Похожие презентации:

Development of technology of ultrasonic modification of starch in the cooling system

1. Ministry of education and science of the Russian Federation Federal STATE Autonomous educational institution « South Ural state

Development of technology of ultrasonicmodification of starch in the cooling system

AUTHOR OF WORK

Student group MB-105

A.V. Tsaturov

2. The problem and its solution

Ural Federal district grows a large amount of grain and thus the market is collapsing, theproblem of surplus.

It is difficult to process a large amount of grain, and it is not economically feasible to sell for a

song.

In consequence, it was taken measures for deep processing of grain, in order to isolate and use the

components of grain, in particular starch.

The development of deep processing of grain will produce high-tech products, the demand for

which is growing on the world market every year.

The most popular are starches and starches, amino acids, glucose, bioplastics.

Production of modified starches is one of the perspective and little developed directions in the Ural

Federal district.

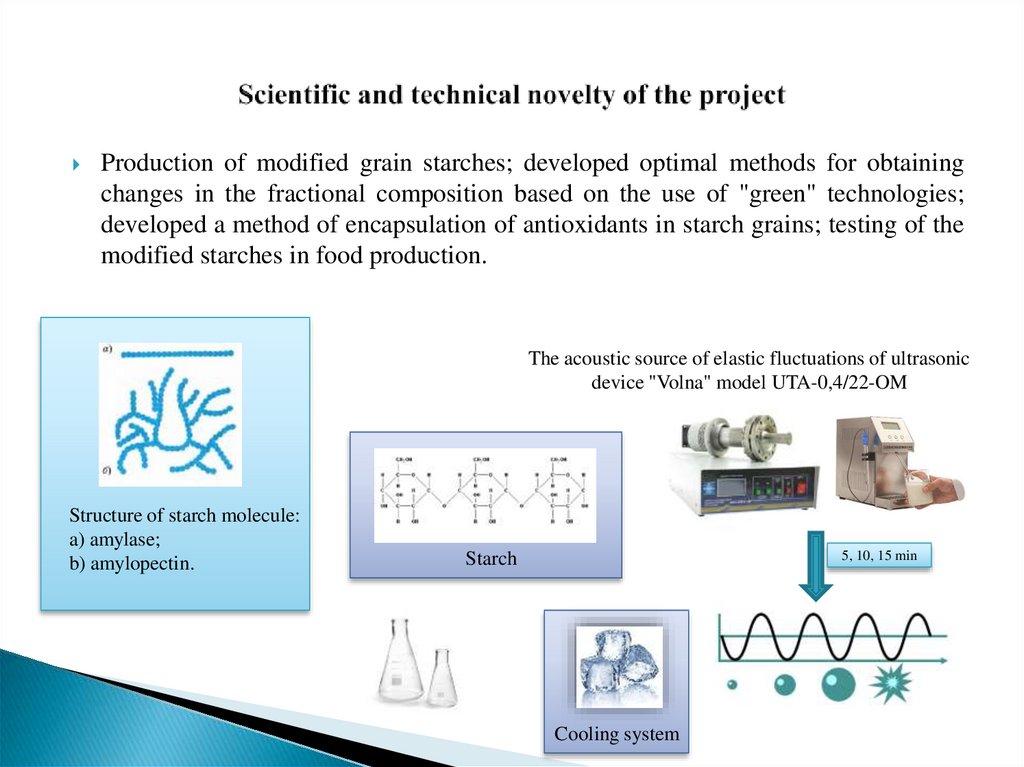

3. Scientific and technical novelty of the project

Production of modified grain starches; developed optimal methods for obtainingchanges in the fractional composition based on the use of "green" technologies;

developed a method of encapsulation of antioxidants in starch grains; testing of the

modified starches in food production.

The acoustic source of elastic fluctuations of ultrasonic

device "Volna" model UTA-0,4/22-OM

Structure of starch molecule:

a) amylase;

b) amylopectin.

5, 10, 15 min

Starch

Cooling system

4. Characteristics of changes in starch suspensions obtained from wheat grain УЗВ in the cooling system

Sample 1 - starch water obtained from wheat flour;Sample 2- starch water obtained from durum wheat flour.

When combined electrophysical effects and acid hydrolysis processes observed

swelling of starch grains and partial binding to each other (starch fractions).

5. Results of evaluation of dispersed system of water suspensions of starch from soft and hard wheat

Grains of wheat starch have a flat elliptical or roundshape with a peephole located in the center. It is

known that the size of the starch grains of wheat

ranges from 2 to 35 microns, there are fractions of

large grains from 20 to 35 microns and small from 2

to 10 microns.

With prolonged ultrasonic treatment in the cooling system, a

decrease in the size of starch grains is observed, and for

starch from soft wheat at RAS after 15 minutes in the range

of 1330 ... 392 nm, and for starch from durum wheat after 10

minutes of RAS in the range of 1280...367nm.

6. Averaged results of determination of viscosity of the obtained samples of wheat starch, MPa*s

Based on the data obtained, the optimal mode of ultrasonic treatment for starchsuspensions of soft wheat for 15 minutes and 10 minutes for starch suspensions of

durum wheat can be recognized. Under these conditions, the effects of ultrasound

observed formation of plastic jelly, preserving the properties during storage.

7. Results of the research

Obtaining samples of modified starches with modified fraction-amyloseand amylopectin;

The use of starch modification technology to produce food additives used

in the production of food products, to obtain a given consistency, to

improve organoleptic characteristics;

Expansion of the range of products of emulsion-gel nature, the

development of import substitution.

Samples of modified wheat starch:

1- Sample obtained under the

conditions of the cooling system;

2- Sample obtained without the

conditions of the cooling system.

Промышленность

Промышленность