operation begins as soon as the compressor stops,

it may cause the overload. So, take care when entering into the Forced Operation.)

1-3) When the Forced Operation is selected, the compressor and the F-Fan operate for 24 hours

without stopping and the Fridge compartment will operate according to the set temperature.

1-4) When the unit is shifted to the Forced Operation, the Freezer and the Fridge temperatures

will be set to -25ºC and 1ºC.

1-5) W

hen the Forced Operation is selected, the Power Freeze function won't work.

And, when the Power Freeze function is selected, the Power Freeze LED will go off in 10 seconds.

1-6) To cancel the Forced Operation in the middle of the Test function, turn off the power and

turn it on again, or select the Test Cancellation mode.

1-7) The alarm sound during the Forced Operation (0.25 sec On and 0.75 sec Off) keeps on until

the Forced Operation completes and there is no cancellation function.

2. Forced Defrost Function

2-1) When the Test button is pressed once more at the Forced Operation (FF), “Fd” lights up on

the Display Panel and the Forced Operation will be cancelled and the Freezer compartment

starts defrosting.

2-2) At this time, it sends out "Beeping" sound for 3 seconds. This alarm sound repeats (0.5 sec

On and 0.5 sec Off) which keeps on until the Forced F-Defrost finishes.

3. Test Cancellation Mode

3-1) W

hen turning the display panel into the Test mode and pressing the TEST button once more during

the Forced F-Defrost, the Forced F-Defrost will be cancelled and it will go back to the normal

operation. Also, when the unit is plugged out and in again, the Test mode is to be deactivated.

52

53.

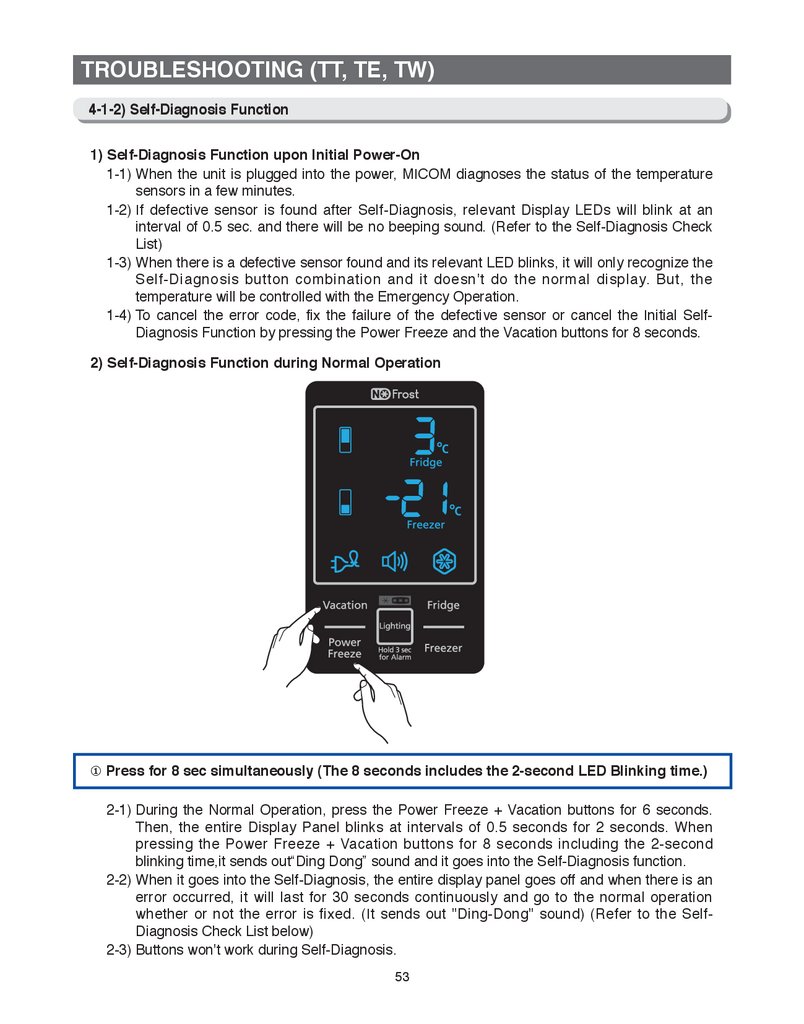

TROUBLESHOOTING (TT, TE, TW)4-1-2) Self-Diagnosis Function

1) Self-Diagnosis Function upon Initial Power-On

1-1) When the unit is plugged into the power, MICOM diagnoses the status of the temperature

sensors in a few minutes.

1-2) If defective sensor is found after Self-Diagnosis, relevant Display LEDs will blink at an

interval of 0.5 sec. and there will be no beeping sound. (Refer to the Self-Diagnosis Check

List)

1-3) When there is a defective sensor found and its relevant LED blinks, it will only recognize the

Self-Diagnosis button combination and it doesn't do the normal display. But, the

temperature will be controlled with the Emergency Operation.

1-4) To cancel the error code, fix the failure of the defective sensor or cancel the Initial SelfDiagnosis Function by pressing the Power Freeze and the Vacation buttons for 8 seconds.

2) Self-Diagnosis Function during Normal Operation

① Press for 8 sec simultaneously (The 8 seconds includes the 2-second LED Blinking time.)

2-1) During the Normal Operation, press the Power Freeze + Vacation buttons for 6 seconds.

Then, the entire Display Panel blinks at intervals of 0.5 seconds for 2 seconds. When

pressing the Power Freeze + Vacation buttons for 8 seconds including the 2-second

blinking time,it sends out“Ding Dong” sound and it goes into the Self-Diagnosis function.

2-2) When it goes into the Self-Diagnosis, the entire display panel goes off and when there is an

error occurred, it will last for 30 seconds continuously and go to the normal operation

whether or not the error is fixed. (It sends out "Ding-Dong" sound) (Refer to the SelfDiagnosis Check List below)

2-3) Buttons won't work during Self-Diagnosis.

53

54.

TROUBLESHOOTING (TT, TE, TW)F-10

R/F-1

a

f

g

e

d

a

b

f

c

e

g

c

d

When there is an 8-segment LED

blinking, it indicates that there

is an error to its related parts.

Ex) R 2nd Digit (R-1) "b" :

R-Sensor Related Error

✽ Self-Diagnosis Check List

NO

Category

Defect Description

Error Code

1

R-SENSOR

Defects in Parts related to R-SENSOR

Fridge Digit (R-1) : "b"

2

CSZ-SENSOR

Defects in Parts related to CSZ-SENSOR

Fridge Digit (R-1) : "f"

3

EXT-SENSOR

Defects in Parts related to EXT-SENSOR

Fre 2nd Digit (F-1) : "a"

4

F-SENSOR

Defects in Parts related to F-SENSOR

Fre 2nd Digit (F-1) : "b"

5

F-DEF-SENSOR

Defects in Parts related to F-DEF-SENSOR

Fre 2nd Digit (F-1) : "c"

6

F-FAN Error

Defects in Parts related to F-FAN

Fre 2nd Digit (F-1) : "d"

7

F-DEFROST Error

Defects in Parts related to F-DEFROST

Fre 2nd Digit (F-1) : "g"

8

Damper Heater

Error

Damper Heater open / Wire Defects

Fre 1st Digit (F-10) : "b"

54

b

55.

TROUBLESHOOTING (TT, TE, TW)✽ Self-Diagnosis Error Description

NO

Item

Description

Trouble Shooting

1

R SENSOR

Connector Slipped-Out or

Open-Contact, Wire damage

or Short-Circuited, Abnormal

Sensing Temp (higher than

+65ºC or lower than -50ºC)

The voltage between MAIN PCB

CN31-"3(Red) ↔ 6(Gray)" should

within 4.5V~0.5V

2

CSZ SENSOR

Same as the R SENSOR

The voltage between MAIN PCB

CN31- "2(Brown) ↔ 6(Gray)"

should be within 4.5V~0.5V.

3

EXT SENSOR

Same as the R SENSOR

The voltage between MAIN PCB

CN30- "1(Yellow) ↔ 3(Yellow)"

should be within 4.5V~0.5V

4

F SENSOR

Same as the R SENSOR

The voltage between MAIN PCB

CN31- "1(Black) ↔ 6(Gray)"

should be within 4.5V~0.5V

5

DEF SENSOR

Same as the R SENSOR

The voltage between MAIN PCB

CN31- "4(Orange) ↔ 6(Gray)"

should be within 4.5V~0.5V

6

7

8

Error Code

When the related Fan Motor

operates, it occurs if the

contact of the Feed Back

F-FAN ERROR

Signal Wire is defective, the

Motor Wire is slipped out or the

Motor is defective.

[ Freezer Defrost Heater ]

Connector Slipped-Out or OpenContact, Wire damage or ShortCircuited, Defective Thermistor

F-DEF

ERROR

[ Fridge Defrost ]

When the defrosting does not

complete even after it does

defrosting for 70 minutes.

DAMPER

HEATER

ERROR

The voltage between MAIN PCB

CN72-"5(Gray) ↔ 4(Sky Blue)"

should be within 7V~12V

Remove the MAIN PCB CN71 connector

from the MAIN PCB and read the

continuity between White ↔ Orange

wires. (It differs according to the energy

consumption.) When it reads 0 Ohm,

check the Heater short and when it

reads ∞ Ohm, check if the Wire/Thermal

Fuse or the Bimetal is Open.

Remove the MAIN PCB CN75 connector

from the MAIN PCB and read the

It occurs when the Damper

Heater is detected as open due continuity between 1(Black) ↔ 2(Brown)

wires. (Around 140 ~ 160 Ohm)

to the slipped-out connector,

the open contact or the open When it reads 0 Ohm, check the Heater

wire of the Damper Heater. short and when it reads ∞ Ohm, check if

the wire is open or slipped out.

55

56.

TROUBLESHOOTING (TT, TE, TW)4-1-3) Load Status Display Function

1) At the normal operation, press the Power Freeze + Vacation buttons for 6 seconds.

Then, the entire Display Panel will blink in an interval of 0.5 second for 2 seconds.

2) At this time, release the Power Freeze + Vacation buttons and press the Fridge button (it sends

out "Ding Dong" sound.) Then, it shifts to the Load Display mode.

3) The Load Display function shows what MICOM signals come out from MAIN PCB.

But, it just indicates that there are MICOM signals coming out. It does not necessarily mean that

the related parts (Loads) are operating. In other word, even though it shows a certain load

working, the related part may not operate due to such as a defective PCB relay or the defective

part itself (it needs checking).

4) The Load Display function lasts for 30 seconds and then it goes back to the normal operation.

① Press the Power Freeze + Vacation

buttons for 6 seconds

simultaneously. Then, the Display

LEDs will blink for 2 seconds.

② At this time, release the buttons and

press the Fridge bu

e.

①

②

①

5) The following image shows load locations with the 7-segment LEDs.

F-10

R/F-1

a

f

g

e

d

56

a

b

f

c

e

g

b

c

d

57.

TROUBLESHOOTING (TT, TE, TW)✽ Load Mode Check List

NO

Defect Item

①

Overload

Defect Description

Error Code

Fridge "e"

LED On when the ambient

temperature is

over 34ºC

Fridge "f"

LED On when the ambient

temperature is

lower than 21ºC

②

Low Temperature

③

Normal Operation

④

Demo Mode

⑤

COMP

Freezer 2nd Digit "a"

LED On when Comp is running

⑥

F FAN HIGH

Freezer 2nd Digit "b"

LED On when the F-Fan runs

High

⑦

F FAN LOW

Freezer 2nd Digit "c"

LED On when the F-Fan runs

Low

⑧

F-DEF HEATER

Freezer 2nd Digit "d"

LED On when the Freezer

Defrost Heater is on

⑨

CSZ Room

Damper Open

Freezer 1st Digit "f"

CSZ Room Damper

Open(OPTION)

⑩

R Room

Damper Open

Freezer 1st Digit "g"

When the Fridge Damper is

Open

Fridge "e","f" LEDs are all off.

When the ambient temperature

is between 22ºC~33ºC

LED On when the unit is on

Demo Mode

Fridge "g"

57

58.

TROUBLESHOOTING (TT, TE, TW)4-1-4) Restoration of Previous Settings upon Instant Power Outage

1) If the Display Panel is initialized by the instant power outage, it will cause customer inquiries. To

prevent this, when the power is restored, the previous settings will be restored or reset based on

the inside temperature of the unit.

2) Upon the initial power on, it checks its Freezer temperature. When it is lower than +5ºC, it is to

be considered as an instant power failure and it brings back all its previous operation functions

(Power Freeze, Vacation, Fridge, Freezer, Alarm On, etc) related to the panel display.

3) When it is higher than +5ºC, it is to be considered as a long-period power failure and it will

initialize the panel display. (Freezer: -20ºC, Fridge: 3ºC)

4-1-5) Demo Mode Function for Store Display

1) At the normal operation, press the Power Freeze + Freezer buttons for 8 seconds.

Then, it shifts to the Demo Mode.

2) When the unit is in Demo Mode, all the functions including the Display Panel works normal.

But, the Compressor does not operate.

3) To cancel the Demo Mode, press the same buttons for 8 seconds as you enter into the Demo

Mode or turn off its power.

4) Also, when the Freezer or Fridge room temperature goes over 65ºC during the Demo Mode, the

Demo Mode will be cancelled and the unit will shift to the normal operation mode.

5) The initial real temperature display function will end.

How to Shift to Demo Mode

Press the Power Freeze + Freezer buttons for 8 seconds simultaneously

58

59.

TROUBLESHOOTING (TT, TE, TW)4-1-6) Option Setting Function

● W

hen the Vacation + Freezer buttons are pressed for 12 seconds during the normal operation

mode, the Display will shift to the Option Setting Mode.

● When there is no button press for 20 seconds at the Option Setting Mode, it will go back to the

normal display mode.

How to Shift to Option Setting Mode

① When pressing the Freezer + Vacation

buttons for 12 seconds simultaneously,

it will shift to the Option Service Mode.

Option Mode & Button Description

Item# 2nd Digit

Item# 1st Digit

00 ~ 09 : All Off

10 ~ 19 : Off – Off - On

20 ~ 29 : Off – On - On

30 ~ 39 : On – On - On

Item Set-Value

Item# Down

Item# Up

Item Set-Value

Down

Item Set-Value

Up

59

60.

TROUBLESHOOTING (TT, TE, TW)● When the Display Panel converts to the Option Setting mode, the entire Display except the

Fridge as shown below Temp LED goes off.

Freezer Temp Setting

Fridge Temp Setting

1) For example, if you want to shift the standard temp of the Freezer compartment by -2ºC, follow the

steps below.

This function is to change the default temperature and when the default temperature of the Freezer

compartment is -20ºC and the default setting is lowered by -2ºC with the Option function, the default

temperature will be controlled at -22ºC.

That is, when changing temperature options, the Freezer compartment will operate at -22ºC internally

even if it shows -20ºC on the display panel.

Therefore, the temperature will be controlled by -2ºC lower than the set temperature on the display panel.

Note Basically, when units being shipped out, all the data in the Option function are cleared.

That is, the Default settings are “0”. However, for the purpose of quality improvement during

mass production, the Default values may change. Therefore, be sure to check quality

information, such as SVC bulletins.

2) After changing into the Option mode, “0"s on both of the Fridge and Freezer compartments lights

up on the display panel. (when units being shipped out, the unit will be shipped out with "0"s set

on both of the Fridge and Freezer compartments. However, for the purpose of quality

improvement during mass production, the Default values may change.)

- When only “0” lights up on the Fridge compartment, the Freezer temperature option can be set

and the current set Freezer temperature will show on the display panel.

3) I f the Freezer temp code is set to "4" as the following table after setting the Fridge section to "0", the

Freezer base temperature is to be lowered by -2ºC (Refer to the Freezer temperature setting image.)

: In 15 seconds after completing the adjustment, MICOM is to store the setting value in EEPROM

and it goes back to the normal display mode, deactivating the Option Setting mode.

5) The Fridge temperature can be adjusted with the same method.

6) Make sure not to change the factory-set default values except in extreme cases.

Also, the Option Setting is to be completed when it goes back to the normal display mode.

So, do not turn off the unit before it goes back to the normal display mode.

60

61.

TROUBLESHOOTING (TT, TE, TW)4-1-7) Option Table

Note T

here are other option setting functions not for repair purposes.

S

o, they are not handled in this manual.

(Except those described in this manual, do not change other values.)

1) Freezer Temp Shift Table

Setting Item

Freezer Temp Shift

MODEL

T, E, W

Option Item

Setting Value

Location : Fridge Temp LED

0

Fridge Temp

Option

Value

0

0

1

-0.5ºC

2

-1.0ºC

3

-1.5ºC

4

-2.0ºC

5

-2.5ºC

6

-3.0ºC

7

-3.5ºC

8

+0.5ºC

9

+1.0ºC

10

+1.5ºC

11

+2.0ºC

12

+2.5ºC

13

+3.0ºC

14

+3.5ºC

15

+4.0ºC

Ex) When shifting the Freezer

default temp by -2.0ºC

61

62.

TROUBLESHOOTING (TT, TE, TW)1) Fridge Temp Shift Table

Setting Item

Fridge Temp Shift

MODEL

T, E, W

Option Item

Setting Value

Location : Freezer Temp LED

1

Freezer Temp

Option

Value

0

0

1

-0.5ºC

2

-1.0ºC

3

-1.5ºC

4

-2.0ºC

5

-2.5ºC

6

-3.0ºC

7

-3.5ºC

8

+0.5ºC

9

+1.0ºC

10

+1.5ºC

11

+2.0ºC

12

+2.5ºC

13

+3.0ºC

14

+3.5ºC

15

+4.0ºC

Ex) When shifting the Fridge

default temp by +2.0ºC

62

63.

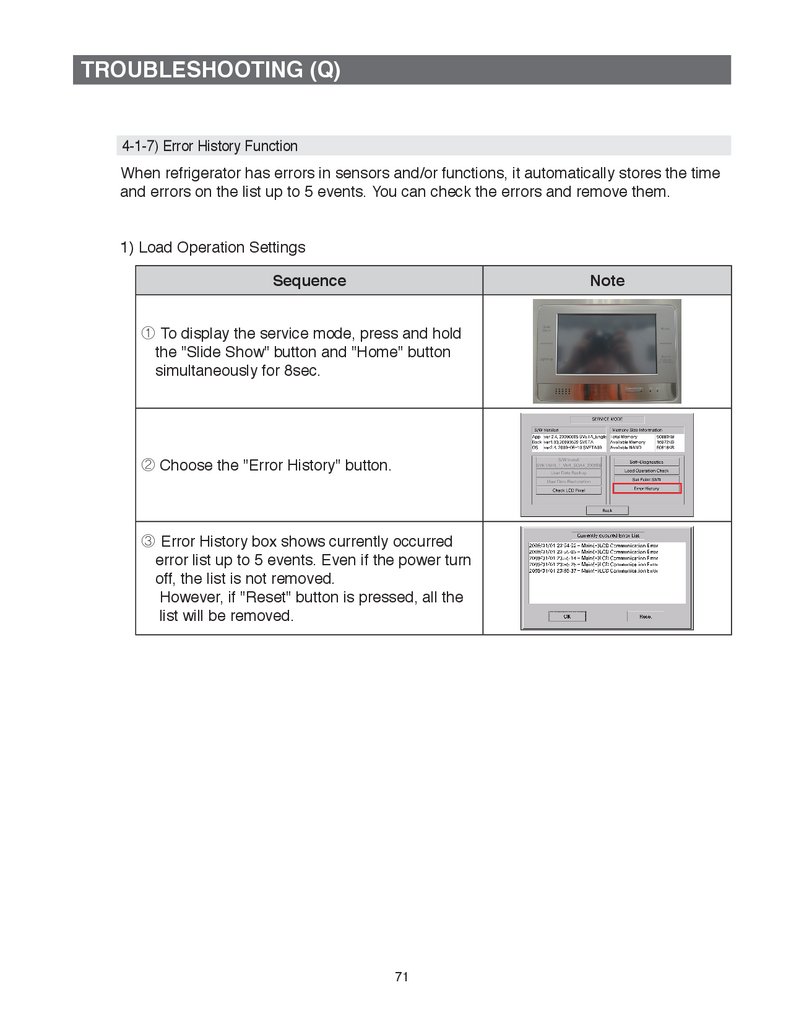

TROUBLESHOOTING (Q)Service Functions

Functions

How to operate

Keys

Time

Use this functions...

Forced Operation

“Lighting” + “Alarm”

To set the forced operation and forced defrost.

Showroom Mode

"Slide Show" + "Lighting"

To set Display Mode at the shop.

To calibrate the stylus pen touch point of LCD

Touch Screen

Touch screen Calibrations “Lighting” + “Home”

Self-Diagnostics

To check the failure modes.

Load Operation Check

Set Point Shift Mode

Error History

8 sec

To check the present operating load of

refrigerator.

To change the setting options about the regrigerator operating

status. Need careful decision for the option change.

“Slide Show” + “Home”

To check the latest 5 errors.

Check LCD Pixel

To check the LCD Pixel failures.

User Data Back up/

Restoration

To back up & restoration the user’s data when

update software and/or replace PBA panel.

63

64.

TROUBLESHOOTING (Q)4-1. Check Points prior to Failure Diagnostics

4-1-1) Forced Operations

1) Forced Operation settings

Sequence

Note

①T

o display the test mode, press and hold the

“Lighting” button and “Alarm” button for 8sec

simulataneously.

② Choose the “NEXT>>” button.

When “NEXT” button is selected, the next

displayed mode is automatically run.

※ Operationg Sequence of the NEXT button

Stop ForceTest -> ForceRun1 -> ForceRun2 ->

ForceRun3 -> Force FZ Defrost ->

Stop ForceTest

2) Force Test (Pull-down)

2-1) At the Force Test mode, press "NEXT>>" button once then the buzzer will beep

until this mode is cancelled.

2-2) At this Force Test (pull-down) mode, the compressor will start immediately and if

the system is in the defrost cycle, defrost cycle will be cancelled right away.

NOTE) I f this Force Test (pull-down) mode begins right after the compressor was off,

the compressor may not start running due to an overload condition.

2-3) At this mode, the compressor and freezer fan will operate continuously for 24

hours and the refrigerator fan will be on and off according to the set temperature.

2-4) When Force Test (pull-down) mode is selected, FZ compartment temperature will

be set as -25℃ and FF compartment temperature will be set as 1℃.

2-5) Power Freeze is not available during Force Test (pull-down) mode.

2-6) In order to cancel this mode at any time, choose the Stop Force Test on the Force

Test mode or power off the system.

3) Force FZ Defrost

3-1) At the Force Run mode, press "NEXT>>" button again on the Force Test mode to

begin the defrost cycle for the refrigerator.

3-2) The beep sound continues until Force FZ Defrost mode is ceased.

64

65.

TROUBLESHOOTING (Q)4) Cancellation

4-1) To return to normal operation during Force FZ Defros mode, turn the DISPLAY

PANEL into Forced Operation mode and select "NEXT>>" button. Then Stop

Force Test message will show up.

4-2) Otherwise, simply unplug the power cord, then plug it again to return to a normal

operation.

4-1-2) Communication Error Displays

1) Displays when Panel ↔ MAIN MICOM communication has error

1-1) If there is no answer for 10 seconds after the panel MICOM received the

requirement of communication, the following error message pops up on the

display panel.

1-2) Cool Select Zone Display will be alternately ON/OFF until the communication

error is cancelled. (0.5sec ALL ON, 0.5sec ALL OFF alternately)

65

66.

TROUBLESHOOTING (Q)4-1-3) Self-Diagnostics

1) Self-Diagnostics in the initial Power ON

1-1) The control board performs a self diagnostics test and checks the temperature

sensors' abilities.

1-2) If a sensor failure occurs, sensor failure message shows on the display panel.

1-3) If "OK" button is selected on the sensor error message box, the box will

disappear. But it can be checked at the Self-Diagnostics mode.

1-4) If any error occurs during initial Power ON, refrigerator will be controlled by the

emergency operation.

1-5) All troubled sensors are corrected, the sensor errors can be cancelled

automatically.

2) Self-Diagnostics in the normal operation

Sequence

Note

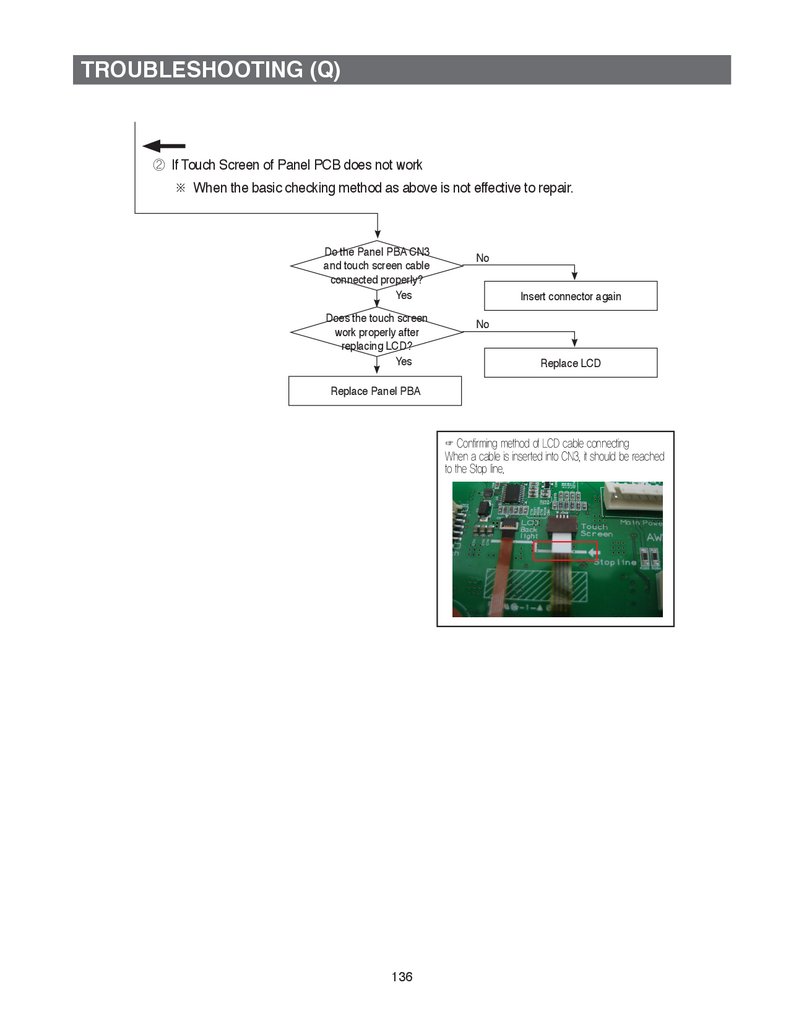

①T

o display the service mode, press and hold