Похожие презентации:

Improvement of organizational performance

1. Improvement Of Organizational Performance

Prepared byDr. Marwa Dewidar

Manager of quality administration –Gharbia Directorate for

health affairs

Associated trainer –IBCT

TQM- AUC

Master Degree in family medicine

Hospital management fellowship

2. Definition:-

Definition:Quality management “QM” / QI:QM / QI is defined as a planned, systematic, Organization

wide, approach to the monitoring, analysis and improvement

of organization performance, thereby continually improving

the quality of patient care and services provided and the

likelihood of desired patient outcomes.

3. Juran Trilogy of QM

• Quality management employs three basicactivities “ Juran trialogy of QM”:

• Quality Planning

• Quality Control

• Quality Improvement

4. Juran Trilogy

QualityPlanning

Quality

Improvement

Quality

Control

The three components work together to provide QM Process

that function like a loop. There is no starting point or end

point, put all components work together in a continuous way

5. Juran Trilogy

• Quality PlanningIt is a structured process designed to create

services that meet the customer’s needs. It

involves six logical steps.

6. Quality Planning

Establish the project

Identify customers

Discover customer’s needs

Develop service features

Develop detailed process

Develop process control / transfer to operation

7. Juran Trilogy

QualityPlanning

Quality

Improvement

Quality

Control

8. Quality Control/Measurement

• Quality control process helps health teams tounderstand and control their every day work

processes, and establish a basis for improvement of

these processes.

• It helps assure that routine activities and

responsibilities are performed correctly and

consistently.

• It involves the following steps:

9. Quality Control/Measurement

• Step 1: Measure actual performance• Step 2: Compare the results with

established standards

• Step 3: Act on the difference

10. Juran Trilogy

QualityPlanning

Quality

Improvement

Quality

Control

11. Quality Improvement

• This process is the means of raising qualityperformance to unprecedented levels

(breakthrough). It involves the following

steps:

12. Problem solving cycle

1- Identifying problems/ opportunities for improvement.2- Defining the problem operationally

3- Selecting the team

4- Analysing and studying the problem to identify its root

causes

5- Developing solutions and actions for improvement

6- Implementing and evaluating quality improvement

efforts

13. The JC (joint commission )Principals for QI:-

The JC (joint commission )Principals for QI:1. Organization wide dedication. تفانى2. Leadership commitment and active

participation.

3. Work on vital processes, i.e., those

processes which have a direct impact on

patient outcomes.

4. Reduction of barriers and conflicts that

may hinder QI in the organization.

5. Use feedback from all customers.

14. The ISO 9000-2000 QM Principals

Principle 1: Customer focused organization.Principle 2: Leadership.

Principle 3: Involvement of people.

Principle 4: Process approach.

Principle 5: System approach to management.

Principle 6: Continual improvement.

Principle 7: Factual approach to decision making.

Principle 8: Mutually beneficial supplier relationships.

15. QI Process Approaches

Plan-Test-Act-Check Approach

FOCUS-PDCA

IMPROVE

FADE cycle

Juran’s Quality Improvement Process (QIP)

Xerox TEN Step benchmarking

16. QI Process Approaches

Process Improvement Model

Decision Making Cycle/ PI Approach (APIE)

“IDEA” Approach

Six Sigma “DMAIC”

Lean Thinking Approach

Kizen QI Process

17.

• SHEWHART (PDCA )AND DEMING MODEL (PDSA)• P = PLAN

• D = DO (PILOT )

• CHECK OR STUDY

• ACT

18.

• (IMPROVE)MODELI = IDENTIFY A PROBLEM

M = MEASURE PERFORMANCE

P =PRIORITIZE POSSIBLE CAUSES

R = RESEARCH ROOT CAUSE

O = OUTLINE REMEDY

V = VALIDATE SOLUTION

E = EXECUTE SOLUTION

19.

• XEROX FOR BENCHMARK1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

WHAT TO BE BENCHMARKED

WHO IS THE COMPARATIVE

DATA COLLECTION

CURRENT LEVEL

FUTURE LEVEL

COMMUNICATE

FUNCTIONAL GOALS

ACTION PLAN

IMPLEMENT

RECALIBRATE

20.

• SIX SIGMA: DMAICDefine.

Measure.

Analyze.

Improve.

Control.

21.

Lean pioneered by Toyota, focuses on the efficient

operation of the entire value chain.

• Focus areas:

– Remove non-value added steps to:

» Reduce cycle time

» Improve quality

– Align production with demand. توافق االنتاج مع المطلوب

– Reduce inventory. خفض المخزون

– Improve process safety and efficiency تحسين كفاءة

وسالمة العملية

22.

23. F-O-C-U-S

Find a process that needs improvementOrganize a team who is knowledgeable in the

process

Clarify the current knowledge of the process

Understand the causes of variation

Select the potential process improvement

24.

Plan the improvement/data collectionDo the improvement/data collection/data

analysis

Check the data for process improvement

Act to hold the gain/continue improvement

25. Find

• What are the process problems?26. Priority matrix

Problem Frequency Importance FeasibilityTotal Ranking

Points

27.

c.k.hتم عمل مصفوفه اولويات الختيار المشاكل

(find ) fمرحله

م

المشكله

التكراريه

الوقت

االسهل حال

االكثر تاثيرا على

سالمه وامان

المريض

التكلفه

تاثيرها

القانونى على

المستشفى

مجموع

1

كثره االخطاء الطبيه

4

3

4

4

2

4

21

2

عدم االلتزام بالزياره

3

4

2

2

4

2

17

3

طول فتره انتظار المترددين على

االستقبال

عدم رضاء مرضى الكلى الصناعى عن

الخدمه

عدم تطبيق سياسه نتائج حرجه

بالمعمل

عدم توافر السريه والخصوصيه

لمريض العنايه المركزه

2

2

3

3

2

2

14

3

1

1

2

1

2

10

2

2

3

2

3

3

15

3

2

2

2

4

2

15

4

5

6

28. Organize

• Representatives from various levels inthe organization.

• Select members who know and work

with this process.

29. Clarify

• What is the actual flow of the process?30. FLOWCHARTS

startFlowcharts tend to

use simple and easily

recognizable symbols.

Activity

The basic symbols :

A Circle (start/end)

A rectangle (activity)

A diamond (decision)

An arrow (direction).

30

–

–

–

–

NO

Decision

Yes

End

31. Fishbone Diagram (( Cause-and-Effect Diagram)) ((( Ishikawa Diagram )))

• Cause-and-Effect diagram is a visual display ofthe suggested causal relationship between a

quality problem and all possible variables related

to that problem

32. Basic Layout of Cause and Effect Diagrams

Manpower(People)

Methods

(Procedures)

EFFECT

Materials

(Policies)

32

Environment

Machines

(Plant)

33. Understand

• What are the major causes of variation?• What.. Who.. Where.. When.. How will data

be collected?

34.

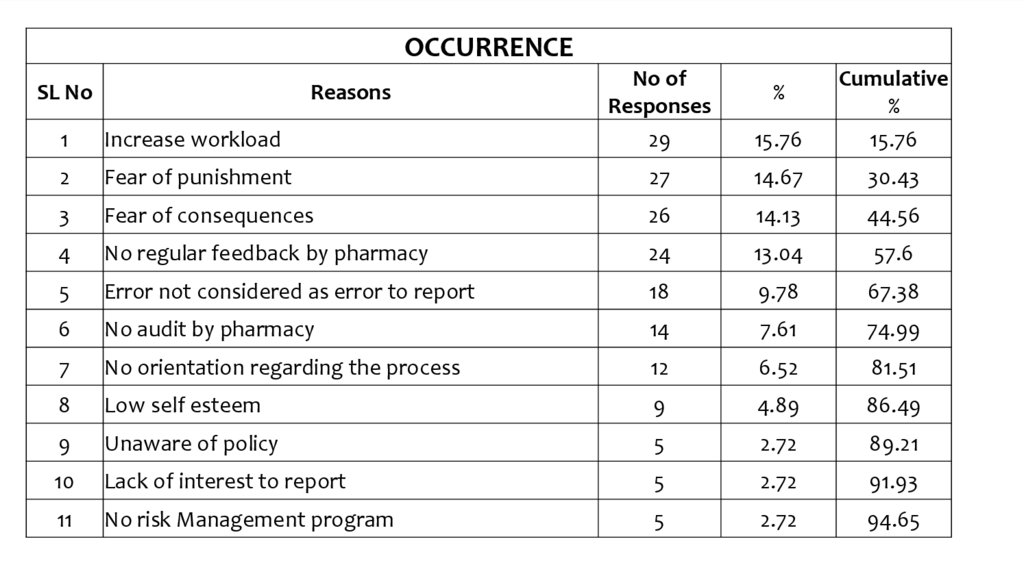

• To confirm the reasons and collect data thefollowing techniques are used:

-Personal Interview

- Observation

35.

OCCURRENCE1

Increase workload

No of

Responses

29

2

Fear of punishment

27

14.67

30.43

3

Fear of consequences

26

14.13

44.56

4

No regular feedback by pharmacy

24

13.04

57.6

5

Error not considered as error to report

18

9.78

67.38

6

No audit by pharmacy

14

7.61

74.99

7

No orientation regarding the process

12

6.52

81.51

8

Low self esteem

9

4.89

86.49

9

Unaware of policy

5

2.72

89.21

10

Lack of interest to report

5

2.72

91.93

11

No risk Management program

5

2.72

94.65

SL No

Reasons

15.76

Cumulative

%

15.76

%

36.

reas

ew

No

or

kl

of

oa

p

d

u

F

ea

re

ni

gu

sh

Er

ro

m

ro

la

fc

en

rf

rn

on

ee

t

ot

se

db

co

q

ac

ue

ns

kb

nc

id

er

es

yp

ed

ha

as

r

m

No

er

ac

ro

or

y

No

rt

ie

o

nt

a

r

ud

at

ep

io

it

or

n

by

t

re

ph

ga

ar

rd

m

in

ac

g

y

th

ep

ro

Lo

ce

w

ss

se

l

f

-e

Un

st

aw

ee

La

ar

ck

m

e

of

No

o

f

i

nt

po

ris

er

lic

kM

es

y

t

an

to

ag

r

e

em

po

en

rt

La

t

pr

ck

N

o

o

of

gr

No

sy

aw

am

st

re

ar

e

in

m

en

fo

in

es

rc

pl

sf

em

ac

or

en

e

M

tb

ed

y

ic a

HO

lE

D

rro

rr

ep

...

Fe

ar

In

c

Number of Responses

35

30

25

74.99

20

15

10

5

81.51

91.93

86.49 89.21

REASONS

99

94.65 97.37

67.38

57.6

44.56

30.43

15.76

0

100 100

90

80

70

60

50

40

30

20

10

0

Series1

Series2

37. Select

• Select a portion of the process to improve.• Determine the needed actions.

38. NEXT STAGE ……

39.

خطوة :6تطبيق الحلولخطط

PDCA

)(Plan

الغايات

األهداف

………

……….

أفعل

)(DO

a pilot study

افحص

)(Check

نفذ

)(Act

Менеджмент

Менеджмент