Похожие презентации:

Insertable Dust Collection Filters

1.

2. Donaldson IASG

Dust Collection Systems2

3.

Insertable DustCollection Filters

4. Dalamatic Reverse Jet Fabric Filters

45. Dalamatic Insertable Filter

56. Which Industries ?

All bulk handling industriesCement

Minerals

Processing

Aggregates

Iron & Steel

Glass

Agro-food

Power generation

6

7. Which Applications ?

Conveyor TransfersAir Slides

Elevators

Silos

Unloading Hoppers

7

8. Conveyor Transfer

Dalamatic Insertable DLM V20/10 F6on Conveyor Transfer Point

8

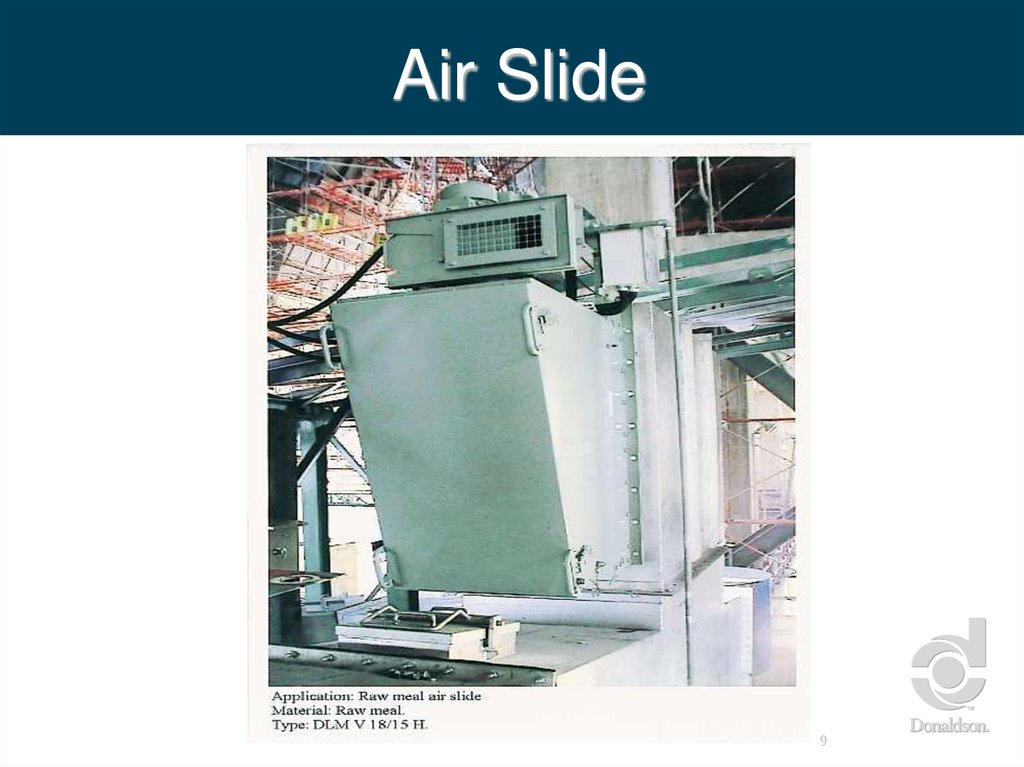

9.

Air Slide9

10. Elevator Venting

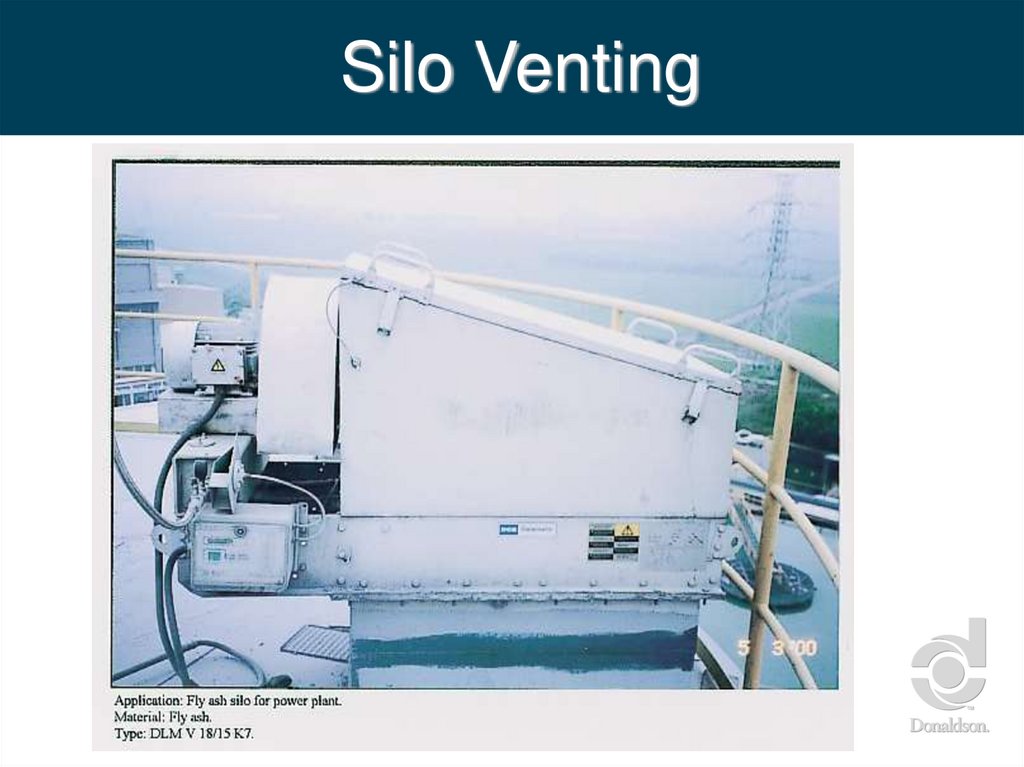

1011. Silo Venting

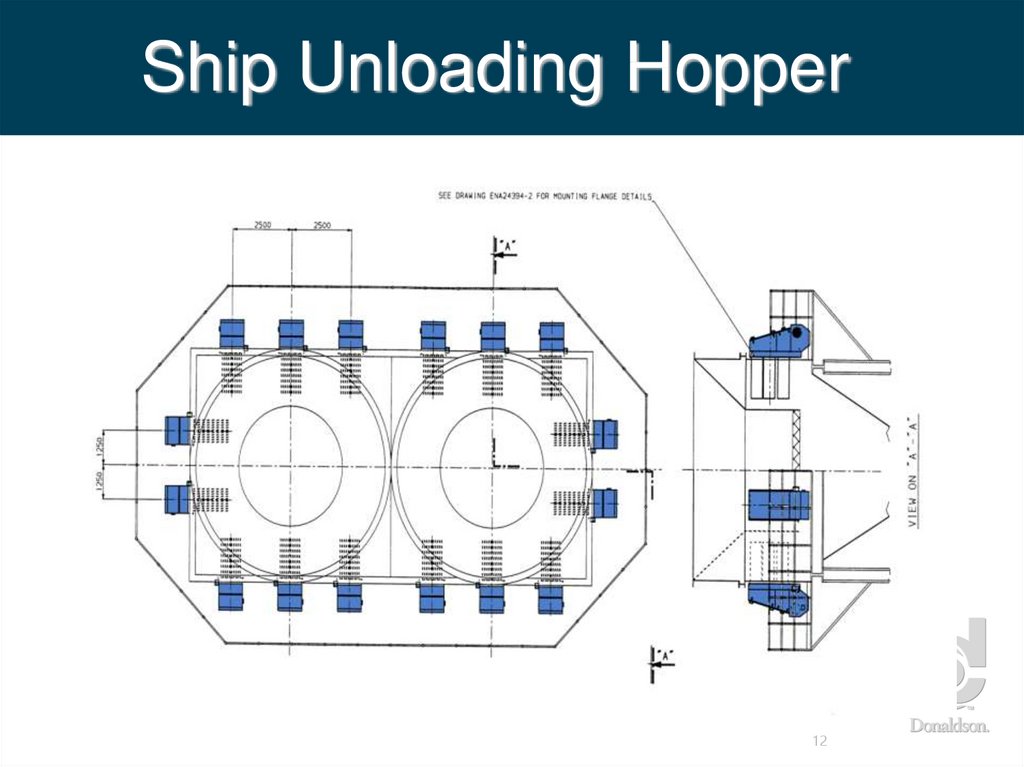

1112. Ship Unloading Hopper

1213. Why Insertable Filters ?

BenefitsEngineering

Maintenance

Financial

13

14. Why Insertable Filters ?

EngineeringThe collected dust product is

‘pulsed’ directly back to the

process.

No ductwork to engineer.

No additional materials handling

equipment.

Integrated dust collector

systems.

14

15. Why Insertable Filters ?

Engineering cont…..Supplementary exhaust for an

existing centralised system.

15

16. Why Insertable Filters ?

MaintenanceNo plant shutdown for

maintenance.

Spread maintenance operation

and cost over a period of time.

No ductwork to maintain.

No additional materials handling

equipment to maintain.

16

17. Why Insertable Filters ?

FinanceSpread the cost of capital

investment over a period of

time.

No ductwork to buy and

maintain.

No additional materials

handling equipment to buy

and maintain.

17

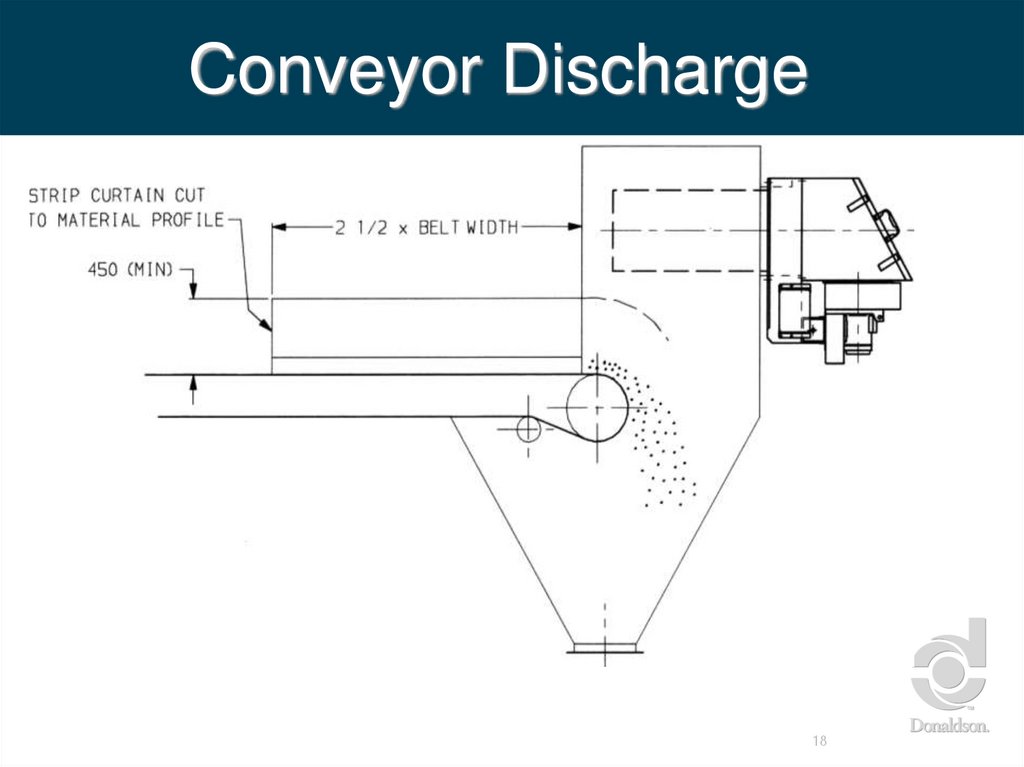

18. Conveyor Discharge

1819. Conveyor Transfer

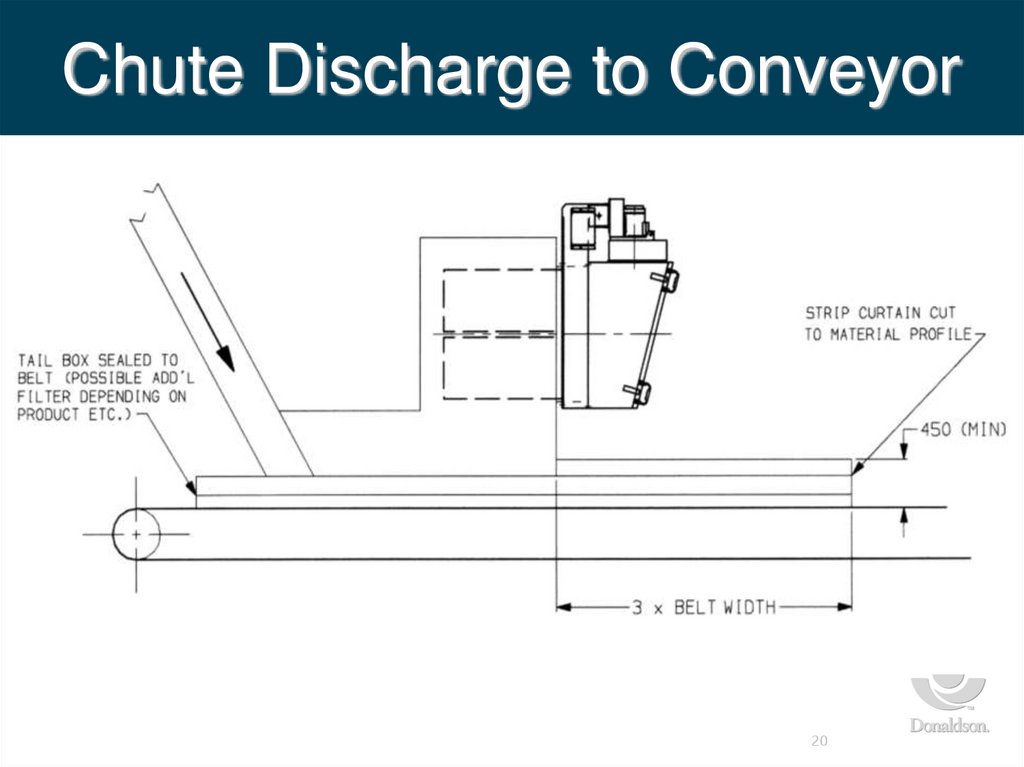

1920. Chute Discharge to Conveyor

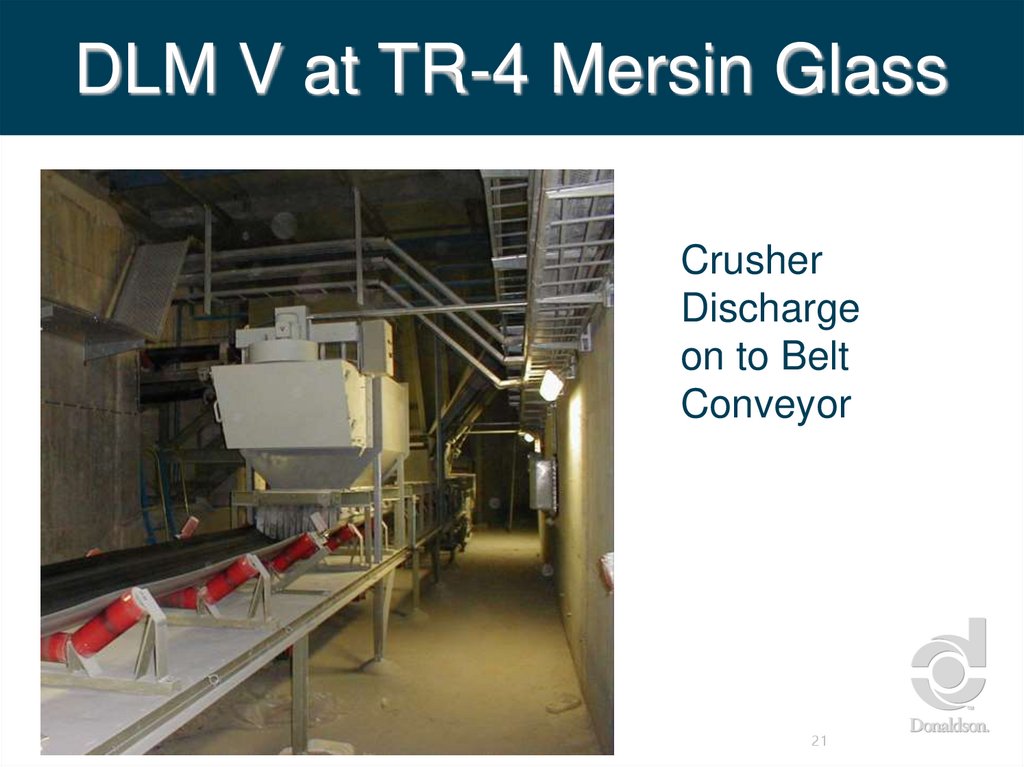

2021. DLM V at TR-4 Mersin Glass

CrusherDischarge

on to Belt

Conveyor

21

22. DLM V - Conveyor Transfer

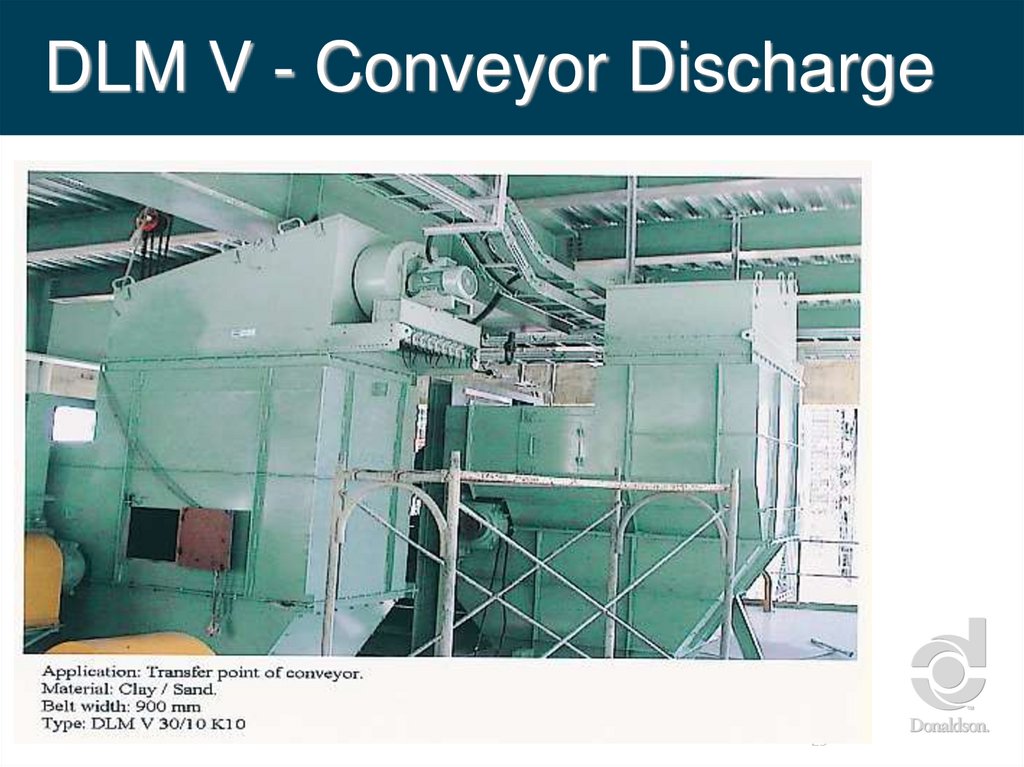

2223. DLM V - Conveyor Discharge

2324. DLM V - Flat Deck Screens

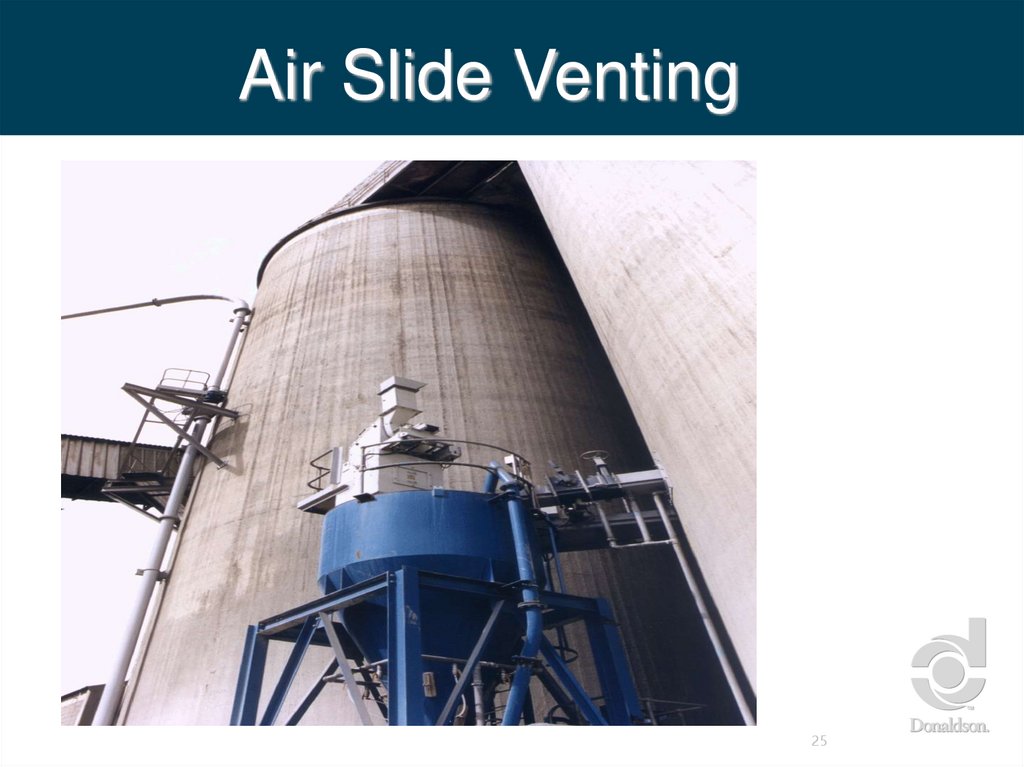

2425.

Air Slide Venting25

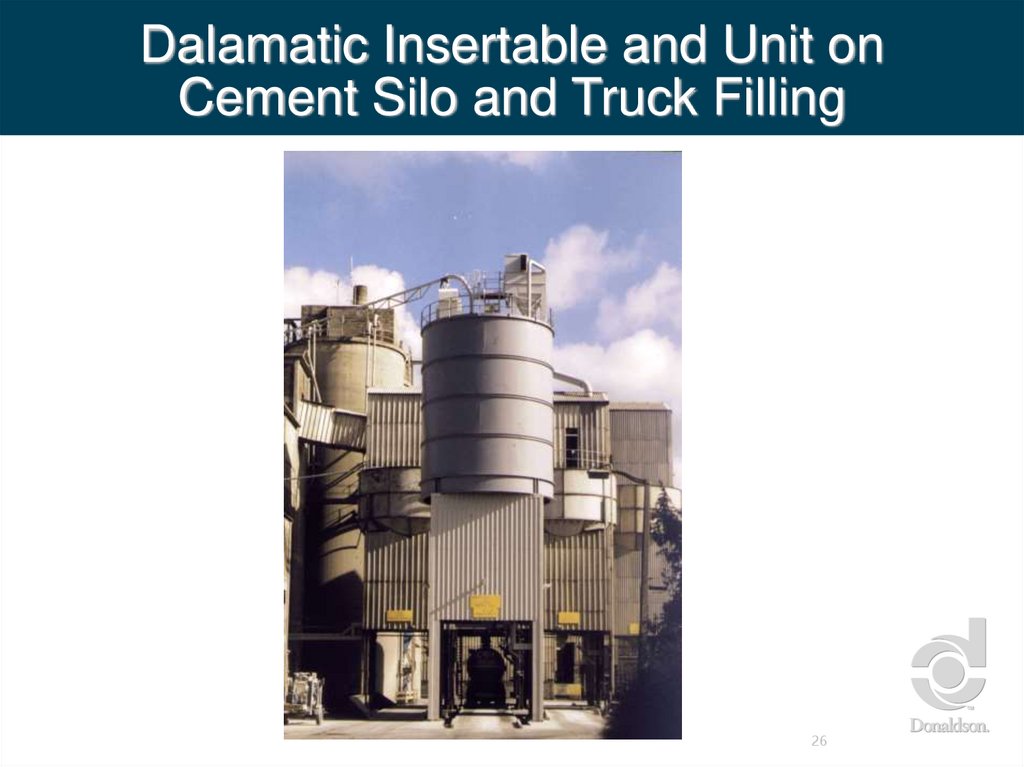

26. Dalamatic Insertable and Unit on Cement Silo and Truck Filling

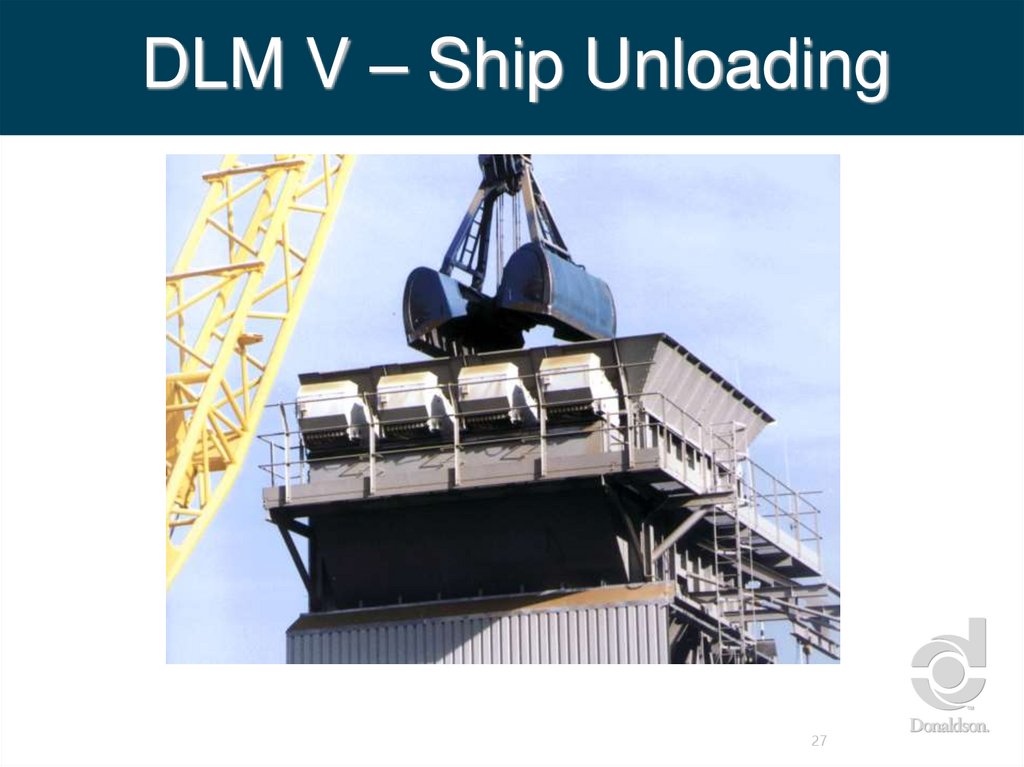

2627. DLM V – Ship Unloading

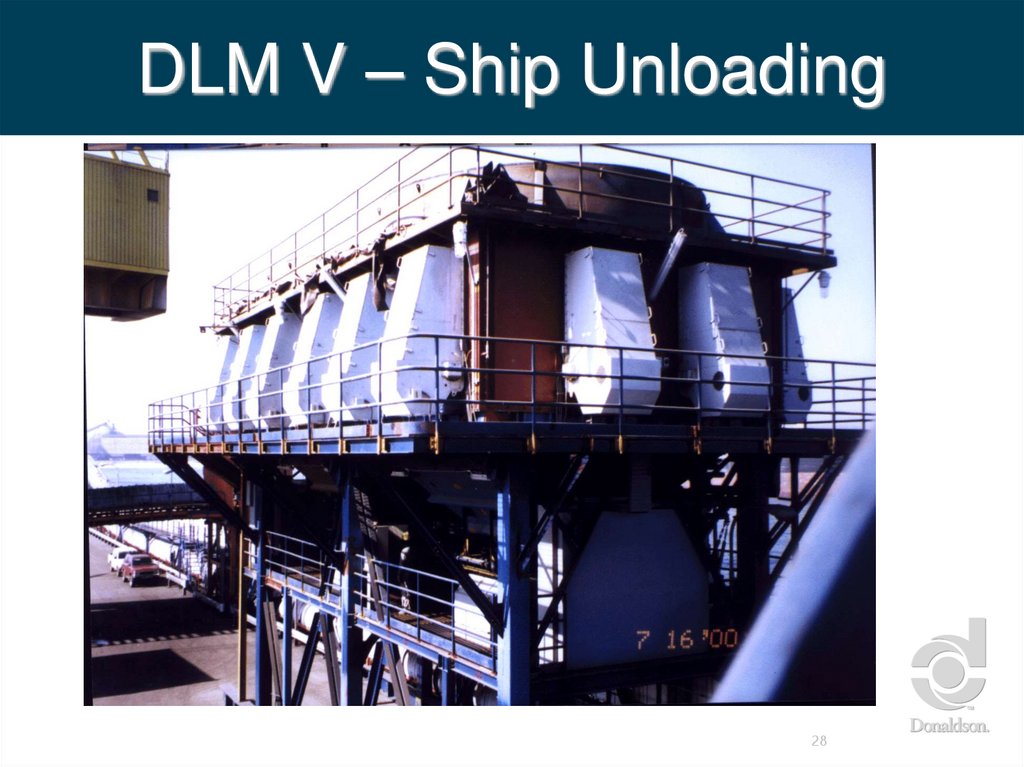

2728. DLM V – Ship Unloading

2829. Other Applications

Truck Tipping EnclosuresMills

Screens

Others ?

29

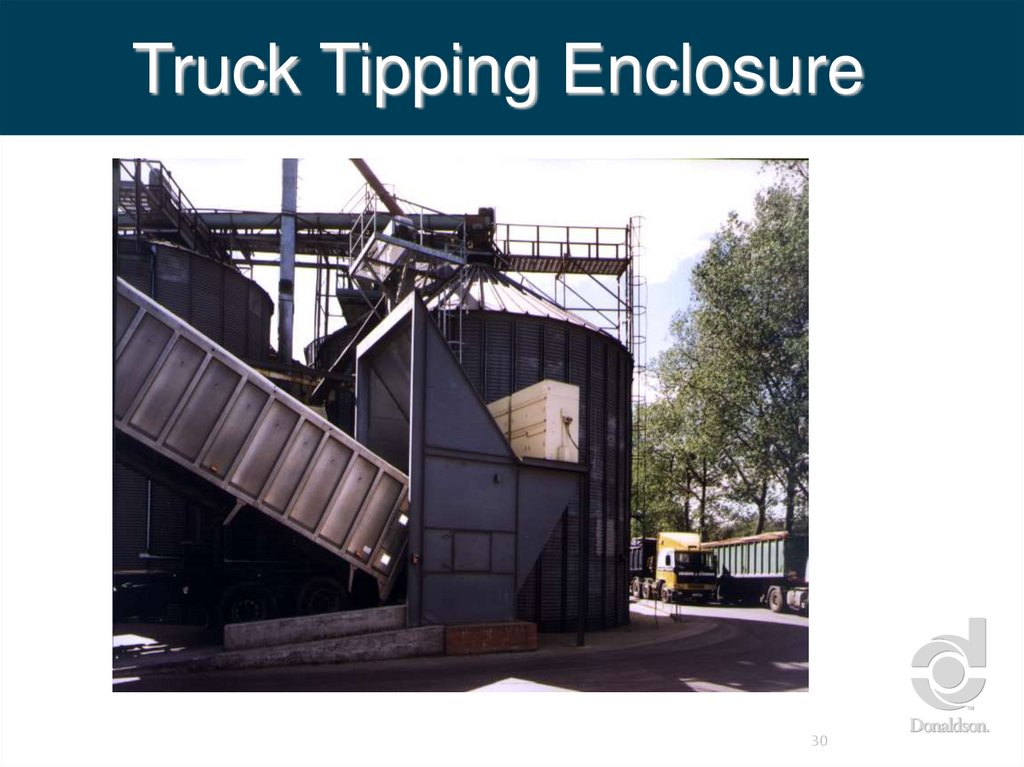

30. Truck Tipping Enclosure

3031. DLM V - Cement Mill

3132. Section through seal frame and two filter elements, showing principle of operation

3233. Dalamatic Insertable Design Features

Horizontal or Vertical

Installation

Flat pad filter elements

– minimum space requirement

– maximum rigidity

– clear passage for pulsed dust

Integral fan and silencer

option

33

34. Dalamatic Insertable Design Features

Alternative standard model

configurations

Suitable for varied process applications

– High Temperature

– Pressure

– Hazardous

Optional stainless steel materials of

construction

34

35. Dalamatic Insertable Options

Op

t

i

o

n

s

:

B

a

s

i

c

(

B

T

y

p

e

)

H

e

a

d

e

r

(

H

T

y

p

e

)

W

e

a

t

h

e

r

C

o

w

l

(

W

T

y

p

e

)

F

a

n

A

s

s

i

s

t

e

d

(

F

T

y

p

e

)

F

a

n

w

i

t

h

A

c

o

u

s

t

i

c

D

i

f

f

u

s

e

r

(

F

A

D

T

y

p

e

)

V

a

c

u

u

m

S

t

i

f

f

e

n

e

d (

S

T

y

p

e

)

35

36. Summary

Reduce and spread the cost ofcapital investment

Simplify engineering and

reduce installation costs

Reduce and spread

maintenance operations

Proven solutions to dust

control problems with world-wide

references

36

Промышленность

Промышленность