Похожие презентации:

High-Density Ac-Dc Power Supplies using Active-Clamp Flyback Topologу

1. High-Density Ac-Dc Power Supplies using Active-Clamp Flyback Topology

Ajay Hari, Bryan McCoy2. Agenda

• Introduction to active-clamp flyback operation (ACF)• ACF light-load efficiency challenge

• Introduction to the NCP1568 – Ac-Dc ACF PWM IC.

• Light load and standby solution

• Design equations for transformer selection of the ACF

• Primary and secondary component selection considerations

• Performance data of ultra-high density active-clamp flyback board.

2

3. Introduction to Active-Clamp Flyback Operation (ACF)

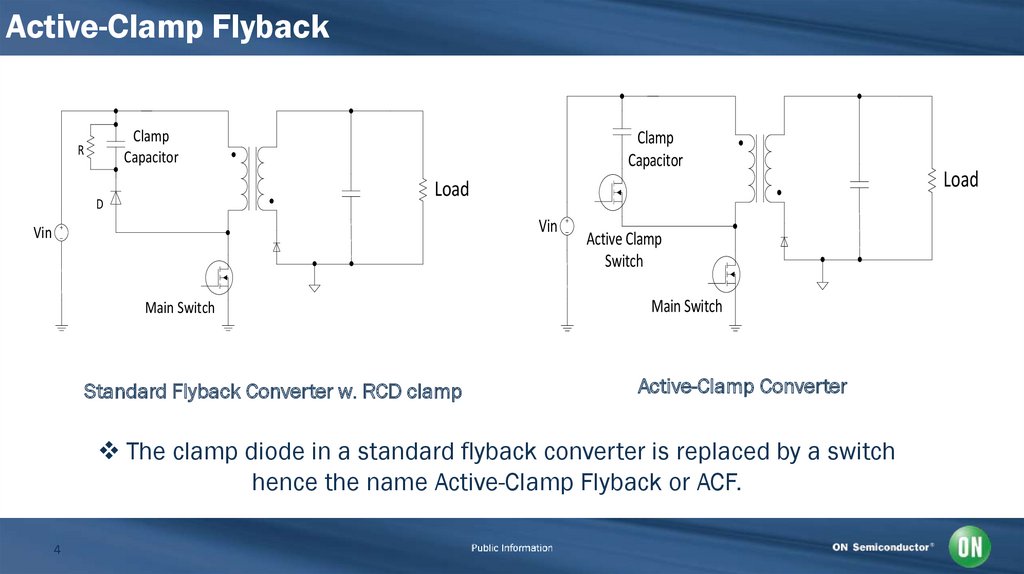

34. Active-Clamp Flyback

ClampCapacitor

R

Clamp

Capacitor

Load

D

Vin

Vin

Main Switch

Standard Flyback Converter w. RCD clamp

Active Clamp

Switch

Main Switch

Active-Clamp Converter

The clamp diode in a standard flyback converter is replaced by a switch

hence the name Active-Clamp Flyback or ACF.

4

Load

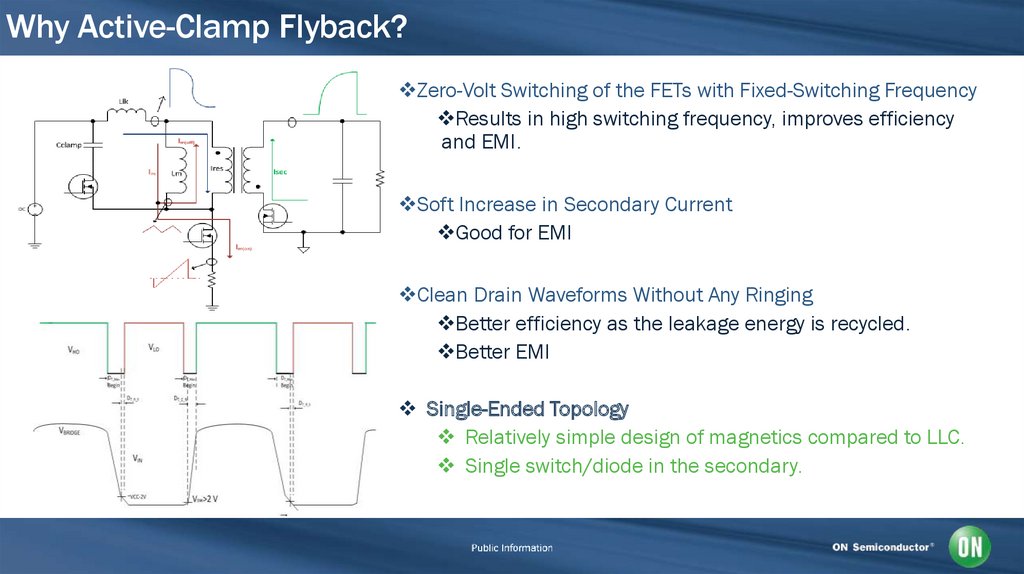

5. Why Active-Clamp Flyback?

Zero-Volt Switching of the FETs with Fixed-Switching FrequencyResults in high switching frequency, improves efficiency

and EMI.

Soft Increase in Secondary Current

Good for EMI

Clean Drain Waveforms Without Any Ringing

Better efficiency as the leakage energy is recycled.

Better EMI

Single-Ended Topology

Relatively simple design of magnetics compared to LLC.

Single switch/diode in the secondary.

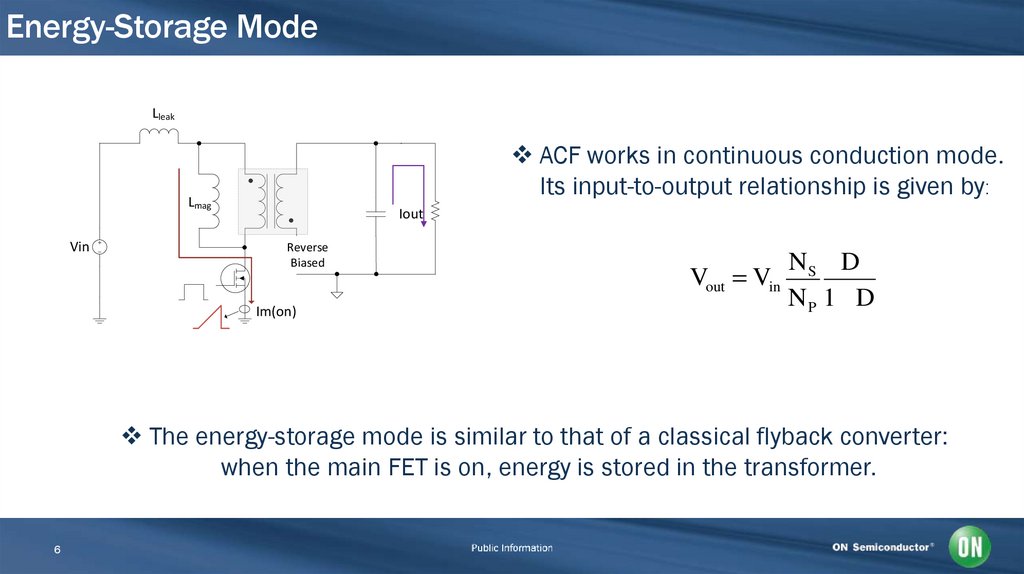

6. Energy-Storage Mode

LleakACF works in continuous conduction mode.

Its input-to-output relationship is given by:

Lmag

Vin

Iout

Reverse

Biased

Im(on)

NS D

Vout = Vin

N P 1- D

The energy-storage mode is similar to that of a classical flyback converter:

when the main FET is on, energy is stored in the transformer.

6

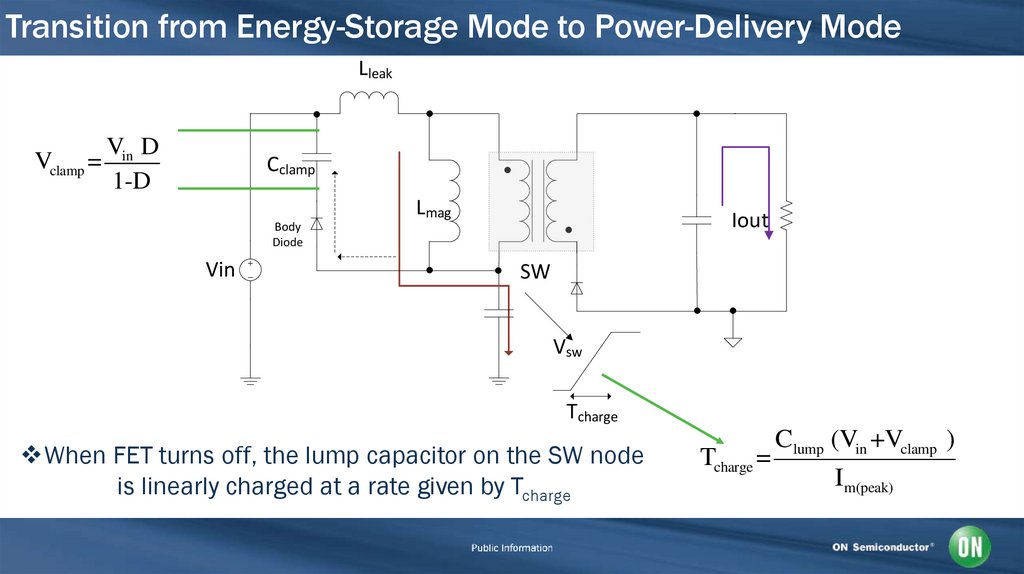

7. Transition from Energy-Storage Mode to Power-Delivery Mode

LleakVclamp =

Vin D

1-D

Cclamp

Body

Diode

Vin

Lmag

Iout

SW

Vsw

Tcharge

When FET turns off, the lump capacitor on the SW node

is linearly charged at a rate given by Tcharge

Tcharge =

Clump (Vin +Vclamp )

Im(peak)

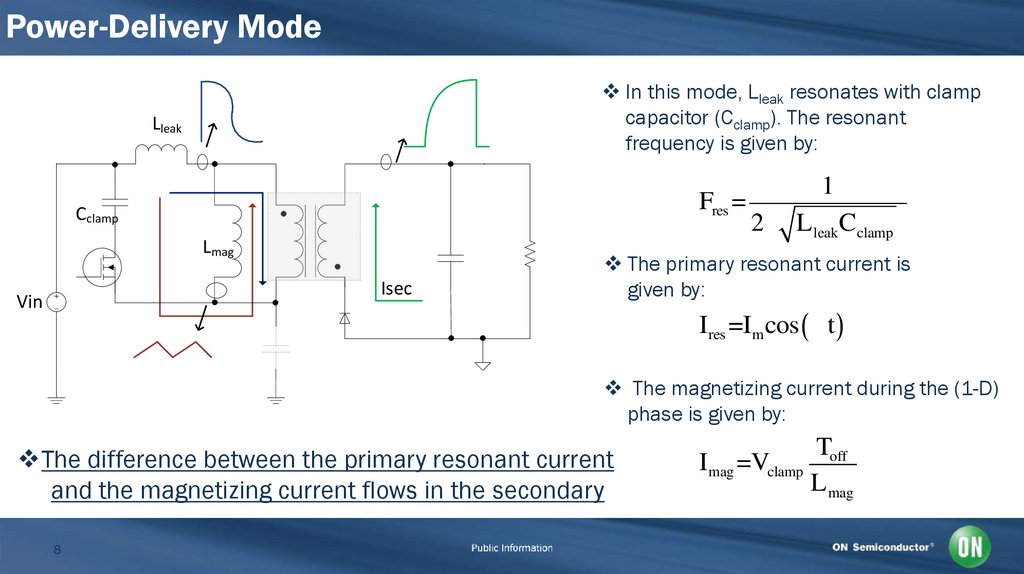

8. Power-Delivery Mode

In this mode, Lleak resonates with clampcapacitor (Cclamp). The resonant

frequency is given by:

Lleak

Fres =

Cclamp

Lmag

Isec

Vin

1

2p L leak Cclamp

The primary resonant current is

given by:

Ires =Im cos ( wt )

The magnetizing current during the (1-D)

phase is given by:

The difference between the primary resonant current

and the magnetizing current flows in the secondary

8

Toff

Imag =Vclamp

L mag

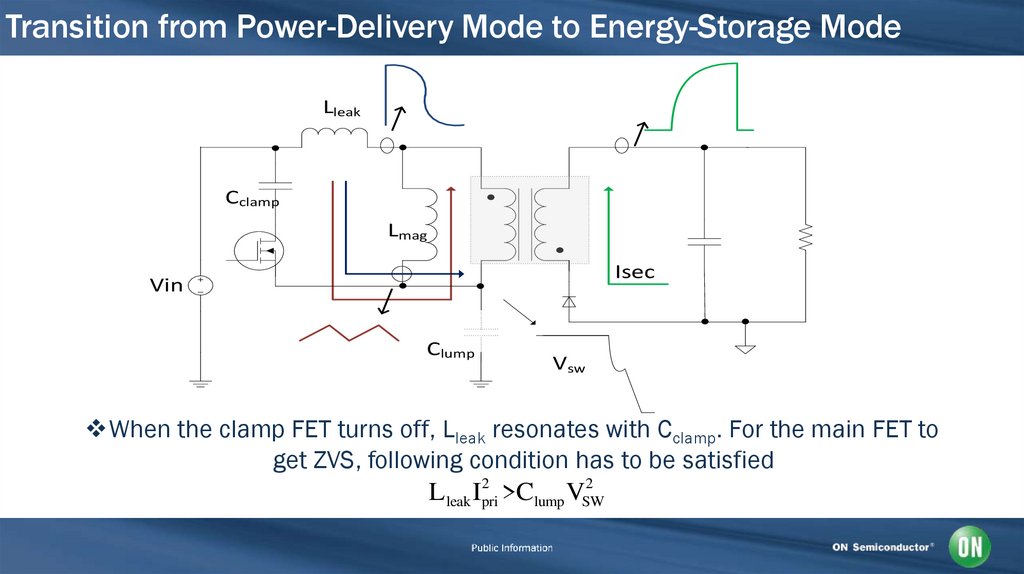

9. Transition from Power-Delivery Mode to Energy-Storage Mode

LleakCclamp

Lmag

Isec

Vin

Clump

Vsw

When the clamp FET turns off, Lleak resonates with Cclamp. For the main FET to

get ZVS, following condition has to be satisfied

2

L leak I2pri >Clump VSW

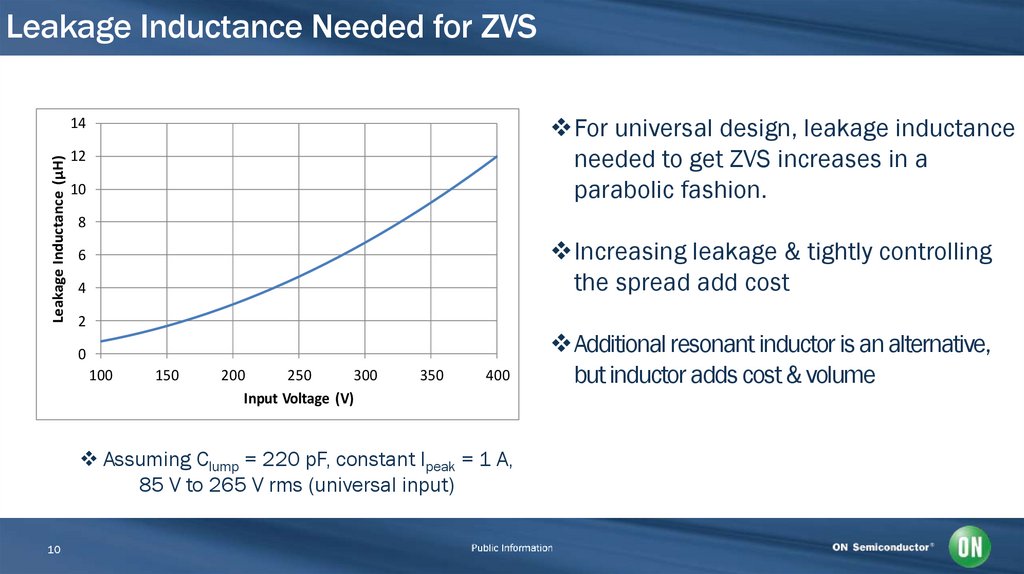

10. Leakage Inductance Needed for ZVS

For universal design, leakage inductanceneeded to get ZVS increases in a

parabolic fashion.

Leakage Inductance (µH)

14

12

10

8

Increasing leakage & tightly controlling

the spread add cost

6

4

2

0

100

150

300

250

200

Input Voltage (V)

350

400

Assuming Clump = 220 pF, constant Ipeak = 1 A,

85 V to 265 V rms (universal input)

10

Additional resonant inductor is an alternative,

but inductor adds cost & volume

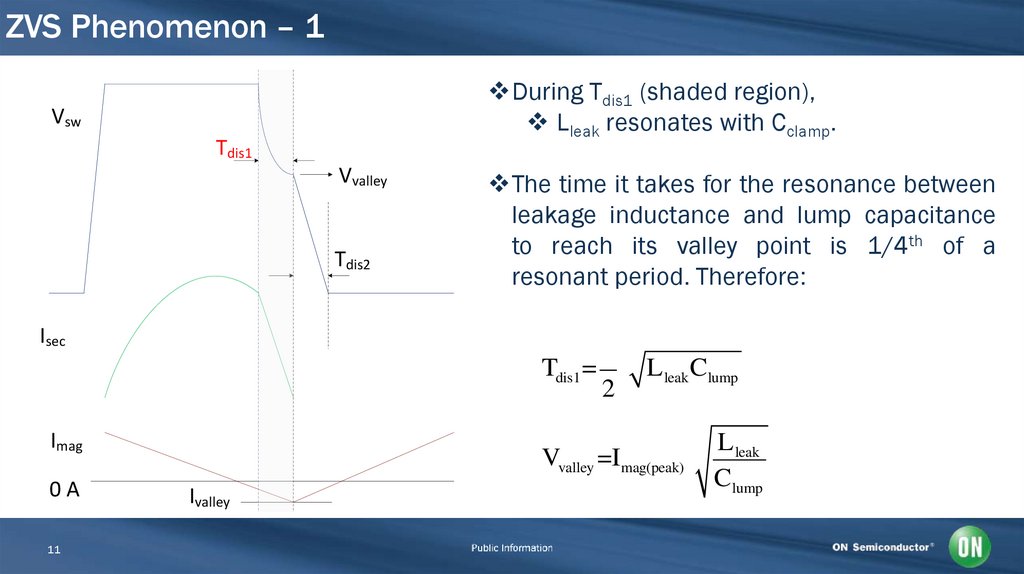

11. ZVS Phenomenon – 1

During Tdis1 (shaded region),Lleak resonates with Cclamp.

Vsw

Tdis1

Vvalley

Tdis2

Isec

p

Tdis1 =

2

Imag

0A

11

The time it takes for the resonance between

leakage inductance and lump capacitance

to reach its valley point is 1/4th of a

resonant period. Therefore:

L leak Clump

Vvalley =Imag(peak)

Ivalley

L leak

Clump

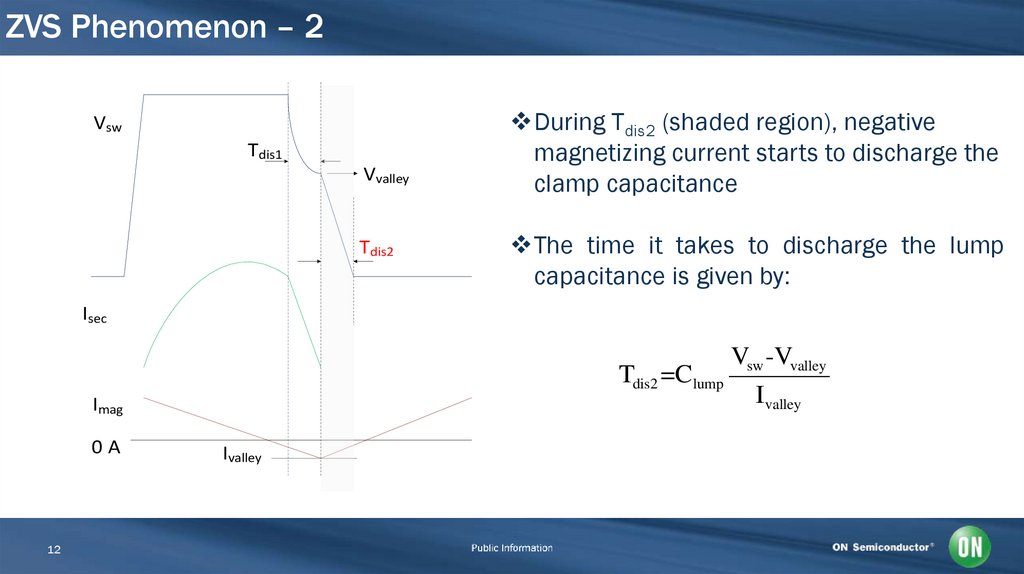

12. ZVS Phenomenon – 2

VswTdis1

Vvalley

Tdis2

During Tdis2 (shaded region), negative

magnetizing current starts to discharge the

clamp capacitance

The time it takes to discharge the lump

capacitance is given by:

Isec

Tdis2 =Clump

Imag

0A

12

Ivalley

Vsw -Vvalley

Ivalley

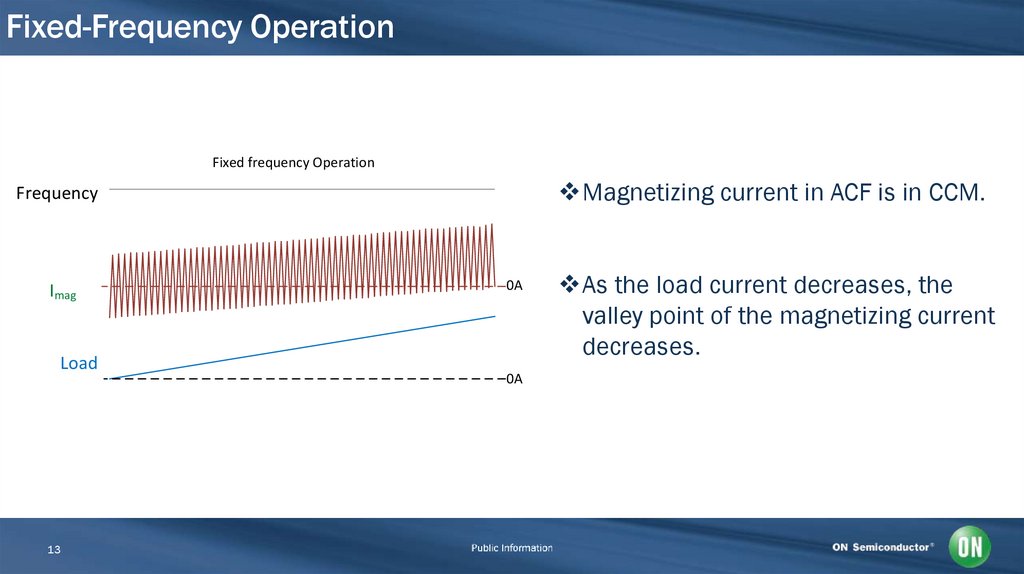

13. Fixed-Frequency Operation

Fixed frequency OperationMagnetizing current in ACF is in CCM.

Frequency

Imag

Load

13

0A

0A

As the load current decreases, the

valley point of the magnetizing current

decreases.

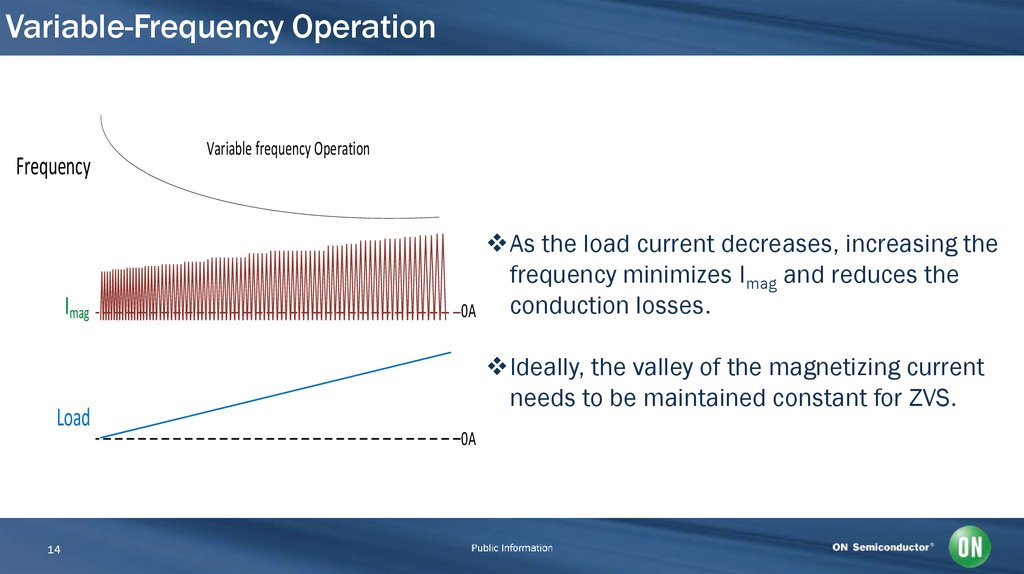

14. Variable-Frequency Operation

FrequencyImag

Load

14

Variable frequency Operation

0A

As the load current decreases, increasing the

frequency minimizes Imag and reduces the

conduction losses.

Ideally, the valley of the magnetizing current

needs to be maintained constant for ZVS.

0A

15. Light-Load Efficiency & Standby Power Challenge

Light-Load Efficiency&

Standby Power Challenge

15

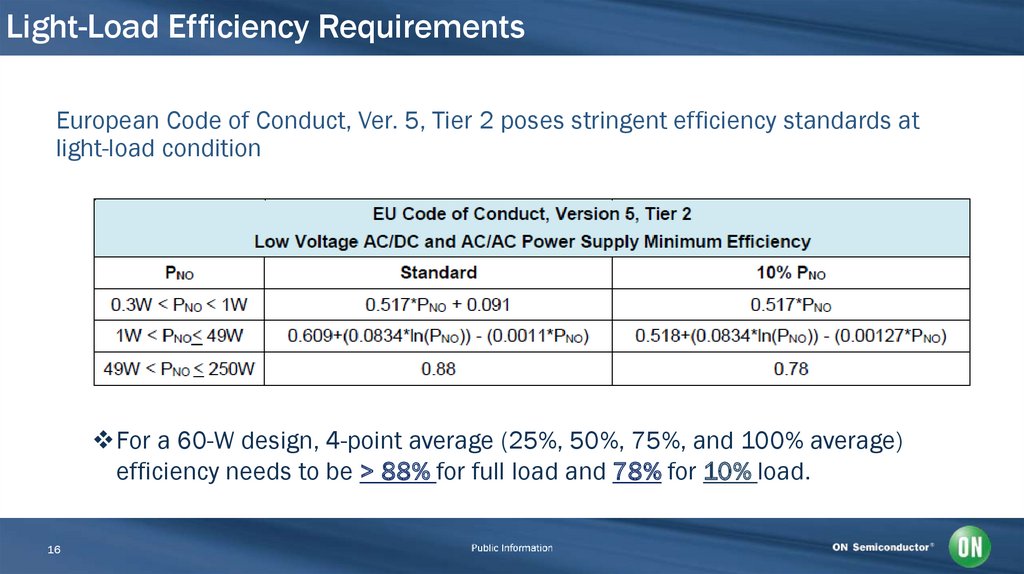

16. Light-Load Efficiency Requirements

European Code of Conduct, Ver. 5, Tier 2 poses stringent efficiency standards atlight-load condition

For a 60-W design, 4-point average (25%, 50%, 75%, and 100% average)

efficiency needs to be > 88% for full load and 78% for 10% load.

16

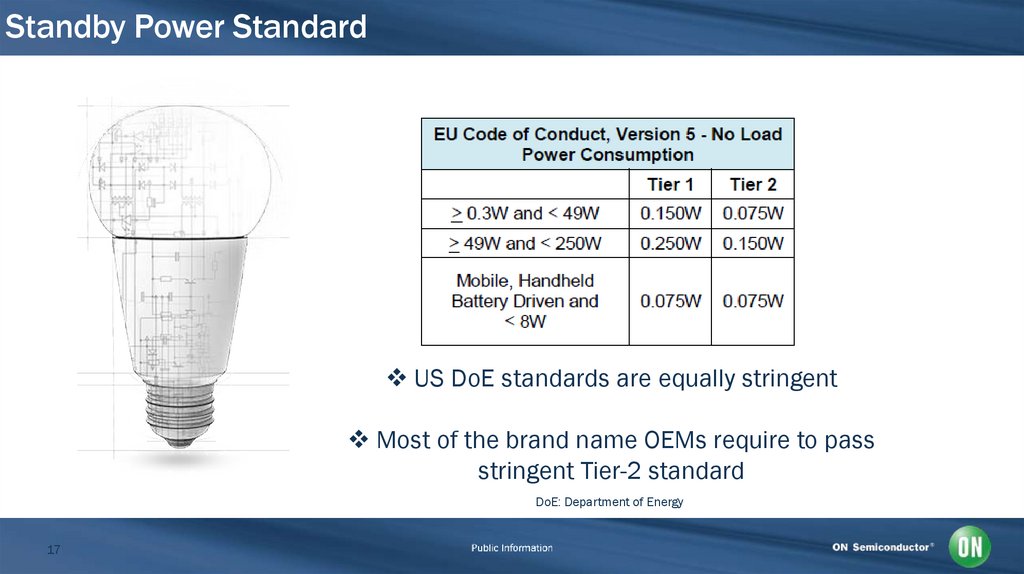

17. Standby Power Standard

US DoE standards are equally stringentMost of the brand name OEMs require to pass

stringent Tier-2 standard

DoE: Department of Energy

17

18. ACF Specific Light-Load Challenges

Magnetizing current is in CCM.Frequency modulation results in high-frequency operation at light

load

Classical frequency foldback is not possible to implement when

magnetizing current is in CCM

18

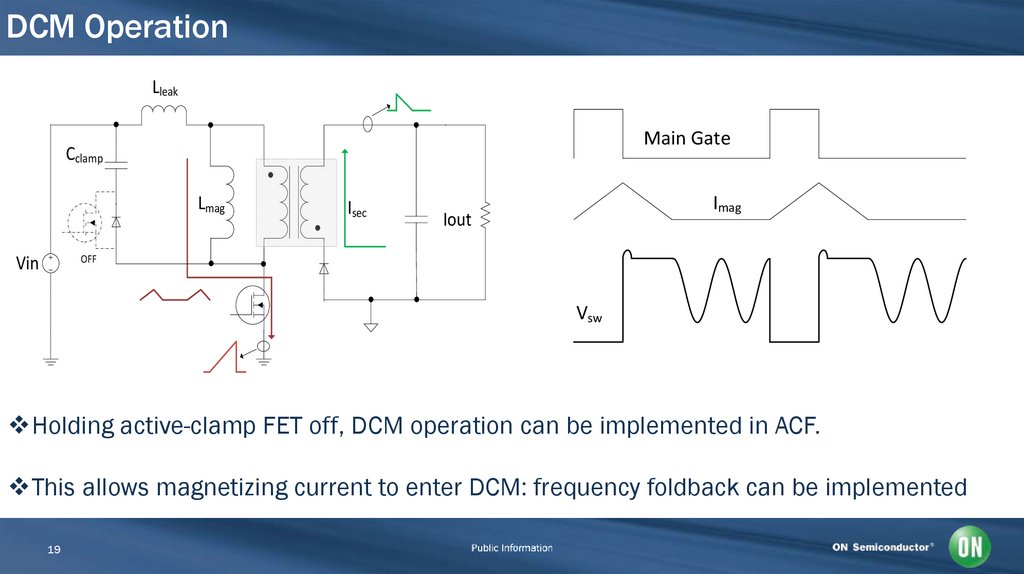

19. DCM Operation

LleakMain Gate

Cclamp

Lmag

Isec

Imag

Iout

OFF

Vin

Vsw

Holding active-clamp FET off, DCM operation can be implemented in ACF.

This allows magnetizing current to enter DCM: frequency foldback can be implemented

19

20. Introduction to NCP1568

Ac-Dc PWM Controller for ACF20

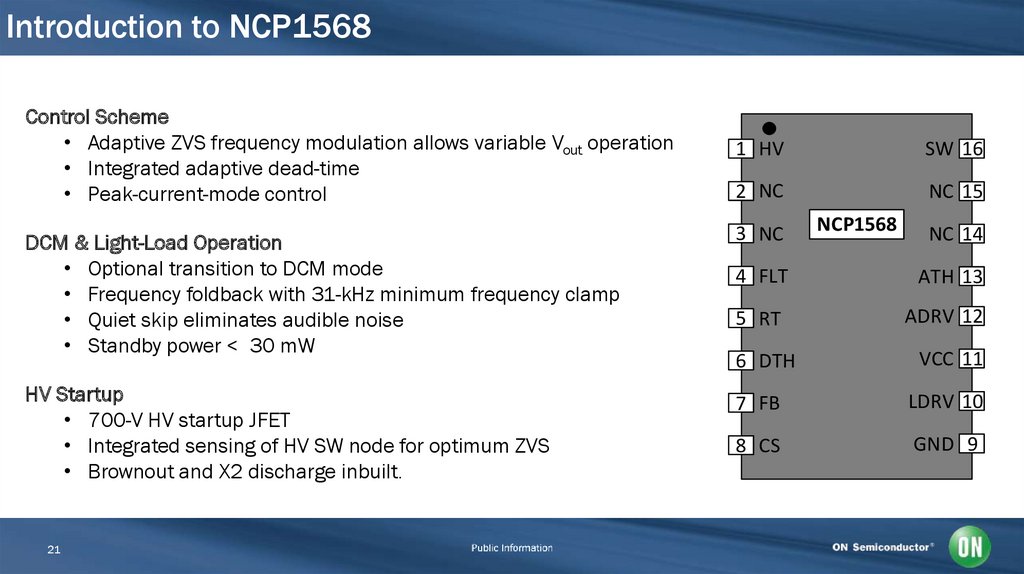

21. Introduction to NCP1568

Control Scheme• Adaptive ZVS frequency modulation allows variable Vout operation

• Integrated adaptive dead-time

• Peak-current-mode control

DCM & Light-Load Operation

• Optional transition to DCM mode

• Frequency foldback with 31-kHz minimum frequency clamp

• Quiet skip eliminates audible noise

• Standby power < 30 mW

HV Startup

• 700-V HV startup JFET

• Integrated sensing of HV SW node for optimum ZVS

• Brownout and X2 discharge inbuilt.

21

1 HV

SW 16

2 NC

NC 15

3 NC

4 FLT

5 RT

6 DTH

NCP1568

NC 14

ATH 13

ADRV 12

VCC 11

7 FB

LDRV 10

8 CS

GND 9

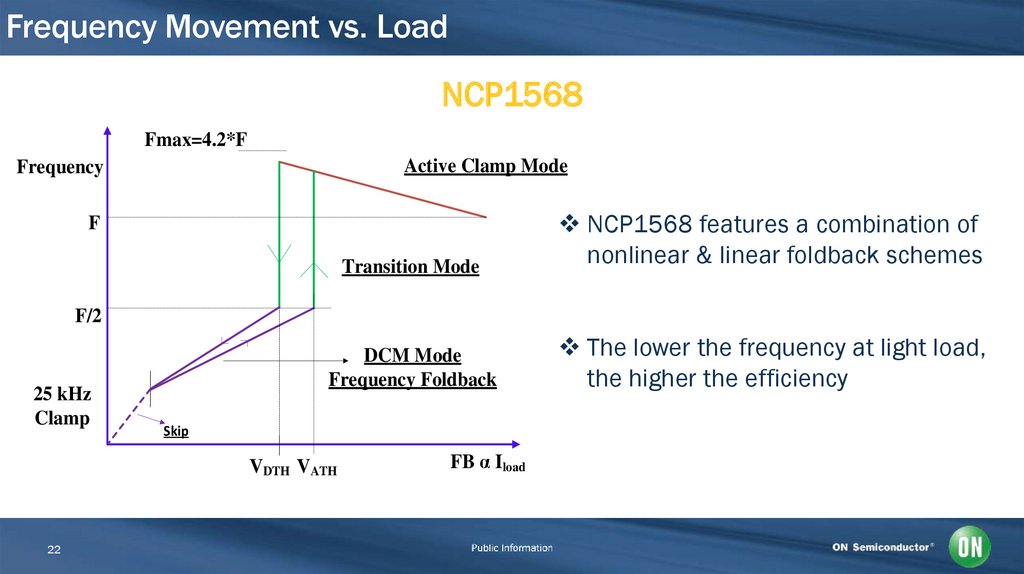

22. Frequency Movement vs. Load

NCP1568Fmax=4.2*F

Active Clamp Mode

Frequency

Transition Mode

NCP1568 features a combination of

nonlinear & linear foldback schemes

DCM Mode

Frequency Foldback

The lower the frequency at light load,

the higher the efficiency

F

F/2

25 kHz

Clamp

Skip

VDTH VATH

22

FB α Iload

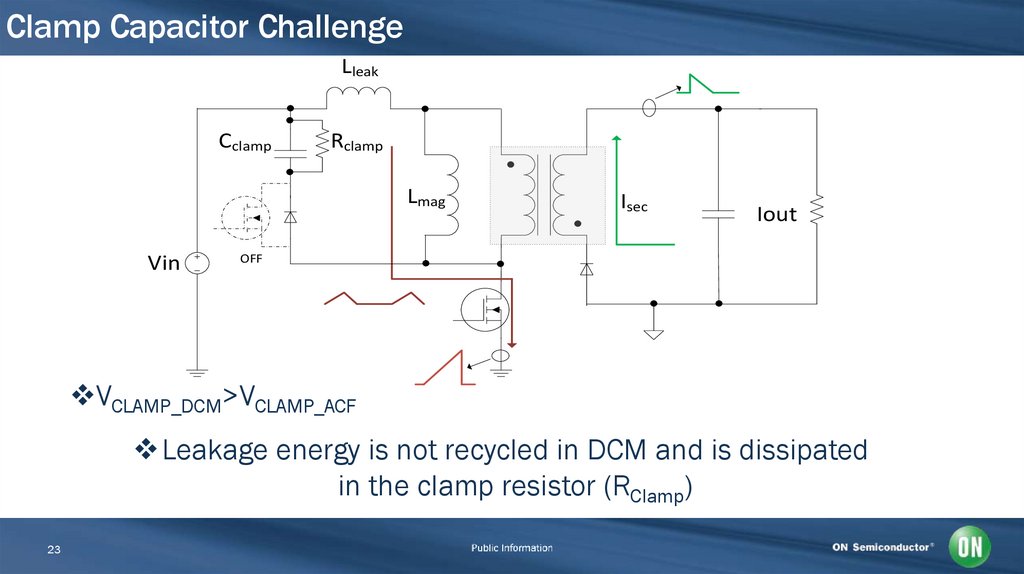

23. Clamp Capacitor Challenge

LleakCclamp

Rclamp

Lmag

Vin

Isec

Iout

OFF

VCLAMP_DCM>VCLAMP_ACF

Leakage energy is not recycled in DCM and is dissipated

in the clamp resistor (RClamp)

23

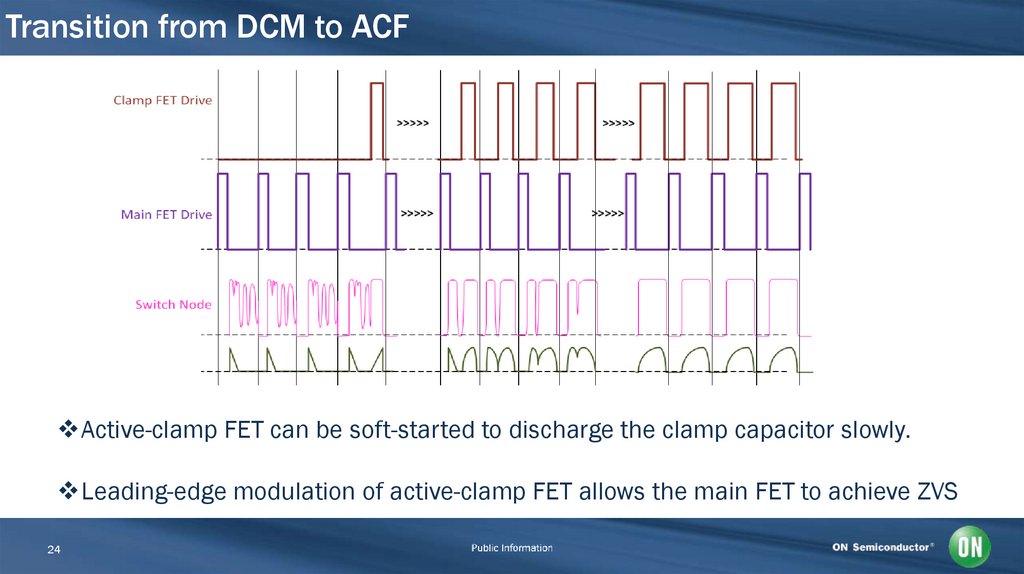

24. Transition from DCM to ACF

Active-clamp FET can be soft-started to discharge the clamp capacitor slowly.Leading-edge modulation of active-clamp FET allows the main FET to achieve ZVS

24

25. DCM Operation Determination

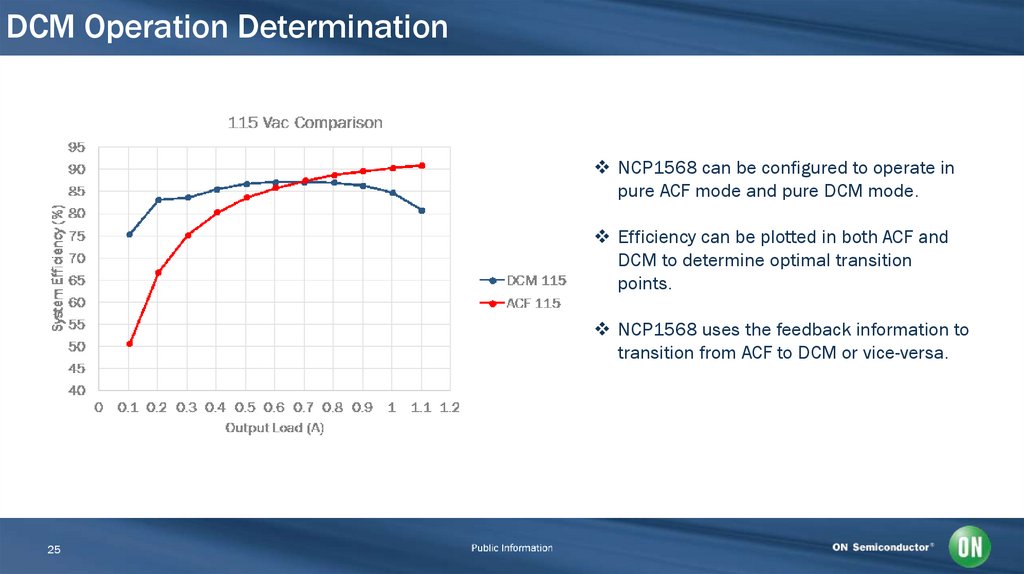

NCP1568 can be configured to operate inpure ACF mode and pure DCM mode.

Efficiency can be plotted in both ACF and

DCM to determine optimal transition

points.

NCP1568 uses the feedback information to

transition from ACF to DCM or vice-versa.

25

26. Key Components Selection

Transformer Design & Key Equations26

27. Design Specifications

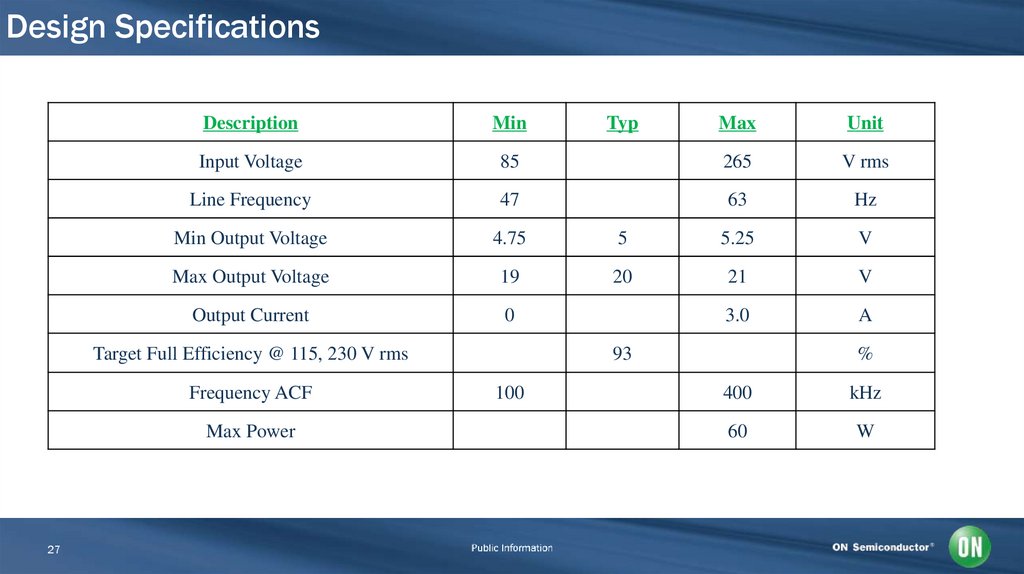

DescriptionMin

Input Voltage

Max

Unit

85

265

V rms

Line Frequency

47

63

Hz

Min Output Voltage

4.75

5

5.25

V

Max Output Voltage

19

20

21

V

Output Current

0

3.0

A

Target Full Efficiency @ 115, 230 V rms

Frequency ACF

Max Power

27

Typ

93

100

%

400

kHz

60

W

28. Turns Ratio Selection

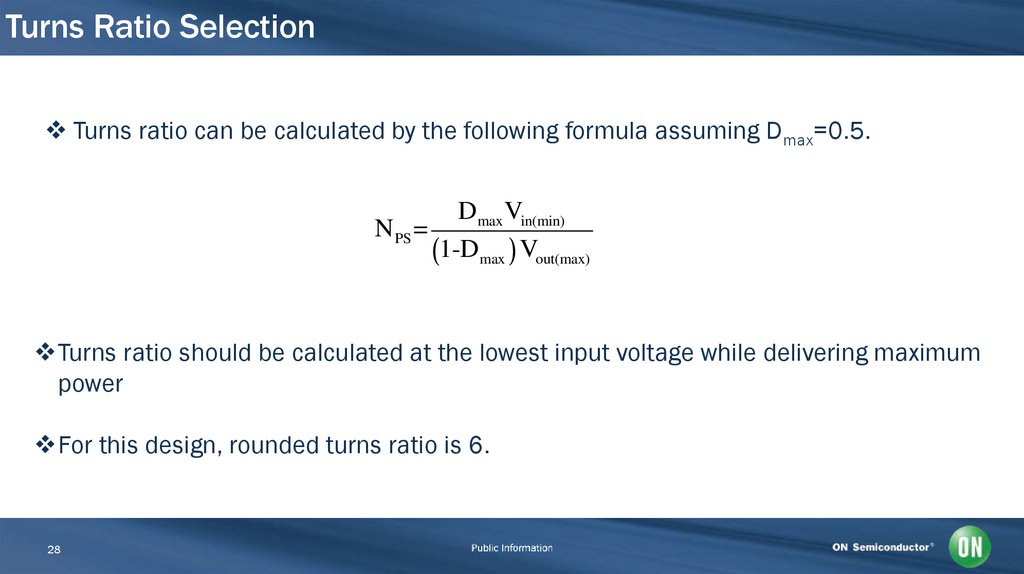

Turns ratio can be calculated by the following formula assuming Dmax=0.5.Dmax Vin(min)

N PS =

(1-Dmax ) Vout(max)

Turns ratio should be calculated at the lowest input voltage while delivering maximum

power

For this design, rounded turns ratio is 6.

28

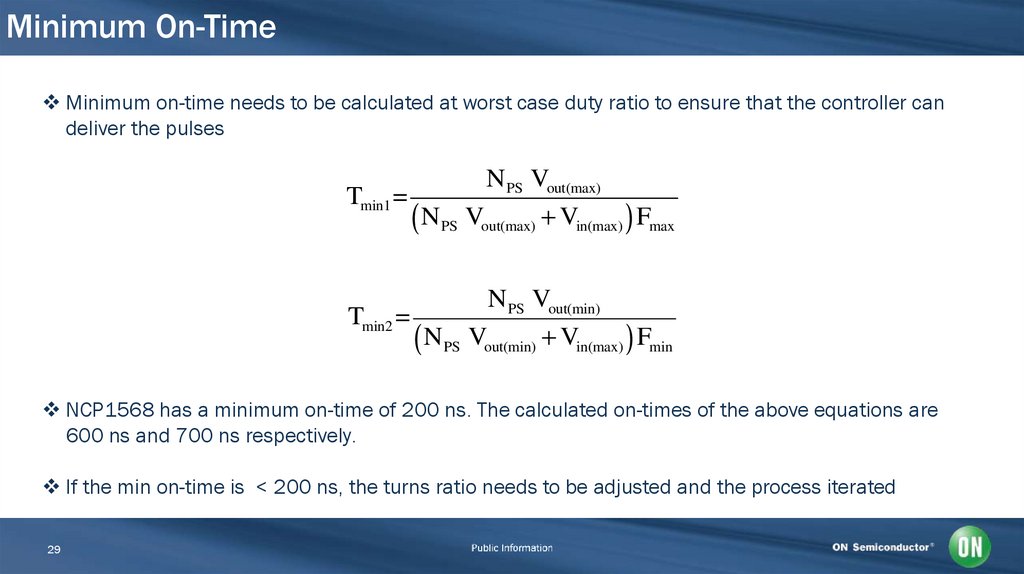

29. Minimum On-Time

Minimum on-time needs to be calculated at worst case duty ratio to ensure that the controller candeliver the pulses

N PS Vout(max)

Tmin1 =

( NPS Vout(max) + Vin(max) ) Fmax

N PS Vout(min)

Tmin2 =

( NPS Vout(min) + Vin(max) ) Fmin

NCP1568 has a minimum on-time of 200 ns. The calculated on-times of the above equations are

600 ns and 700 ns respectively.

If the min on-time is < 200 ns, the turns ratio needs to be adjusted and the process iterated

29

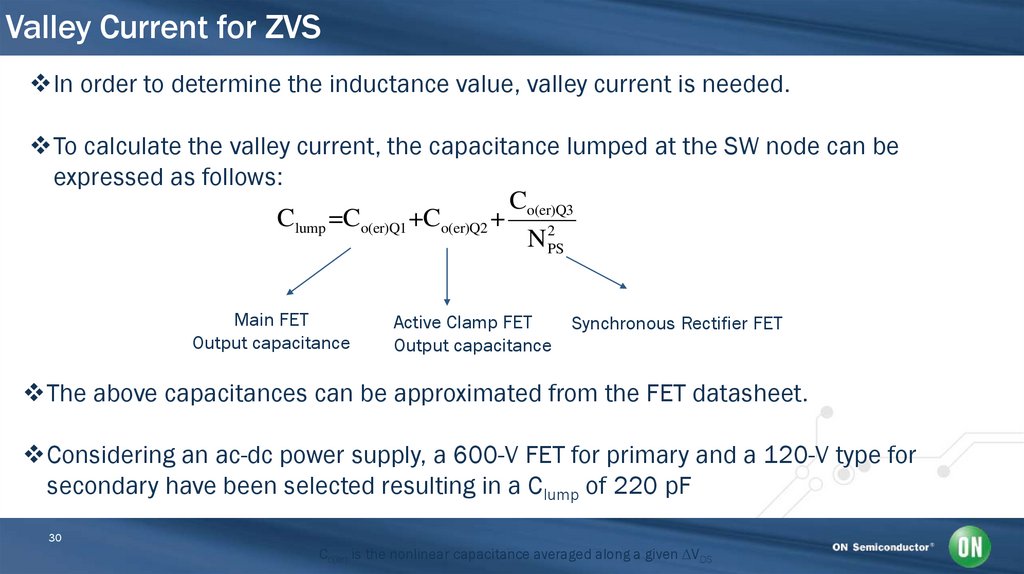

30. Valley Current for ZVS

In order to determine the inductance value, valley current is needed.To calculate the valley current, the capacitance lumped at the SW node can be

expressed as follows:

Co(er)Q3

Clump =Co(er)Q1 +Co(er)Q2 +

N 2PS

Main FET

Output capacitance

Active Clamp FET

Synchronous Rectifier FET

Output capacitance

The above capacitances can be approximated from the FET datasheet.

Considering an ac-dc power supply, a 600-V FET for primary and a 120-V type for

secondary have been selected resulting in a Clump of 220 pF

30

Co(er) is the nonlinear capacitance averaged along a given VDS

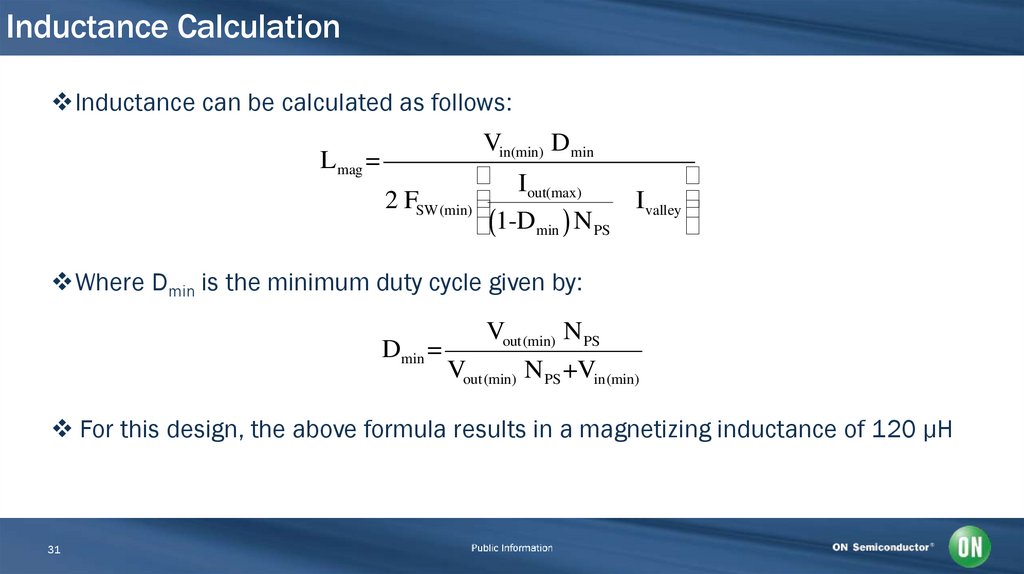

31. Inductance Calculation

Inductance can be calculated as follows:Vin(min) Dmin

L mag =

æ I

æ

out(max)

2 FSW(min) æ

æ 1-D N - Ivalley æ

æ

(

)

æ

æ

min

PS

Where Dmin is the minimum duty cycle given by:

Vout(min) N PS

Dmin =

Vout(min) N PS +Vin(min)

For this design, the above formula results in a magnetizing inductance of 120 µH

31

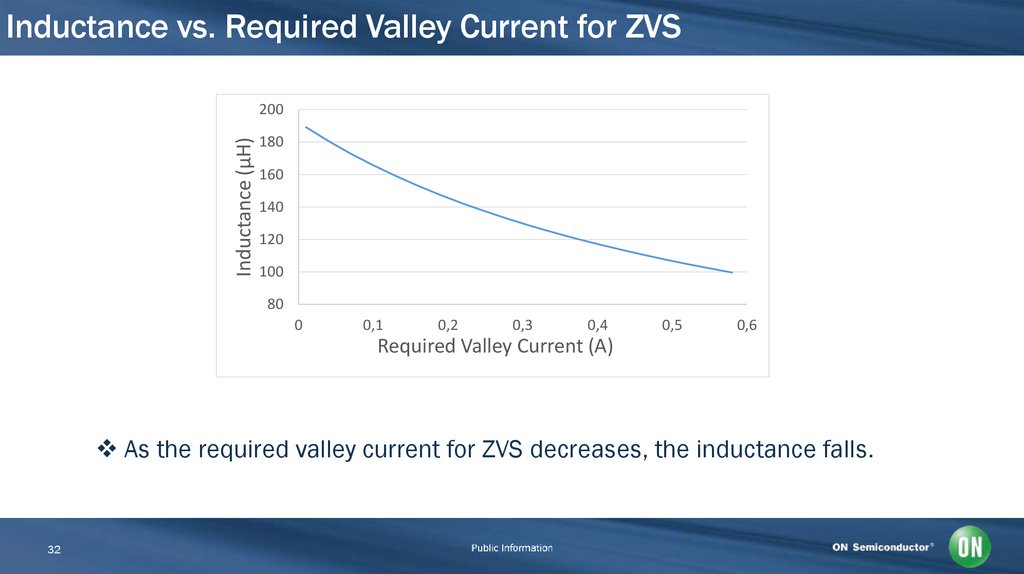

32. Inductance vs. Required Valley Current for ZVS

Inductance (µH)200

180

160

140

120

100

80

0

0,1

0,2

0,3

0,4

0,5

0,6

Required Valley Current (A)

As the required valley current for ZVS decreases, the inductance falls.

32

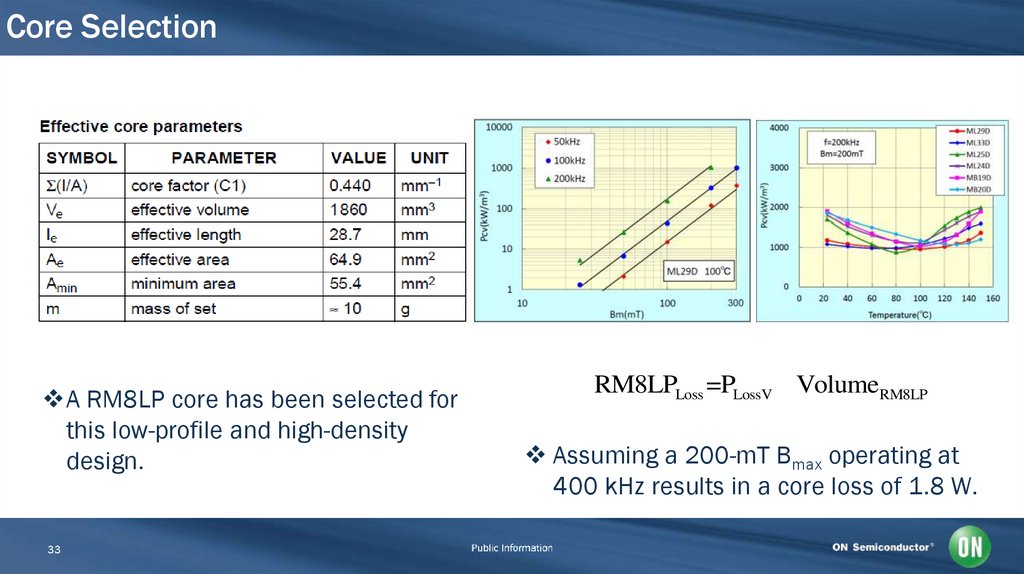

33. Core Selection

A RM8LP core has been selected forthis low-profile and high-density

design.

33

RM8LPLoss =PLossV ´ VolumeRM8LP

Assuming a 200-mT Bmax operating at

400 kHz results in a core loss of 1.8 W.

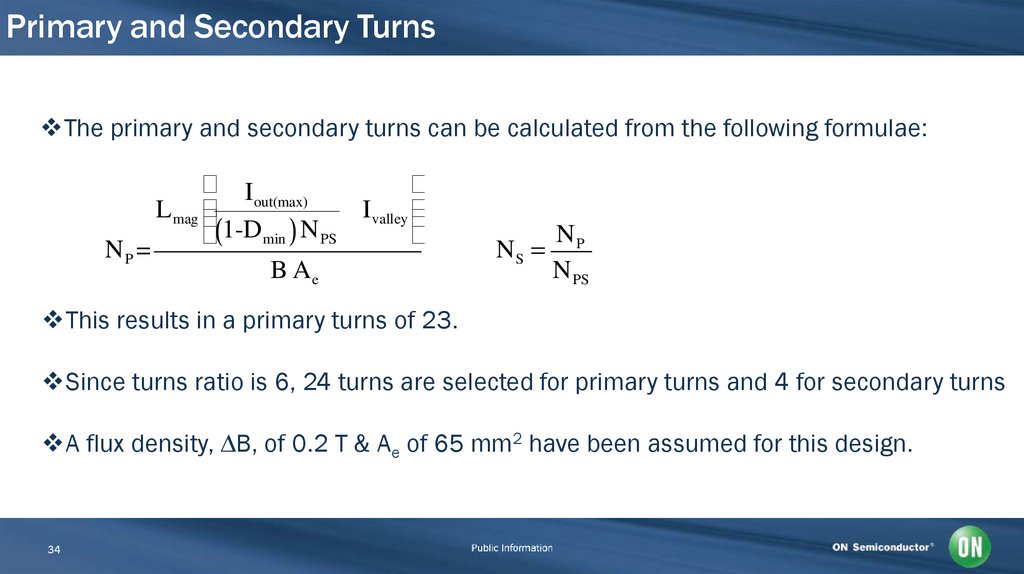

34. Primary and Secondary Turns

The primary and secondary turns can be calculated from the following formulae:æ I

æ

out(max)

L mag æ

æ 1-D N - Ivalley æ

æ

(

)

æ

æ

min

PS

NP =

DB A e

NP

NS =

N PS

This results in a primary turns of 23.

Since turns ratio is 6, 24 turns are selected for primary turns and 4 for secondary turns

A flux density, ∆B, of 0.2 T & Ae of 65 mm2 have been assumed for this design.

34

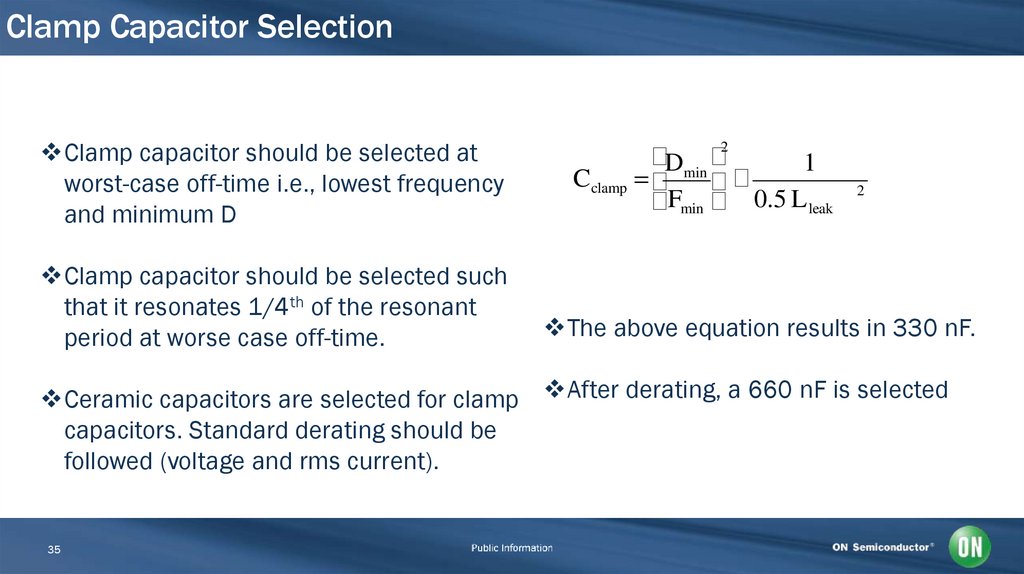

35. Clamp Capacitor Selection

Clamp capacitor should be selected atworst-case off-time i.e., lowest frequency

and minimum D

Clamp capacitor should be selected such

that it resonates 1/4th of the resonant

period at worse case off-time.

æDmin æ

1

Cclamp = æ

ææ

2

æFmin æ 0.5 L leak p

2

The above equation results in 330 nF.

Ceramic capacitors are selected for clamp After derating, a 660 nF is selected

capacitors. Standard derating should be

followed (voltage and rms current).

35

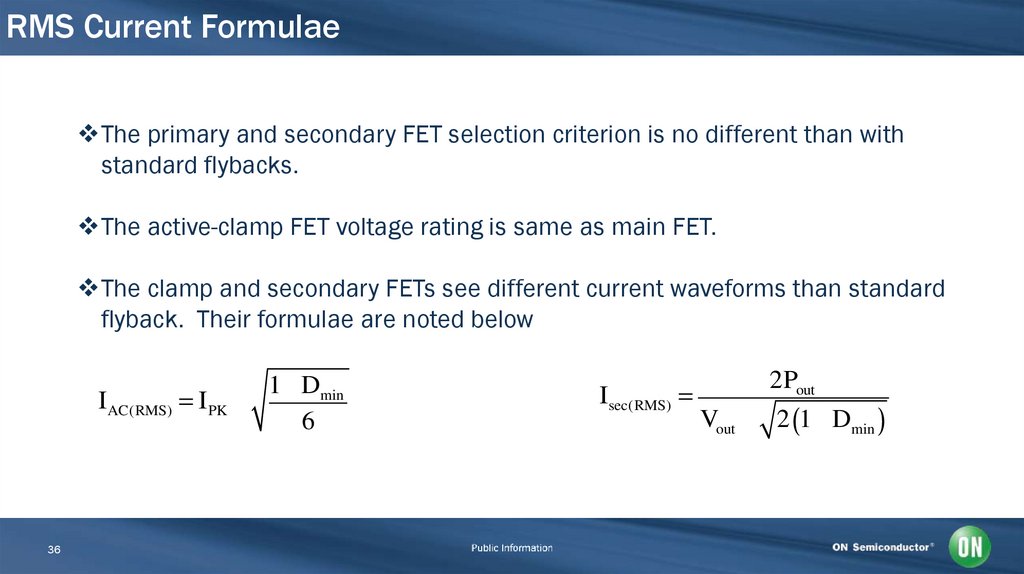

36. RMS Current Formulae

The primary and secondary FET selection criterion is no different than withstandard flybacks.

The active-clamp FET voltage rating is same as main FET.

The clamp and secondary FETs see different current waveforms than standard

flyback. Their formulae are noted below

1- Dmin

IAC(RMS) = I PK ´

6

36

Isec(RMS) =

2Pout

Vout ´ 2 (1- Dmin )

37. 60-W UHD-Board Performance

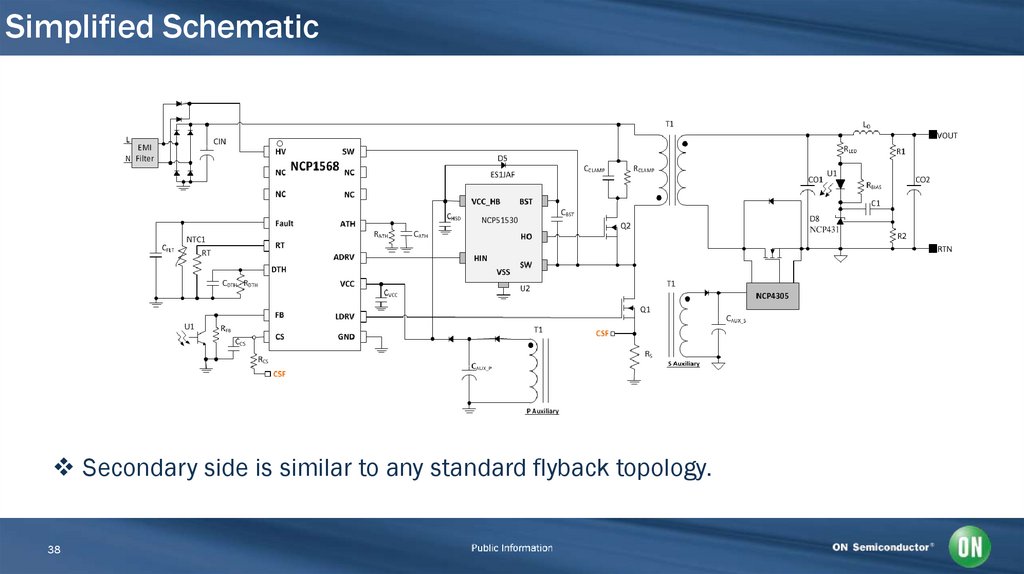

3738. Simplified Schematic

Secondary side is similar to any standard flyback topology.38

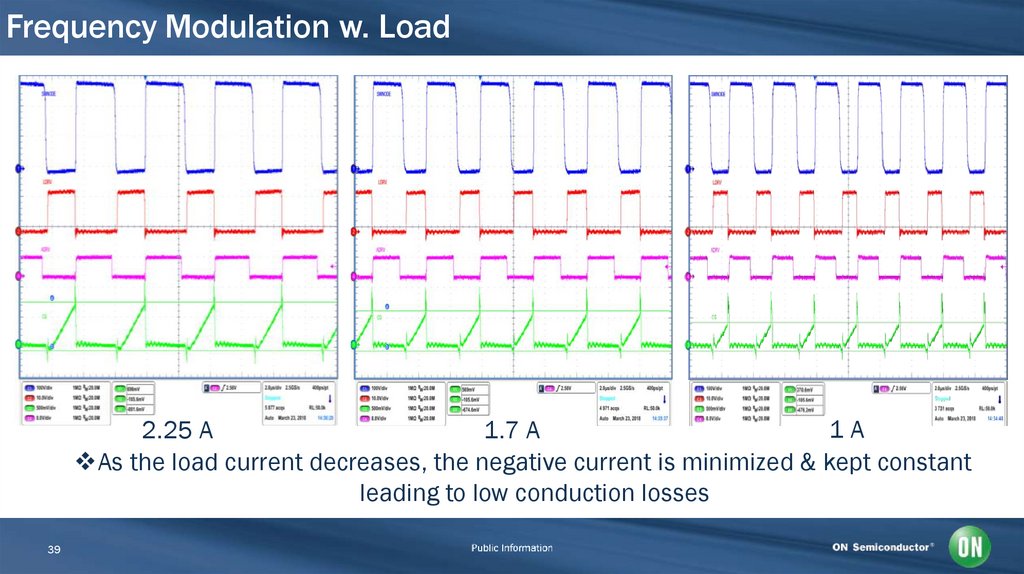

39. Frequency Modulation w. Load

1A2.25 A

1.7 A

As the load current decreases, the negative current is minimized & kept constant

leading to low conduction losses

39

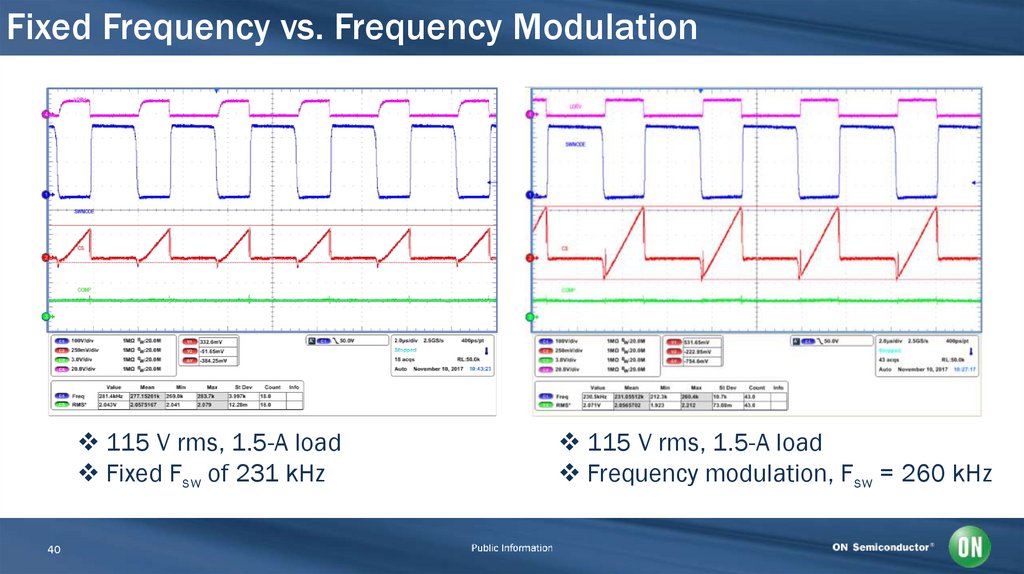

40. Fixed Frequency vs. Frequency Modulation

115 V rms, 1.5-A loadFixed Fsw of 231 kHz

40

115 V rms, 1.5-A load

Frequency modulation, Fsw = 260 kHz

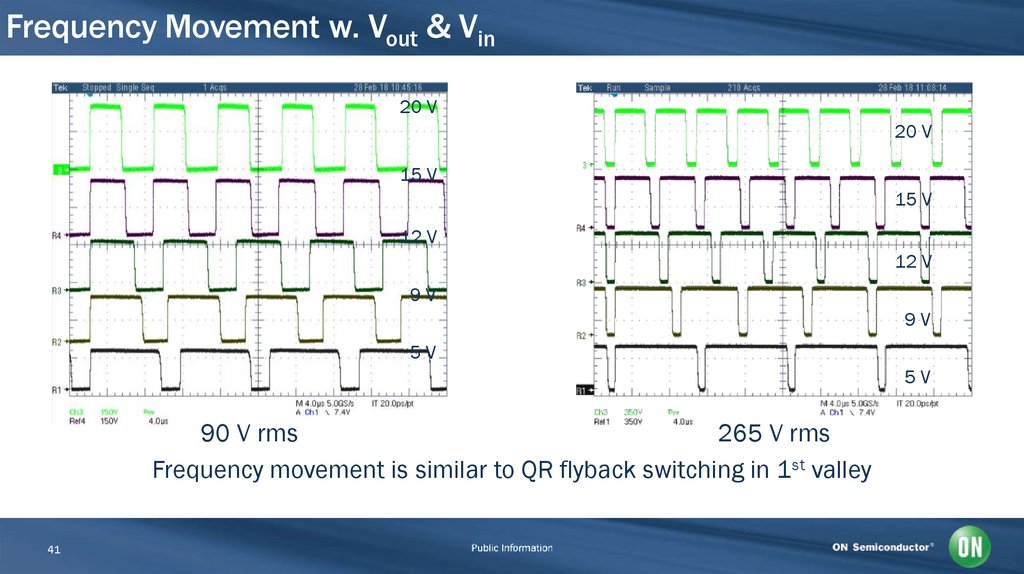

41. Frequency Movement w. Vout & Vin

Frequency Movement w. Vout & Vin20 V

20 V

15 V

15 V

12 V

12 V

9V

9V

5V

5V

90 V rms

265 V rms

Frequency movement is similar to QR flyback switching in 1st valley

41

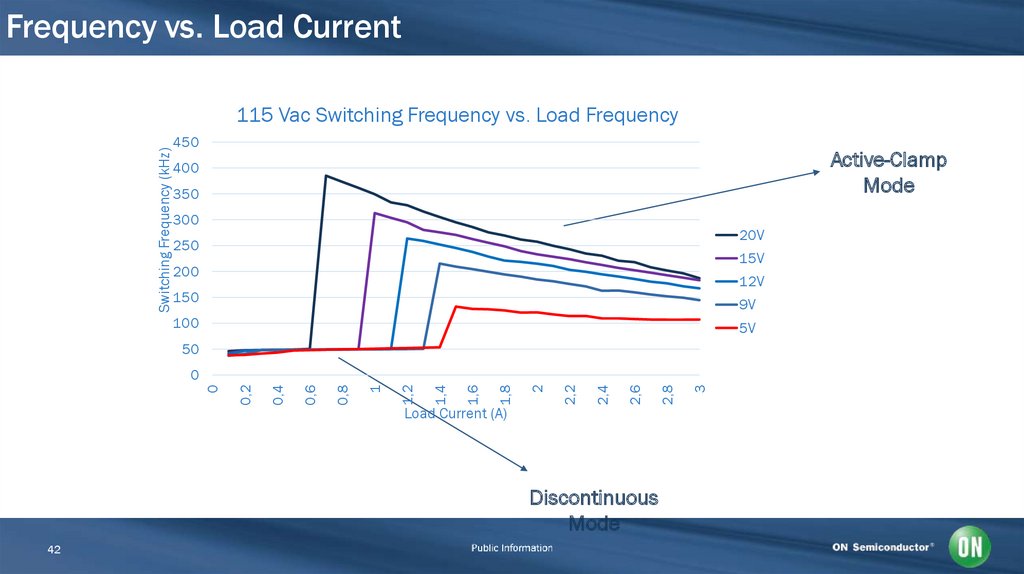

42. Frequency vs. Load Current

Switching Frequency (kHz)115 Vac Switching Frequency vs. Load Frequency

450

Active-Clamp

Mode

400

350

300

20V

250

15V

200

12V

150

9V

100

5V

50

Discontinuous

Mode

42

3

2,8

2,6

2,4

2,2

Load Current (A)

2

1,8

1,6

1,4

1,2

1

0,8

0,6

0,4

0,2

0

0

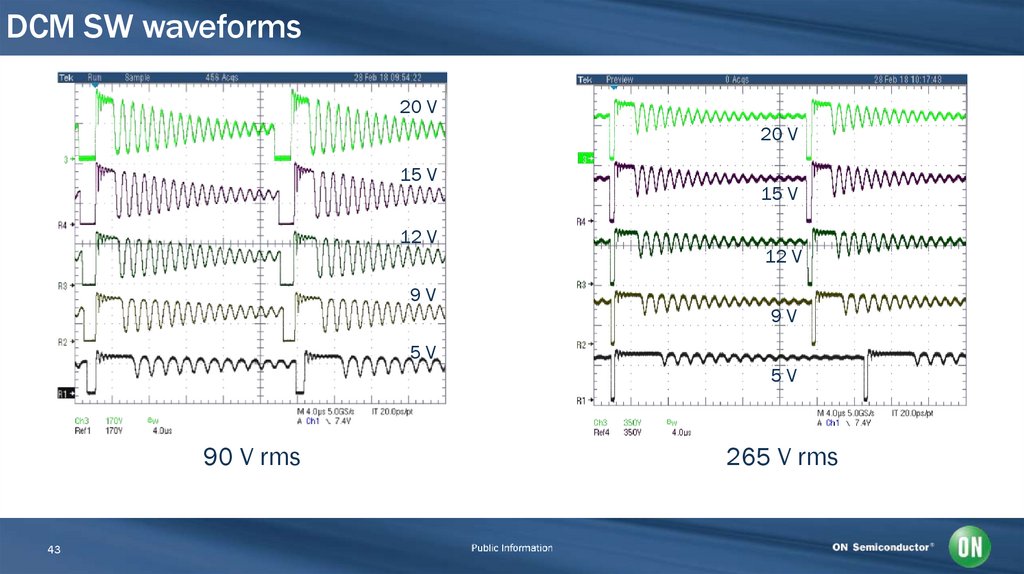

43. DCM SW waveforms

20 V20 V

15 V

12 V

9V

15 V

12 V

9V

5V

5V

90 V rms

43

265 V rms

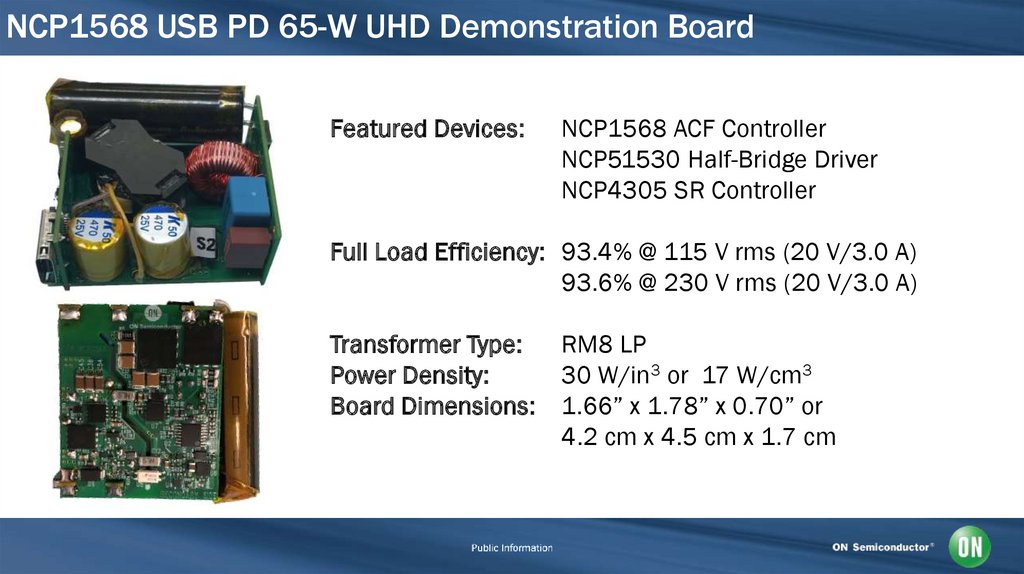

44. NCP1568 USB PD 65-W UHD Demonstration Board

Featured Devices:NCP1568 ACF Controller

NCP51530 Half-Bridge Driver

NCP4305 SR Controller

Full Load Efficiency: 93.4% @ 115 V rms (20 V/3.0 A)

93.6% @ 230 V rms (20 V/3.0 A)

Transformer Type:

Power Density:

Board Dimensions:

RM8 LP

30 W/in3 or 17 W/cm3

1.66” x 1.78” x 0.70” or

4.2 cm x 4.5 cm x 1.7 cm

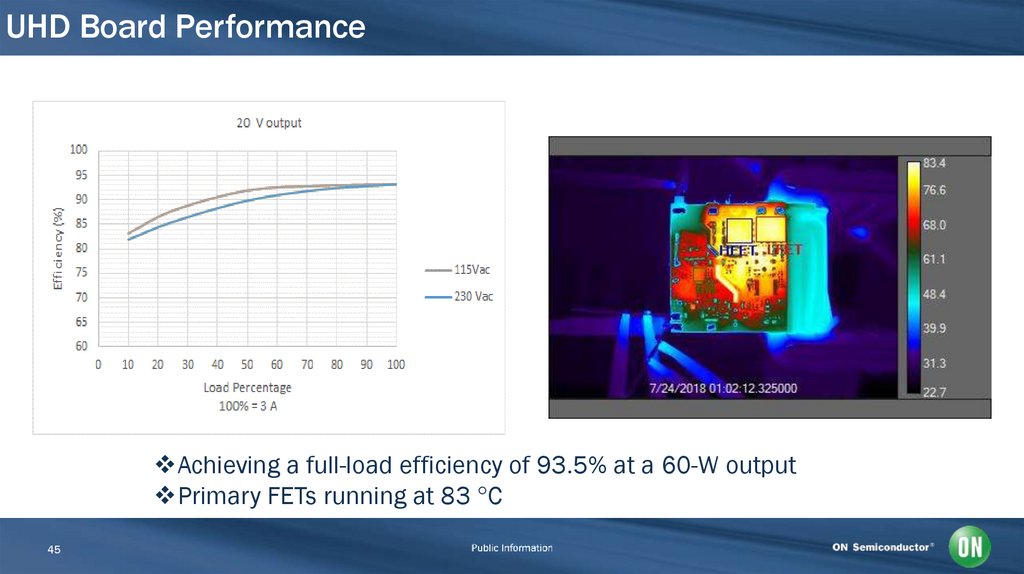

45. UHD Board Performance

Achieving a full-load efficiency of 93.5% at a 60-W outputPrimary FETs running at 83 C

45

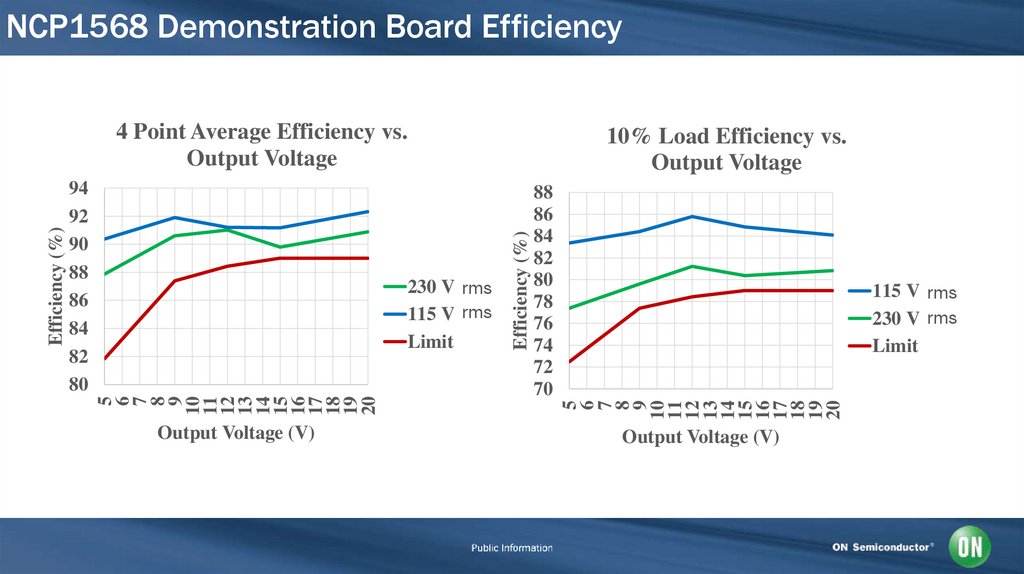

46. NCP1568 Demonstration Board Efficiency

Output Voltage (V)88

86

84

82

80

78

76

74

72

70

115 VAC

rms

rms

230 VAC

Limit

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

230 VAC

rms

rms

115 VAC

Limit

10% Load Efficiency vs.

Output Voltage

Efficiency (%)

94

92

90

88

86

84

82

80

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

Efficiency (%)

4 Point Average Efficiency vs.

Output Voltage

Output Voltage (V)

47. Key Takeaways

ACF results in ZVS for both main and active-clamp FETs.High-frequency operation while achieving high efficiency is possible.

DCM transition is needed to pass stringent regulatory standards.

Elimination of heat sinks is possible with ACF topology.

Power density while employing ACF is 2 to 3 times that of a standard ac-dc supplies

Industry standard super-junction FETs yield excellent results up to 400 kHz.

47