Похожие презентации:

Investigation, of the use of planetary-circular gears in machine. Tool drives

1.

INVESTIGATION OFTHE USE OF

PLANETARY-CIRCULAR

GEARS IN MACHINE

TOOL DRIVES

2.

The modernization of the CNC machine isusually associated with the replacement of

the CNC system. After replacing the CNC

device, the user would like to get a modern

machine that is superior to the old in terms

of performance and reliability.

But the reliability of the machine is

unlikely to increase if it has left the old

drives, the measuring system and the

devices of electroautomatics. A significant

increase in reliability can be expected only

when new drives are installed along with

the CNC

3.

Turning-rotary double-standmachine mod. 1А563F4 is

equipped with an outdated CNC

system. It is made on an outdated

element base and has long been

discontinued, the search for

accessories for it is a big problem

and it does not take into account

its limited capabilities, low

reliability and moral aging.

4.

When installing modern CNC systems and modernized drive mechanisms of the machinetools, the following benefits are achieved:

- increasing the reliability of the machine;

- production of parts with given precise parameters;

- increase of productivity and convenience of work;

- expansion of technological possibilities for work with modern cutting tools;

- improvement of maintenance;

- the ability to diagnose, assemble and install control programs from a remote computer;

- turning the machine into a single computer network to control its loading and

downtime.

5.

As a gutter for the study, consider amultipurpose turning carousel double-stand

machine. 1А563F4. The machine tool is

intended for roughing and finishing of steel and

cast iron parts, products made of non-ferrous

metals and their alloys. On the machine you

can perform the following technological

operations:

-processing of internal, external, end surfaces

of rotation of a simple and complex form

(cylinder, cone, sphere, etc.);

-cutting of screws or screw grooves on surfaces;

-processing of coaxial axes of rotation of the

faceplate (cylinder, cone, end face);

-mixing of complex surfaces;

- drilling, boring, winding, deployment and

cutting of chains in the openings, co-axis of

rotation of the milling spindle.

6.

The most important trend in the design ofhigh-tech products of modern production:

aircraft, modern CNC machines, power

plants, is the use of high-precision

reducers, which are one of the types of

mechatronic modules. Their application

has a significant impact on ensuring high

output technical and economic

performance of the whole product.

7.

Along with the common industrialcylindrical, cylindrical-conical gearboxes

are becoming increasingly relevant

gearboxes based on planetary, cycloid,

treadmill and wave transmissions.

The application of these gearboxes is due

to the combination of compactness, high

power, high accuracy, durability and

reliability. Planetary-сircular reducers

allow reaching transmission numbers for

one transmission up to 191.

8.

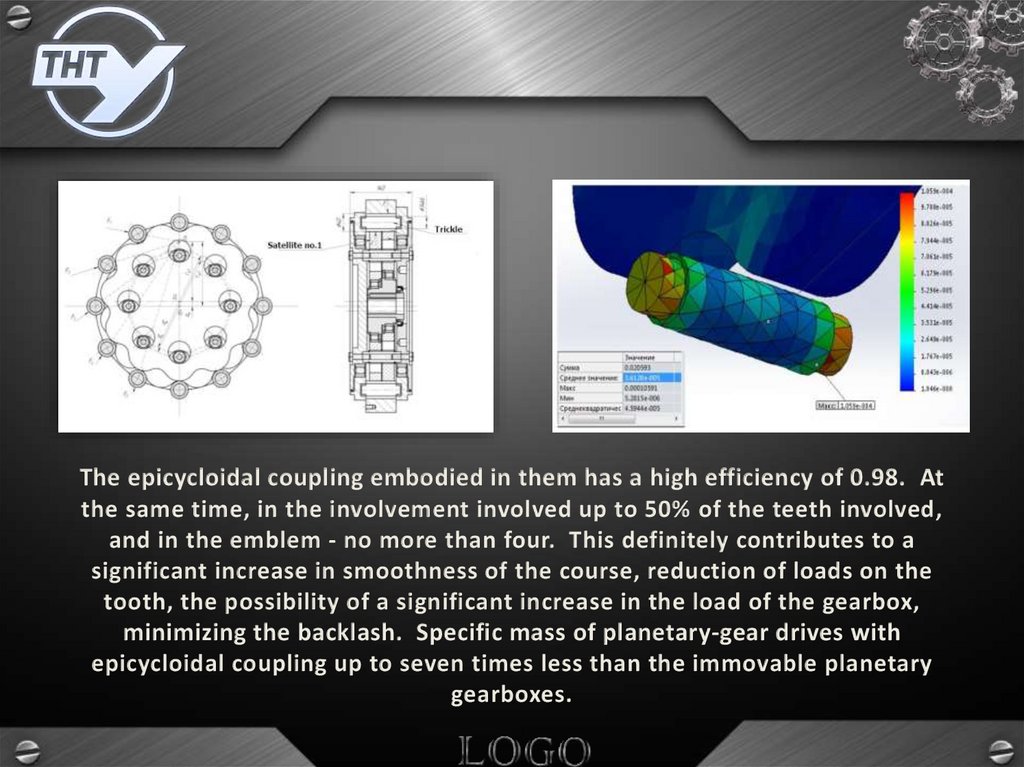

The epicycloidal coupling embodied in them has a high efficiency of 0.98. Atthe same time, in the involvement involved up to 50% of the teeth involved,

and in the emblem - no more than four. This definitely contributes to a

significant increase in smoothness of the course, reduction of loads on the

tooth, the possibility of a significant increase in the load of the gearbox,

minimizing the backlash. Specific mass of planetary-gear drives with

epicycloidal coupling up to seven times less than the immovable planetary

gearboxes.

9.

In a planetary gearbox, the concentratedrotation of the input shaft with the

eccentric provides eccentric rotation of the

satellites installed on these eccentrics. The

peculiarity of this gear, in addition to the

profile of the teeth, is the location of the

tread casing and the condition for the

routing of the satellites according to these

treads - the role of treadings in modern

gearboxes is performed by rollers. The

output flange, as well as the input, carries

out a concentric movement. In this case,

the gear unit is attached to the executive

unit of the mechatronic module.

10.

So, planetary gear units of generalpurpose, having good vibroacoustic,

specific mass-grossing characteristics

realize transmission ratios of 7 to 100 in

one degree, transmission capacity up to

250 kW, torque 10 ... 50,000 Nm.

Good dynamic characteristics, small

moments of inertia of the rotating units

and their low angular velocity (with a large

transmission ratio) provide sufficient speed

of such transmission during transient

processes (start, stop, change of direction

of movement).

11.

Wide introduction to the drives of planetary gear reducers is constrained bythe following: the finishing of the cycloid profile of the tooth in traditional

equipment with high accuracy, the profile of the cutting tool, low sensitivity

to mounting errors, and the change in intermediate distance of the coupling

and the linearity of the rigidity characteristics.

The greatest difficulty is the technological finishing of the cycloidal profile

of the tooth, especially in hardened wheels.

12.

The further development of the productionof planetary gear drives will significantly

expand their application in precision drives

of feeder CNC machines, mechanisms of

launching launchers, drives antennas and

other machines, which will ensure their

further reduction in mass -general

dimensions while maintaining the realized

capacity, increasing the accuracy of

positioning, increasing the technical

resource , reducing vibration and

increasing the efficiency.

13.

14.

First stage:From the received calculation data, a two-dimensional drawing of a two-stage

planetary gear transmission was constructed (see appendix). The task of which is

to give an understanding of the dimensions and dimensions obtained in the design

process for their further use in 3D modeling.

15.

16.

Second stage:The purpose of the second stage is to simulate a 3-dimensional model,

which gives more insight into the design of tire wheels and their profile of

engagement. Guided by the data of the used literature and the analysis of

known analogs of tread gears, a prototype gearbox with advanced structural

elements was designed.

In the modeling of solid-state components of the assembly, the CAD-system

of the higher level Autodesk Inventor was used.

At the same time, two features are taken into account:

-The first is due to the presence of an epicycloid profile of the gear wheel;

-The other one is connected with the features of combinations of gearbox

elements.

17.

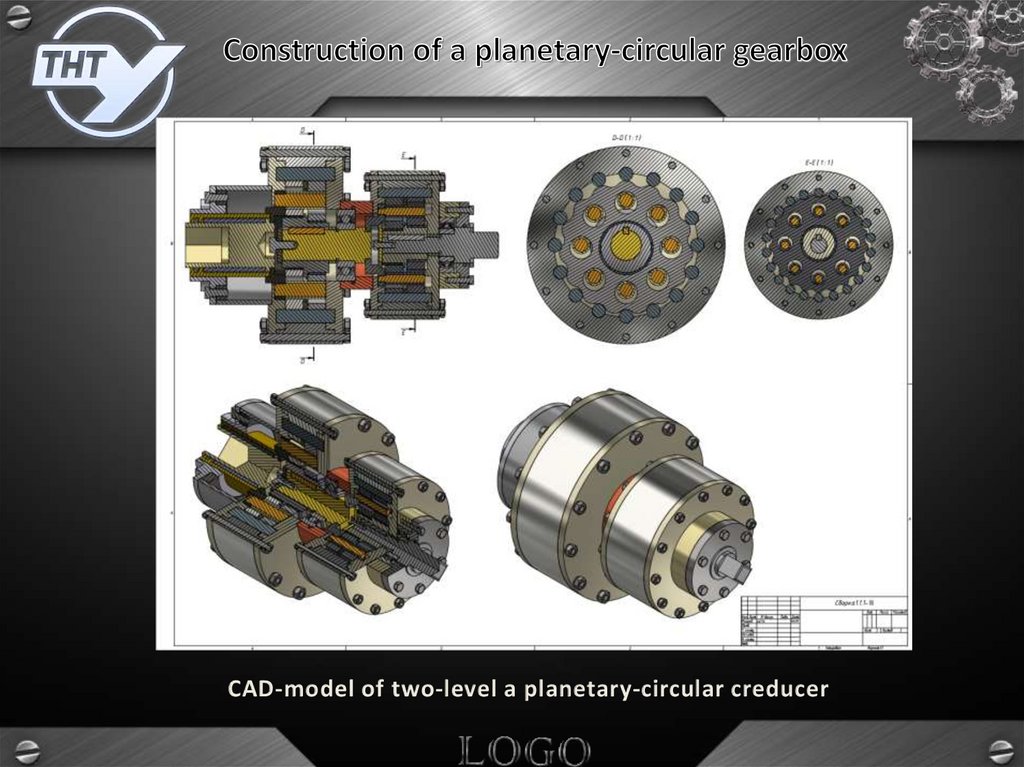

CAD-model of two-level a planetary-circular сreducer18.

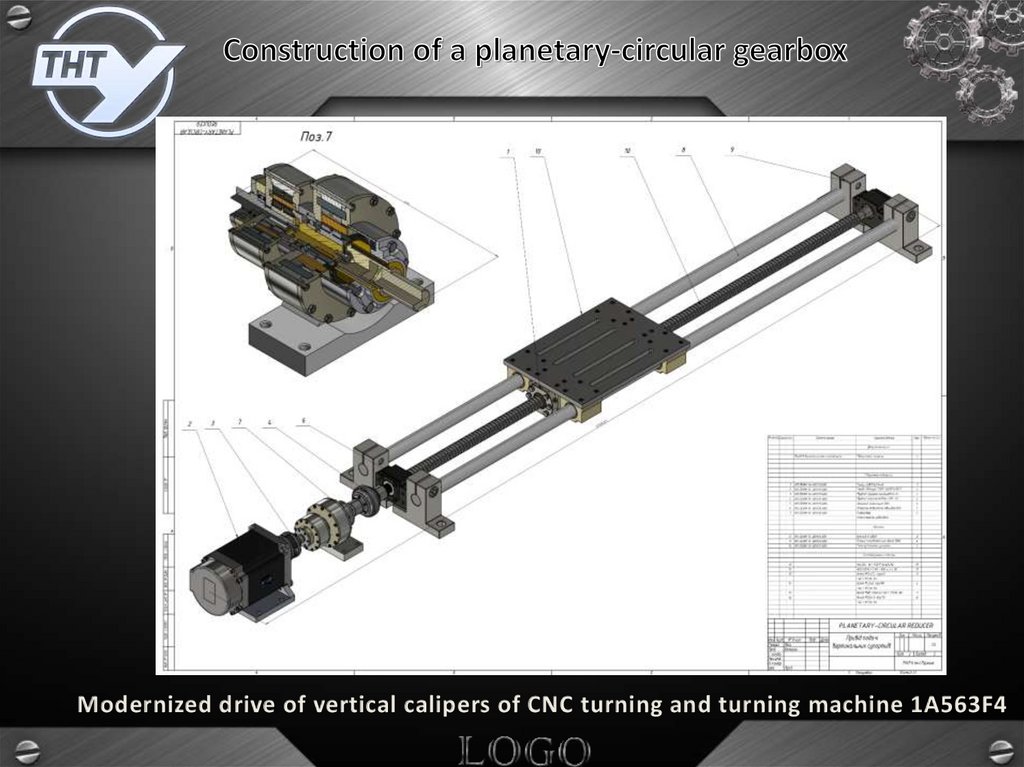

Third stage:Using the characteristics of the turning-carousel machine, its drive system, the

electric system, and mass-dimensional indicators and a pre-modeled gearbox, a 3dimensional model of the drive of the feed of the turning servo (see dod) was

designed.

The purpose was to analyze the design of the drive. Get data for further

development of this issue.

Механика

Механика