Похожие презентации:

Carbon Optimizer

1.

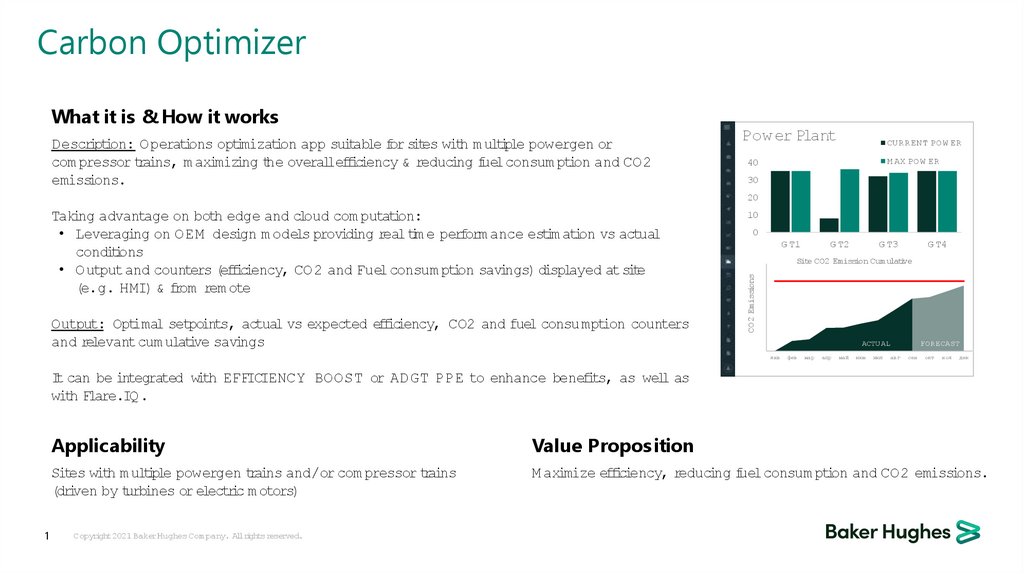

Carbon OptimizerWhat it is & How it works

Description: Operations optimization app suitable for sites with m ultiple powergen or

com pressor trains, m aximizing the overallefficiency & reducing fuel consum ption and CO2

emissions.

Power Plant

CU R R EN T PO W ER

M AX PO W ER

40

30

20

Output: Optimal setpoints, actual vs expected efficiency, CO2 and fuel consumption counters

and relevantcum ulative savings

10

0

G T1

G T2

G T3

G T4

Site CO2 Emission Cumulative

CO2 Emissions

Taking advantage on both edge and cloud com putation:

• Leveraging on OEM design m odels providing real tim e perform ance estim ation vs actual

conditions

• O utput and counters (efficiency, CO2 and Fuel consum ption savings) displayed at site

(e.g. HMI) & from rem ote

ACTU AL

янв

фев

мар

апр

май

июн

июл

FOR ECAST

авг

сен

окт

ноя

дек

It can be integrated with EFFICIENCY BOOST or ADGT PPE to enhance benefits, as well as

with Flare.IQ .

1

Applicability

Value Propos ition

Sites with m ultiple powergen trains and/or com pressor trains

(driven by turbines or electric m otors)

M aximize efficiency, reducing fuel consum ption and CO2 emissions.

Copyright 2021 Baker Hughes Com pany. Allrights reserved.

2.

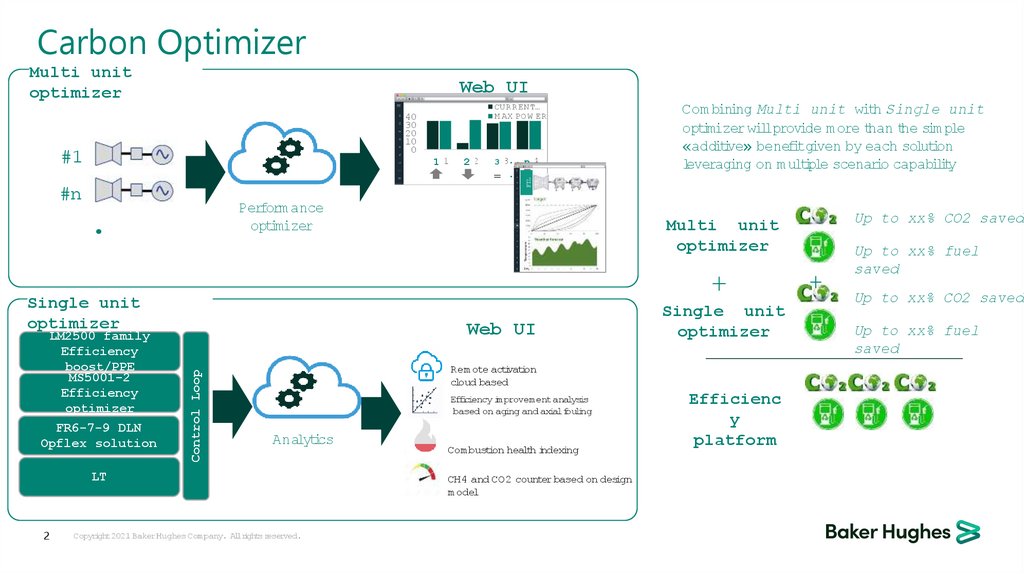

Carbon OptimizerMulti unit

optimizer

Web UI

G1T1

Perform ance

optimizer

Control Loop

Web UI

Single unit

optimizer

Rem ote activation

cloud based

Efficiency im provem ent analysis

based on aging and axial fouling

Analytics

Copyright 2021 Baker Hughes Company. Allrights reserved.

Up to xx% CO2 saved

Multi unit

optimizer

+

LT

2

G3T3..GnT4

= .

Single unit

optimizer

FR6-7-9 DLN

Opflex solution

G2T2

Com bining Multi unit with Single unit

optimizer willprovide m ore than the sim ple

«additive» benefitgiven by each solution

leveraging on m ultiple scenario capability

FIL

TE

R

H

O

US

E

.

#n .

.

#1

LM2500 family

Efficiency

boost/PPE

MS5001-2

Efficiency

optimizer

CU R R EN T…

M AX PO W ER

40

30

20

10

0

Com bustion health indexing

CH4 and CO2 counter based on design

m odel

Efficienc

y

platform

+

Up to xx% fuel

saved

Up to xx% CO2 saved

Up to xx% fuel

saved

3.

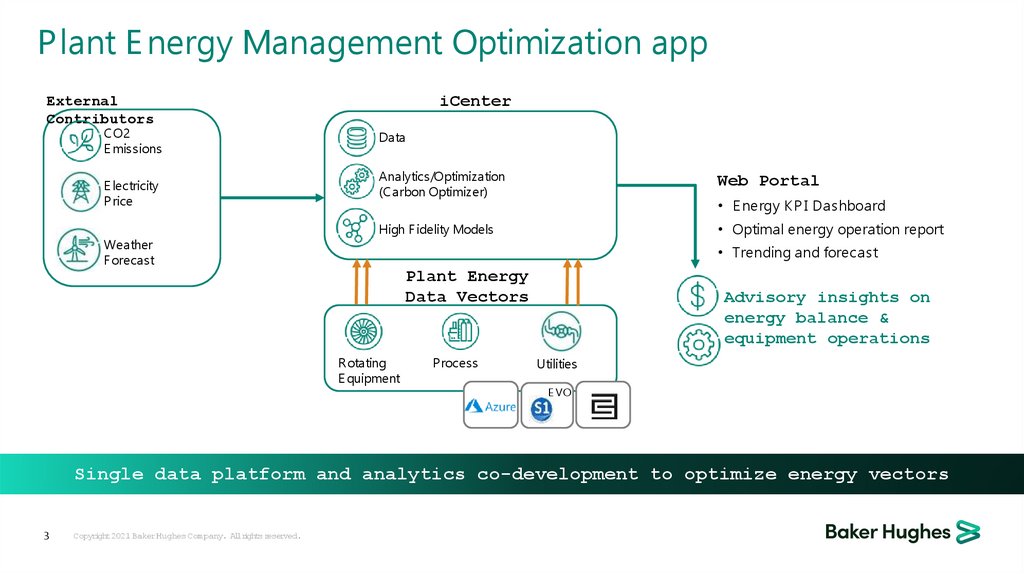

Plant E nergy Management Optimization appiCenter

External

Contributors

C O2

E missions

E lectricity

P rice

Weather

F orecast

Data

Analytics/Optimization

(Carbon Optimizer)

Web Portal

High F idelity Models

• Optimal energy operation report

• E nergy KP I Dashboard

• Trending and forecast

Plant Energy

Data Vectors

R otating

E quipment

P rocess

Advisory insights on

energy balance &

equipment operations

Utilities

E VO

Single data platform and analytics co-development to optimize energy vectors

3

Copyright 2021 Baker Hughes Company. Allrights reserved.

4.

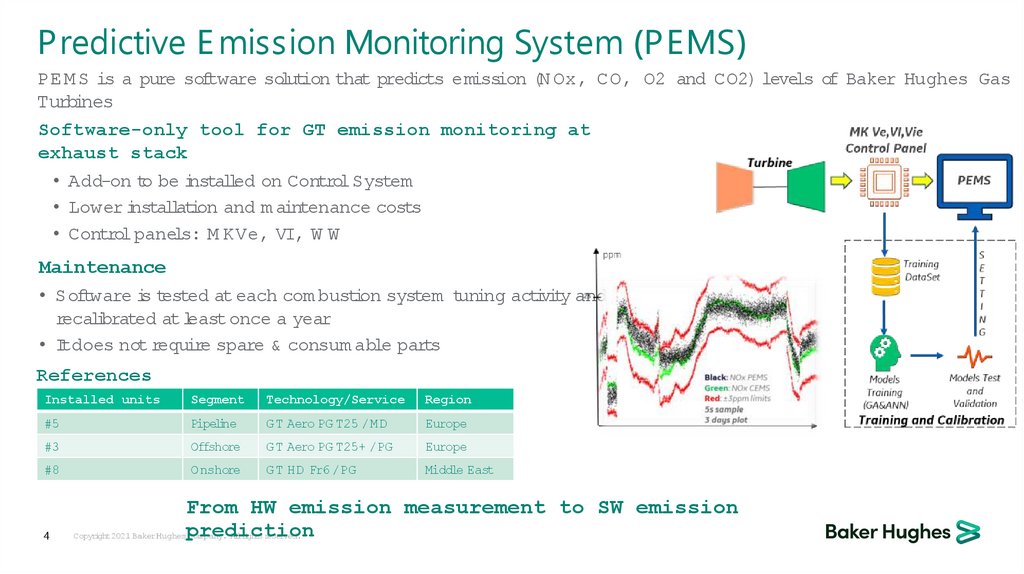

Predictive E mission Monitoring System (P EMS)PE M S is a pure software solution that predicts emission (N Ox, CO, O2 and CO2) levels of Baker Hughes Gas

Turbines

Software-only tool for GT emission monitoring at

exhaust stack

• Add-on to be installed on Control System

• Lower installation and m aintenance costs

• Control panels: M KVe, VI, W W

Maintenance

• Software is tested at each com bustion system tuning activity and

recalibrated at least once a year

• Itdoes not require spare & consum able parts

References

Installed units

Segment

Technology/Service

Region

#5

Pipeline

G T Aero PG T25 /M D

Europe

#3

Offshore

G T Aero PG T25+ /PG

Europe

#8

O nshore

G T HD Fr6 /PG

Middle East

4

From HW emission measurement to SW emission

Copyright 2021 Baker Hughesprediction

Company. Allrights reserved.

5.

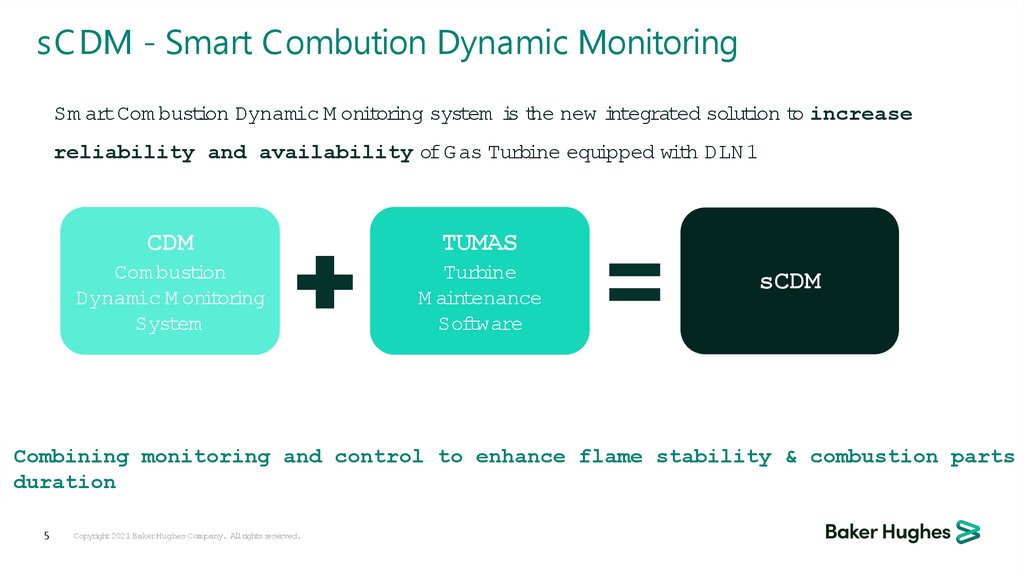

sC DM - Smart Combution Dynamic MonitoringSm art Com bustion Dynamic M onitoring system is the new integrated solution to increase

reliability and availability of G as Turbine equipped with DLN1

CDM

TUMAS

Com bustion

Dynamic M onitoring

System

Turbine

M aintenance

Software

sCDM

Combining monitoring and control to enhance flame stability & combustion parts

duration

5

Copyright 2021 Baker Hughes Company. Allrights reserved.

6.

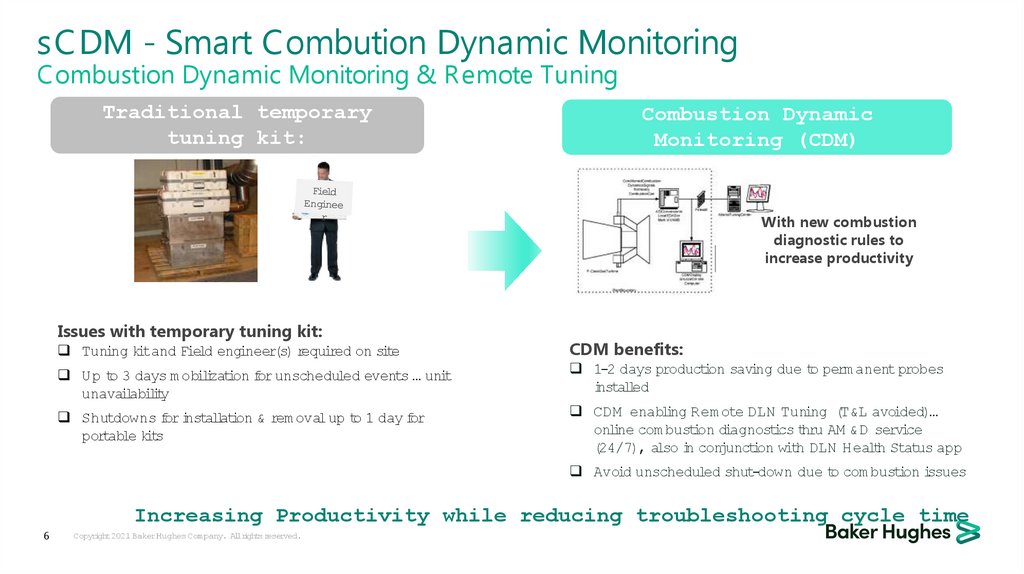

sC DM - Smart Combution Dynamic MonitoringCombustion Dynamic Monitoring & Remote Tuning

Traditional temporary

tuning kit:

Combustion Dynamic

Monitoring (CDM)

With new combustion

diagnostic rules to

increase productivity

Issues with temporary tuning kit:

Tuning kitand Field engineer(s) required on site

CDM benefits:

Up to 3 days m obilization for unscheduled events … unit

unavailability

1-2 days production saving due to perm anent probes

installed

Shutdowns for installation & rem oval up to 1 day for

portable kits

CDM enabling Rem ote DLN Tuning (T&L avoided)…

online com bustion diagnostics thru AM &D service

(24/7), also in conjunction with DLN Health Status app

Avoid unscheduled shut-down due to com bustion issues

Increasing Productivity while reducing troubleshooting cycle time

6

Copyright 2021 Baker Hughes Company. Allrights reserved.

7.

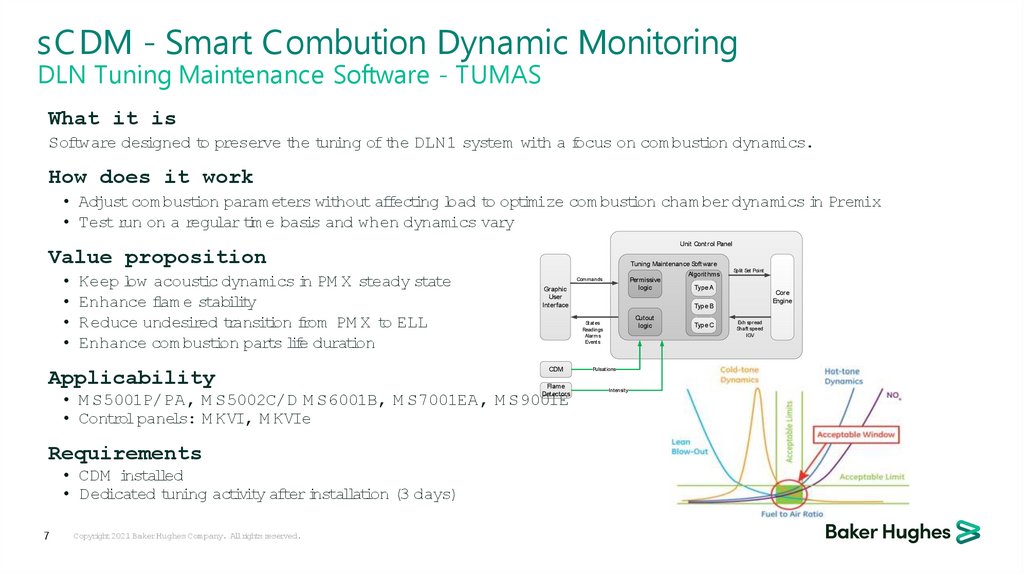

sC DM - Smart Combution Dynamic MonitoringDLN Tuning Maintenance Software - TUMAS

What it is

Software designed to preserve the tuning of the DLN1 system with a focus on com bustion dynamics.

How does it work

• Adjust com bustion param eters without affecting load to optimize com bustion cham ber dynamics in Premix

• Test run on a regular tim e basis and when dynamics vary

Unit Control Panel

Value proposition

Keep low acoustic dynamics in PM X steady state

Enhance flam e stability

Reduce undesired transition from PM X to ELL

Enhance com bustion parts life duration

Applicability

Tuning Maintenance Software

Graphic

User

Interface

CDM

Flame

Detectors

• CDM installed

• Dedicated tuning activity after installation (3 days)

7

Copyright 2021 Baker Hughes Company. Allrights reserved.

Algorithms

Split Set Point

Type A

Core

Engine

Type B

Cutout

logic

States

Readings

Alarms

Events

• M S5001P/PA, M S5002C/D M S6001B, M S7001EA, M S9001E

• Control panels: M KVI, M KVIe

Requirements

Permissive

logic

Commands

Pulsations

Intensity

Type C

Exh spread

Shaft speed

IGV

8.

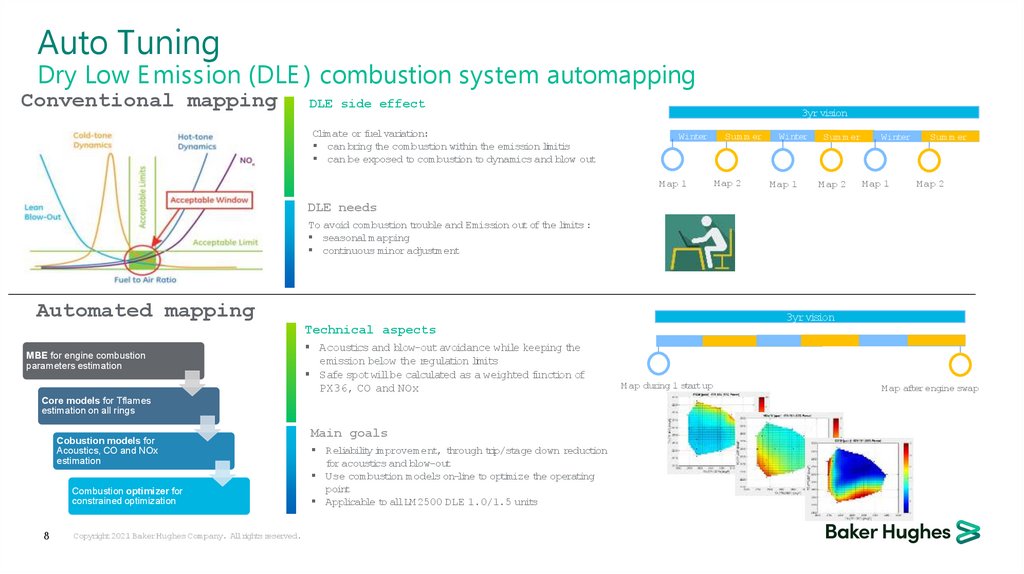

Auto TuningDry Low E mission (DLE ) combustion system automapping

Conventional mapping

DLE side effect

Clim ate or fuel variation:

can bring the com bustion within the emission limitis

can be exposed to com bustion to dynamics and blow out

3yr vision

Winter

M ap 1

Sum m er

M ap 2

Winter

M ap 1

Sum m er

M ap 2

Winter

M ap 1

Sum m er

M ap 2

DLE needs

To avoid com bustion trouble and Emission out of the limits :

seasonal m apping

continuous minor adjustm ent

Automated mapping

3yr vision

Technical aspects

MBE for engine combustion

parameters estimation

Acoustics and blow-out avoidance while keeping the

emission below the regulation limits

Safe spot willbe calculated as a weighted function of

PX36, CO and NOx

Core models for Tflames

estimation on all rings

Cobustion models for

Acoustics, CO and NOx

estimation

Combustion optimizer for

constrained optimization

8

Copyright 2021 Baker Hughes Company. Allrights reserved.

Main goals

Reliability im provem ent, through trip/stage down reduction

for acoustics and blow-out

Use com bustion m odels on-line to optimize the operating

point

Applicable to allLM 2500 DLE 1.0/1.5 units

M ap during 1 start up

M ap after engine swap

9.

Advisory ServicesRem ote guidance to organize flawless m aintenance events and identify im provem ent opportunities

Site Assessment

Parts Analysis

Technical Package

• 3D laser scanner of the plant to

virtually sim ulate the execution in

advance

• Spares gap analysis

• Special & standard tools gap

analysis vs. capabilities

• NIC/TIL/TEC/SB analysis for

perform ance enhancem ent and

HSE

• Plant rehabilitation

• Parts & tools obsolescence &

preservation valuation

• FM EA for mitigating standard and

specific execution risks

• Customized inspections with specific

advanced devices rem otely

m anageable

• Analysis of site and fleet LL to

prevent recurrent issues

• Brown Field Study

• Rem ote Assessm ent

• Decarbonization opportunities

9

Copyright 2021 Baker Hughes Company.

Allrights reserved.

The best operation support without m obilizing personnel

at site

Электроника

Электроника