Похожие презентации:

Chain reaction 2016

1. Chain reaction 2016

CHAIN REACTION 2016PROJECT CONCEPT

2. DRIVERS of attractiveness

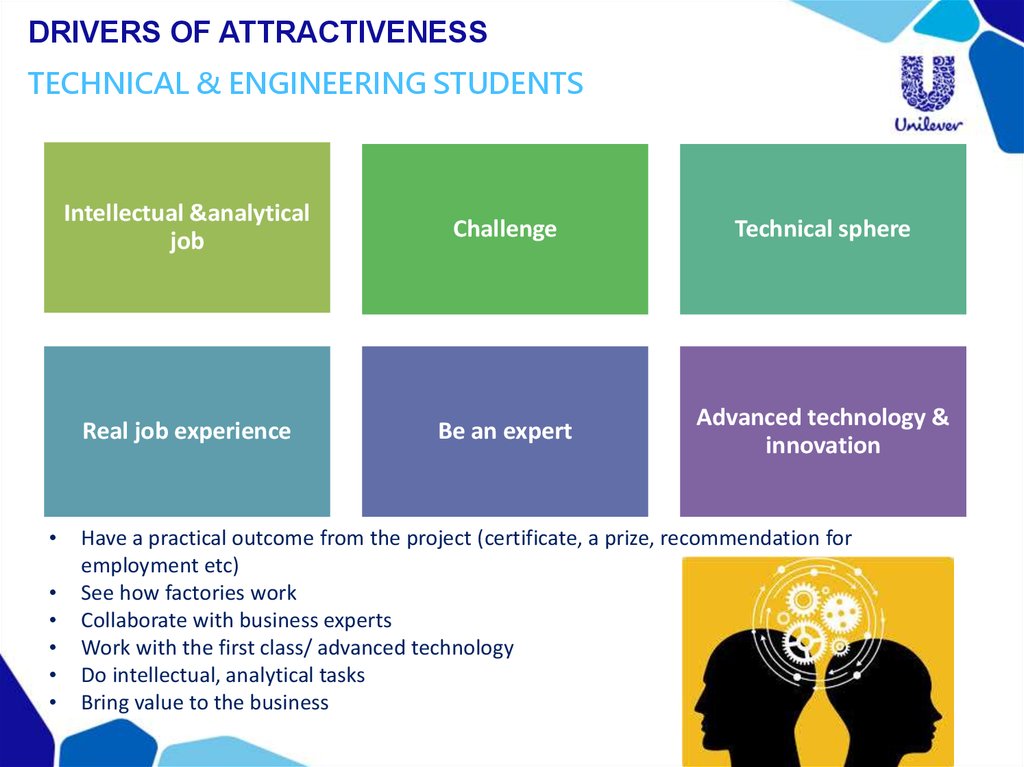

DRIVERS OF ATTRACTIVENESSTECHNICAL & ENGINEERING STUDENTS

Intellectual &analytical

job

Challenge

Technical sphere

Real job experience

Be an expert

Advanced technology &

innovation

Have a practical outcome from the project (certificate, a prize, recommendation for

employment etc)

See how factories work

Collaborate with business experts

Work with the first class/ advanced technology

Do intellectual, analytical tasks

Bring value to the business

3. Chain reaction

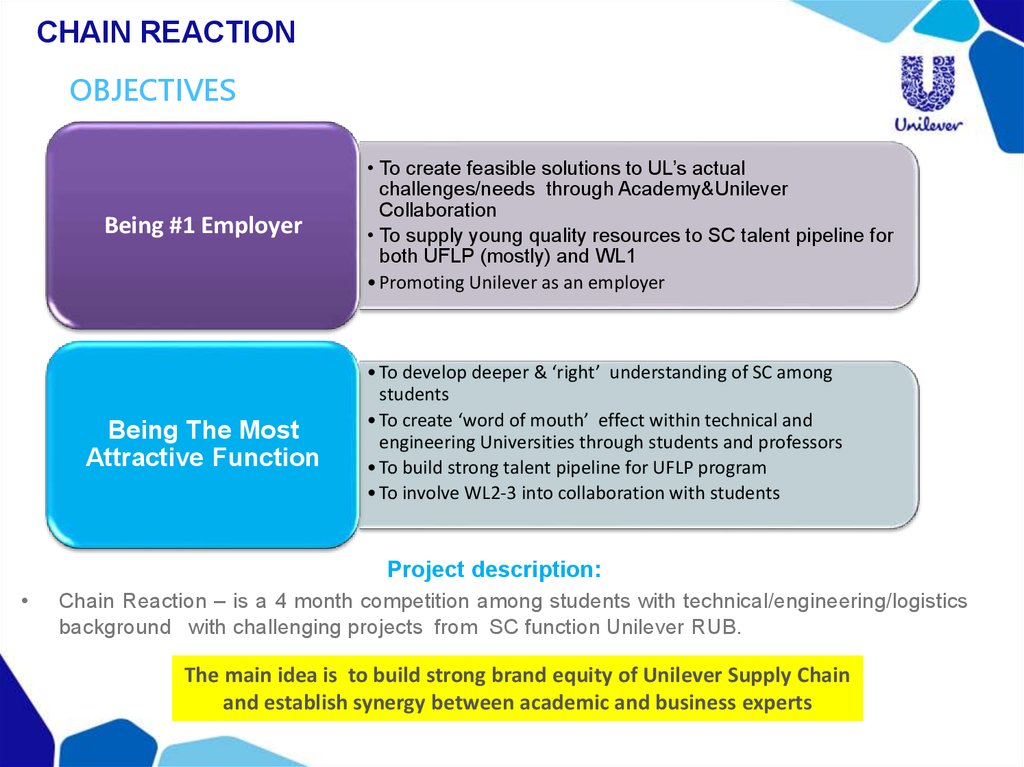

CHAIN REACTIONOBJECTIVES

Being #1 Employer

Being The Most

Attractive Function

• To create feasible solutions to UL’s actual

challenges/needs through Academy&Unilever

Collaboration

• To supply young quality resources to SC talent pipeline for

both UFLP (mostly) and WL1

• Promoting Unilever as an employer

• To develop deeper & ‘right’ understanding of SC among

students

• To create ‘word of mouth’ effect within technical and

engineering Universities through students and professors

• To build strong talent pipeline for UFLP program

• To involve WL2-3 into collaboration with students

Project description:

Chain Reaction – is a 4 month competition among students with technical/engineering/logistics

background with challenging projects from SC function Unilever RUB.

The main idea is to build strong brand equity of Unilever Supply Chain

and establish synergy between academic and business experts

4. New in 2016

NEW IN 2016New schools strong in technical field:

HSE (logistics)

UNECON (engineering)

Wider promo reach:

on-campus (130 participants)

online ( 21 Universities)

New format

Competition between teams

Better ownership from SC function

WL3 as sponsors

New format of projects

Challenging and practical

5. Chain reaction

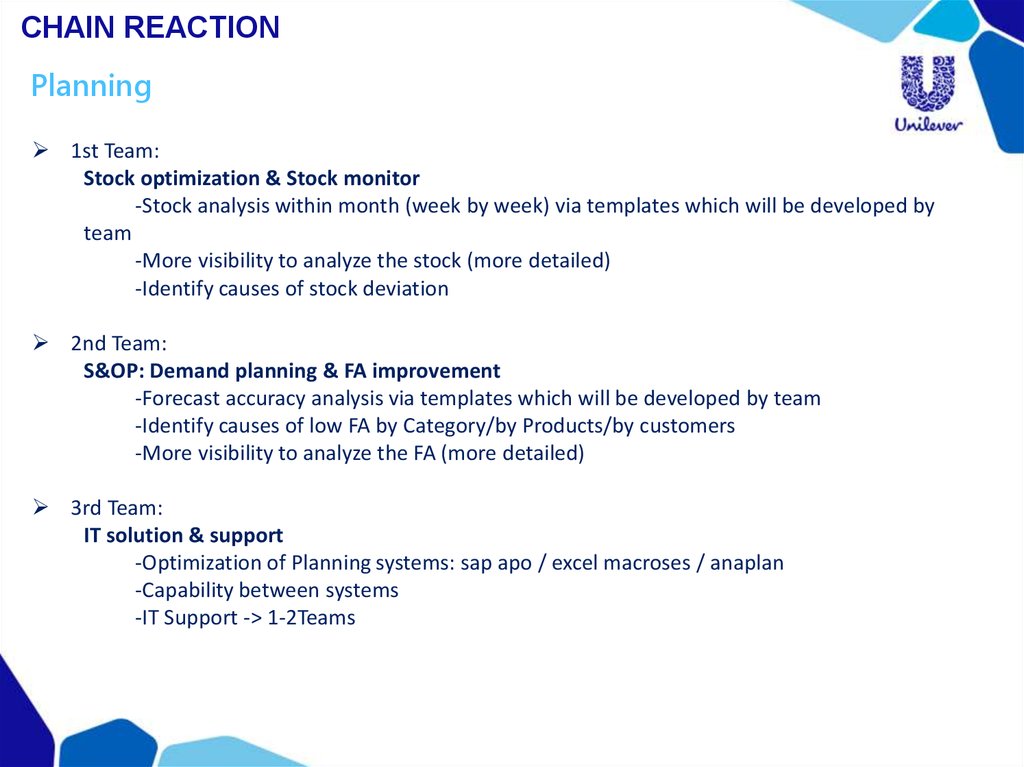

CHAIN REACTIONPlanning

1st Team:

Stock optimization & Stock monitor

-Stock analysis within month (week by week) via templates which will be developed by

team

-More visibility to analyze the stock (more detailed)

-Identify causes of stock deviation

2nd Team:

S&OP: Demand planning & FA improvement

-Forecast accuracy analysis via templates which will be developed by team

-Identify causes of low FA by Category/by Products/by customers

-More visibility to analyze the FA (more detailed)

3rd Team:

IT solution & support

-Optimization of Planning systems: sap apo / excel macroses / anaplan

-Capability between systems

-IT Support -> 1-2Teams

6. Chain reaction

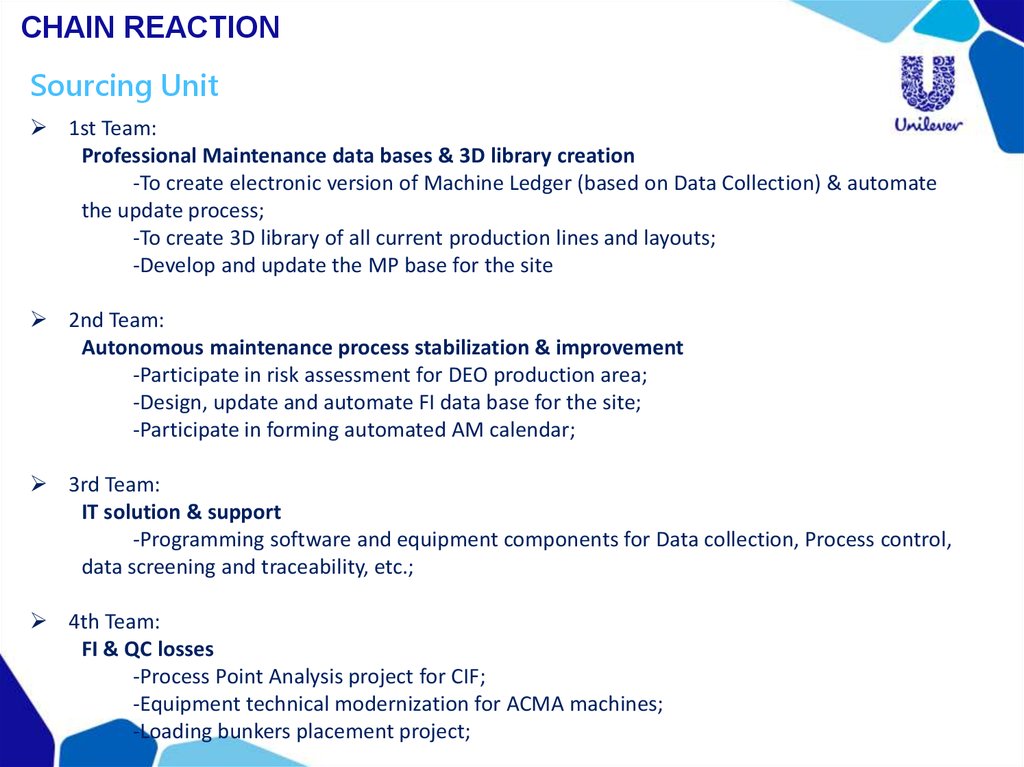

CHAIN REACTIONSourcing Unit

1st Team:

Professional Maintenance data bases & 3D library creation

-To create electronic version of Machine Ledger (based on Data Collection) & automate

the update process;

-To create 3D library of all current production lines and layouts;

-Develop and update the MP base for the site

2nd Team:

Autonomous maintenance process stabilization & improvement

-Participate in risk assessment for DEO production area;

-Design, update and automate FI data base for the site;

-Participate in forming automated AM calendar;

3rd Team:

IT solution & support

-Programming software and equipment components for Data collection, Process control,

data screening and traceability, etc.;

4th Team:

FI & QC losses

-Process Point Analysis project for CIF;

-Equipment technical modernization for ACMA machines;

-Loading bunkers placement project;

7. Projects

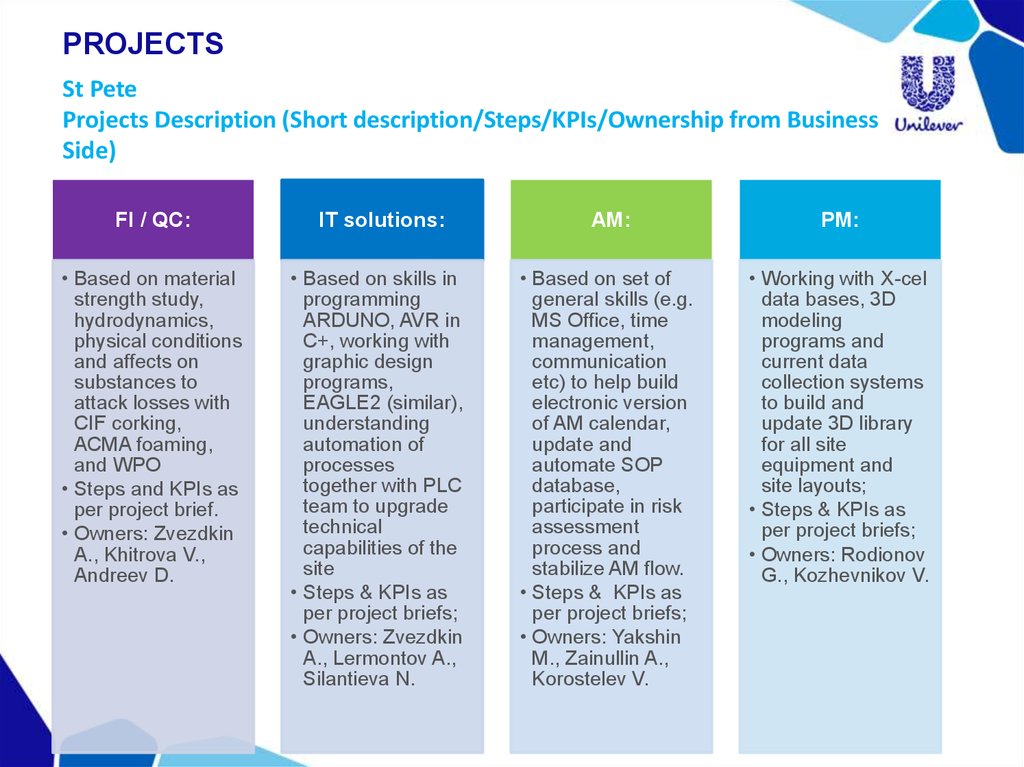

PROJECTSSt Pete

Projects Description (Short description/Steps/KPIs/Ownership from Business

Side)

FI / QC:

IT solutions:

AM:

PM:

• Based on material

strength study,

hydrodynamics,

physical conditions

and affects on

substances to

attack losses with

CIF corking,

ACMA foaming,

and WPO

• Steps and KPIs as

per project brief.

• Owners: Zvezdkin

A., Khitrova V.,

Andreev D.

• Based on skills in

programming

ARDUNO, AVR in

C+, working with

graphic design

programs,

EAGLE2 (similar),

understanding

automation of

processes

together with PLC

team to upgrade

technical

capabilities of the

site

• Steps & KPIs as

per project briefs;

• Owners: Zvezdkin

A., Lermontov A.,

Silantieva N.

• Based on set of

general skills (e.g.

MS Office, time

management,

communication

etc) to help build

electronic version

of AM calendar,

update and

automate SOP

database,

participate in risk

assessment

process and

stabilize AM flow.

• Steps & KPIs as

per project briefs;

• Owners: Yakshin

M., Zainullin A.,

Korostelev V.

• Working with X-cel

data bases, 3D

modeling

programs and

current data

collection systems

to build and

update 3D library

for all site

equipment and

site layouts;

• Steps & KPIs as

per project briefs;

• Owners: Rodionov

G., Kozhevnikov V.

Образование

Образование