Похожие презентации:

Sichuan Liuhe Forging Co., Ltd. Manufacturer of High Quality Special Steel. www.lhforging.com

1.

Sichuan Liuhe Forging Co., Ltd.Manufacturer of High Quality Special Steel

www.lhforging.com

2.

TABLE OF CONTENTSBrief Introduction

Application of High Quality Special

Steel

Process and Equipments

Technical Research

1

3.

1. Brief IntroductionThe company is established in April, 2004 in Jiangyou,

Sichuan

with the registered capital of USD13 Million. Its fxed asset

equals USD230 Million with the total occupies area of

296,000 M2 and 823

stafs. Its sales income in 2017 is USD96 Million. The

company is a

mixed ownership enterprice with state shares.

The company is mainly engaged in the production of high

quality stainless steel, heat-resistant steel, superalloy,

precision alloy forged products, forgings and machined

parts.

2

4.

Brief IntroductionSichuan Liuhe Forging Co.,

Ltd.

• Daily management

• Primary steelmaking,

forging, inspection

Beichuan ESR

Workshop

ESR

Wholly-owned subsidiary

Deyang Liuhe

Heat treatment & machining

Wholly-owned subsidiary

3

5.

Brief IntroductionNational High-Tec. Enterprise

Gas Turbine Enterprise Alliance of Sichuan Province

in 2014

Research Base of Blade Materials Used for Steam

Turbine Units

4

6.

Vocation Health & Safety Management System:GB/T 28001-2011 OHSAS 18001 2007

Environmental Management System:

GB/T 24001-2004 idt ISO 14001:200

Test Center: CNAS Approved

5

7.

2. Application of High Quality Special Steel6

8.

ApplicationHigh Quality Special Steel Manufacturer

Blades, strengthening rings

applied for supercritical and

ultra-supercritical units and

nuclear power steam

turbines,forgings for bolts

Superior forged alloy

and tool steel round

bars & blocks

Top grade heat-resistant,

corrosion-resistant special

steel, superalloy,

corrosion-resistant alloy,

precision alloy

7

9.

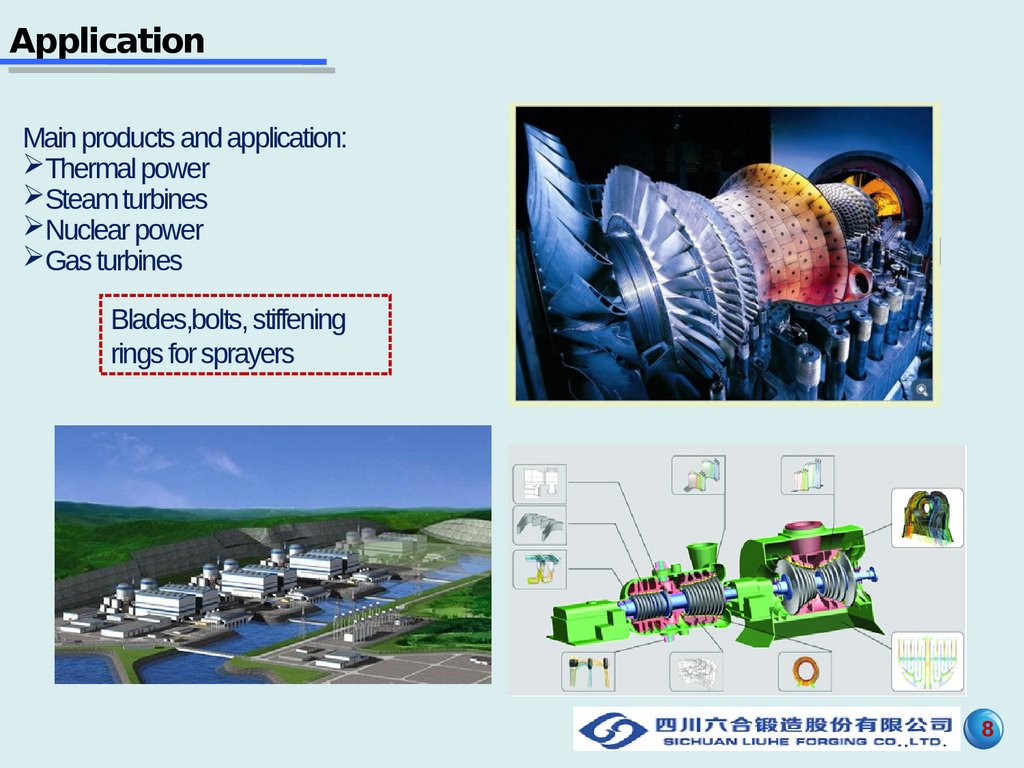

ApplicationMain products and application:

Thermal power

Steam turbines

Nuclear power

Gas turbines

Blades,bolts, stiffening

rings for sprayers

8

10.

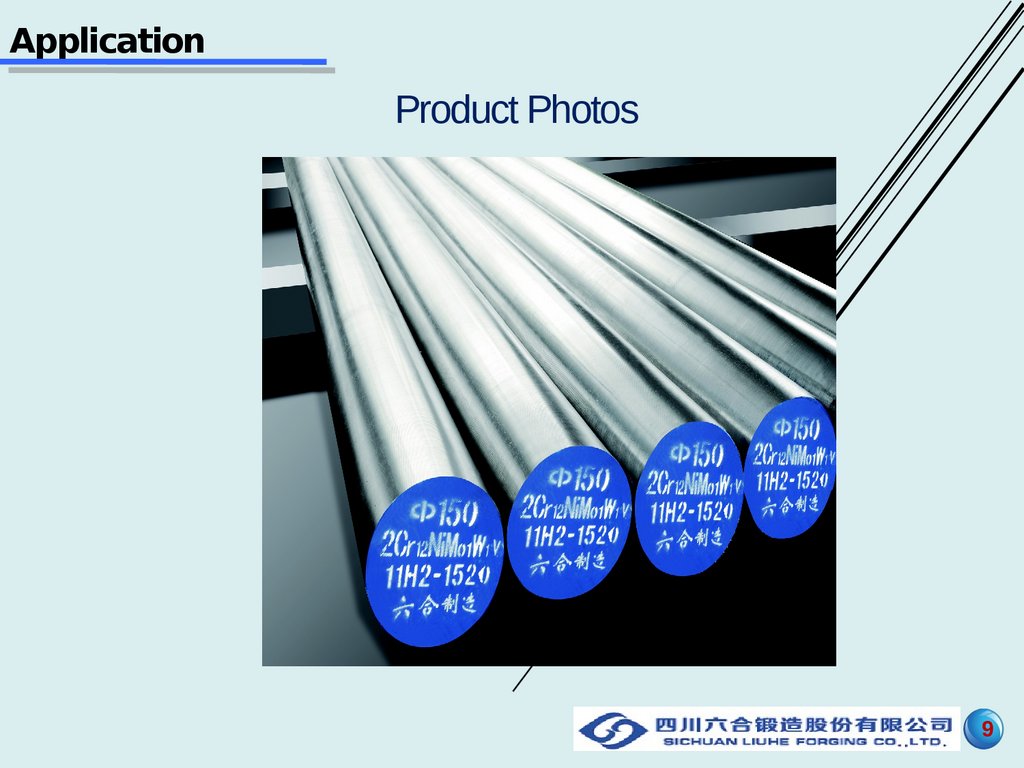

ApplicationProduct Photos

10

9

11.

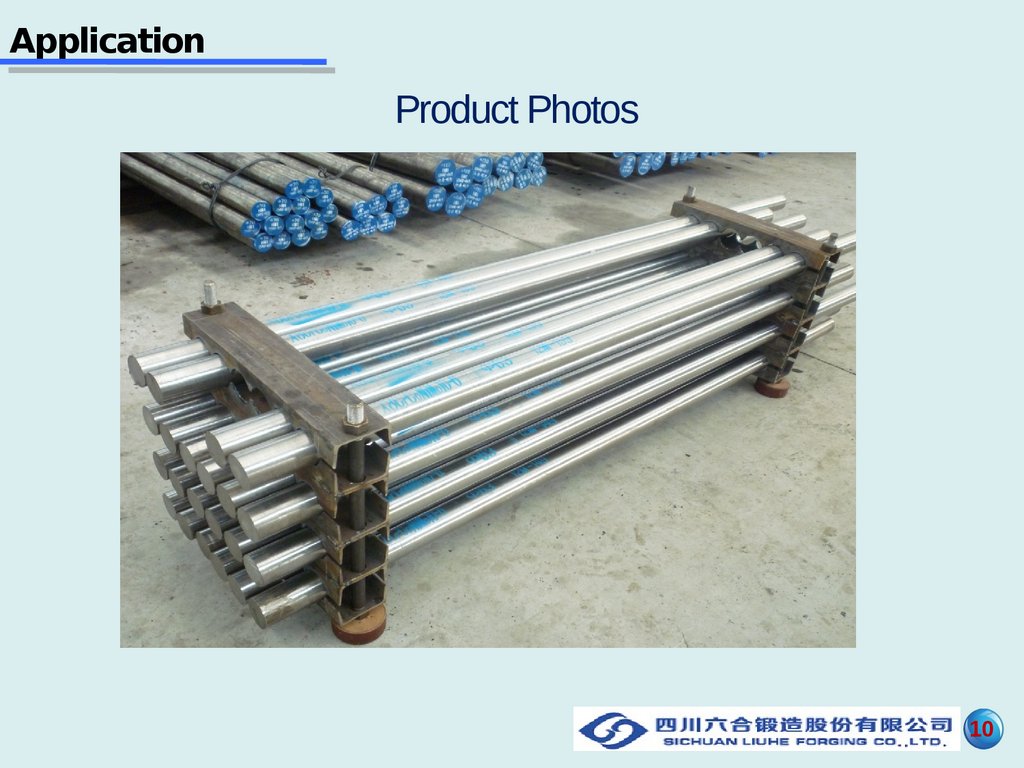

ApplicationProduct Photos

10

12.

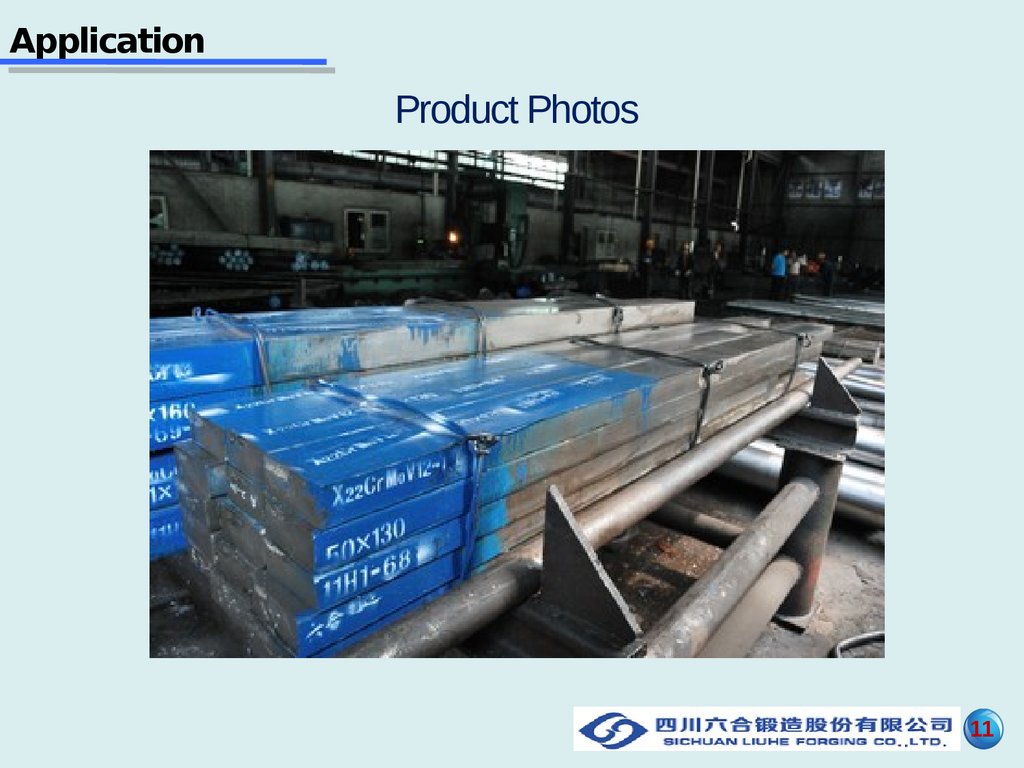

ApplicationProduct Photos

11

13.

ApplicationProduct Photos

12

14.

ApplicationPacking Photos

13

15.

Product Photos14

16.

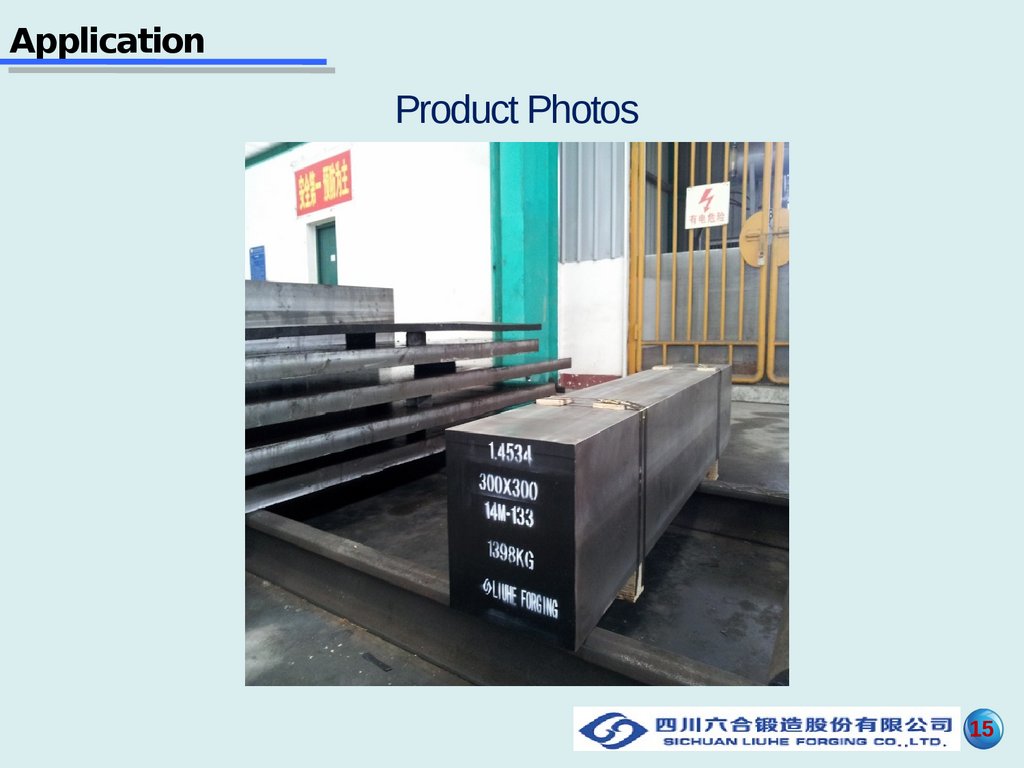

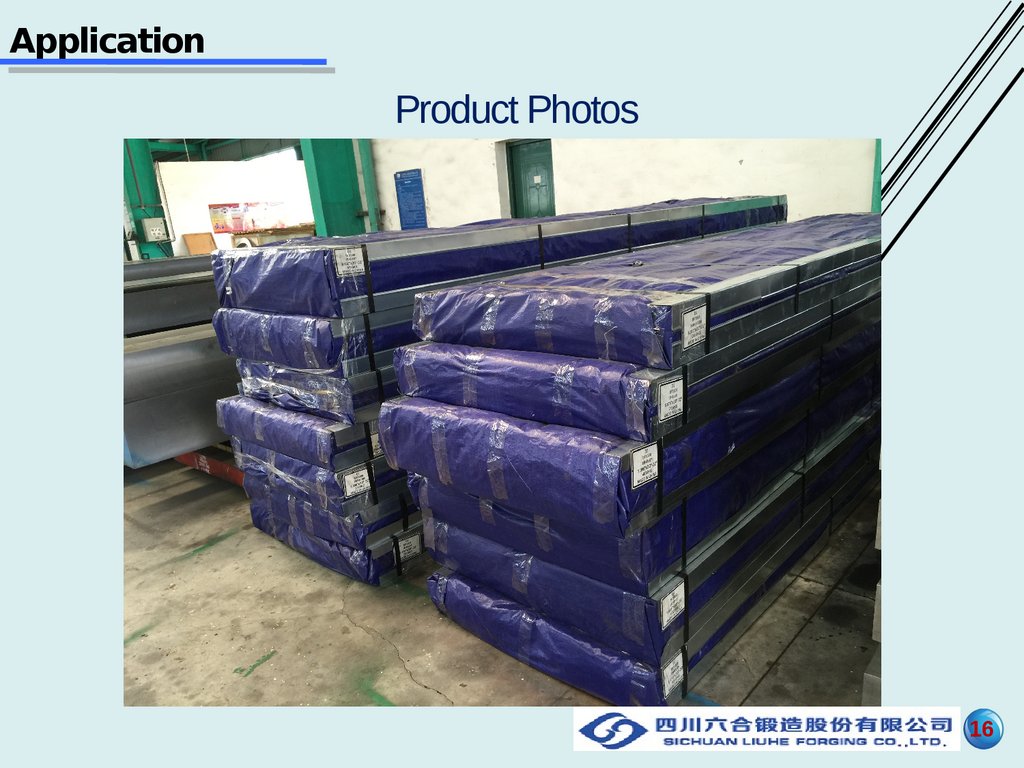

ApplicationProduct Photos

15

17.

ApplicationProduct Photos

17

16

18.

ApplicationProduct Photos

18

17

19.

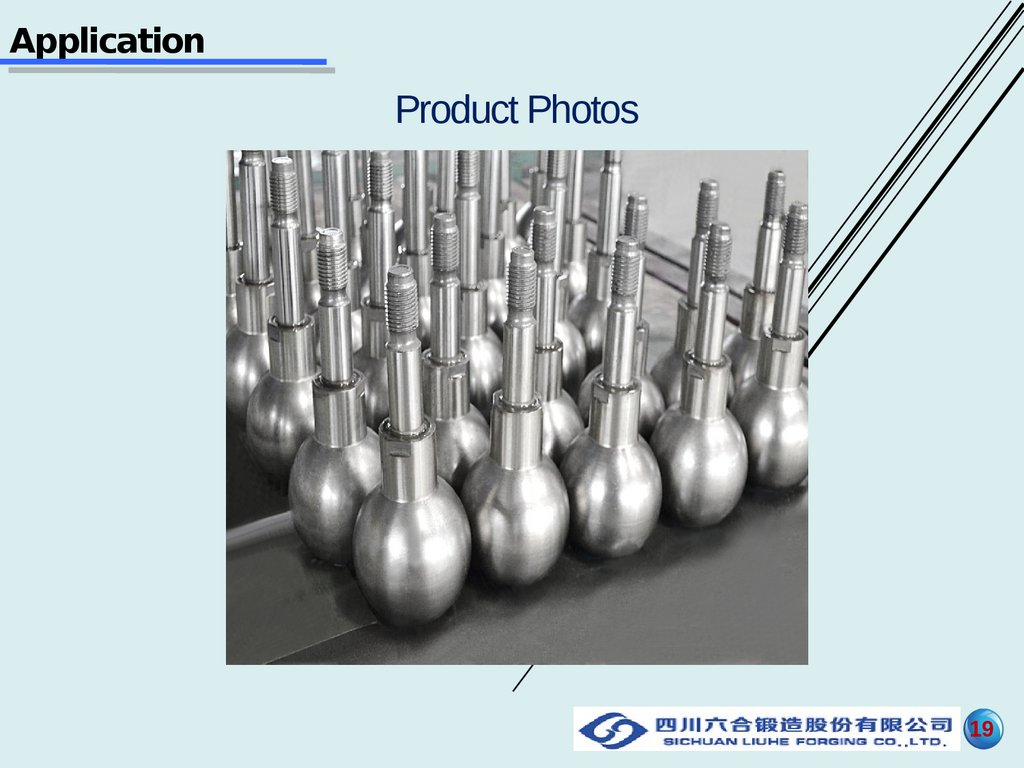

ApplicationProduct Photos

19

18

20.

ApplicationProduct Photos

20

19

21.

ApplicationProduct Photos

21

20

22.

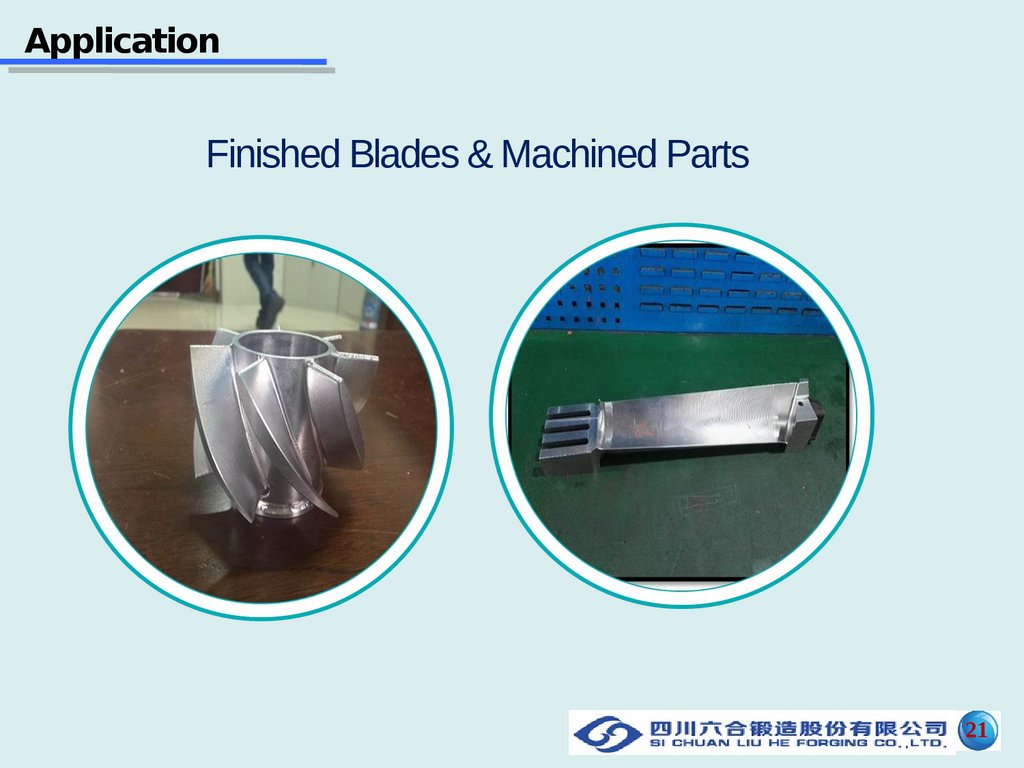

ApplicationFinished Blades & Machined Parts

21

23.

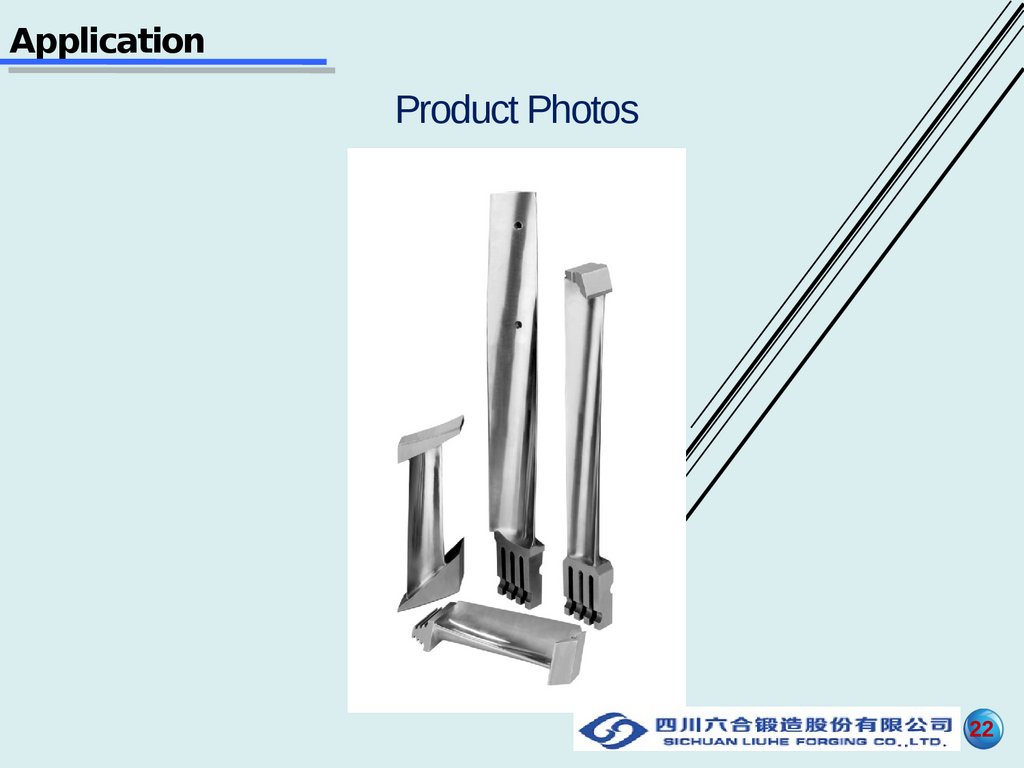

ApplicationProduct Photos

23

22

24.

ApplicationProduct Photos

24

23

25.

ApplicationPacking Photos

24

26.

ApplicationMiddle and small forgings:

Small rotors, stiffening rings, fastening rings, tangential supporting plates,

diaphragms

Precision alloy rings for aviation field: 4J32

GH 600 tubeplates for chemical industry; 17-4 forgings for impellers

Forging of 1Cr10Mo1NiWVNbN rotors

Forging of GH600 tubeplates

Tangential supporting

forgings

Stiffening rings (Co3W2)

Forged rings (4J32)

5

Forged rings (C422)

25

27.

3. Process and Equipments26

28.

Process andEquipments

Typical process chart

One cycle

melting

Secondary

remelting

Forging

Heat treatment

Machining

IM

VIM

AOD

LF

VD

ESR: 14 sets (1MT - 6MT) ; VAR: 1MT 12MT

Electro-hydraulic hammers

Air hammers

2000MT forging press (Rolling milll of round bars

and fflat bars: under construction)

High-temperature furnace: 4 sets

Medium-temperature furnace: 4 sets

Machining center

Lathes

Milling machines

Delivery

27

29.

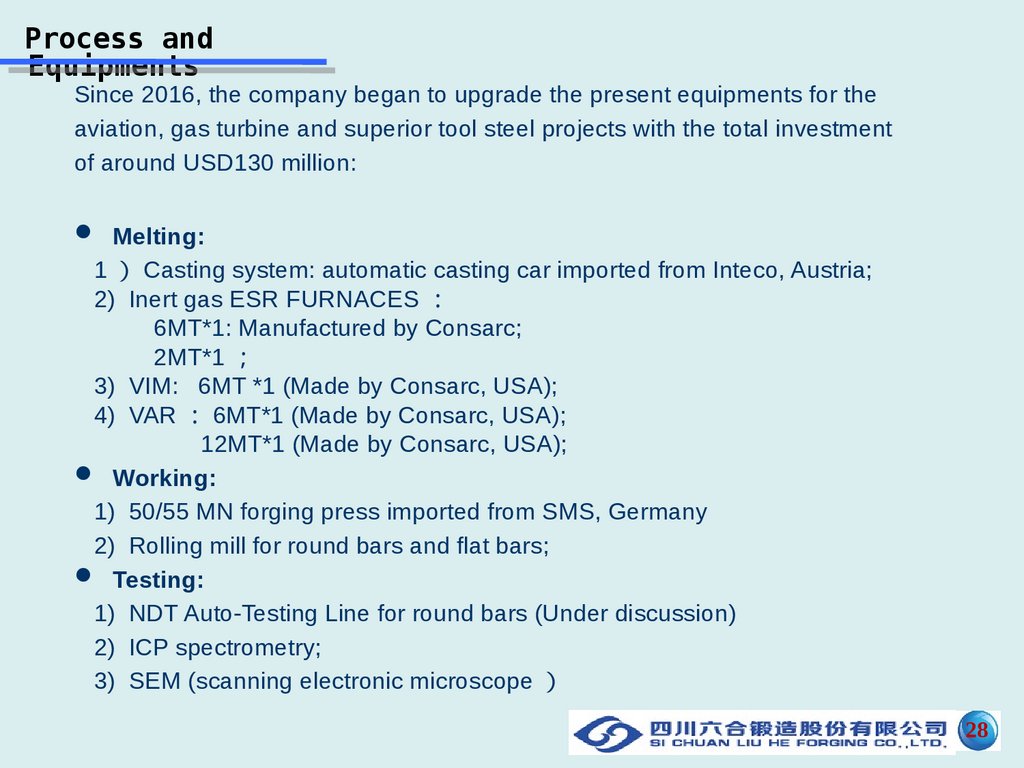

Process andEquipments

Since 2016, the company began to upgrade the present equipments for the

aviation, gas turbine and superior tool steel projects with the total investment

of around USD130 million:

Melting:

1 Casting system: automatic casting car imported from Inteco, Austria;

2) Inert gas ESR FURNACES

6MT*1: Manufactured by Consarc;

2MT*1

3) VIM: 6MT *1 (Made by Consarc, USA);

4) VAR 6MT*1 (Made by Consarc, USA);

12MT*1 (Made by Consarc, USA);

Working:

1) 50/55 MN forging press imported from SMS, Germany

2) Rolling mill for round bars and flat bars;

Testing:

1) NDT Auto-Testing Line for round bars (Under discussion)

2) ICP spectrometry;

3) SEM (scanning electronic microscope

28

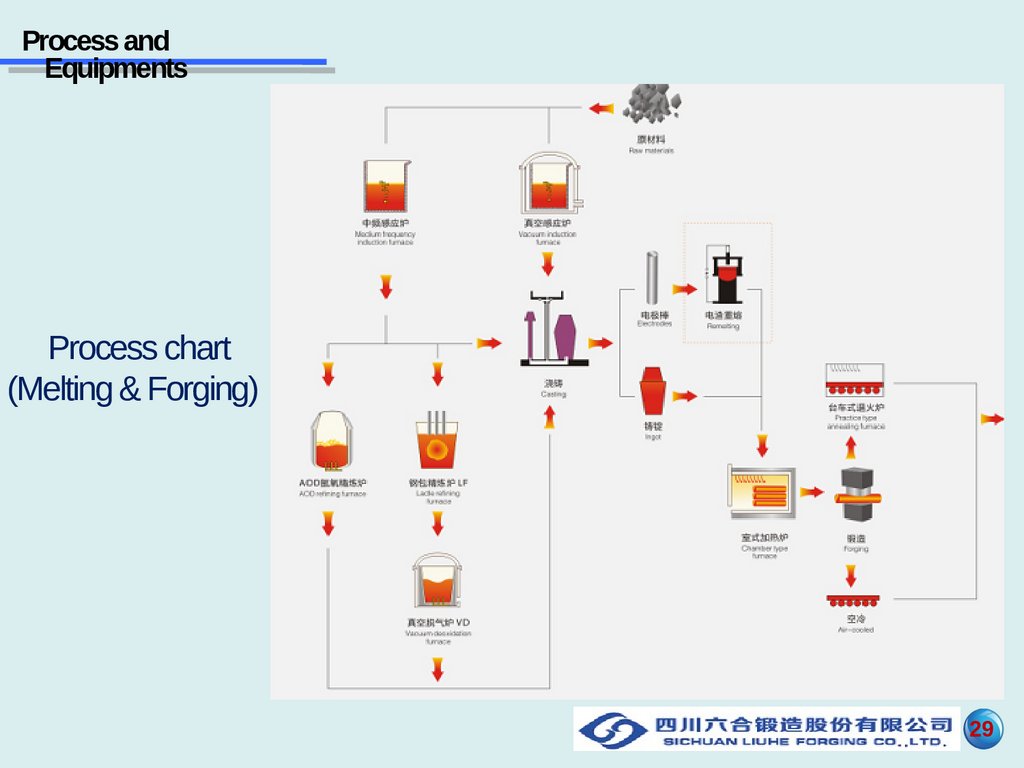

30.

Process andEquipments

Process chart

(Melting & Forging)

29

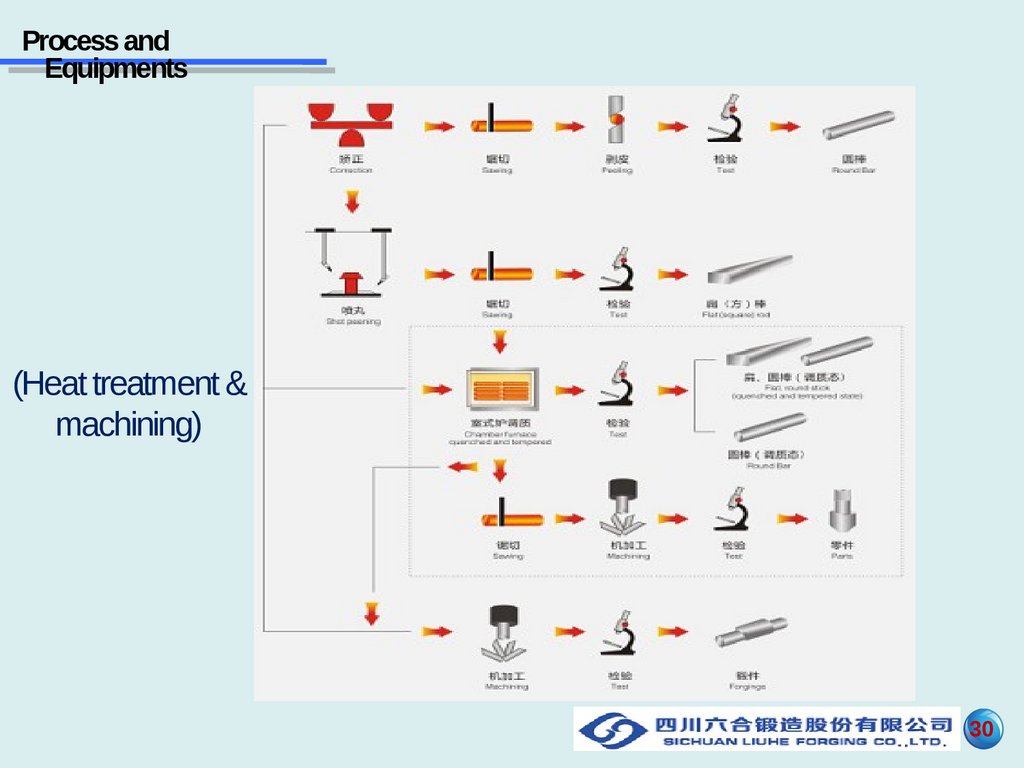

31.

Process andEquipments

(Heat treatment &

machining)

30

32.

Process and Equipments31

33.

Process and EquipmentsNewly installed 6MT VIM

Under installation

After instalation

32

34.

Process and EquipmentsSecondary remelting Equipments

Ordinary ESR

furnaces: 5MT

Inert gas ESR: 6MT

12MT VAR

33

35.

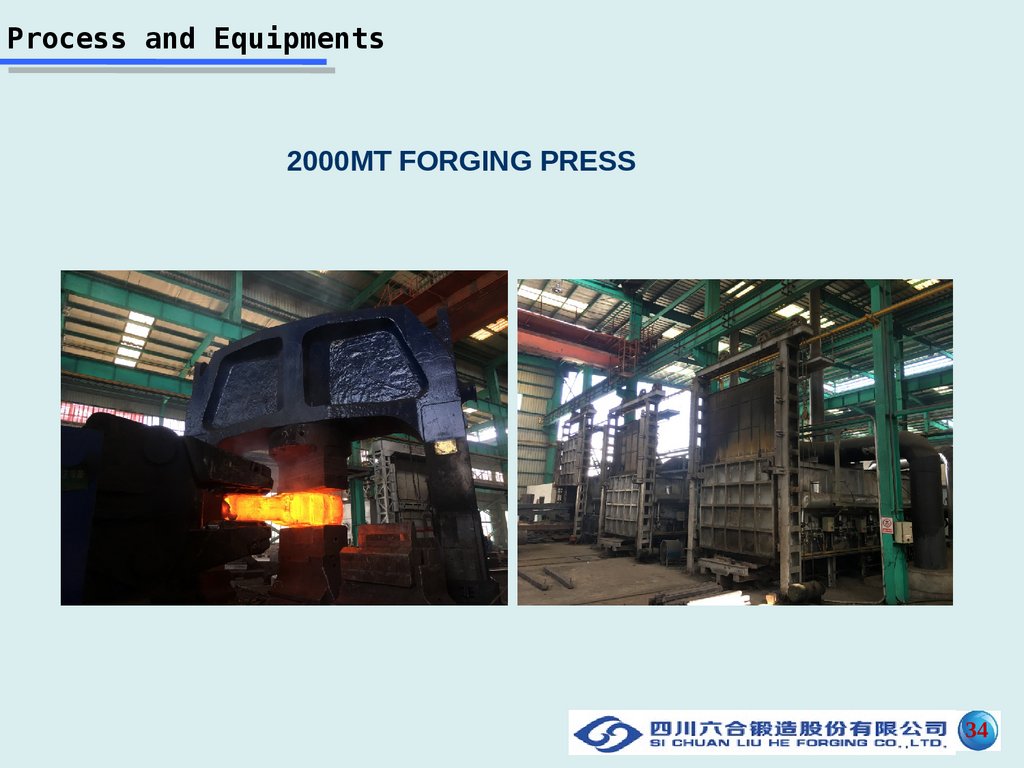

Process and Equipments2000MT FORGING PRESS

34

36.

Process and Equipments6000MT forging press

35

37.

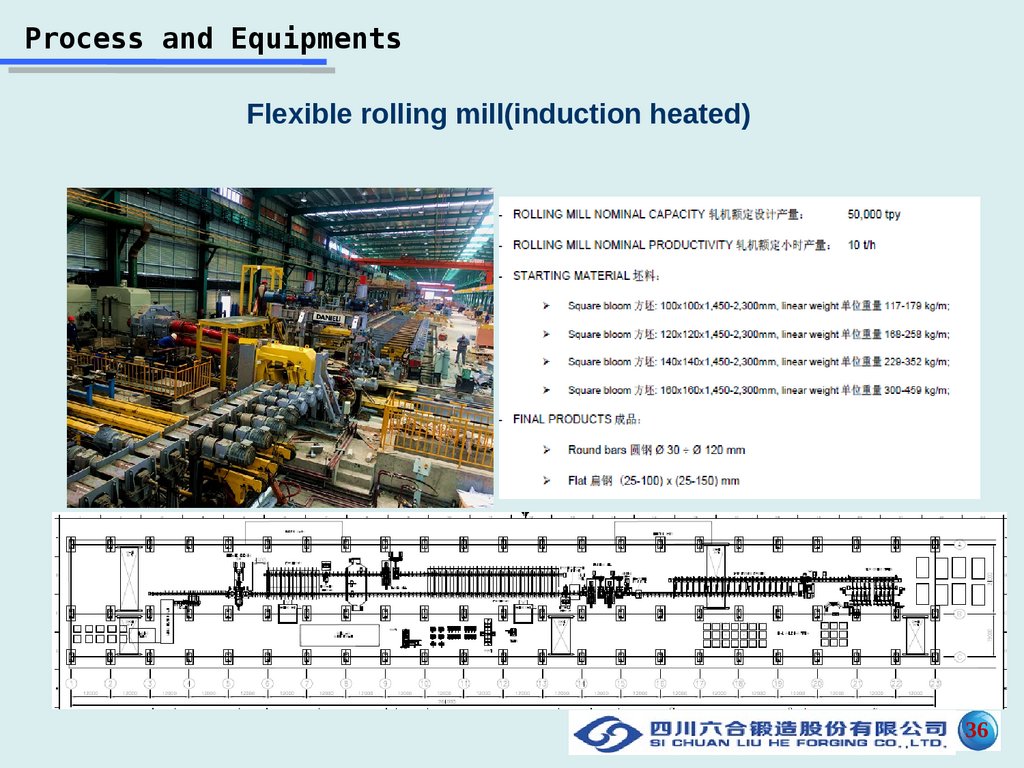

Process and EquipmentsFlexible rolling mill(induction heated)

36

38.

Process and EquipmentsHeat treatment furnaces

37

39.

Process and EquipmentsTest Equipements 1

检测项目

化学成分

chemistry

热处理

Heat

treatment

检测设备 QA

Inspection Equipment

型号

数量

QTY

直读光谱仪 Direct-reading spectrometer

SPECTRO MAXx

LMF

2

氮氧仪 N/O analyzer

Eltra ON-900

1

碳硫仪 C/S analyzer

Eltra CS-800

1

碳硫分析仪 C/S analyzer

QL-CS1

1

手持式 XRF 分析仪

Portable Alloy Analysis Niton XL2 800

XL2

1

看谱镜 SPECTRUM TESTER

WX-5

3

1000 度箱式电炉 heat treatment furnace

SX-G16103

3

1000 度箱式电炉 heat treatment furnace

SX-G07103

2

1200 度箱式电炉 heat treatment furnace

SX-G07103

1

1300 度箱式电炉 heat treatment furnace

SX-G07103

1

38

40.

Process and EquipmentsTest Equipements 2

检测项目

物理性能

Mechanical

property

高倍组织

Microscopes

探伤

NDT

测温

检测设备 QA

Inspection Equipment

型号

数量

QTY

拉伸试验机 Tension test

room temperature & high temperature

冲击试验机 Impact test 80℃

Zwick

Z250 、 GNT100

ZBC3302-A

高温持久蠕变试验机 high temperature rapture

test

GWT1304A

12

洛氏硬度计 RC tester

HR 150

1

电子布氏硬度计 HB tester

MC010-HBE-3000A

3

携带式里氏硬度计 Portable HL tester

金相显微镜 图像分析仪

HT 120

Axio Scope

1

1

金相显微镜 图像分析仪

Leica

1

金相显微镜

Axio Lab Al

3

磁粉探伤机 MT

CJW-3000L

1

超声波探伤仪 UT

CTS-22A/CTS-9006

5

光学高温计 SPECTROPYROMETER

WGG2-210

1

3

4

39

41.

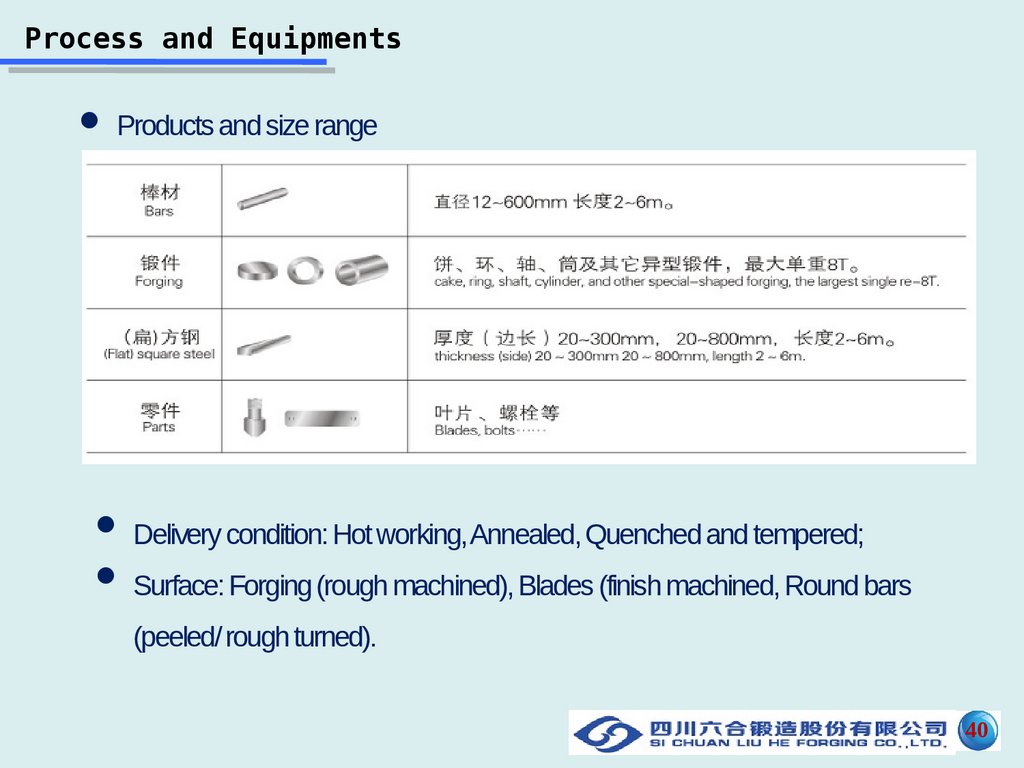

Process and EquipmentsProducts and size range

Delivery condition: Hot working, Annealed, Quenched and tempered;

Surface: Forging (rough machined), Blades (finish machined, Round bars

(peeled/ rough turned).

40

42.

Process and EquipmentsCapability and Features of High Quality Special Steel

Capability:

1) Melting: 60,000MT (one cycle melting); 30,000MT (ESR)

2) Machining: 50,000MT

3 Heat treatment:25,000MT

4 Finish machining of blades: 30,000 pieces

Features:

1) Full process: Raw material, melting, ESR, forging, rolling, heat treatment,

machining;

2) High alloy, high value added;

3 Specific applications;

4 Easily arranged for small quantity and big lots

5) Outsourcing ability

41

43.

4. Technical Development42

44.

Technical DevelopmentTechnical research

成都理工大学硕士博士生工作站

授牌仪式

Participated in the drafting and revision of

national standards:

Second revision unit of ‘Steam Blade

Materials’

‘Stainless steel for nuclear steam

turbines’

Drafting unit of national standard of

‘Duplex stainless steel’

Five national tool steel specifications.

43

45.

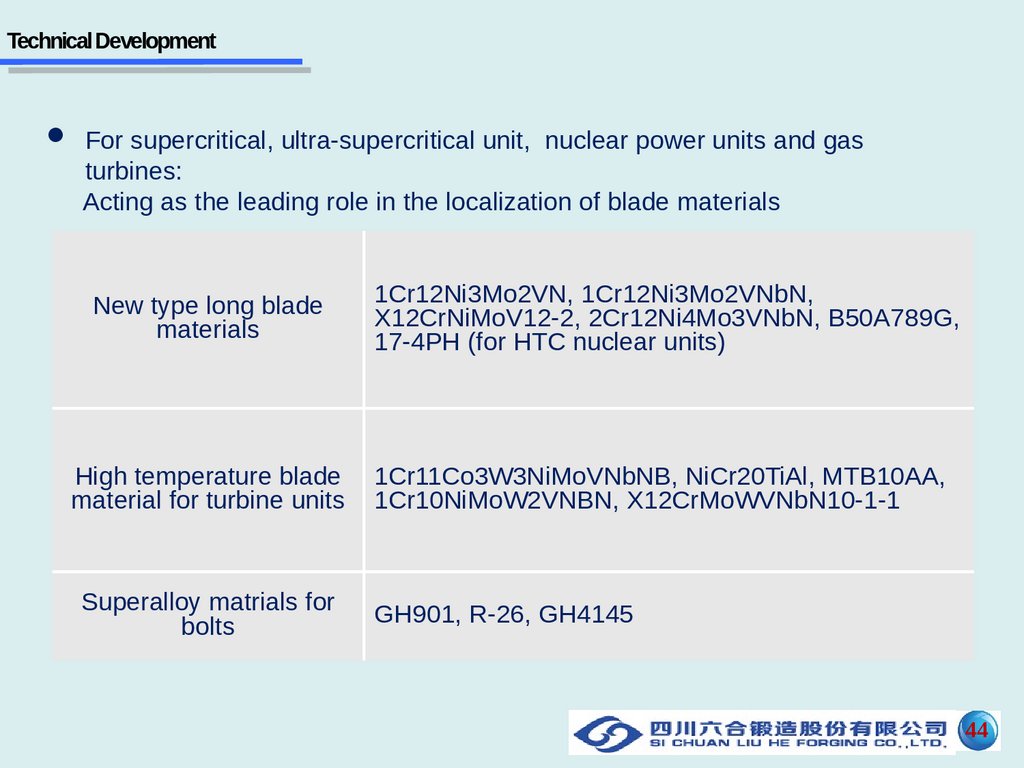

Technical DevelopmentFor supercritical, ultra-supercritical unit, nuclear power units and gas

turbines:

Acting as the leading role in the localization of blade materials

New type long blade

materials

1Cr12Ni3Mo2VN, 1Cr12Ni3Mo2VNbN,

X12CrNiMoV12-2, 2Cr12Ni4Mo3VNbN, B50A789G,

17-4PH (for HTC nuclear units)

High temperature blade

material for turbine units

1Cr11Co3W3NiMoVNbNB, NiCr20TiAl, MTB10AA,

1Cr10NiMoW2VNBN, X12CrMoWVNbN10-1-1

Superalloy matrials for

bolts

GH901, R-26, GH4145

44

46.

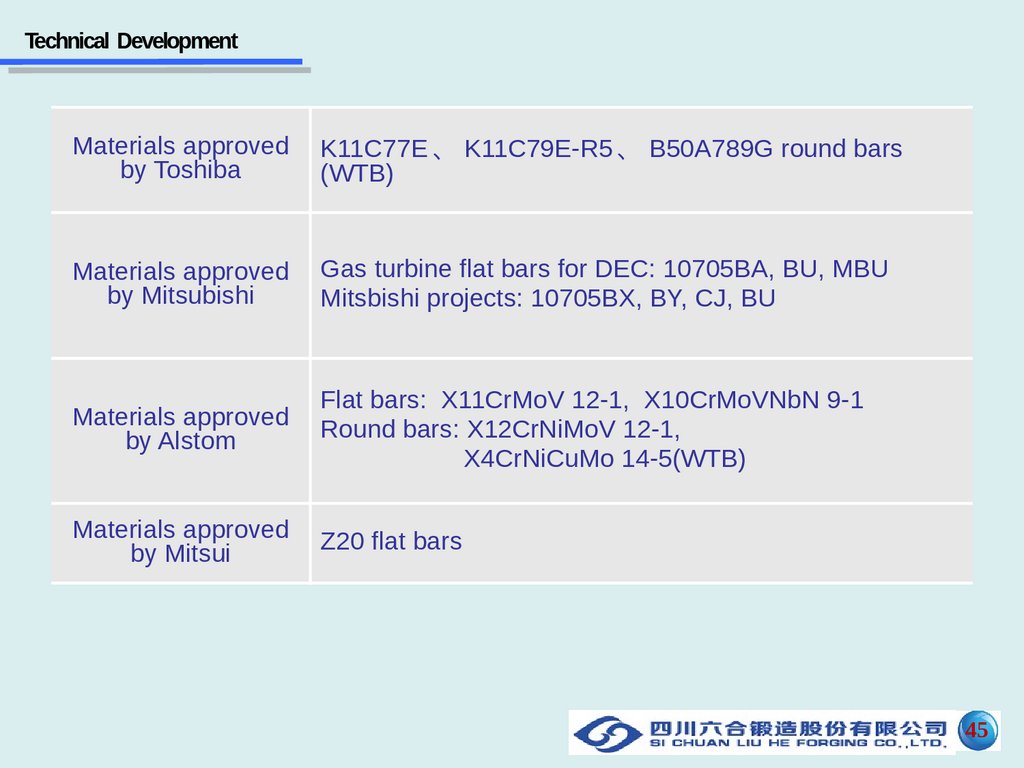

Technical DevelopmentMaterials approved

by Toshiba

K11C77E 、 K11C79E-R5 、 B50A789G round bars

(WTB)

Materials approved

by Mitsubishi

Gas turbine flat bars for DEC: 10705BA, BU, MBU

Mitsbishi projects: 10705BX, BY, CJ, BU

Materials approved

by Alstom

Flat bars: X11CrMoV 12-1, X10CrMoVNbN 9-1

Round bars: X12CrNiMoV 12-1,

X4CrNiCuMo 14-5(WTB)

Materials approved

by Mitsui

Z20 flat bars

45

47.

Technical DevelopmentAustenitic stainless steel with higher alloy from ordinary grades to

duplex stainless steel

Nuclear power projects

for DEC

Duplex stainless steel

F304LN, SUS 310S

S31803, S32550, S32750, 1Cr21Ni5Ti

Tool steel: Tool steel round bars and blocks for export:

D2,H13, SKD 11, SKD 61, A2, A8, S7,1.2379, 1.2344,

1.2343,

1.2767,1.2083,1.2390, M2, 4Cr13, NAK80, FS136, etc.

46

48.

Technical DevelopmentSuperalloy, corrosion-resistant alloy and precision alloy:

Superalloy

GH825, GH80A, GH4033/GH4133, Inconel600,

Inconel625, Nimonic90A, HastelloyX, Haynes230

Precision alloy

4J32, 4J40, 4J42, 4J36

Corrosion alloy

UNS NO8020, UNS NO8825

47

49.

Technical DevelopmentOrientation of key technical development in the next 5 years

Process

1) Automatic controlling technology for casting;

2) Process control and simulation of secondary melting;

3) Automatic controlling and simulation of high alloy rolling

Product

1) Development of stainless steel, heat resistant steel, super

strengh steel, super alloy for aviation industry

2) Development of material for gas turbines;

3) Development of super strength steel;

4) Development of top fastener materials;

5) Development of top hot working tool steel and plastic mould

steel

48

50.

THANK YOUSichuan Liuhe Forging Co. Ltd.

www.lhforging.com

Промышленность

Промышленность Реклама

Реклама