Похожие презентации:

Schoepentoeter Plus: Message to Sales

1. Schoepentoeter Plus: Message to Sales

Sulzer Chemtech – Moving AheadSchoepentoeter Plus: Message to Sales

Giuseppe Mosca; Pierre Schaeffer; Bart Griepsma | January 2010

Sulzer Chemtech

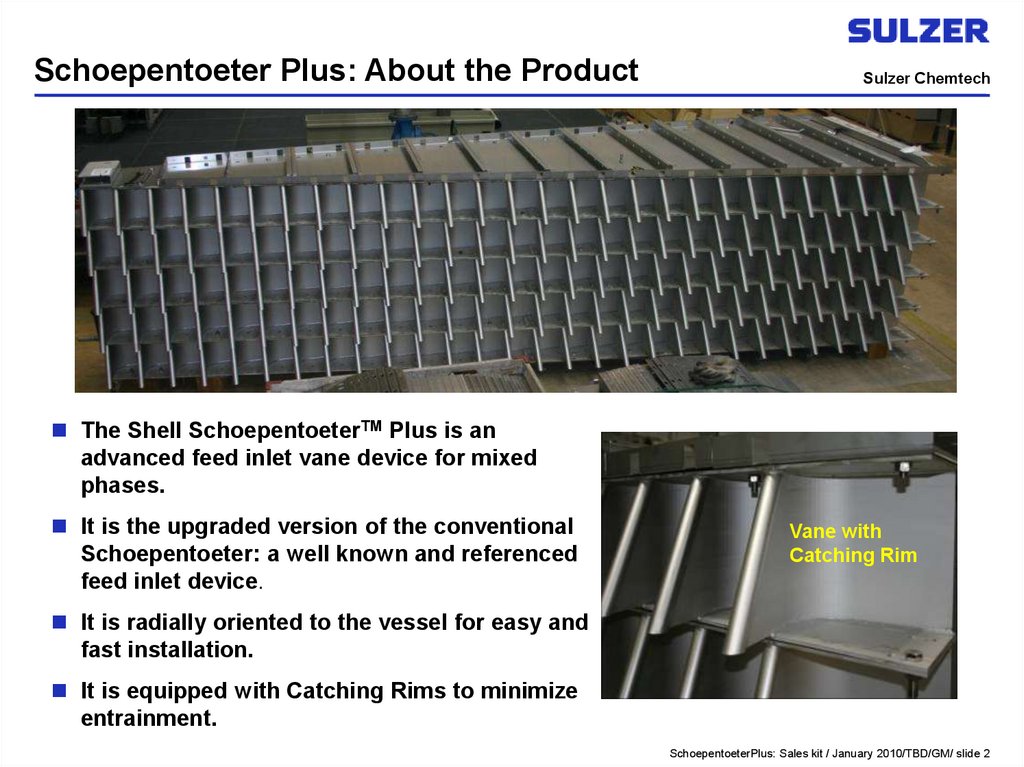

2. Schoepentoeter Plus: About the Product

Sulzer ChemtechThe Shell SchoepentoeterTM Plus is an

advanced feed inlet vane device for mixed

phases.

It is the upgraded version of the conventional

Schoepentoeter: a well known and referenced

feed inlet device.

Vane with

Catching Rim

It is radially oriented to the vessel for easy and

fast installation.

It is equipped with Catching Rims to minimize

entrainment.

SchoepentoeterPlus: Sales kit / January 2010/TBD/GM/ slide 2

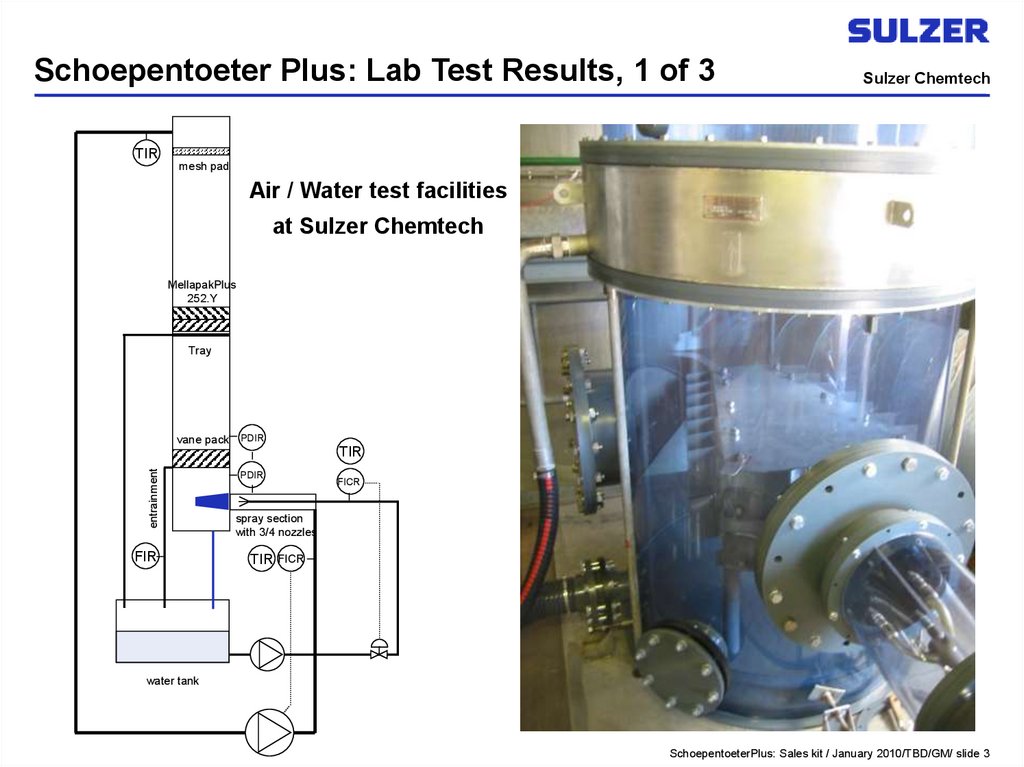

3. Schoepentoeter Plus: Lab Test Results, 1 of 3

Sulzer ChemtechTIR

mesh pad

Air / Water test facilities

at Sulzer Chemtech

MellapakPlus

252.Y

Tray

vane pack PDIR

entrainment

TIR

FIR

PDIR

FICR

spray section

with 3/4 nozzles

TIR FICR

water tank

SchoepentoeterPlus: Sales kit / January 2010/TBD/GM/ slide 3

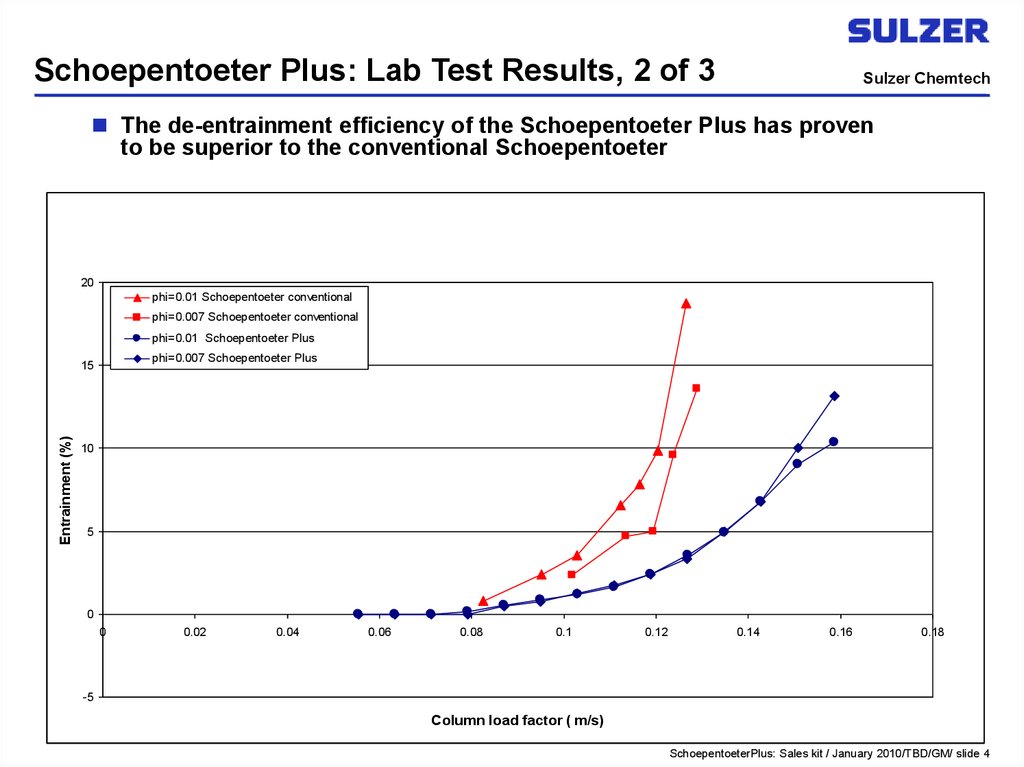

4. Schoepentoeter Plus: Lab Test Results, 2 of 3

Sulzer ChemtechThe de-entrainment efficiency of the Schoepentoeter Plus has proven

to be superior to the conventional Schoepentoeter

20

phi=0.01 Schoepentoeter conventional

phi=0.007 Schoepentoeter conventional

phi=0.01 Schoepentoeter Plus

phi=0.007 Schoepentoeter Plus

Entrainment (%)

15

10

5

0

0

0.02

0.04

0.06

0.08

0.1

0.12

0.14

0.16

0.18

-5

Column load factor ( m/s)

SchoepentoeterPlus: Sales kit / January 2010/TBD/GM/ slide 4

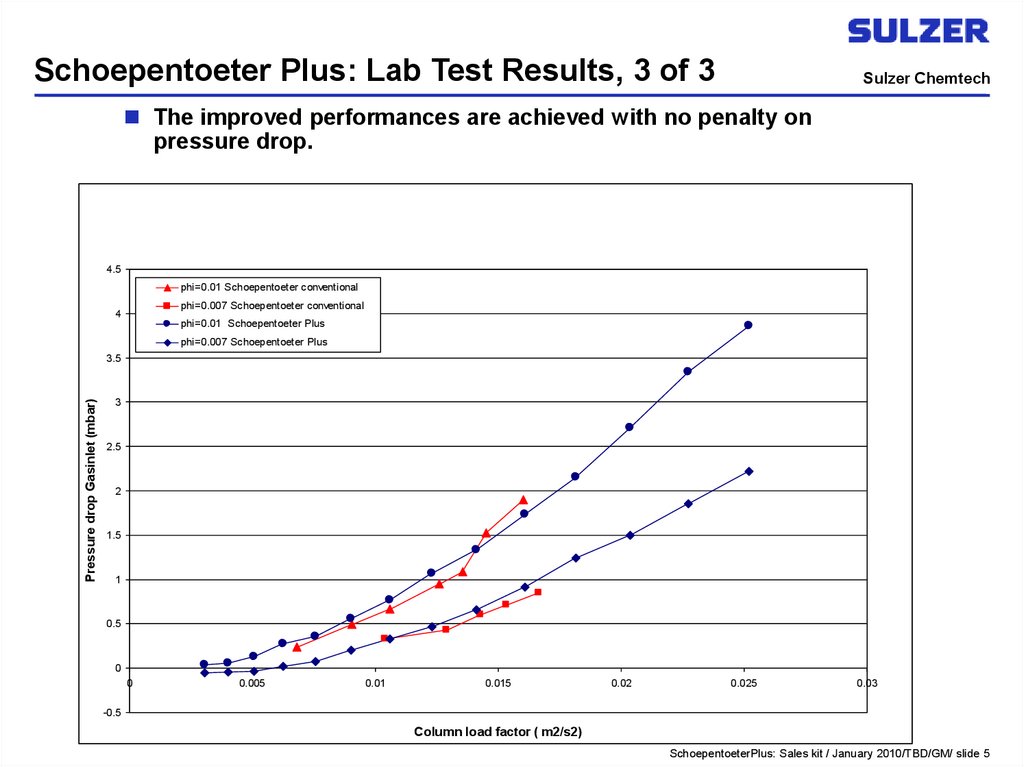

5. Schoepentoeter Plus: Lab Test Results, 3 of 3

Sulzer ChemtechThe improved performances are achieved with no penalty on

pressure drop.

4.5

phi=0.01 Schoepentoeter conventional

phi=0.007 Schoepentoeter conventional

4

phi=0.01 Schoepentoeter Plus

phi=0.007 Schoepentoeter Plus

Pressure drop Gasinlet (mbar)

3.5

3

2.5

2

1.5

1

0.5

0

0

0.005

0.01

0.015

0.02

0.025

0.03

-0.5

Column load factor ( m2/s2)

SchoepentoeterPlus: Sales kit / January 2010/TBD/GM/ slide 5

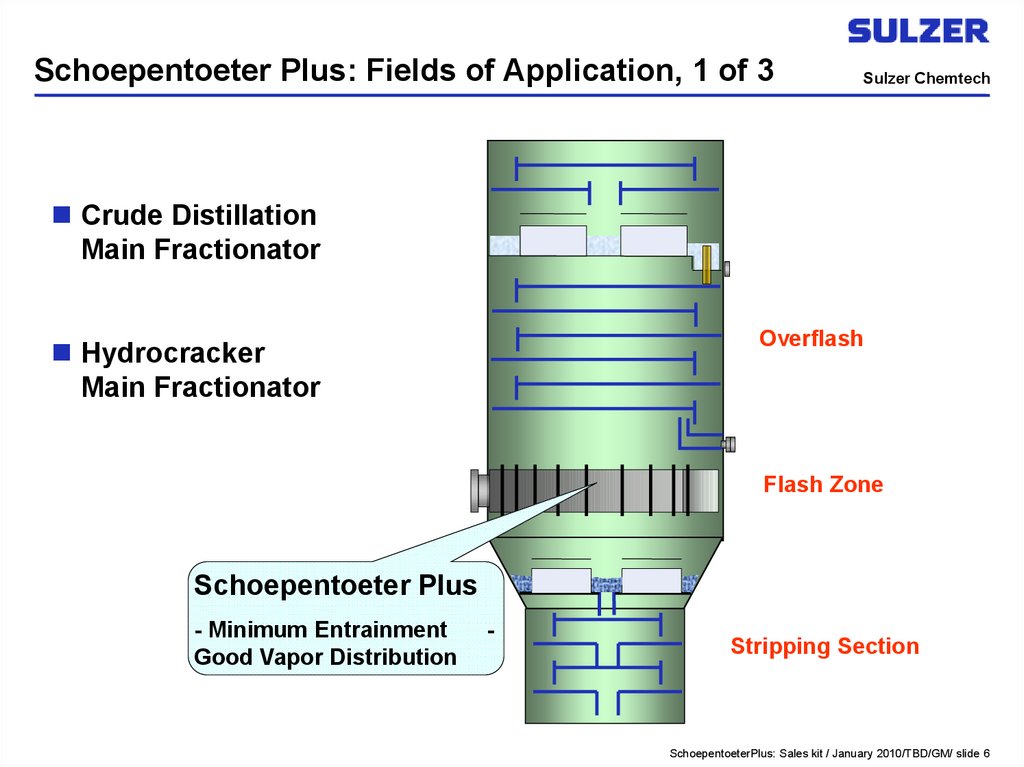

6. Schoepentoeter Plus: Fields of Application, 1 of 3

Sulzer ChemtechCrude Distillation

Main Fractionator

Overflash

Hydrocracker

Main Fractionator

Flash Zone

Schoepentoeter Plus

- Minimum Entrainment

Good Vapor Distribution

-

Stripping Section

SchoepentoeterPlus: Sales kit / January 2010/TBD/GM/ slide 6

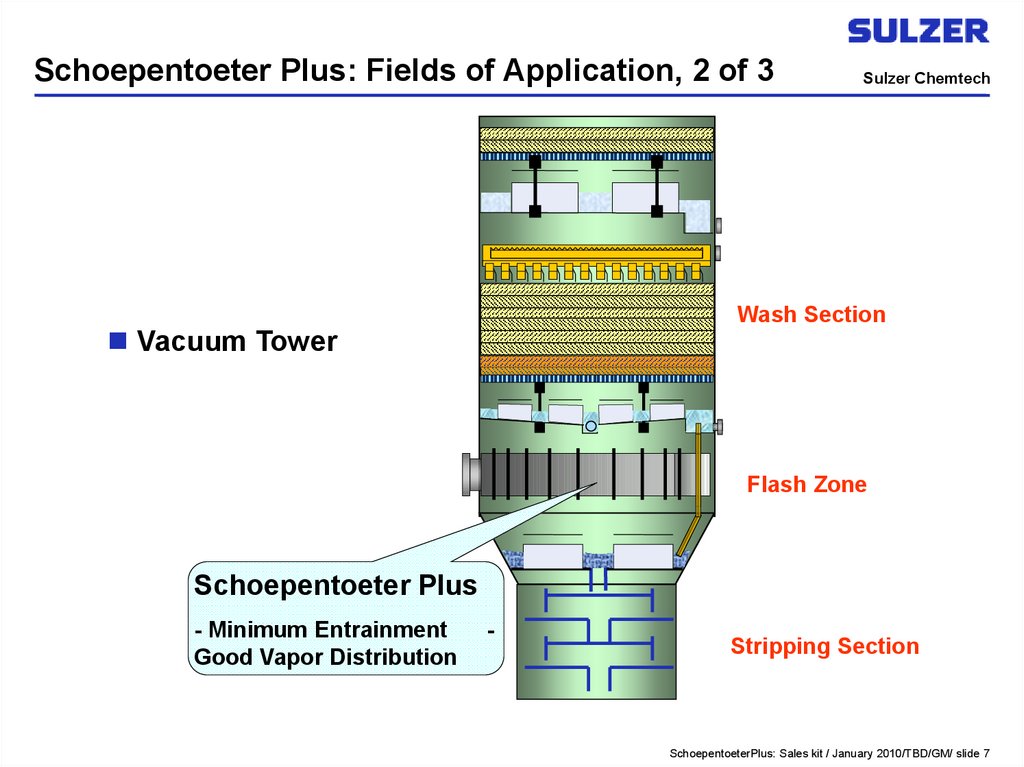

7. Schoepentoeter Plus: Fields of Application, 2 of 3

Sulzer ChemtechWash Section

Vacuum Tower

Flash Zone

Schoepentoeter Plus

- Minimum Entrainment

Good Vapor Distribution

-

Stripping Section

SchoepentoeterPlus: Sales kit / January 2010/TBD/GM/ slide 7

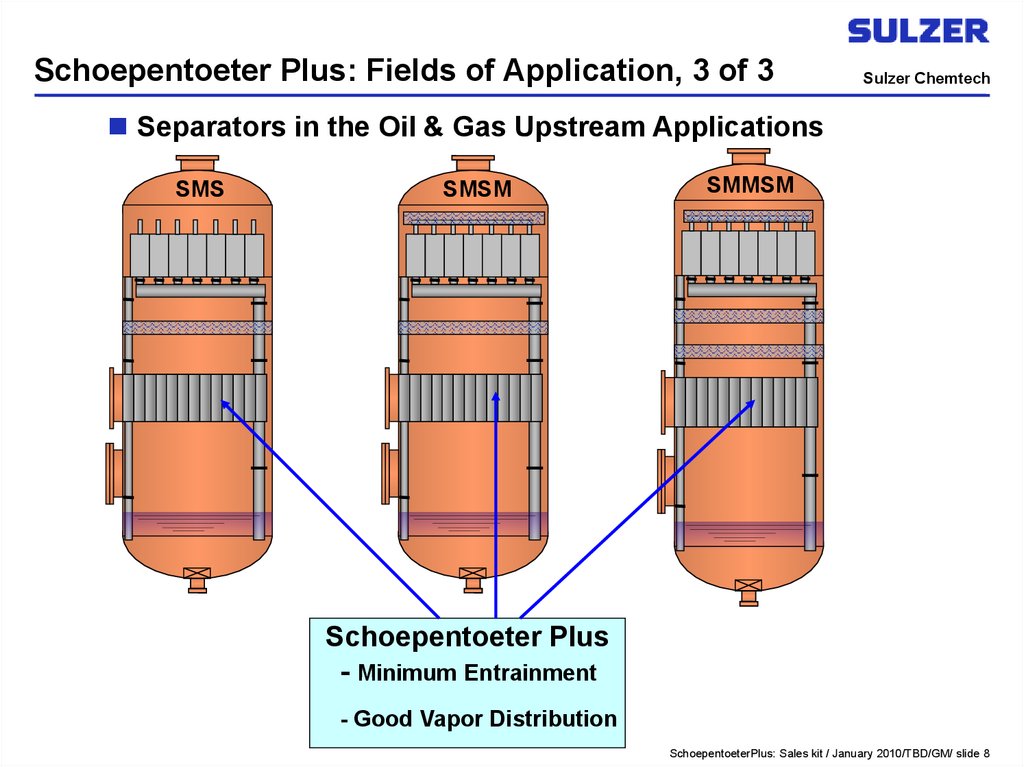

8. Schoepentoeter Plus: Fields of Application, 3 of 3

Sulzer ChemtechSeparators in the Oil & Gas Upstream Applications

SMS

SMSM

SMMSM

Schoepentoeter Plus

- Minimum Entrainment

- Good Vapor Distribution

SchoepentoeterPlus: Sales kit / January 2010/TBD/GM/ slide 8

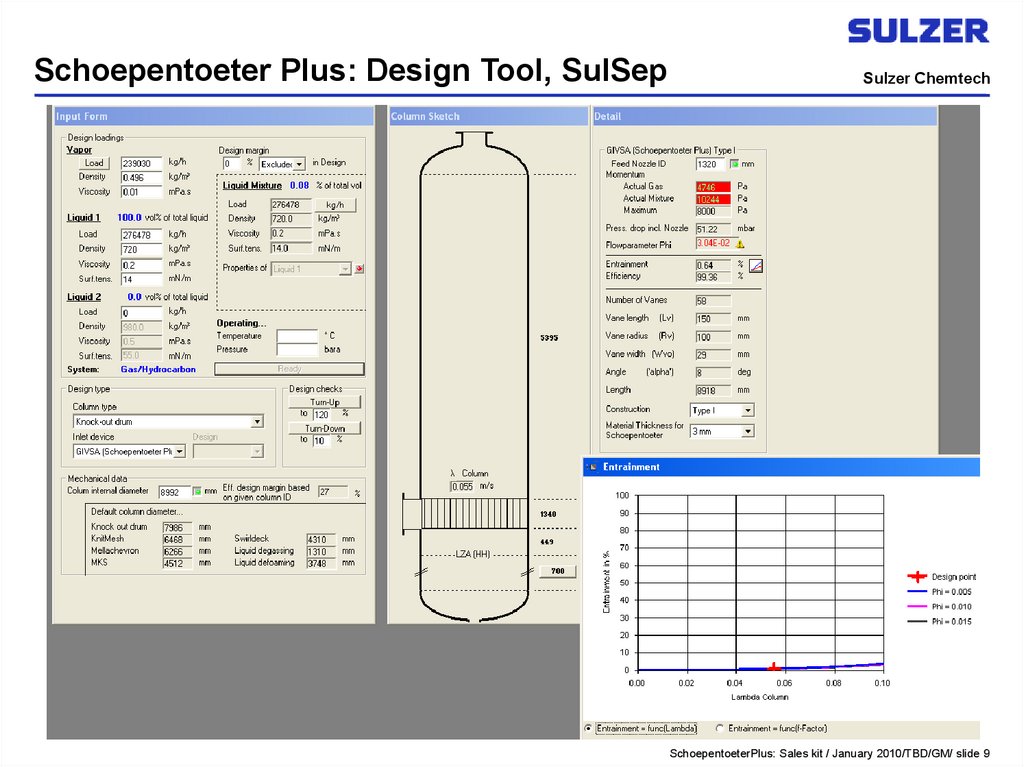

9. Schoepentoeter Plus: Design Tool, SulSep

Sulzer ChemtechSchoepentoeterPlus: Sales kit / January 2010/TBD/GM/ slide 9

10. Schoepentoeter Plus: Costing

Sulzer ChemtechSchoepentoeter Plus is generally more expensive

than the conventional one; the delta depends on

column diameter and type of material.

Presently, Costs estimation can only be done by Bart

Griepsma.

It will be included in Sulprice by June 2010.

SchoepentoeterPlus: Sales kit / January 2010/TBD/GM/ slide 10

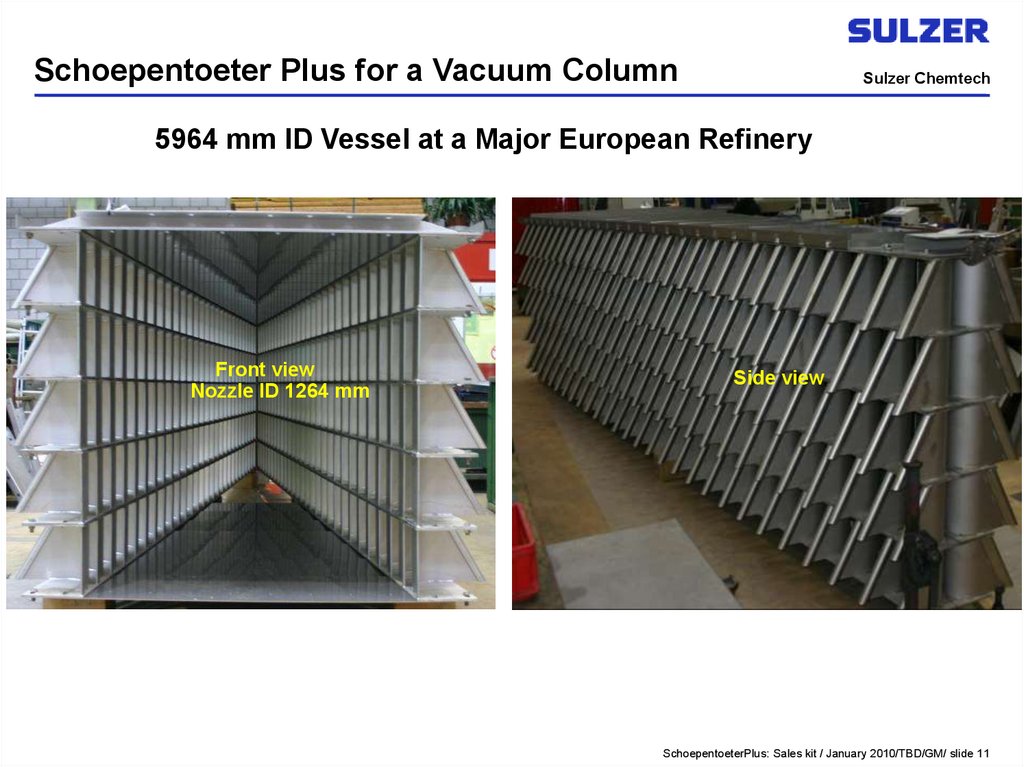

11. Schoepentoeter Plus for a Vacuum Column

Sulzer Chemtech5964 mm ID Vessel at a Major European Refinery

Front view

Nozzle ID 1264 mm

Side view

SchoepentoeterPlus: Sales kit / January 2010/TBD/GM/ slide 11

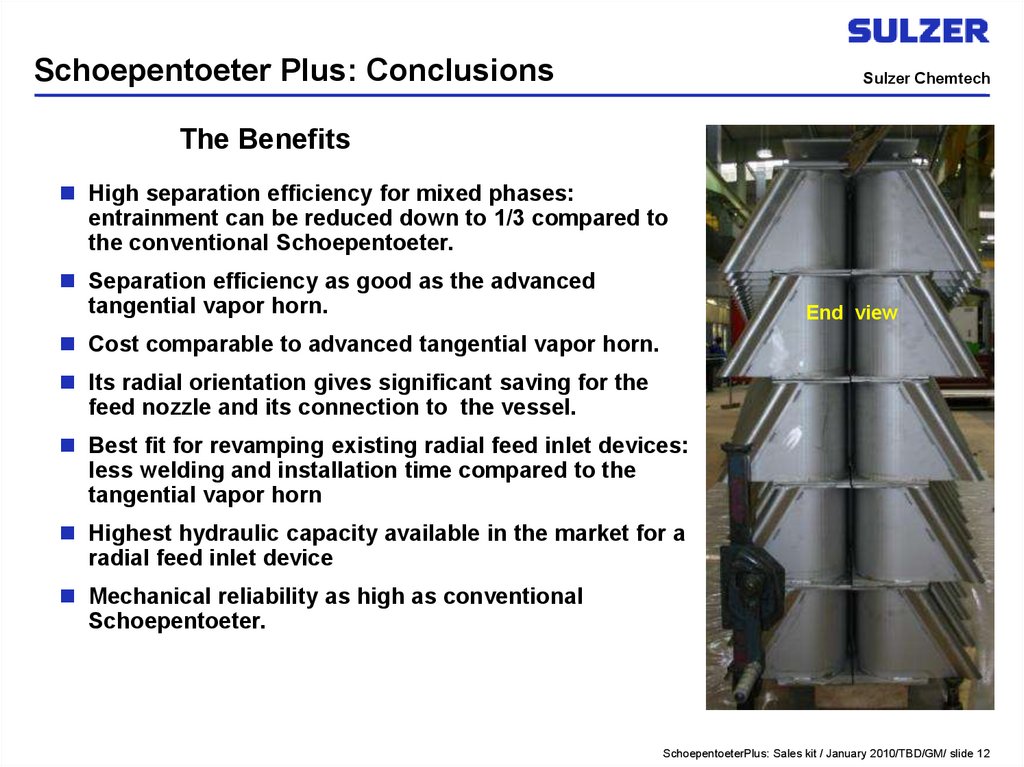

12. Schoepentoeter Plus: Conclusions

Sulzer ChemtechThe Benefits

High separation efficiency for mixed phases:

entrainment can be reduced down to 1/3 compared to

the conventional Schoepentoeter.

Separation efficiency as good as the advanced

tangential vapor horn.

End view

Cost comparable to advanced tangential vapor horn.

Its radial orientation gives significant saving for the

feed nozzle and its connection to the vessel.

Best fit for revamping existing radial feed inlet devices:

less welding and installation time compared to the

tangential vapor horn

Highest hydraulic capacity available in the market for a

radial feed inlet device

Mechanical reliability as high as conventional

Schoepentoeter.

SchoepentoeterPlus: Sales kit / January 2010/TBD/GM/ slide 12

Маркетинг

Маркетинг