Похожие презентации:

Leadership Practices in purchasing

1.

Leadership Practices inpurchasing

Confidential questionnaire

February 1997

Version 3

Copyright 1996

A.T. Kearney, Inc.

A.T. Kearney 7/17030/1/B

2.

Table of contentsSection

Page

I

Instructions

3

II

Procurement Strategy Development

4

III

Procurement Organization

16

IV

Sourcing Process

22

V

Supplier Management/Development

26

VI

Day-To-Day Purchasing/

Controlling

31

VII

Performance Management

34

VIII

Information Management

37

IX

Additional Information

40

A.T. Kearney 7/17030/2/B

3.

I. InstructionsPurpose

• This questionnaire is designed to be completed by procurement management with the

support of other functional organizations as appropriate. Along with quantitative data

collection, the information from the questionnaire will help A.T. Kearney to

—Assess your procurement practices for comparison with A.T. Kearney Leadership

Practices in Procurement benchmarks

—Identify and quantify opportunities for improvement and cost reduction

• All data will be treated as strictly confidential

• It is important that all questions be answered completely in order for A.T. Kearney to

develop valid comparisons and improvement opportunities

Questionnaire completion

• This questionnaire can be completed either as part of a face-to-face interview with A.T.

Kearney consultant(s) or individually

• This questionnaire is intended to be completed by procurement executives across

business units. Each separate purchasing group should complete the questionnaire in

full

• The participation of others outside the procurement function engaged in significant

procurement activities is encouraged as well

• Approximate answers will suffice when answering quantitative questions

• Please attach any documents you believe would be helpful in clarifying your responses,

marking those responses with the page and number of the question they refer to

• At the end of each section, there is space for additional comments

Principal respondent

Name

Title

Company

Business Unit/Division

Address 1

Address 2

City

State/Province

Country

Mail Code

Region

Phone

Fax

E-Mail Address

A.T. Kearney 7/17030/3/B

4.

II. Procurement Strategy DevelopmentStrategy overview

1.

Please describe your procurement strategy and how it relates to the overall

business goals/objectives of your business unit/division and to those of your company. We

are primarily interested in overall mission, goals, strategies and targeted overall results and

how these strategies are linked to the company’s strategic and/or business plans

A.T. Kearney 7/17030/4/B

5.

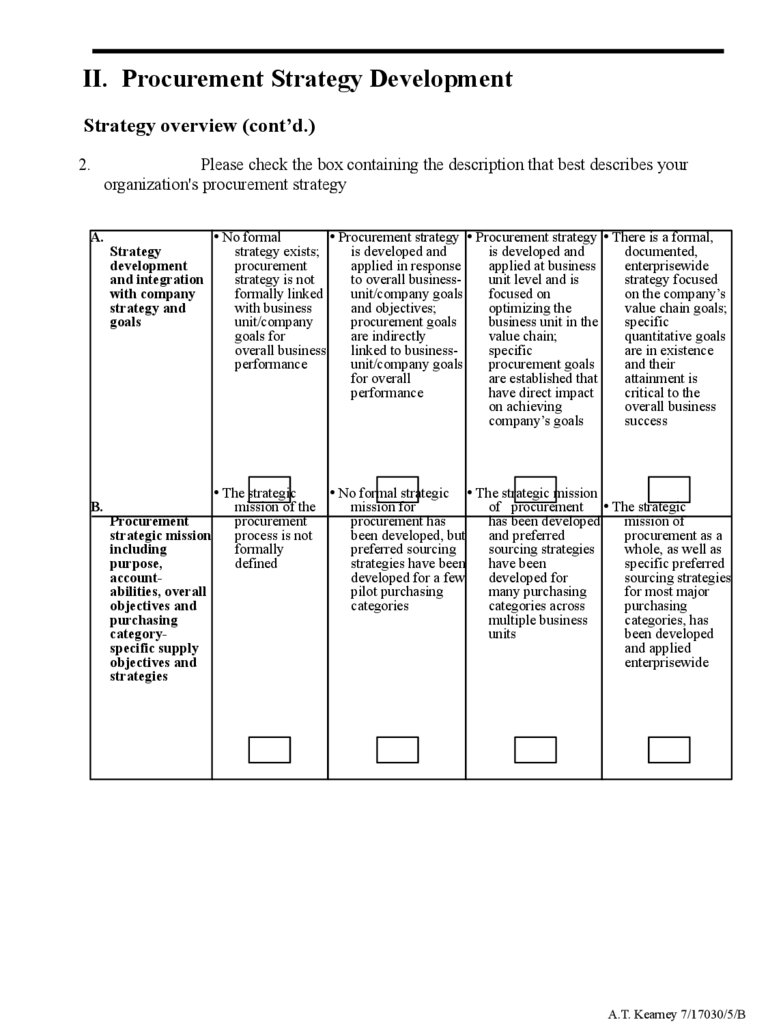

II. Procurement Strategy DevelopmentStrategy overview (cont’d.)

2.

Please check the box containing the description that best describes your

organization's procurement strategy

A.

B.

Strategy

development

and integration

with company

strategy and

goals

• No formal

• Procurement strategy • Procurement strategy • There is a formal,

strategy exists;

is developed and

is developed and

documented,

procurement

applied in response

applied at business

enterprisewide

strategy is not

to overall businessunit level and is

strategy focused

formally linked

unit/company goals

focused on

on the company’s

with business

and objectives;

optimizing the

value chain goals;

unit/company

procurement goals

business unit in the

specific

goals for

are indirectly

value chain;

quantitative goals

overall business

linked to businessspecific

are in existence

performance

unit/company goals

procurement goals

and their

for overall

are established that

attainment is

performance

have direct impact

critical to the

on achieving

overall business

company’s goals

success

• The strategic

• No formal strategic • The strategic mission

mission of the

mission for

of procurement • The strategic

Procurement

procurement

procurement has

has been developed

mission of

strategic mission

process is not

been developed, but

and preferred

procurement as a

including

formally

preferred sourcing

sourcing strategies

whole, as well as

purpose,

defined

strategies have been

have been

specific preferred

accountdeveloped for a few

developed for

sourcing strategies

abilities, overall

pilot purchasing

many purchasing

for most major

objectives and

categories

categories across

purchasing

purchasing

multiple business

categories, has

categoryunits

been developed

specific supply

and applied

objectives and

enterprisewide

strategies

A.T. Kearney 7/17030/5/B

6.

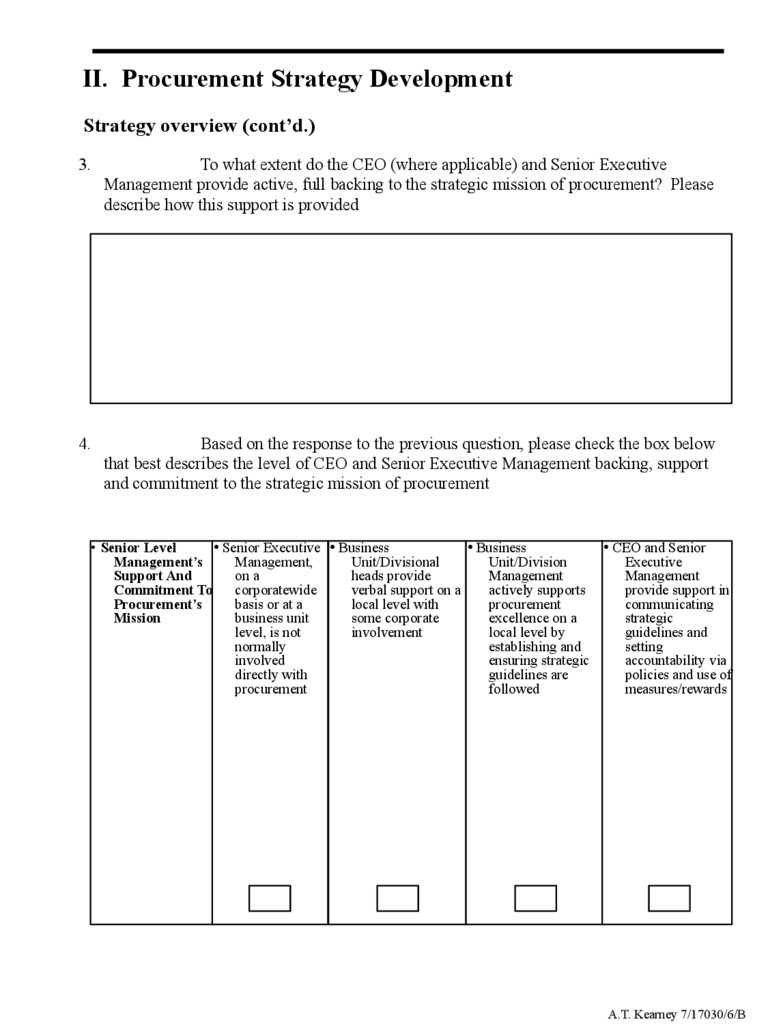

II. Procurement Strategy DevelopmentStrategy overview (cont’d.)

3.

To what extent do the CEO (where applicable) and Senior Executive

Management provide active, full backing to the strategic mission of procurement? Please

describe how this support is provided

4.

Based on the response to the previous question, please check the box below

that best describes the level of CEO and Senior Executive Management backing, support

and commitment to the strategic mission of procurement

• Senior Level

• Senior Executive • Business

• Business

• CEO and Senior

Management’s

Management,

Unit/Divisional

Unit/Division

Executive

Support And

on a

heads provide

Management

Management

Commitment To

corporatewide

verbal support on a

actively supports

provide support in

Procurement’s

basis or at a

local level with

procurement

communicating

Mission

business unit

some corporate

excellence on a

strategic

level, is not

involvement

local level by

guidelines and

normally

establishing and

setting

involved

ensuring strategic

accountability via

directly with

guidelines are

policies and use of

procurement

followed

measures/rewards

A.T. Kearney 7/17030/6/B

7.

II. Procurement Strategy DevelopmentApplication of procurement methodologies

5.

Please complete the following table for each expenditure category

Major Category

Category

Spend(1)

(Millions)

1995

A.

B.

Materials

C.

D.

E.

Services

F.

G.

Capital

Expenditures

Other

H.

1996

Within the last two years the

majority of expenditures in this category have

undergone a thorough analysis of sourcing

Which

options and resulting strategies have been function/departme

developed and implemented

nt is responsible

for majority of

expenditure in

What % of annualized spend each category

Yes/No/NA

is covered?

Raw/

production material

resale

Goods for

Operating

supplies(2)

Packaging(3)

Nonoperating

supplies(4)

Operating(5)

Professional(6)

Administrative(7)

I.

Utilities

J.

Major

capital projects(8)

K.

Yearly

recurring capital

expenditures

L.

M.Spend

Total

Notes:

(1) Use U.S. dollars for multinational operations with purchases across borders; use local

currency for operations with purchases in one currency

(2) Materials used in the production process (MRO, etc.)

(3) All packaging materials

(4) Goods purchased not used in production (office supplies, printed materials, etc.)

(5) Transportation, facilities management, production work

(6) Accounting, legal, investment services, consulting, etc.

(7) Nonprofessional services including training

(8) Expenditures budgeted for separately as capital and may include both goods and

bundled services

A.T. Kearney 7/17030/7/B

8.

II. Procurement Strategy DevelopmentApplication of procurement methodologies (cont’d.)

6.

List below key Sourcing Groups(1) included in the categories answered “yes”

in question 5 above. What approaches have you implemented for these Sourcing Groups in

the last two years and how effective have they been in improving business performance?

Please quantify business impact in percent cost savings on total Sourcing Group spend.

Possible approaches could include one or more of the following six approaches to Strategic

Sourcing

Approach

Definition

Volume Concentration

• Increasing the total purchases from one or more suppliers to increase

negotiating leverage

Best Price Evaluation

• Using techniques such as price and cost benchmarking, cost unbundling,

competitive bidding and total cost analysis to evaluate and select suppliers

with the best prices

Global Sourcing

• Sourcing from the most competitive suppliers on a worldwide basis

Product Specification

Improvement

• Changing specifications for your purchases to improve the overall

cost/performance relationship of end products

Joint Process Improvement

• Working with suppliers to eliminate cost inefficiencies

Relationship Restructuring

• Establishing stronger relationships (e.g., alliances, joint ventures) with

suppliers to reduce overall purchase cost, support business expansion

Sourcing Group

Approach

Baseline Expenditure

($000s)

Percent Savings

Note: (1) Sourcing Groups are defined as groupings of purchased items that are likely to be sourced from the

same set of suppliers using the same approaches

A.T. Kearney 7/17030/8/B

9.

II. Procurement Strategy DevelopmentStrategy development

7.

Does procurement actively review the operations to identify opportunities

for outsourcing/insourcing? Yes/No (Please circle one) If “yes,” please describe your

process.

8.

Based on the response to the previous question, please check the box below

containing the description that best fits your organization’s activities to identify outsourcing/

insourcing opportunities

Strategic Make

Versus Buy

• Procurement has

• A make-versus-buy • Procurement

• Procurement

little or no

process exists for

proactively

drives/leads the

involvement in

new products and

examines

strategic makemake-versus-buy

services

opportunities for

versus-buy

decisions

insourcing/outsour decision making

• There is a periodic

review of makecing

• No formal process

• Core competencies

exists to evaluate

versus-buy

are well-developed

make-versus- buy

decisions for

and drive

opportunities

existing

insourcing/outsour

products/services

cing efforts which

are supported by

in-depth makeversus-buy

analyses

A.T. Kearney 7/17030/9/B

10.

II. Procurement Strategy DevelopmentStrategy development (cont’d.)

9.

To what degree are the following factors considered in the formulation of

procurement strategies for individual purchasing categories. (Please check the appropriate

box)

Factor

Not

Considered

Considered

Implicitly

Key Factors That

Considered

Drive The

Explicitly

But Do Not Drive Development Of

Procurement

The Development

Strategy

Of Procurement

Strategy

A.

Future purchasing environment

based on

1.

Supplier’s

growth/expansion plans

2.

Product or process

technology breakthroughs

3.

Political, environmental or

regulatory factors

4.

New-end product or

customer requirements

B.

Use of the entire supply chain in

formulating strategy

C.

Use of full life cycle costs of

materials and services

D.

Simplification and

standardization across product

lines and geographic locations

E.

Cost reduction based on all

A.T. Kearney 7/17030/10/B

11.

II. Procurement Strategy DevelopmentStrategy elements

10.

Many firms are facing rapid changes in technology, market demands, and

other key external factors which shift customer requirements and impact market

competitiveness. How do you incorporate changes such as these in your procurement

strategic planning process?

11.

Similarly, supply markets are changing and new technologies emerging to

enable process improvements and/or cost reductions. Please describe formal programs

utilized to monitor technology shifts in your supply markets. What role does procurement

play in this process? What resources are applied to monitor the supply markets? Are these

resources dedicated on a full-time basis?

A.T. Kearney 7/17030/11/B

12.

II. Procurement Strategy DevelopmentStrategy elements (cont’d.)

12.

Based on your response to the previous two questions, please check the box

below that best describes the procurement organization’s activity to stay abreast of

technological changes or other dynamics in the supply market

Supply Market

Monitoring

13.

• Procurement develops

• Procurement

• Procurement monitors

• Procurement

understanding of

selectively monitors supply market to

continually

the supply market

market for a few

anticipate change

monitors the supply

primarily through

purchasing

for several

market to anticipate

contacts made via a categories to track

purchasing

changes or other

competitive bidding price and capacity

categories for

dynamics that

process

trends to meet

future product

impact the supply

• Focus is at the local

current product

innovations

market for most key

level

needs

purchasing

• Supply market

monitoring is

categories

• Focus is at the local

level

across multiple • Enterprisewide

business units

procurement

viewpoint

Describe the role of the procurement organization in the new product

development

process

A.T. Kearney 7/17030/12/B

13.

II. Procurement Strategy DevelopmentStrategy elements (cont’d.)

14.

What role do the following play in the new product development process?

(Please check the appropriate box)

Category

No Role In The Pilot Programs For Typical For Most New Major Feature Of All

New Product

Some New Product Product Develoment

New Product

Development Development Efforts

Efforts

Development Efforts

Effort

New Product

Development

Process

A.

B.

C.

Procurement plays a

participating role in

the early stages of

the new product

development process

The appropriate

internal functions

and external

suppliers are

involved in the early

stages of the new

product

development process

Procurement drives

the implementation

of

specification/product

sim-plification, standardization and

value engineering

approaches

A.T. Kearney 7/17030/13/B

14.

II. Procurement Strategy DevelopmentStrategy elements (cont’d.)

15.

Describe the role of the procurement organization in the development and

management of external relationships (e.g., joint ventures, marketing

alliances)

16.

Has the procurement organization led the establishment of major strategic

relationships with key suppliers? Yes/No (Please circle one). If yes, please describe nature

of the most significant of these relationships

Supply Category

Nature Of Relationship

A.T. Kearney 7/17030/14/B

15.

II. Procurement Strategy DevelopmentStrategy elements (cont’d.)

17.

What role does procurement play in the following processes? (Please check

the appropriate box)

Category

Procurement Procurement Plays A

Plays No Role In Support Role And

The Process

Has No DecisionMaking Authority

Procurement Is A

Participant In The

Process, And Has

Limited DecisionMaking Authority

Procurement

Takes On A

Leading Role

External

Relationships

A.

B.

C.

Structuring

supplier

relationships

Structuring

joint-venture

relationships and

marketing alliances

Providing strategic

input into customer

and competitor

relationships

A.T. Kearney 7/17030/15/B

16.

III. Procurement OrganizationOrganization overview

1.

Please describe your procurement department’s organizational structure and

reporting relationships (enclose organizational charts)

2.

Has the procurement organization changed substantially in the last two years?

Yes/No (please circle one). If yes, please describe any changes. Do you anticipate any

changes in the future? Yes/No (please circle one). If yes, please describe

A.T. Kearney 7/17030/16/B

17.

III. Procurement OrganizationDecision making

3. Please describe procurement’s major decision-making responsibilities within the

organization. Which decisions are led by procurement?

4.

Please check the box containing the description that best describes your

procurement organization

Procurement

Organization

A. Corporate

Level

B. Business Unit/

Division Level

• Top procurement • Top level

• Top procurement • A global

management

procurement

management

procurement

generally reports

management is a

reports to a

officer, with

to a functional or

corporate staff

member of the top

overall

geographic

position with

executive-level

responsibility for

organization

limited decisioncouncil. Position

purchasing

making authority

carries significant

policies, practices

decision-making

and infrastructure

authority

is a member of

the top-level

executive council

• Procurement

• Procurement

function is locally

function is

based (plant

centrally based at

level) and reports

the business unit/

to a materials and/

division level and

or operations

reports to a

manager

functional staff

manager

• Procurement

• Central procurement

function is

centrally based

manager, serves

and reports to a

as member of the

member of

business

business

unit/division

unit/division

senior

senior

management

management

team, with

team. Position

responsibility for

carries significant

purchasing

decision-making

policies, practices

authority

and infrastructure

A.T. Kearney 7/17030/17/B

18.

III. Procurement OrganizationDecision making (cont’d.)

5.

Please indicate which level in your organization makes decisions about the

following procurement-related activities. (Please check the appropriate box.)

Activity

For Major Key Categories

Ad Hoc,

Locally

Limited

CrossDecided (By

Informal

Local Entity, Coordination Function,

Cross-Unit

Individual,

Across

Teams

Function, Etc.)

Functions

A.

Product Development

B.

Product Specification

C.

Supplier Identification

D.

Supplier Selection

E.

Supplier Negotiation

Strategies

F.

Contract Provisions

G.

Supplier Management

H.

1.

Quality

2.

Service

3.

Delivery

Decision

Making Led

By

Procurement

Center*

Feedback To Suppliers

Note: * Procurement center is defined as a formal, standing, cross-functional organization/team with overall

responsibility for supply strategy, tactics and supplier relationships in a defined area of purchasing

expertise (material or service acquisition). It may be a part of the corporate procurement organization

may reside at a lead-business unit or lead-country procurement organization

or

A.T. Kearney 7/17030/18/B

19.

III. Procurement OrganizationTraining

6.

Please describe company initiatives utilized in managing and developing

procurement human resources and training/continuing education programs. Also, describe

efforts to train non-procurement professionals involved in procurement activities

7.

Based on your response to the previous question, please check the boxes

below that best describe your company’s practices

A.

• Procurement

• Procurement

• Procurement

• Procurement is

personnel are

contains some

personnel are

staffed by

Procure-ment

normally hired

category experts,

category experts

professionals with

Human

into purchasing,

people from

and some pursue

a mix of technical

Resources/Co

trained in

operations,

advanced degrees

and business

ntinuing

purchasing and

engineering or

or rotations across

backgrounds with

Education

generally remain

other functional

other functions

bachelor’s and

there during their

areas

advanced degrees

careers

• Training programs • Training programs • An established

• A formal, systematic

for procurement

are established at

training program

development/train

are on an asthe local

is in place for

ing program is in

B.

needed basis; no

purchasing level

most personnel

place for all

formal continuing

and utilize

involved in

personnel

Procure-ment

education

publicly available

purchasing; a

involved in

Training

programs exist

seminars and

combination of inpurchasing

training courses

house and public

enterprisewide.

training vehicles is

Advancement and

utilized. Training

compensation are

is standardized

based on

with limited

demonstrated

control and

capability in

coordination

established areas

required

of skill

A.T. Kearney 7/17030/19/B

20.

III. Procurement OrganizationTraining (cont’d.)

8.

Which of the following formal internal

training programs do you use?

A.

analyses

B.

time

C.

management

D.

➡

➡

➡

➡

➡

➡

➡

Supplier management

I.

Contract management

J.

Cost/price analysis

K.

Procurement procedures L.

➡

➡

Statistical

➡

➡

Just-in➡

➡

Quality

➡

Supplier

quality standards

E.

F.

Procurement

function

Negotiation

skills

9.

Procurement law M.

Supply market analysis

Company culture

N.

G.

Procurement ethics

O.

Personal

Please describe how you use both external

computer

skillssources (other parts of the company) to recruit procurement staff.

sources

and internal

H.

Other recruit

(specify)

Describe

procurement recruitment efforts and typical

profile (e.g., background, skill

___________________________________________

sets, etc.)

________________________________________________________

________________________________________________________

A.T. Kearney 7/17030/20/B

21.

III. Procurement OrganizationProcurement function (cont’d)

10. Are the procurement staff experienced primarily in procurement or do they represent a

cross-fertilized experience with background in multiple disciplines (e.g., engineering,

marketing, finance, operations, etc.) (Please rate staff on the following scale)

Procurement Experts

1

Cross-Fertilized

2

3

4

11. Does the procurement function work within cross-functional teams, or as a “stand-alone”

organization? (Please rate procurement function on the following scale)

Stand-Alone

1

Cross-Functional Teams

2

3

4

A.T. Kearney 7/17030/21/B

22.

IV. Sourcing ProcessSupplier selection

1.

2.

What processes do you use to identify potential suppliers?

Do you follow an established process for supplier qualification and selection? Yes/No

(Please circle one). If yes, please describe the qualification criteria. If possible, please

attach supplier qualification, certification and selection documents

A.T. Kearney 7/17030/22/B

23.

IV. Sourcing ProcessSupplier selection (cont’d.)

3.

What process is utilized in selecting a sourcing approach for a particular purchasing

category? Is the process formalized/documented? Yes/No (Please circle one). How is the

sourcing approach customized to incorporate specific requirements of the different

purchasing categories?

4.

What roles do purchasing’s internal “customers” (i.e., materials, operations/production,

quality control, engineering, maintenance) play in the selection/implementation of the

sourcing approach for specific categories of materials and services?

A.T. Kearney 7/17030/23/B

24.

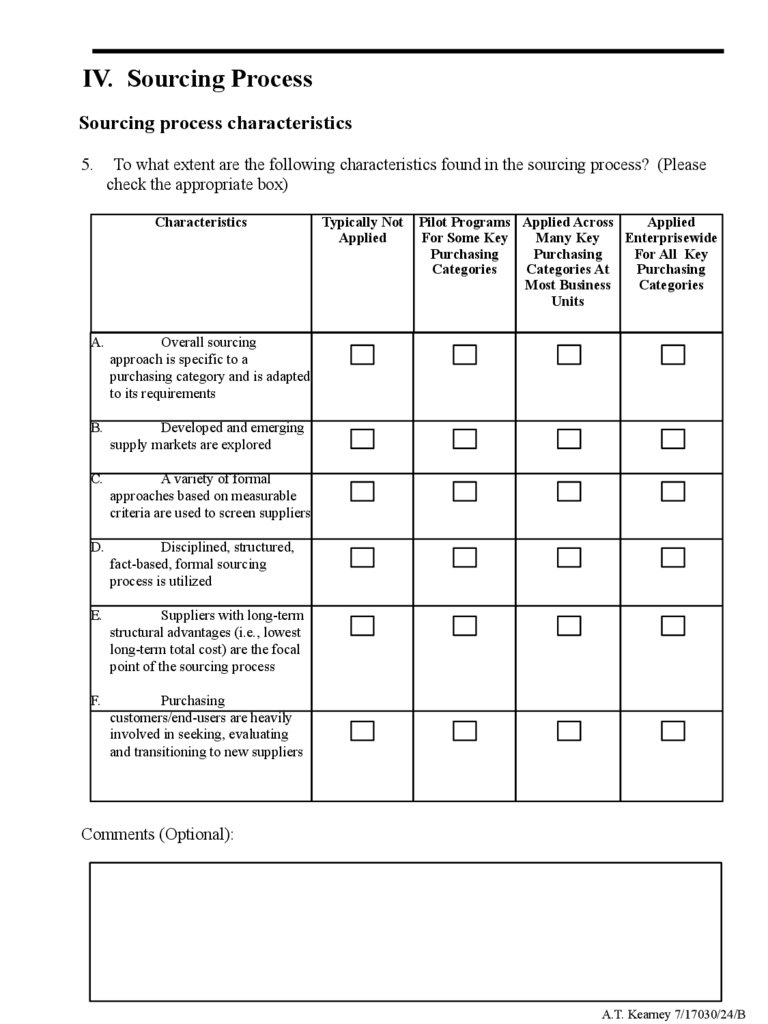

IV. Sourcing ProcessSourcing process characteristics

5.

To what extent are the following characteristics found in the sourcing process? (Please

check the appropriate box)

Characteristics

A.

Overall sourcing

approach is specific to a

purchasing category and is adapted

to its requirements

B.

Developed and emerging

supply markets are explored

C.

A variety of formal

approaches based on measurable

criteria are used to screen suppliers

D.

Disciplined, structured,

fact-based, formal sourcing

process is utilized

E.

Suppliers with long-term

structural advantages (i.e., lowest

long-term total cost) are the focal

point of the sourcing process

F.

Purchasing

customers/end-users are heavily

involved in seeking, evaluating

and transitioning to new suppliers

Typically Not

Applied

Pilot Programs Applied Across

Applied

For Some Key

Many Key

Enterprisewide

Purchasing

Purchasing

For All Key

Categories

Categories At

Purchasing

Most Business

Categories

Units

Comments (Optional):

A.T. Kearney 7/17030/24/B

25.

IV. Sourcing ProcessProduct/specifications review

6.

Is there a formal process for specifications and requirements review (e.g., value analysis)?

Yes/No (Please circle one). If yes, please describe the review process

7.

Based on your response to the previous question, please check the box below that best

describes the process for establishing specifications for materials, products and services

Materials, Products

• Specifications

• Category

• Specifications and • Procurement works

And Service

provided by

specifications are

requirements are

directly with

Specifications

engineering and/or

challenged on a

challenged by

product

Development

end-users are

case-by-case

procurement or

engineers/end-users

accepted at face

basis

suppliers at

to define

value without

multiple business

specifications of

being challenged

units for critical

current and new

by procurement

categories

products

• Procurement is

• Suppliers work

involved with

directly with endengineering/endusers to define

users on an ad hoc

specifications and

basis in the

requirements for

development of

key purchasing

specifications/requi

categories

rements

enterprisewide

A.T. Kearney 7/17030/25/B

26.

V. Supplier Management/DevelopmentSupplier management overview

1.

To what extent are the following characteristics found throughout your organization?

(Please check the appropriate box)

Characteristics

A.

Resource investment

(people, capital) into the supply

base with long-term

development in mind

B.

Value-added

relationships (based on

formalized frameworks) with

key suppliers are managed over

time through benchmarking

and open communication

C.

Suppliers’ core

competencies are identified and

tools/programs (loans, credits,

etc.) are created to enhance

their ability to serve you in new

geographic areas, new

materials and new products

D

Suppliers are

integrated into the business

process through their active

involvement in day-to-day

activities

E.

Regular formal

feedback of supplier

performance, with adaptations

of relationships to meet

situational needs (e.g., openbook policies on cost, joint goal

setting, information sharing,

etc.)

Typically Not

Applied

Pilot Programs

For Some Key

Purchasing

Categories

Applied Across

Most Key

Purchasing

Categories At

Most Business

Units

Applied

Enterprisewide

For All Key

Purchasing

Categories

Comments (Optional):

A.T. Kearney 7/17030/26/B

27.

V. Supplier Management/DevelopmentTwo-way learning/enhancing supplier performance

2.

Which of the following do you engage in with your suppliers on a regular basis? (Please

check the appropriate box)

Used With A

Few Key

Suppliers On

Pilot Basis

Not Used

A.

Cross-company meetings,

workshops, feedback sessions

B.

Utilization of supplier knowhow to improve purchasing practices

C.

Incentive programs with

suppliers

D.

Joint value-added programs for

first and second tier suppliers

Used With

Many Key

Suppliers

Used With All

Key Suppliers

Please describe the working relationship with key suppliers

A.T. Kearney 7/17030/27/B

28.

V. Supplier Management/DevelopmentSupplier development

3.

Do you use any of the following criteria to certify your suppliers’ quality processes?

(Please check the appropriate box)

Used With A

Few Key

Suppliers On

Pilot Basis

Not Used

A.

ISO 9000 Series

B.

Balridge Criteria

C.

Deming Criteria

D.

Internally Developed

Used With

Many Key

Suppliers

Used With All

Key Suppliers

Criteria

E.

Other Criteria (Please

Specify)

Please explain the certification process(es) used

A.T. Kearney 7/17030/28/B

29.

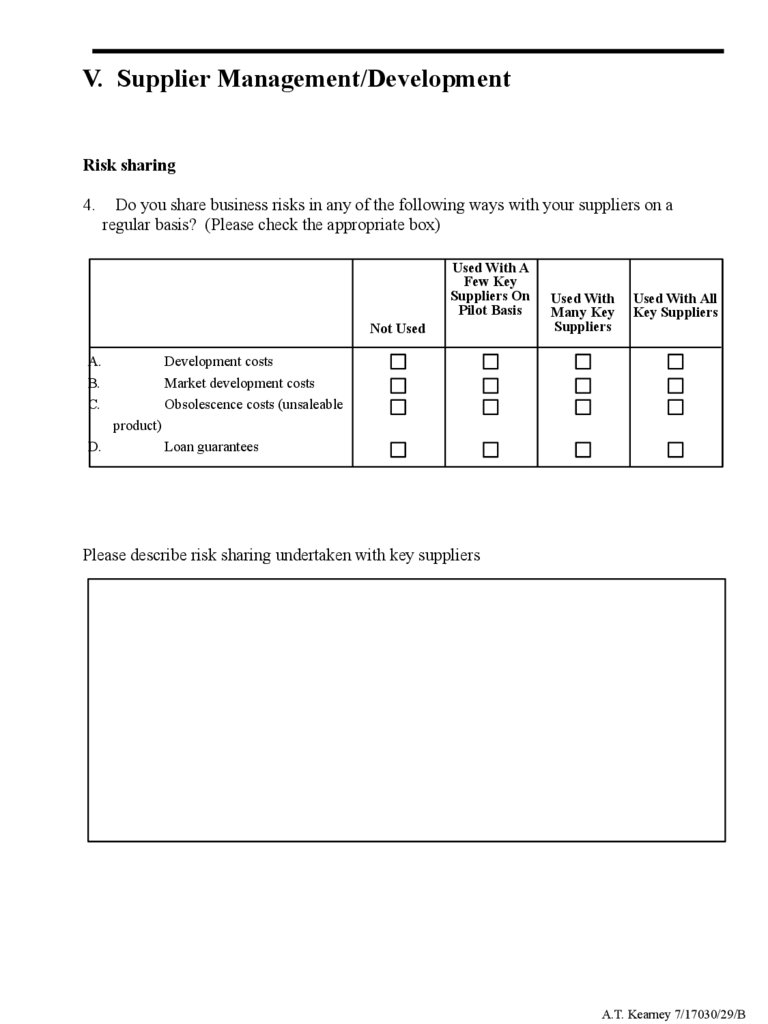

V. Supplier Management/DevelopmentRisk sharing

4.

Do you share business risks in any of the following ways with your suppliers on a

regular basis? (Please check the appropriate box)

Used With A

Few Key

Suppliers On

Pilot Basis

Not Used

A.

B.

C.

Used With

Many Key

Suppliers

Used With All

Key Suppliers

Development costs

Market development costs

Obsolescence costs (unsaleable

product)

D.

Loan guarantees

Please describe risk sharing undertaken with key suppliers

A.T. Kearney 7/17030/29/B

30.

V. Supplier Management/DevelopmentRisk sharing (cont’d.)

5.

In which of the following ways do you invest in your suppliers? (Please check the

appropriate box)

Used With A

Few Key

Suppliers On

Pilot Basis

Not Used

Used With

Many Key

Suppliers

Used With All

Key Suppliers

A.

B.

C.

Short-term loans

Long-term loans

Purchase production equipment

and tooling

D.

Equity investment

E.

Ownership of controlling

interest

Please describe investment activities with key suppliers

A.T. Kearney 7/17030/30/B

31.

VI. Day-To-Day Purchasing/ControllingProcess overview

1.

How have you reduced the number of steps and/or costs in your day-to-day procurement

activities? What role does technology play in the process?

2.

What additional activities do you currently have planned for further reducing the

steps/costs of your day-to-day procurement activities?

A.T. Kearney 7/17030/31/B

32.

VI. Day-To-Day Purchasing/ControllingProcess simplification and improvement

3.

To what extent are each of the following practices applied in your organization?

(Please check the appropriate box)

Characteristics

A.

Suppliers have full access

to company order and stock

information (e.g., virtual shelf,

vendor managed replenishment)

B.

Continuous process

simplification is sought for all

procurement activities:

1.

Transactionoriented work is

outsourced

2.

Pre-established

agreements in place (e.g.,

electronic supplier

catalogs, on-line access to

agreements)

3.

Express buy

systems in place (e.g.,

direct computer linkages

bypass procurement

activities)

4.

Procurement/

credit card payments

reduce transactional costs

Typically Not

Applied

Pilot Programs Applied Across

Applied

For Some HighMost HighEnterprisewide

Volume, Low- Volume, LowFor All HighValue Purchasing

Value

Volume, LowCategories

Purchasing Value Purchasing

Categories At

Categories

Most Business

Units

Comments (Optional):

A.T. Kearney 7/17030/32/B

33.

VI. Day-To-Day Purchasing/ControllingProcess simplification and improvement (cont’d.)

4.

To what extent has information technology been used to streamline procurement

processes? (Please circle the number that applies)

Characteristics

Not At All

To A Great Extent

A.

Repetitive

activities are automated

0

1

2

3

B.

Paperwork is

eliminated

0

1

2

3

C.

Procurement cycle

times and costs are

dramatically reduced

0

1

2

3

D.

Both buyer and

end-user are provided

decision-making tools to

improve productivity

0

1

2

3

E.

Requisitions are

created, routed and

approved on-line

0

1

2

3

Comments (Optional)

A.T. Kearney 7/17030/33/B

34.

VII. Performance ManagementInternal performance

1.

2.

Describe your internal performance measurement system. Please enclose sample

performance reports

Describe the internal feedback and continuous improvement process

Supplier performance

3.

How do you measure supplier performance? Please provide a sample supplier performance

report

A.T. Kearney 7/17030/34/B

35.

VII. Performance ManagementPerformance management systems

4.

To what extent are the following characteristics found throughout your organization?

(Please check the appropriate box)

Characteristics

A.

Formal measurement

systems are used to track and

improve performance of the

overall procurement process

B.

Performance and cost

objectives are based on:

1.

End-product target

pricing

2.

External

benchmarking of

marketplace price trends

3.

Customer

satisfaction

4.

Purchase category

market conditions

5.

Company buying

power

C.

Procurement personnel

are evaluated and rewarded based

on team or individual

performance

D.

General management is

measured upon the success of

implementing corporate

procurement initiatives

E.

Formal supplier

feedback/continuous

improvement programs are in

place

F.

Formal measurement

systems are used to track and

improve performance of the

supply base

G.

Performance

Typically Not

Applied

Pilot Programs Applied Across

Applied

For Some Key

Most Key

Enterprisewide

Purchasing

Purchasing

For All Key

Categories

Categories At

Purchasing

Most Business

Categories

Units

A.T. Kearney 7/17030/35/B

36.

VII. Performance ManagementGoal setting

5.

To what extent are the following business goals used in the performance measurement of

procurement management? (Please circle the number that best describes the performance

measurement criteria)

Corporate Goals Impacted By Procurement

A.

Reduction in purchasing price of all

external purchases

B.

Reduction in total cost of all external

purchases

C.

Reduction in lead times

D.

Reduction in customer order cycle time

E.

Improvement in purchased goods/service

quality

F.

G.

Improvement in end-product quality

Attainment of target costs for key

purchased goods/services

H.

Reduction in raw materials/components

inventory

I.

Used

As A Measure

Of

Not

At All

To A Great

Procurement Performance?

Extent

0

1

2

3

0

1

2

3

0

1

2

3

0

1

2

3

0

1

2

3

0

1

2

3

0

1

2

3

0

1

2

3

0

1

2

3

Reduction in new product development

cycle time

A.T. Kearney 7/17030/36/B

37.

VIII. Information ManagementProcurement strategy enablers

1.

To what extent do information systems enable procurement strategies (i.e.,

lowered cost, increased efficiency) to work? (Please circle the number that applies)

Characteristics

A.

Information technology systems

are used by the procurement staff to

perform and facilitate value-added

analysis to support the development of

specific and overall procurement

strategies

B.

Supplier metrics/trends

immediately available, automatically

captured and correlated against relevant

market and internal company

performance data to support continuous

improvement

C.

Information systems speed up and

simplify routine transactions and lower

costs

D.

Information systems allow for

global control and integration in a

standardized way

E.

Information systems allow end

users to smooth operational procedures

and optimize cycle time and accuracy

F.

Information technology is used to

help shape the procurement strategy:

—Expanding visibility of supply

markets

—Enabling integration across the

supply chain

Comments (Optional):

Not At All

To A Great Extent

0

1

2

3

0

1

2

3

0

1

2

3

0

1

2

3

0

1

2

3

0

1

2

3

A.T. Kearney 7/17030/37/B

38.

VIII. Information ManagementSystems capability

2.

To what extent do information systems integrate data across the supply chain? (Please

circle the number that applies)

Characteristics

A.

Electronic commerce techniques in place

(e.g., electronic ordering, order status, and

payment; electronic linkages for planning;

electronic catalogues; express-buy systems)

to make procurement more efficient

B.

Numerous tiers in the supply chain are

integrated

C.

D.

Systems link material requirements

planning (MRP) systems with suppliers and

automate the interface between customers

and suppliers enabling EDI to work —

paperless operations for order placement,

planning, scheduling and order tracking and

CAD/CAM links for simultaneous product

development, if applicable

Electronic routing of requisitions to

supplier or buyer for purchase order

processing

Not At All

To A Great Extent

0

1

2

3

0

1

2

3

0

1

2

3

0

1

2

3

Comments (Optional):

A.T. Kearney 7/17030/38/B

39.

VIII. Information ManagementInformation/data accessibility

3.

To what extent is information available when and where it is needed to create value?

(Please circle the number that applies)

Characteristics

Not At All

To A Great Extent

A.

Procurement data widely accessible across

the procurement function on a real-time basis

0

1

2

3

B.

Procurement data widely accessible across

other functions

0

1

2

3

C.

Easy exchange of information with your

major suppliers

0

1

2

3

0

1

2

3

D.

Customer information shared with suppliers

E.

Purchases categorized with common

commodity and supplier codes

0

1

2

3

F.

Data access and reporting is flexible to meet 0

needs

1

2

3

1

2

3

G.

Supplier order status readily available

0

Comments (Optional):

A.T. Kearney 7/17030/39/B

40.

IX. Additional InformationSuccess stories

1.

We would like to hear about three of the successes you feel most proud of. These

successes could be the result of a one-time effort, or a long-term process. They could be

about your organization, strategy development or about sourcing a product. Please describe

the situation, critical issues, solution and end result

Success #1

Success #2

Success #3

A.T. Kearney 7/17030/40/B

41.

IX. Additional InformationCost reduction opportunities

2.

Please identify the two or three most significant opportunity areas where the procurement

organization should be focused for cost reduction

A.T. Kearney 7/17030/41/B

42.

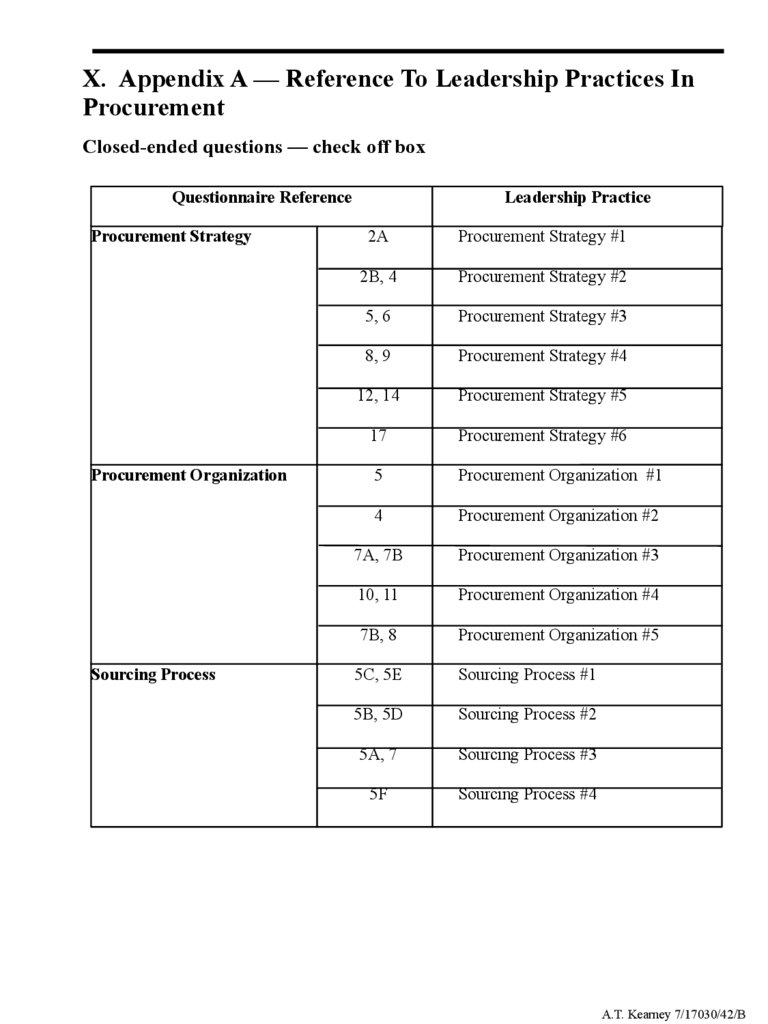

X. Appendix A — Reference To Leadership Practices InProcurement

Closed-ended questions — check off box

Questionnaire Reference

Procurement Strategy

Procurement Organization

Sourcing Process

Leadership Practice

2A

Procurement Strategy #1

2B, 4

Procurement Strategy #2

5, 6

Procurement Strategy #3

8, 9

Procurement Strategy #4

12, 14

Procurement Strategy #5

17

Procurement Strategy #6

5

Procurement Organization #1

4

Procurement Organization #2

7A, 7B

Procurement Organization #3

10, 11

Procurement Organization #4

7B, 8

Procurement Organization #5

5C, 5E

Sourcing Process #1

5B, 5D

Sourcing Process #2

5A, 7

Sourcing Process #3

5F

Sourcing Process #4

A.T. Kearney 7/17030/42/B

43.

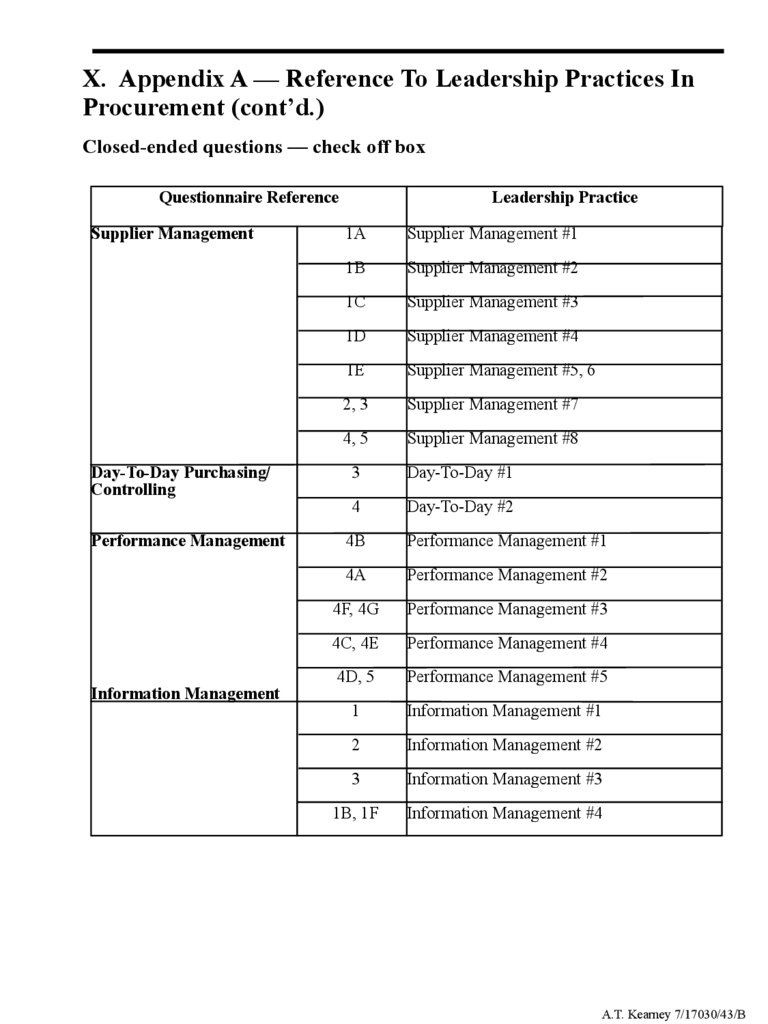

X. Appendix A — Reference To Leadership Practices InProcurement (cont’d.)

Closed-ended questions — check off box

Questionnaire Reference

Supplier Management

Day-To-Day Purchasing/

Controlling

Performance Management

Information Management

Leadership Practice

1A

Supplier Management #1

1B

Supplier Management #2

1C

Supplier Management #3

1D

Supplier Management #4

1E

Supplier Management #5, 6

2, 3

Supplier Management #7

4, 5

Supplier Management #8

3

Day-To-Day #1

4

Day-To-Day #2

4B

Performance Management #1

4A

Performance Management #2

4F, 4G

Performance Management #3

4C, 4E

Performance Management #4

4D, 5

Performance Management #5

1

Information Management #1

2

Information Management #2

3

Information Management #3

1B, 1F

Information Management #4

A.T. Kearney 7/17030/43/B

44.

X. Appendix B — Reference To Leadership Practices InProcurement

Open-ended questions — supporting information

Questionnaire Reference

Procurement Strategy

Procurement Organization

Leadership Practice

1

Procurement Strategy #1

7

Procurement Strategy #1, 4

3

Procurement Strategy #2

Performance Management #5

15

Procurement Strategy #6

13, 15, 16

Procurement Strategy #5

10, 11

Procurement Strategy #6

3

Procurement Organization #2

6

Procurement Organization #3, 5

9

Procurement Organization #4

1, 2

Procurement Organization #5

Performance Management #4

A.T. Kearney 7/17030/44/B

45.

X. Appendix B — Reference To Leadership Practices InProcurement (Cont’d)

Open-ended questions — supporting information

Questionnaire Reference

Sourcing Process

Day-To-Day Purchasing And

Controlling

Performance Management

Leadership Practice

1, 2

Sourcing Process #1, 2

3

Sourcing Process #2, 3

6

Sourcing Process #3

4

Sourcing Process #4

1, 2

Day-To-Day #1, 2

1

Performance Management #1, 2, 3, 4

3

Performance Management #3

2

Performance Management #4

A.T. Kearney 7/17030/45/B

46.

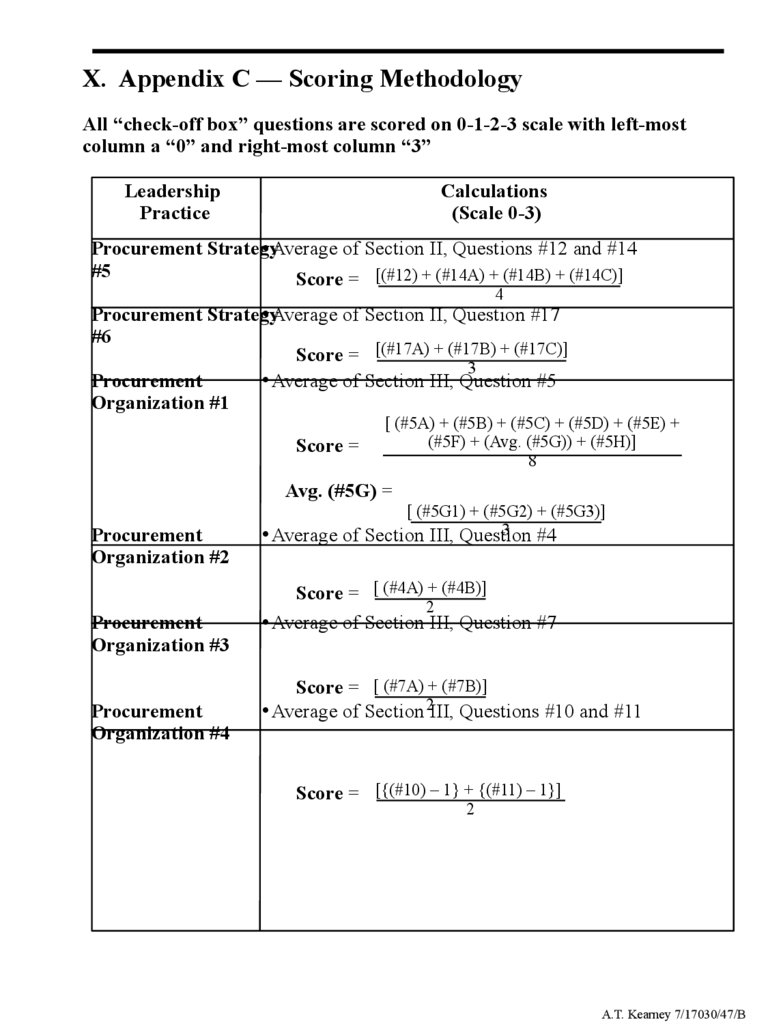

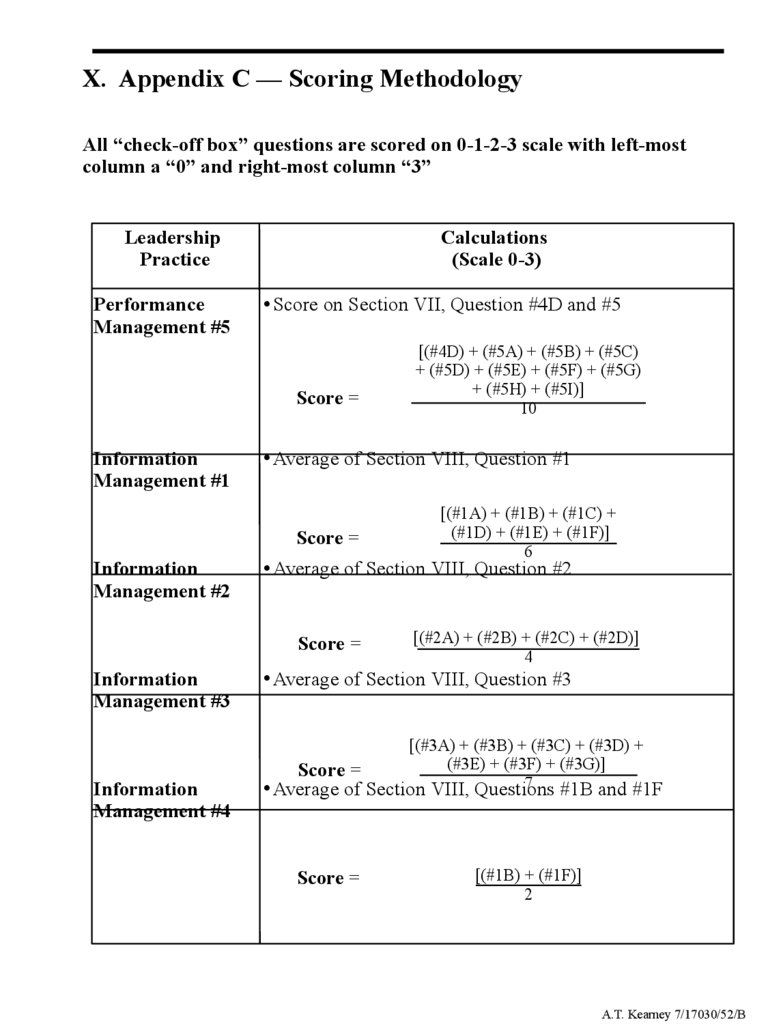

X. Appendix C — Scoring MethodologyAll “check-off box” questions are scored on 0-1-2-3 scale with left-most

column a “0” and right-most column “3”

Leadership

Practice

Calculations

(Scale 0-3)

Procurement Strategy

•Score on Section II, Question #2A

#1

Score = (#2A)

Procurement Strategy

•Average of scores on Section II, Questions #2B and #4

#2

[(#2B) + (#4)]

Score =

2

Procurement Strategy

•Section II, Question #5

#3

—Percent categories answered “yes” = A =

Range of A: 0% 1%-33% 33%-66% 67%-100%

Score = B

0

1

2

3

•Section II, Question #6

Number Of

Sourcing Groups

0

1-3

4-6

Score = C

0

1

2

•Leadership practice

Score = (0.4) B + [(0.6) (Avg. (C))] (A)

7-8

3

Procurement Strategy

•Average of Section II, Questions #8 and #9

#4

[(#8) + (Avg. (#9A)) + (#9B) + (#9C)

+ (#9D) + (#9E) + (#9F) + (#9G) + (#9H)]

Avg.Score

(#9A)= =

9

[(#9A1) + (#9A2) + (#9A3)

+ (#9A4)]

4

A.T. Kearney 7/17030/46/B

47.

X. Appendix C — Scoring MethodologyAll “check-off box” questions are scored on 0-1-2-3 scale with left-most

column a “0” and right-most column “3”

Leadership

Practice

Calculations

(Scale 0-3)

Procurement Strategy

•Average of Section II, Questions #12 and #14

#5

Score = [(#12) + (#14A) + (#14B) + (#14C)]

4

Procurement Strategy

•Average of Section II, Question #17

#6

Score = [(#17A) + (#17B) + (#17C)]

3

Procurement

•Average of Section III, Question #5

Organization #1

Score =

[ (#5A) + (#5B) + (#5C) + (#5D) + (#5E) +

(#5F) + (Avg. (#5G)) + (#5H)]

8

Avg. (#5G) =

Procurement

Organization #2

[ (#5G1) + (#5G2) + (#5G3)]

3

#4

•Average of Section III, Question

Score = [ (#4A) + (#4B)]

Procurement

Organization #3

Procurement

Organization #4

2

•Average of Section III, Question #7

Score = [ (#7A) + (#7B)]

•Average of Section 2III, Questions #10 and #11

Score = [{(#10) – 1} + {(#11) – 1}]

2

A.T. Kearney 7/17030/47/B

48.

X. Appendix C — Scoring MethodologyAll “check-off box” questions are scored on 0-1-2-3 scale with left-most

column a “0” and right-most column “3”

Leadership

Practice

Procurement

Organization #5

Calculations

(Scale 0-3)

•Average of Section III, Questions #7B and #8

Score =

[(#7B) + (#8)]

2

•Question #8

Number Of Training

Programs Checked

Score (#8)

Sourcing Process

#1

Sourcing Process

#2

Sourcing Process

#3

Sourcing Process

#4

0-1

2-4

5-7

8-14

0

1

2

3

•Average of Section IV, Questions #5C and #5E

Score = [(#5C) + (#5E)]

•Average of Section IV,2 Questions #5B and #5D

[(#5B) + (#5D)]

Score

of =

Section IV,2 Questions #5A and #7

•Average

Score = [(#5A) + (#7)]

•Score on Section IV,2Question #5F

Score = (#5F)

A.T. Kearney 7/17030/48/B

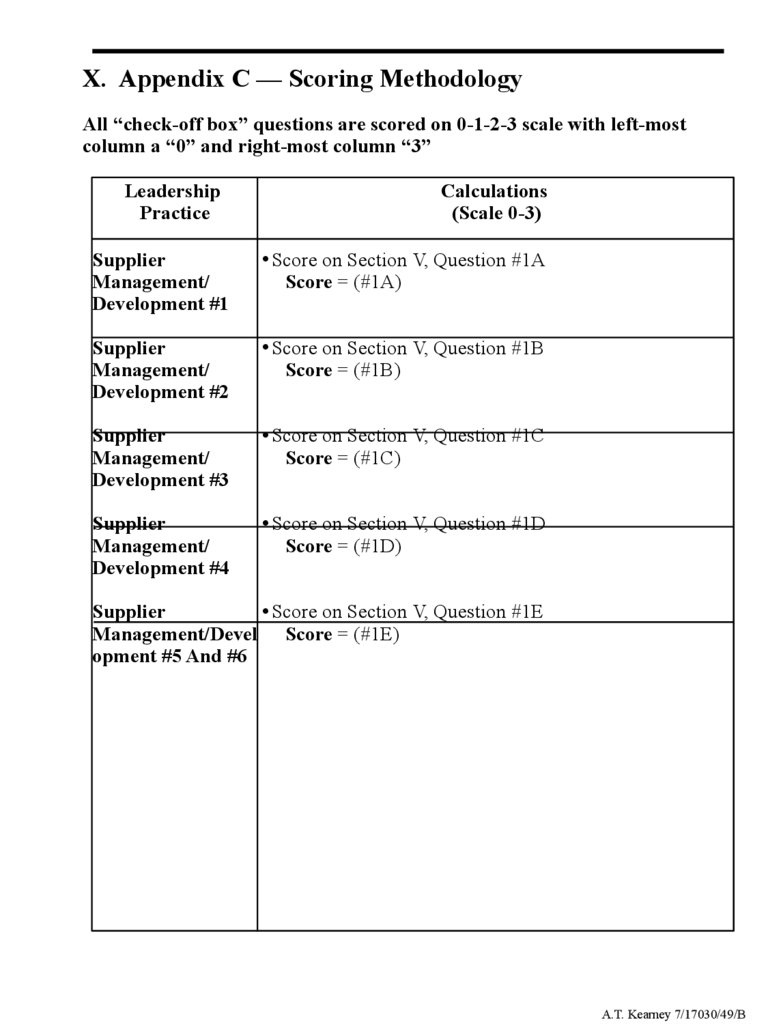

49.

X. Appendix C — Scoring MethodologyAll “check-off box” questions are scored on 0-1-2-3 scale with left-most

column a “0” and right-most column “3”

Leadership

Practice

Calculations

(Scale 0-3)

Supplier

Management/

Development #1

•Score on Section V, Question #1A

Score = (#1A)

Supplier

Management/

Development #2

•Score on Section V, Question #1B

Score = (#1B)

Supplier

Management/

Development #3

•Score on Section V, Question #1C

Score = (#1C)

Supplier

Management/

Development #4

•Score on Section V, Question #1D

Score = (#1D)

Supplier

•Score on Section V, Question #1E

Management/Devel Score = (#1E)

opment #5 And #6

A.T. Kearney 7/17030/49/B

50.

X. Appendix C — Scoring MethodologyAll “check-off box” questions are scored on 0-1-2-3 scale with left-most

column a “0” and right-most column “3”

Leadership

Practice

Calculations

(Scale 0-3)

Supplier Management/

•Average of Section V, Questions #2 and #3

Development #7

[Avg. (#2) + Max. (#3)]

Score =

2

Avg. (#2) =

[(#2A) + (#2B) + (#2C) + (#2D)]

4

Max. (#3) =

Max. [(#3A) or (#3B) or (#3C) or (#3D)]

Supplier Management/

Development #8

•Average of Section V, Questions #4 and #5

Score =

Avg. (#4) =

Avg. (#5) =

[Avg. (#4) + Avg. (#5)]

2

[(#4A) + (#4B) + (#4C) + (#4D)]

4

[(#5A) + (#5B) + (#5C) + (#5D) + (#5E)]

5

A.T. Kearney 7/17030/50/B

51.

X. Appendix C — Scoring MethodologyAll “check-off box” questions are scored on 0-1-2-3 scale with left-most

column a “0” and right-most column “3”

Leadership

Practice

Calculations

(Scale 0-3)

Day-To-Day

•Average of Section VI, Question #3

Purchasing/Controllin

[(#3A) + (#3B1) + (#3B2) + (#3B3) + (#3B4)]

Score =

g #1

5

Day-To-Day

•Average of Section VI, Question #4

Purchasing/Controllin

g #2

[(#4A) + (#4B) + (#4C) + (#4D) + (#4E)]

Score =

5

Performance

Management #1

Performance

Management #2

•Average of Section VII, Question #4B

[(#4B1) + (#4B2) + (#4B3)

+ (#4B4) + (#4B5)]

5

Score =

•Score on Section VII, Question #4A

Score = (#4A)

Performance

Management #3

•Average of Section VII, Questions #4F and #4G

Performance

Management #4

[(#4F) + (#4G)]

Score of

= Section

VII, Questions #4C and #4E

•Average

2

Score = [(#4C) + (#4E)]

2

A.T. Kearney 7/17030/51/B

52.

X. Appendix C — Scoring MethodologyAll “check-off box” questions are scored on 0-1-2-3 scale with left-most

column a “0” and right-most column “3”

Leadership

Practice

Performance

Management #5

Calculations

(Scale 0-3)

•Score on Section VII, Question #4D and #5

Score =

Information

Management #1

•Average of Section VIII, Question #1

Score =

Information

Management #2

Information

Management #4

[(#1A) + (#1B) + (#1C) +

(#1D) + (#1E) + (#1F)]

6

•Average of Section VIII, Question #2

Score =

Information

Management #3

[(#4D) + (#5A) + (#5B) + (#5C)

+ (#5D) + (#5E) + (#5F) + (#5G)

+ (#5H) + (#5I)]

10

[(#2A) + (#2B) + (#2C) + (#2D)]

4

•Average of Section VIII, Question #3

[(#3A) + (#3B) + (#3C) + (#3D) +

(#3E) + (#3F) + (#3G)]

Score =

7

#1B and #1F

•Average of Section VIII, Questions

Score =

[(#1B) + (#1F)]

2

A.T. Kearney 7/17030/52/B

Английский язык

Английский язык