Похожие презентации:

Introduction to overpressure protection

1.

INTRODUCTIONTO

OVERPRESSURE PROTECTION

2.

Why Needed• PROTECTION OF PERSONNEL AND

PROPERTY

• SATISFY REQUIREMENTS OF

APPLICABLE

CODES AND REGULATIONS

3.

Most Common CausesOf Overpressure

• BLOCKED DISCHARGE

• EXPOSURE TO EXTERNAL

FLAMES

• THERMAL EXPANSION

4.

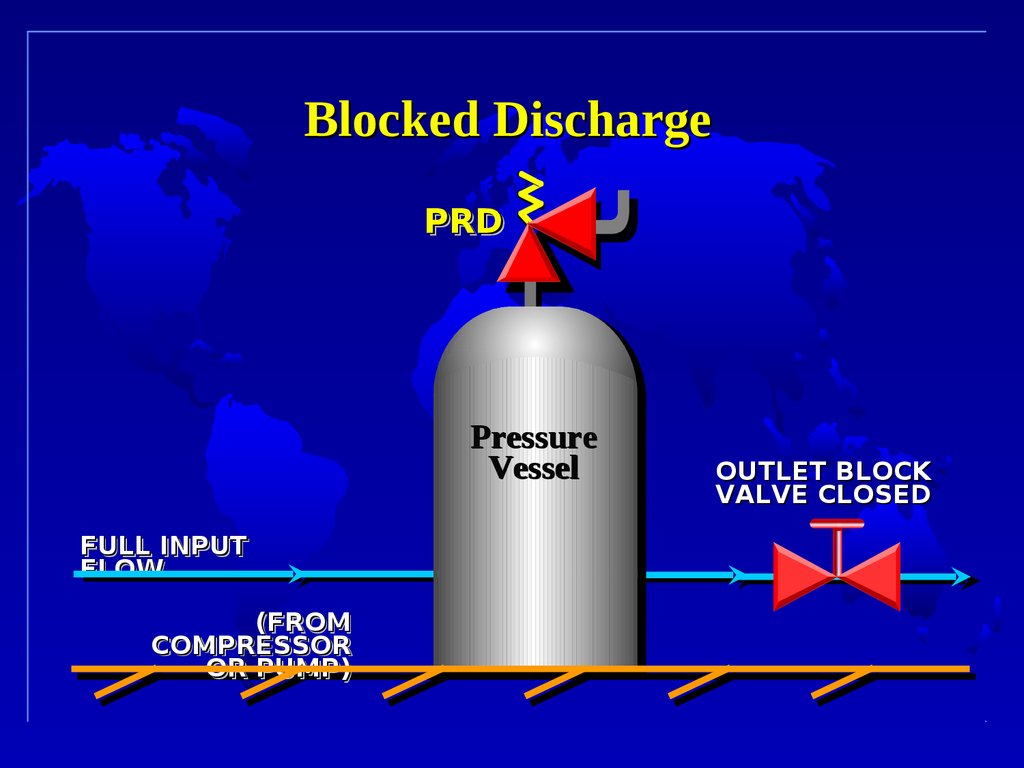

Blocked DischargePRD

Pressure

Vessel

FULL

FULL INPUT

INPUT

FLOW

(FROM

(FROM

COMPRESSOR

COMPRESSOR

OR

OR PUMP)

PUMP)

OUTLET BLOCK

VALVE CLOSED

5.

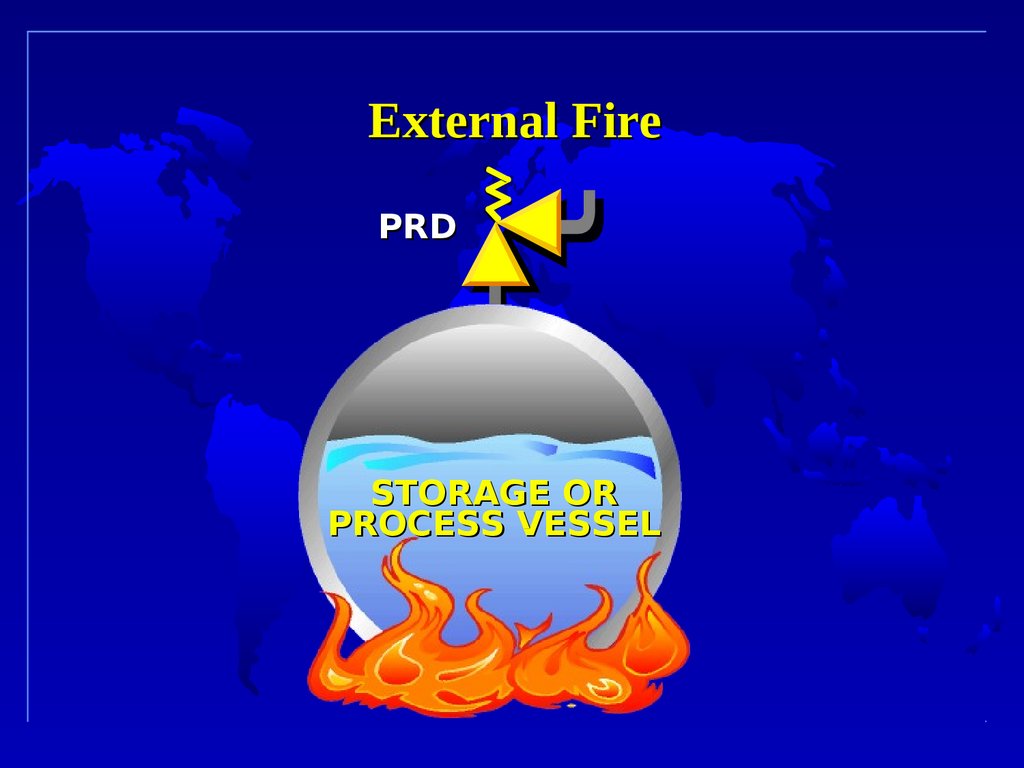

External FirePRD

STORAGE OR

PROCESS VESSEL

6.

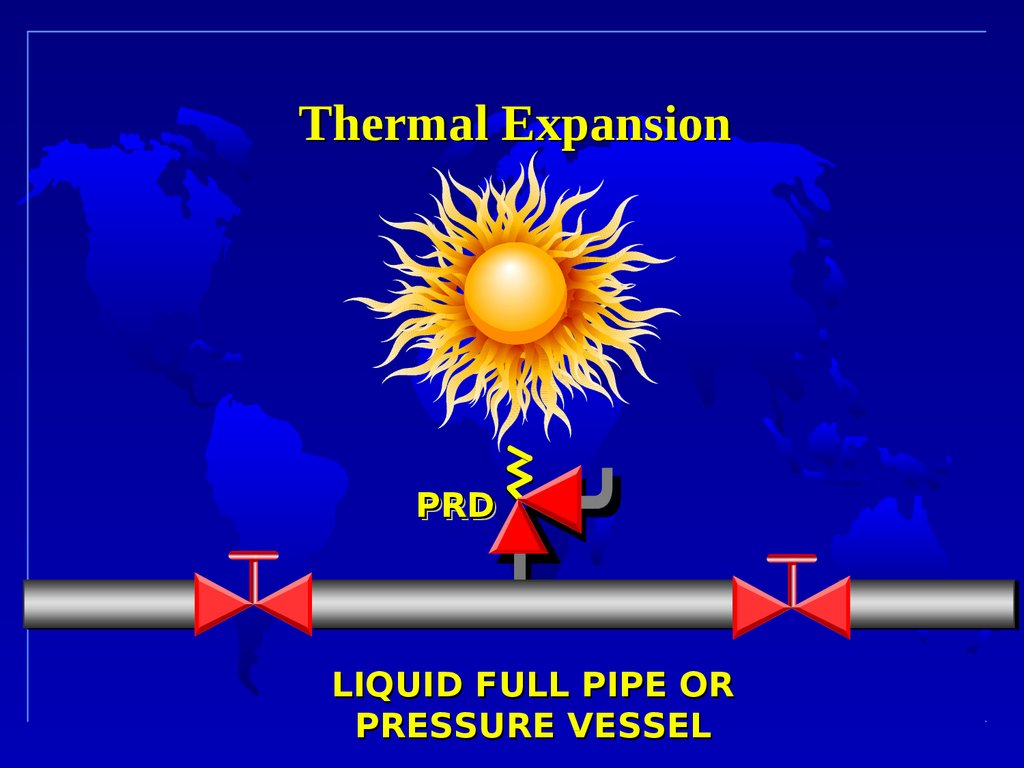

Thermal ExpansionPRD

LIQUID FULL PIPE OR

PRESSURE VESSEL

7.

Must Consider The OneWorst Case

BLOCKED

DISCHARGE

EXTERNAL FIRE

THERMAL

EXPANSION

8.

Overpressure Relief Devices• PRESSURE RELIEF

VALVE

• RUPTURE DISC

• RUPTURE DISC UNDER

PRV

9.

Pressure Relief Valve(PRV)

• OPENS AT SET PRESSURE

• CLOSES AT RESEAT PRESSURE

10.

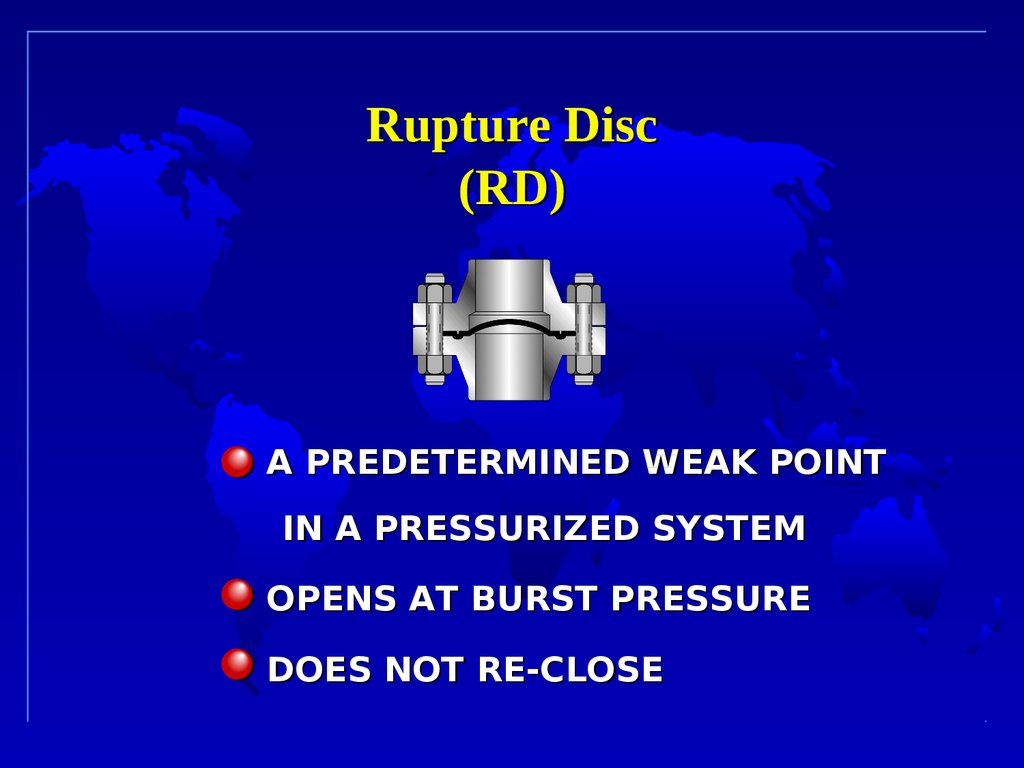

Rupture Disc(RD)

• A PREDETERMINED WEAK POINT

IN A PRESSURIZED SYSTEM

• OPENS AT BURST PRESSURE

• DOES NOT RE-CLOSE

11.

Pressure Relief Valve &Rupture Disc

• RD BURSTS OPEN

• PRV OPENS IMMEDIATELY

• PRV RE-CLOSES AT A

PRESSURE BELOW RD BURST

12.

Maximum AllowableWorking Pressure (MAWP)

• “DESIGN PRESSURE”

• NORMALLY USED WITH

PROCESS

VESSELS AND ASSOCIATED

PIPING

• NORMALLY PRV SET PRESSURE

OR

RD BURST PRESSURE

13.

Maximum OperatingWorking Pressure (MOWP)

• “DESIGN PRESSURE”

• NORMALLY USED IN NATURAL

GAS TRANSMISSION AND

DISTRIBUTION

SYSTEMS

• DEPENDENT ON PIPE

MATERIAL , TEMPERATURE OF

AMBIENT & GAS,

LOCATION OF PIPE (SPARSELY

OR

14.

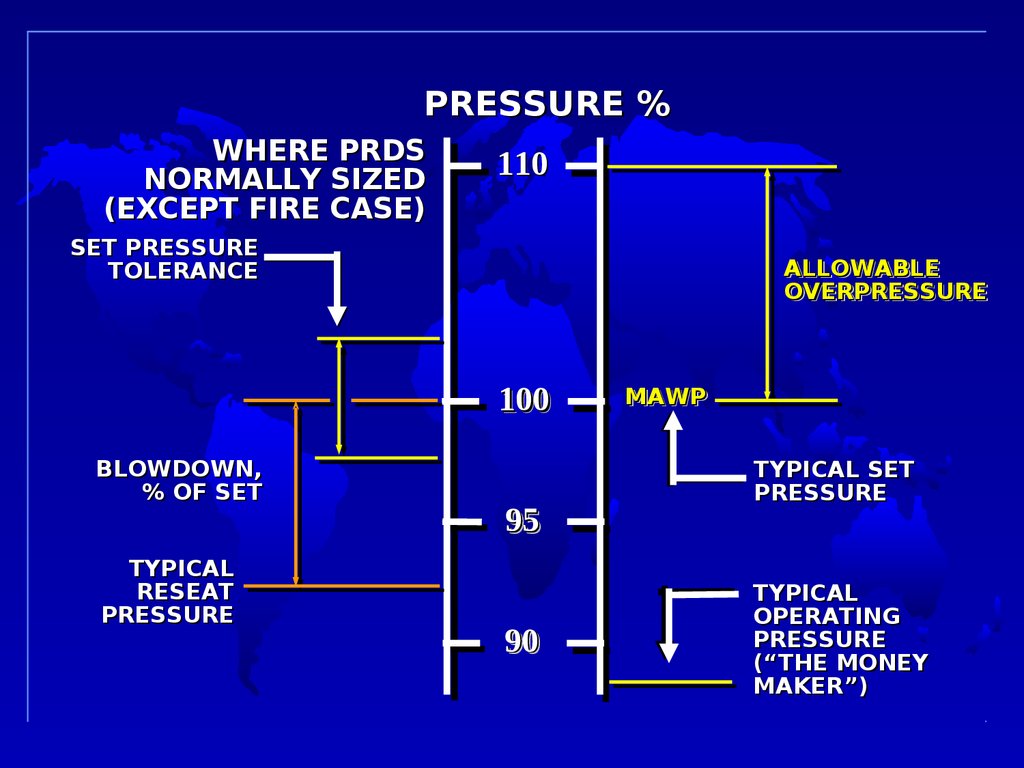

PRESSURE %WHERE PRDS

NORMALLY SIZED

(EXCEPT FIRE CASE)

110

SET PRESSURE

TOLERANCE

ALLOWABLE

ALLOWABLE

OVERPRESSURE

OVERPRESSURE

100

BLOWDOWN,

% OF SET

TYPICAL

RESEAT

PRESSURE

95

90

MAWP

MAWP

TYPICAL SET

PRESSURE

TYPICAL

OPERATING

PRESSURE

(“THE MONEY

MAKER”)

15.

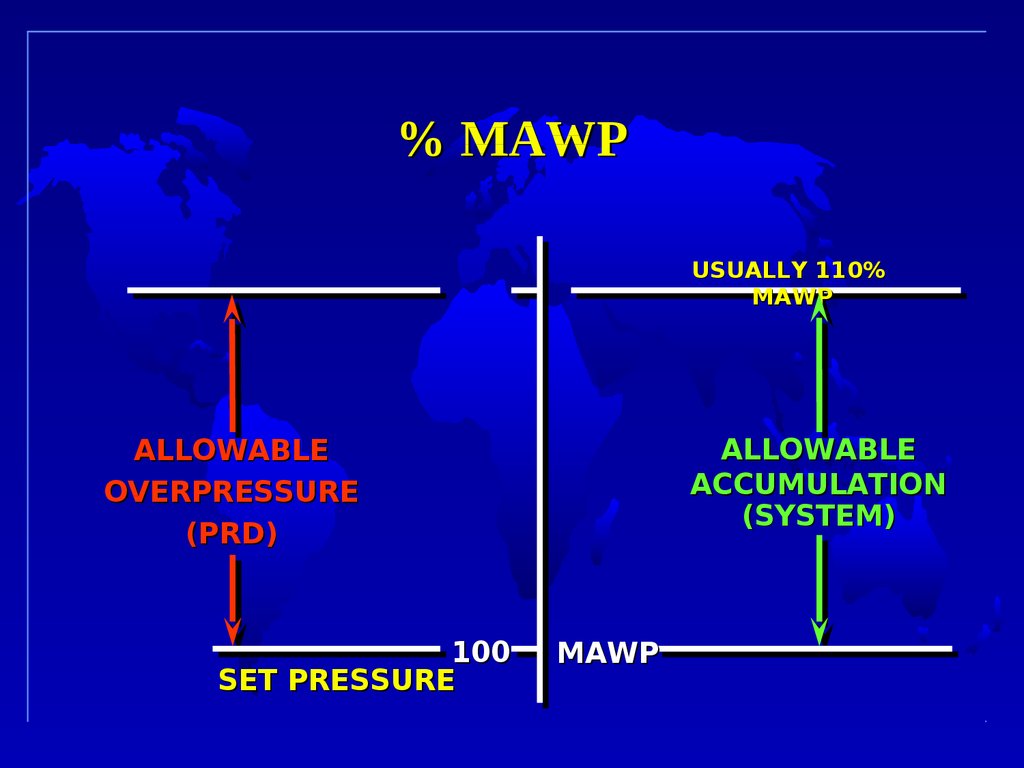

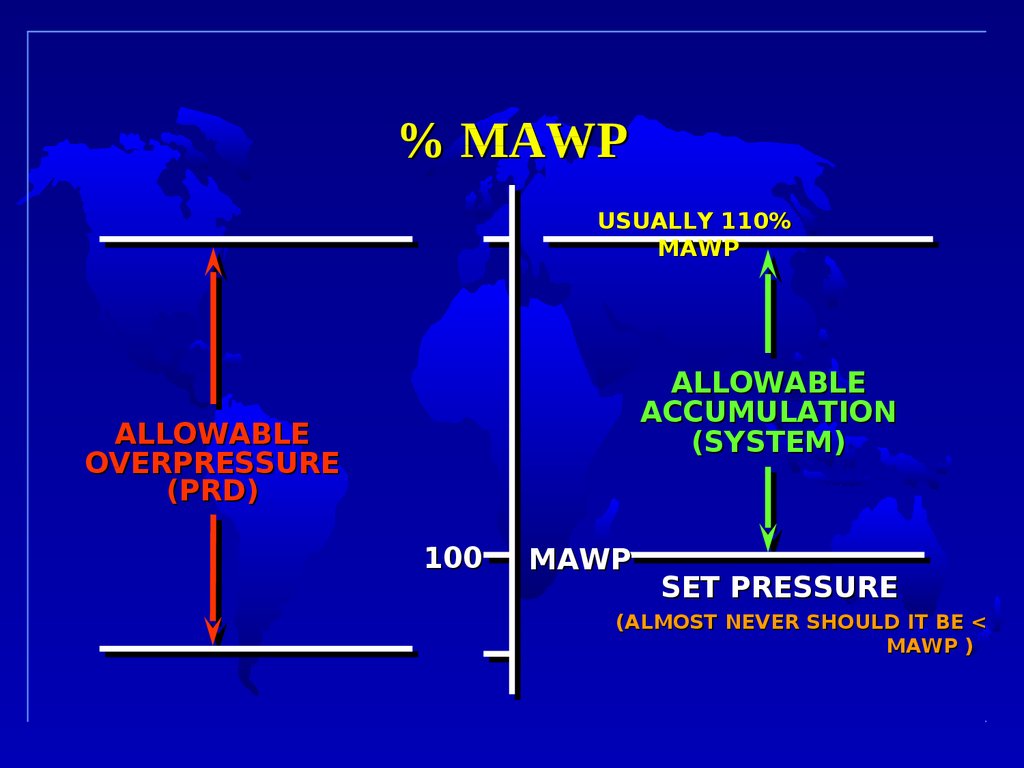

% MAWPUSUALLY 110%

MAWP

ALLOWABLE

ACCUMULATION

(SYSTEM)

ALLOWABLE

OVERPRESSURE

(PRD)

100

SET PRESSURE

MAWP

16.

% MAWPUSUALLY 110%

MAWP

ALLOWABLE

ACCUMULATION

(SYSTEM)

ALLOWABLE

OVERPRESSURE

(PRD)

100

MAWP

SET PRESSURE

(ALMOST NEVER SHOULD IT BE <

MAWP )

17.

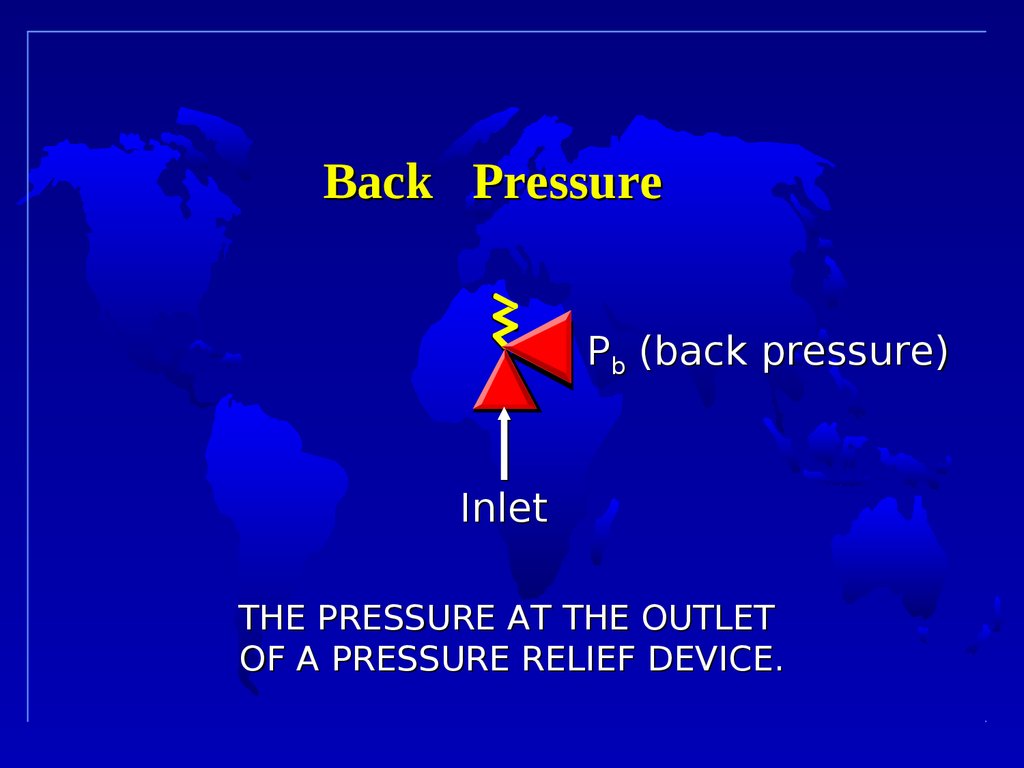

Back PressurePb (back pressure)

Inlet

THE PRESSURE AT THE OUTLET

OF A PRESSURE RELIEF DEVICE.

18.

Built-up Back PressureDISCHARGE

PRV IS OPEN

AND IS FLOWING

In

19.

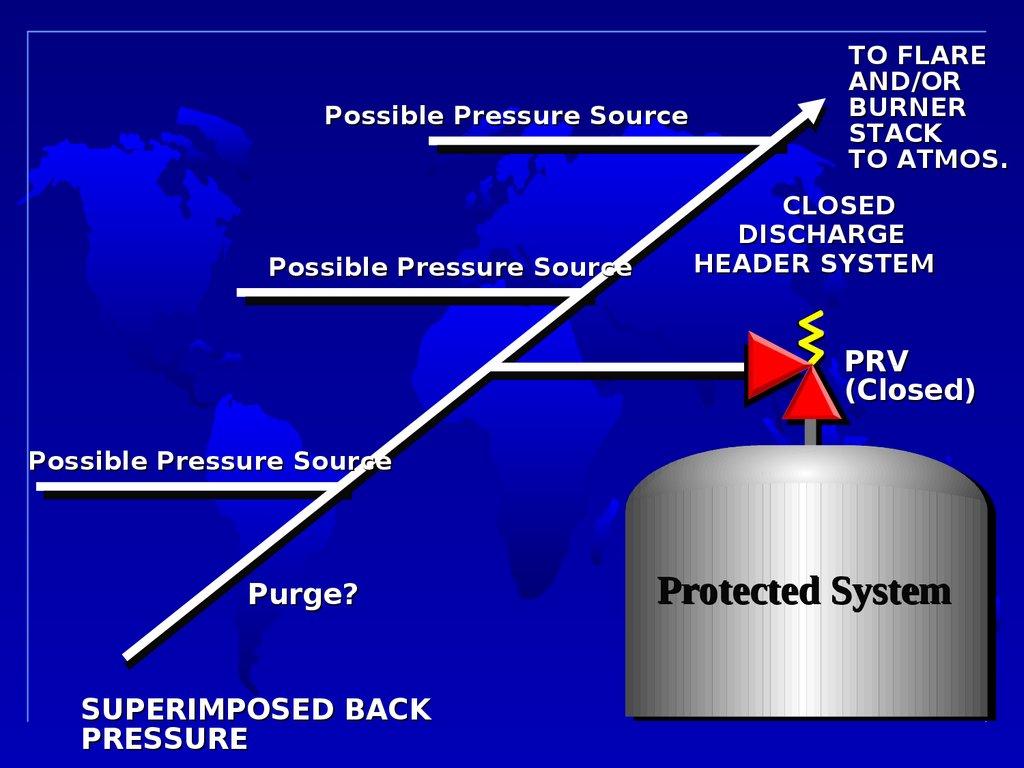

Possible Pressure SourcePossible Pressure Source

TO FLARE

AND/OR

BURNER

STACK

TO ATMOS.

CLOSED

DISCHARGE

HEADER SYSTEM

PRV

(Closed)

Possible Pressure Source

Purge?

SUPERIMPOSED BACK

PRESSURE

Protected System

20.

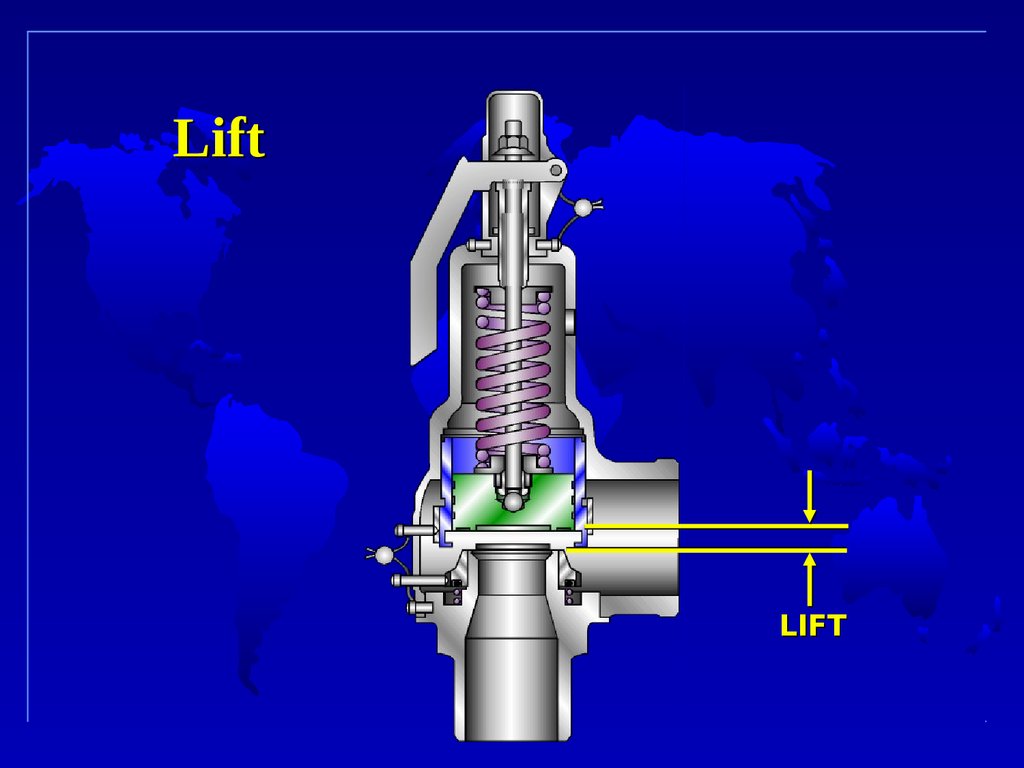

LiftLIFT

21.

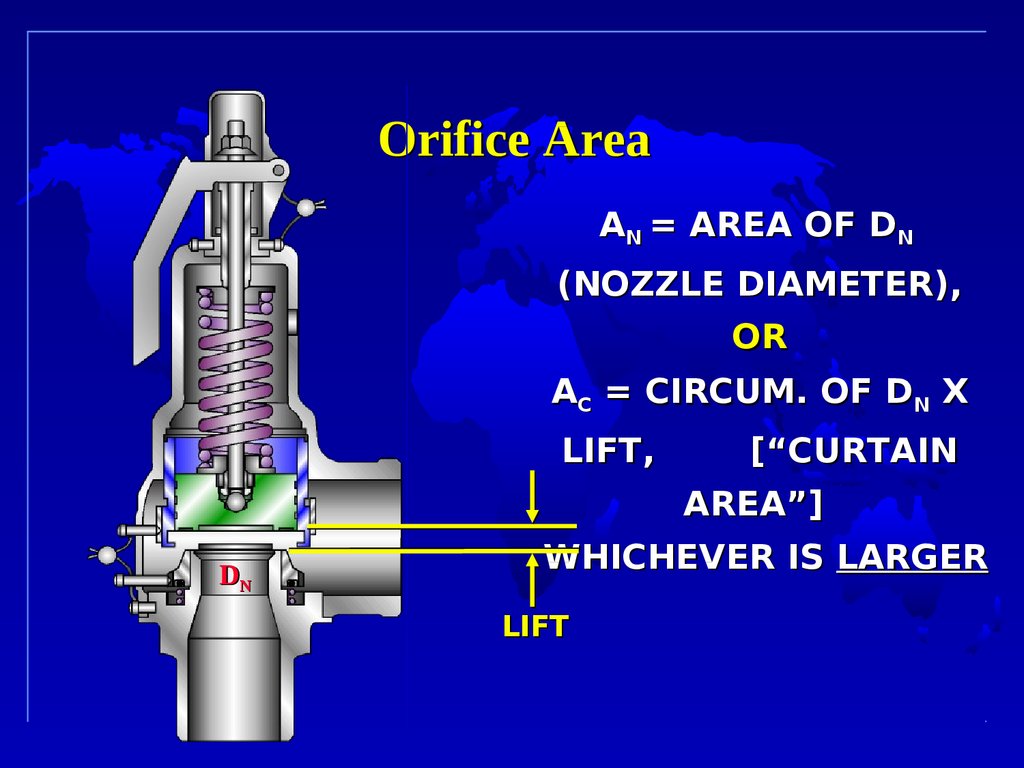

Orifice AreaAN = AREA OF DN

(NOZZLE DIAMETER),

OR

AC = CIRCUM. OF DN X

LIFT,

[“CURTAIN

AREA”]

DN

WHICHEVER IS LARGER

LIFT

22.

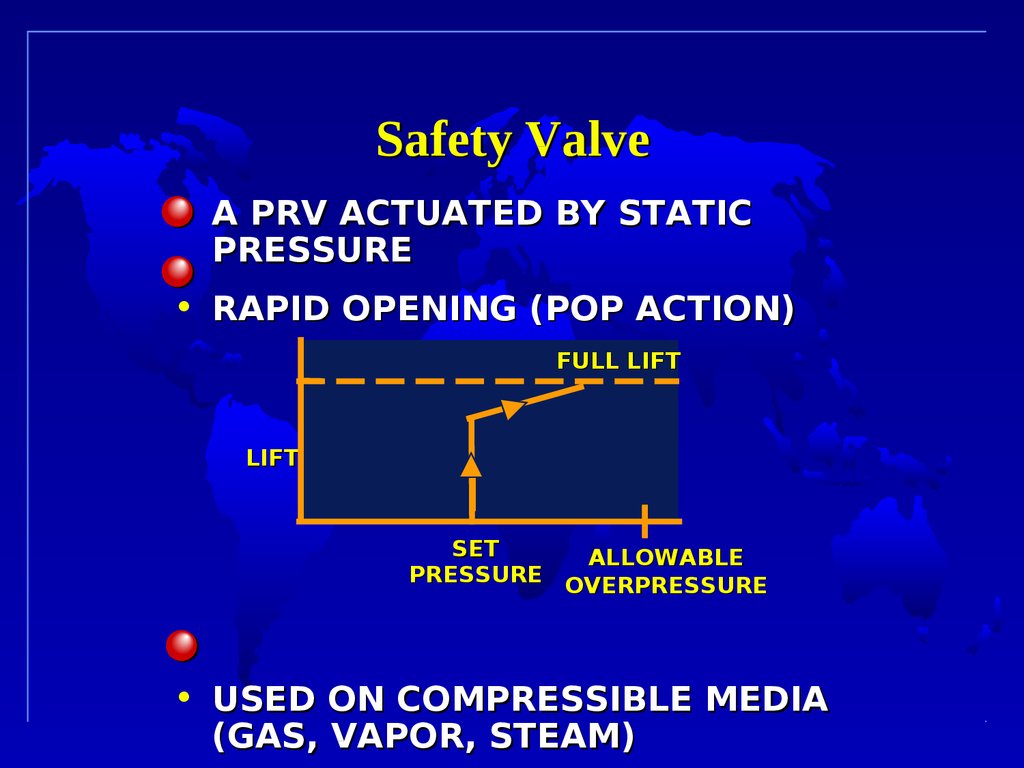

Safety Valve• A PRV ACTUATED BY STATIC

PRESSURE

• RAPID OPENING (POP ACTION)

FULL LIFT

LIFT

SET

ALLOWABLE

PRESSURE OVERPRESSURE

• USED ON COMPRESSIBLE MEDIA

(GAS, VAPOR, STEAM)

23.

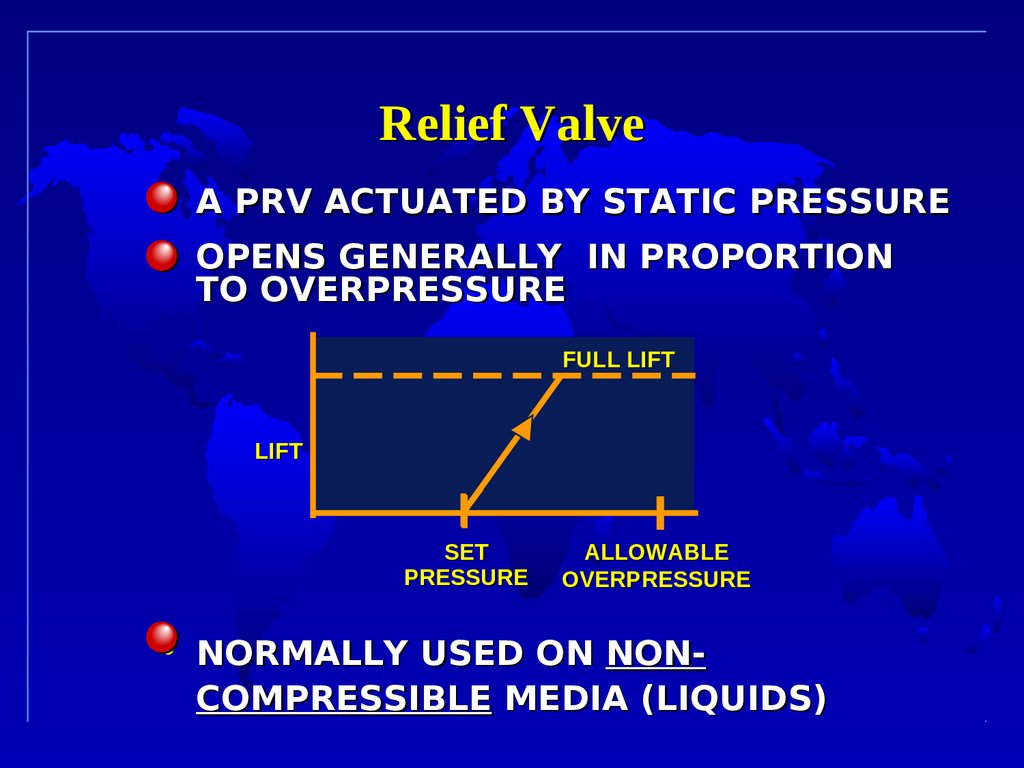

Relief Valve• A PRV ACTUATED BY STATIC PRESSURE

• OPENS GENERALLY IN PROPORTION

TO OVERPRESSURE

FULL LIFT

LIFT

SET

PRESSURE

ALLOWABLE

OVERPRESSURE

• NORMALLY USED ON NONCOMPRESSIBLE MEDIA (LIQUIDS)

24.

Safety Relief Valve(SRV)

• A PRV THAT MAY FUNCTION AS

EITHER A SAFETY OR RELIEF

VALVE

WITH SATISFACTORY

PERFORMANCE

25.

Pressure Relief Valve(PRV)

A GENERIC TERM WHICH INCLUDES

SAFETY VALVES, RELIEF VALVES,

AND

SAFETY RELIEF VALVES (A “SAFE

& ALL-ENCOMPASSING TERM”)

26.

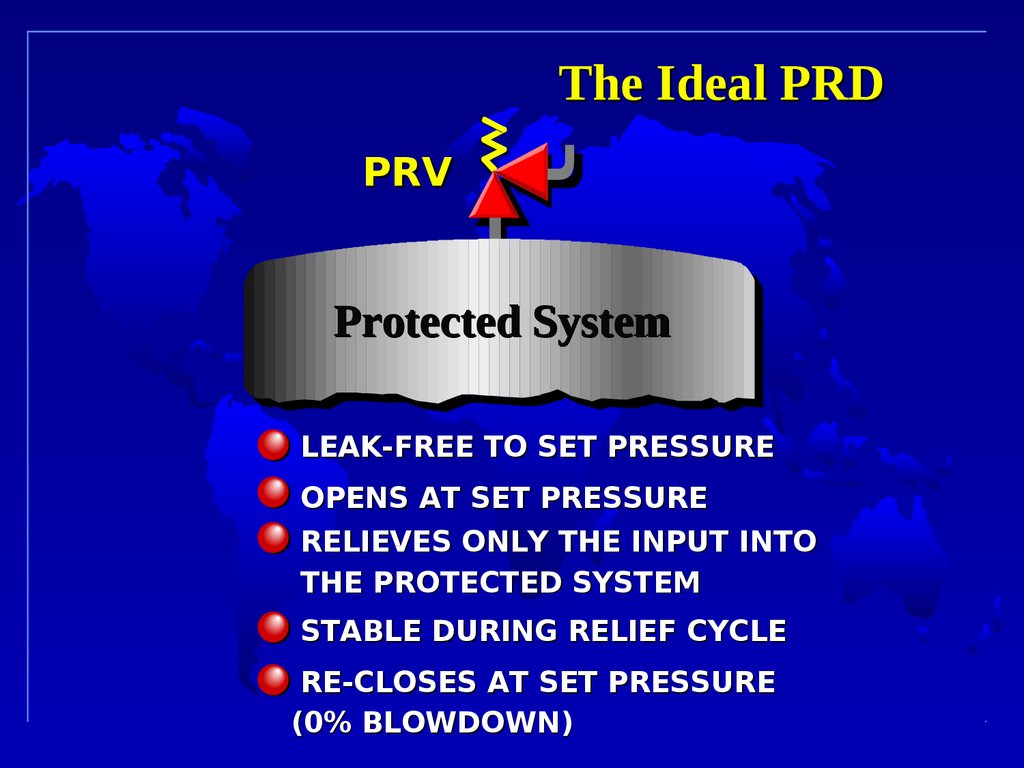

The Ideal PRDPRV

Protected System

LEAK-FREE TO SET PRESSURE

OPENS AT SET PRESSURE

RELIEVES ONLY THE INPUT INTO

THE PROTECTED SYSTEM

STABLE DURING RELIEF CYCLE

RE-CLOSES AT SET PRESSURE

(0% BLOWDOWN)

Промышленность

Промышленность