Похожие презентации:

Furnaces bases operation

1.

FURNACES BASESOPERATION

Th Roustan DT Melting 09/2021

2.

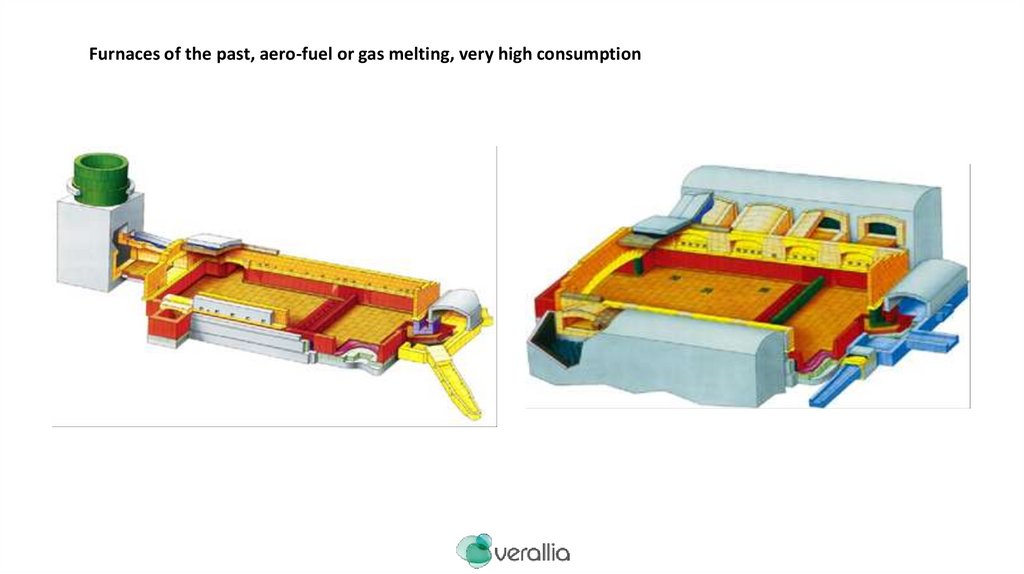

Furnaces of the past, aero-fuel or gas melting, very high consumption3.

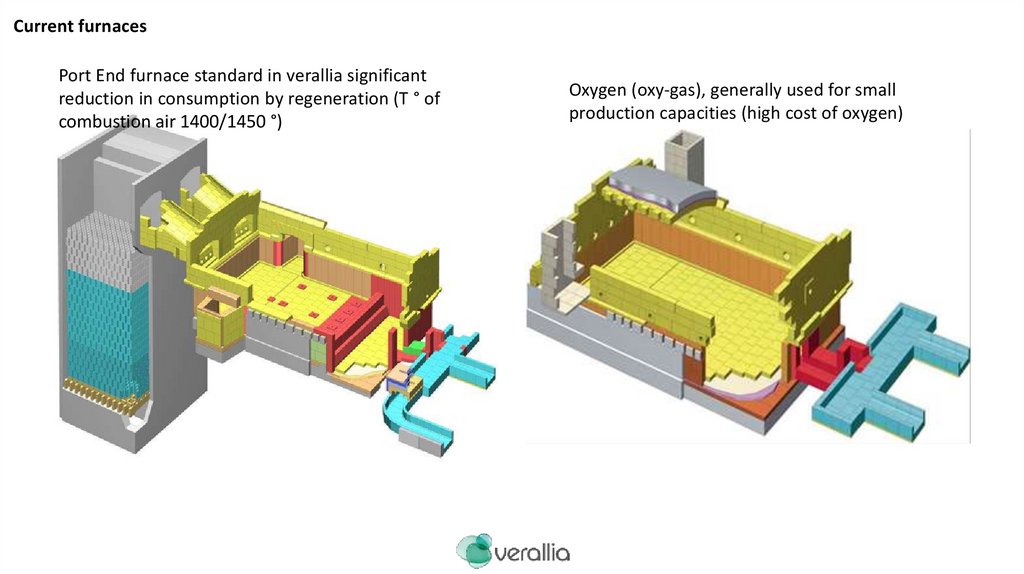

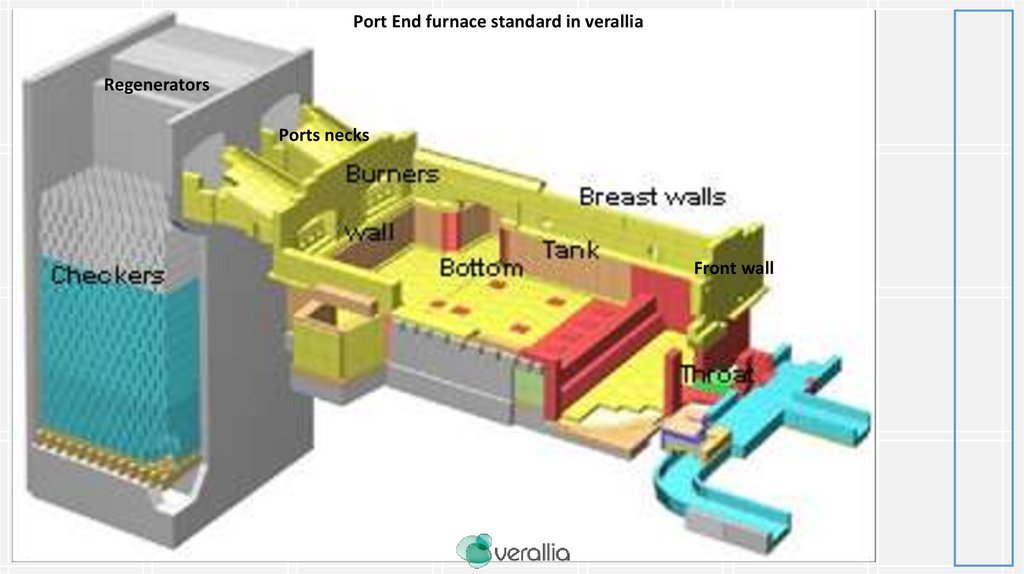

Current furnacesPort End furnace standard in verallia significant

reduction in consumption by regeneration (T ° of

combustion air 1400/1450 °)

Oxygen (oxy-gas), generally used for small

production capacities (high cost of oxygen)

4.

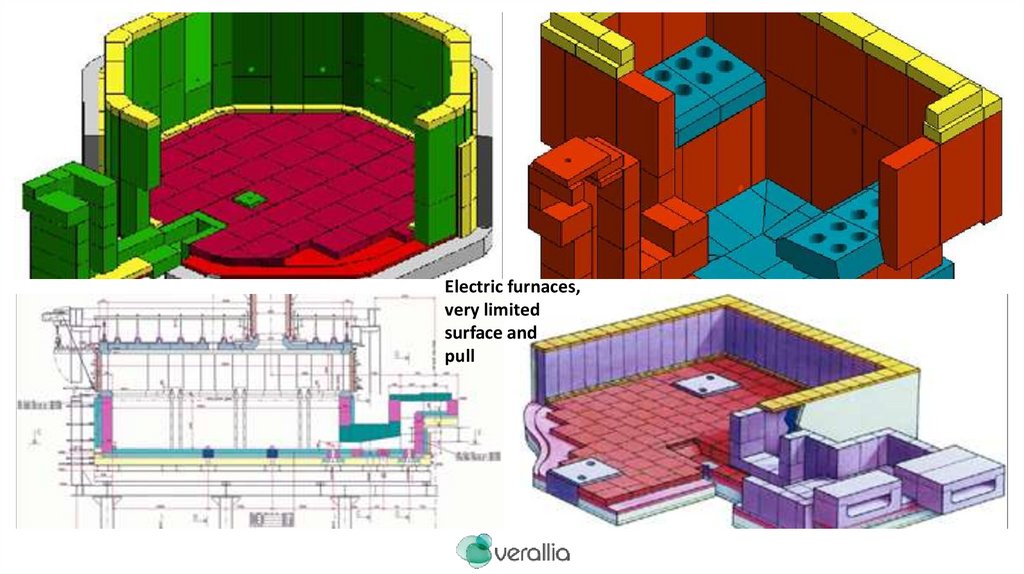

Electric furnaces,very limited

surface and

pull

5.

Port End furnace standard in veralliaRegenerators

Ports necks

Front wall

6.

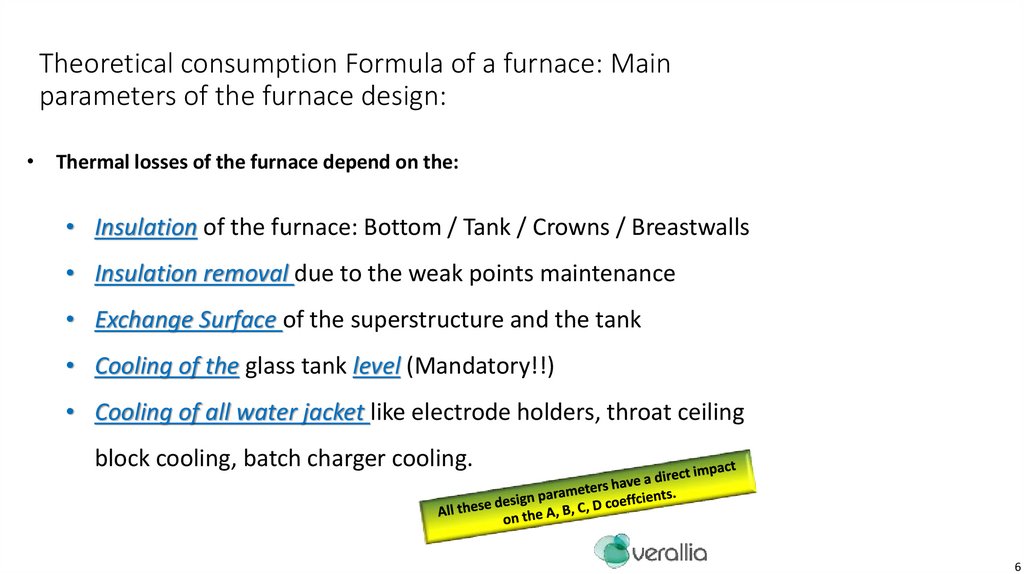

Theoretical consumption Formula of a furnace: Mainparameters of the furnace design:

• Thermal losses of the furnace depend on the:

• Insulation of the furnace: Bottom / Tank / Crowns / Breastwalls

• Insulation removal due to the weak points maintenance

• Exchange Surface of the superstructure and the tank

• Cooling of the glass tank level (Mandatory!!)

• Cooling of all water jacket like electrode holders, throat ceiling

block cooling, batch charger cooling.

6

7.

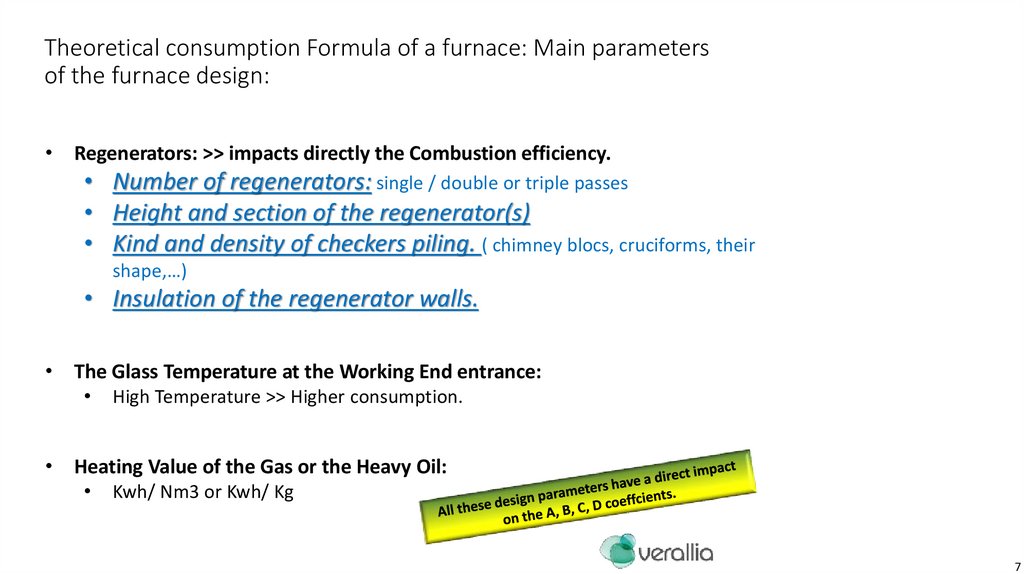

Theoretical consumption Formula of a furnace: Main parametersof the furnace design:

• Regenerators: >> impacts directly the Combustion efficiency.

• Number of regenerators: single / double or triple passes

• Height and section of the regenerator(s)

• Kind and density of checkers piling. ( chimney blocs, cruciforms, their

shape,…)

• Insulation of the regenerator walls.

• The Glass Temperature at the Working End entrance:

High Temperature >> Higher consumption.

• Heating Value of the Gas or the Heavy Oil:

Kwh/ Nm3 or Kwh/ Kg

7

8.

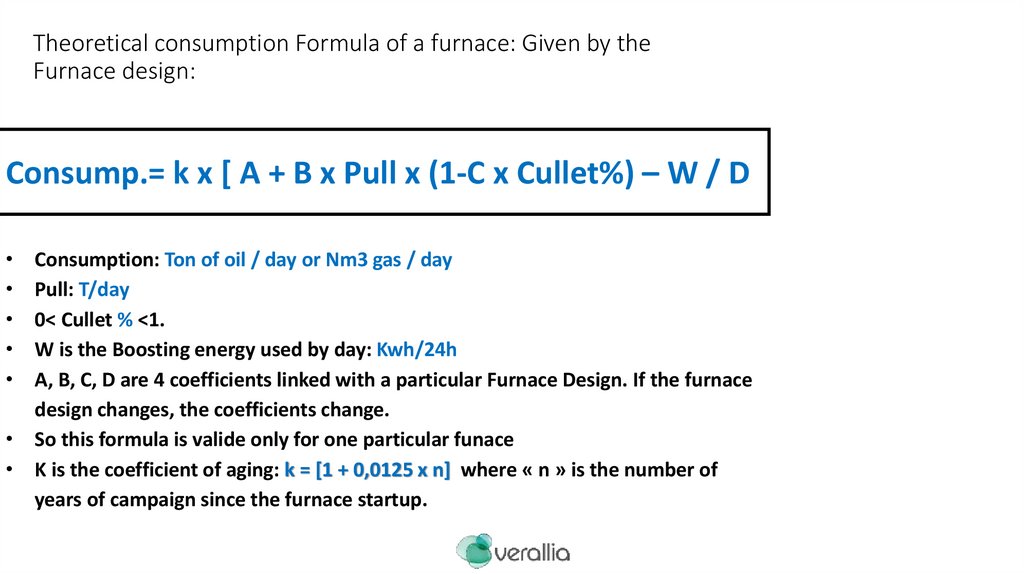

Theoretical consumption Formula of a furnace: Given by theFurnace design:

Consump.= k x [ A + B x Pull x (1-C x Cullet%) – W / D

Consumption: Ton of oil / day or Nm3 gas / day

Pull: T/day

0< Cullet % <1.

W is the Boosting energy used by day: Kwh/24h

A, B, C, D are 4 coefficients linked with a particular Furnace Design. If the furnace

design changes, the coefficients change.

• So this formula is valide only for one particular funace

• K is the coefficient of aging: k = [1 + 0,0125 x n] where « n » is the number of

years of campaign since the furnace startup.

9.

Furnace Operation & Steering:The operation parameter necessary for a good steering: With pull or cullet%

or boosting Power changes.

IS Machines Production changes management:

It is necessary to plan precise pull changes and the production must respect the hour of changes, otherwise

it’s not possible to control the furnace energy and temperatures.

Change time and pull variation clearly defined for each IS machine.

Purge a forehearth with uncontroled pull to recover fast the setpoint temperatures at the last moment is a

current practice to be prohibited. No possible control of the furnace pull, no time to react in real time, loss of furnace

temperatures, delay to be compensated, and final T variations in the working end.

Put clear instructions to ajust the furnace total power and the time of each machines pull changes.

Use the excel sheet software to do the power calculation.

The Excel file is setup with particular Coefficients relative to one single furnace .

It takes in consideration the furnace aging (date of startup), the pull , the electrical power and total cullet %

variations.

10.

Furnace Operation & Steering:Flint Glass

• In the production of flint or extra flint glass (low concentration of iron oxide Fe2O3), the transmission of

energy in the glass (infrared spectrum) is sufficient to transmit the energy to the bottom (1.5m).

• Up to 2.9 t / m² of pull, the T ° of the crowns is gradually adjusted (only by fossil fuels) between 1550 and

1620 °.

• As soon as the pull reaches 2.9t (coverage of the glass surface overcrowding), the boosting will be started and

gradually adjusted according to the bottom T°.

• Bottom T° beyond 1300 ° (through equivalent) are excessive and unnecessary (energy cost, premature

corrosion of infrastructures, the relationship between T ° of glass and corrosion of refractory is expotential)

• Economical control: daily energy saving work is necessary (excluding pull change time), maintaining the T ° to

have sufficient quality (quality specifications), i.e. just above the threshold for the appearance of melting

defects (low consumption and low corrosion of the furnace). From 2.9 t / m² the energy adjustment is carried

out by boosting (for this pull you must absolutely melt the raw materials correctly, silica inclusions)

11.

Furnace Operation & Steering:Dark Glass

• Dark Reduced Glass (High concentration of Fe2O3 and FeO):

• In the production of colored glass the transmission of energy by the flames is very reduced

(maximum 300mm of depth), to activate the convection it will be necessary to add electric

boosting, (a furnace which has a low convection will produce a glass with a lot of of

nephelinization inclusion defects, seeds).

• The raw materials are melted by the flames (maximum T ° beyond pull sup or equal to 2.1 t / m²),

then we will adjust the electric boosting to have a correct convection (the T ° of bottom dog

houses, middle before dam and WE raiser)

• Bottom T° beyond 1300 ° (through equivalent) are excessive and unnecessary (energy cost,

premature corrosion of infrastructures, the relationship between T ° of glass and corrosion of

refractory is expotential

• Economical control: daily energy saving work is necessary (excluding pull change time),

maintaining the T ° to have sufficient quality (quality specifications), i.e. just above the threshold

for the appearance of melting defects (low consumption and low corrosion of the furnace). The

energy adjustment is carried out by boosting, from 2.1 t / m² the T ° of the crowns are stabilized

between 1610/20 ° (you must absolutely melt the raw materials correctly, silica inclusions)

12.

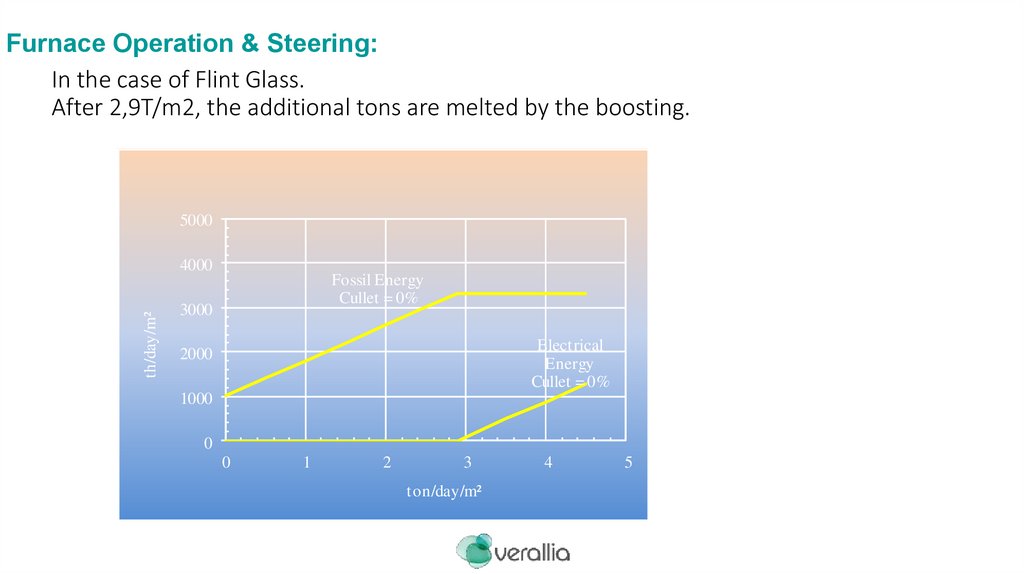

Furnace Operation & Steering:In the case of Flint Glass.

After 2,9T/m2, the additional tons are melted by the boosting.

5000

th/day/m²

4000

Fossil Energy

Cullet = 0%

3000

Electrical

Energy

Cullet = 0%

2000

1000

0

0

1

2

3

ton/day/m²

4

5

13.

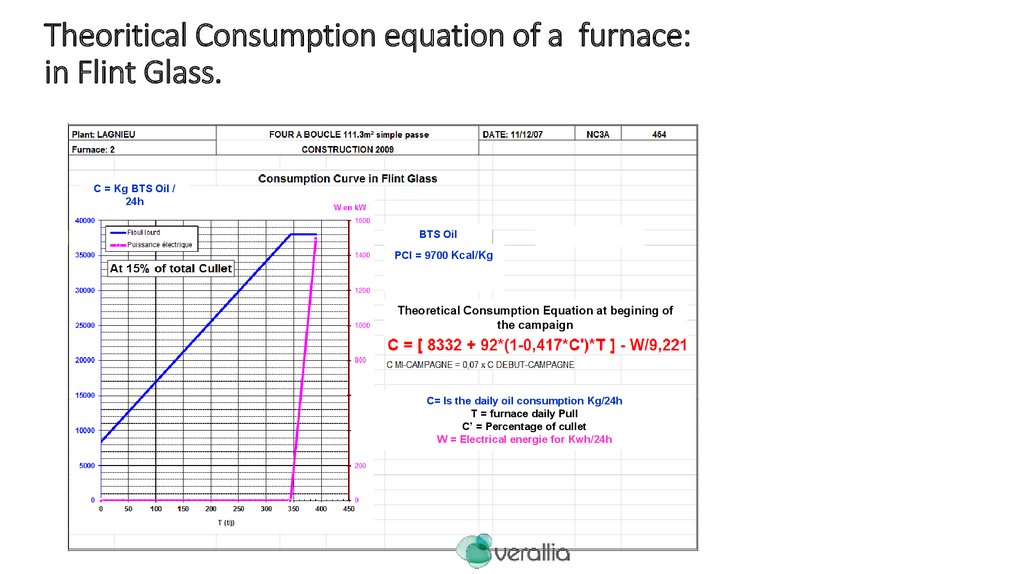

Theoritical Consumption equation of a furnace:in Flint Glass.

C = Kg BTS Oil /

24h

BTS Oil

PCI = 9700 Kcal/Kg

Theoretical Consumption Equation at begining of

the campaign

C= Is the daily oil consumption Kg/24h

T = furnace daily Pull

C’ = Percentage of cullet

W = Electrical energie for Kwh/24h

14.

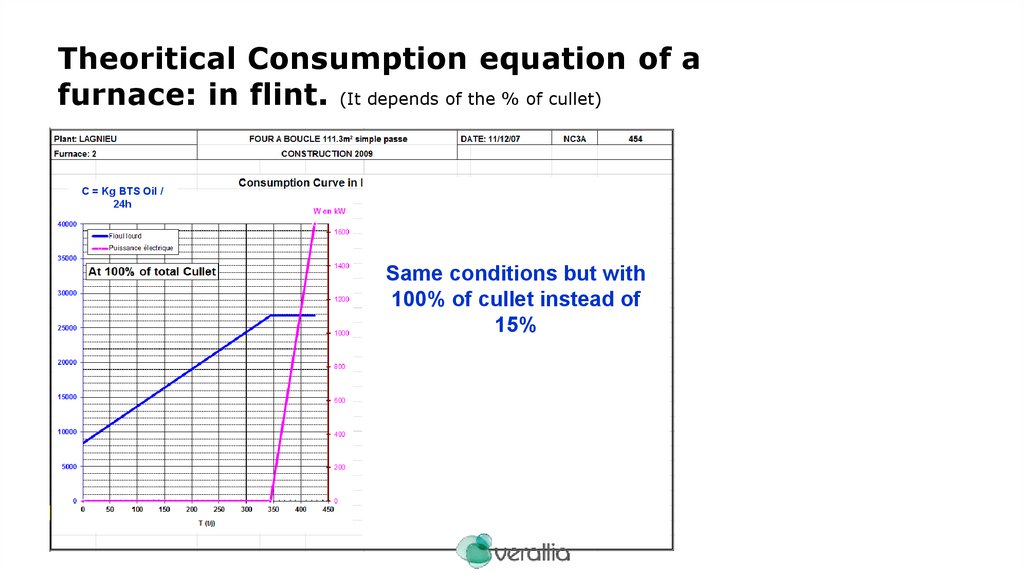

Theoritical Consumption equation of afurnace: in flint. (It depends of the % of cullet)

C = Kg BTS Oil /

24h

Same conditions but with

100% of cullet instead of

15%

15.

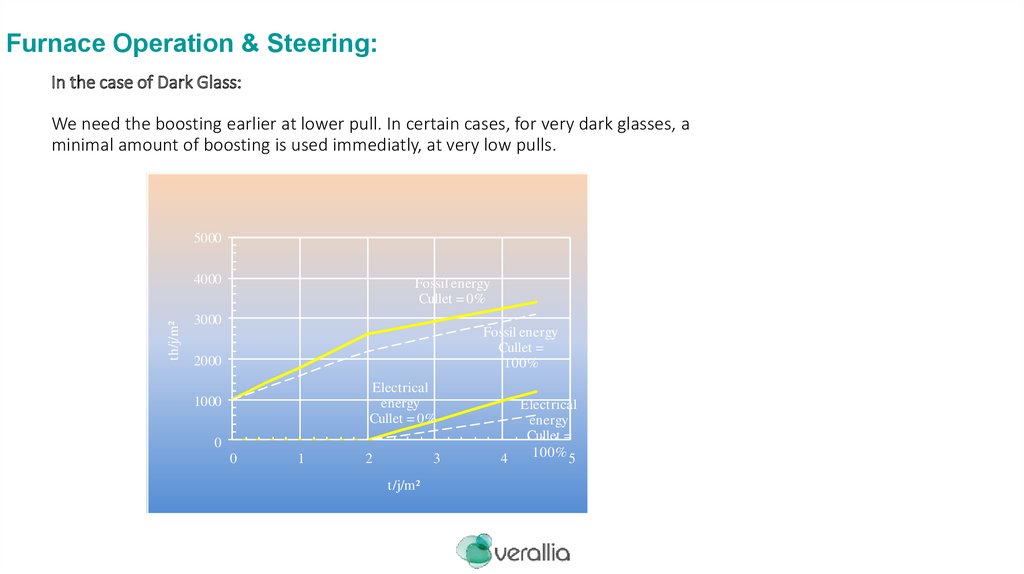

Furnace Operation & Steering:In the case of Dark Glass:

We need the boosting earlier at lower pull. In certain cases, for very dark glasses, a

minimal amount of boosting is used immediatly, at very low pulls.

5000

th/j/m²

4000

Fossil energy

Cullet = 0%

3000

Fossil energy

Cullet =

100%

2000

Electrical

energy

Cullet = 0%

1000

0

0

1

2

3

t/j/m²

Electrical

energy

Cullet =

100% 5

4

16.

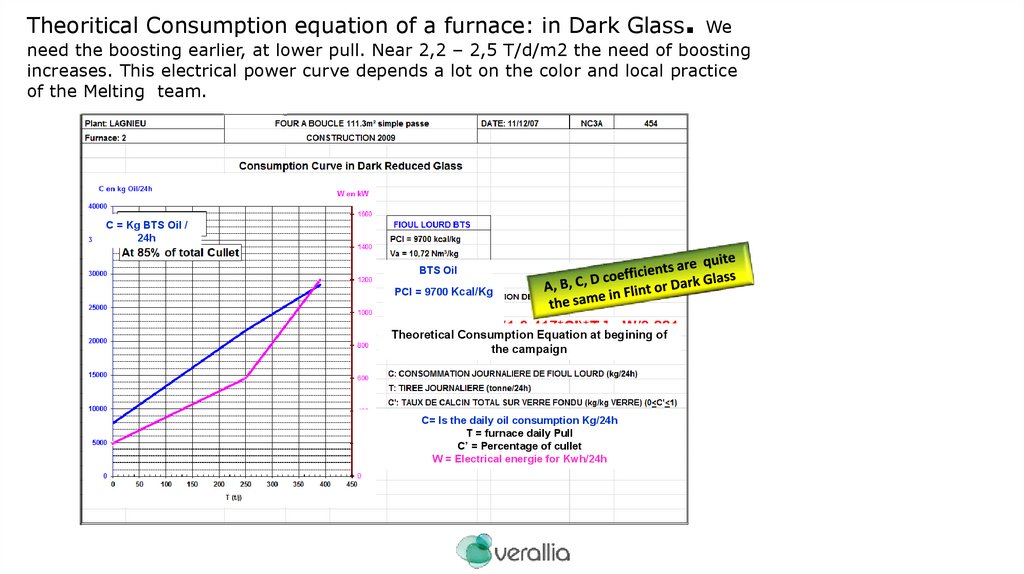

Theoritical Consumption equation of a furnace: in Dark Glass.We

need the boosting earlier, at lower pull. Near 2,2 – 2,5 T/d/m2 the need of boosting

increases. This electrical power curve depends a lot on the color and local practice

of the Melting team.

C = Kg BTS Oil /

24h

BTS Oil

PCI = 9700 Kcal/Kg

Theoretical Consumption Equation at begining of

the campaign

C= Is the daily oil consumption Kg/24h

T = furnace daily Pull

C’ = Percentage of cullet

W = Electrical energie for Kwh/24h

17.

Furnace Operation & Steering:Optical Furnace superstructure Temperature control: Crowns silica Backup

Fast Control of the crowns temperatures profil above the flames:

(confortable and fast in case of doubt)

From the opposite breastwalls peephole in front of the flames.

Remove 20°C from the measurements (to consider the flame

presence ).

It’s a fast control, that allows in two reversal times (L/R) to have a

quite clear vision of the flame power distribution inside the furnace

laboratory and to check also the crowns thermocouples condition.

Very convenient in case of defecting or missing crown

thermocouples or bad thermocouples tip position (too inside or too

outside, compared to the crowns inner surface).

2 minutes before the end of flame time.

Target the crown silica above the flame on Ring 1, Ring 2 and Ring 3

if there is one.

18.

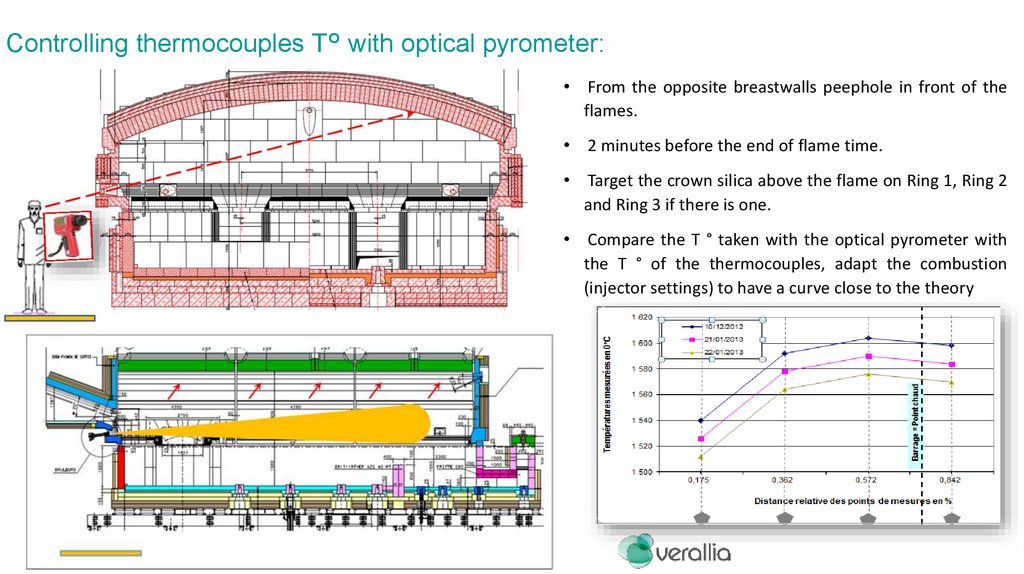

Controlling thermocouples T° with optical pyrometer:Optical

Furnace

Temperature

control:

Backup

superstructure

Crowns

silica

Fast

Control

of

the

crowns

temperatures

profil

above

the

flames:

(confortable and fast in case of doubt)

• From the opposite breastwalls peephole in front of the

flames.

• 2 minutes before the end of flame time.

• Target the crown silica above the flame on Ring 1, Ring 2

and Ring 3 if there is one.

• Compare the T ° taken with the optical pyrometer with

the T ° of the thermocouples, adapt the combustion

(injector settings) to have a curve close to the theory

19.

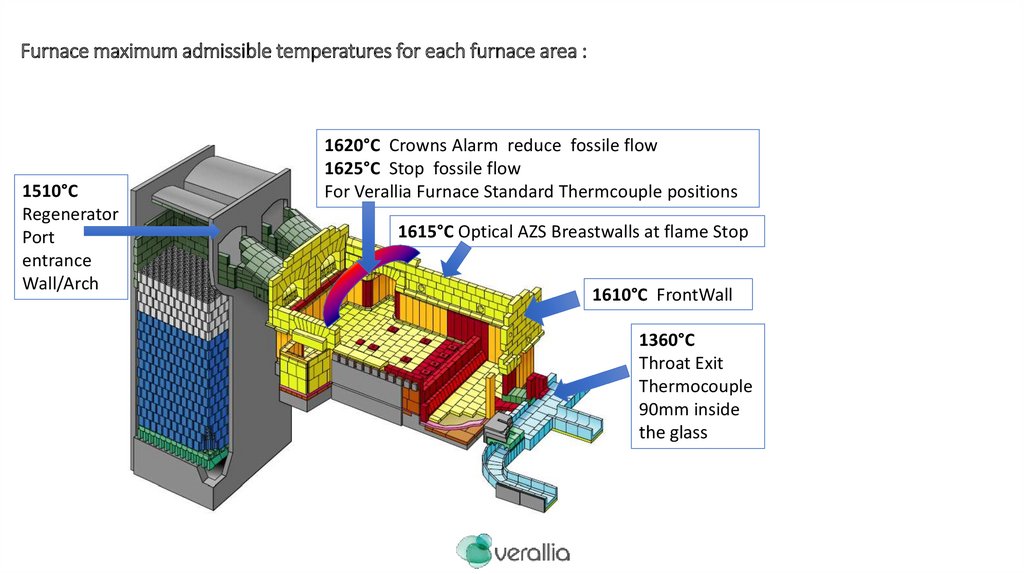

Furnace maximum admissible temperatures for each furnace area :1510°C

Regenerator

Port

entrance

Wall/Arch

1620°C Crowns Alarm reduce fossile flow

1625°C Stop fossile flow

For Verallia Furnace Standard Thermcouple positions

1615°C Optical AZS Breastwalls at flame Stop

1610°C FrontWall

1360°C

Throat Exit

Thermocouple

90mm inside

the glass

20.

Dogs houses : batch piles distributionExemple of batch piles distribution:

OK

NOT OK = Seeds risks

21.

Furnace Operation & Steering:The operation parameters necessary for a good steering: At stable pull.

Which Furnace Steering Setpoints and Why:

On the superstructure:

Combustion parameters: (contrôle des NOx).

Specific thrust Mini – Maxi. (Adaptation of injection diameters)

Inclination / Azimut.

Condition of injectors: Cleanliness and status.

Fumes analyze at the port neck sides (CO 5000ppm maxi, NOx)

Fumes analyzes at the stach, with reaction standard procedure in

case of deviation on CO or NOx

Flame

shape

and

endoscope screen.

development

looking

at

the

front

wall

22.

Electric Boosting :The operation parameters necessary for a good steering: At stable pull.

Which Furnace Steering Setpoints and Why:

On the infrastructure: Tank bottom

Define a pilot thermocouple as the reference temperature (with a setpoint) to drive the

boosting: Ideally melting bottom thermocouple in front of the doghouses, distante from

the electrodes blocks.

The Electrical Power steering is operated following the evolution of the impedance of an

electrode group that changes when the average glass temperature evolves. (fine

tuning).

(Electrical power steering).

When the glass tank temperature decreases (the bottom temperature will

decrease very soon), the conductivity of the glass decreases, so the

impedance of the glass increases, so you must inject more tension to increase

the power, and increase the glass temperature.

+1°C bottom temperature -0,3 mOhm impedance.

-1°C bottom temperature +0,3 mOhm impedance.

It is the finest and fastest way to anticipate any bottom temperature drift!!

Define the step of maximale power variation (KW), and minimum delay before

adjusting the power setpoint another time.

23.

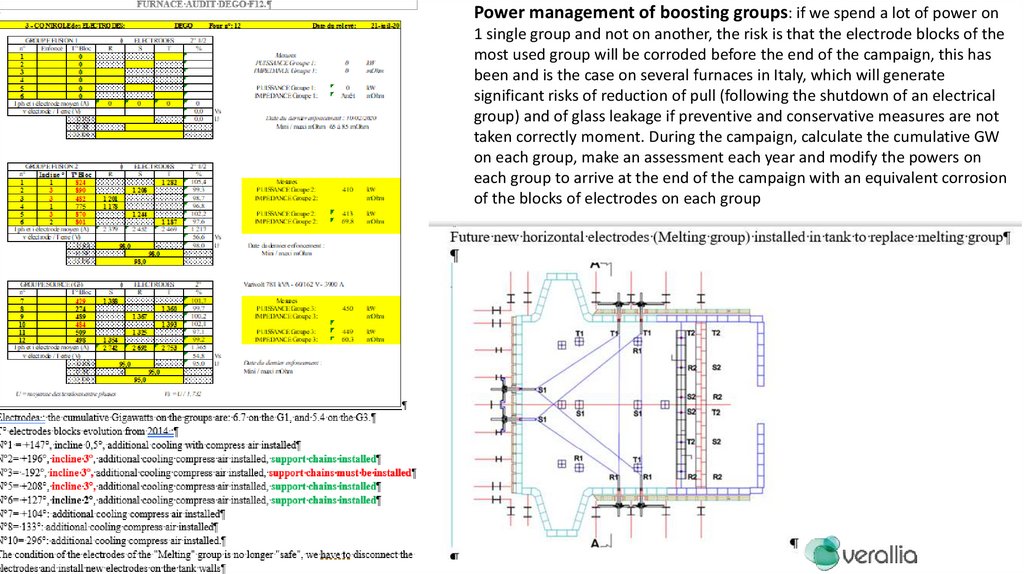

Electric Boosting :The operation parameters necessary for a good steering: At stable pull.

Which Furnace Steering Setpoints and Why:

On the infrastructure: Electrical power steering and distribution.

Power management of boosting groups: if we spend a lot of power on 1 single group and not on another, the risk is that the

electrode blocks of the most used group will be corroded before the end of the campaign, this has been and is the case on several

furnaces in Italy, which will generate significant risks of reduction of pull (following the shutdown of an electrical group) and of

glass leakage if preventive and conservative measures are not taken correctly moment. During the campaign, calculate the

cumulative GW on each group, make an assessment each year and modify the powers on each group to arrive at the end of the

campaign with an equivalent corrosion of the blocks of electrodes on each group

Define and manage the power distribution between the electrode groups G3/G2/G1, and identify which electrode group power will

be adjusted to stabilize the impedance.

In flint glass, put max of power on G3 near the barrage and complete with G2. If G2 is at the maximum, start using G1.

In Dark glass, try to balance the power on each group equally.

Define on which electrode group you steer the boosting power to adjust the impedance and the bottom temperature.

It depends on the power reserve of each group.

24.

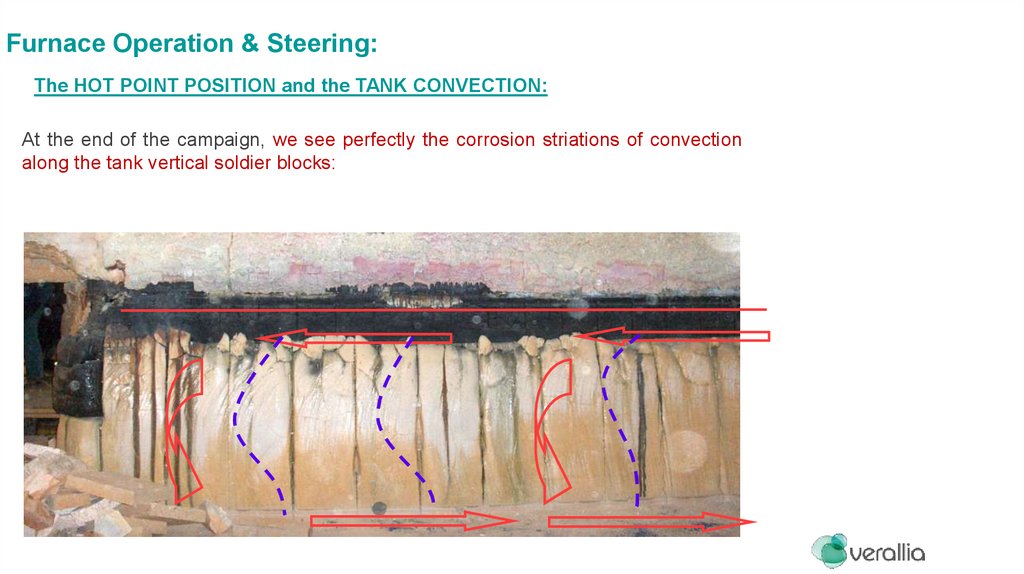

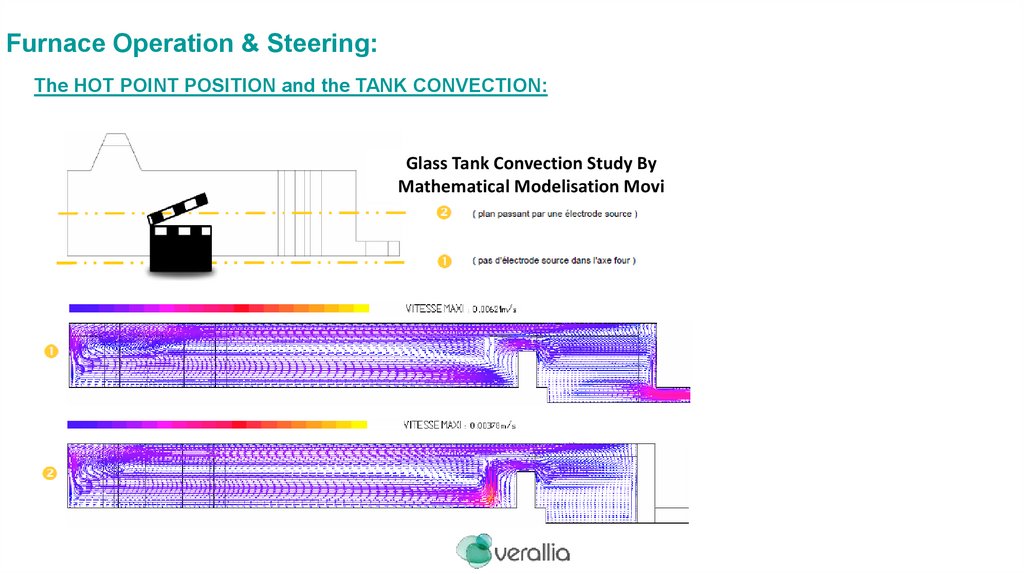

Furnace Operation & Steering:The HOT POINT POSITION and the TANK CONVECTION:

At the end of the campaign, we see perfectly the corrosion striations of convection

along the tank vertical soldier blocks:

D. Grand MP & EV 2012

25.

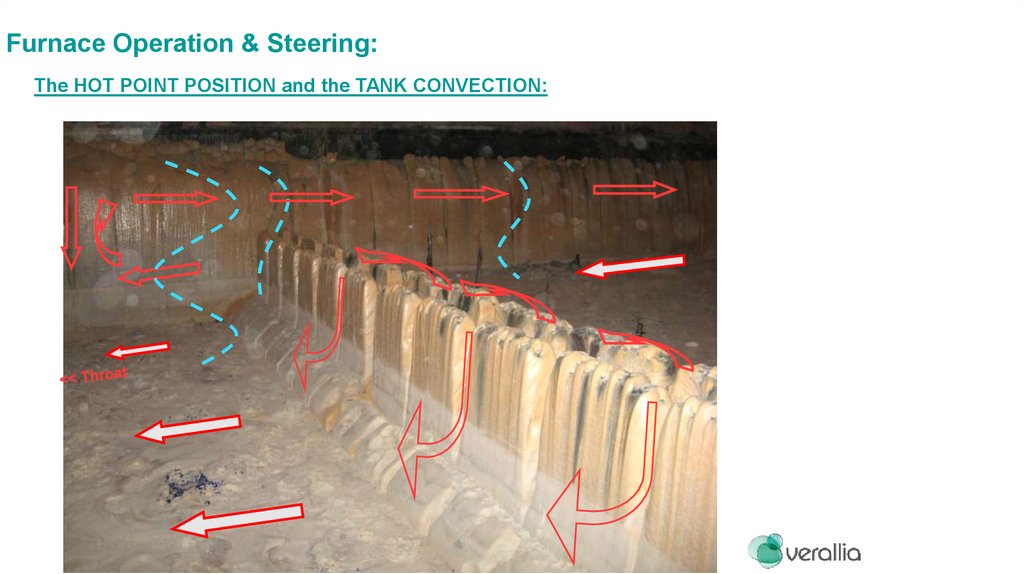

Furnace Operation & Steering:The HOT POINT POSITION and the TANK CONVECTION:

26.

Furnace Operation & Steering:The HOT POINT POSITION and the TANK CONVECTION:

Glass Tank Convection Study By

Mathematical Modelisation Movi

D. Grand MP & EV 2012

27.

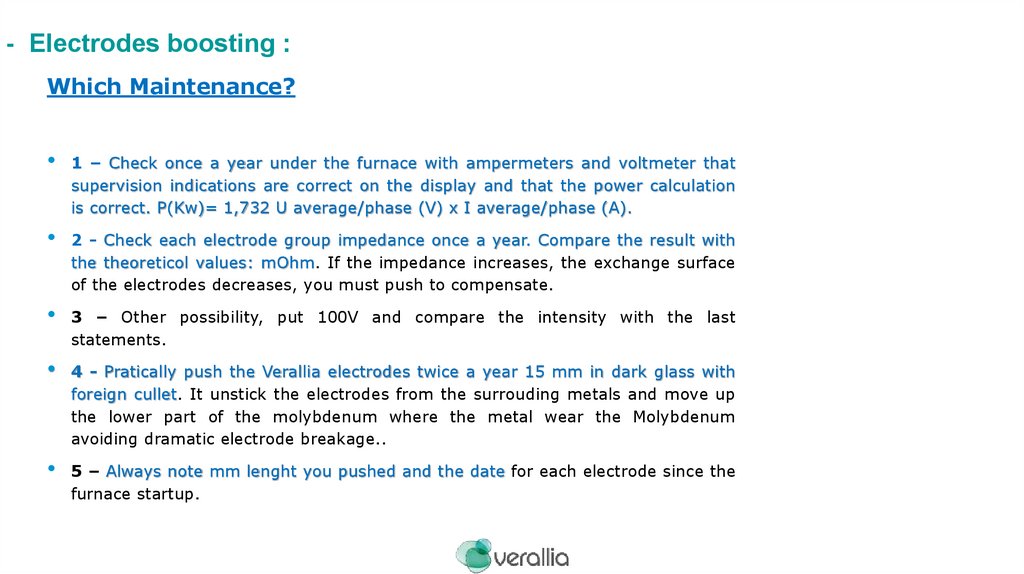

- Electrodes boosting :Which Maintenance?

1 – Check once a year under the furnace with ampermeters and voltmeter that

supervision indications are correct on the display and that the power calculation

is correct. P(Kw)= 1,732 U average/phase (V) x I average/phase (A).

2 - Check each electrode group impedance once a year. Compare the result with

the theoreticol values: mOhm. If the impedance increases, the exchange surface

of the electrodes decreases, you must push to compensate.

3 – Other possibility, put 100V and compare the intensity with the last

statements.

4 - Pratically push the Verallia electrodes twice a year 15 mm in dark glass with

foreign cullet. It unstick the electrodes from the surrouding metals and move up

the lower part of the molybdenum where the metal wear the Molybdenum

avoiding dramatic electrode breakage..

5 – Always note mm lenght you pushed and the date for each electrode since the

furnace startup.

28.

Power management of boosting groups: if we spend a lot of power on1 single group and not on another, the risk is that the electrode blocks of the

most used group will be corroded before the end of the campaign, this has

been and is the case on several furnaces in Italy, which will generate

significant risks of reduction of pull (following the shutdown of an electrical

group) and of glass leakage if preventive and conservative measures are not

taken correctly moment. During the campaign, calculate the cumulative GW

on each group, make an assessment each year and modify the powers on

each group to arrive at the end of the campaign with an equivalent corrosion

of the blocks of electrodes on each group

29.

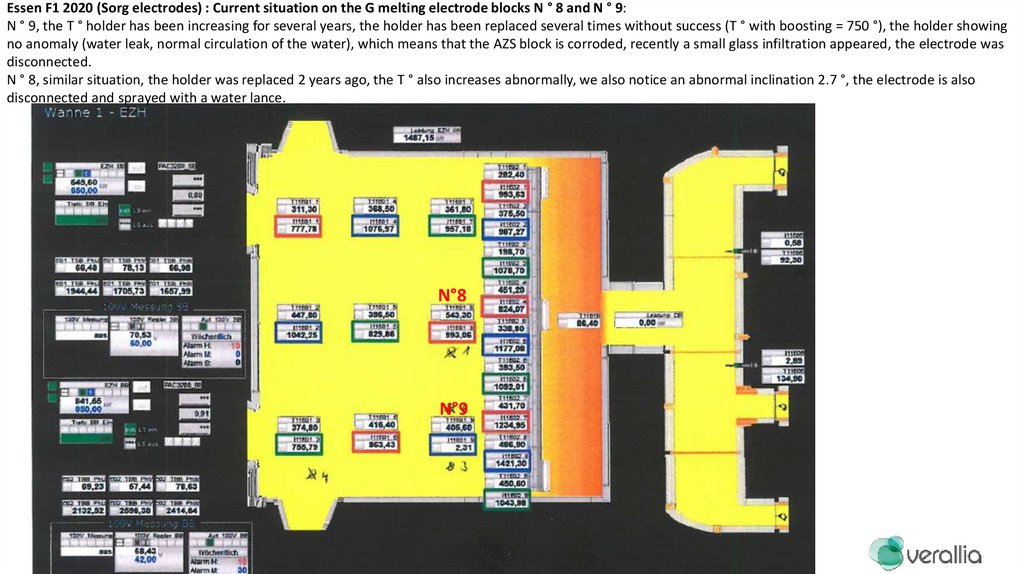

Essen F1 2020 (Sorg electrodes) : Current situation on the G melting electrode blocks N ° 8 and N ° 9:N ° 9, the T ° holder has been increasing for several years, the holder has been replaced several times without success (T ° with boosting = 750 °), the holder showing

no anomaly (water leak, normal circulation of the water), which means that the AZS block is corroded, recently a small glass infiltration appeared, the electrode was

disconnected.

N ° 8, similar situation, the holder was replaced 2 years ago, the T ° also increases abnormally, we also notice an abnormal inclination 2.7 °, the electrode is also

disconnected and sprayed with a water lance.

N°8

N°9

30.

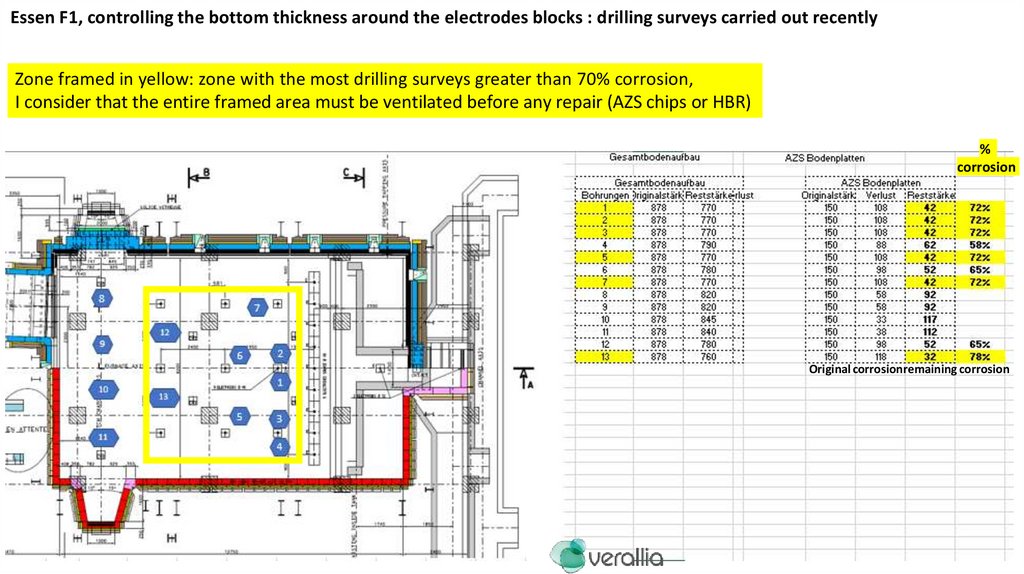

Essen F1, controlling the bottom thickness around the electrodes blocks : drilling surveys carried out recentlyZone framed in yellow: zone with the most drilling surveys greater than 70% corrosion,

I consider that the entire framed area must be ventilated before any repair (AZS chips or HBR)

%

corrosion

Original corrosionremaining corrosion

31.

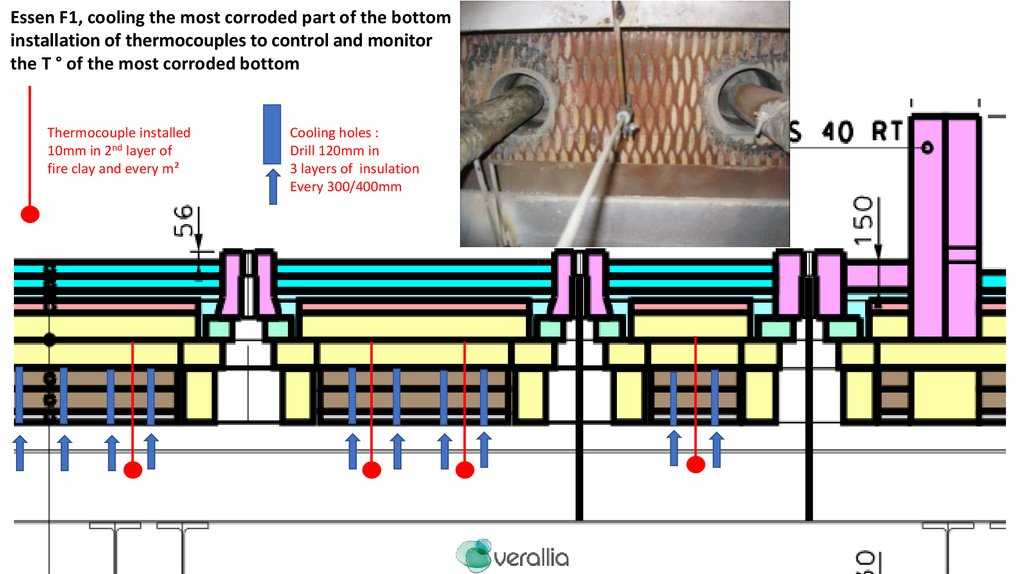

Essen F1, cooling the most corroded part of the bottominstallation of thermocouples to control and monitor

the T ° of the most corroded bottom

Thermocouple installed

10mm in 2nd layer of

fire clay and every m²

Cooling holes :

Drill 120mm in

3 layers of insulation

Every 300/400mm

32.

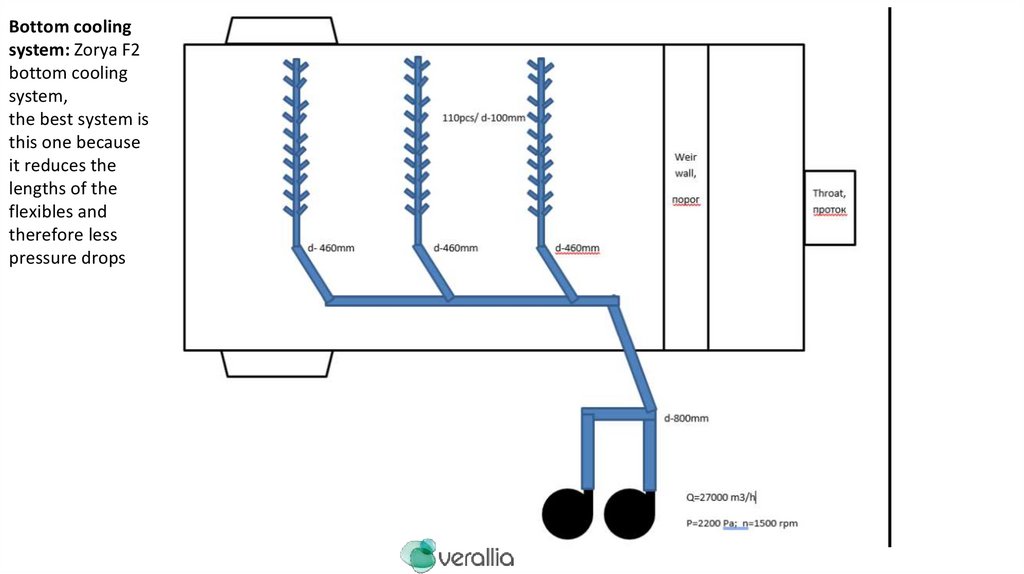

Bottom coolingsystem: Zorya F2

bottom cooling

system,

the best system is

this one because

it reduces the

lengths of the

flexibles and

therefore less

pressure drops

33.

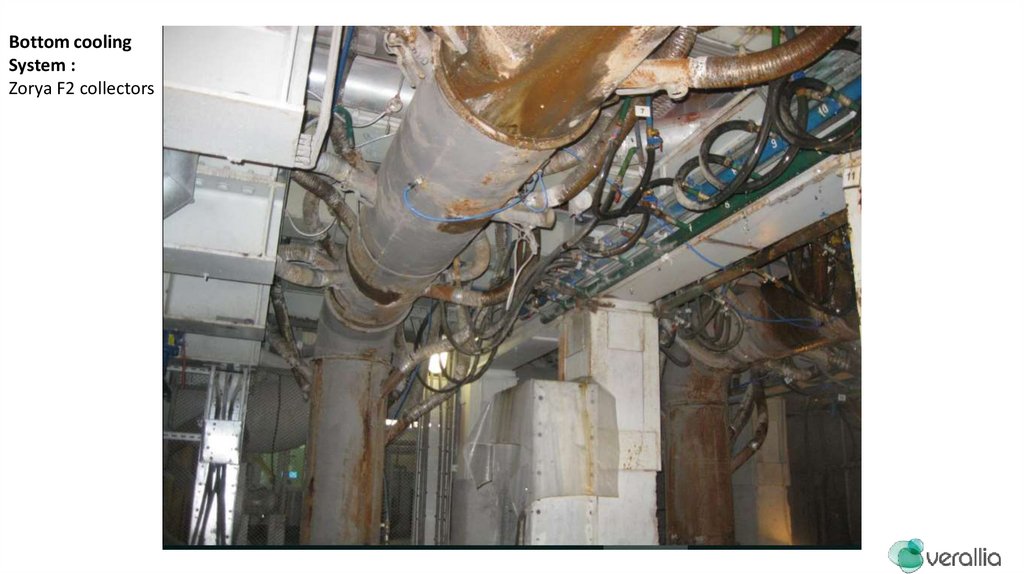

Bottom coolingSystem :

Zorya F2 collectors

34.

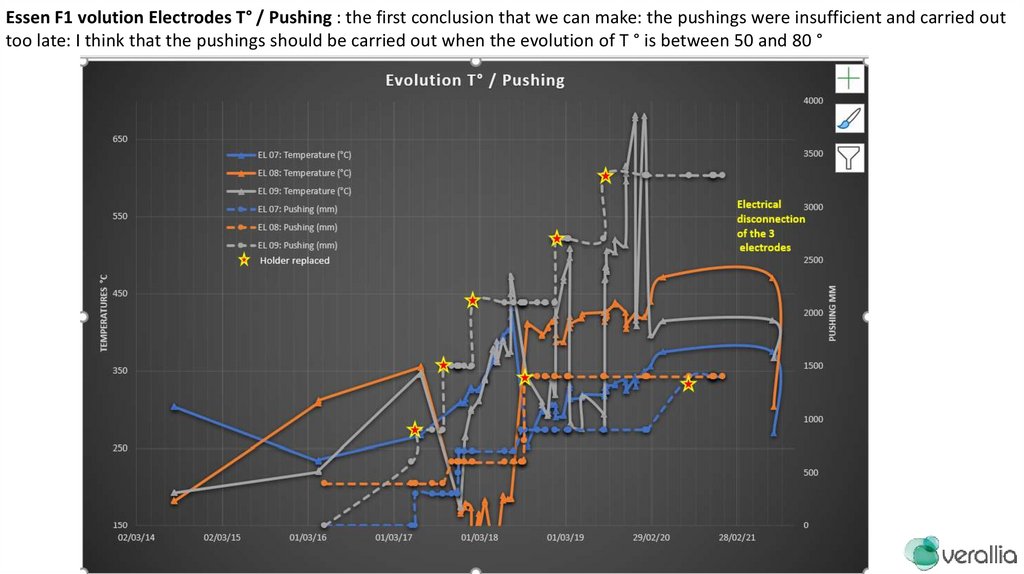

Essen F1 volution Electrodes T° / Pushing : the first conclusion that we can make: the pushings were insufficient and carried outtoo late: I think that the pushings should be carried out when the evolution of T ° is between 50 and 80 °

35.

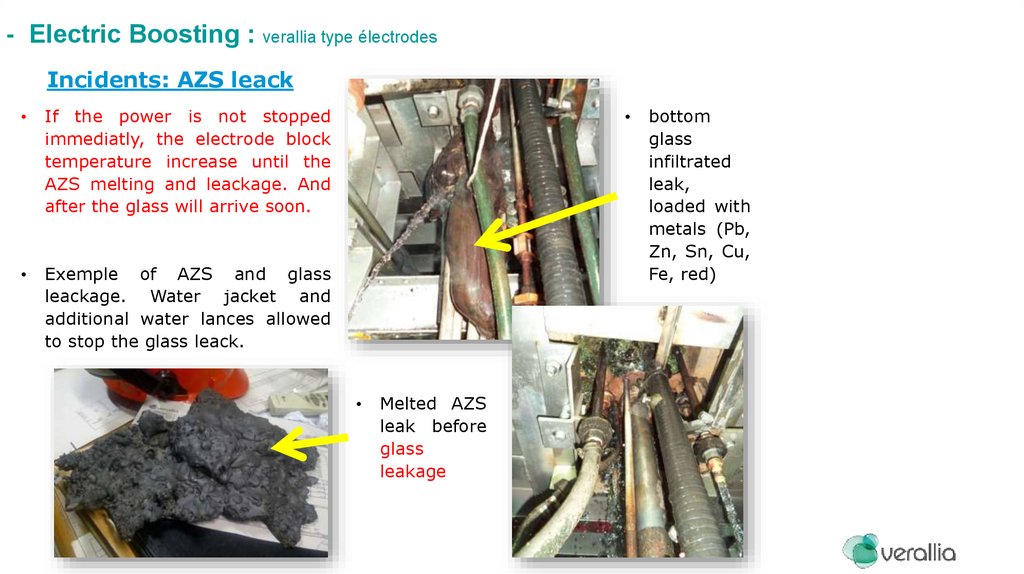

- Electric Boosting : verallia type électrodesIncidents: AZS leack

If the power is not stopped

immediatly, the electrode block

temperature increase until the

AZS melting and leackage. And

after the glass will arrive soon.

Exemple of AZS and glass

leackage. Water jacket and

additional water lances allowed

to stop the glass leack.

Melted AZS

leak before

glass

leakage

bottom

glass

infiltrated

leak,

loaded with

metals (Pb,

Zn, Sn, Cu,

Fe, red)

36.

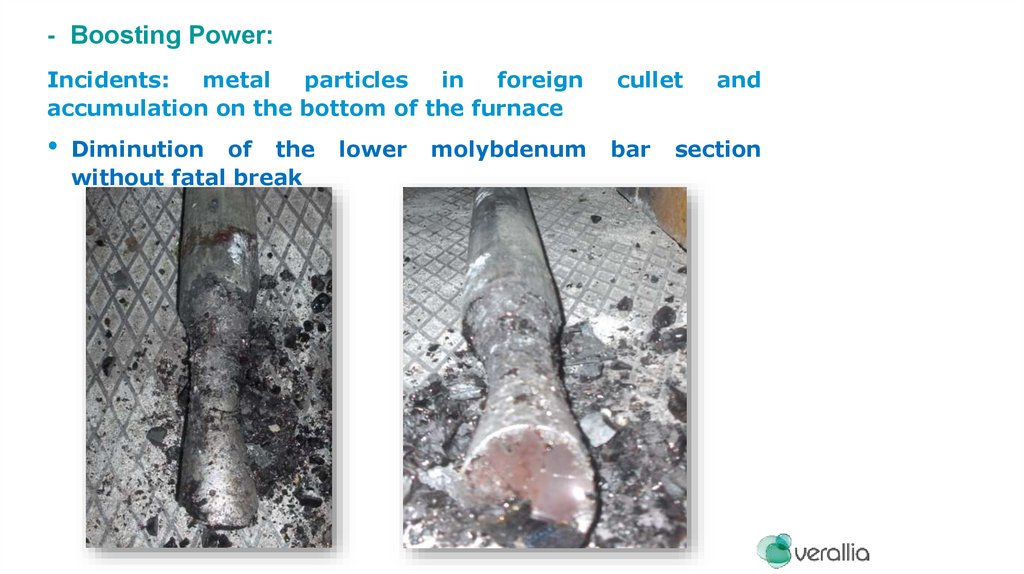

- Boosting Power:Incidents:

metal

particles

in

foreign

accumulation on the bottom of the furnace

cullet

bar

Diminution of the

without fatal break

lower

molybdenum

and

section

37.

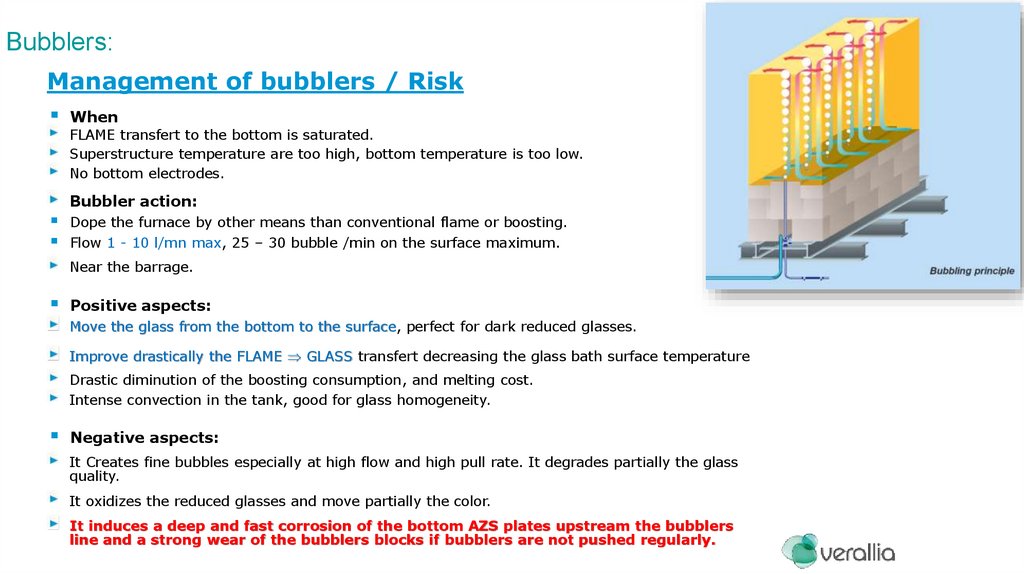

Bubblers:Management of bubblers / Risk

When

FLAME transfert to the bottom is saturated.

Superstructure temperature are too high, bottom temperature is too low.

No bottom electrodes.

Bubbler action:

Dope the furnace by other means than conventional flame or boosting.

Flow 1 - 10 l/mn max, 25 – 30 bubble /min on the surface maximum.

Near the barrage.

Positive aspects:

Move the glass from the bottom to the surface, perfect for dark reduced glasses.

Improve drastically the FLAME GLASS transfert decreasing the glass bath surface temperature

Drastic diminution of the boosting consumption, and melting cost.

Intense convection in the tank, good for glass homogeneity.

Negative aspects:

It Creates fine bubbles especially at high flow and high pull rate. It degrades partially the glass

quality.

It oxidizes the reduced glasses and move partially the color.

It induces a deep and fast corrosion of the bottom AZS plates upstream the bubblers

line and a strong wear of the bubblers blocks if bubblers are not pushed regularly.

38.

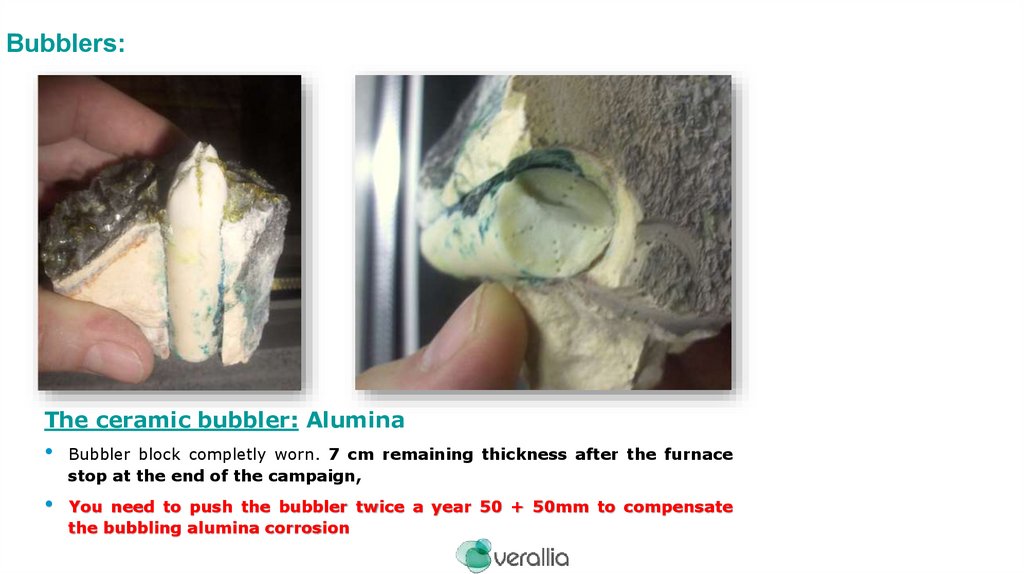

Bubblers:The ceramic bubbler: Alumina

Bubbler block completly worn. 7 cm remaining thickness after the furnace

stop at the end of the campaign,

You need to push the bubbler twice a year 50 + 50mm to compensate

the bubbling alumina corrosion

39.

Furnace Operation & Steering:The operation parameters necessary for a good steering: At stable pull.

Which Furnace Steering Setpoints and Why:

On the superstructure:

Furnace Pressure: By automatic regulation, target 5 Pa. Look at the peep holes on the

opposite side of the flame: flame must be 1/3 inside and 2/3 outside the peep hole, it’s a good

indicator to check fast the situation.

Too Low pressure >> Cold air entrances increase, energy consumption increase.

Too High Pressure >> furnace and regenerators silica superstrucutre degradation,

flames coming out corroding the silica crowns and the walls. Beyond + 10Pa without

being able to go down again, it is absolutely necessary to reduce the pull in order to

reduce the energy and consequently the pressure which must be less than 10Pa

Check the upper tank walls joint (hermetic), to limit air ventilation leaks inside the furnace, that

impacts the furnace pressure in case of bad situation on the checkers and increase the energy

consumption.

Check once by month the fumes pressure along the fumes circuit from the checker base until

the stack. To identify the pluggings or the atmosferic air entrances positions. Operate targeted

cleanings and sealings, in order to keep the furnace pressure in a correct range of value.

40.

Furnace Operation & Steering:The operation parameters necessary for a good steering: At stable pull.

• Which Furnace Steering Setpoints and Why:

Upper and lower

Températures:

Enable to verify if the combustion proceeds normally , and that the flames do not

lengthen, that the combustion inside the furnace is stable and the heat transfert flow to

the batch compostion doesn’t change. It’s a good reference point of the end of

combustion area (at constant power) and it is a good complement to O2 and CO fumes

analysis at the port neck : The target is not to burn inside the checker’s packs in the

regenerators, but to end the combustion inside the furnace.

Measure of the temperature by pyrometer on the port entrance arch key at the end of the

flame time. Allow the compare the temperature with the crown thermocouple indication

and a max temperature (1510°). It’s a safe precaution for silica superstructures and AZS

cruciform checkers that don’t appreciate excess of CO inside the regenerators aswell as

excessive temperatures.

regenerators

and

fumes

circuit

41.

Regenerator Checker Maintenance:1 – Never leave the thickness of sulfates deposites increase under the

rider arches more than the half height between the bootom and the

rider arches key. It favours preferential passages inside the checkers

packs, accelerate the local corrosion and wear with risks of premature

collapses, create pluggings in other cold areas.

2 – Proceed with yearly thermal cleanings, dice the 4th year of

campaign to eliminate dark areas on the light pattern under the checker.

3 – Prefer local thermal cleaning with localized air/gas lances. Prohibite

global thermal cleaning with big burners that lead sometime to dramatic

collapses of the rider arches.

42.

Regenerator Checker maintenance:5 – Control moisture and plasticity of the batch . Pay attention to the

fines raw material particules that stick to the regenerator’s chechers,

corrode and plug them. Moisture 3,5%, batch temperature > 37°,

6 – Never exceed 5000ppm CO at the prot neck. To reduced combustion

favour corrosion of cruciform 1682RX.

7 – Never proceed disbalancing the flame time to clean the checkers. It

increase all the volume of the checker and increase overall the

preferential passages. Risk of un-crontrolled collapse.

8 – Long periodes with very low pull and cold regenerator favours the

condensation inside the checkers packs. Plan a checker yearly cleaning.

9 – Changes of combustible from gas to oil and vice versa modify the

thermal field inside the checkers and favour the condensations especially

in gas firing condition.

43.

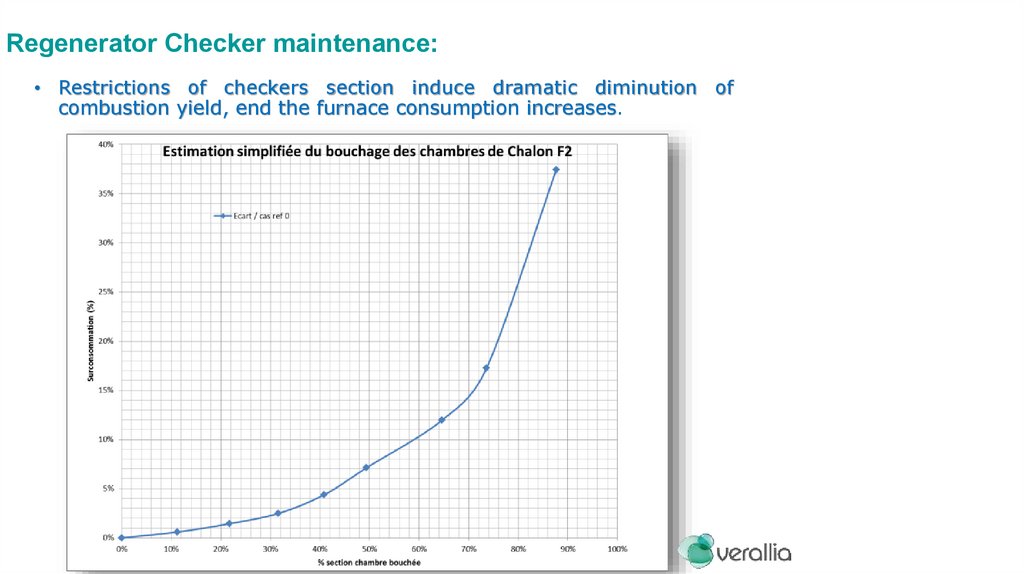

Regenerator Checker maintenance:• Restrictions of checkers section induce dramatic diminution of

combustion yield, end the furnace consumption increases.

44.

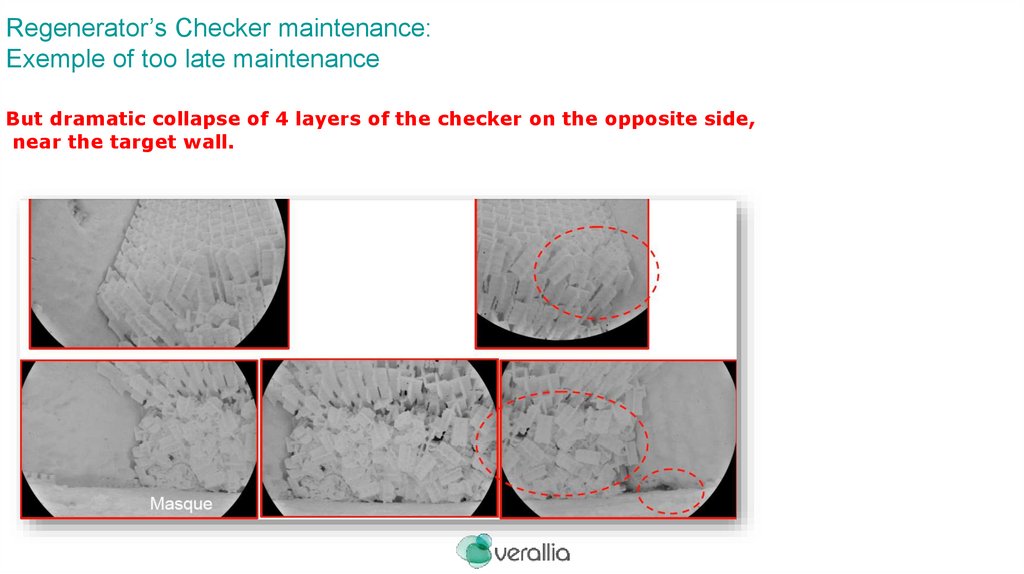

Regenerator’s Checker maintenance:Exemple of too late maintenance

But dramatic collapse of 4 layers of the checker on the opposite side,

near the target wall.

Промышленность

Промышленность