Похожие презентации:

Rotary clipper school

1. Rotary clipper school

14 December, 2006Raute Controller, 24 GPM Servo Proportional Valves

www.raute.com

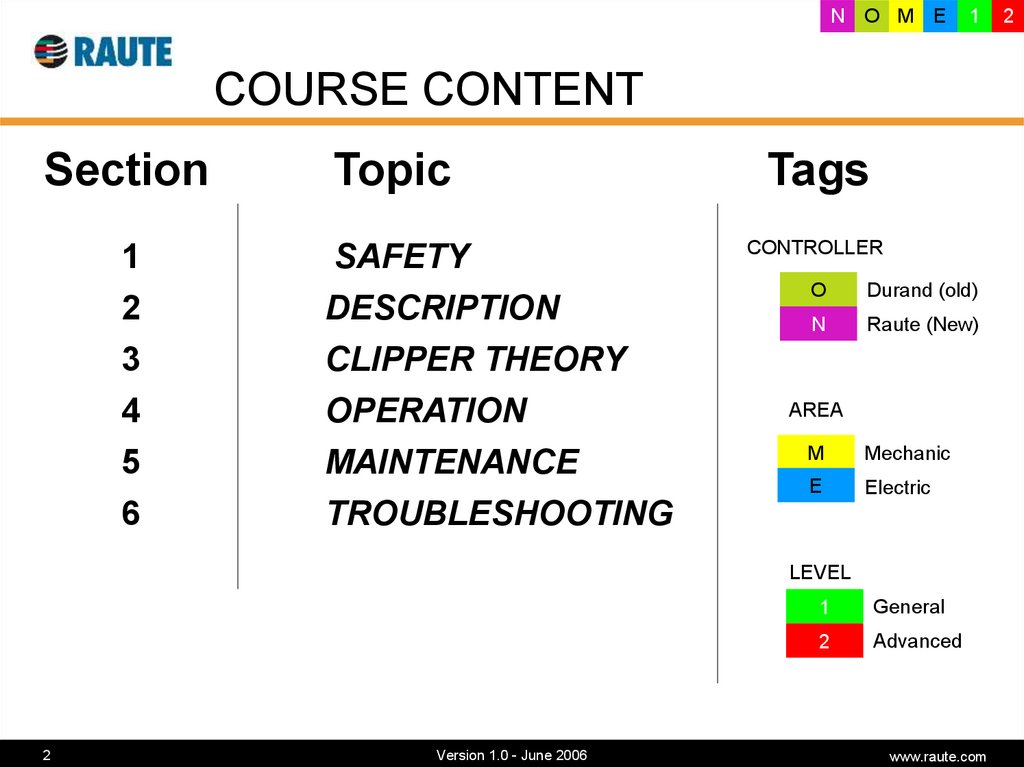

2. COURSE CONTENT

N O M E1

COURSE CONTENT

Section

1

2

3

4

5

6

Topic

SAFETY

DESCRIPTION

CLIPPER THEORY

OPERATION

MAINTENANCE

TROUBLESHOOTING

Tags

CONTROLLER

O

Durand (old)

N

Raute (New)

AREA

M

Mechanic

E

Electric

LEVEL

2

Version 1.0 - June 2006

1

General

2

Advanced

www.raute.com

2

3. Section 1 SAFETY

Section 1 - SAFETYN O M E

1

Section 1

SAFETY

GENERAL

References:

Plant safety procedures

Clipper Manual - Section 1

SPECIFIC

Critical points:

Hydraulic Power Unit (Knife & Rolls)

Conveyors and hold-downs

Non critical points:

Controller cabinet power

3

Version 1.0 - June 2006

www.raute.com

2

4. Section 1 SAFETY

Section 1 - SAFETYM E

1

Section 1

SAFETY

IMPORTANT:

The safety procedures described in the following pages are

intended only to highlight some specific points regarding the

Rotary Clipper and are not meant to replace nor substitute, in any

case nor to any extent, any other safety procedures applicable,

whether issued by the mill or by any other local, federal or

otherwise relevant authority.

In case of conflict or contradiction between the recommendations

contained in this document and those emanating from these

authorities, the latter will take precedence.

4

Version 1.0 - June 2006

www.raute.com

5. GENERAL PROCEDURES

Section 1 - SAFETY - GENERAL PROCEDURESM E

1

GENERAL PROCEDURES

MAIN POINTS

5

1.

DO NOT OPERATE NOR SERVICE ANY MACHINERY UNTIL

YOU GET THE APROPRIATE TRAINING TO DO SO.

2.

ALWAYS USE SAFETY GEAR: HIGH VISIBILITY VEST,

HARD HAT, SAFETY GLASSES, EAR PLUGS AND STEEL

TOE SHOES.

3.

LOCATE AND KNOW HOW TO USE THE EMERGENCY

STOP BUTTONS.

4.

LOCK-OUT ALL SYSTEMS AS REQUIRED, BEFORE

SERVICING ANY MACHINERY OR ENTERING ANY

HAZARDOUS AREAS.

5.

REFER AND COMPLY WITH PLANT SPECIFIC SAFETY

PROCEDURES.

Version 1.0 - June 2006

www.raute.com

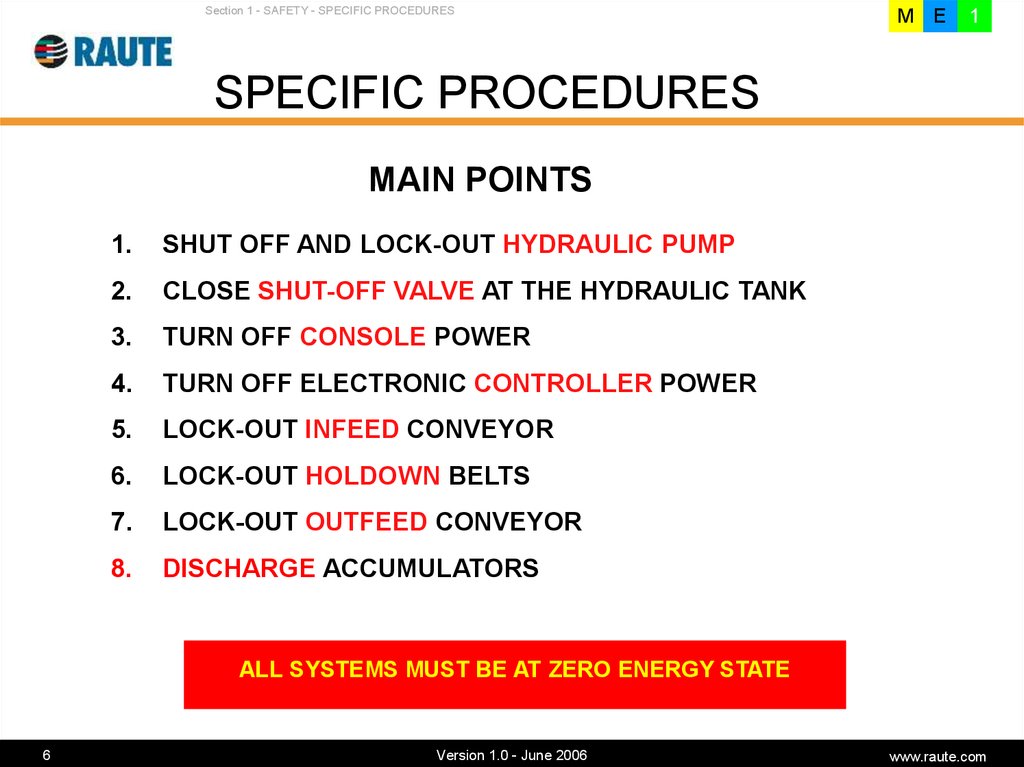

6. SPECIFIC PROCEDURES

Section 1 - SAFETY - SPECIFIC PROCEDURESM E

1

SPECIFIC PROCEDURES

MAIN POINTS

1.

SHUT OFF AND LOCK-OUT HYDRAULIC PUMP

2.

CLOSE SHUT-OFF VALVE AT THE HYDRAULIC TANK

3.

TURN OFF CONSOLE POWER

4.

TURN OFF ELECTRONIC CONTROLLER POWER

5.

LOCK-OUT INFEED CONVEYOR

6.

LOCK-OUT HOLDOWN BELTS

7.

LOCK-OUT OUTFEED CONVEYOR

8.

DISCHARGE ACCUMULATORS

ALL SYSTEMS MUST BE AT ZERO ENERGY STATE

6

Version 1.0 - June 2006

www.raute.com

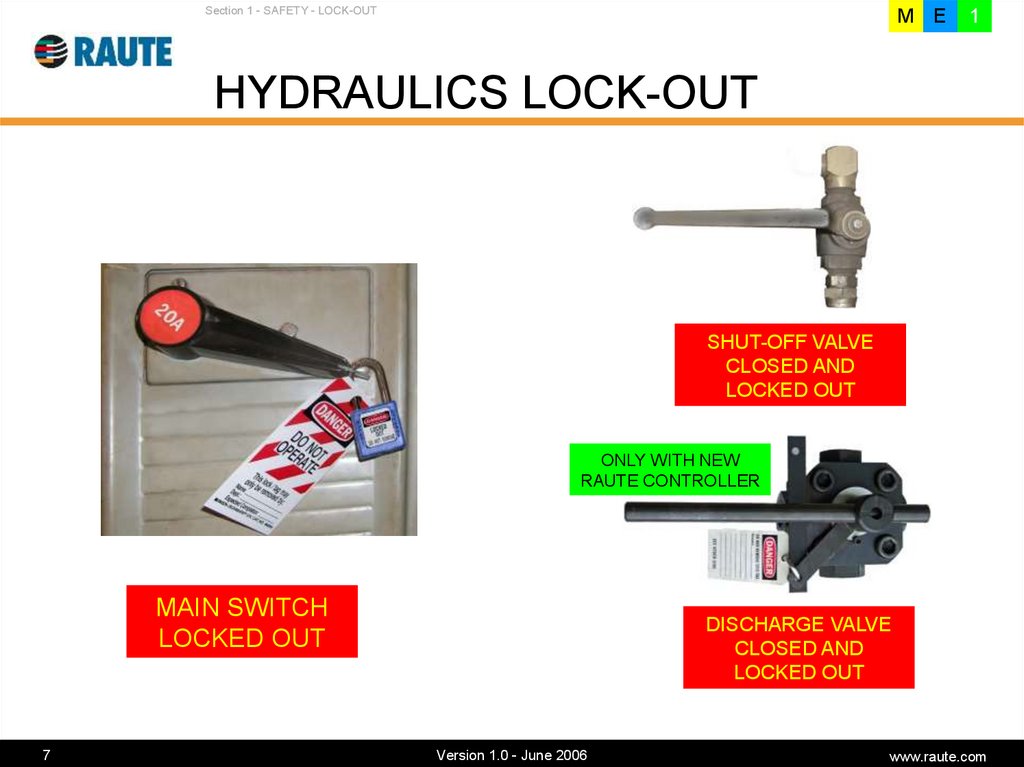

7. HYDRAULICS LOCK-OUT

Section 1 - SAFETY - LOCK-OUTM E

1

HYDRAULICS LOCK-OUT

SHUT-OFF VALVE

CLOSED AND

LOCKED OUT

ONLY WITH NEW

RAUTE CONTROLLER

MAIN SWITCH

LOCKED OUT

7

DISCHARGE VALVE

CLOSED AND

LOCKED OUT

Version 1.0 - June 2006

www.raute.com

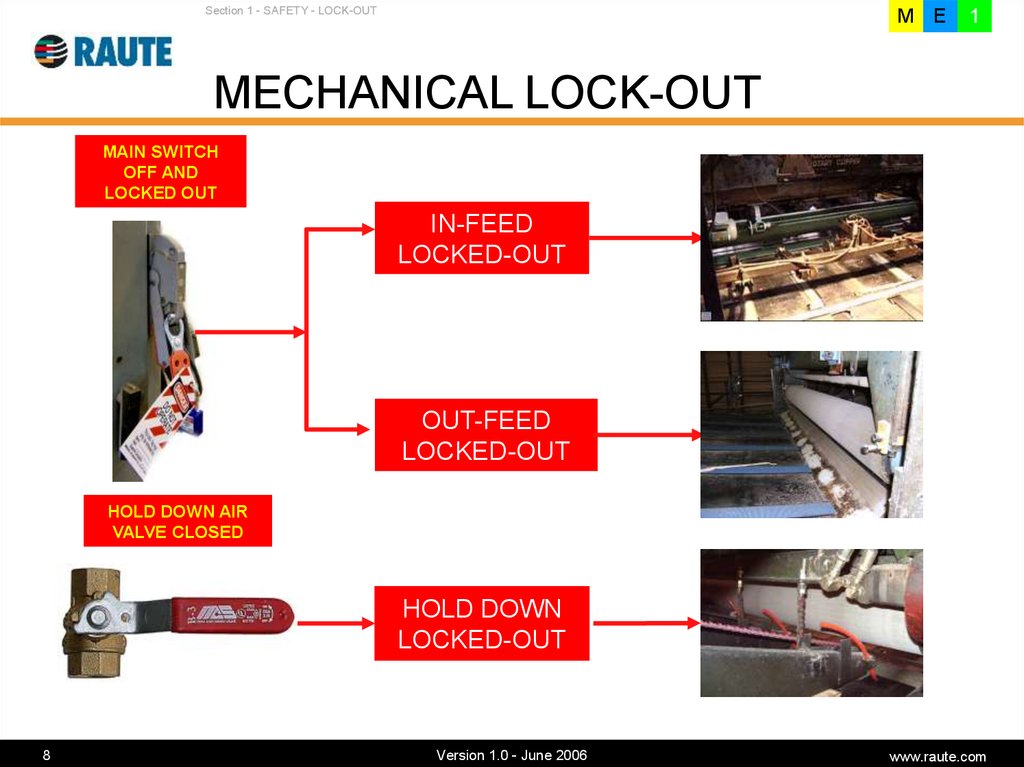

8. MECHANICAL LOCK-OUT

Section 1 - SAFETY - LOCK-OUTM E

1

MECHANICAL LOCK-OUT

MAIN SWITCH

OFF AND

LOCKED OUT

IN-FEED

LOCKED-OUT

OUT-FEED

LOCKED-OUT

HOLD DOWN AIR

VALVE CLOSED

HOLD DOWN

LOCKED-OUT

8

Version 1.0 - June 2006

www.raute.com

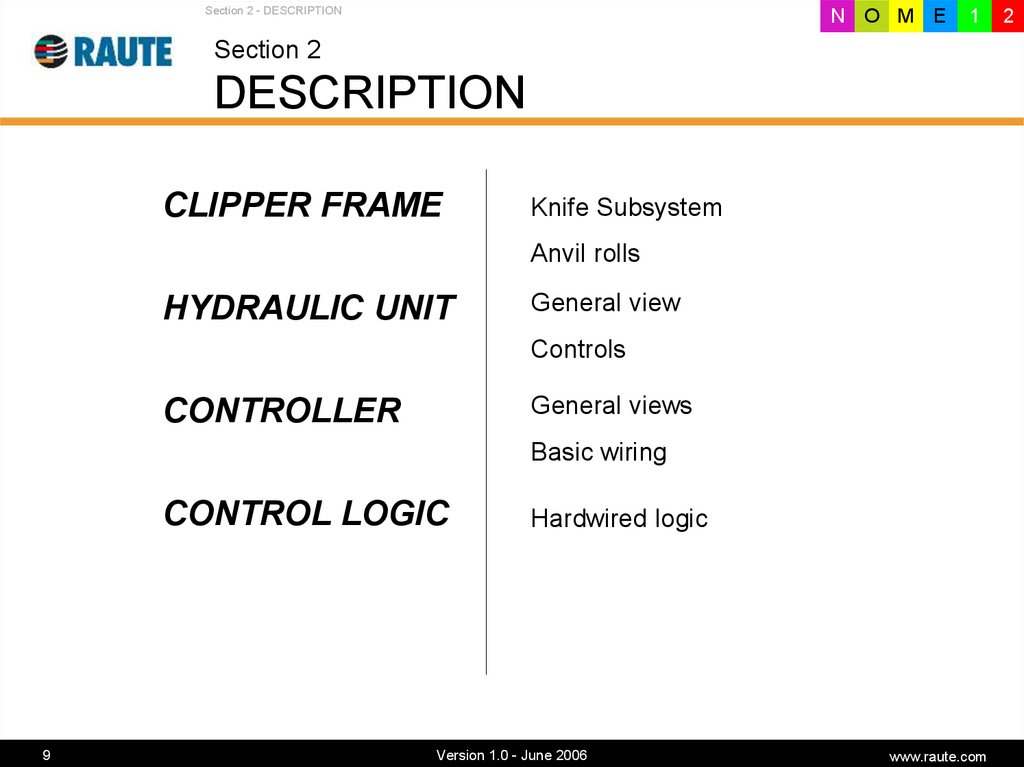

9. Section 2 DESCRIPTION

Section 2 - DESCRIPTIONN O M E

1

Section 2

DESCRIPTION

CLIPPER FRAME

Knife Subsystem

Anvil rolls

HYDRAULIC UNIT

General view

Controls

General views

CONTROLLER

Basic wiring

CONTROL LOGIC

9

Hardwired logic

Version 1.0 - June 2006

www.raute.com

2

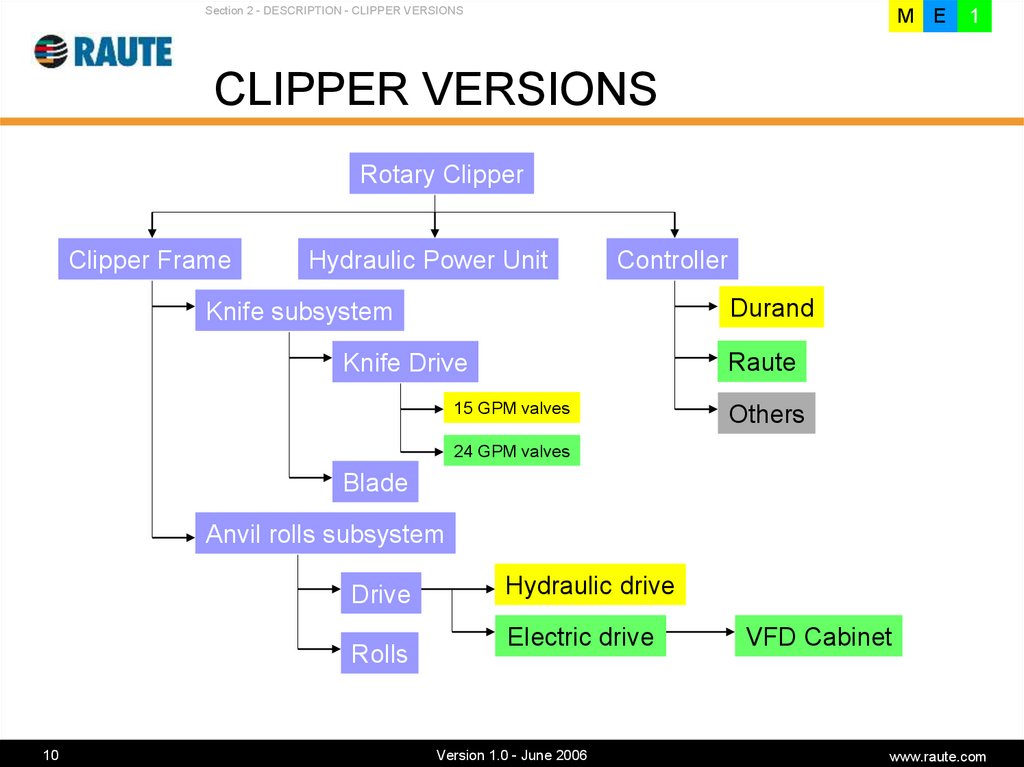

10. CLIPPER VERSIONS

Section 2 - DESCRIPTION - CLIPPER VERSIONSM E

1

CLIPPER VERSIONS

Rotary Clipper

Clipper Frame

Hydraulic Power Unit

Controller

Durand

Knife subsystem

Raute

Knife Drive

15 GPM valves

Others

24 GPM valves

Blade

Anvil rolls subsystem

Drive

Rolls

10

Hydraulic drive

Electric drive

Version 1.0 - June 2006

VFD Cabinet

www.raute.com

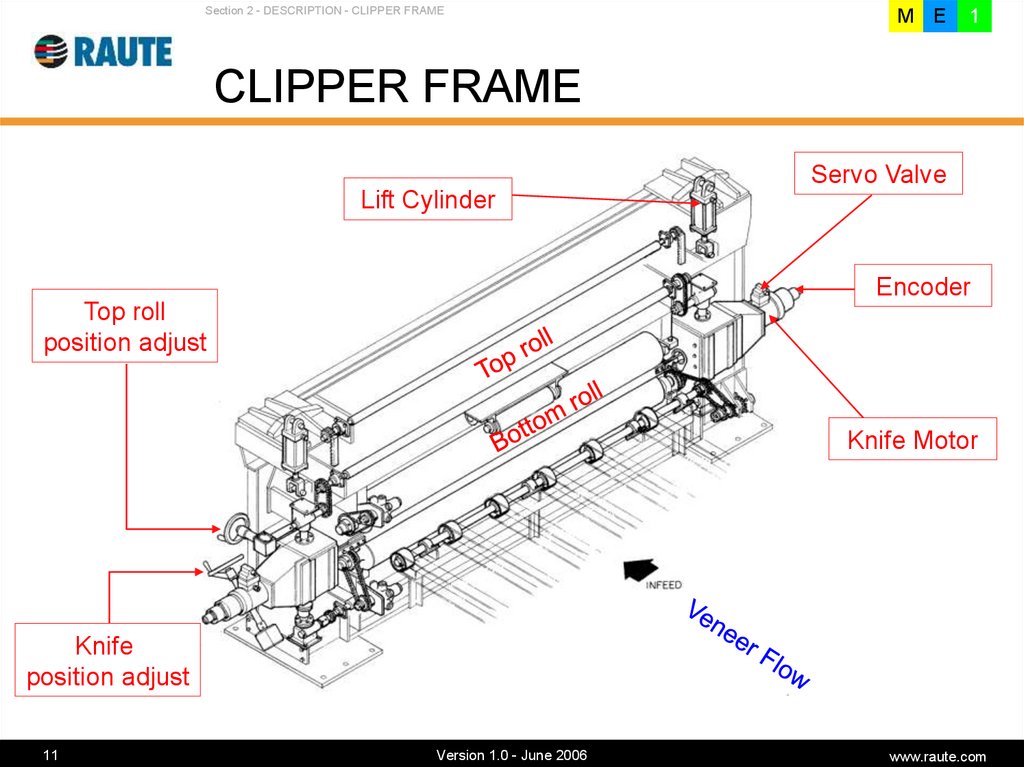

11. CLIPPER FRAME

Section 2 - DESCRIPTION - CLIPPER FRAMEM E

1

CLIPPER FRAME

Servo Valve

Lift Cylinder

Encoder

Top roll

position adjust

Knife Motor

Knife

position adjust

11

Version 1.0 - June 2006

www.raute.com

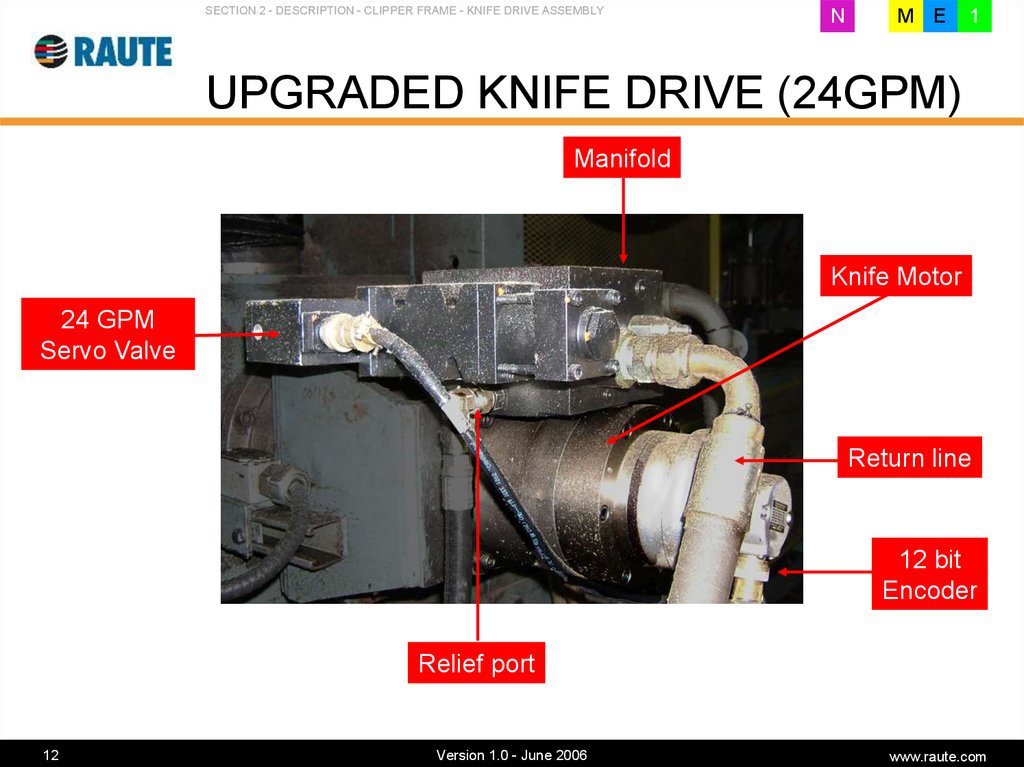

12. UPGRADED KNIFE DRIVE (24GPM)

SECTION 2 - DESCRIPTION - CLIPPER FRAME - KNIFE DRIVE ASSEMBLYN

M E

1

UPGRADED KNIFE DRIVE (24GPM)

Manifold

Knife Motor

24 GPM

Servo Valve

Return line

12 bit

Encoder

Relief port

12

Version 1.0 - June 2006

www.raute.com

13. KNIFE LINKAGE

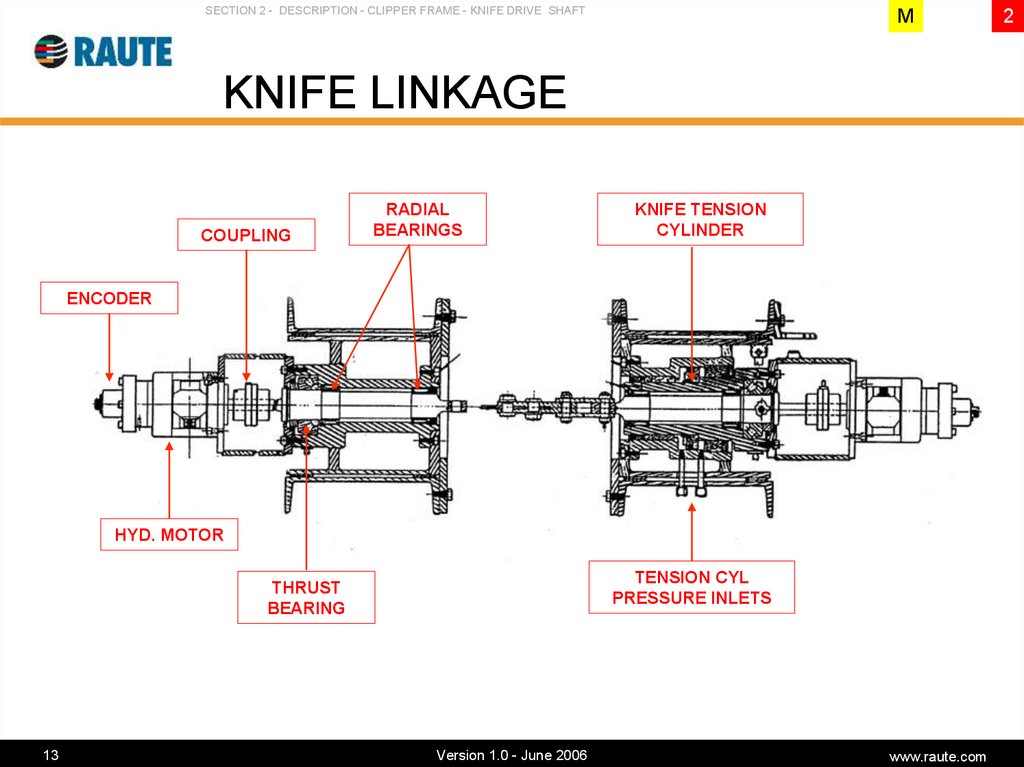

SECTION 2 - DESCRIPTION - CLIPPER FRAME - KNIFE DRIVE SHAFTM

KNIFE LINKAGE

COUPLING

RADIAL

BEARINGS

KNIFE TENSION

CYLINDER

ENCODER

HYD. MOTOR

TENSION CYL

PRESSURE INLETS

THRUST

BEARING

13

Version 1.0 - June 2006

www.raute.com

2

14. KNIFE DRIVE ASSEMBLY

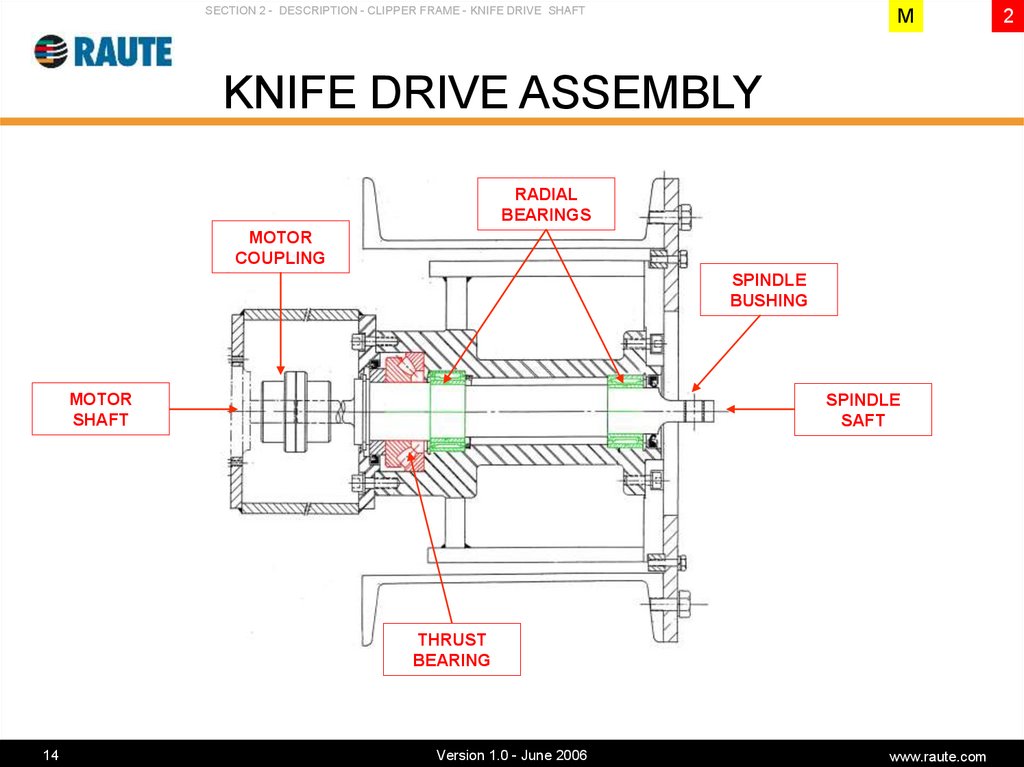

SECTION 2 - DESCRIPTION - CLIPPER FRAME - KNIFE DRIVE SHAFTM

KNIFE DRIVE ASSEMBLY

RADIAL

BEARINGS

MOTOR

COUPLING

SPINDLE

BUSHING

MOTOR

SHAFT

SPINDLE

SAFT

THRUST

BEARING

14

Version 1.0 - June 2006

www.raute.com

2

15. KNIFE COUPLINGS ASSEMBLY

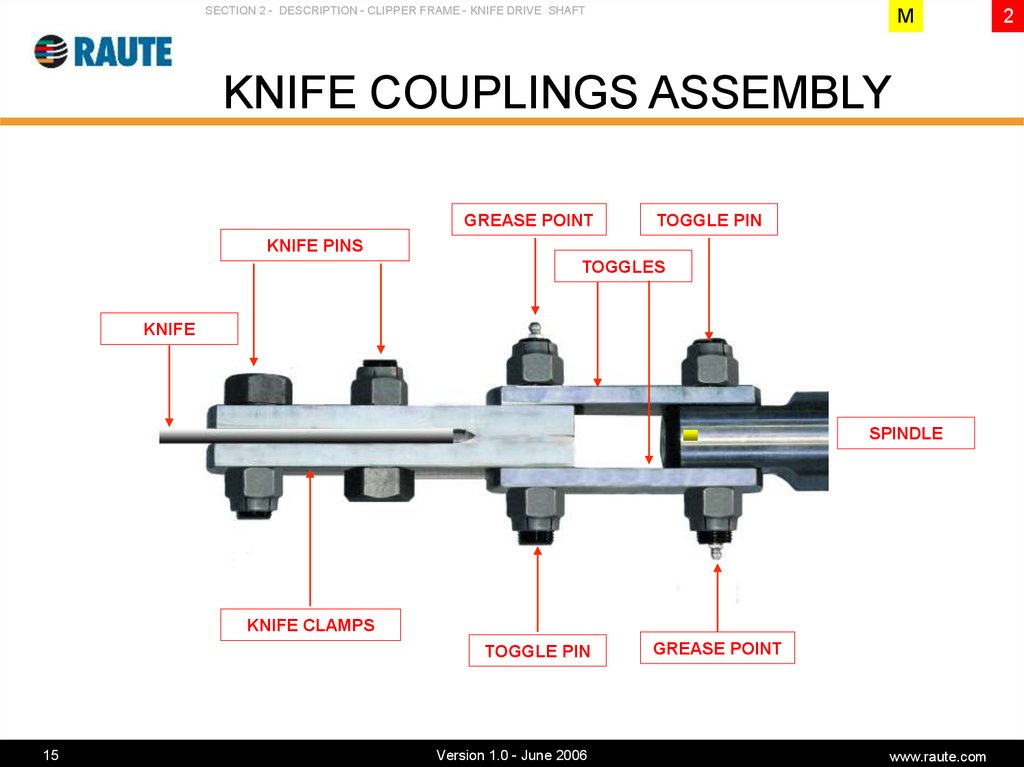

SECTION 2 - DESCRIPTION - CLIPPER FRAME - KNIFE DRIVE SHAFTM

KNIFE COUPLINGS ASSEMBLY

GREASE POINT

TOGGLE PIN

KNIFE PINS

TOGGLES

KNIFE

SPINDLE

KNIFE CLAMPS

TOGGLE PIN

15

Version 1.0 - June 2006

GREASE POINT

www.raute.com

2

16. KNIFE BLADE

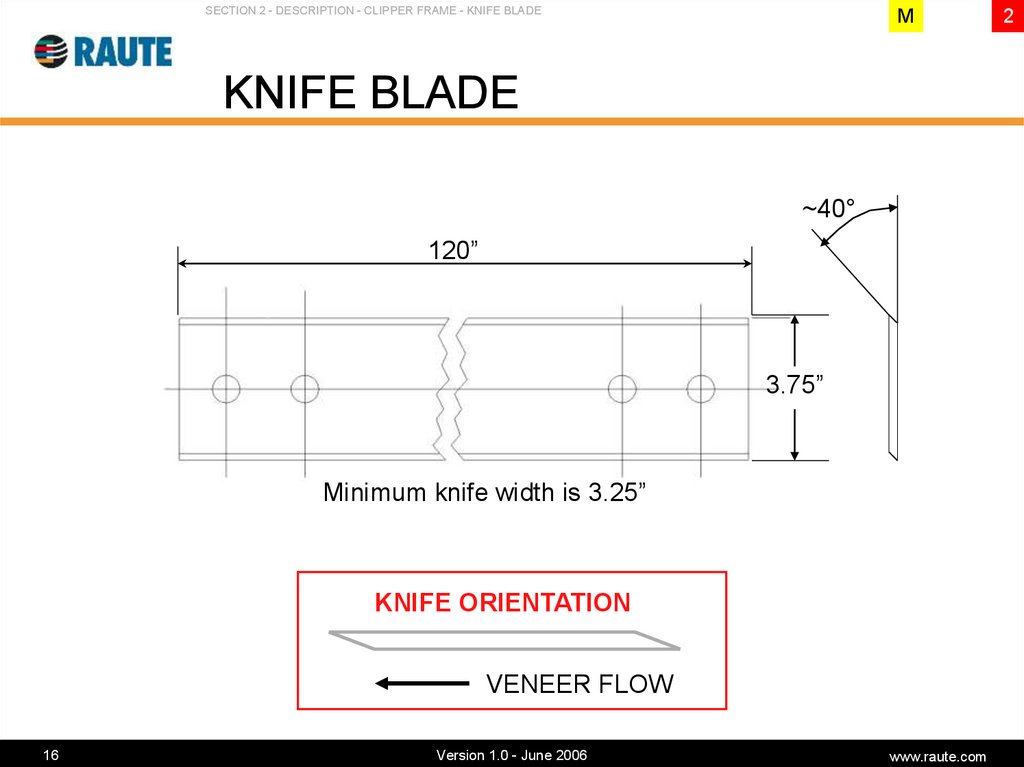

SECTION 2 - DESCRIPTION - CLIPPER FRAME - KNIFE BLADEM

KNIFE BLADE

~40°

120”

3.75”

Minimum knife width is 3.25”

KNIFE ORIENTATION

VENEER FLOW

16

Version 1.0 - June 2006

www.raute.com

2

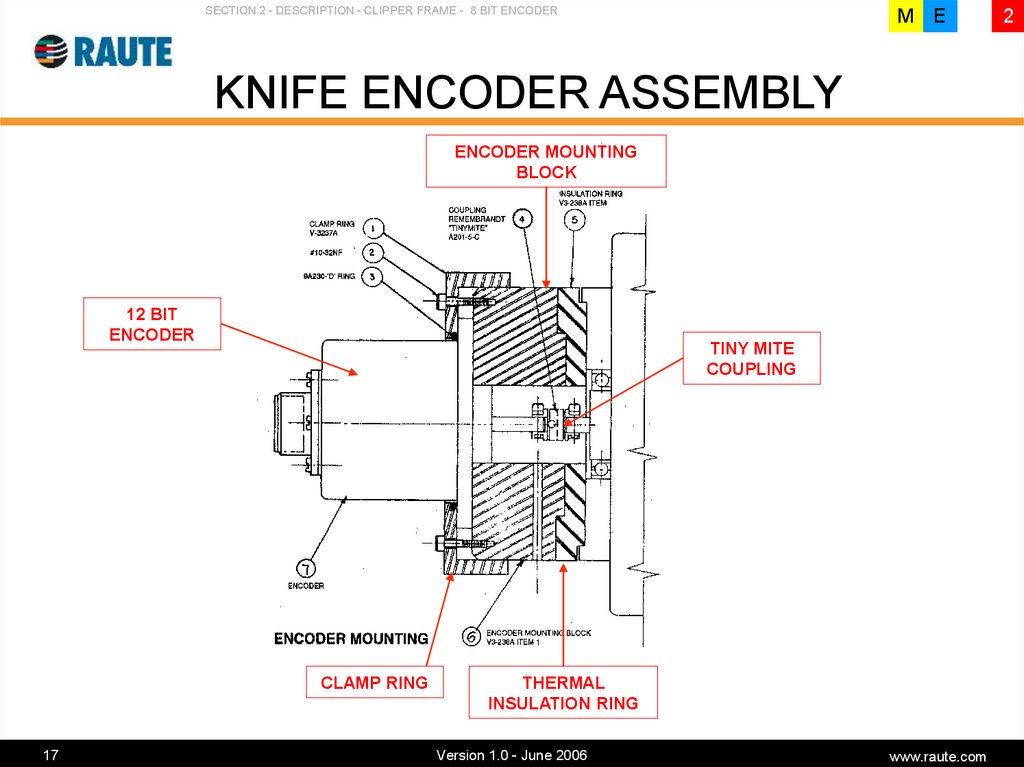

17. KNIFE ENCODER ASSEMBLY

SECTION 2 - DESCRIPTION - CLIPPER FRAME - 8 BIT ENCODERM E

KNIFE ENCODER ASSEMBLY

ENCODER MOUNTING

BLOCK

12 BIT

ENCODER

TINY MITE

COUPLING

CLAMP RING

17

THERMAL

INSULATION RING

Version 1.0 - June 2006

www.raute.com

2

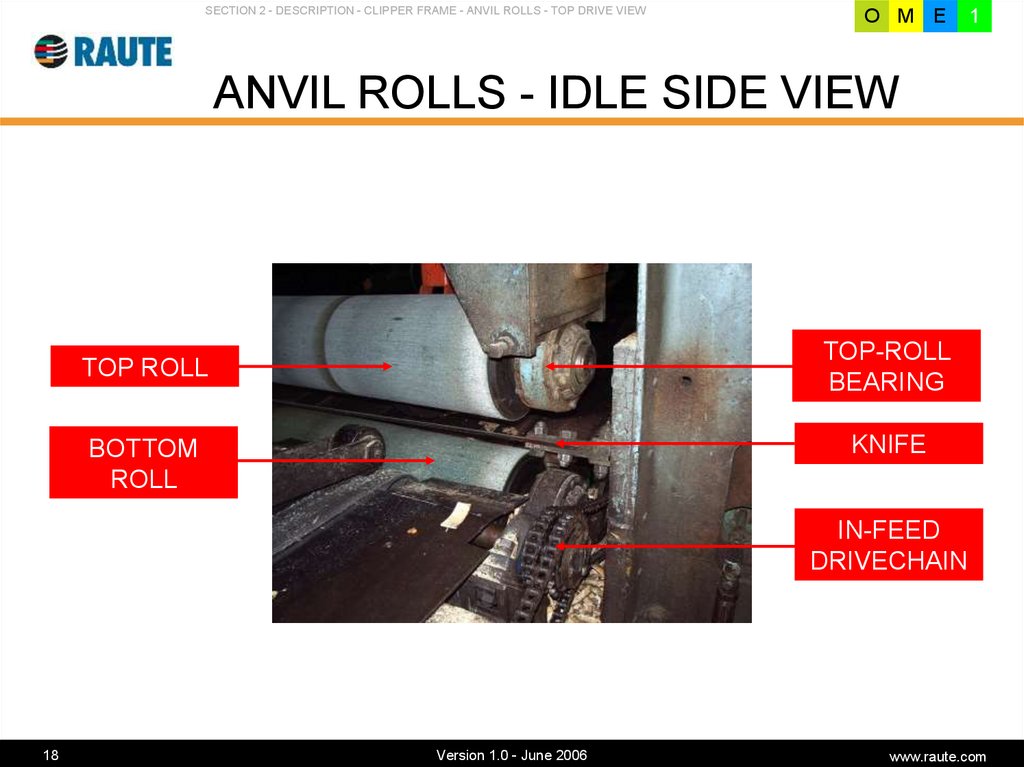

18. ANVIL ROLLS - IDLE SIDE VIEW

SECTION 2 - DESCRIPTION - CLIPPER FRAME - ANVIL ROLLS - TOP DRIVE VIEWO M E

1

ANVIL ROLLS - IDLE SIDE VIEW

TOP-ROLL

BEARING

TOP ROLL

KNIFE

BOTTOM

ROLL

IN-FEED

DRIVECHAIN

18

Version 1.0 - June 2006

www.raute.com

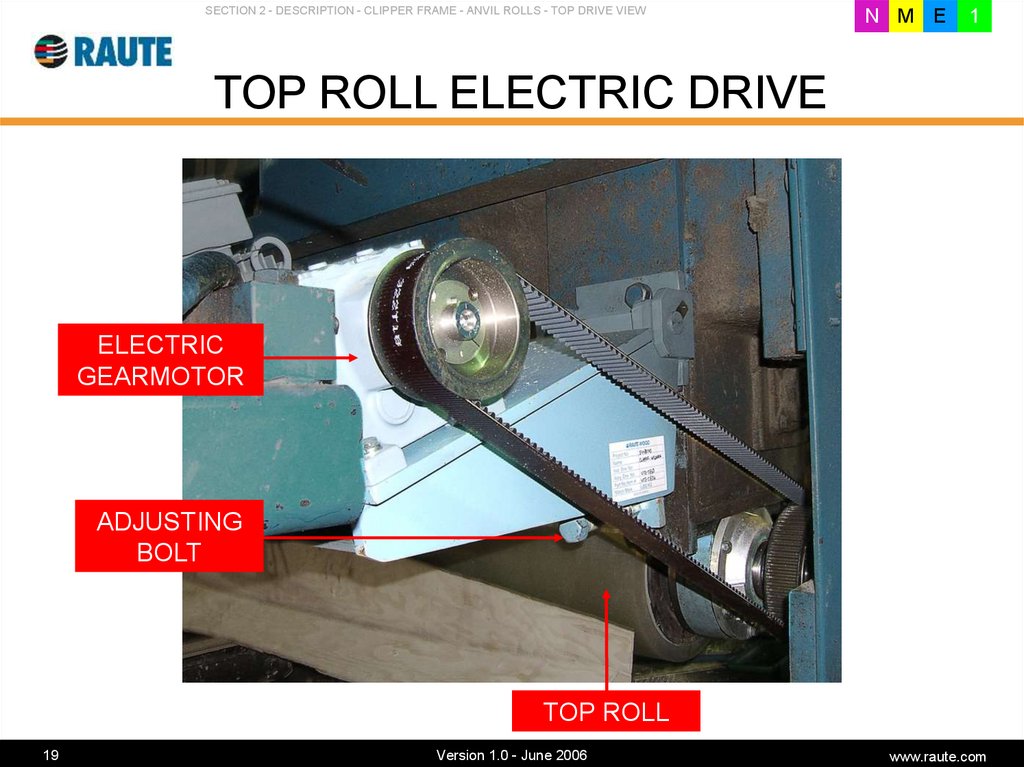

19. TOP ROLL ELECTRIC DRIVE

SECTION 2 - DESCRIPTION - CLIPPER FRAME - ANVIL ROLLS - TOP DRIVE VIEWN M E

1

TOP ROLL ELECTRIC DRIVE

ELECTRIC

GEARMOTOR

ADJUSTING

BOLT

TOP ROLL

19

Version 1.0 - June 2006

www.raute.com

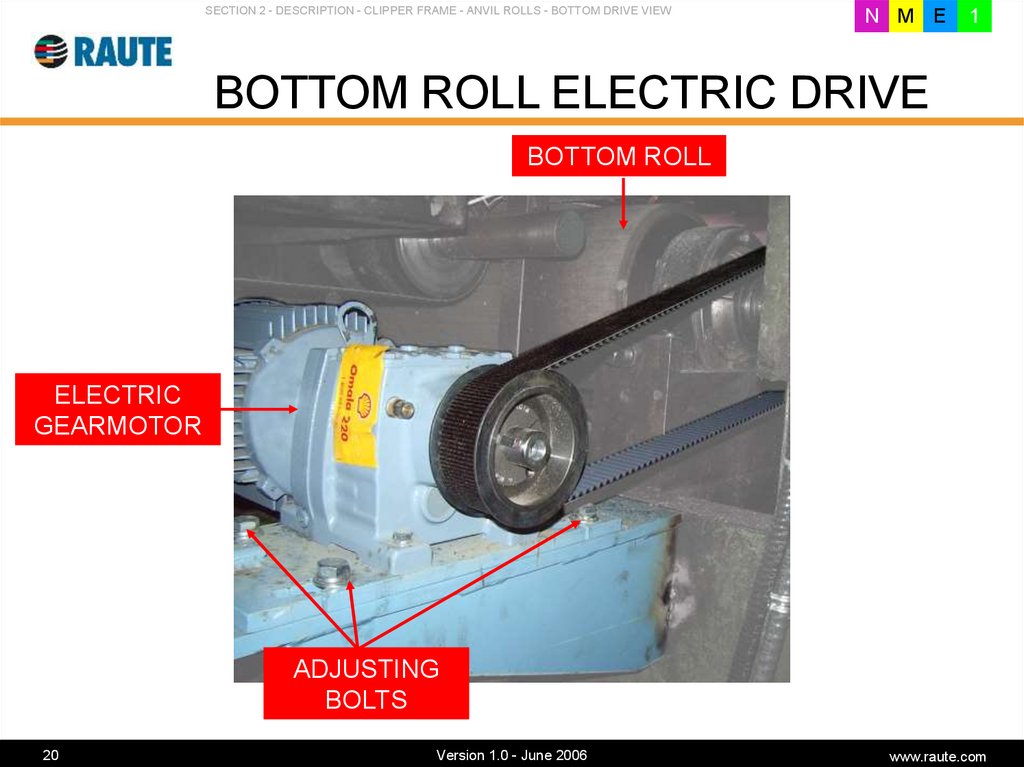

20. BOTTOM ROLL ELECTRIC DRIVE

SECTION 2 - DESCRIPTION - CLIPPER FRAME - ANVIL ROLLS - BOTTOM DRIVE VIEWN M E

1

BOTTOM ROLL ELECTRIC DRIVE

BOTTOM ROLL

ELECTRIC

GEARMOTOR

ADJUSTING

BOLTS

20

Version 1.0 - June 2006

www.raute.com

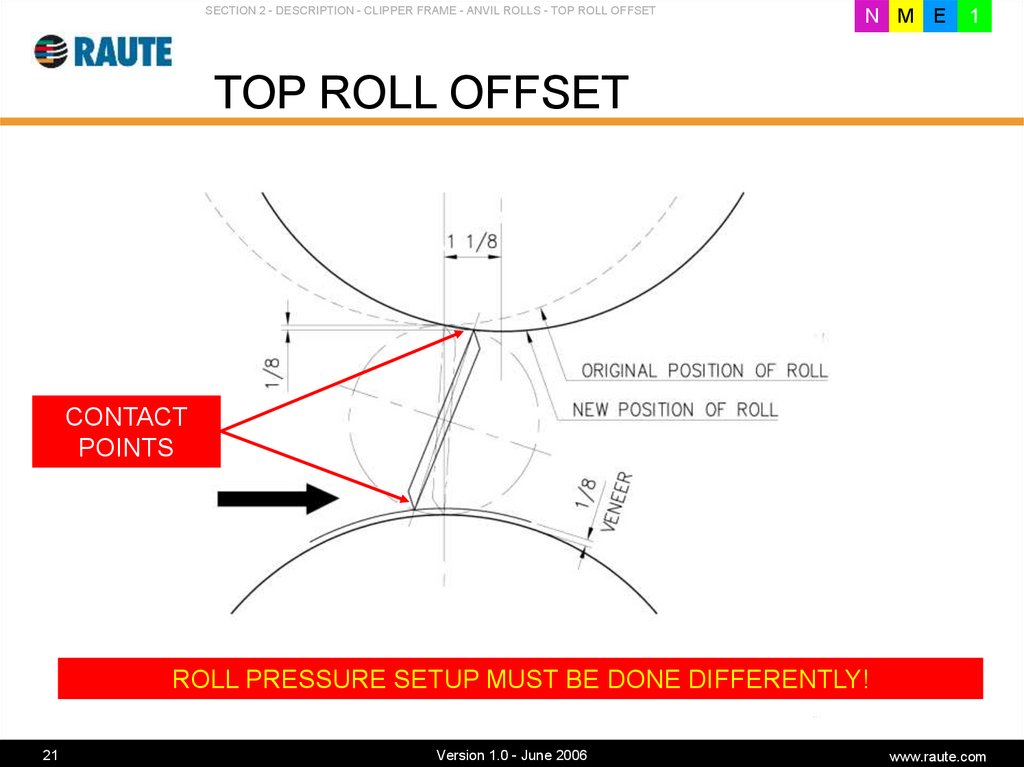

21. TOP ROLL OFFSET

SECTION 2 - DESCRIPTION - CLIPPER FRAME - ANVIL ROLLS - TOP ROLL OFFSETN M E

1

TOP ROLL OFFSET

CONTACT

POINTS

ROLL PRESSURE SETUP MUST BE DONE DIFFERENTLY!

21

Version 1.0 - June 2006

www.raute.com

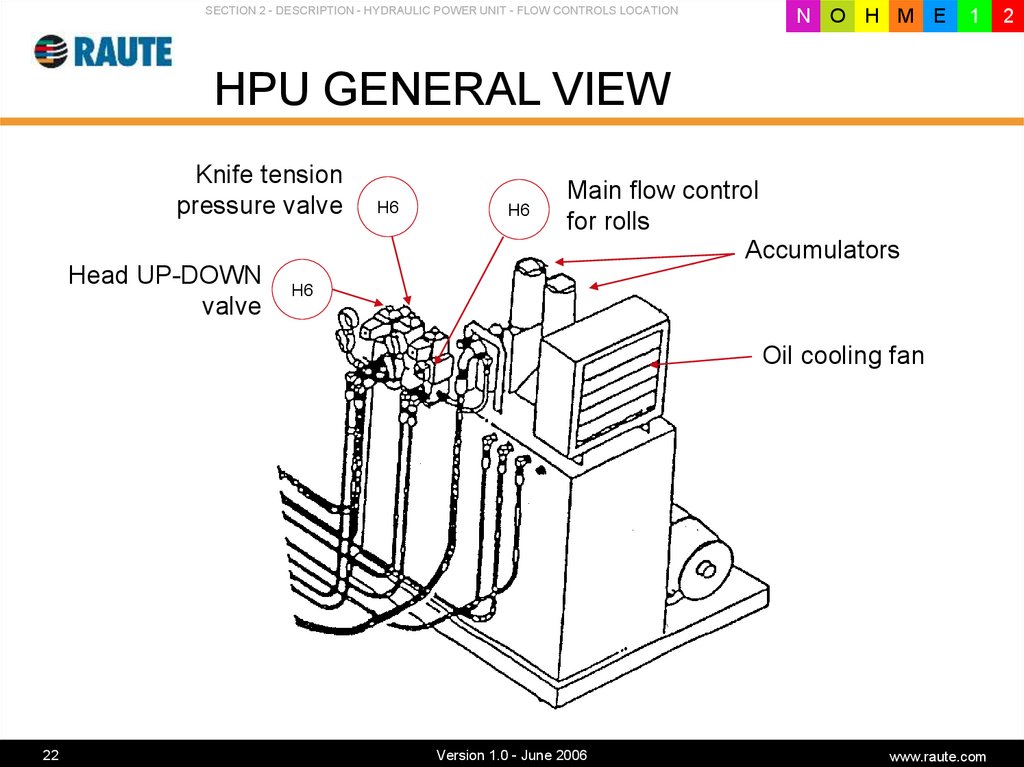

22. HPU GENERAL VIEW

SECTION 2 - DESCRIPTION - HYDRAULIC POWER UNIT - FLOW CONTROLS LOCATIONN O H M E

1

HPU GENERAL VIEW

Knife tension

pressure valve

Head UP-DOWN

valve

H6

H6

Main flow control

for rolls

Accumulators

H6

Oil cooling fan

22

Version 1.0 - June 2006

www.raute.com

2

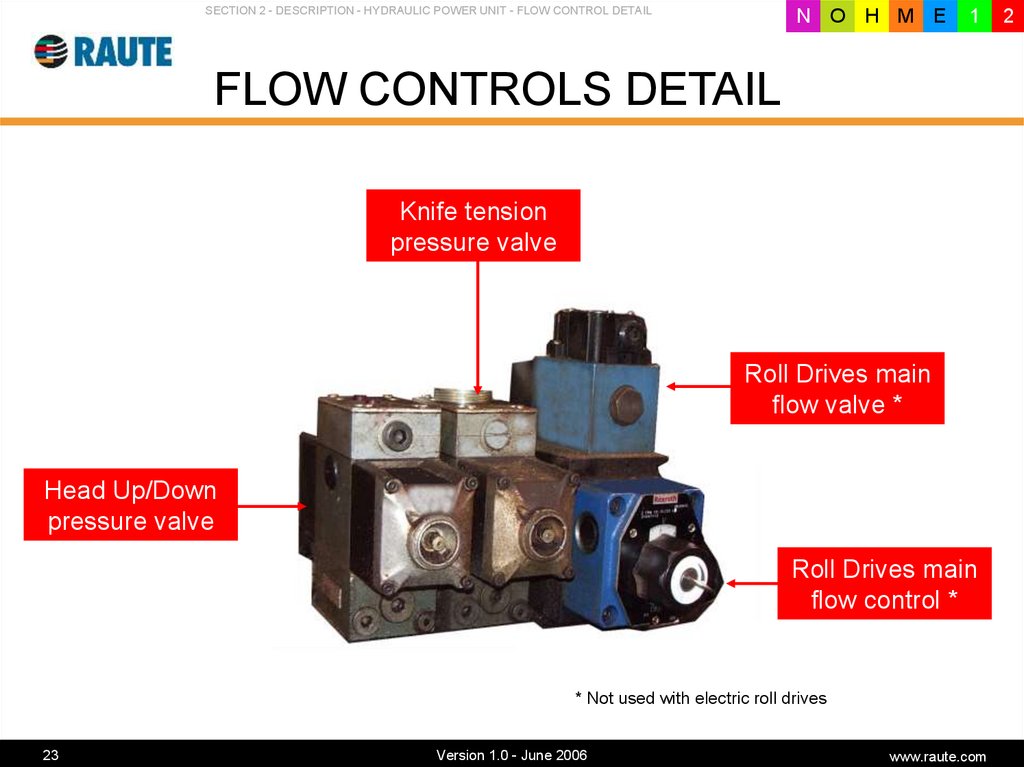

23. FLOW CONTROLS DETAIL

SECTION 2 - DESCRIPTION - HYDRAULIC POWER UNIT - FLOW CONTROL DETAILN O H M E

1

FLOW CONTROLS DETAIL

Knife tension

pressure valve

Roll Drives main

flow valve *

Head Up/Down

pressure valve

Roll Drives main

flow control *

* Not used with electric roll drives

23

Version 1.0 - June 2006

www.raute.com

2

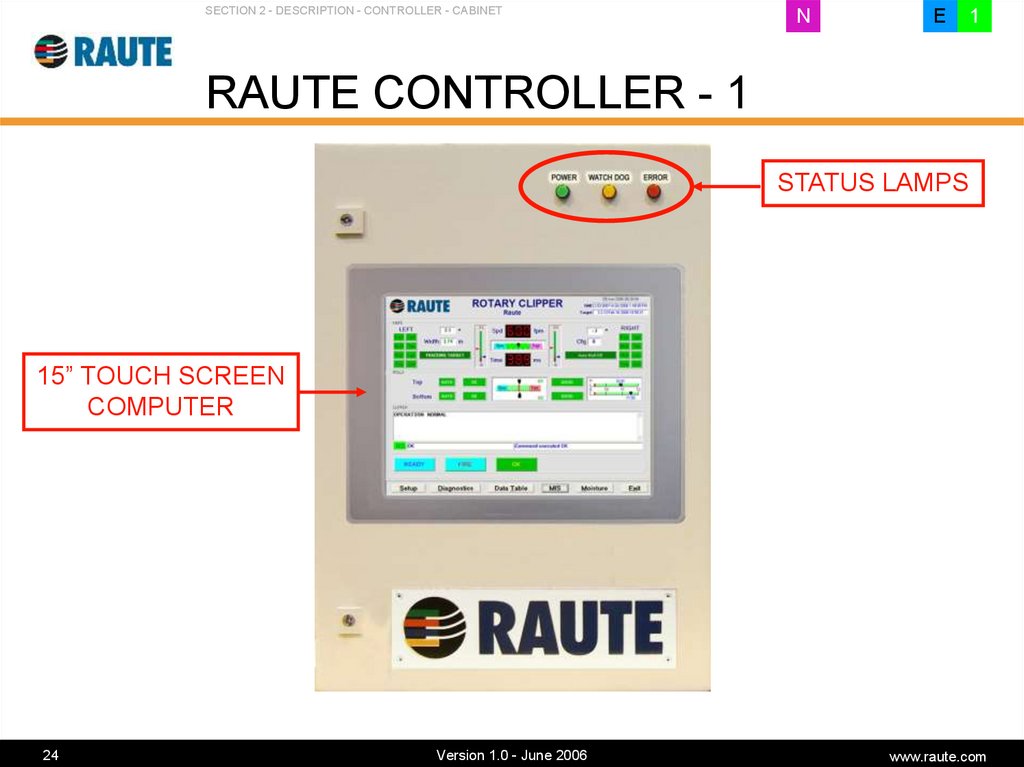

24. RAUTE CONTROLLER - 1

SECTION 2 - DESCRIPTION - CONTROLLER - CABINETN

E

1

RAUTE CONTROLLER - 1

STATUS LAMPS

15” TOUCH SCREEN

COMPUTER

24

Version 1.0 - June 2006

www.raute.com

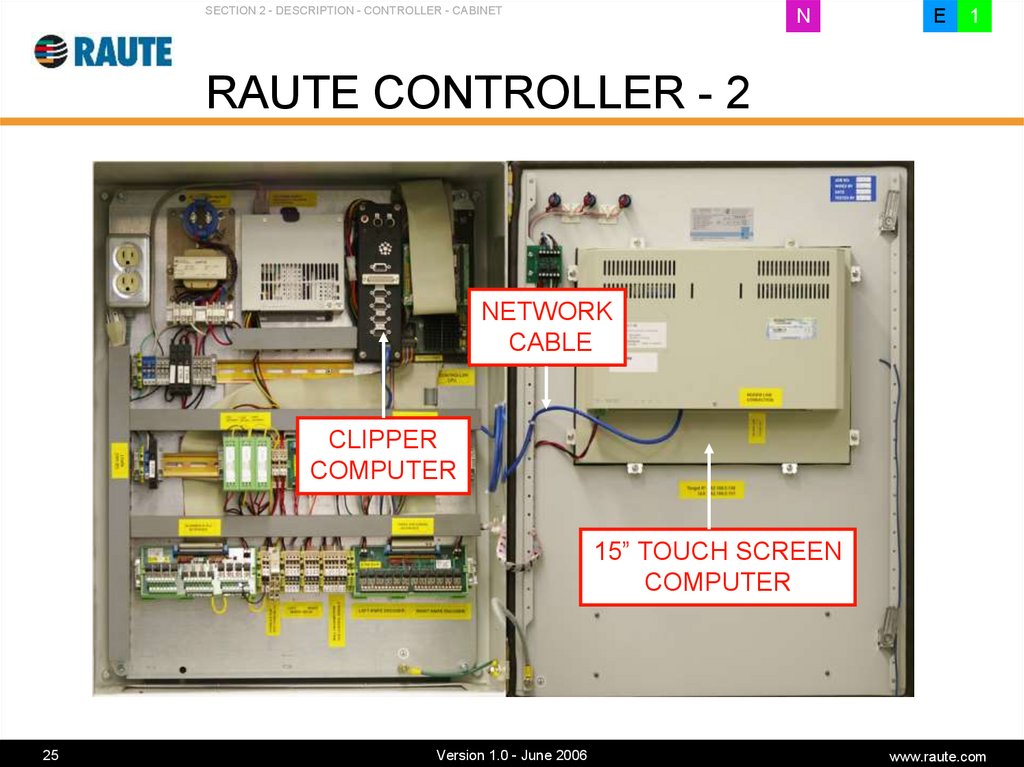

25. RAUTE CONTROLLER - 2

SECTION 2 - DESCRIPTION - CONTROLLER - CABINETN

E

1

RAUTE CONTROLLER - 2

NETWORK

CABLE

CLIPPER

COMPUTER

15” TOUCH SCREEN

COMPUTER

25

Version 1.0 - June 2006

www.raute.com

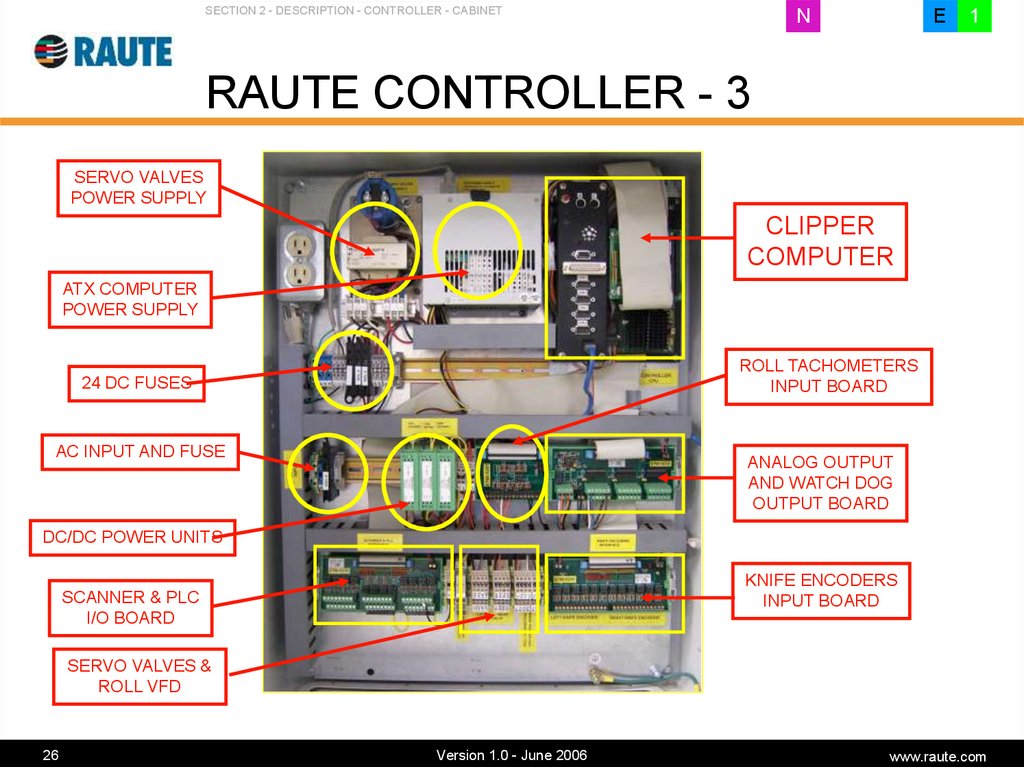

26. RAUTE CONTROLLER - 3

SECTION 2 - DESCRIPTION - CONTROLLER - CABINETN

E

1

RAUTE CONTROLLER - 3

SERVO VALVES

POWER SUPPLY

CLIPPER

COMPUTER

ATX COMPUTER

POWER SUPPLY

ROLL TACHOMETERS

INPUT BOARD

24 DC FUSES

AC INPUT AND FUSE

ANALOG OUTPUT

AND WATCH DOG

OUTPUT BOARD

DC/DC POWER UNITS

KNIFE ENCODERS

INPUT BOARD

SCANNER & PLC

I/O BOARD

SERVO VALVES &

ROLL VFD

26

Version 1.0 - June 2006

www.raute.com

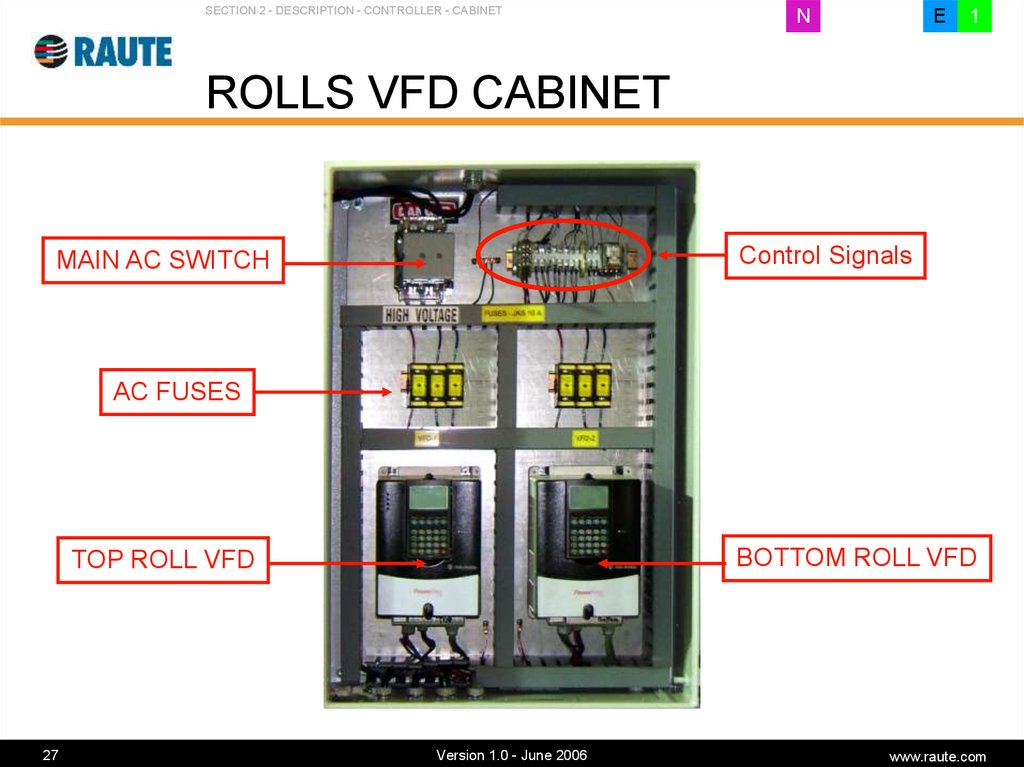

27. ROLLS VFD CABINET

SECTION 2 - DESCRIPTION - CONTROLLER - CABINETN

E

1

ROLLS VFD CABINET

Control Signals

MAIN AC SWITCH

AC FUSES

BOTTOM ROLL VFD

TOP ROLL VFD

27

Version 1.0 - June 2006

www.raute.com

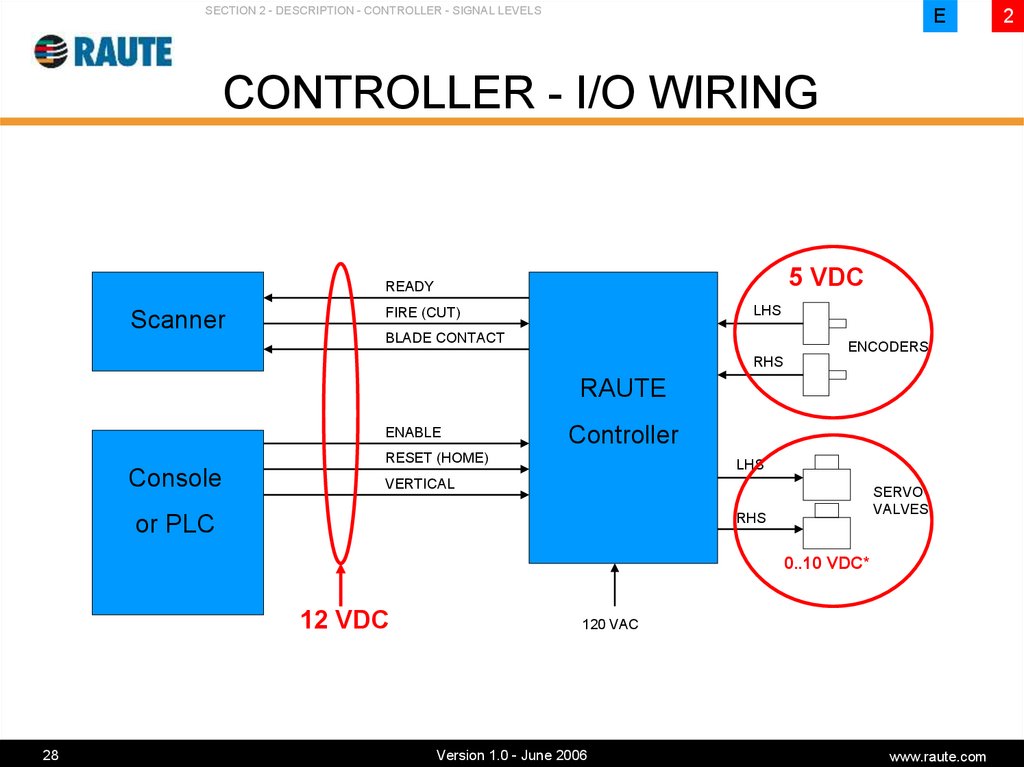

28. CONTROLLER - I/O WIRING

SECTION 2 - DESCRIPTION - CONTROLLER - SIGNAL LEVELSE

CONTROLLER - I/O WIRING

5 VDC

READY

Scanner

LHS

FIRE (CUT)

BLADE CONTACT

ENCODERS

RHS

RAUTE

ENABLE

Controller

RESET (HOME)

Console

LHS

VERTICAL

SERVO

VALVES

RHS

or PLC

0..10 VDC*

12 VDC

28

120 VAC

Version 1.0 - June 2006

www.raute.com

2

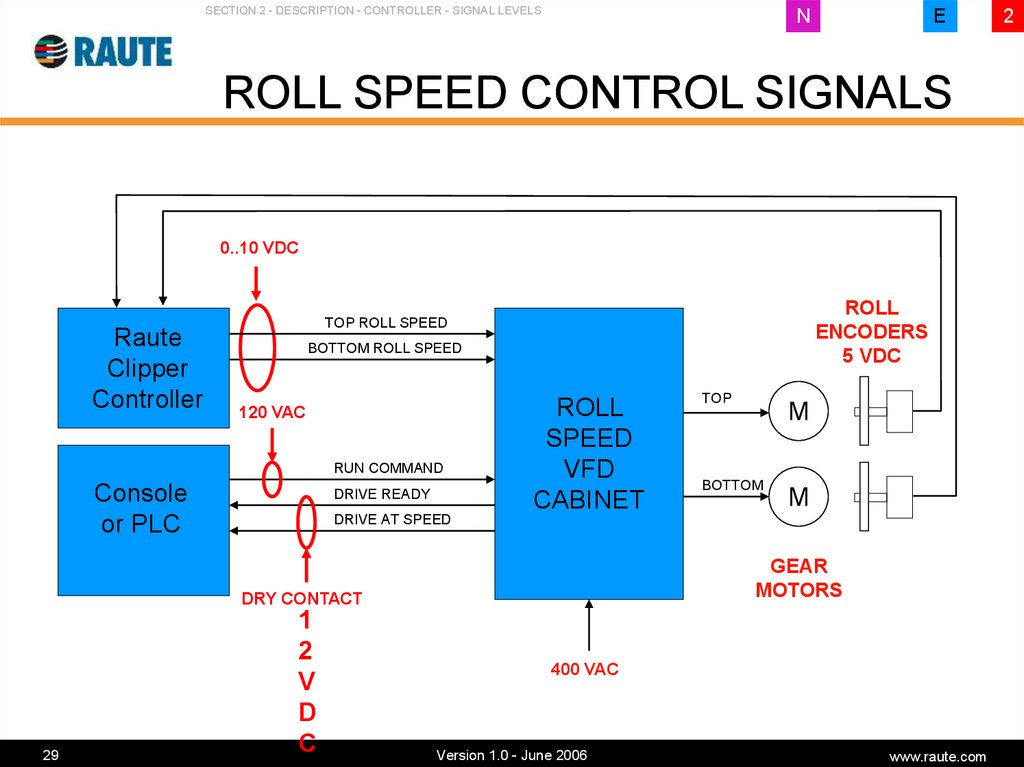

29. ROLL SPEED CONTROL SIGNALS

SECTION 2 - DESCRIPTION - CONTROLLER - SIGNAL LEVELSN

E

ROLL SPEED CONTROL SIGNALS

0..10 VDC

Raute

Clipper

Controller

ROLL

ENCODERS

5 VDC

TOP ROLL SPEED

BOTTOM ROLL SPEED

120 VAC

RUN COMMAND

Console

or PLC

DRIVE READY

ROLL

SPEED

VFD

CABINET

M

BOTTOM

M

DRIVE AT SPEED

GEAR

MOTORS

DRY CONTACT

29

TOP

1

2

V

D

C

400 VAC

Version 1.0 - June 2006

www.raute.com

2

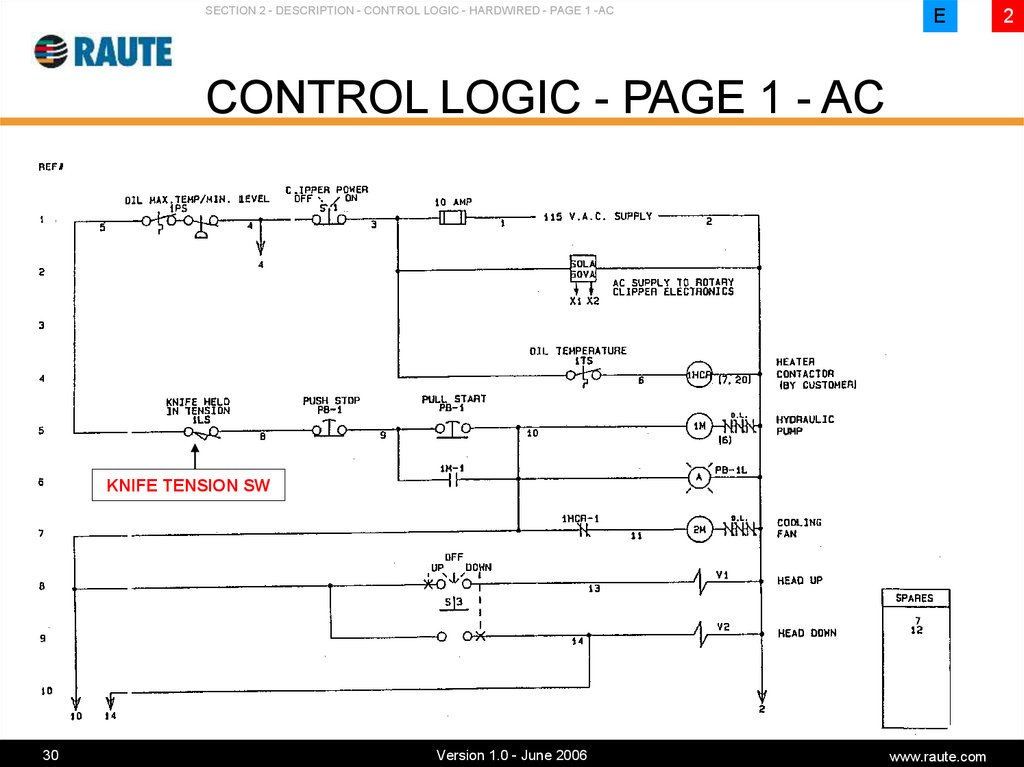

30. CONTROL LOGIC - PAGE 1 - AC

SECTION 2 - DESCRIPTION - CONTROL LOGIC - HARDWIRED - PAGE 1 -ACE

CONTROL LOGIC - PAGE 1 - AC

KNIFE TENSION SW

30

Version 1.0 - June 2006

www.raute.com

2

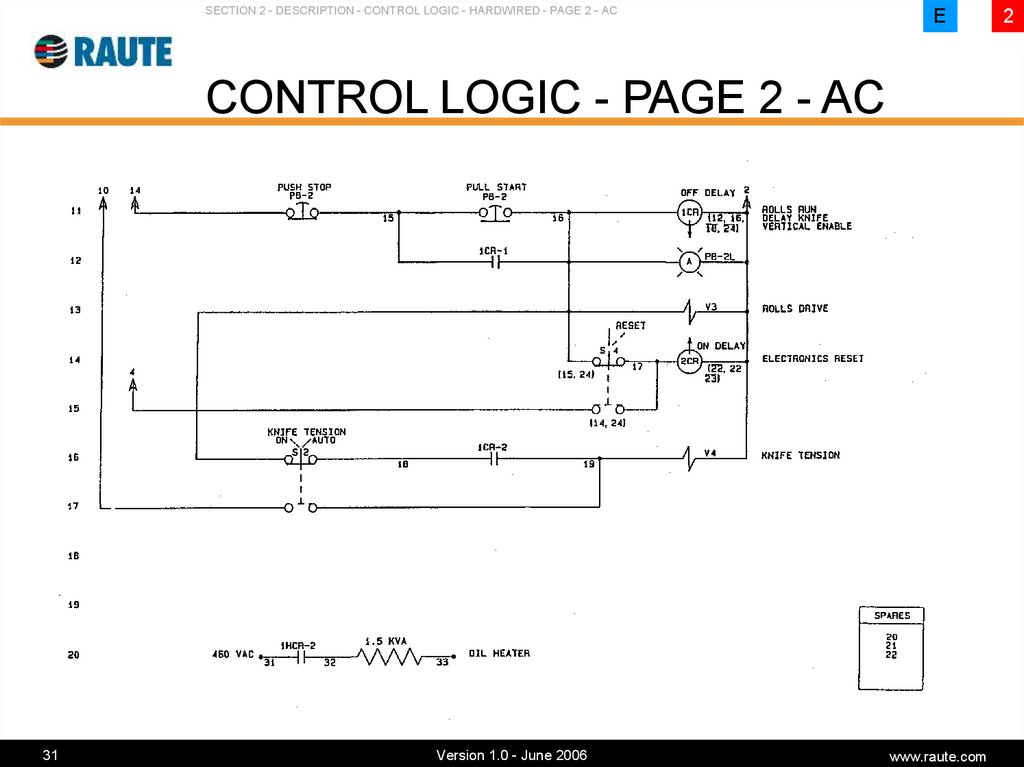

31. CONTROL LOGIC - PAGE 2 - AC

SECTION 2 - DESCRIPTION - CONTROL LOGIC - HARDWIRED - PAGE 2 - ACE

CONTROL LOGIC - PAGE 2 - AC

31

Version 1.0 - June 2006

www.raute.com

2

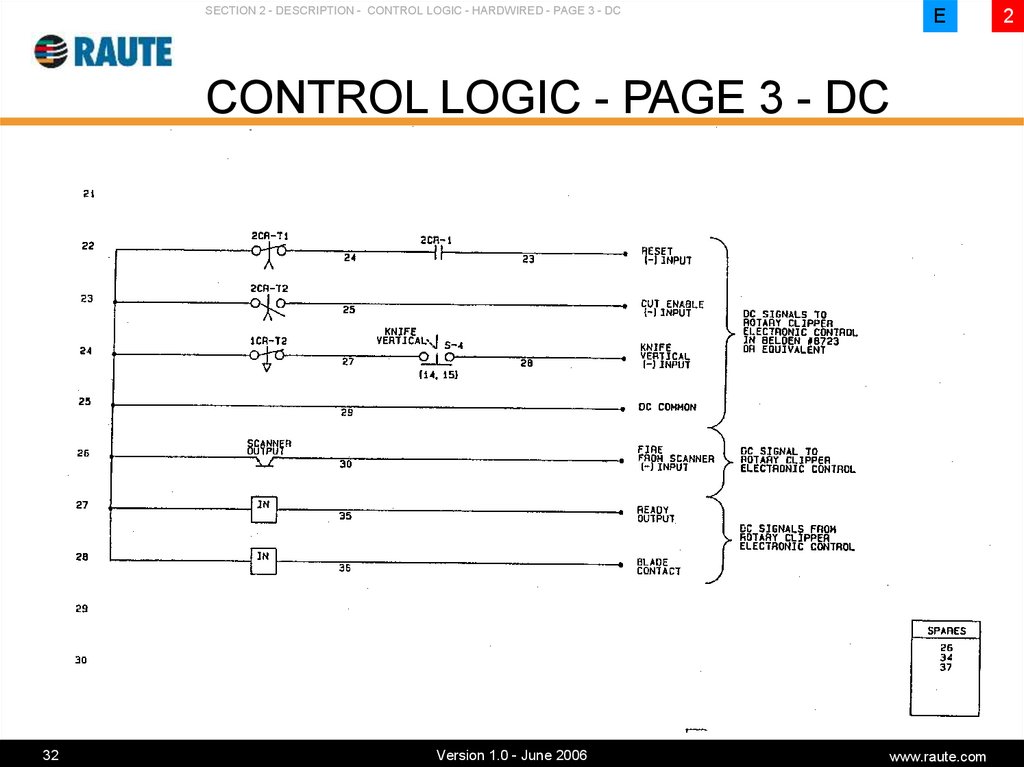

32. CONTROL LOGIC - PAGE 3 - DC

SECTION 2 - DESCRIPTION - CONTROL LOGIC - HARDWIRED - PAGE 3 - DCE

CONTROL LOGIC - PAGE 3 - DC

32

Version 1.0 - June 2006

www.raute.com

2

33. SECTION 3 CLIPPER THEORY

SECTION 3 - CLIPPER THEORYN O M E

1

SECTION 3

CLIPPER THEORY

CLIPPER GOALS

• Exact clip point

•Parallel clips

• Match knife/roll speeds

• Minimize response time

• Straight clips (no bias)

OPERATION

• Knife positions

• Clip steps

• Clip cycle

• Clip zone

• Knife/roll speed mismatch effects

33

Version 1.0 - June 2006

www.raute.com

2

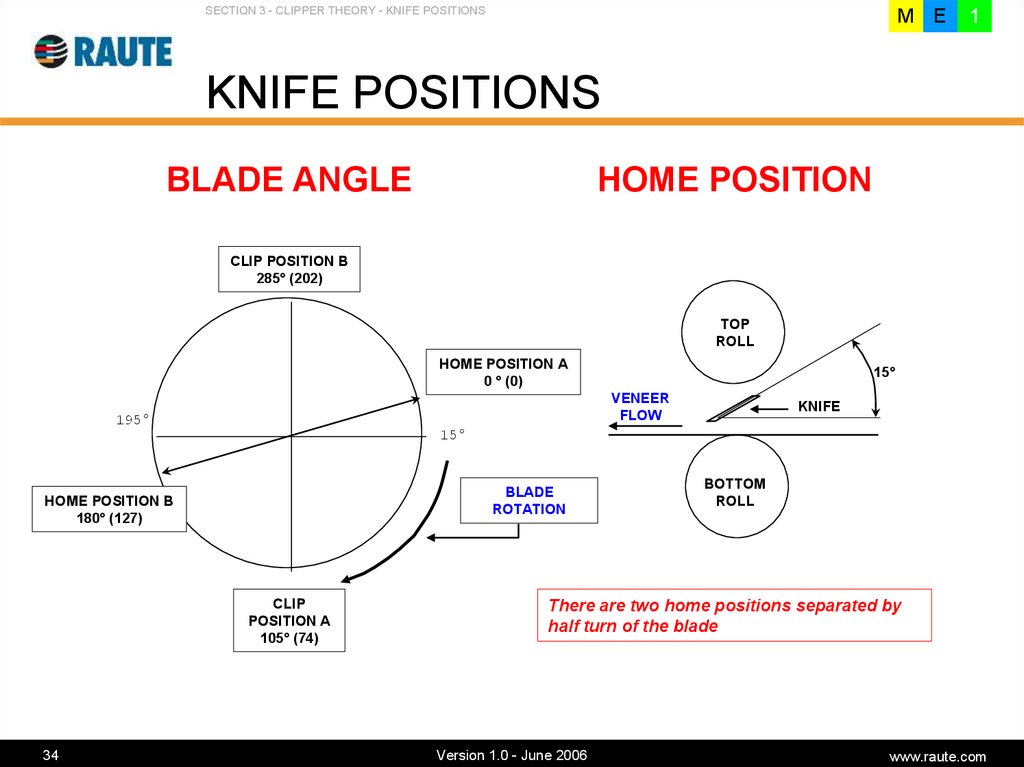

34. KNIFE POSITIONS

SECTION 3 - CLIPPER THEORY - KNIFE POSITIONSM E

1

KNIFE POSITIONS

BLADE ANGLE

HOME POSITION

CLIP POSITION B

285° (202)

TOP

ROLL

HOME POSITION A

0 ° (0)

15°

VENEER

FLOW

195°

KNIFE

15°

BLADE

ROTATION

HOME POSITION B

180° (127)

CLIP

POSITION A

105° (74)

34

BOTTOM

ROLL

There are two home positions separated by

half turn of the blade

Version 1.0 - June 2006

www.raute.com

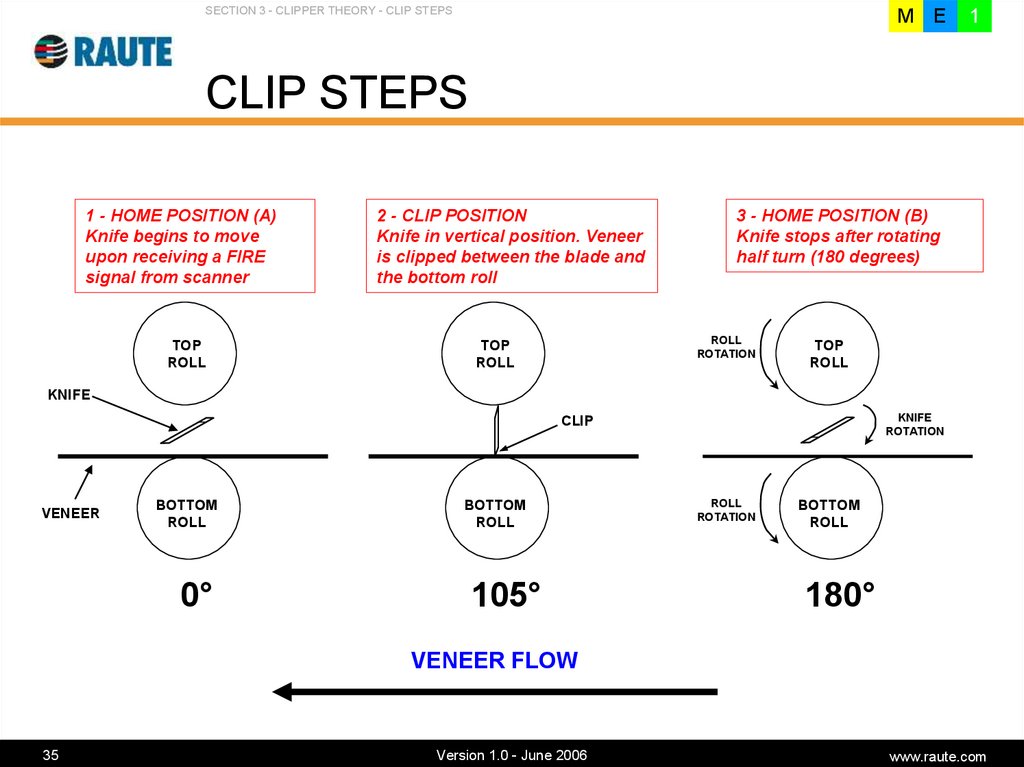

35. CLIP STEPS

SECTION 3 - CLIPPER THEORY - CLIP STEPSM E

1

CLIP STEPS

1 - HOME POSITION (A)

Knife begins to move

upon receiving a FIRE

signal from scanner

TOP

ROLL

2 - CLIP POSITION

Knife in vertical position. Veneer

is clipped between the blade and

the bottom roll

3 - HOME POSITION (B)

Knife stops after rotating

half turn (180 degrees)

ROLL

ROTATION

TOP

ROLL

TOP

ROLL

KNIFE

KNIFE

ROTATION

CLIP

VENEER

BOTTOM

ROLL

0°

BOTTOM

ROLL

105°

ROLL

ROTATION

BOTTOM

ROLL

180°

VENEER FLOW

35

Version 1.0 - June 2006

www.raute.com

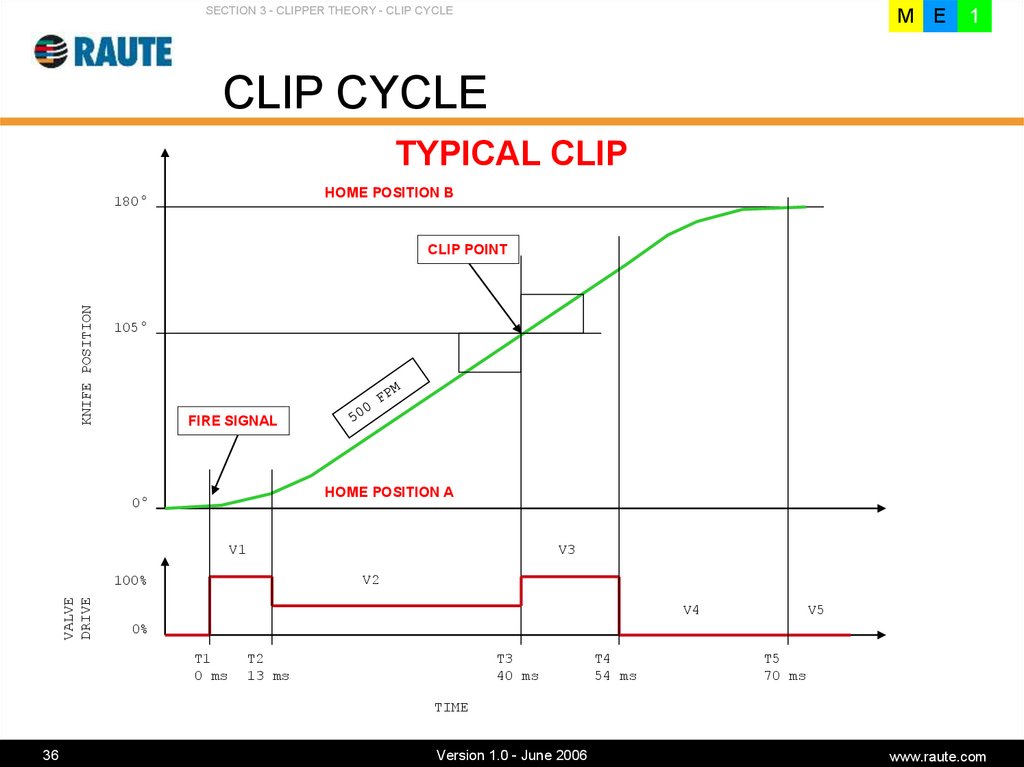

36. CLIP CYCLE

SECTION 3 - CLIPPER THEORY - CLIP CYCLEM E

1

CLIP CYCLE

TYPICAL CLIP

HOME POSITION B

180°

KNIFE POSITION

CLIP POINT

105°

FIRE SIGNAL

HOME POSITION A

0°

V1

V3

V2

VALVE

DRIVE

100%

V4

V5

0%

T1

0 ms

T2

13 ms

T3

40 ms

T4

54 ms

T5

70 ms

TIME

36

Version 1.0 - June 2006

www.raute.com

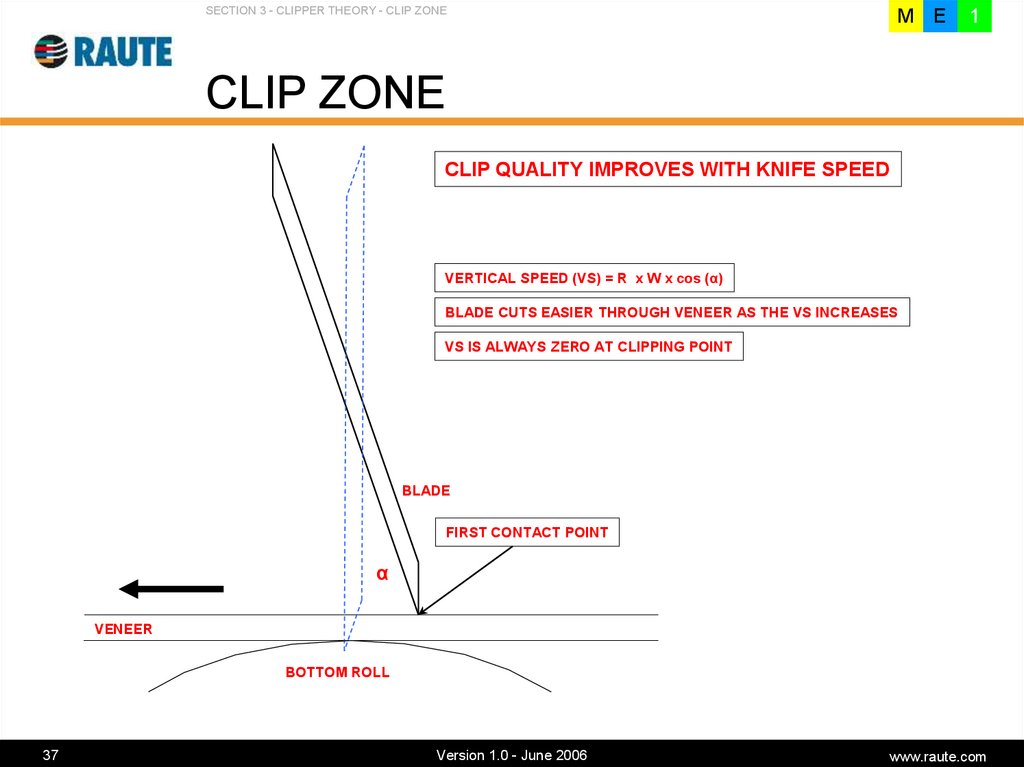

37. CLIP ZONE

SECTION 3 - CLIPPER THEORY - CLIP ZONEM E

1

CLIP ZONE

CLIP QUALITY IMPROVES WITH KNIFE SPEED

VERTICAL SPEED (VS) = R x W x cos (α)

BLADE CUTS EASIER THROUGH VENEER AS THE VS INCREASES

VS IS ALWAYS ZERO AT CLIPPING POINT

BLADE

FIRST CONTACT POINT

α

VENEER

BOTTOM ROLL

37

Version 1.0 - June 2006

www.raute.com

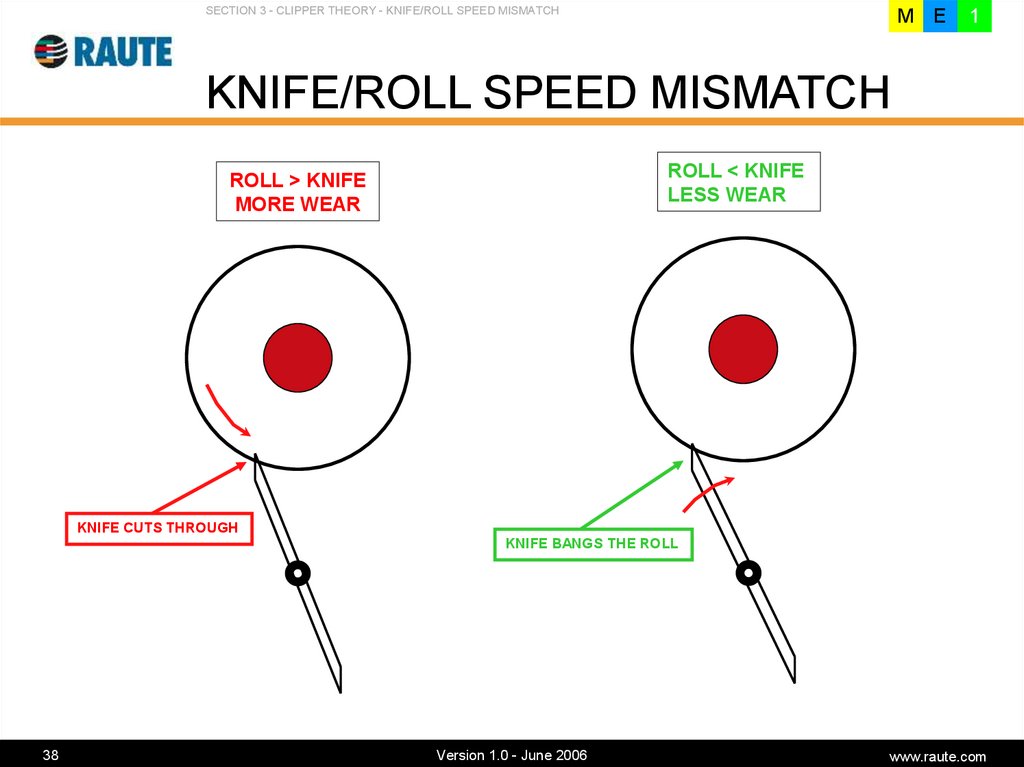

38. KNIFE/ROLL SPEED MISMATCH

SECTION 3 - CLIPPER THEORY - KNIFE/ROLL SPEED MISMATCHM E

1

KNIFE/ROLL SPEED MISMATCH

ROLL < KNIFE

LESS WEAR

ROLL > KNIFE

MORE WEAR

KNIFE CUTS THROUGH

KNIFE BANGS THE ROLL

38

Version 1.0 - June 2006

www.raute.com

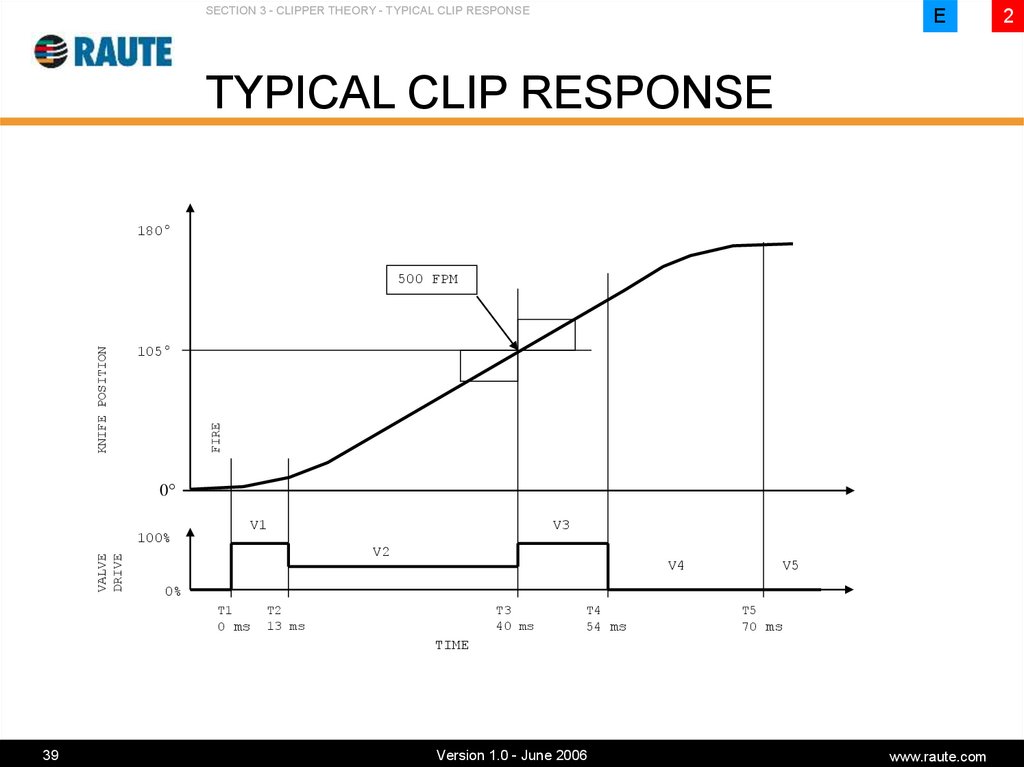

39. TYPICAL CLIP RESPONSE

SECTION 3 - CLIPPER THEORY - TYPICAL CLIP RESPONSEE

TYPICAL CLIP RESPONSE

180°

105°

FIRE

KNIFE POSITION

500 FPM

0°

VALVE

DRIVE

100%

V1

V3

V2

V4

V5

0%

T1

0 ms

T2

13 ms

T3

40 ms

T4

54 ms

T5

70 ms

TIME

39

Version 1.0 - June 2006

www.raute.com

2

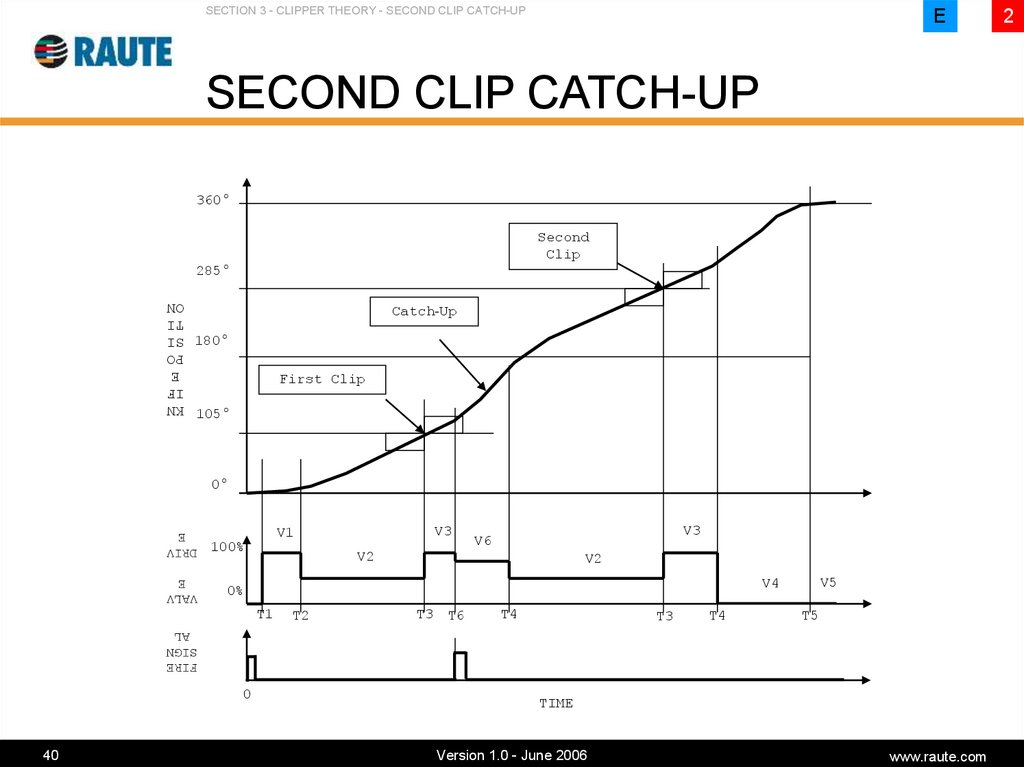

40. SECOND CLIP CATCH-UP

SECTION 3 - CLIPPER THEORY - SECOND CLIP CATCH-UPE

SECOND CLIP CATCH-UP

360°

Second

Clip

285°

Catch-Up

180°

First Clip

105°

KN

IF

E

PO

SI

TI

ON

0°

DRIV

E

100%

VALV

E

0%

V3

V1

V3

V6

V2

V2

V5

V4

T1

T2

T3 T6

T4

T3

T4

T5

FIRE

SIGN

AL

0

40

TIME

Version 1.0 - June 2006

www.raute.com

2

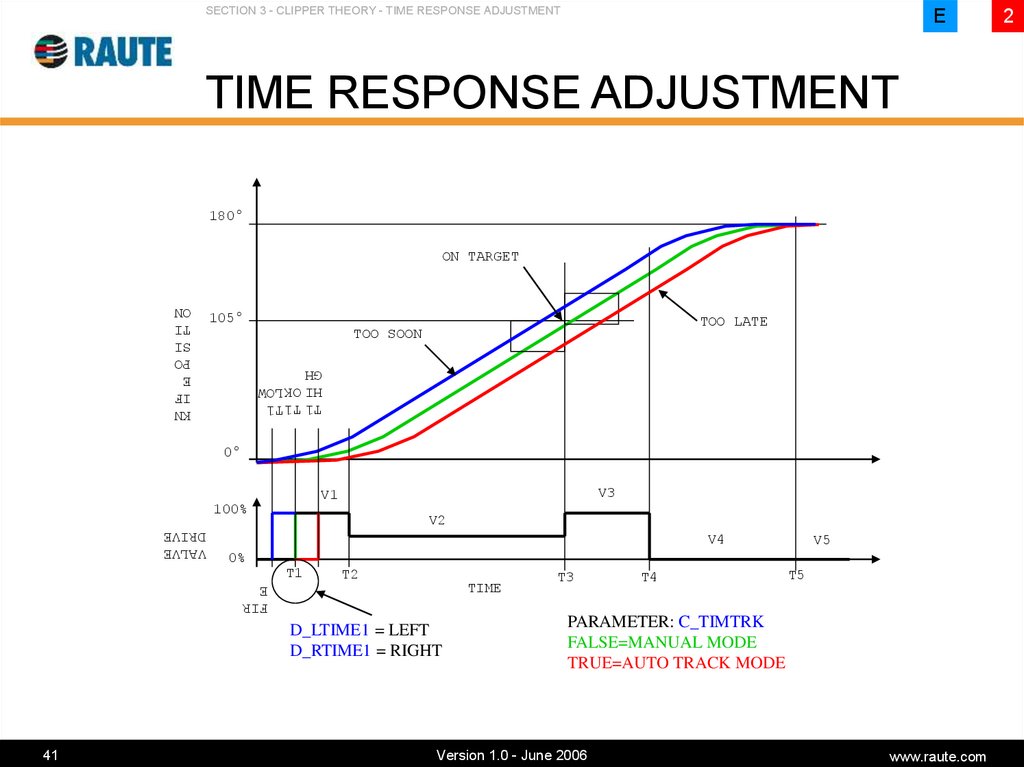

41. TIME RESPONSE ADJUSTMENT

SECTION 3 - CLIPPER THEORY - TIME RESPONSE ADJUSTMENTE

TIME RESPONSE ADJUSTMENT

180°

ON TARGET

105°

TOO LATE

TOO SOON

T1 T1 T1

HI OK LOW

GH

KN

IF

E

PO

SI

TI

ON

0°

V3

V1

100%

V2

V4

VALVE

DRIVE

T1

T2

TIME

FIR

E

D_LTIME1 = LEFT

D_RTIME1 = RIGHT

41

V5

0%

T3

T4

T5

PARAMETER: C_TIMTRK

FALSE=MANUAL MODE

TRUE=AUTO TRACK MODE

Version 1.0 - June 2006

www.raute.com

2

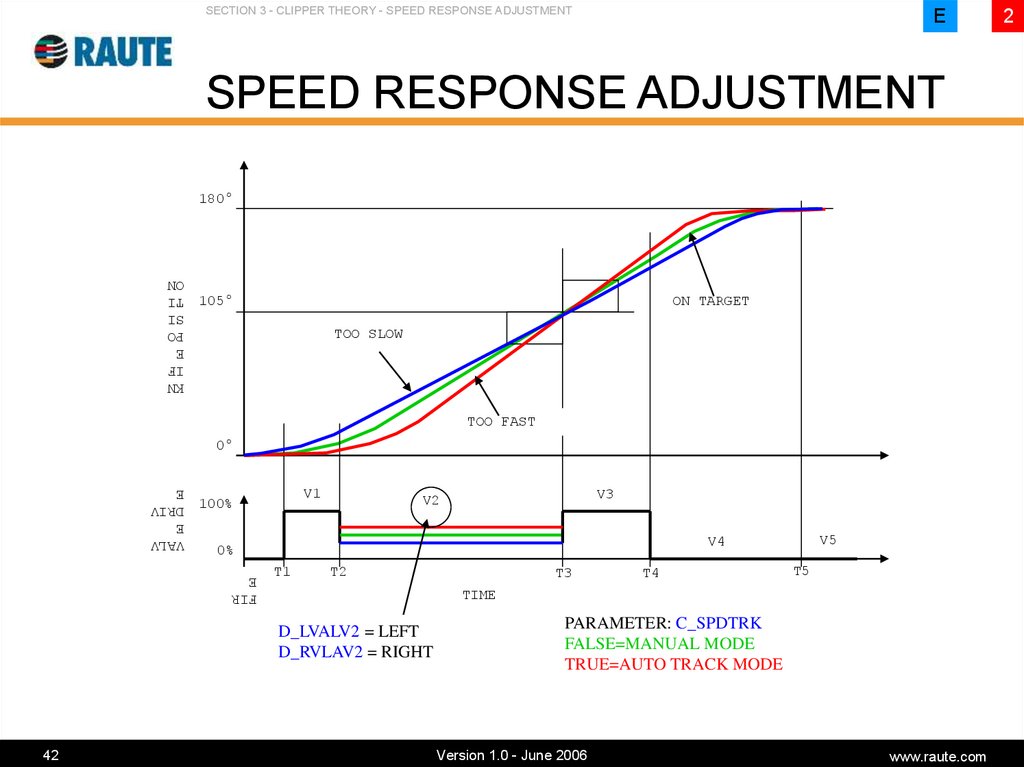

42. SPEED RESPONSE ADJUSTMENT

SECTION 3 - CLIPPER THEORY - SPEED RESPONSE ADJUSTMENTE

SPEED RESPONSE ADJUSTMENT

180°

105°

ON TARGET

TOO SLOW

KN

IF

E

PO

SI

TI

ON

TOO FAST

0°

V1

100%

V5

V4

0%

T1

T2

T3

T4

T5

TIME

VALV

E

DRIV

E

FIR

E

D_LVALV2 = LEFT

D_RVLAV2 = RIGHT

42

V3

V2

PARAMETER: C_SPDTRK

FALSE=MANUAL MODE

TRUE=AUTO TRACK MODE

Version 1.0 - June 2006

www.raute.com

2

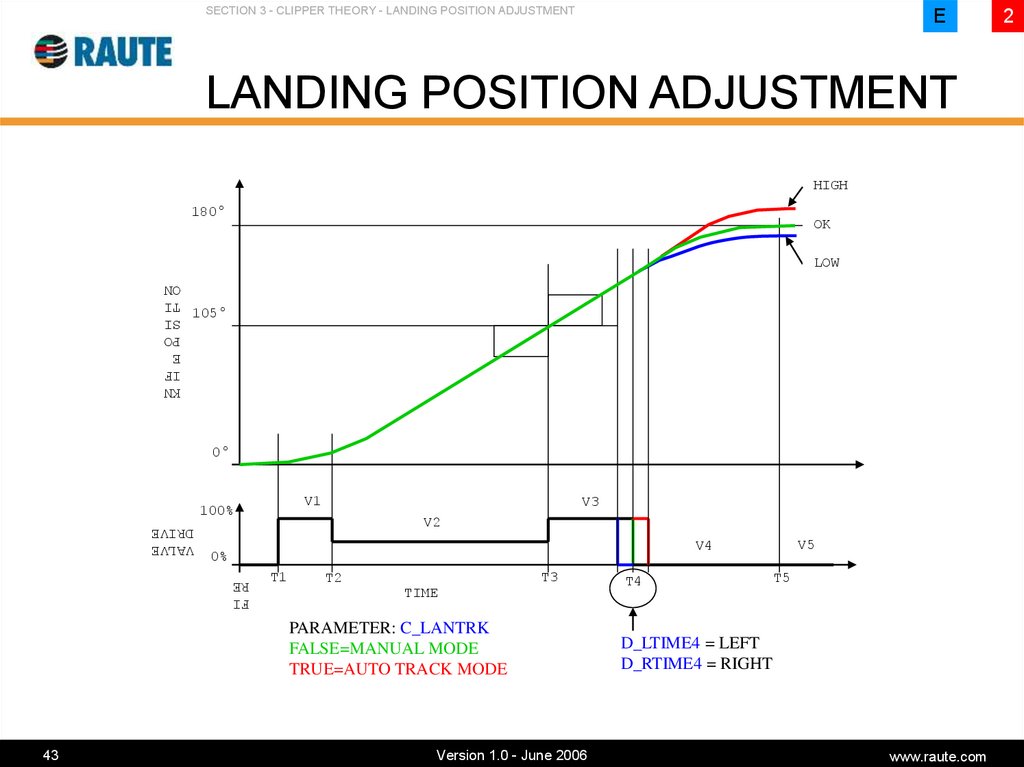

43. LANDING POSITION ADJUSTMENT

SECTION 3 - CLIPPER THEORY - LANDING POSITION ADJUSTMENTE

LANDING POSITION ADJUSTMENT

HIGH

180°

OK

LOW

105°

KN

IF

E

PO

SI

TI

ON

0°

V1

100%

V3

V2

T1

T3

T2

TIME

VALVE

DRIVE

FI

RE

PARAMETER: C_LANTRK

FALSE=MANUAL MODE

TRUE=AUTO TRACK MODE

43

V5

V4

0%

Version 1.0 - June 2006

T4

T5

D_LTIME4 = LEFT

D_RTIME4 = RIGHT

www.raute.com

2

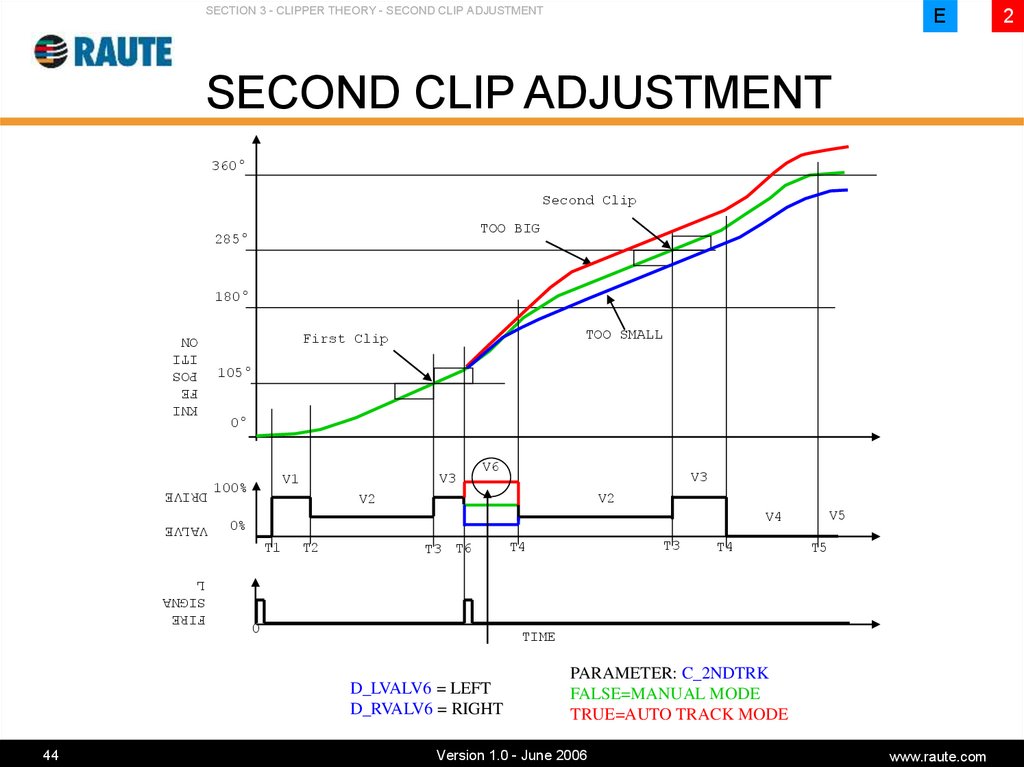

44. SECOND CLIP ADJUSTMENT

SECTION 3 - CLIPPER THEORY - SECOND CLIP ADJUSTMENTE

SECOND CLIP ADJUSTMENT

360°

Second Clip

TOO BIG

285°

180°

TOO SMALL

First Clip

105°

0°

V3

V1

100%

V6

V2

V2

V5

V4

0%

KNI

FE

POS

ITI

ON

DRIVE

VALVE

T1

T2

T3 T6

0

T3

T4

T4

T5

TIME

FIRE

SIGNA

L

D_LVALV6 = LEFT

D_RVALV6 = RIGHT

44

V3

PARAMETER: C_2NDTRK

FALSE=MANUAL MODE

TRUE=AUTO TRACK MODE

Version 1.0 - June 2006

www.raute.com

2

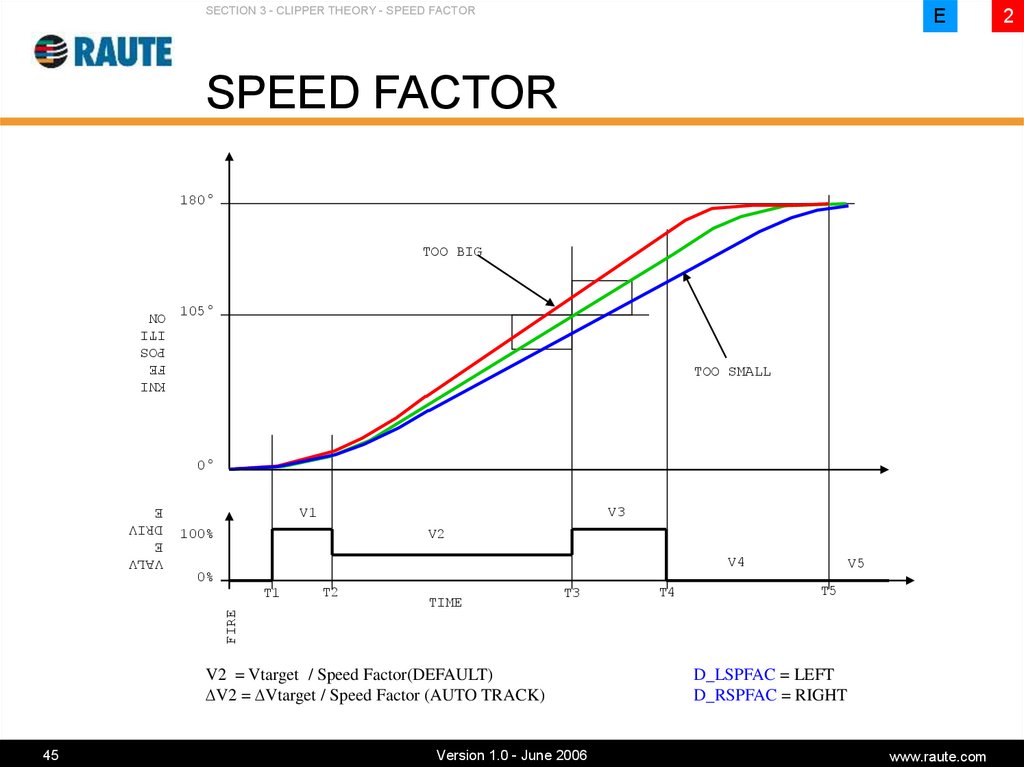

45. SPEED FACTOR

SECTION 3 - CLIPPER THEORY - SPEED FACTORE

SPEED FACTOR

180°

TOO BIG

105°

TOO SMALL

KNI

FE

POS

ITI

ON

0°

V3

V1

100%

V2

V4

0%

VALV

E

DRIV

E

T2

TIME

T3

T4

T5

FIRE

T1

V5

V2 = Vtarget / Speed Factor(DEFAULT)

V2 = Vtarget / Speed Factor (AUTO TRACK)

45

Version 1.0 - June 2006

D_LSPFAC = LEFT

D_RSPFAC = RIGHT

www.raute.com

2

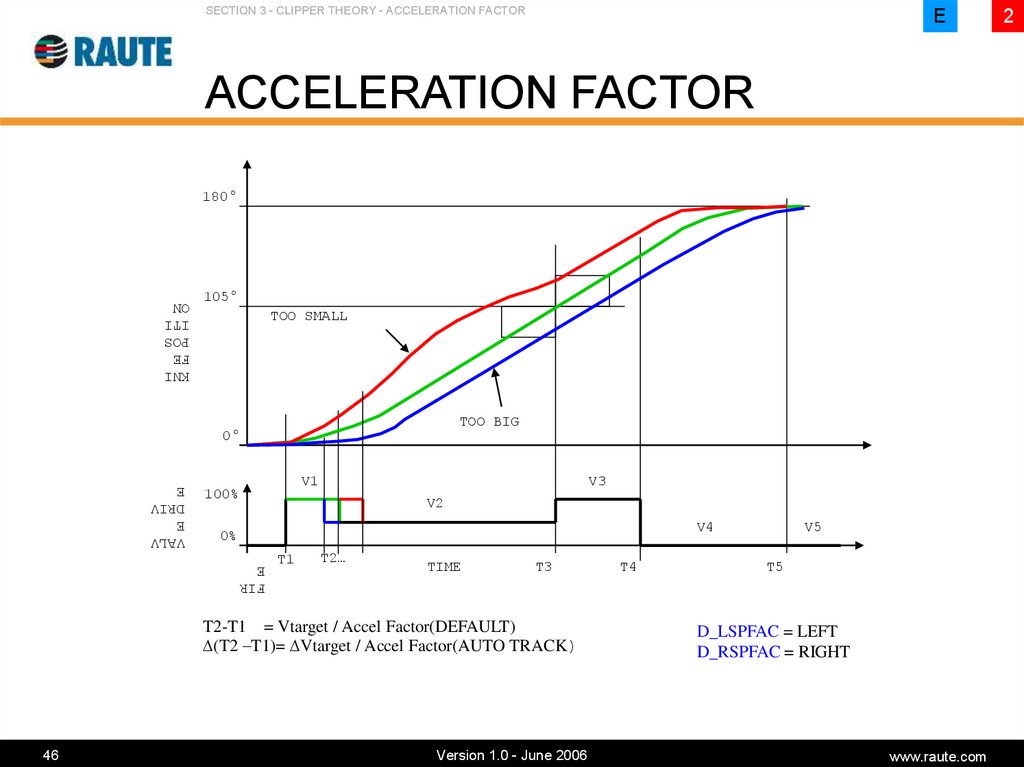

46. ACCELERATION FACTOR

SECTION 3 - CLIPPER THEORY - ACCELERATION FACTORE

ACCELERATION FACTOR

180°

105°

TOO SMALL

KNI

FE

POS

ITI

ON

TOO BIG

0°

V1

100%

V3

V2

V4

0%

T1

T2…

TIME

T3

VALV

E

DRIV

E

FIR

E

T2-T1 = Vtarget / Accel Factor(DEFAULT)

(T2 –T1)= Vtarget / Accel Factor(AUTO TRACK)

46

Version 1.0 - June 2006

T4

V5

T5

D_LSPFAC = LEFT

D_RSPFAC = RIGHT

www.raute.com

2

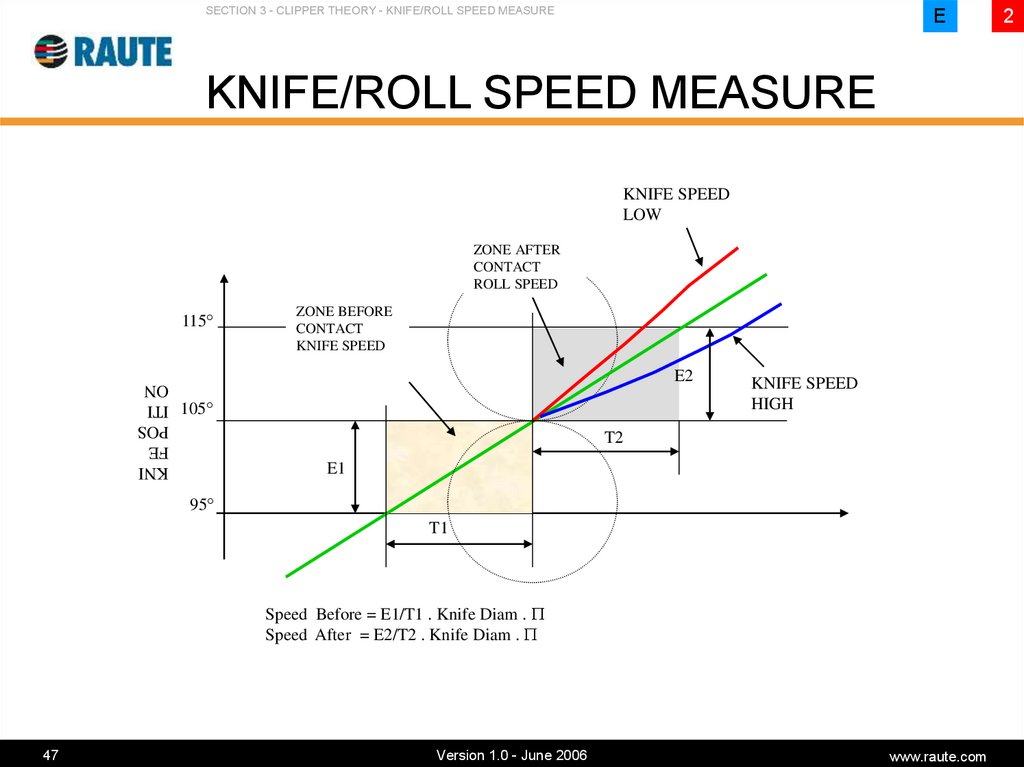

47. KNIFE/ROLL SPEED MEASURE

SECTION 3 - CLIPPER THEORY - KNIFE/ROLL SPEED MEASUREE

KNIFE/ROLL SPEED MEASURE

KNIFE SPEED

LOW

ZONE AFTER

CONTACT

ROLL SPEED

115°

ZONE BEFORE

CONTACT

KNIFE SPEED

E2

105°

KNIFE SPEED

HIGH

T2

E1

KNI

FE

POS

ITI

ON

95°

T1

Speed Before = E1/T1 . Knife Diam .

Speed After = E2/T2 . Knife Diam .

47

Version 1.0 - June 2006

www.raute.com

2

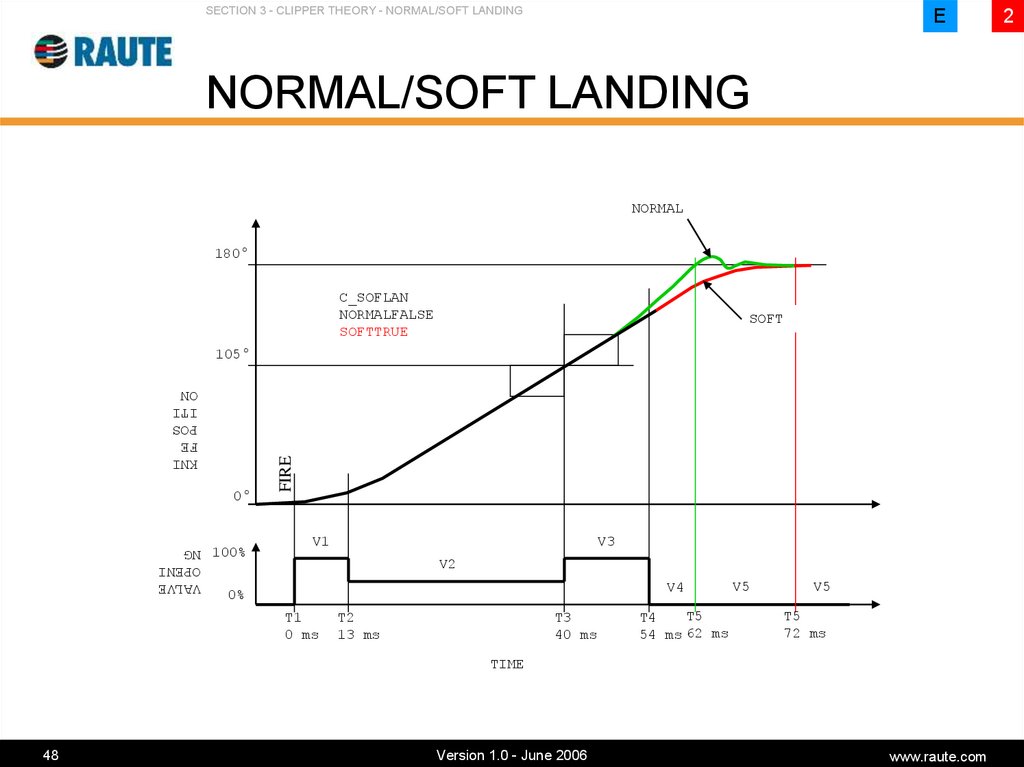

48. NORMAL/SOFT LANDING

SECTION 3 - CLIPPER THEORY - NORMAL/SOFT LANDINGE

NORMAL/SOFT LANDING

NORMAL

180°

C_SOFLAN

NORMALFALSE

SOFTTRUE

SOFT

KNI

FE

POS

ITI

ON

0°

100%

FIRE

105°

V1

V3

V2

V4

0%

VALVE

OPENI

NG

T1

0 ms

T2

13 ms

T3

40 ms

T5

T4

54 ms 62 ms

V5

V5

T5

72 ms

TIME

48

Version 1.0 - June 2006

www.raute.com

2

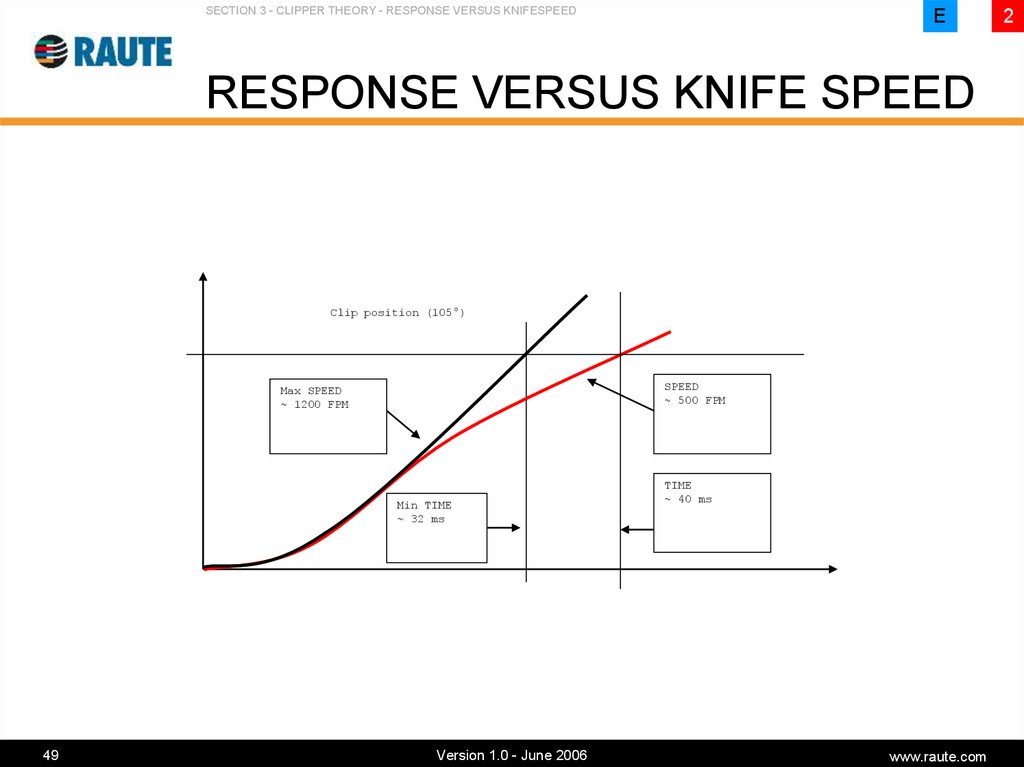

49. RESPONSE VERSUS KNIFE SPEED

SECTION 3 - CLIPPER THEORY - RESPONSE VERSUS KNIFESPEEDE

RESPONSE VERSUS KNIFE SPEED

Clip position (105°)

SPEED

~ 500 FPM

Max SPEED

~ 1200 FPM

Min TIME

~ 32 ms

49

Version 1.0 - June 2006

TIME

~ 40 ms

www.raute.com

2

50. SECTION 4 OPERATION

SECTION 4 - OPERATIONN O M E

1

SECTION 4

OPERATION

CLIPPER

CONSOLE

CONTROLLER

50

Operator’s PB and SW console

Raute controller cabinet

Version 1.0 - June 2006

www.raute.com

2

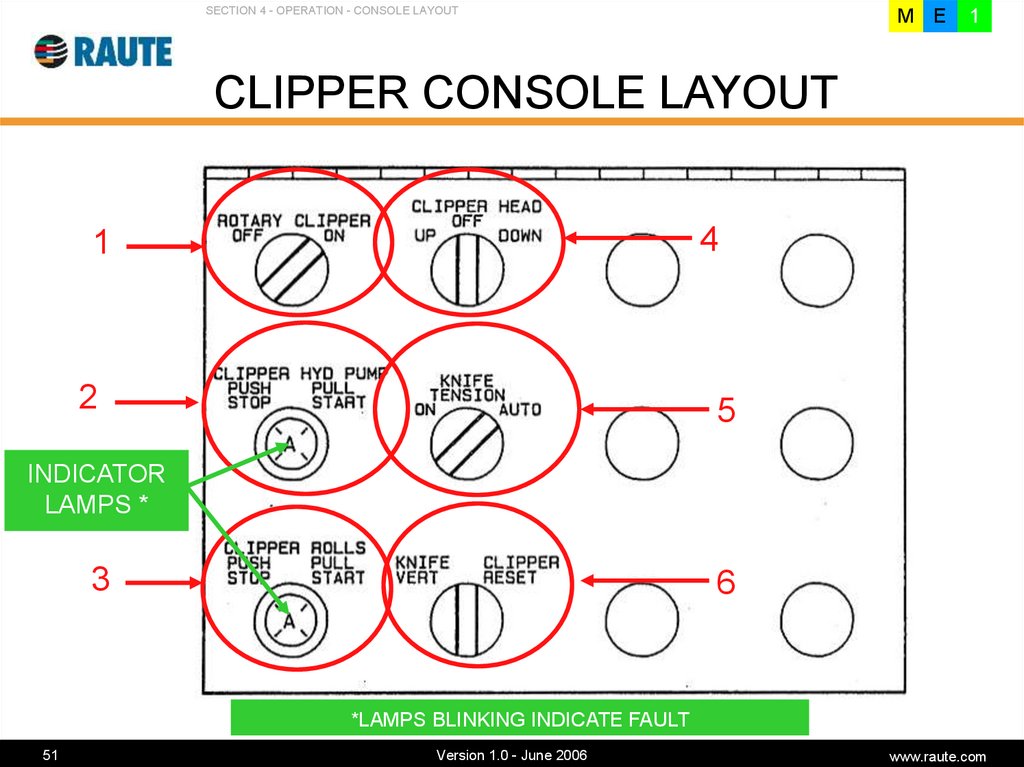

51. CLIPPER CONSOLE LAYOUT

SECTION 4 - OPERATION - CONSOLE LAYOUTM E

1

CLIPPER CONSOLE LAYOUT

4

1

2

5

INDICATOR

LAMPS *

3

6

*LAMPS BLINKING INDICATE FAULT

51

Version 1.0 - June 2006

www.raute.com

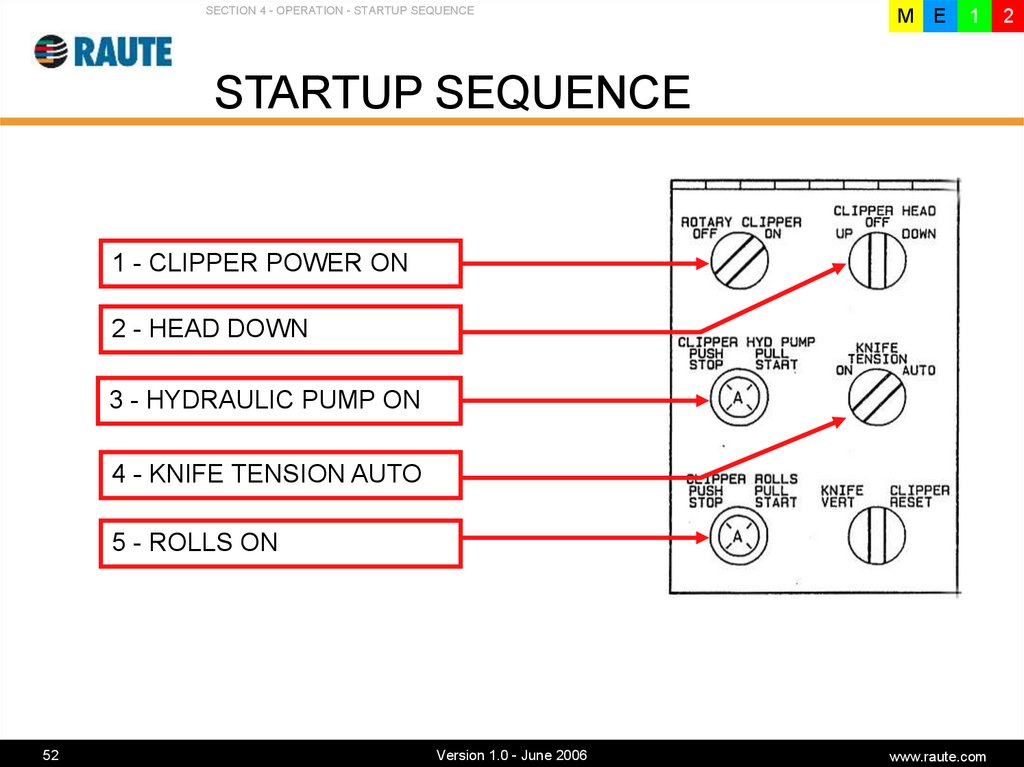

52. STARTUP SEQUENCE

SECTION 4 - OPERATION - STARTUP SEQUENCEM E

1

STARTUP SEQUENCE

1 - CLIPPER POWER ON

2 - HEAD DOWN

3 - HYDRAULIC PUMP ON

4 - KNIFE TENSION AUTO

5 - ROLLS ON

52

Version 1.0 - June 2006

www.raute.com

2

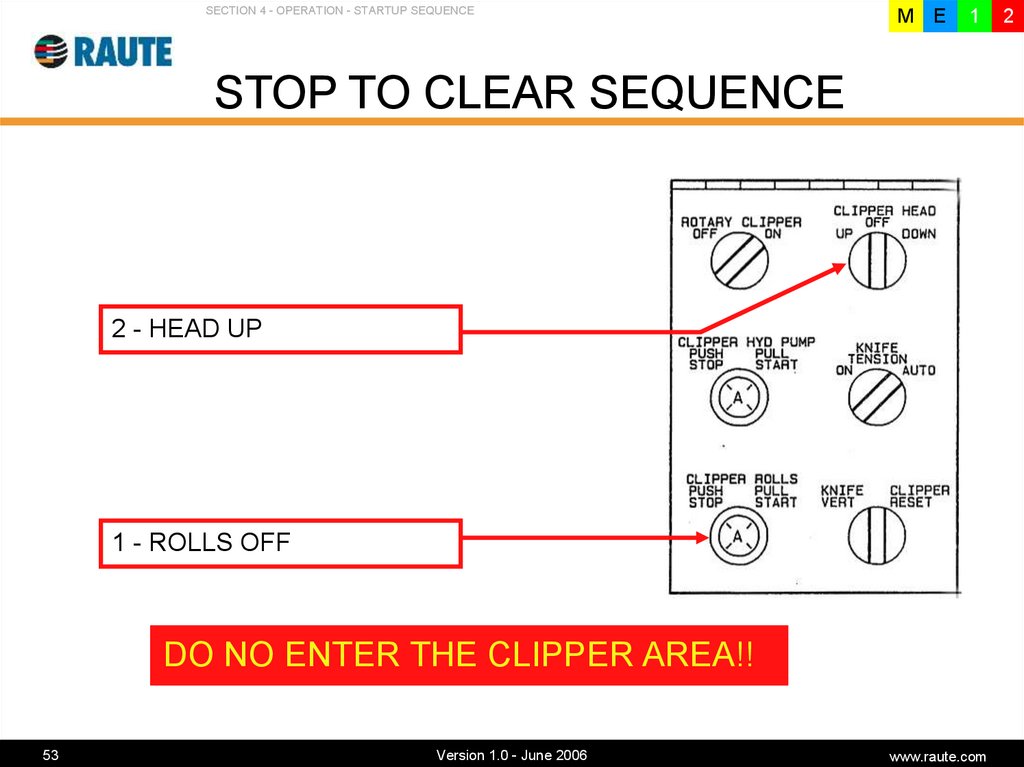

53. STOP TO CLEAR SEQUENCE

SECTION 4 - OPERATION - STARTUP SEQUENCEM E

1

STOP TO CLEAR SEQUENCE

2 - HEAD UP

1 - ROLLS OFF

DO NO ENTER THE CLIPPER AREA!!

53

Version 1.0 - June 2006

www.raute.com

2

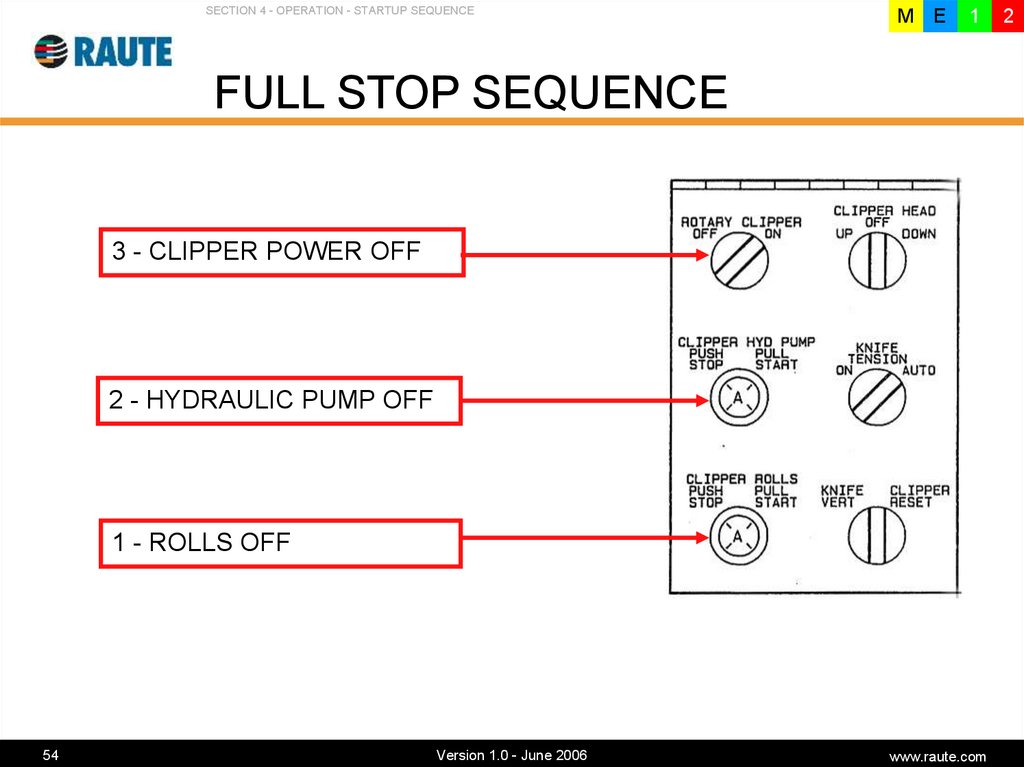

54. FULL STOP SEQUENCE

SECTION 4 - OPERATION - STARTUP SEQUENCEM E

1

FULL STOP SEQUENCE

3 - CLIPPER POWER OFF

2 - HYDRAULIC PUMP OFF

1 - ROLLS OFF

54

Version 1.0 - June 2006

www.raute.com

2

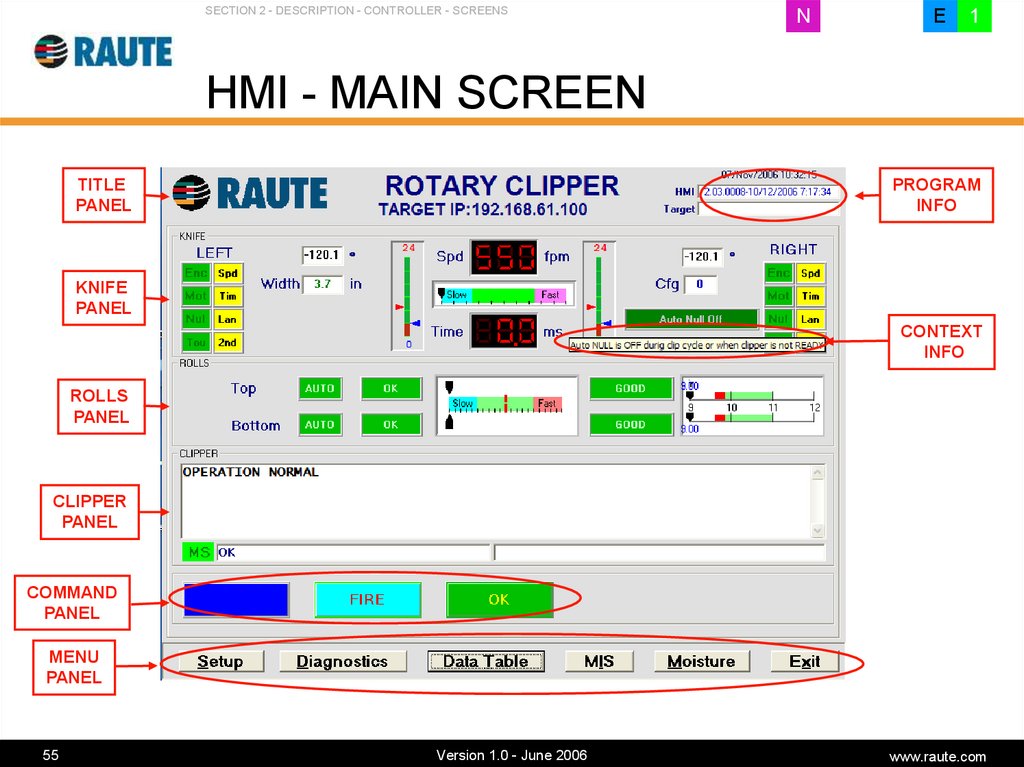

55. HMI - MAIN SCREEN

SECTION 2 - DESCRIPTION - CONTROLLER - SCREENSN

E

1

HMI - MAIN SCREEN

TITLE

PANEL

PROGRAM

INFO

KNIFE

PANEL

CONTEXT

INFO

ROLLS

PANEL

CLIPPER

PANEL

COMMAND

PANEL

MENU

PANEL

55

Version 1.0 - June 2006

www.raute.com

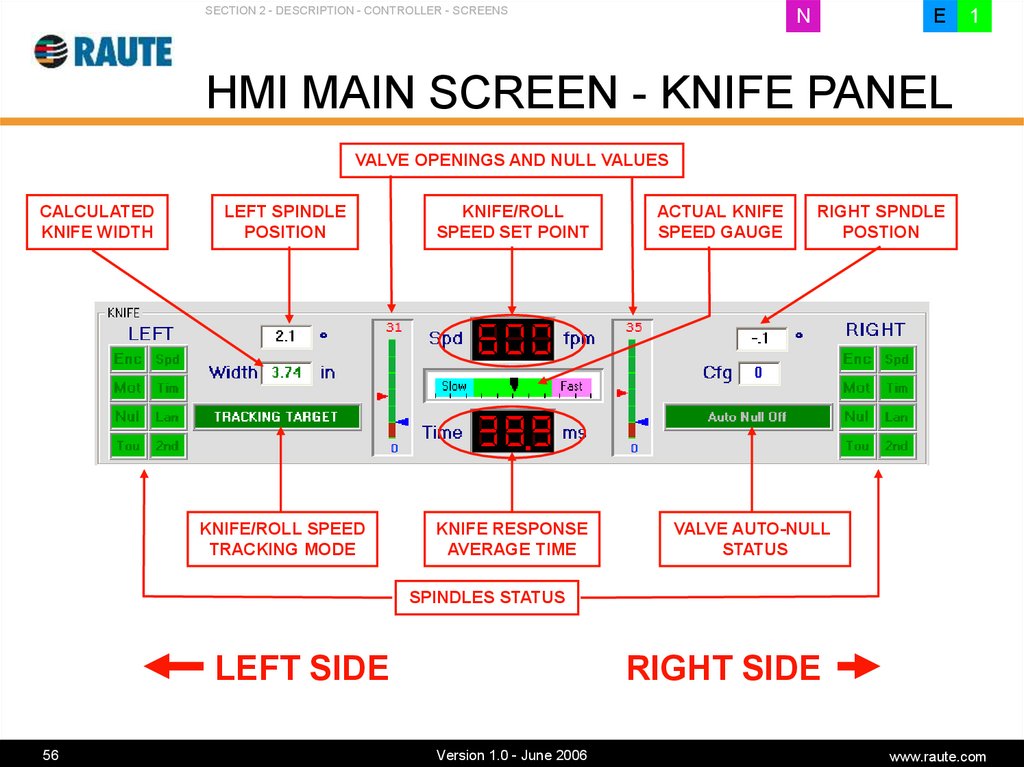

56. HMI MAIN SCREEN - KNIFE PANEL

SECTION 2 - DESCRIPTION - CONTROLLER - SCREENSN

E

1

HMI MAIN SCREEN - KNIFE PANEL

VALVE OPENINGS AND NULL VALUES

CALCULATED

KNIFE WIDTH

LEFT SPINDLE

POSITION

KNIFE/ROLL

SPEED SET POINT

KNIFE/ROLL SPEED

TRACKING MODE

KNIFE RESPONSE

AVERAGE TIME

ACTUAL KNIFE

SPEED GAUGE

RIGHT SPNDLE

POSTION

VALVE AUTO-NULL

STATUS

SPINDLES STATUS

LEFT SIDE

56

RIGHT SIDE

Version 1.0 - June 2006

www.raute.com

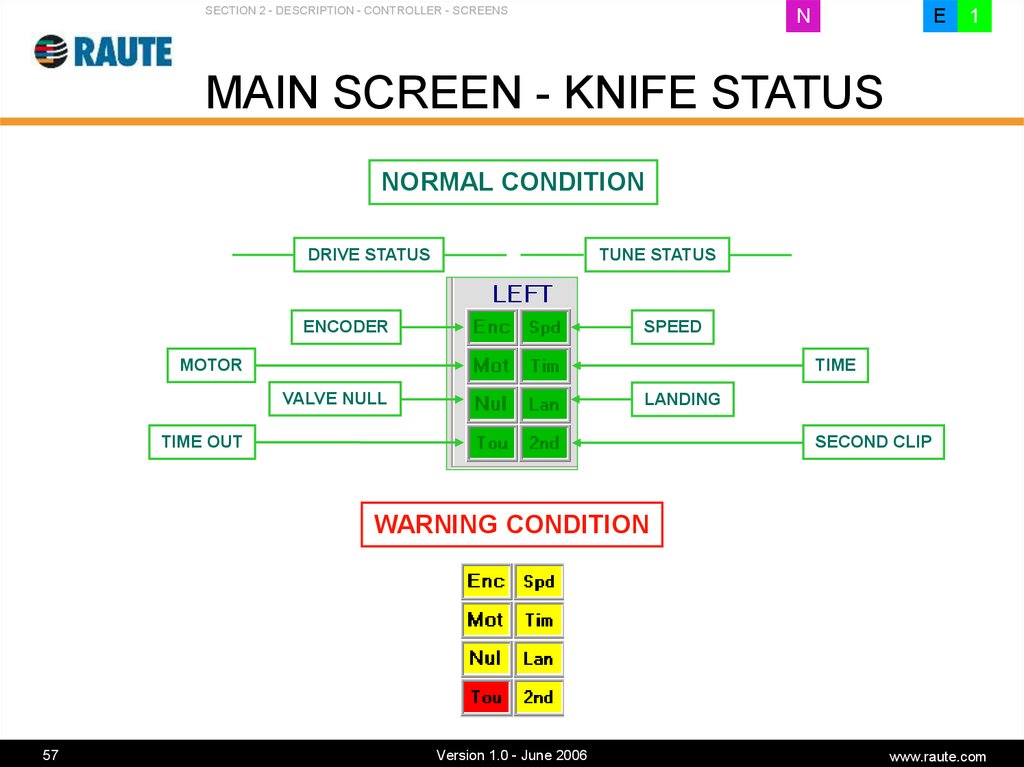

57. MAIN SCREEN - KNIFE STATUS

SECTION 2 - DESCRIPTION - CONTROLLER - SCREENSN

E

1

MAIN SCREEN - KNIFE STATUS

NORMAL CONDITION

DRIVE STATUS

TUNE STATUS

ENCODER

SPEED

MOTOR

TIME

VALVE NULL

LANDING

TIME OUT

SECOND CLIP

WARNING CONDITION

57

Version 1.0 - June 2006

www.raute.com

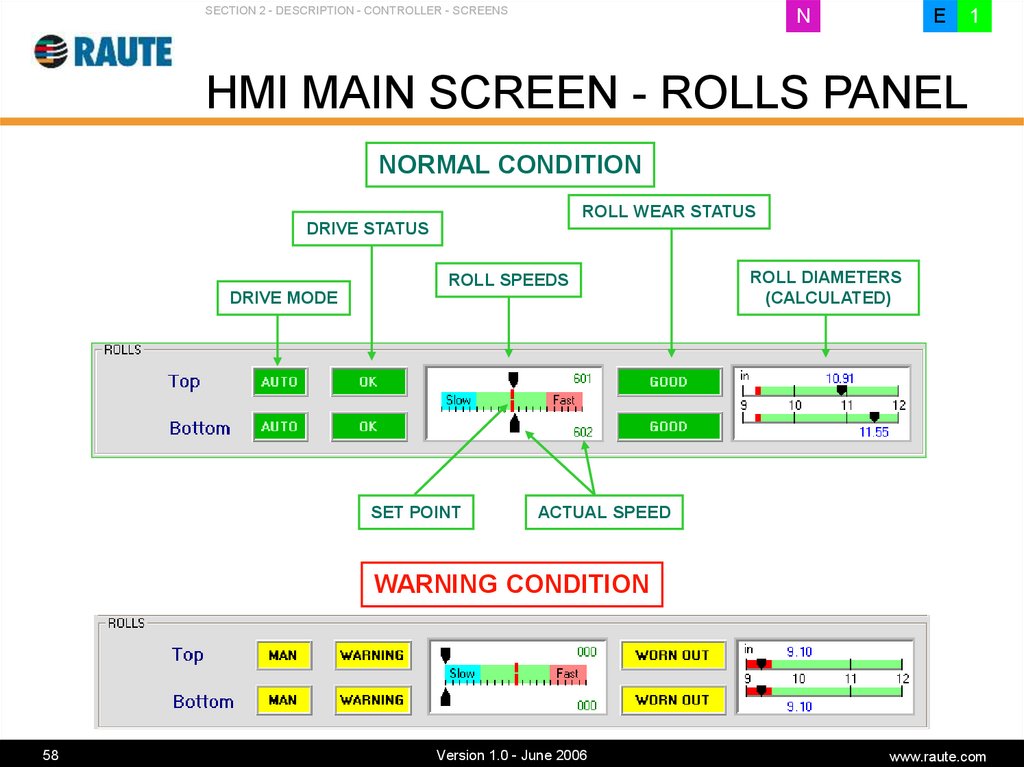

58. HMI MAIN SCREEN - ROLLS PANEL

SECTION 2 - DESCRIPTION - CONTROLLER - SCREENSN

E

1

HMI MAIN SCREEN - ROLLS PANEL

NORMAL CONDITION

ROLL WEAR STATUS

DRIVE STATUS

ROLL SPEEDS

DRIVE MODE

SET POINT

ROLL DIAMETERS

(CALCULATED)

ACTUAL SPEED

WARNING CONDITION

58

Version 1.0 - June 2006

www.raute.com

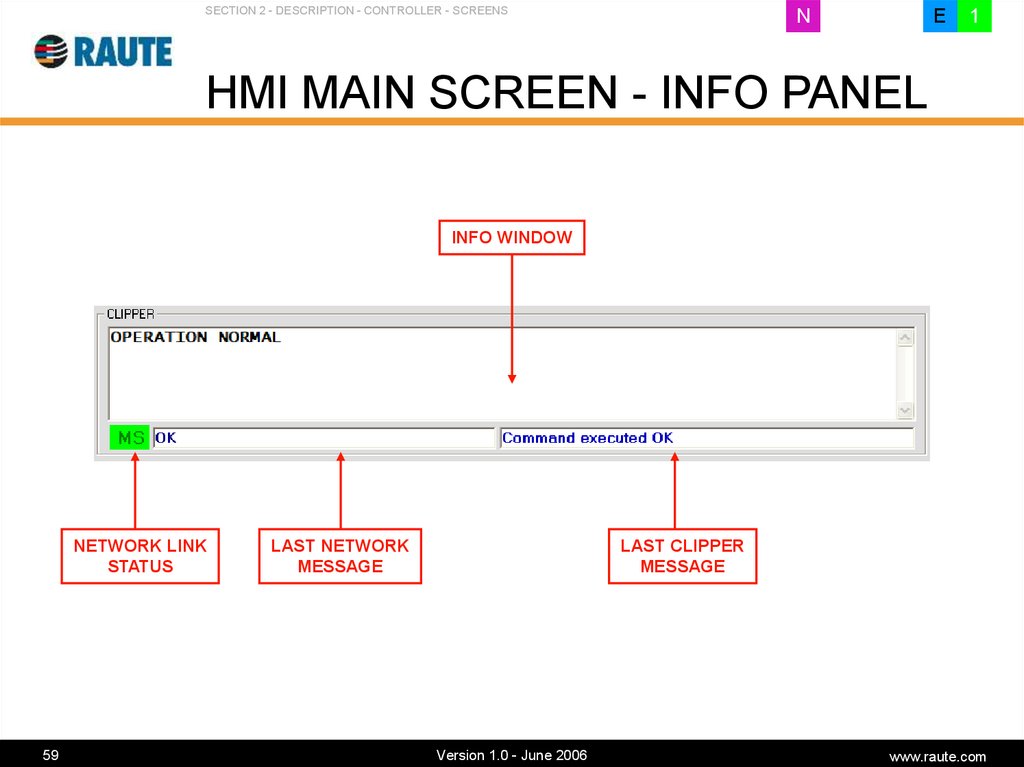

59. HMI MAIN SCREEN - INFO PANEL

SECTION 2 - DESCRIPTION - CONTROLLER - SCREENSN

E

1

HMI MAIN SCREEN - INFO PANEL

INFO WINDOW

NETWORK LINK

STATUS

59

LAST NETWORK

MESSAGE

LAST CLIPPER

MESSAGE

Version 1.0 - June 2006

www.raute.com

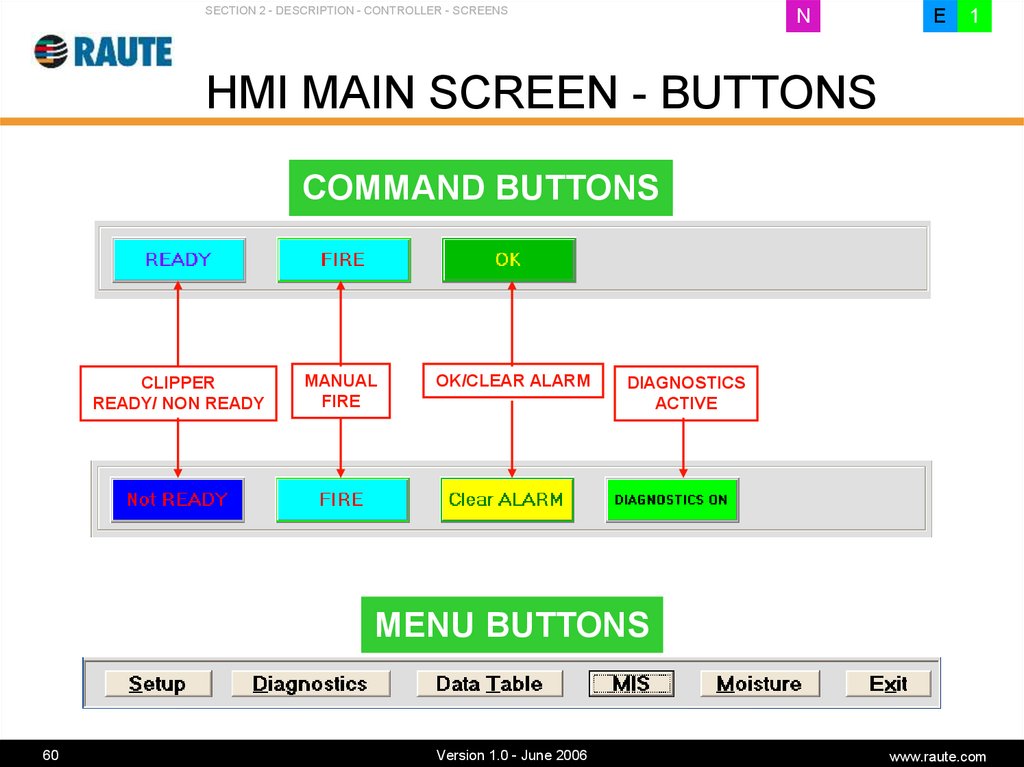

60. HMI MAIN SCREEN - BUTTONS

SECTION 2 - DESCRIPTION - CONTROLLER - SCREENSN

E

1

HMI MAIN SCREEN - BUTTONS

COMMAND BUTTONS

CLIPPER

READY/ NON READY

MANUAL

FIRE

OK/CLEAR ALARM

DIAGNOSTICS

ACTIVE

MENU BUTTONS

60

Version 1.0 - June 2006

www.raute.com

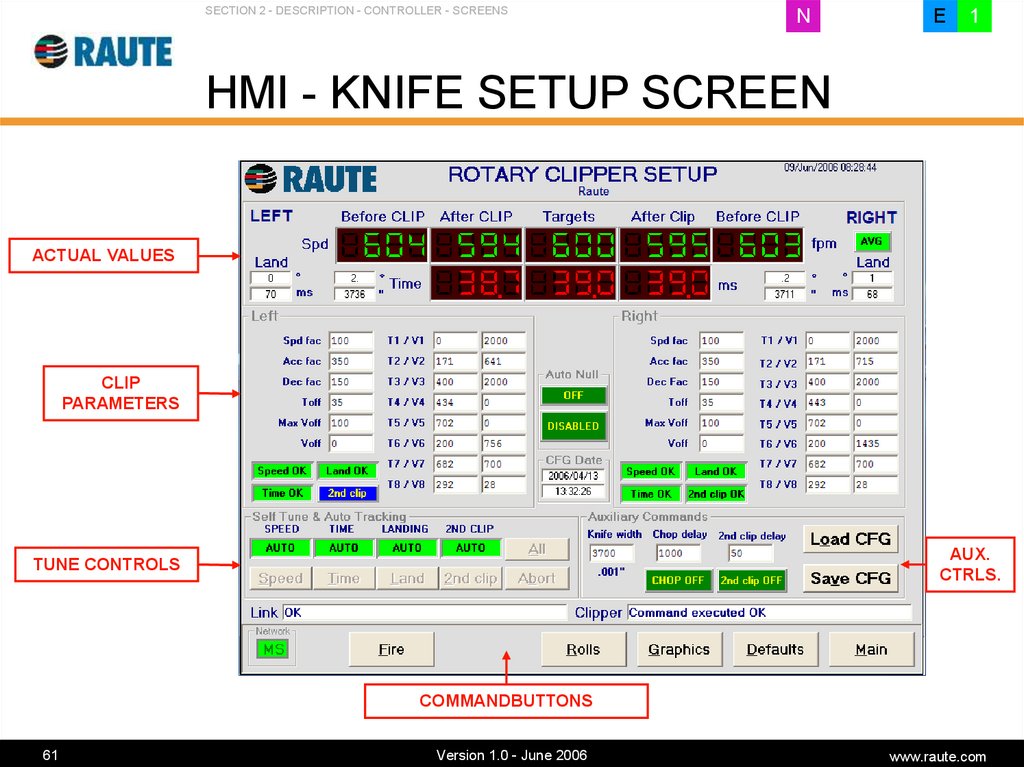

61. HMI - KNIFE SETUP SCREEN

SECTION 2 - DESCRIPTION - CONTROLLER - SCREENSN

E

1

HMI - KNIFE SETUP SCREEN

ACTUAL VALUES

CLIP

PARAMETERS

AUX.

CTRLS.

TUNE CONTROLS

COMMANDBUTTONS

61

Version 1.0 - June 2006

www.raute.com

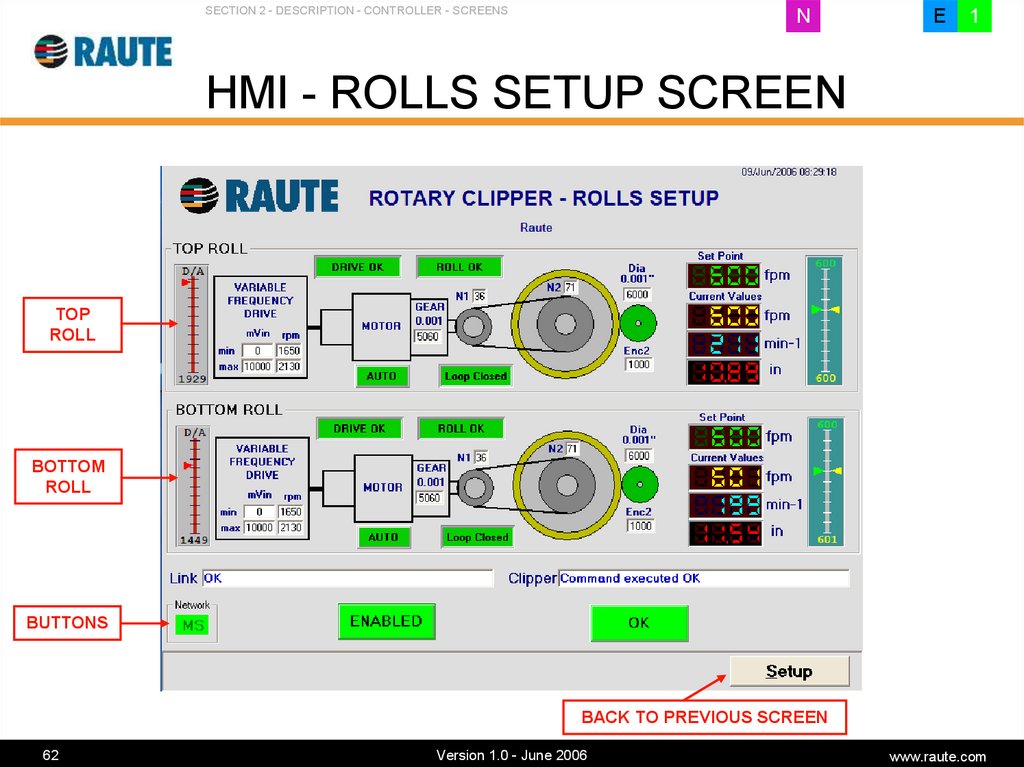

62. HMI - ROLLS SETUP SCREEN

SECTION 2 - DESCRIPTION - CONTROLLER - SCREENSN

E

1

HMI - ROLLS SETUP SCREEN

TOP

ROLL

BOTTOM

ROLL

BUTTONS

BACK TO PREVIOUS SCREEN

62

Version 1.0 - June 2006

www.raute.com

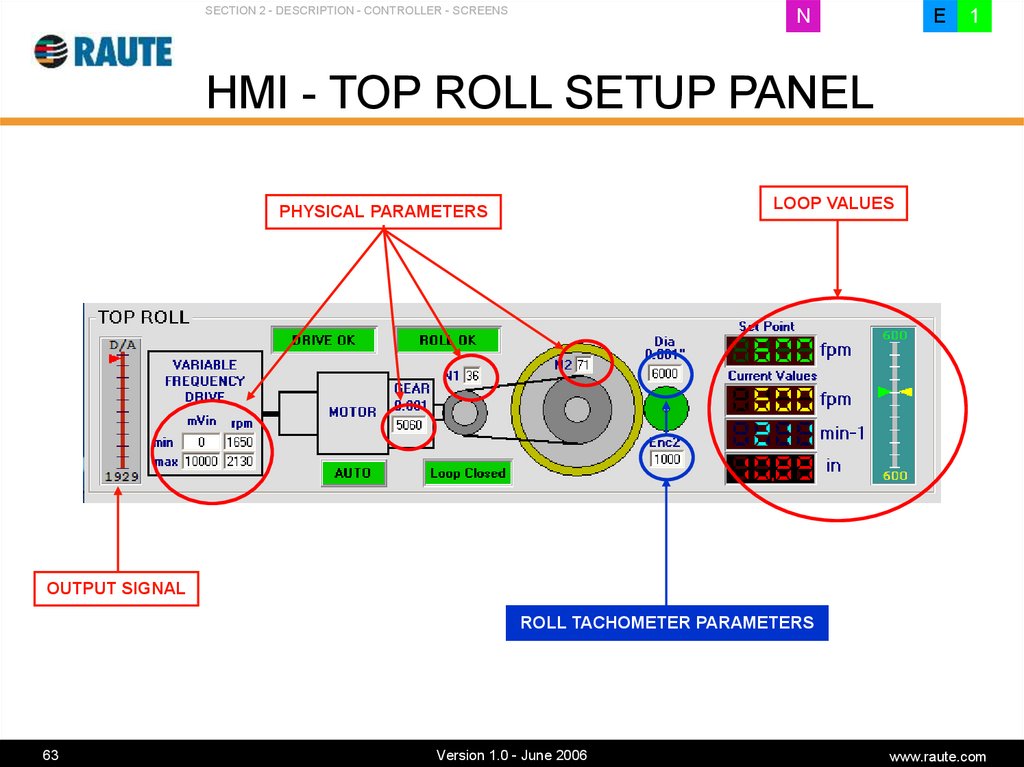

63. HMI - TOP ROLL SETUP PANEL

SECTION 2 - DESCRIPTION - CONTROLLER - SCREENSN

E

1

HMI - TOP ROLL SETUP PANEL

LOOP VALUES

PHYSICAL PARAMETERS

OUTPUT SIGNAL

ROLL TACHOMETER PARAMETERS

63

Version 1.0 - June 2006

www.raute.com

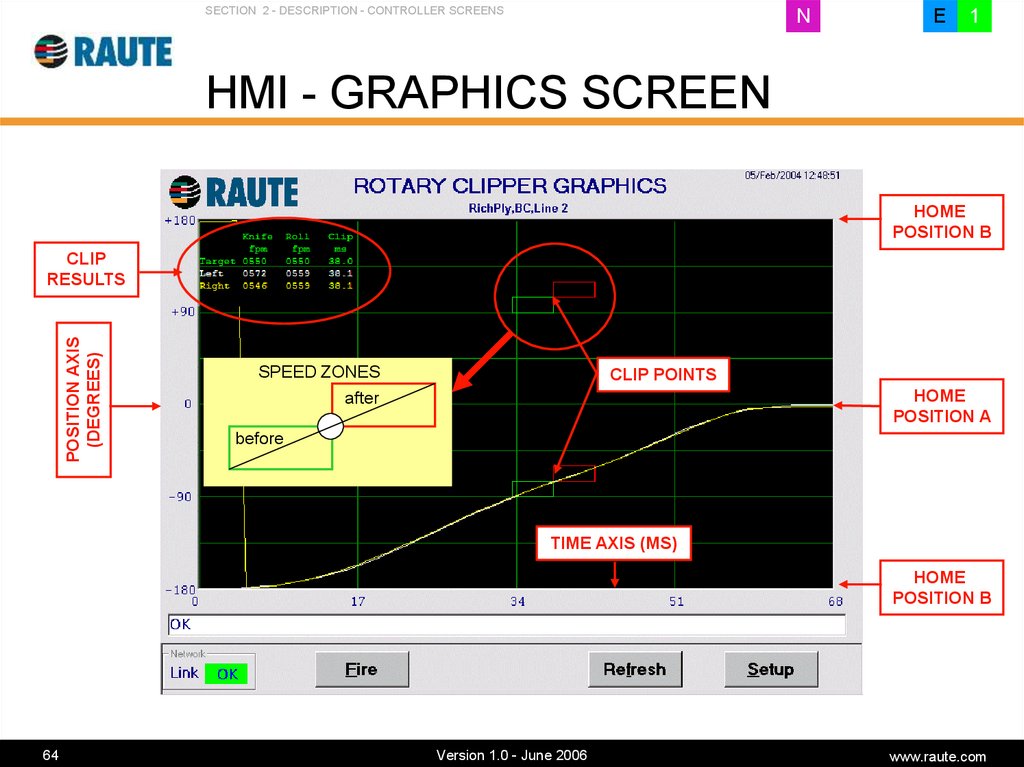

64. HMI - GRAPHICS SCREEN

SECTION 2 - DESCRIPTION - CONTROLLER SCREENSN

E

1

HMI - GRAPHICS SCREEN

HOME

POSITION B

POSITION AXIS

(DEGREES)

CLIP

RESULTS

SPEED ZONES

after

CLIP POINTS

HOME

POSITION A

before

TIME AXIS (MS)

HOME

POSITION B

64

Version 1.0 - June 2006

www.raute.com

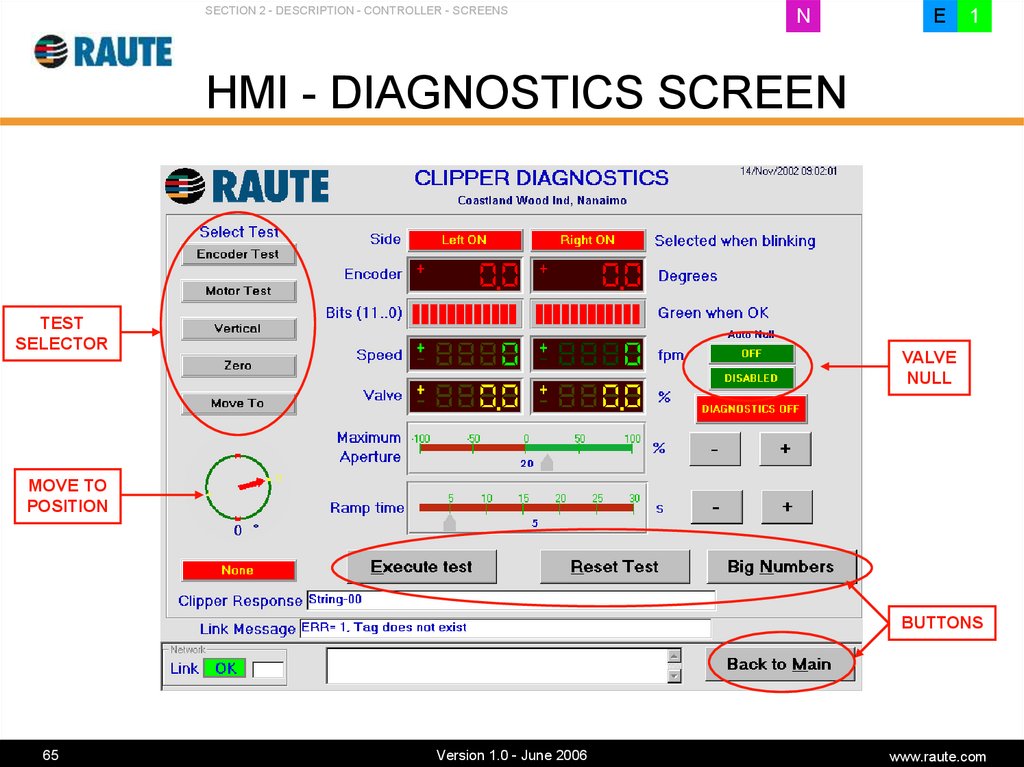

65. HMI - DIAGNOSTICS SCREEN

SECTION 2 - DESCRIPTION - CONTROLLER - SCREENSN

E

1

HMI - DIAGNOSTICS SCREEN

TEST

SELECTOR

VALVE

NULL

MOVE TO

POSITION

BUTTONS

65

Version 1.0 - June 2006

www.raute.com

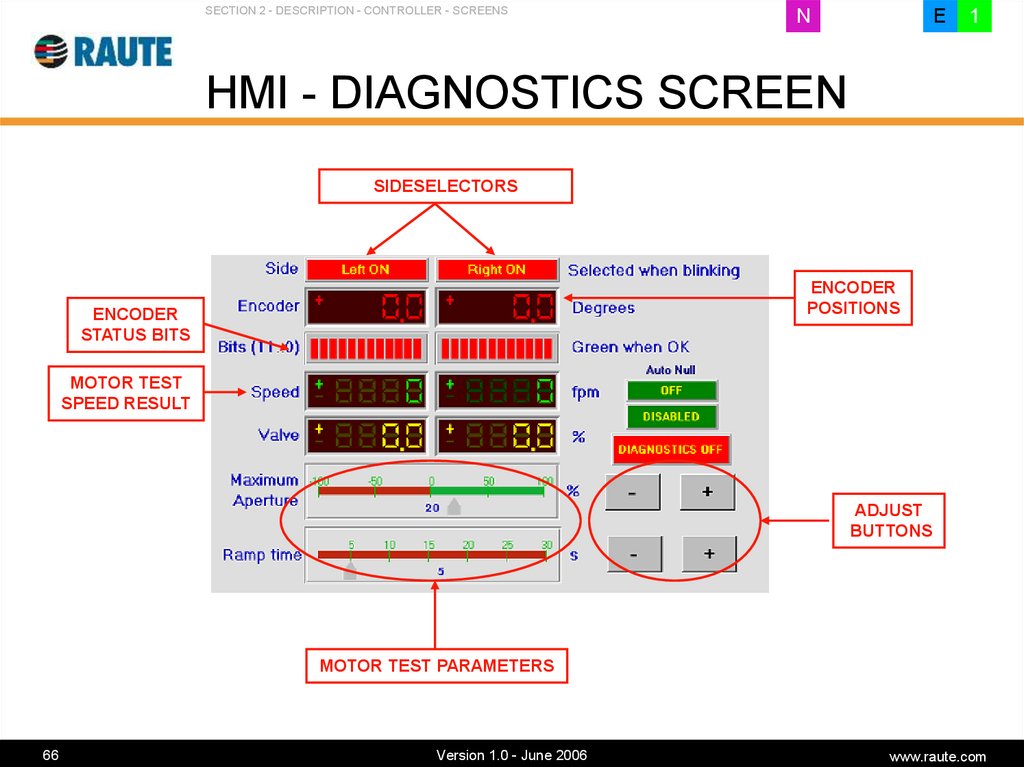

66. HMI - DIAGNOSTICS SCREEN

SECTION 2 - DESCRIPTION - CONTROLLER - SCREENSN

E

1

HMI - DIAGNOSTICS SCREEN

SIDESELECTORS

ENCODER

POSITIONS

ENCODER

STATUS BITS

MOTOR TEST

SPEED RESULT

ADJUST

BUTTONS

MOTOR TEST PARAMETERS

66

Version 1.0 - June 2006

www.raute.com

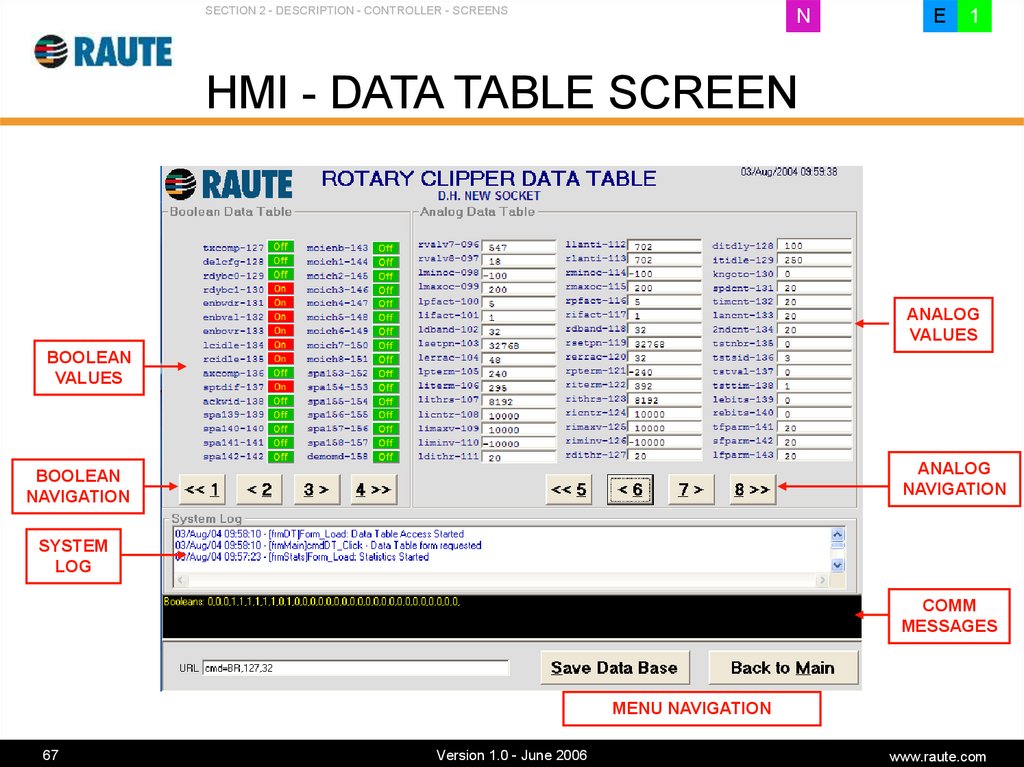

67. HMI - DATA TABLE SCREEN

SECTION 2 - DESCRIPTION - CONTROLLER - SCREENSN

E

1

HMI - DATA TABLE SCREEN

ANALOG

VALUES

BOOLEAN

VALUES

ANALOG

NAVIGATION

BOOLEAN

NAVIGATION

SYSTEM

LOG

COMM

MESSAGES

MENU NAVIGATION

67

Version 1.0 - June 2006

www.raute.com

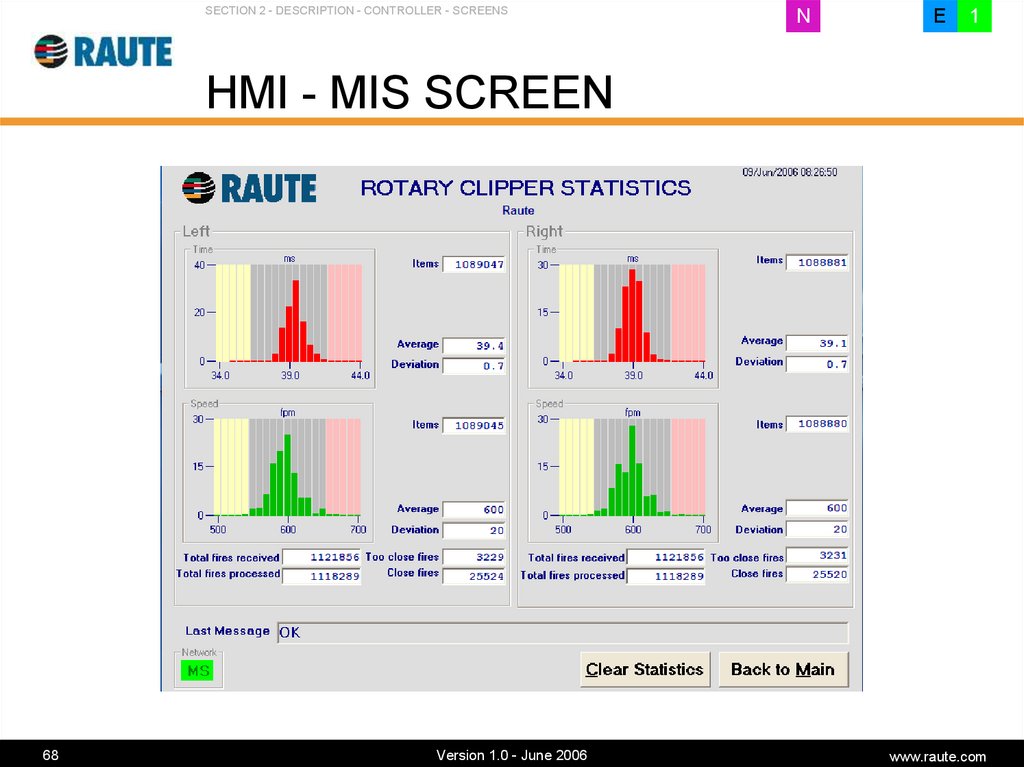

68. HMI - MIS SCREEN

SECTION 2 - DESCRIPTION - CONTROLLER - SCREENSN

E

1

HMI - MIS SCREEN

68

Version 1.0 - June 2006

www.raute.com

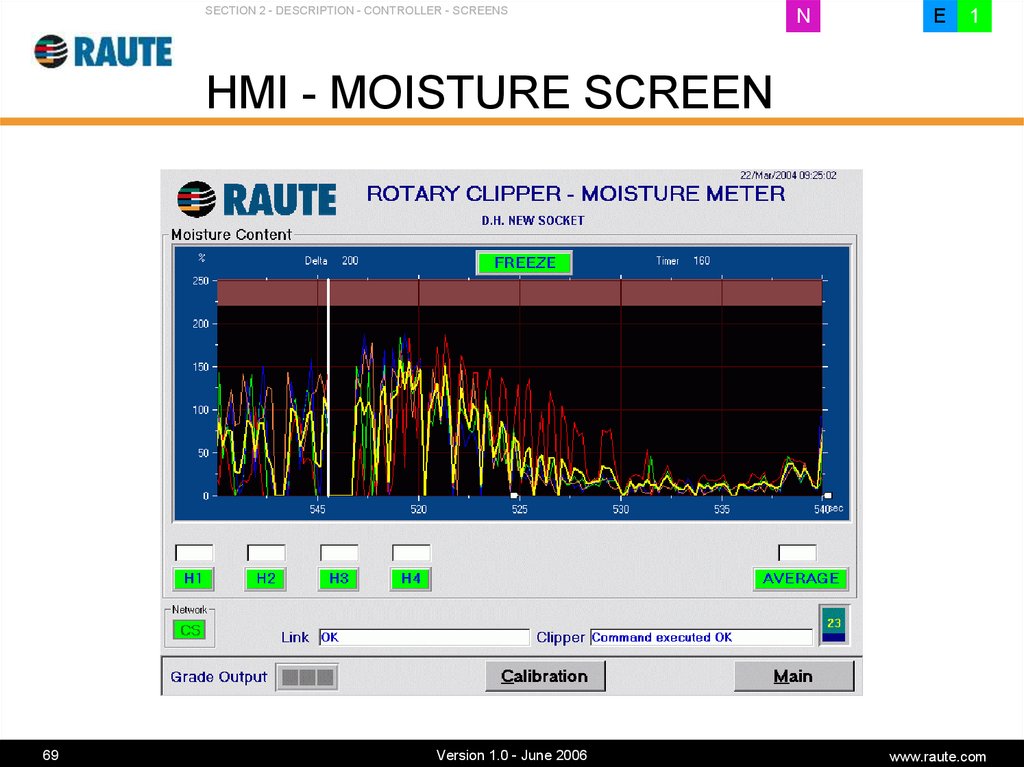

69. HMI - MOISTURE SCREEN

SECTION 2 - DESCRIPTION - CONTROLLER - SCREENSN

E

1

HMI - MOISTURE SCREEN

69

Version 1.0 - June 2006

www.raute.com

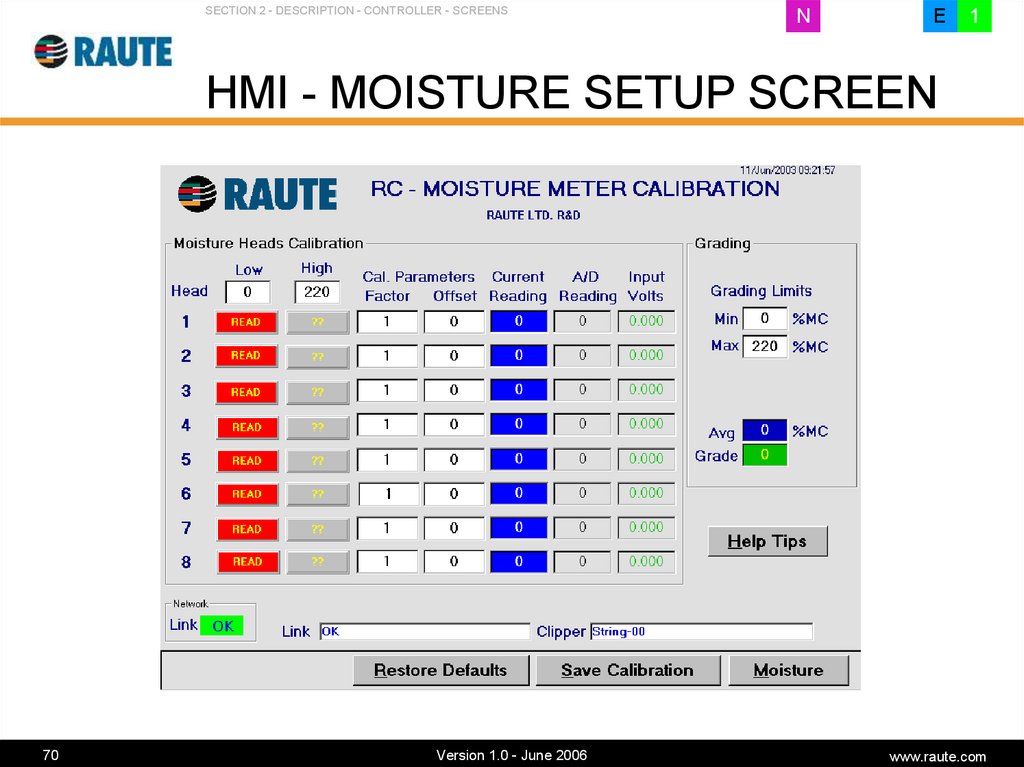

70. HMI - MOISTURE SETUP SCREEN

SECTION 2 - DESCRIPTION - CONTROLLER - SCREENSN

E

1

HMI - MOISTURE SETUP SCREEN

70

Version 1.0 - June 2006

www.raute.com

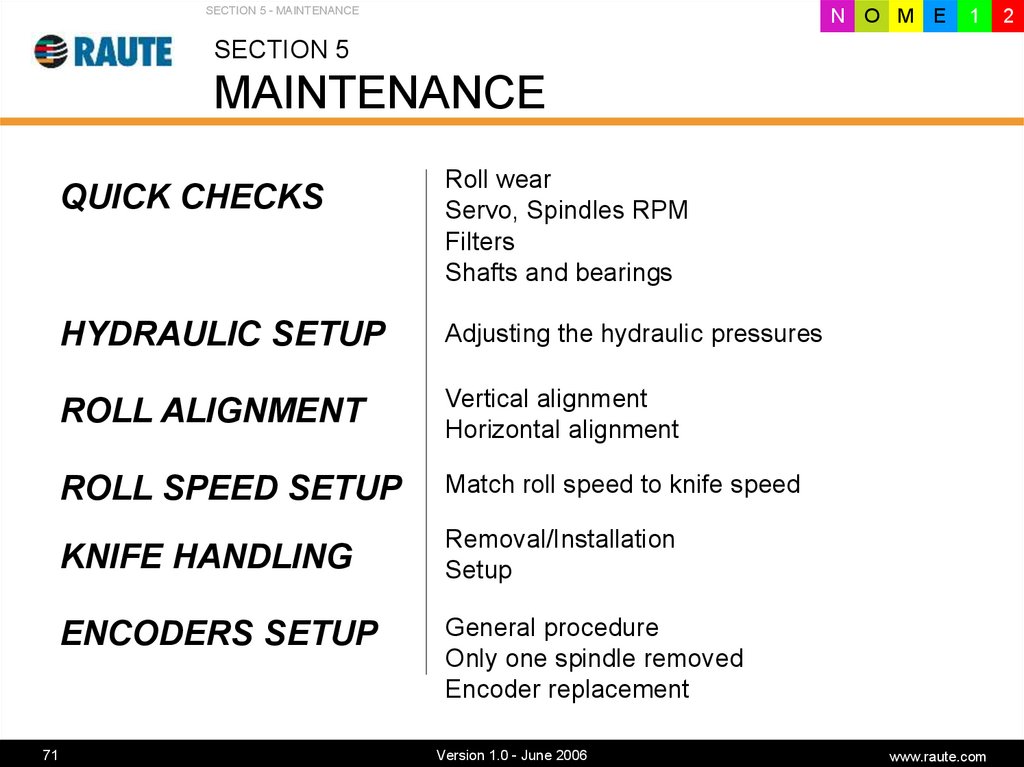

71. SECTION 5 MAINTENANCE

SECTION 5 - MAINTENANCEN O M E

1

SECTION 5

MAINTENANCE

QUICK CHECKS

HYDRAULIC SETUP

Adjusting the hydraulic pressures

ROLL ALIGNMENT

Vertical alignment

Horizontal alignment

ROLL SPEED SETUP

Match roll speed to knife speed

KNIFE HANDLING

Removal/Installation

Setup

ENCODERS SETUP

71

Roll wear

Servo, Spindles RPM

Filters

Shafts and bearings

General procedure

Only one spindle removed

Encoder replacement

Version 1.0 - June 2006

www.raute.com

2

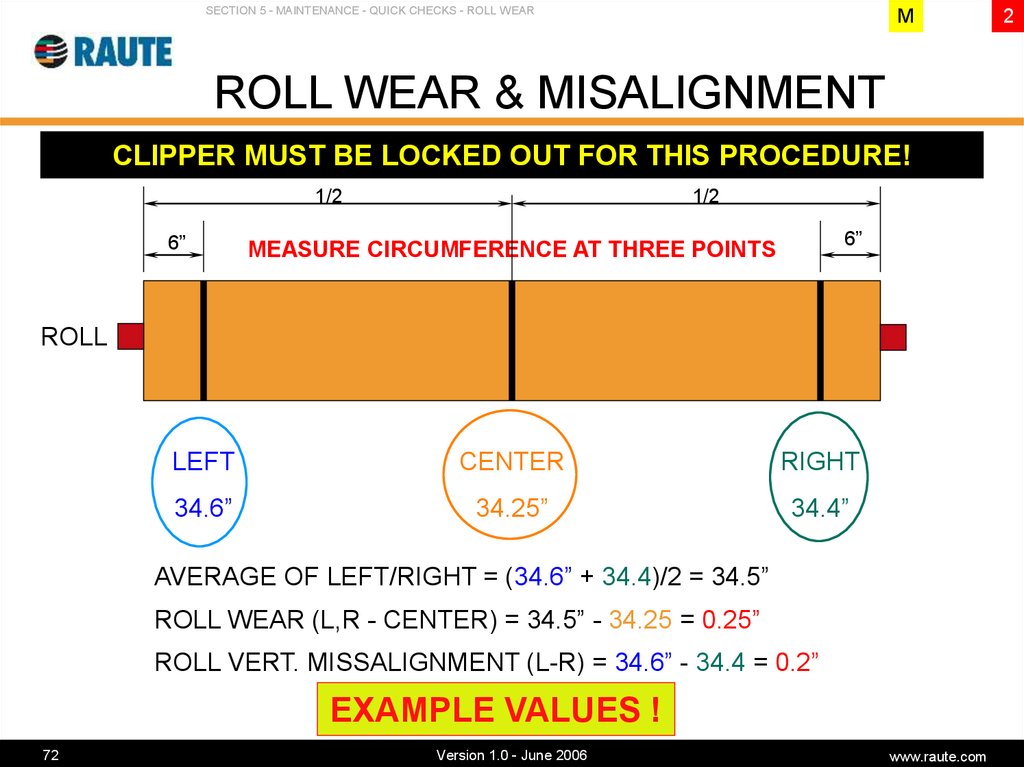

72. ROLL WEAR & MISALIGNMENT

SECTION 5 - MAINTENANCE - QUICK CHECKS - ROLL WEARM

ROLL WEAR & MISALIGNMENT

CLIPPER MUST BE LOCKED OUT FOR THIS PROCEDURE!

1/2

6”

1/2

6”

MEASURE CIRCUMFERENCE AT THREE POINTS

ROLL

LEFT

CENTER

RIGHT

34.6”

34.25”

34.4”

AVERAGE OF LEFT/RIGHT = (34.6” + 34.4)/2 = 34.5”

ROLL WEAR (L,R - CENTER) = 34.5” - 34.25 = 0.25”

ROLL VERT. MISSALIGNMENT (L-R) = 34.6” - 34.4 = 0.2”

EXAMPLE VALUES !

72

Version 1.0 - June 2006

www.raute.com

2

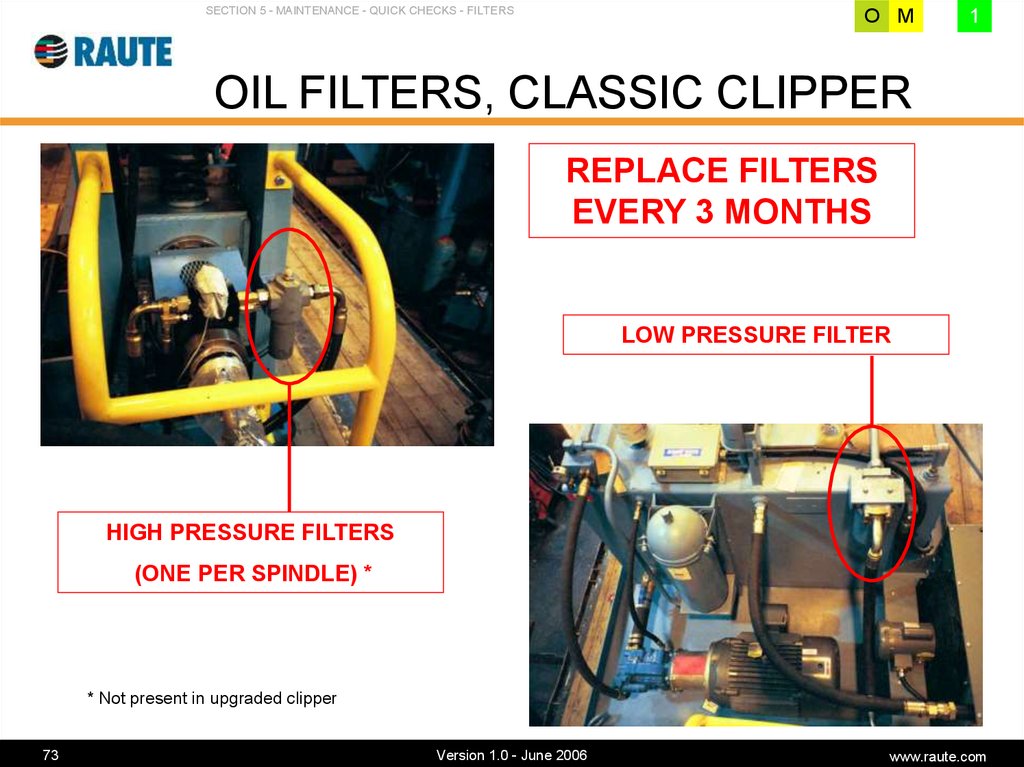

73. OIL FILTERS, CLASSIC CLIPPER

SECTION 5 - MAINTENANCE - QUICK CHECKS - FILTERSO M

1

OIL FILTERS, CLASSIC CLIPPER

REPLACE FILTERS

EVERY 3 MONTHS

LOW PRESSURE FILTER

HIGH PRESSURE FILTERS

(ONE PER SPINDLE) *

* Not present in upgraded clipper

73

Version 1.0 - June 2006

www.raute.com

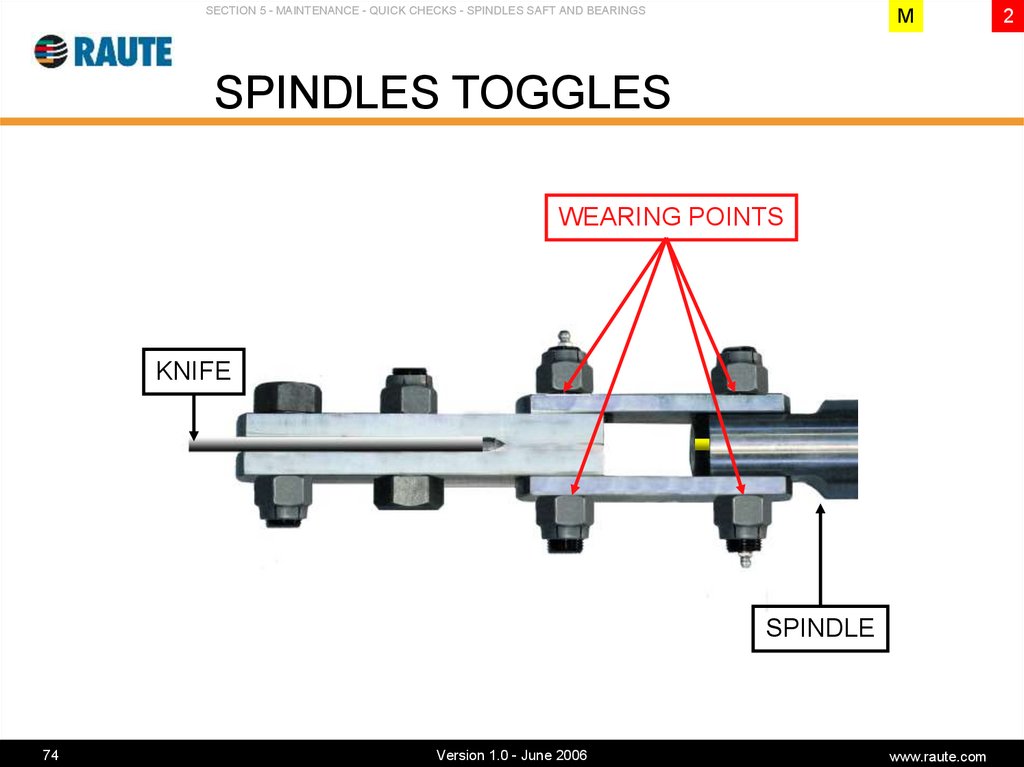

74. SPINDLES TOGGLES

SECTION 5 - MAINTENANCE - QUICK CHECKS - SPINDLES SAFT AND BEARINGSM

SPINDLES TOGGLES

WEARING POINTS

KNIFE

SPINDLE

74

Version 1.0 - June 2006

www.raute.com

2

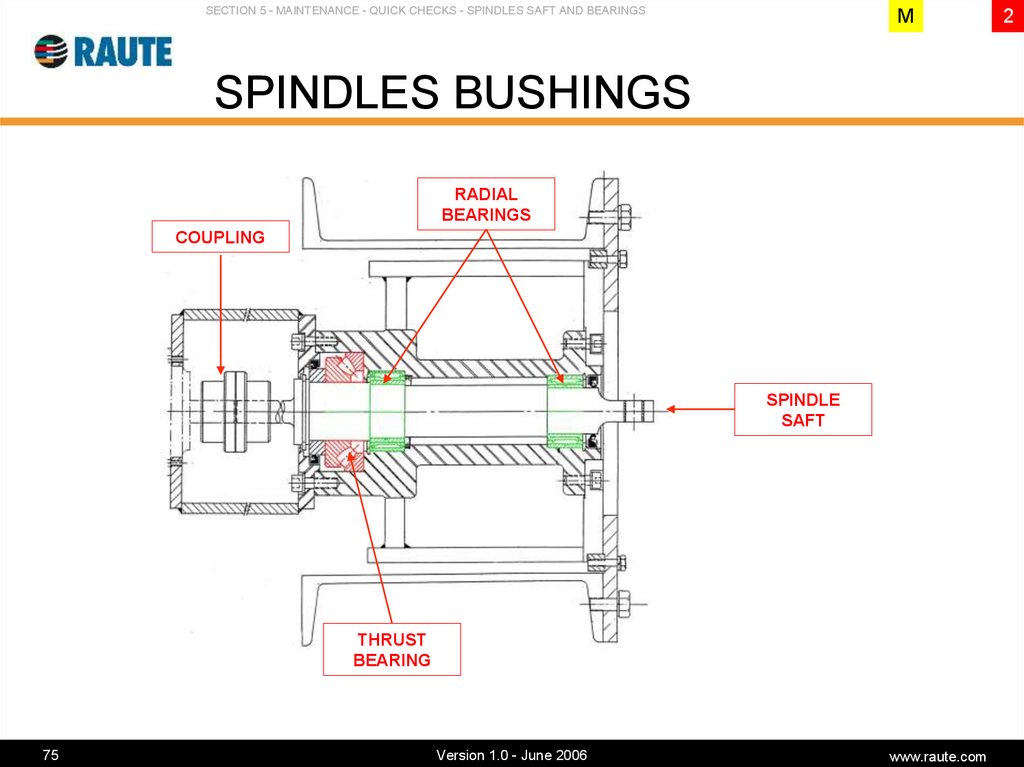

75. SPINDLES BUSHINGS

SECTION 5 - MAINTENANCE - QUICK CHECKS - SPINDLES SAFT AND BEARINGSM

SPINDLES BUSHINGS

RADIAL

BEARINGS

COUPLING

SPINDLE

SAFT

THRUST

BEARING

75

Version 1.0 - June 2006

www.raute.com

2

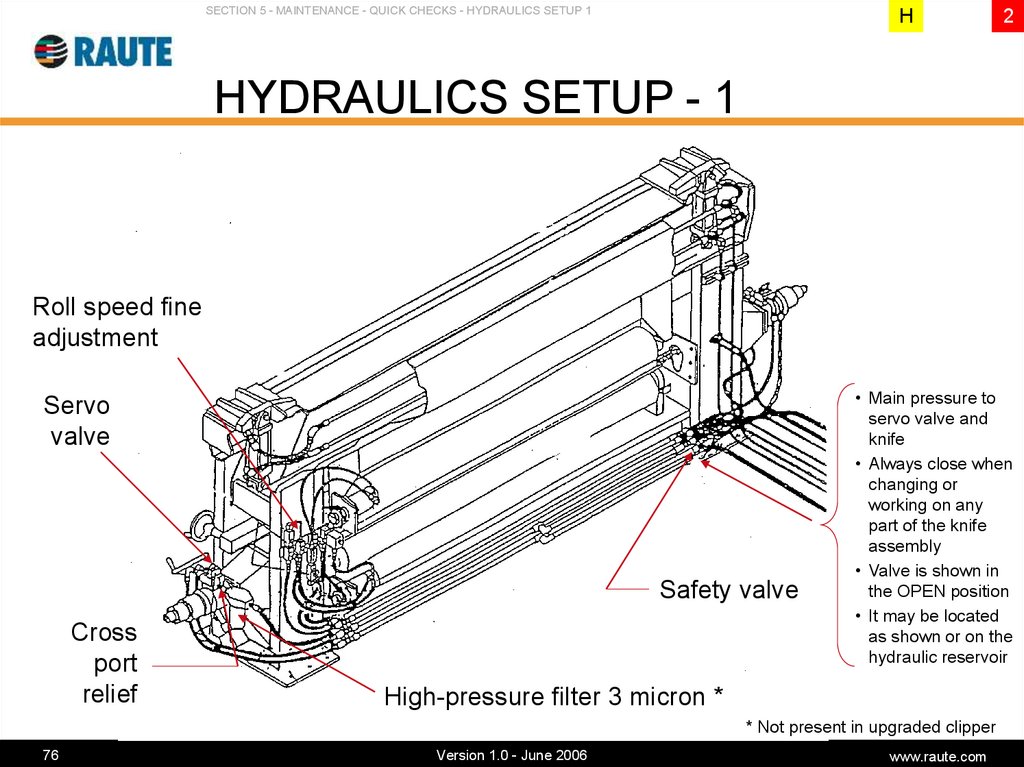

76. HYDRAULICS SETUP - 1

SECTION 5 - MAINTENANCE - QUICK CHECKS - HYDRAULICS SETUP 1H

2

HYDRAULICS SETUP - 1

Roll speed fine

adjustment

Servo

valve

Safety valve

Cross

port

relief

• Main pressure to

servo valve and

knife

• Always close when

changing or

working on any

part of the knife

assembly

• Valve is shown in

the OPEN position

• It may be located

as shown or on the

hydraulic reservoir

High-pressure filter 3 micron *

* Not present in upgraded clipper

76

Version 1.0 - June 2006

www.raute.com

77. HYDRAULICS SETUP - 2

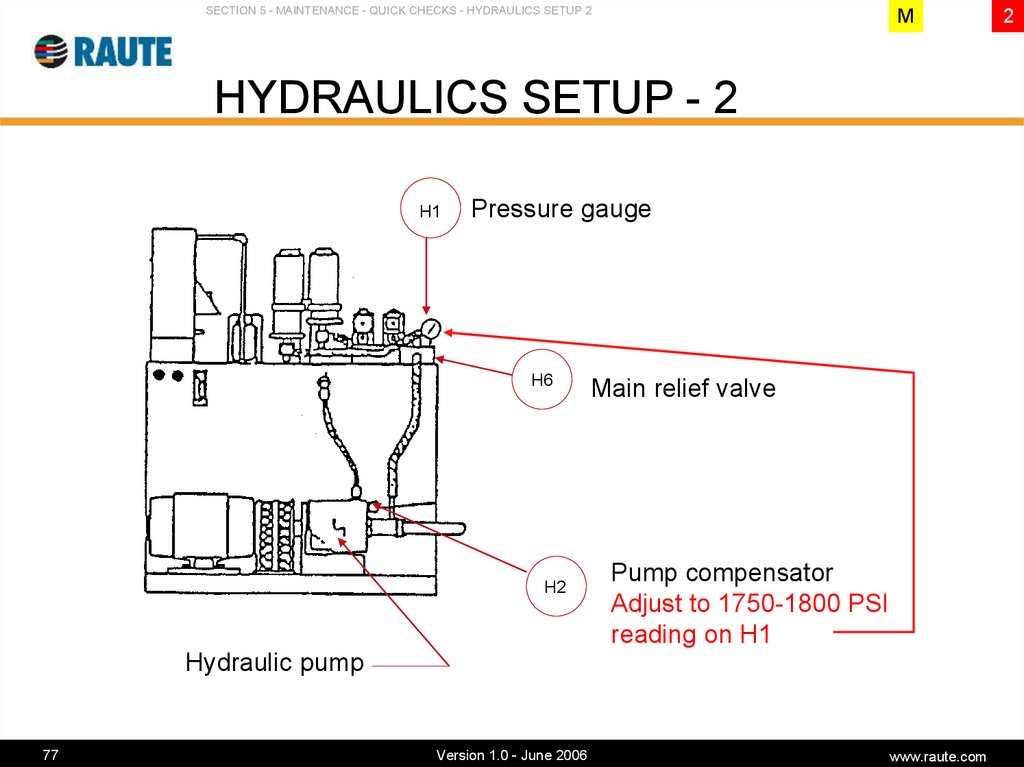

SECTION 5 - MAINTENANCE - QUICK CHECKS - HYDRAULICS SETUP 2M

HYDRAULICS SETUP - 2

H1

Pressure gauge

H6

H2

Main relief valve

Pump compensator

Adjust to 1750-1800 PSI

reading on H1

Hydraulic pump

77

Version 1.0 - June 2006

www.raute.com

2

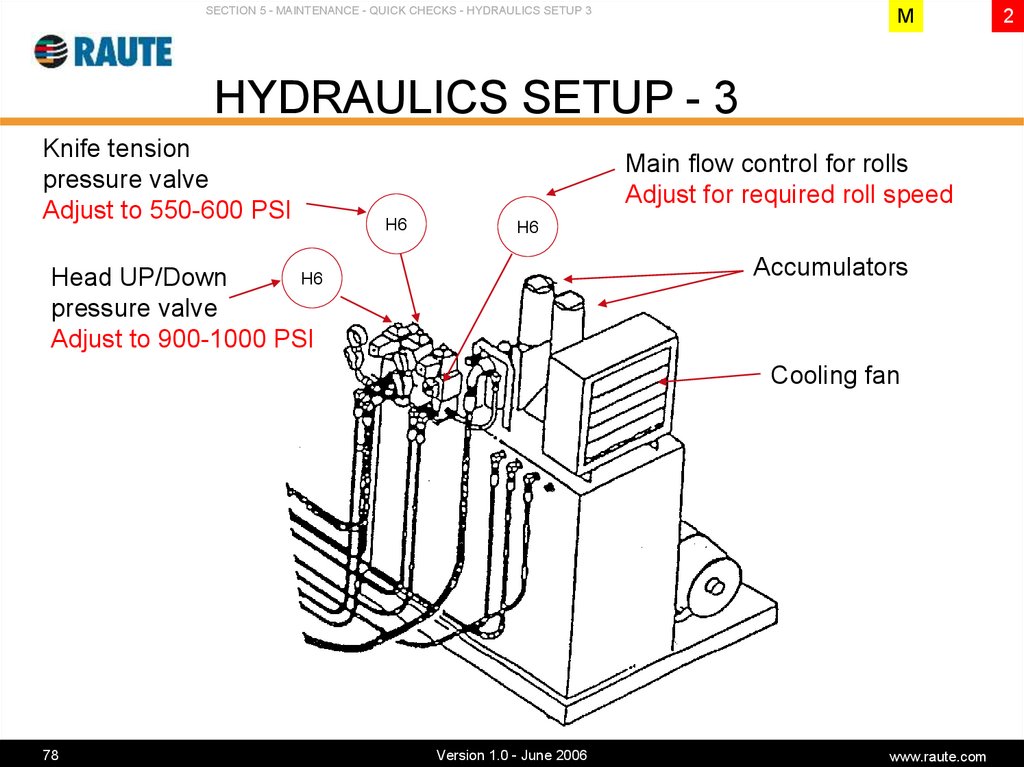

78. HYDRAULICS SETUP - 3

SECTION 5 - MAINTENANCE - QUICK CHECKS - HYDRAULICS SETUP 3M

HYDRAULICS SETUP - 3

Knife tension

pressure valve

Adjust to 550-600 PSI

Main flow control for rolls

Adjust for required roll speed

H6

H6

Accumulators

H6

Head UP/Down

pressure valve

Adjust to 900-1000 PSI

Cooling fan

78

Version 1.0 - June 2006

www.raute.com

2

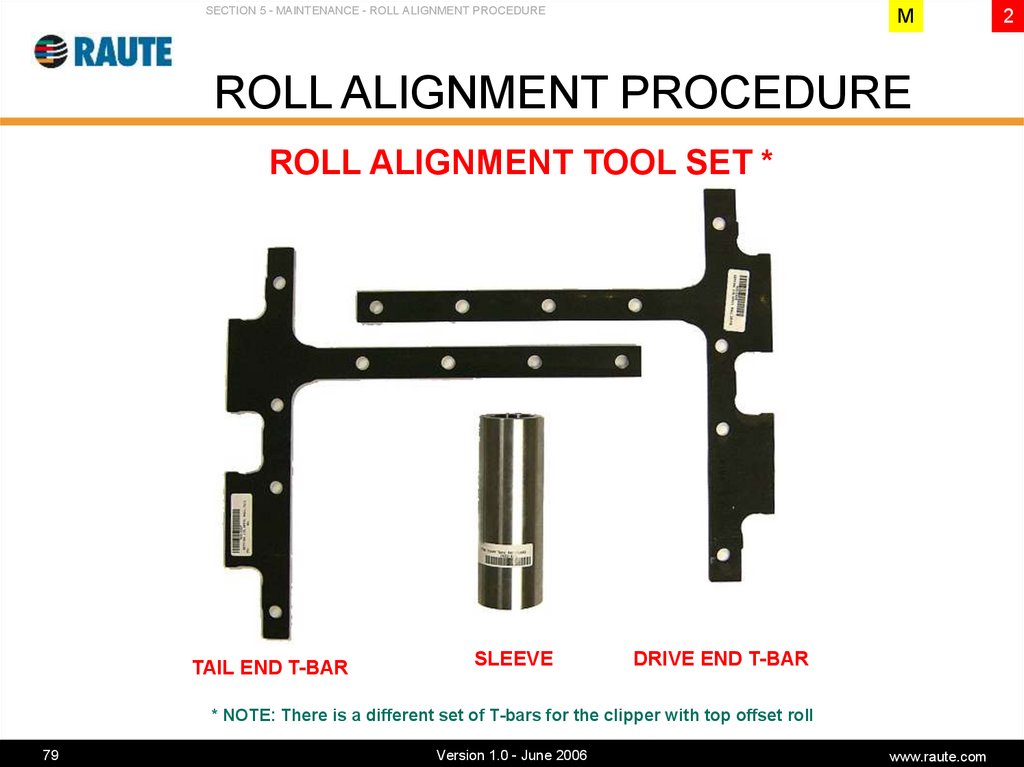

79. ROLL ALIGNMENT PROCEDURE

SECTION 5 - MAINTENANCE - ROLL ALIGNMENT PROCEDUREM

ROLL ALIGNMENT PROCEDURE

ROLL ALIGNMENT TOOL SET *

TAIL END T-BAR

SLEEVE

DRIVE END T-BAR

* NOTE: There is a different set of T-bars for the clipper with top offset roll

79

Version 1.0 - June 2006

www.raute.com

2

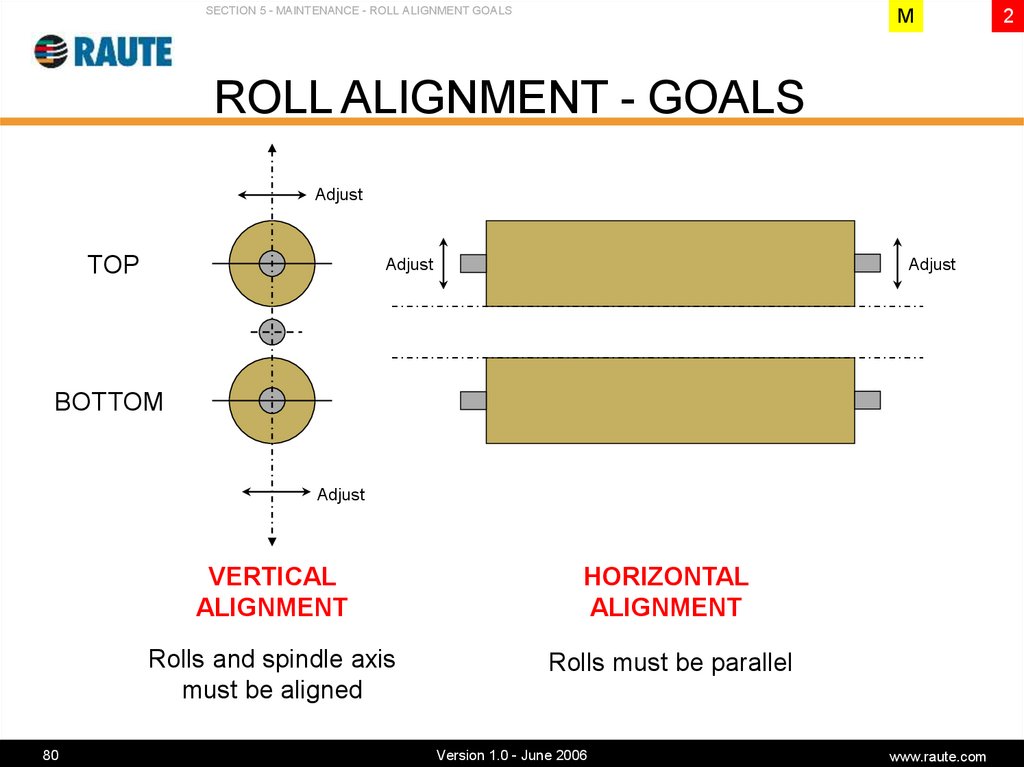

80. ROLL ALIGNMENT - GOALS

SECTION 5 - MAINTENANCE - ROLL ALIGNMENT GOALSM

ROLL ALIGNMENT - GOALS

Adjust

TOP

Adjust

Adjust

BOTTOM

Adjust

80

VERTICAL

ALIGNMENT

HORIZONTAL

ALIGNMENT

Rolls and spindle axis

must be aligned

Rolls must be parallel

Version 1.0 - June 2006

www.raute.com

2

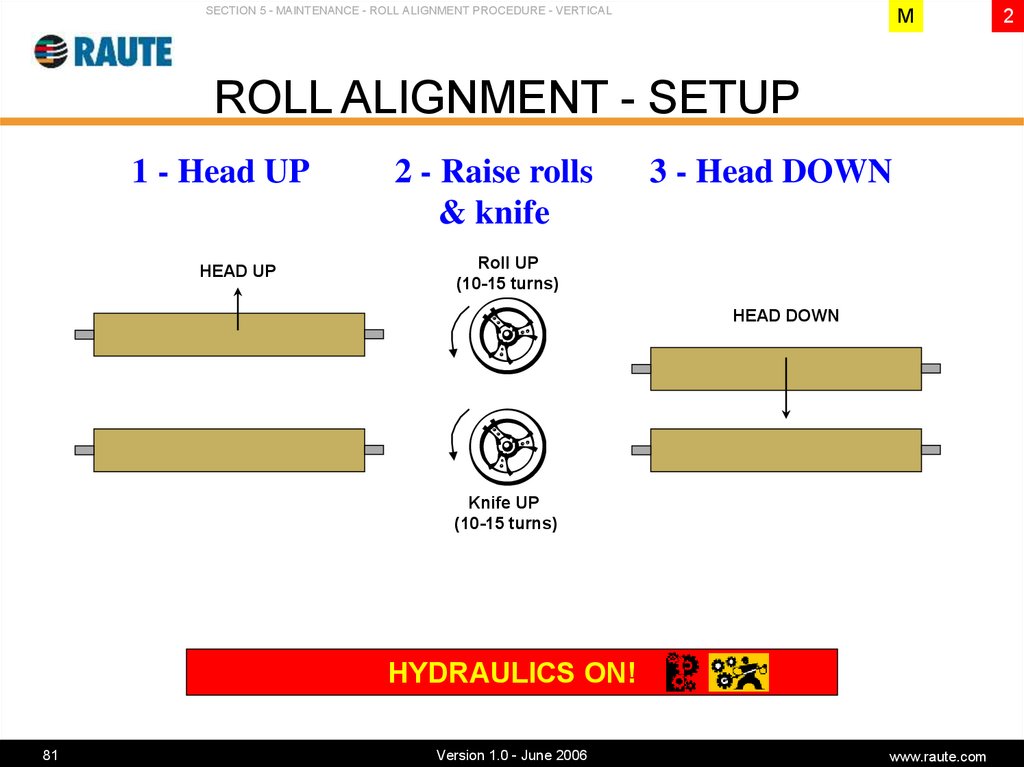

81. ROLL ALIGNMENT - SETUP

SECTION 5 - MAINTENANCE - ROLL ALIGNMENT PROCEDURE - VERTICALM

ROLL ALIGNMENT - SETUP

1 - Head UP

HEAD UP

2 - Raise rolls

& knife

3 - Head DOWN

Roll UP

(10-15 turns)

HEAD DOWN

Knife UP

(10-15 turns)

HYDRAULICS ON!

81

Version 1.0 - June 2006

www.raute.com

2

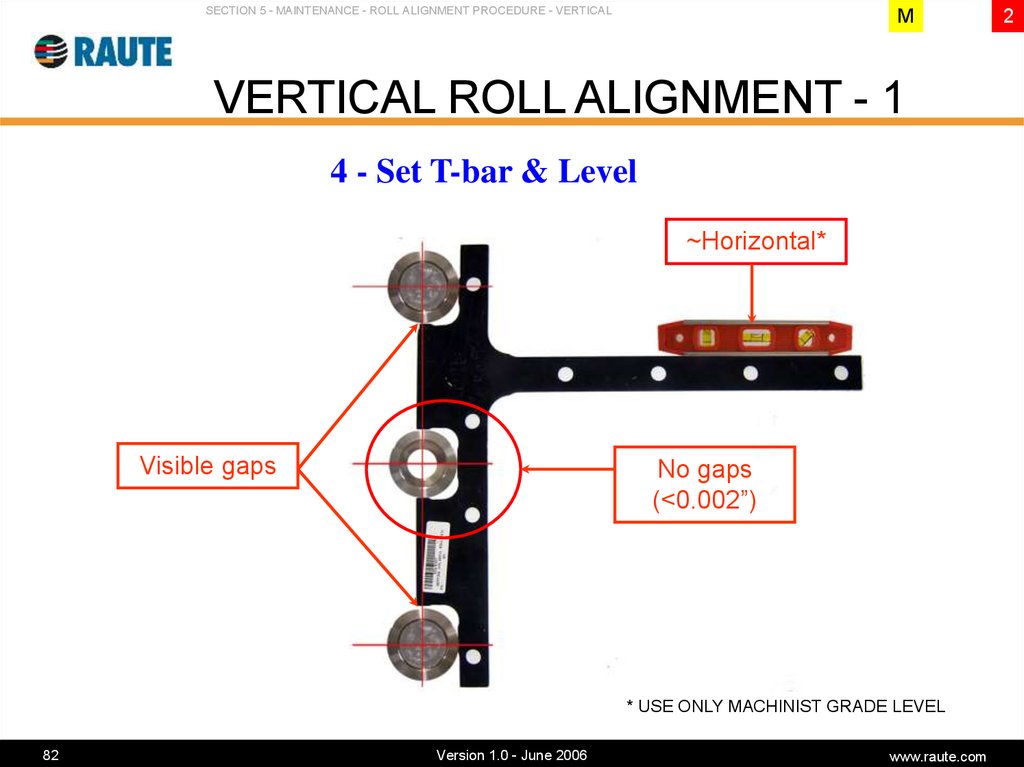

82. VERTICAL ROLL ALIGNMENT - 1

SECTION 5 - MAINTENANCE - ROLL ALIGNMENT PROCEDURE - VERTICALM

VERTICAL ROLL ALIGNMENT - 1

4 - Set T-bar & Level

~Horizontal*

Visible gaps

No gaps

(<0.002”)

* USE ONLY MACHINIST GRADE LEVEL

82

Version 1.0 - June 2006

www.raute.com

2

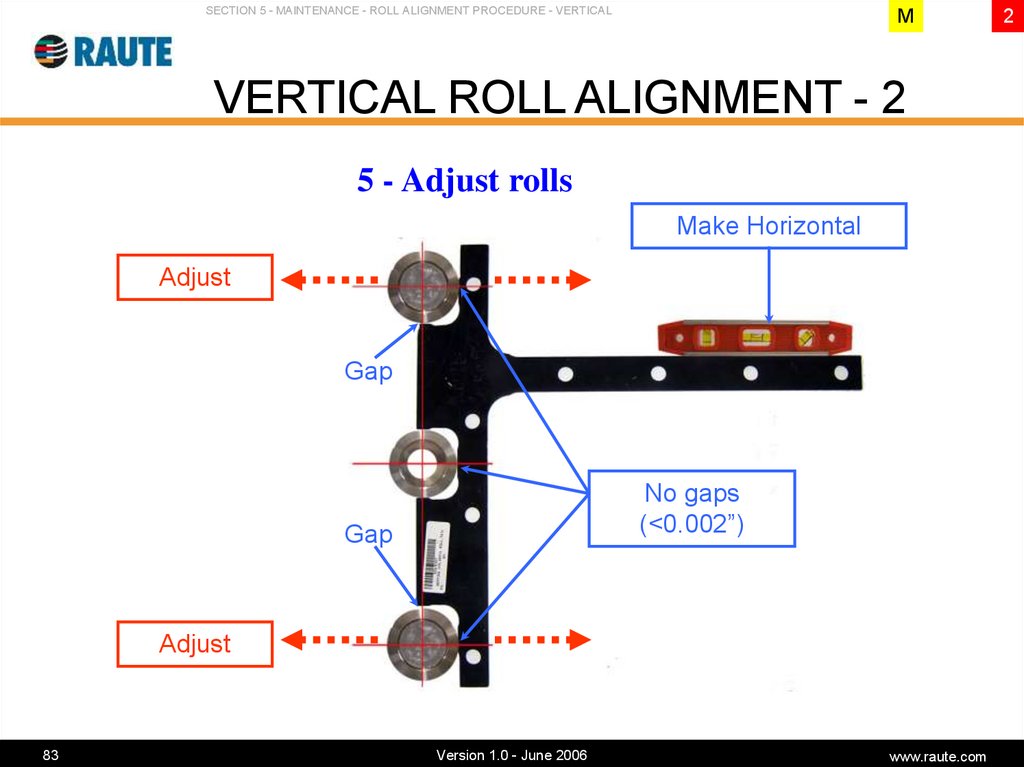

83. VERTICAL ROLL ALIGNMENT - 2

SECTION 5 - MAINTENANCE - ROLL ALIGNMENT PROCEDURE - VERTICALM

VERTICAL ROLL ALIGNMENT - 2

5 - Adjust rolls

Make Horizontal

Adjust

Gap

No gaps

(<0.002”)

Gap

Adjust

83

Version 1.0 - June 2006

www.raute.com

2

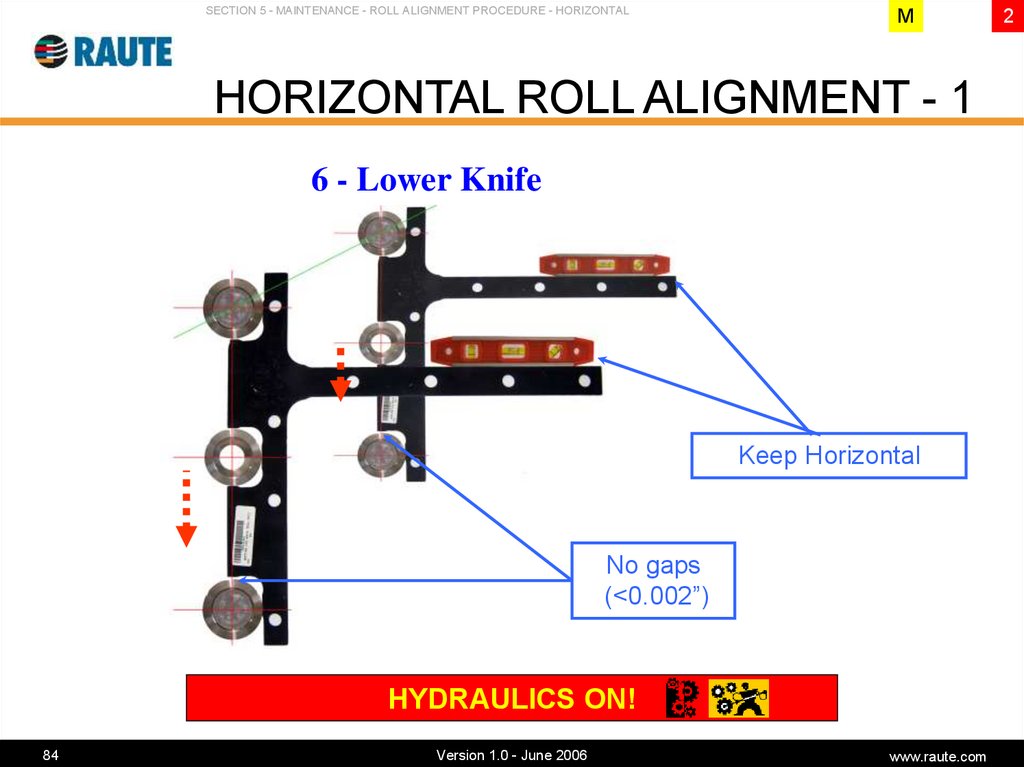

84. HORIZONTAL ROLL ALIGNMENT - 1

SECTION 5 - MAINTENANCE - ROLL ALIGNMENT PROCEDURE - HORIZONTALM

HORIZONTAL ROLL ALIGNMENT - 1

6 - Lower Knife

Keep Horizontal

No gaps

(<0.002”)

HYDRAULICS ON!

84

Version 1.0 - June 2006

www.raute.com

2

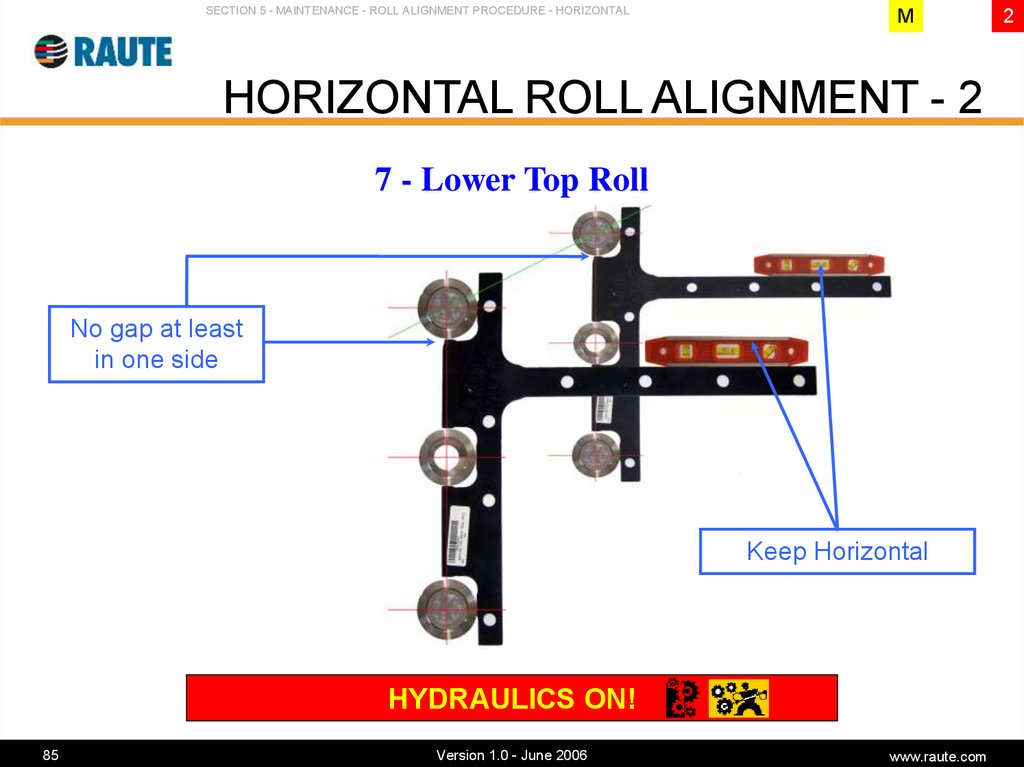

85. HORIZONTAL ROLL ALIGNMENT - 2

SECTION 5 - MAINTENANCE - ROLL ALIGNMENT PROCEDURE - HORIZONTALM

HORIZONTAL ROLL ALIGNMENT - 2

7 - Lower Top Roll

No gap at least

in one side

Keep Horizontal

HYDRAULICS ON!

85

Version 1.0 - June 2006

www.raute.com

2

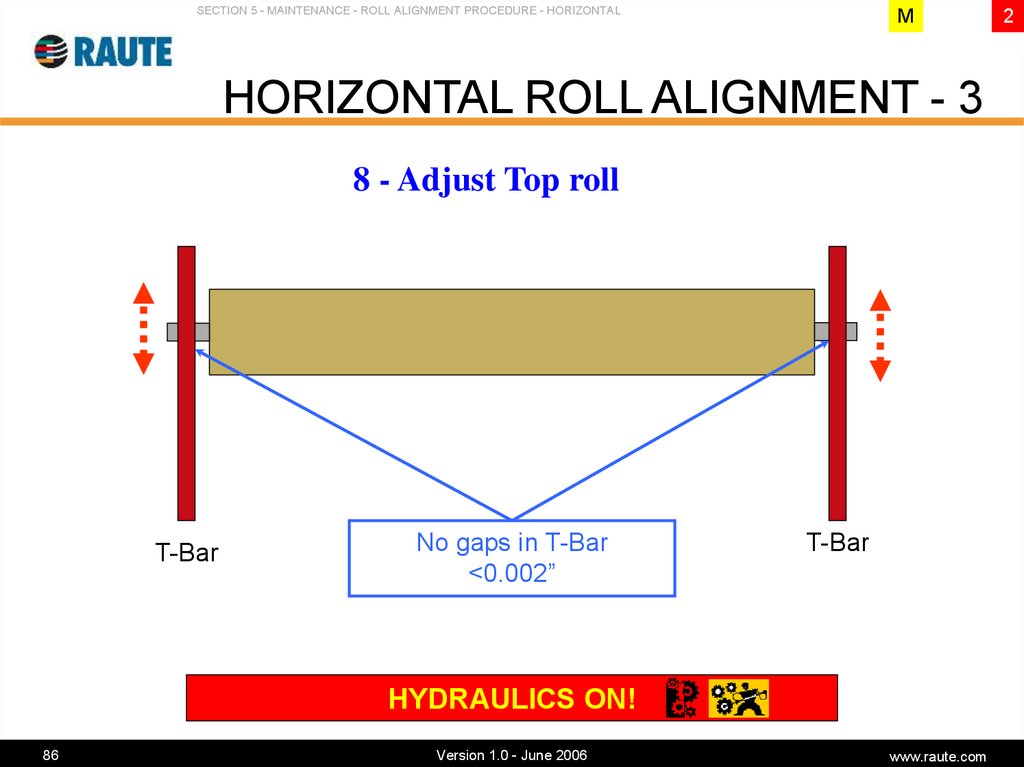

86. HORIZONTAL ROLL ALIGNMENT - 3

SECTION 5 - MAINTENANCE - ROLL ALIGNMENT PROCEDURE - HORIZONTALM

HORIZONTAL ROLL ALIGNMENT - 3

8 - Adjust Top roll

T-Bar

No gaps in T-Bar

<0.002”

T-Bar

HYDRAULICS ON!

86

Version 1.0 - June 2006

www.raute.com

2

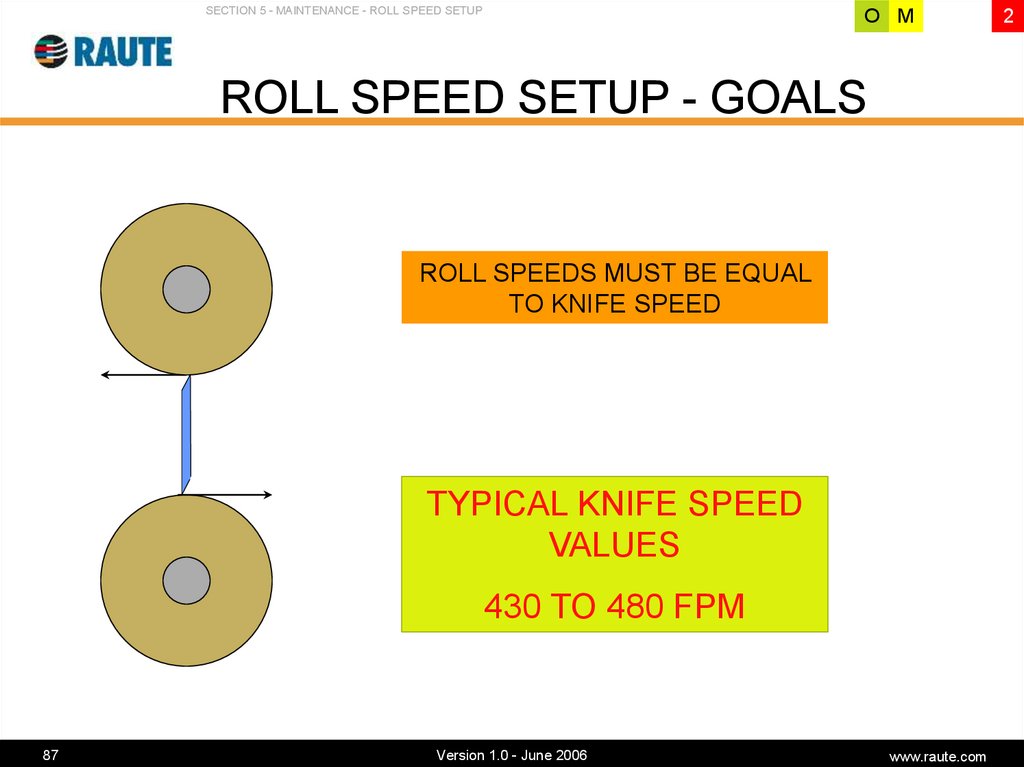

87. ROLL SPEED SETUP - GOALS

SECTION 5 - MAINTENANCE - ROLL SPEED SETUPO M

ROLL SPEED SETUP - GOALS

ROLL SPEEDS MUST BE EQUAL

TO KNIFE SPEED

TYPICAL KNIFE SPEED

VALUES

430 TO 480 FPM

87

Version 1.0 - June 2006

www.raute.com

2

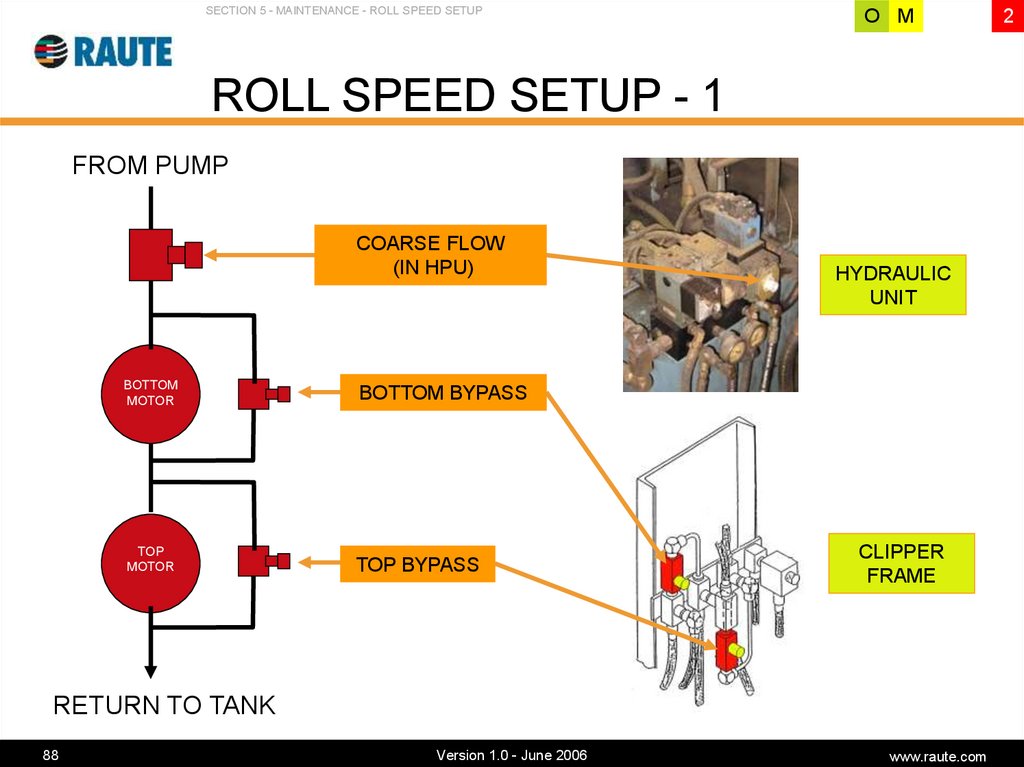

88. ROLL SPEED SETUP - 1

SECTION 5 - MAINTENANCE - ROLL SPEED SETUPO M

ROLL SPEED SETUP - 1

FROM PUMP

COARSE FLOW

(IN HPU)

BOTTOM

MOTOR

BOTTOM BYPASS

TOP

MOTOR

TOP BYPASS

HYDRAULIC

UNIT

CLIPPER

FRAME

RETURN TO TANK

88

Version 1.0 - June 2006

www.raute.com

2

89. ROLL SPEED SETUP - 2

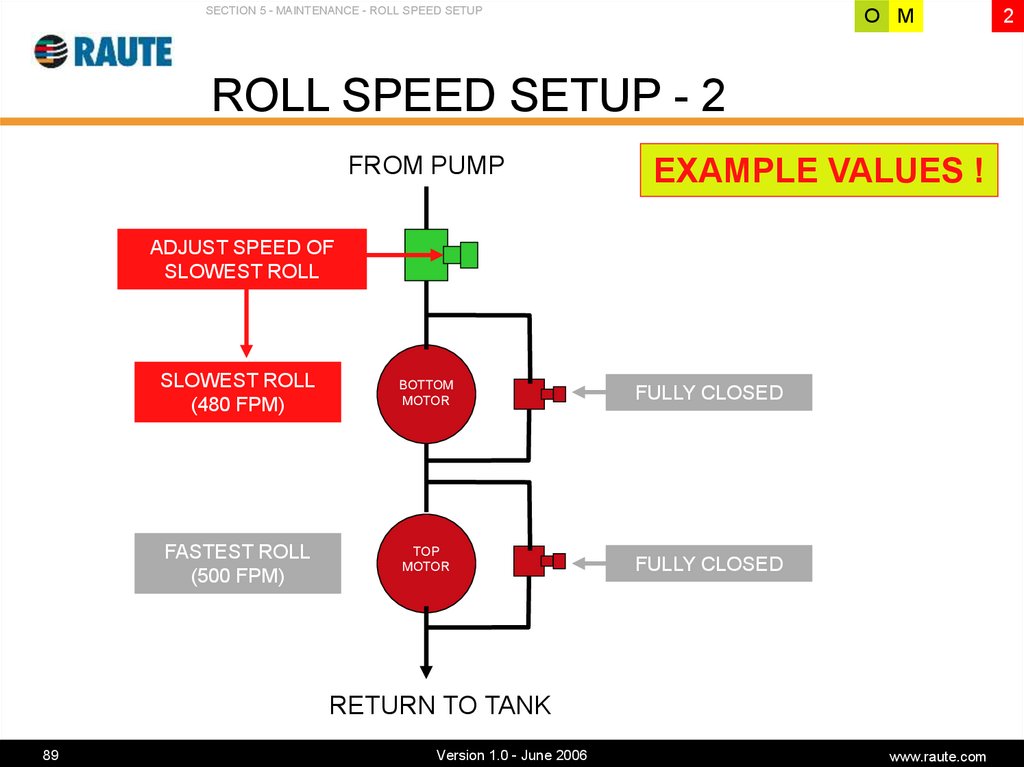

SECTION 5 - MAINTENANCE - ROLL SPEED SETUPO M

ROLL SPEED SETUP - 2

FROM PUMP

EXAMPLE VALUES !

ADJUST SPEED OF

SLOWEST ROLL

SLOWEST ROLL

(480 FPM)

BOTTOM

MOTOR

FULLY CLOSED

FASTEST ROLL

(500 FPM)

TOP

MOTOR

FULLY CLOSED

RETURN TO TANK

89

Version 1.0 - June 2006

www.raute.com

2

90. ROLL SPEED SETUP - 3

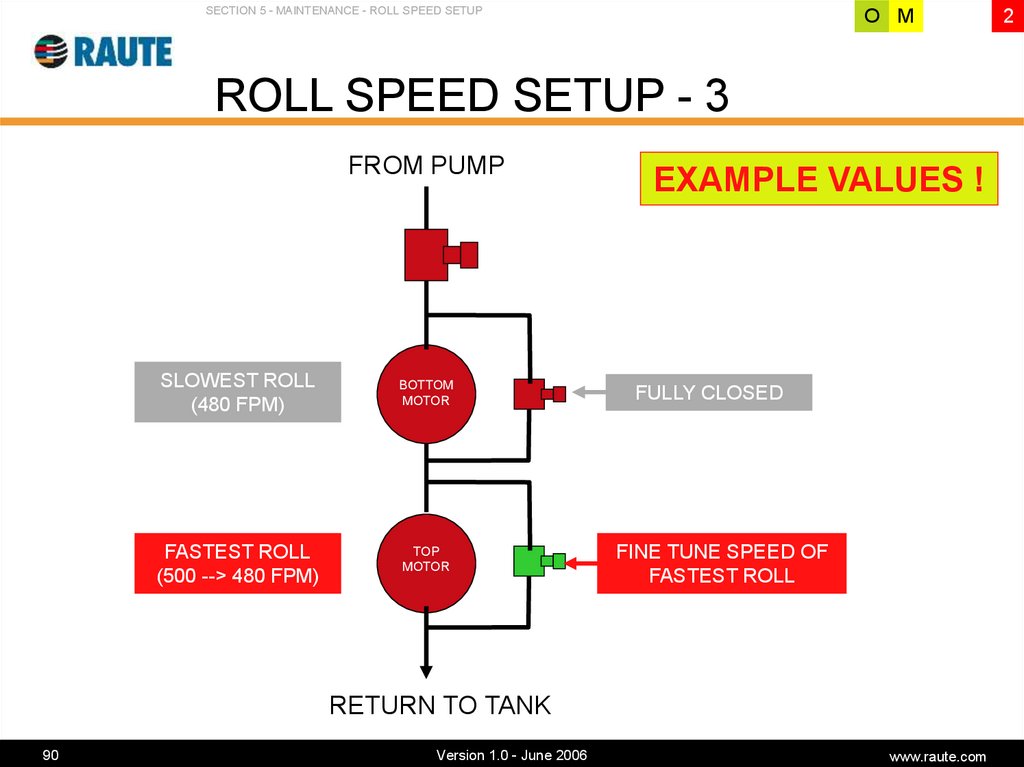

SECTION 5 - MAINTENANCE - ROLL SPEED SETUPO M

ROLL SPEED SETUP - 3

FROM PUMP

SLOWEST ROLL

(480 FPM)

BOTTOM

MOTOR

FASTEST ROLL

(500 --> 480 FPM)

TOP

MOTOR

EXAMPLE VALUES !

FULLY CLOSED

FINE TUNE SPEED OF

FASTEST ROLL

RETURN TO TANK

90

Version 1.0 - June 2006

www.raute.com

2

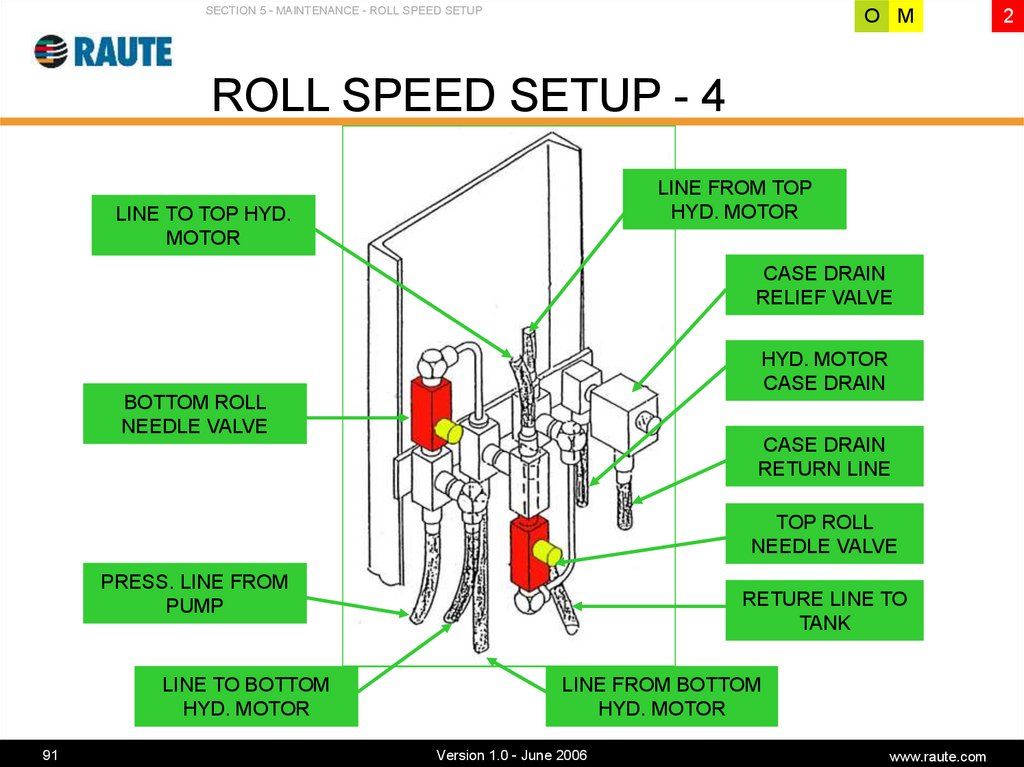

91. ROLL SPEED SETUP - 4

SECTION 5 - MAINTENANCE - ROLL SPEED SETUPO M

ROLL SPEED SETUP - 4

LINE FROM TOP

HYD. MOTOR

LINE TO TOP HYD.

MOTOR

CASE DRAIN

RELIEF VALVE

HYD. MOTOR

CASE DRAIN

BOTTOM ROLL

NEEDLE VALVE

CASE DRAIN

RETURN LINE

TOP ROLL

NEEDLE VALVE

PRESS. LINE FROM

PUMP

LINE TO BOTTOM

HYD. MOTOR

91

RETURE LINE TO

TANK

LINE FROM BOTTOM

HYD. MOTOR

Version 1.0 - June 2006

www.raute.com

2

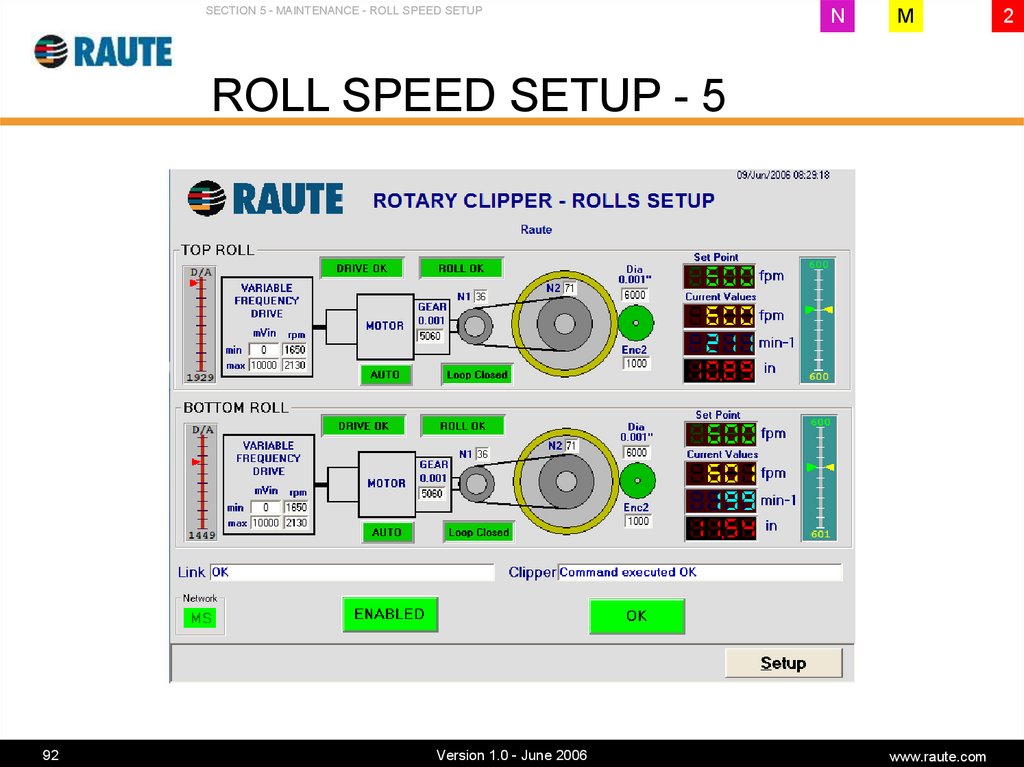

92. ROLL SPEED SETUP - 5

SECTION 5 - MAINTENANCE - ROLL SPEED SETUPN

M

ROLL SPEED SETUP - 5

92

Version 1.0 - June 2006

www.raute.com

2

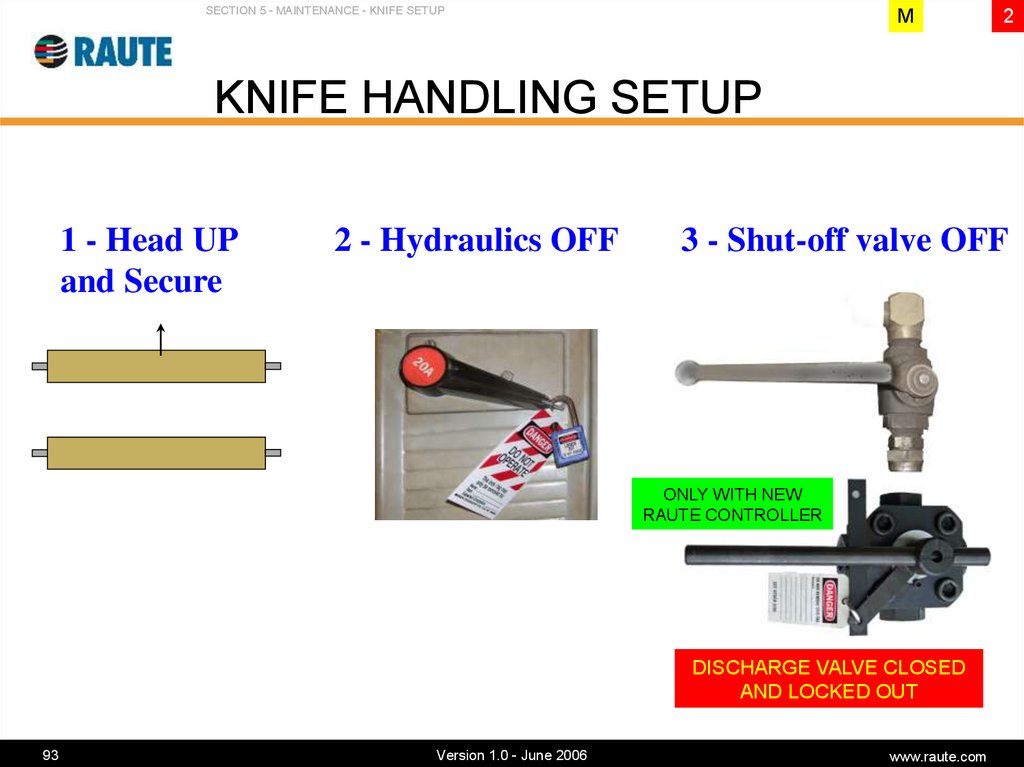

93. KNIFE HANDLING SETUP

SECTION 5 - MAINTENANCE - KNIFE SETUPM

2

KNIFE HANDLING SETUP

1 - Head UP

and Secure

2 - Hydraulics OFF

3 - Shut-off valve OFF

ONLY WITH NEW

RAUTE CONTROLLER

DISCHARGE VALVE CLOSED

AND LOCKED OUT

93

Version 1.0 - June 2006

www.raute.com

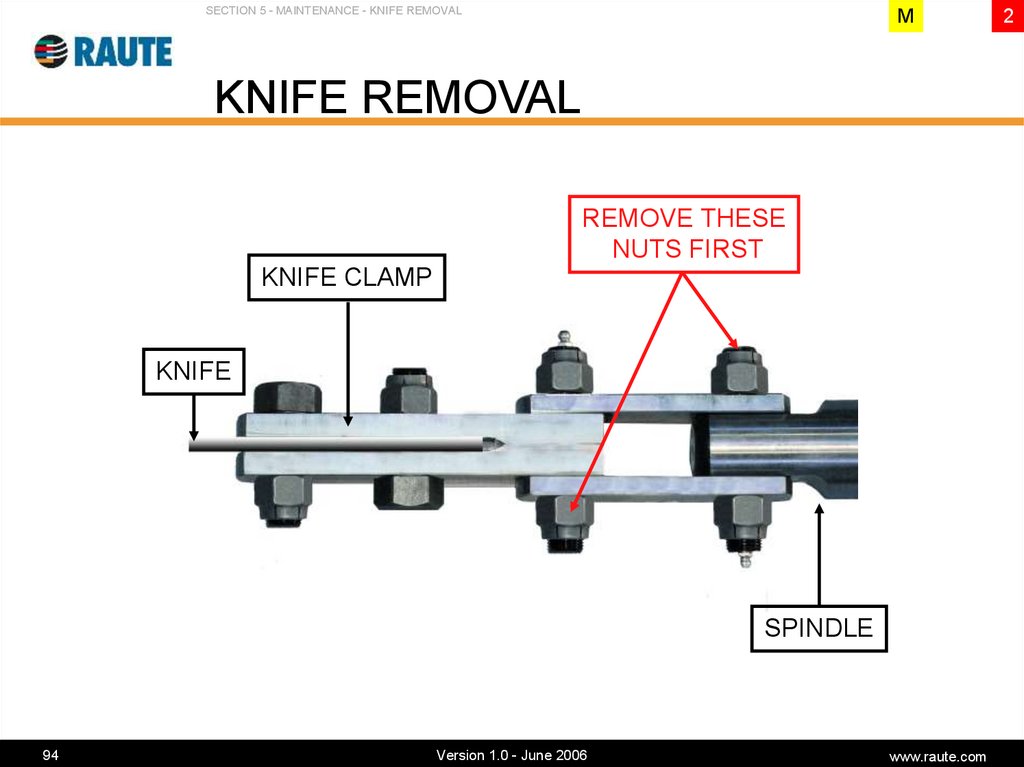

94. KNIFE REMOVAL

SECTION 5 - MAINTENANCE - KNIFE REMOVALM

KNIFE REMOVAL

REMOVE THESE

NUTS FIRST

KNIFE CLAMP

KNIFE

SPINDLE

94

Version 1.0 - June 2006

www.raute.com

2

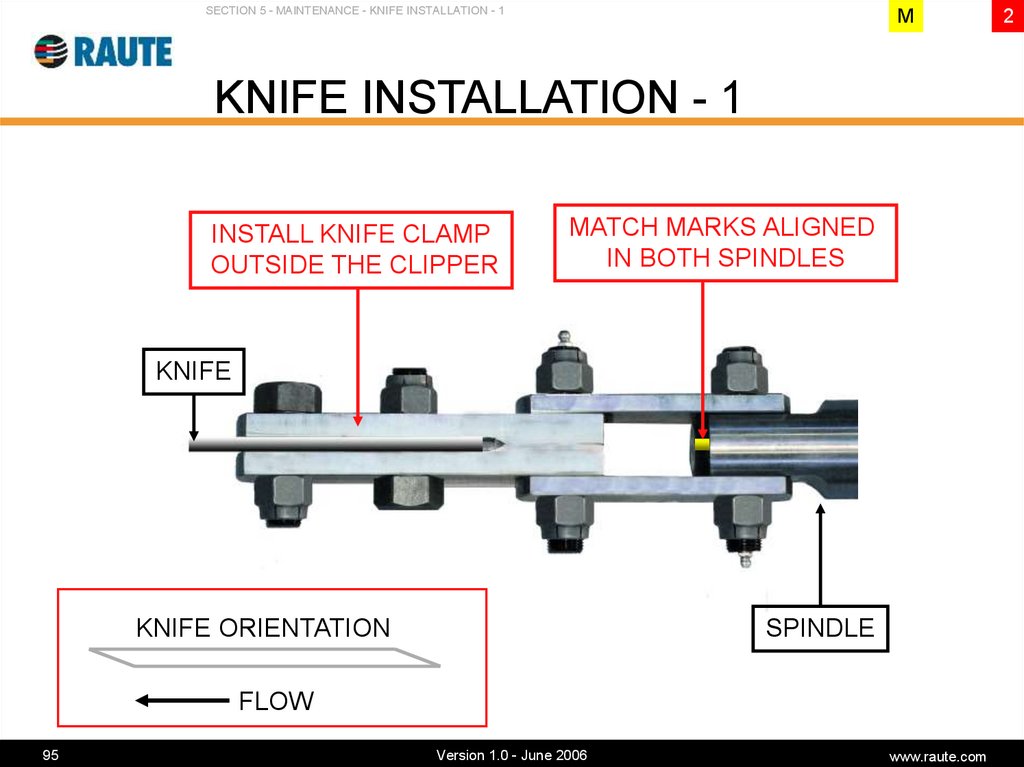

95. KNIFE INSTALLATION - 1

SECTION 5 - MAINTENANCE - KNIFE INSTALLATION - 1M

KNIFE INSTALLATION - 1

INSTALL KNIFE CLAMP

OUTSIDE THE CLIPPER

MATCH MARKS ALIGNED

IN BOTH SPINDLES

KNIFE

KNIFE ORIENTATION

SPINDLE

FLOW

95

Version 1.0 - June 2006

www.raute.com

2

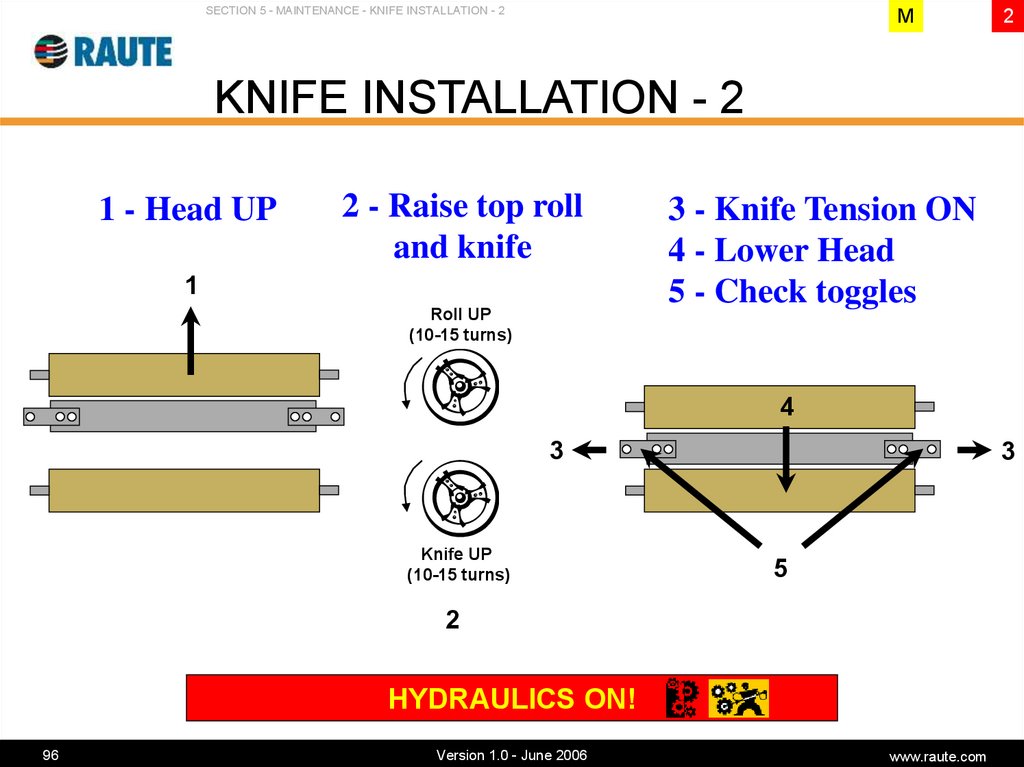

96. KNIFE INSTALLATION - 2

SECTION 5 - MAINTENANCE - KNIFE INSTALLATION - 2M

2

KNIFE INSTALLATION - 2

1 - Head UP

2 - Raise top roll

and knife

1

Roll UP

(10-15 turns)

3 - Knife Tension ON

4 - Lower Head

5 - Check toggles

4

3

Knife UP

(10-15 turns)

3

5

2

HYDRAULICS ON!

96

Version 1.0 - June 2006

www.raute.com

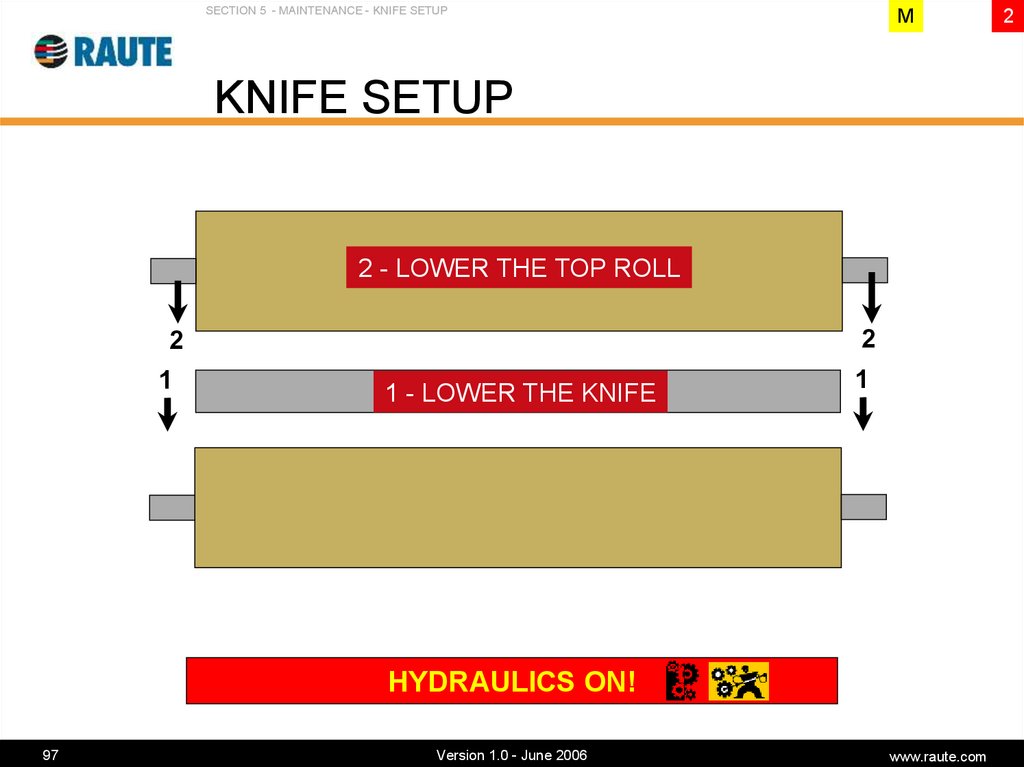

97. KNIFE SETUP

SECTION 5 - MAINTENANCE - KNIFE SETUPM

KNIFE SETUP

2 - LOWER THE TOP ROLL

2

2

1

1 - LOWER THE KNIFE

1

HYDRAULICS ON!

97

Version 1.0 - June 2006

www.raute.com

2

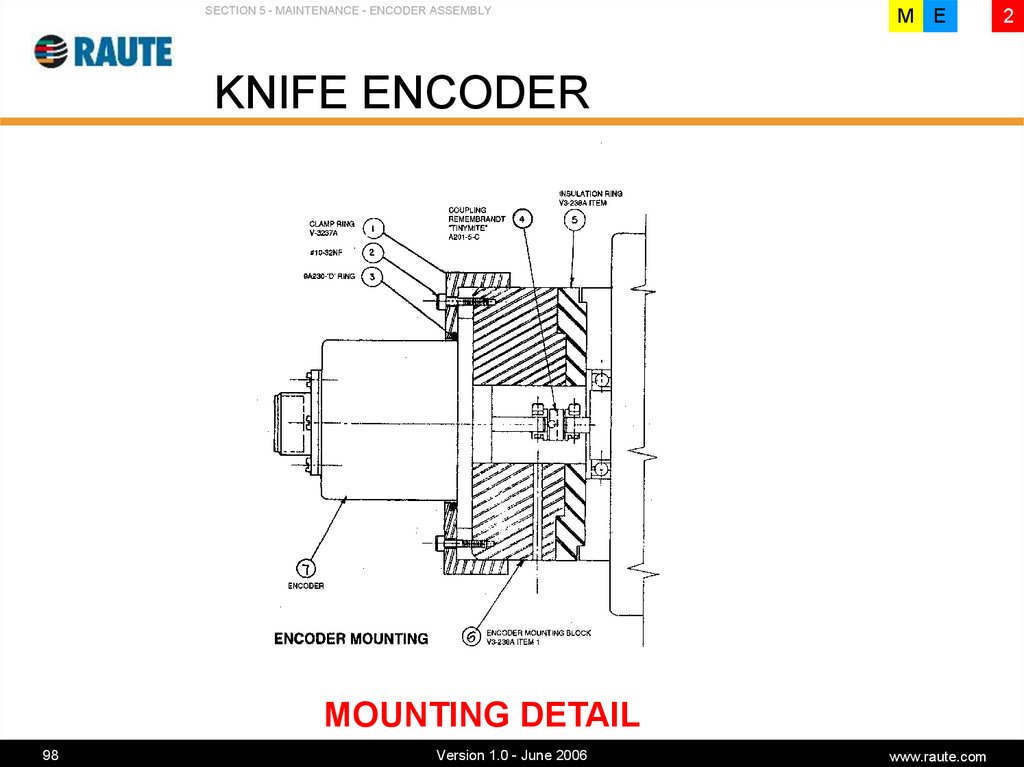

98. KNIFE ENCODER

SECTION 5 - MAINTENANCE - ENCODER ASSEMBLYM E

KNIFE ENCODER

MOUNTING DETAIL

98

Version 1.0 - June 2006

www.raute.com

2

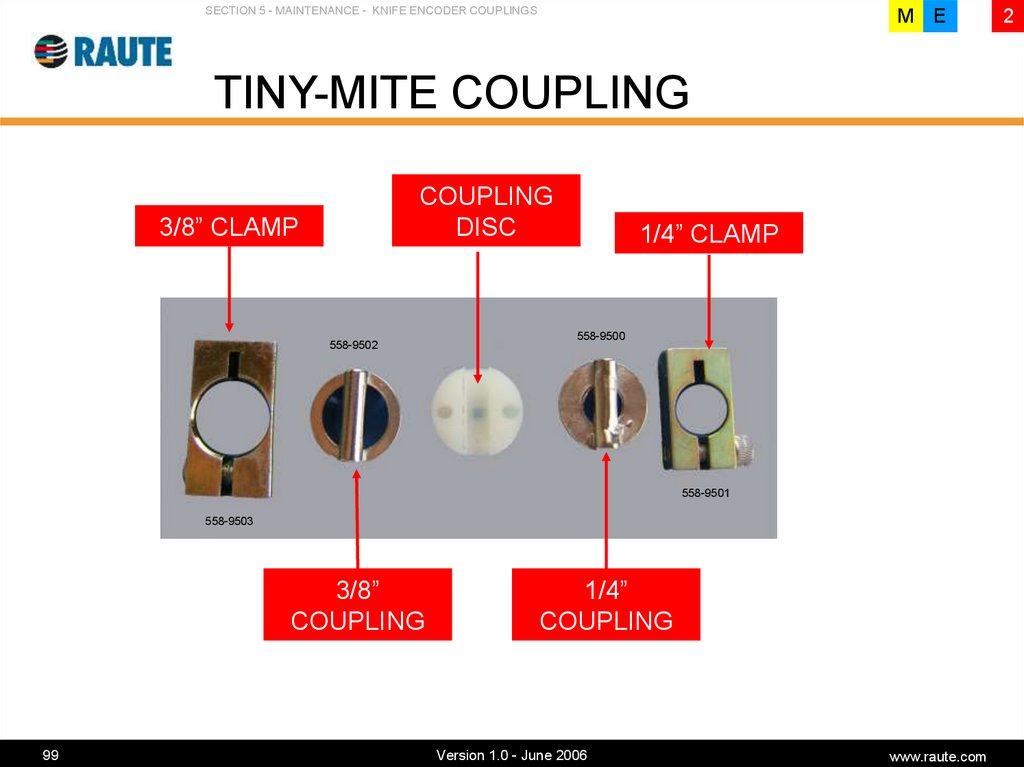

99. TINY-MITE COUPLING

SECTION 5 - MAINTENANCE - KNIFE ENCODER COUPLINGSM E

TINY-MITE COUPLING

COUPLING

DISC

3/8” CLAMP

558-9502

1/4” CLAMP

558-9500

558-9501

558-9503

3/8”

COUPLING

99

1/4”

COUPLING

Version 1.0 - June 2006

www.raute.com

2

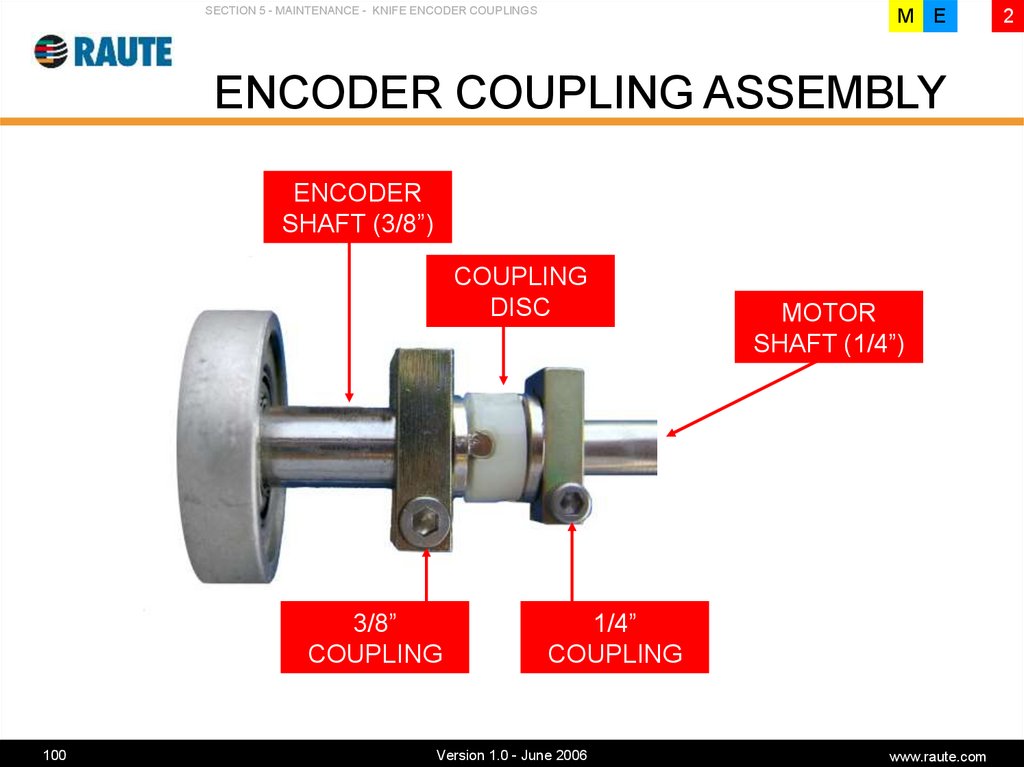

100. ENCODER COUPLING ASSEMBLY

SECTION 5 - MAINTENANCE - KNIFE ENCODER COUPLINGSM E

ENCODER COUPLING ASSEMBLY

ENCODER

SHAFT (3/8”)

COUPLING

DISC

3/8”

COUPLING

100

MOTOR

SHAFT (1/4”)

1/4”

COUPLING

Version 1.0 - June 2006

www.raute.com

2

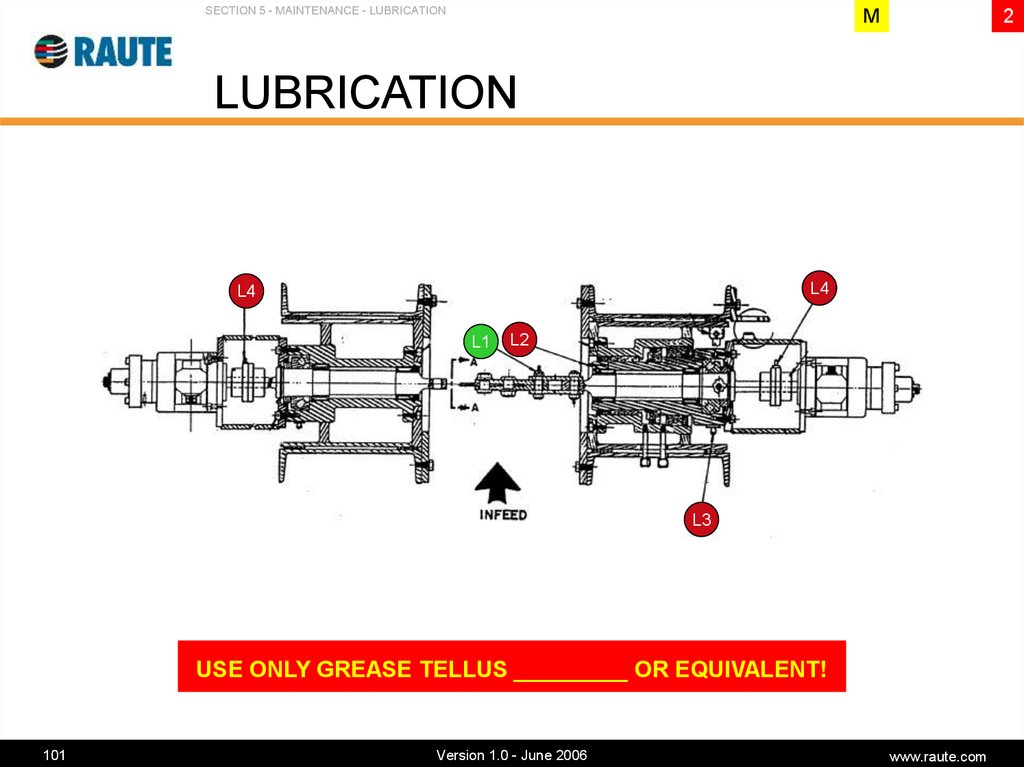

101. LUBRICATION

SECTION 5 - MAINTENANCE - LUBRICATIONM

2

LUBRICATION

L4

L4

4

L1

L2

L3

USE ONLY GREASE TELLUS _________ OR EQUIVALENT!

101

Version 1.0 - June 2006

www.raute.com

102. Section 6 TROUBLESHOOTING

SECTION 5 - TROUBLESHOOTINGN O M E

1

Section 6

TROUBLESHOOTING

GENERAL

Normal failures

Threshold failures

QUICK GUIDE

Symptom

Cause

Solution

CONTROLLER BASED

Diagnostics tests

Graphics

102

Version 1.0 - June 2006

www.raute.com

2

103. GENERAL

SECTION 5 - TROUBLESHOOTING - GENERALM E

GENERAL

NORMAL FAILURES

• Originated by a single element (e.g.: broken spindle)

• Easy to diagnose

• Direct fixing by repair/substitution of parts

THRESHOLD FAILURES

• Multiple origins (e.g: Bias clip)

• Effects only seen after a certain “threshold” is passed

• Difficult to diagnose

• Multiple actions required to fix the problem

103

Version 1.0 - June 2006

www.raute.com

2

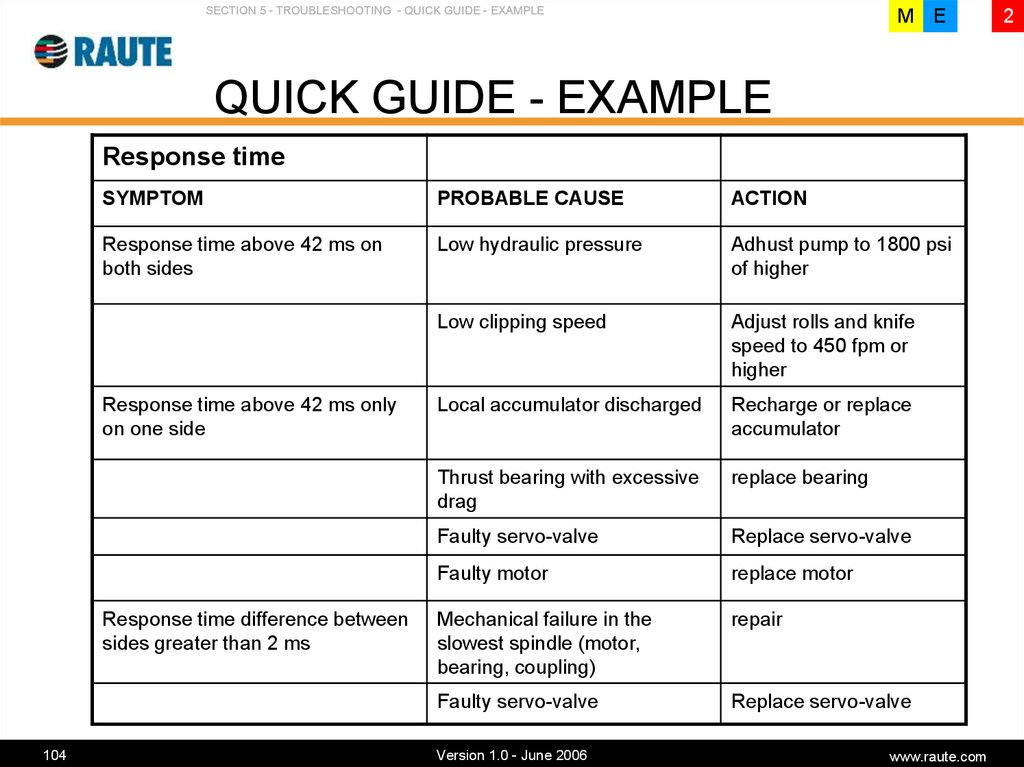

104. QUICK GUIDE - EXAMPLE

SECTION 5 - TROUBLESHOOTING - QUICK GUIDE - EXAMPLEM E

QUICK GUIDE - EXAMPLE

Response time

SYMPTOM

PROBABLE CAUSE

ACTION

Response time above 42 ms on

both sides

Low hydraulic pressure

Adhust pump to 1800 psi

of higher

Low clipping speed

Adjust rolls and knife

speed to 450 fpm or

higher

Local accumulator discharged

Recharge or replace

accumulator

Thrust bearing with excessive

drag

replace bearing

Faulty servo-valve

Replace servo-valve

Faulty motor

replace motor

Mechanical failure in the

slowest spindle (motor,

bearing, coupling)

repair

Faulty servo-valve

Replace servo-valve

Response time above 42 ms only

on one side

Response time difference between

sides greater than 2 ms

104

Version 1.0 - June 2006

www.raute.com

2

105. THRESHOLD ISSUES - EXAMPLE

SECTION 5 - TROUBLESHOOTING - THRESHOLD ISSUES - EXAMPLEM E

THRESHOLD ISSUES - EXAMPLE

BIAS CLIP

• Symptoms: Veneer sheets are not perfect rectangles but

parallelograms.

• Possible causes

A. Spindles with different response times (1 ms ~ 0.1 in @ 500 FPM)

B. Outer in-feed belts with different speeds in both sides. Worn belt is a

typical cause.

C. Hold down belts with different gap in each side. Incorrect hold down

alignment.

105

Solution: Multiple actions may be required.

Version 1.0 - June 2006

www.raute.com

2

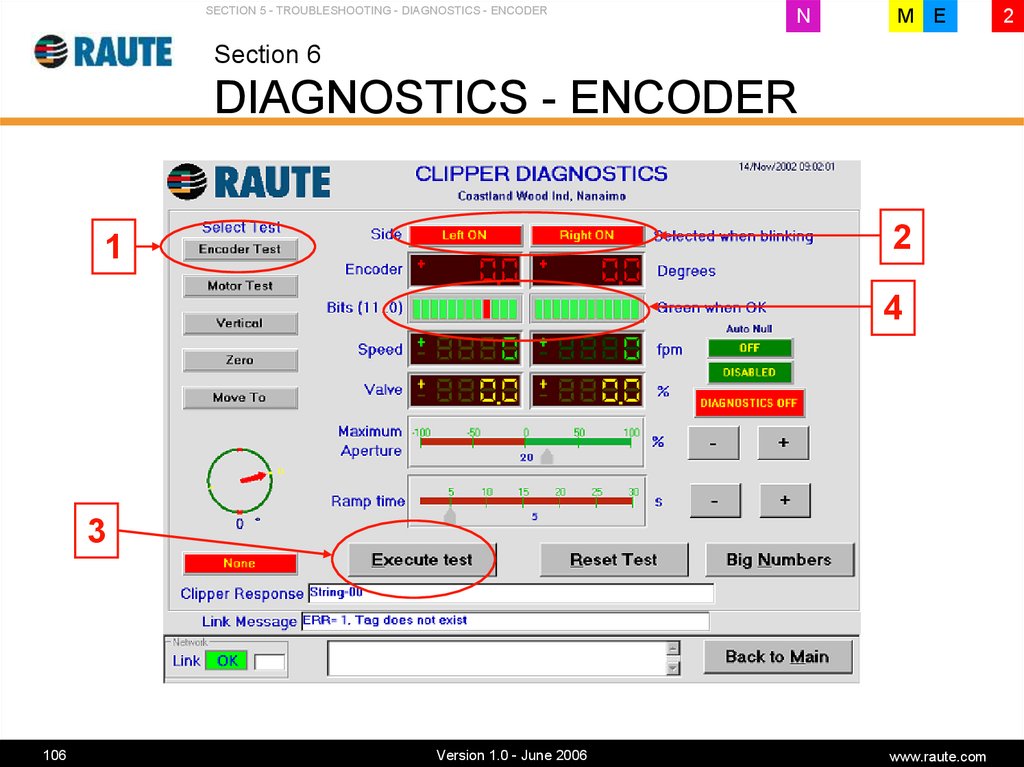

106. Section 6 DIAGNOSTICS - ENCODER

SECTION 5 - TROUBLESHOOTING - DIAGNOSTICS - ENCODERN

M E

Section 6

DIAGNOSTICS - ENCODER

2

1

4

3

106

Version 1.0 - June 2006

www.raute.com

2

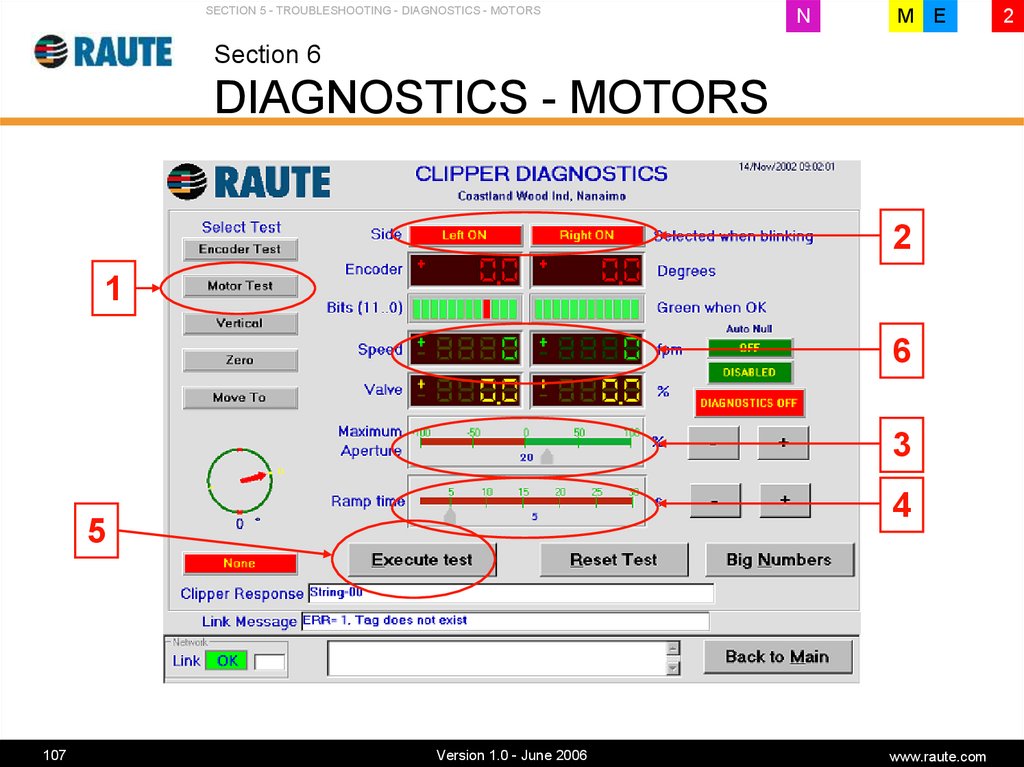

107. Section 6 DIAGNOSTICS - MOTORS

SECTION 5 - TROUBLESHOOTING - DIAGNOSTICS - MOTORSN

M E

Section 6

DIAGNOSTICS - MOTORS

2

1

6

3

4

5

107

Version 1.0 - June 2006

www.raute.com

2

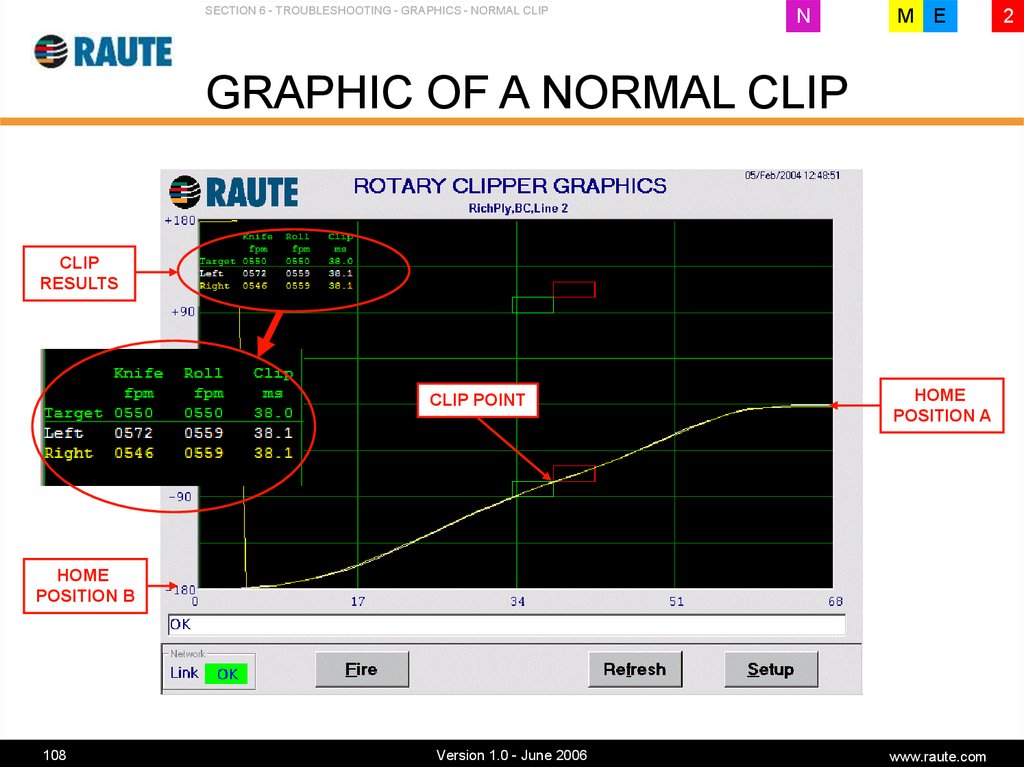

108. GRAPHIC OF A NORMAL CLIP

SECTION 6 - TROUBLESHOOTING - GRAPHICS - NORMAL CLIPN

M E

GRAPHIC OF A NORMAL CLIP

CLIP

RESULTS

CLIP POINT

HOME

POSITION A

HOME

POSITION B

108

Version 1.0 - June 2006

www.raute.com

2

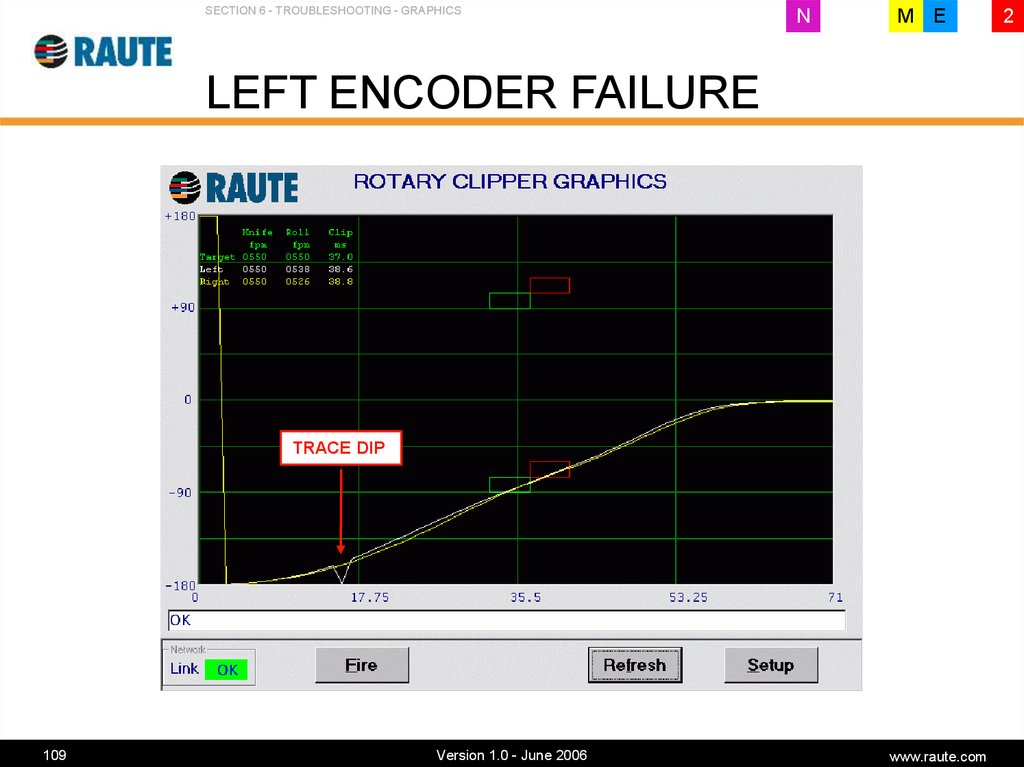

109. LEFT ENCODER FAILURE

SECTION 6 - TROUBLESHOOTING - GRAPHICSN

M E

LEFT ENCODER FAILURE

TRACE DIP

109

Version 1.0 - June 2006

www.raute.com

2

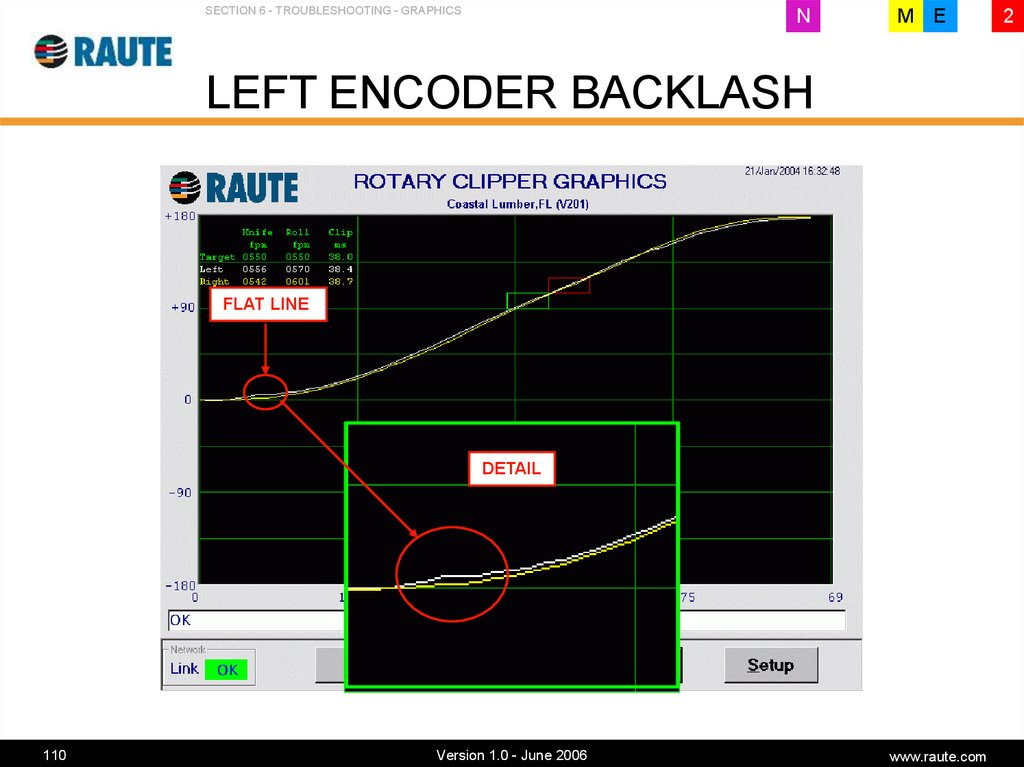

110. LEFT ENCODER BACKLASH

SECTION 6 - TROUBLESHOOTING - GRAPHICSN

M E

LEFT ENCODER BACKLASH

FLAT LINE

DETAIL

110

Version 1.0 - June 2006

www.raute.com

2

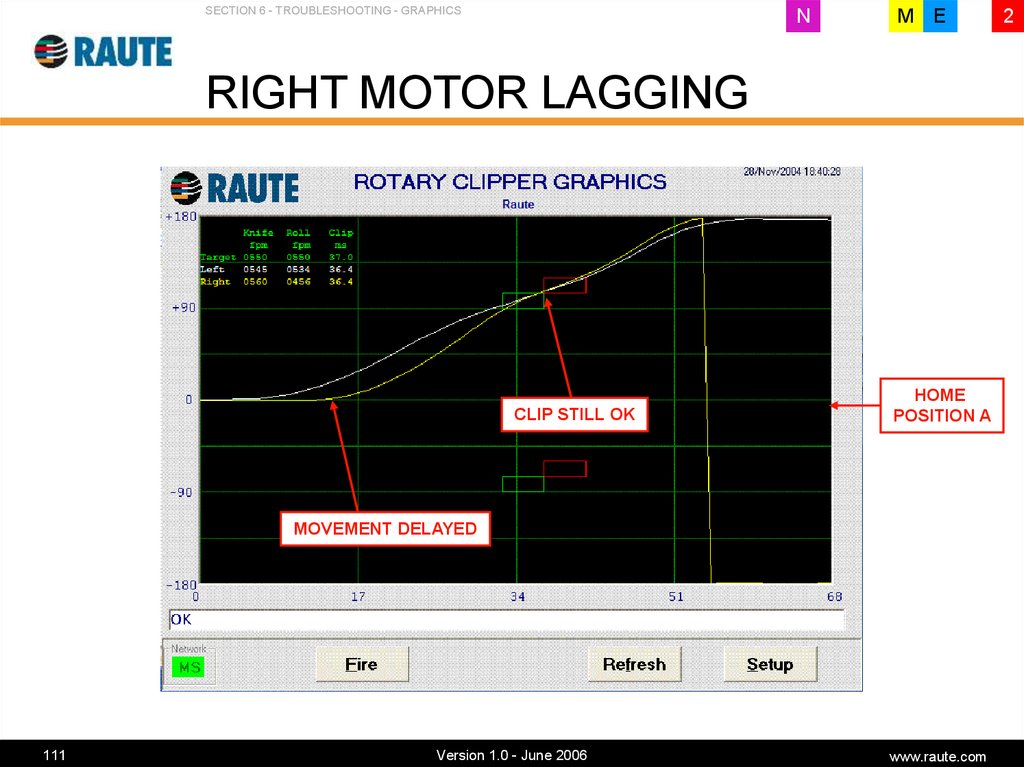

111. RIGHT MOTOR LAGGING

SECTION 6 - TROUBLESHOOTING - GRAPHICSN

M E

RIGHT MOTOR LAGGING

CLIP STILL OK

HOME

POSITION A

MOVEMENT DELAYED

111

Version 1.0 - June 2006

www.raute.com

2

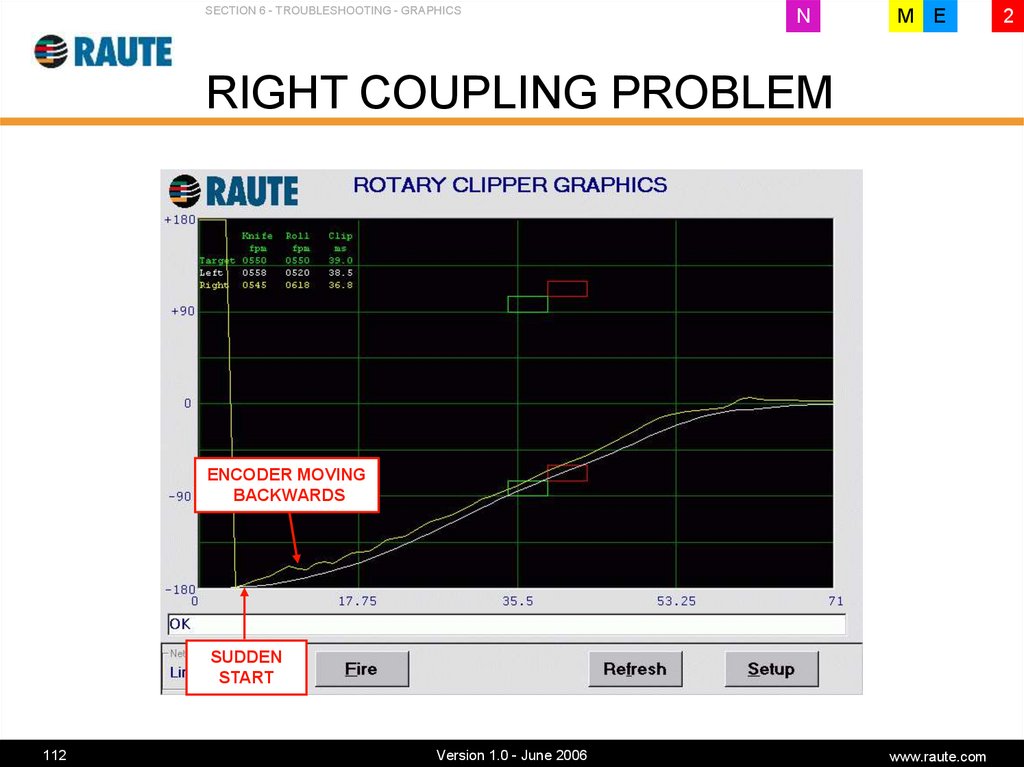

112. RIGHT COUPLING PROBLEM

SECTION 6 - TROUBLESHOOTING - GRAPHICSN

M E

RIGHT COUPLING PROBLEM

ENCODER MOVING

BACKWARDS

SUDDEN

START

112

Version 1.0 - June 2006

www.raute.com

2

113. Section 7 APPENDIX

SECTION 7 - APENDIXSection 7

APPENDIX

113

Version 1.0 - June 2006

www.raute.com

114. PARTS

SECTION 7 - APENDIXPARTS

QUALITY RAUTE PARTS

114

Version 1.0 - June 2006

www.raute.com

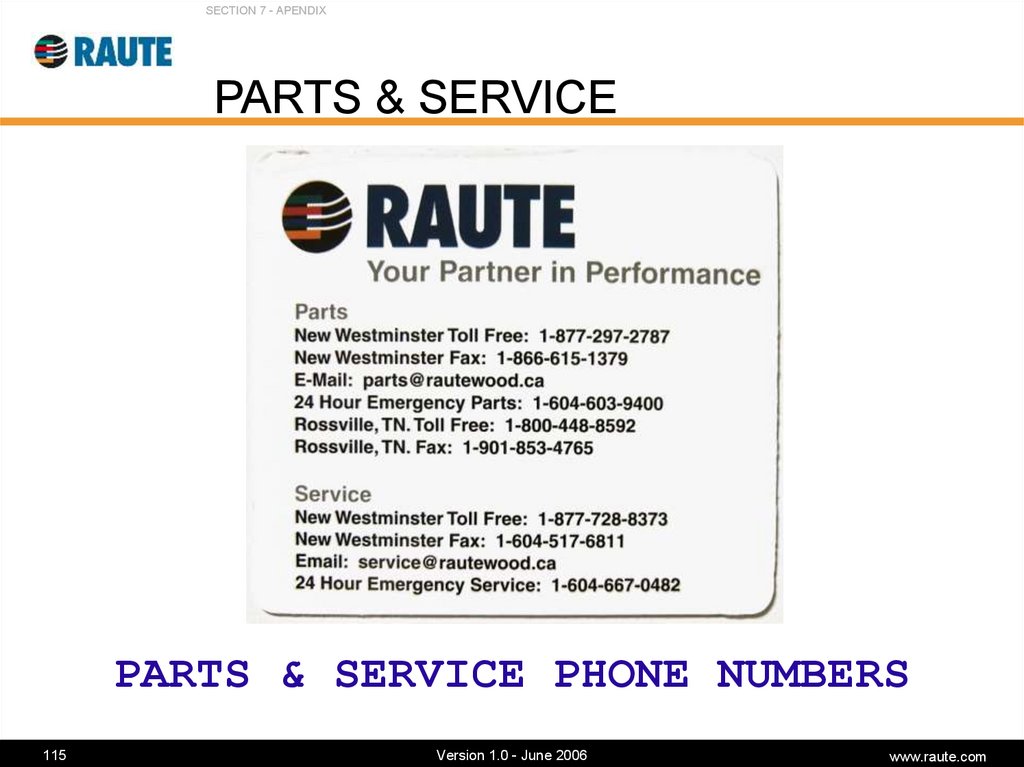

115. PARTS & SERVICE

SECTION 7 - APENDIXPARTS & SERVICE

PARTS & SERVICE PHONE NUMBERS

115

Version 1.0 - June 2006

www.raute.com

Образование

Образование