Похожие презентации:

Formation of cold characteristics of the thermal input when welding steel with high strength and capacity of 500 ma

1. DEPENDENCE OF COLD CRACKS FORMATION FROM THE HEAT INPUT WHEN WELDING OF HIGH STRENGTH STEEL WITH YIELD STRENGTH OF 500 MPA

DEPENDENCE OF COLD CRACKS FORMATION FROMTHE HEAT INPUT WHEN WELDING OF HIGH STRENGTH

STEEL WITH YIELD STRENGTH OF 500 MPA

Postgraduate: Alruhaimi Anmar Ghareeb

Supervisor:

Ivanov M.A.

2. Table 1 - Mechanical properties of steel 10G2FBU according to technical regulations 14-101-725-2009.

Grade10G2FB

U

Ultimate

strength,

MPa, not less

620

Impact strength,

J/cm2, not less

Yield

strength,

MPa, not

less

Elongation,

%, not less

550

24

CET, %,

not less

KCU-60

KCV-20

250

250

0,43

Table 1 - Mechanical properties of steel 10G2FBU according to

technical regulations 14-101-725-2009.

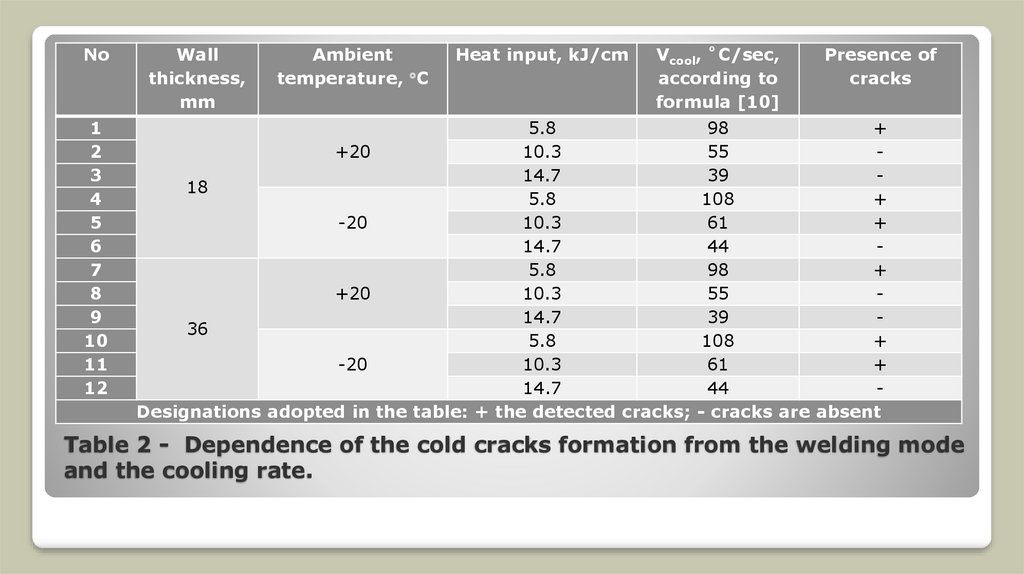

3. Table 2 - Dependence of the cold cracks formation from the welding mode and the cooling rate.

No1

2

3

4

5

6

7

8

9

10

11

12

Wall

thickness,

mm

Ambient

temperature, C

Heat input, kJ/cm

Vcool, ˚C/sec,

according to

formula [10]

5.8

+20

10.3

14.7

18

5.8

-20

10.3

14.7

5.8

+20

10.3

14.7

36

5.8

-20

10.3

14.7

Designations adopted in the table: + the detected cracks;

Presence of

cracks

98

+

55

39

108

+

61

+

44

98

+

55

39

108

+

61

+

44

- cracks are absent

Table 2 - Dependence of the cold cracks formation from the welding mode

and the cooling rate.

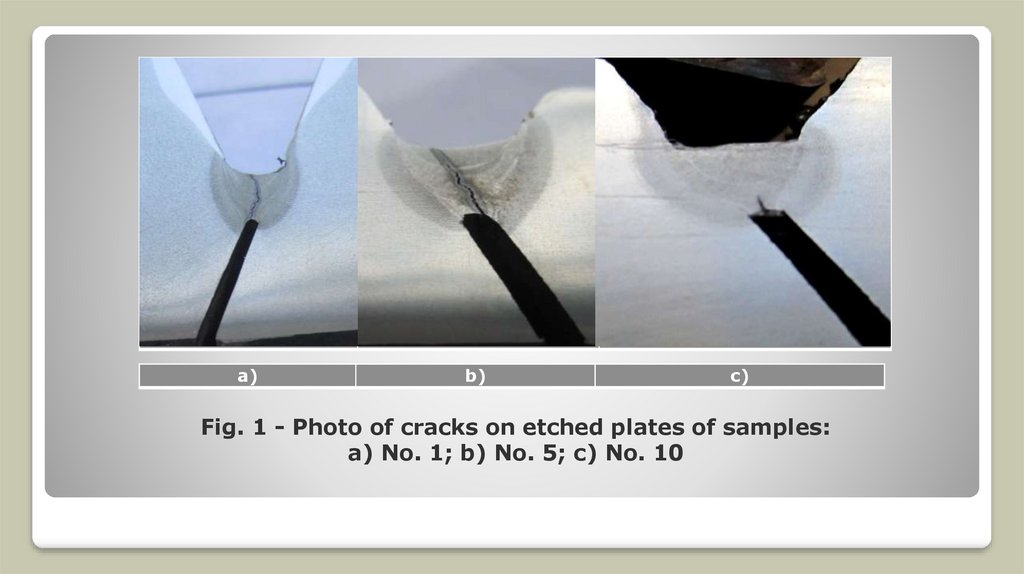

4. Fig. 1 - Photo of cracks on etched plates of samples: a) No. 1; b) No. 5; c) No. 10

a)b)

c)

Fig. 1 - Photo of cracks on etched plates of samples:

a) No. 1; b) No. 5; c) No. 10

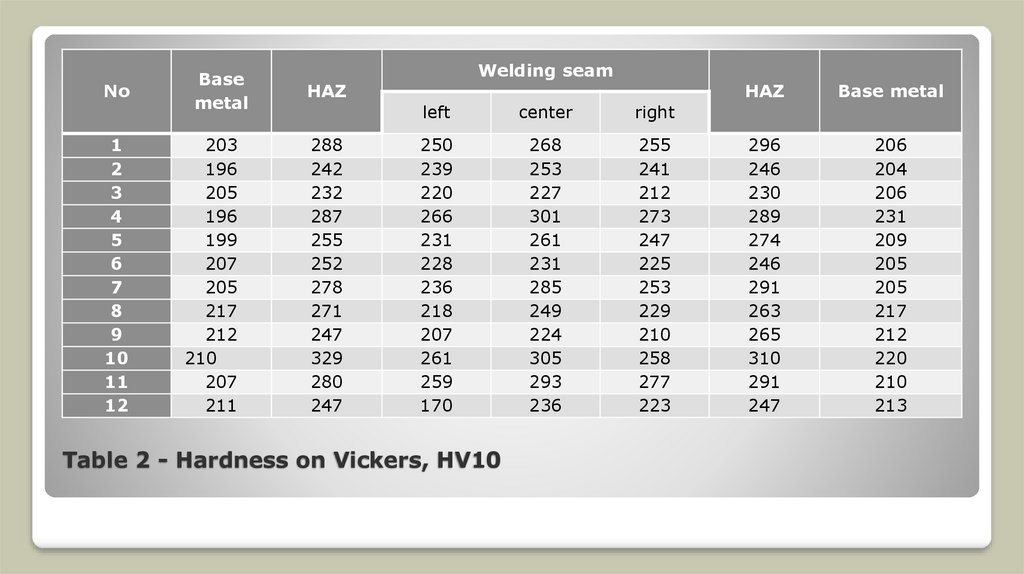

5. Table 2 - Hardness on Vickers, HV10

No1

2

3

4

5

6

7

8

9

10

11

12

Base

metal

203

196

205

196

199

207

205

217

212

210

207

211

Welding seam

HAZ

288

242

232

287

255

252

278

271

247

329

280

247

left

center

right

250

239

220

266

231

228

236

218

207

261

259

170

268

253

227

301

261

231

285

249

224

305

293

236

255

241

212

273

247

225

253

229

210

258

277

223

Table 2 - Hardness on Vickers, HV10

HAZ

Base metal

296

246

230

289

274

246

291

263

265

310

291

247

206

204

206

231

209

205

205

217

212

220

210

213

6. Fig.2 - Graph of hardness on Vickers of the template of the sample No. 10

Sample10HV10

350

329

297

294

289

300

275

291

276

250

210

215

264

261

240

258

220

228

194

200

289

306

276

310

305

305

205

Welding Seam

198

206

204

Base Metal

HAZ

150

Base Metal

HAZ

Cracking

Overheating Area

100

50

0

0

2

2

2

0,5

0,5

0,5

0,5

0,5

0,5

0,5

0,5

0,5

0,5

0,5

0,5

0,5

0,5

0,5

0,5

0,5

0,5

0,5

0,5

2

2

2

length , mm

Fig.2 - Graph of hardness on Vickers of the template of the sample No. 10

7. Summary

Cold cracks in high strength steel 10G2FBU for thicknesses of 18 and 36 mm are notdetected in heat input over 10.3 kJ/cm by welding at the temperature of +20 С, at

the same time when welding at an ambient temperature of –20 С cracks are not

detected when heat input is over 14.7 kJ/cm.

Critical cooling rate in which no cracking appeared is 55 С/s at the temperature of

welding +20 С, as well as 44 С/s at the temperature of welding –20 С for both

thicknesses.

The criterion HVmax < 300 HV is a necessary but insufficient condition for

prevention of cold cracks in steels of the type 10G2FBU. In the conditions of the

experiment, cold cracks in the welding seam are absent at a hardness of no more than

250-260 HV, which is probably due to the presence of diffusive hydrogen, which is

not regulated in the regulations for the supply of this steel grade.

Промышленность

Промышленность