Похожие презентации:

System Configuration

1.

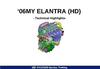

VHMS CONTROLLERSystem Configuration ( Example : Engine for HD465/605-5, HD785/985-5)

Additional sensors

Engine oil Temp. Sensor

Engine Speed Sensor

Exhaust Gas Temp. Sensor

Engine Oil Pressure Sensor

Engine Blow-by Sensor

Rack Position Sensor

Sensors

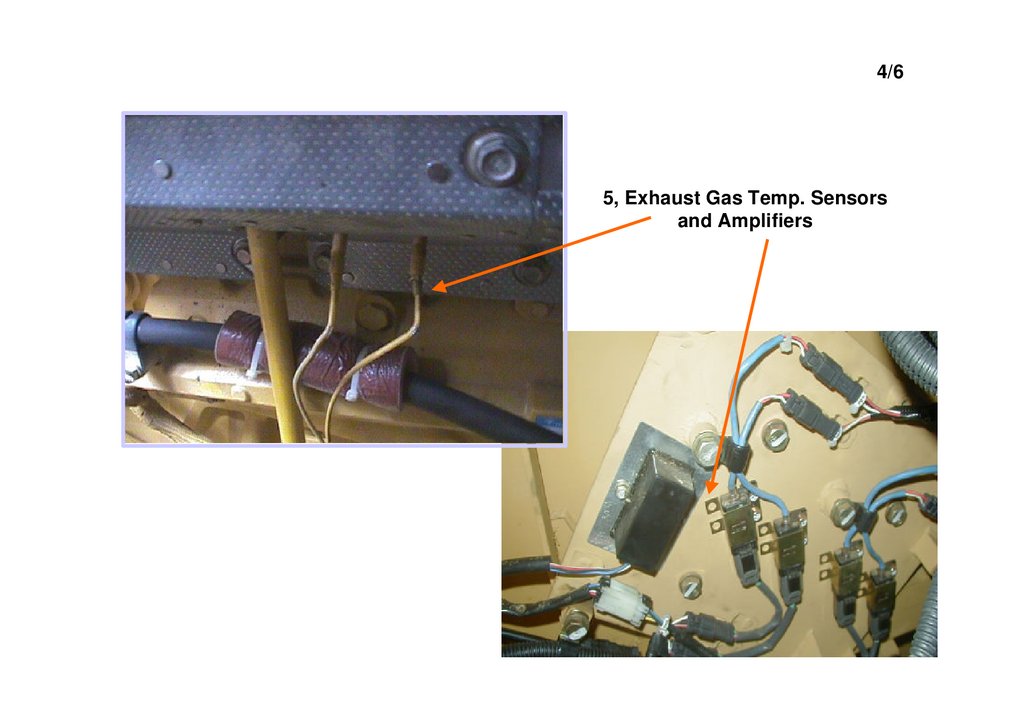

Basically, Use the electrical data on machine’s operation.

Controllers

Pay Load

Engine

Transmission

Monitor

Meter (Option)

Controller

Controller

Panel

Rack

Position

Payload meter

data

Data

VHMS CONTROLLER

Orbcomm

Controller

Snapshot

Switch

Download PC

Antenna

Error Code

SMR

2.

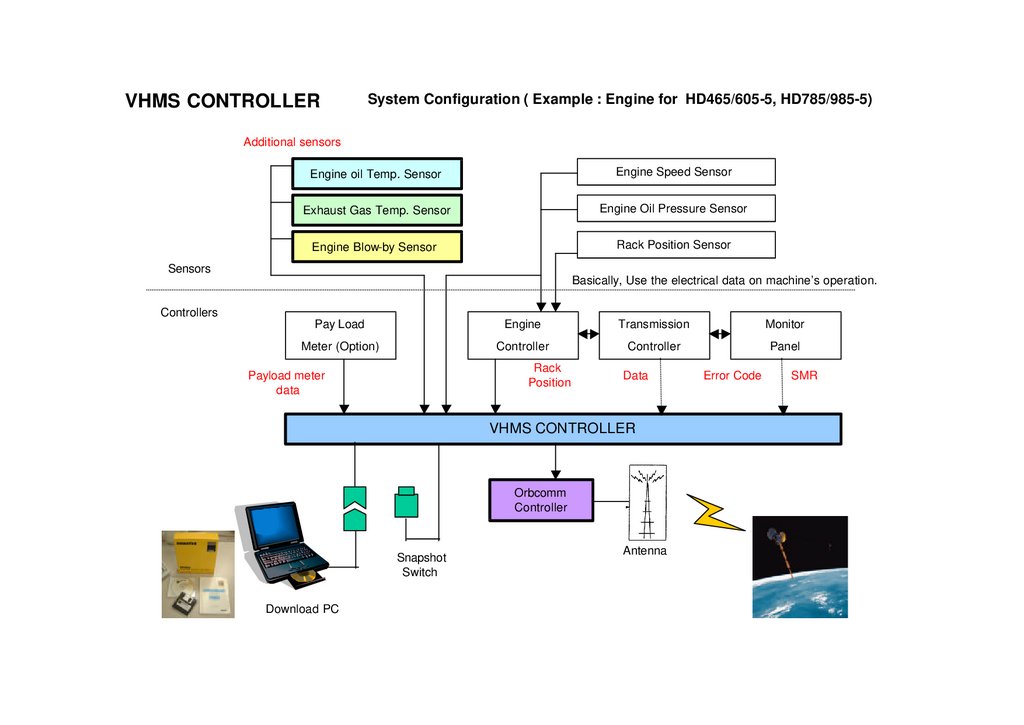

VHMS CONTROLLER1) Engine oil temperature sensor

Additional sensors

3.

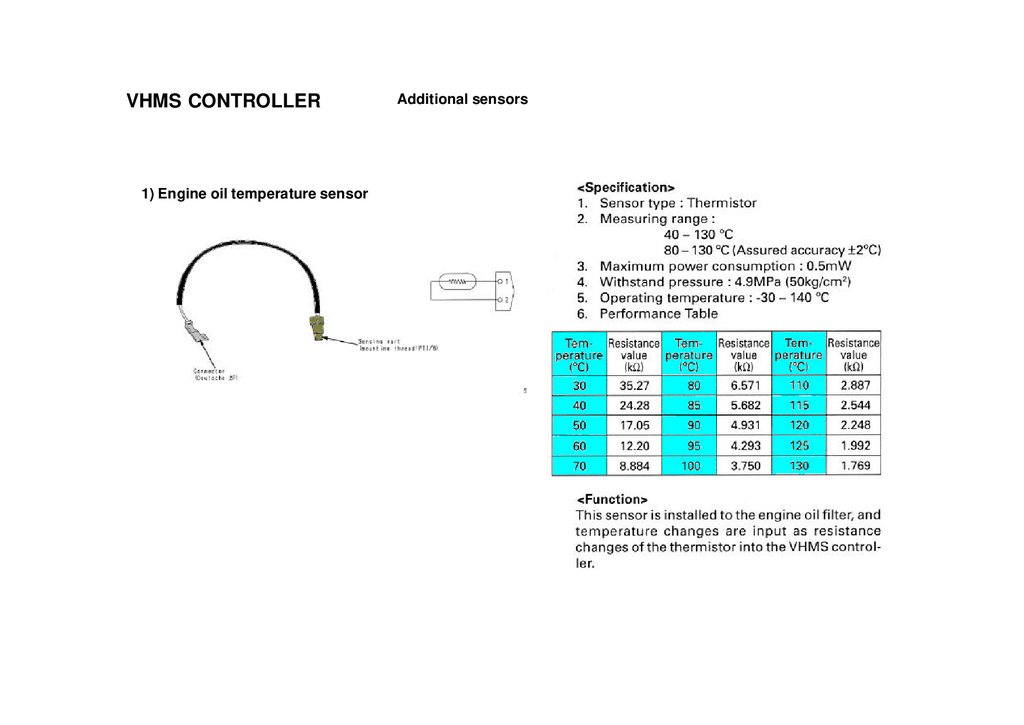

VHMS CONTROLLER2) Engine exhaust temperature sensor

& Amplifier (For Komatsu Engine)

<Note> The sensor is the same one which is used for

Pm-CLINIC Service.

4.

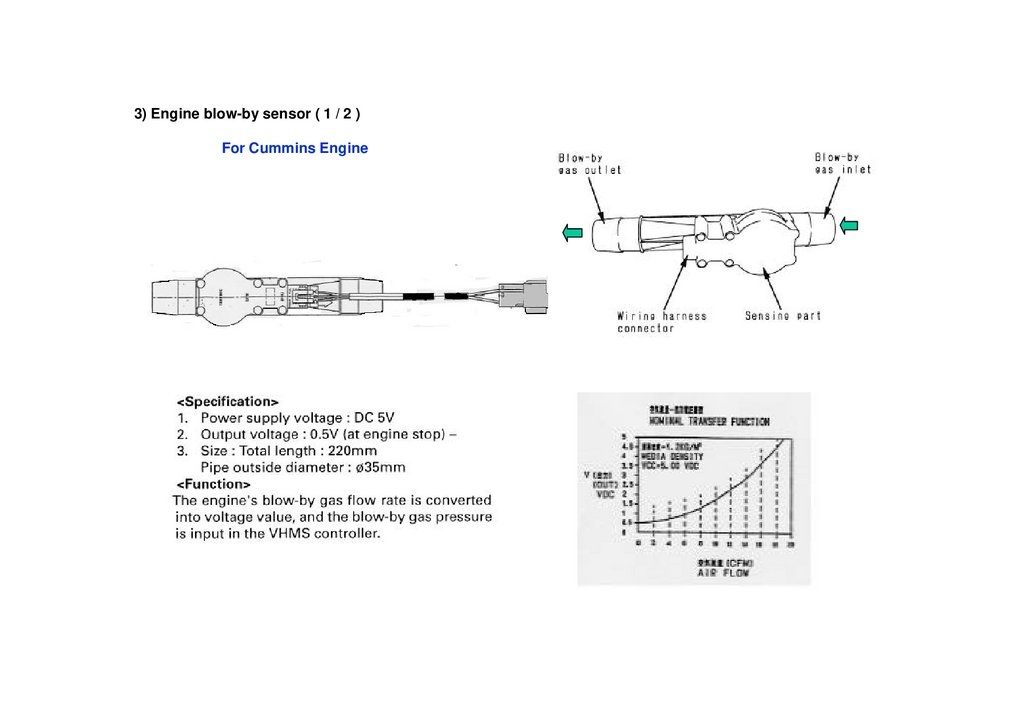

3) Engine blow-by sensor ( 1 / 2 )For Cummins Engine

5.

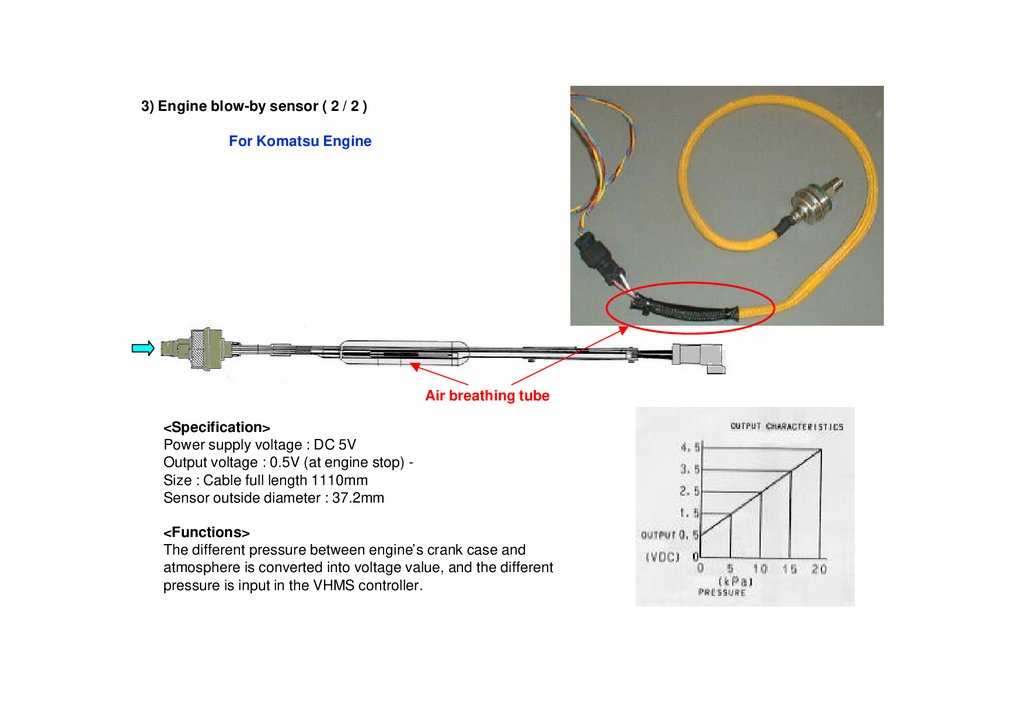

3) Engine blow-by sensor ( 2 / 2 )For Komatsu Engine

Air breathing tube

<Specification>

Power supply voltage : DC 5V

Output voltage : 0.5V (at engine stop) Size : Cable full length 1110mm

Sensor outside diameter : 37.2mm

<Functions>

The different pressure between engine’s crank case and

atmosphere is converted into voltage value, and the different

pressure is input in the VHMS controller.

6.

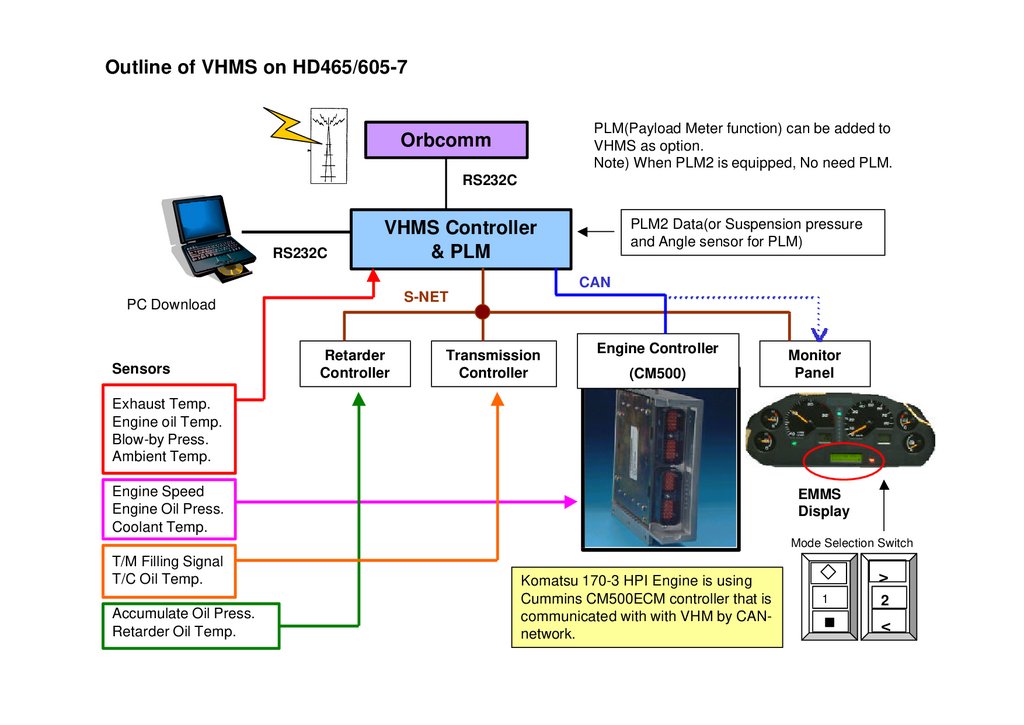

Outline of VHMS on HD465/605-7PLM(Payload Meter function) can be added to

VHMS as option.

Note) When PLM2 is equipped, No need PLM.

Orbcomm

RS232C

RS232C

PLM2 Data(or Suspension pressure

and Angle sensor for PLM)

VHMS Controller

& PLM

CAN

S-NET

PC Download

Sensors

Retarder

Controller

Transmission

Controller

Engine Controller

(CM500)

Monitor

Panel

Exhaust Temp.

Engine oil Temp.

Blow-by Press.

Ambient Temp.

Engine Speed

Engine Oil Press.

Coolant Temp.

EMMS

Display

Mode Selection Switch

T/M Filling Signal

T/C Oil Temp.

Accumulate Oil Press.

Retarder Oil Temp.

Komatsu 170170-3 HPI Engine is using

Cummins CM500ECM controller that is

communicated with with VHM by CANCANnetwork.

>

1

2

<

7.

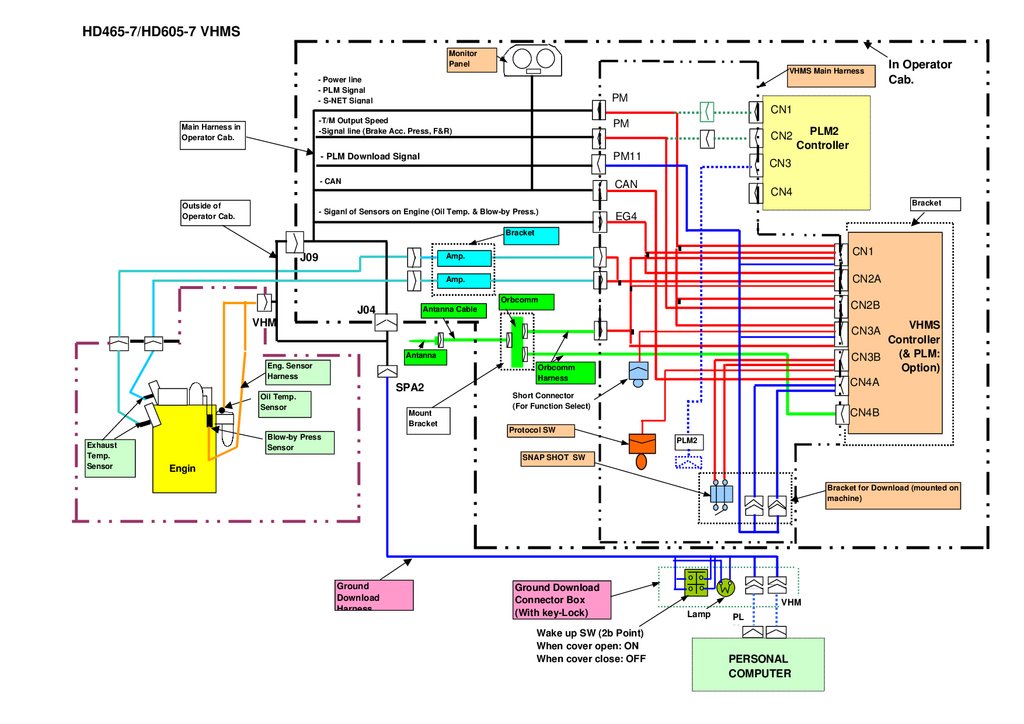

HD465-7/HD605-7 VHMSMonitor

Panel

VHMS Main Harness

- Power line

- PLM Signal

- S-NET Signal

PM

1

PM

-T/M Output Speed

-Signal line (Brake Acc. Press, F&R)

Main Harness in

Operator Cab.

CN1

CN2

- PLM Download Signal

PM11

- CAN

CAN

PLM2

Controller

CN3

CN4

Bracket

Outside of

Operator Cab.

- Siganl of Sensors on Engine (Oil Temp. & Blow-by Press.)

Bracket

J09

Amp.

Amp.

Orbcomm

J04

Antanna Cable

VHM

EG4

. .

..

.

.

CN1

CN2A

CN2B

VHMS

Controller

(& PLM:

CN3B

Option)

CN4A

CN3A

Antanna

Eng. Sensor

Harness

Orbcomm

Harness

SPA2

Oil Temp.

Sensor

Exhaust

Temp.

Sensor

In Operator

Cab.

Mount

Bracket

Blow-by Press

Sensor

Short Connector

(For Function Select)

CN4B

Protocol SW

PLM2

SNAP SHOT SW

Engin

e

Bracket for Download (mounted on

machine)

O O

Ground

Download

Harness

Ground Download

Connector Box

(With key-Lock)

Wake up SW (2b Point)

When cover open: ON

When cover close: OFF

O

O

VHM

Lamp

PL

M

PERSONAL

COMPUTER

8.

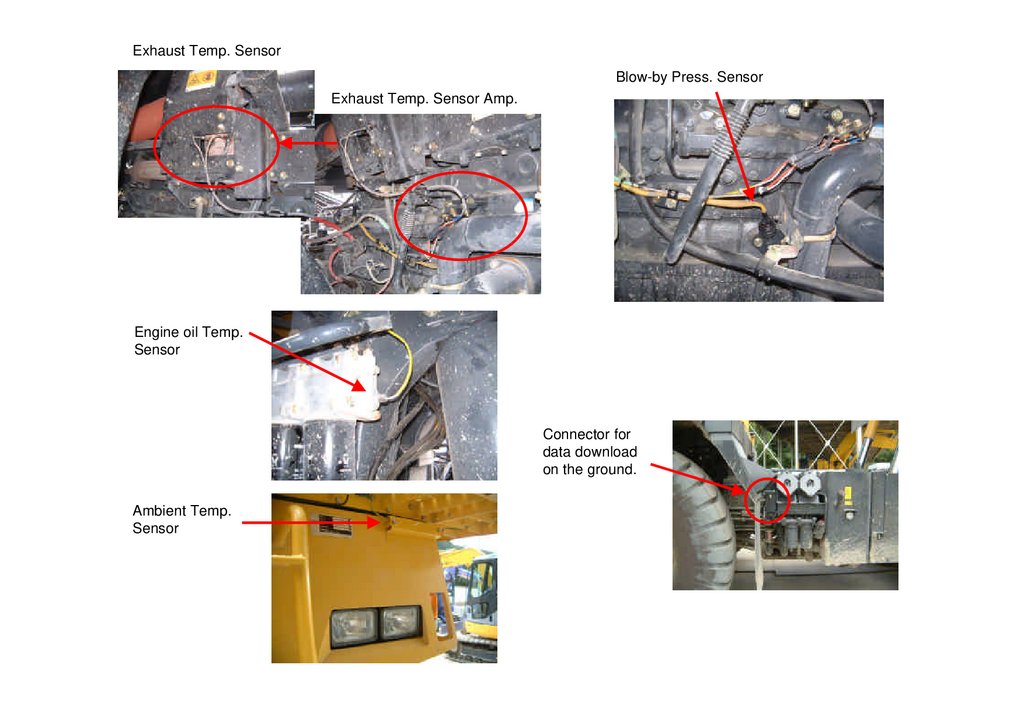

Exhaust Temp. SensorBlow-by Press. Sensor

Exhaust Temp. Sensor Amp.

Engine oil Temp.

Sensor

Connector for

data download

on the ground.

Ambient Temp.

Sensor

9.

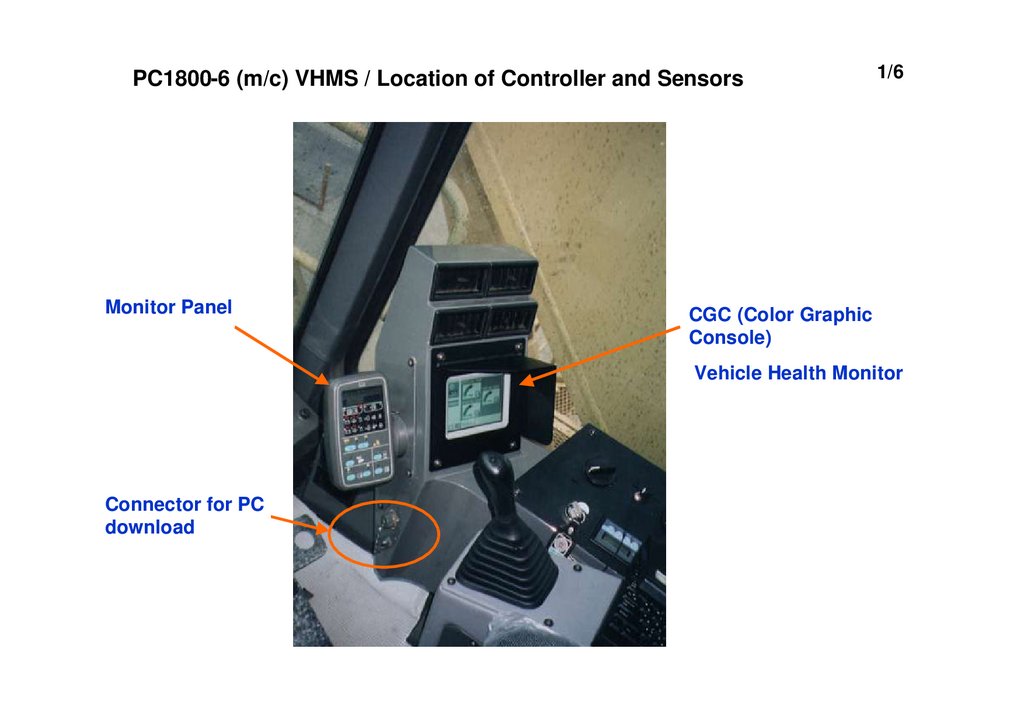

PC1800-6 (m/c) VHMS / Location of Controller and SensorsMonitor Panel

1/6

CGC (Color Graphic

Console)

Vehicle Health Monitor

Connector for PC

download

10.

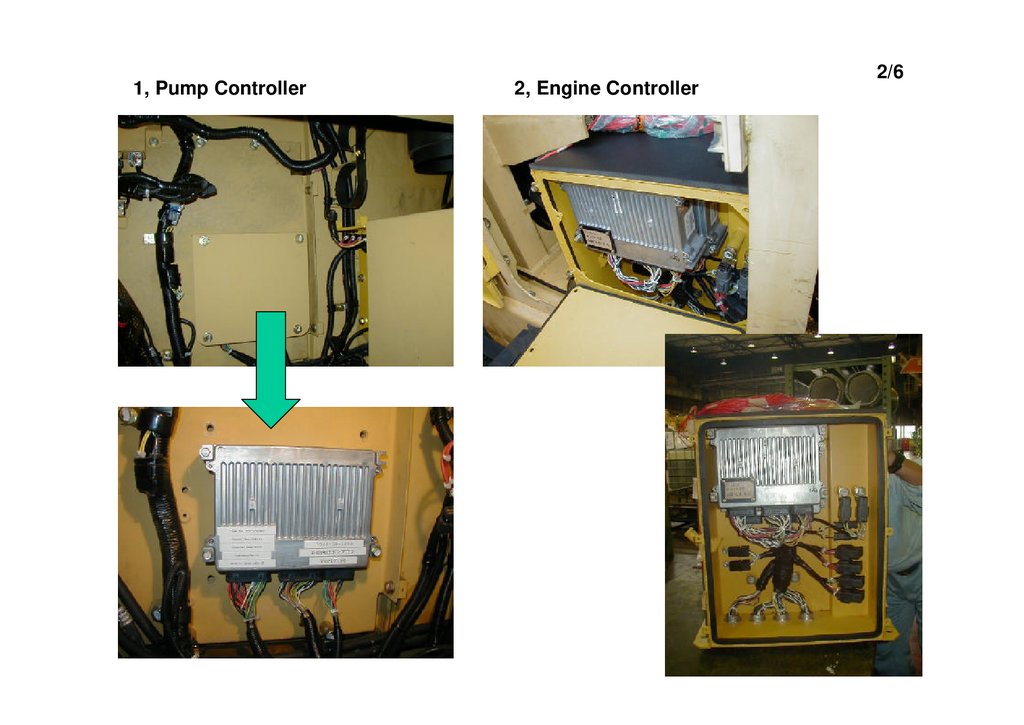

1, Pump Controller2, Engine Controller

2/6

11.

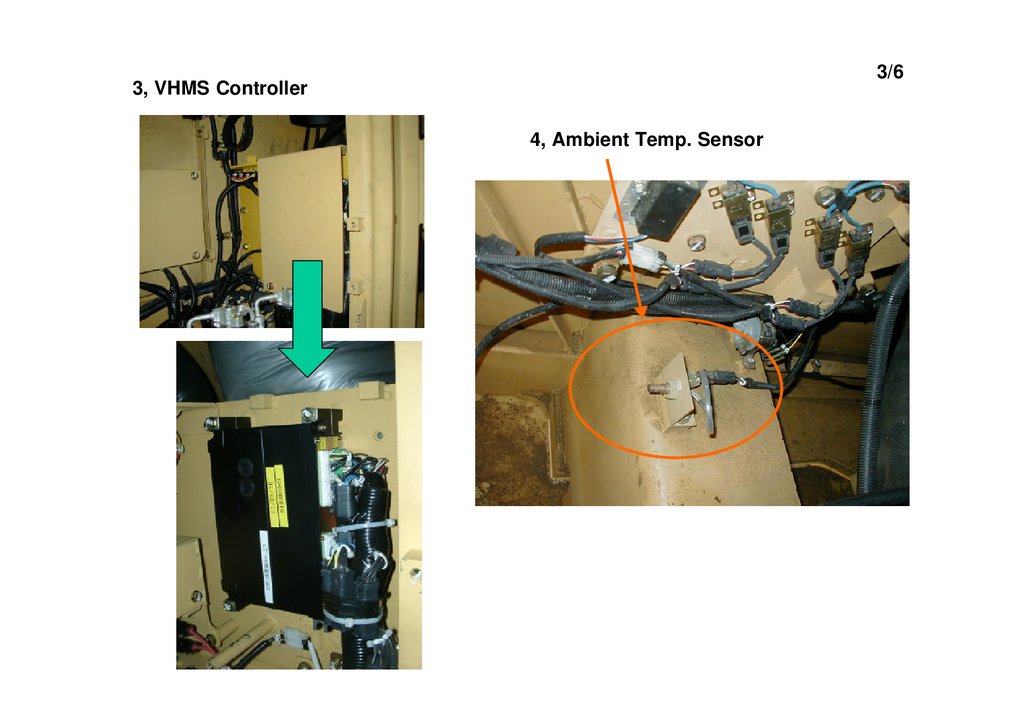

3/63, VHMS Controller

4, Ambient Temp. Sensor

12.

4/65, Exhaust Gas Temp. Sensors

and Amplifiers

13.

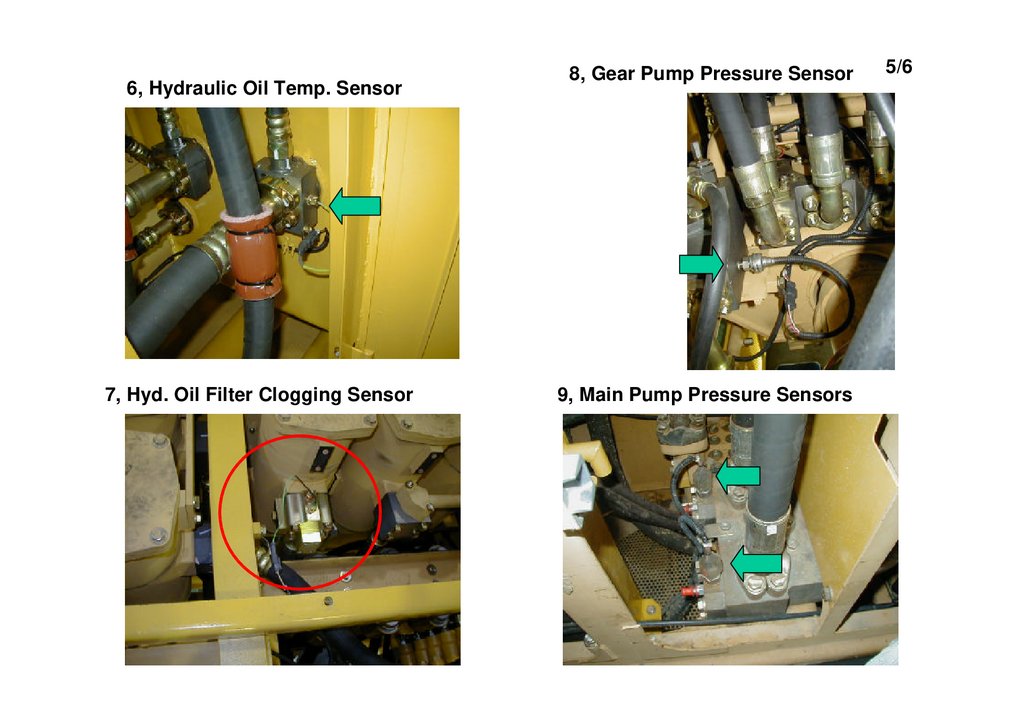

6, Hydraulic Oil Temp. Sensor7, Hyd. Oil Filter Clogging Sensor

8, Gear Pump Pressure Sensor

9, Main Pump Pressure Sensors

5/6

14.

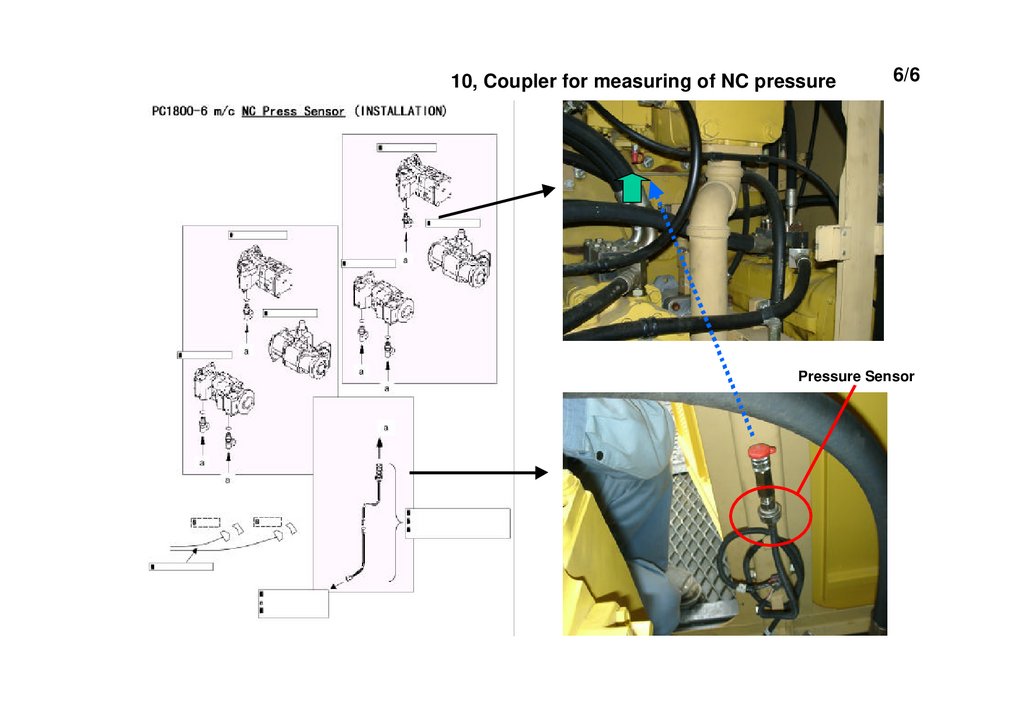

10, Coupler for measuring of NC pressure6/6

Pressure Sensor

15.

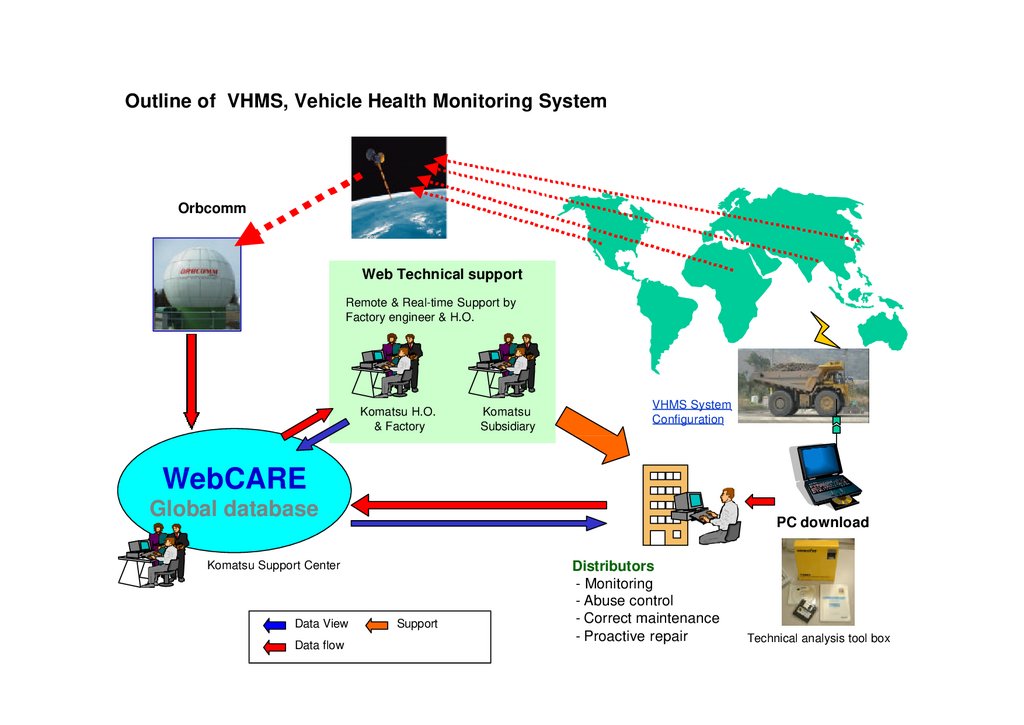

Outline of VHMS, Vehicle Health Monitoring SystemOrbcomm

Web Technical support

Remote & Real-time Support by

Factory engineer & H.O.

Komatsu H.O.

& Factory

Komatsu

Subsidiary

VHMS System

Configuration

WebCARE

Global database

PC download

Komatsu Support Center

Data View

Data flow

Support

Distributors

- Monitoring

- Abuse control

- Correct maintenance

- Proactive repair

Technical analysis tool box

16.

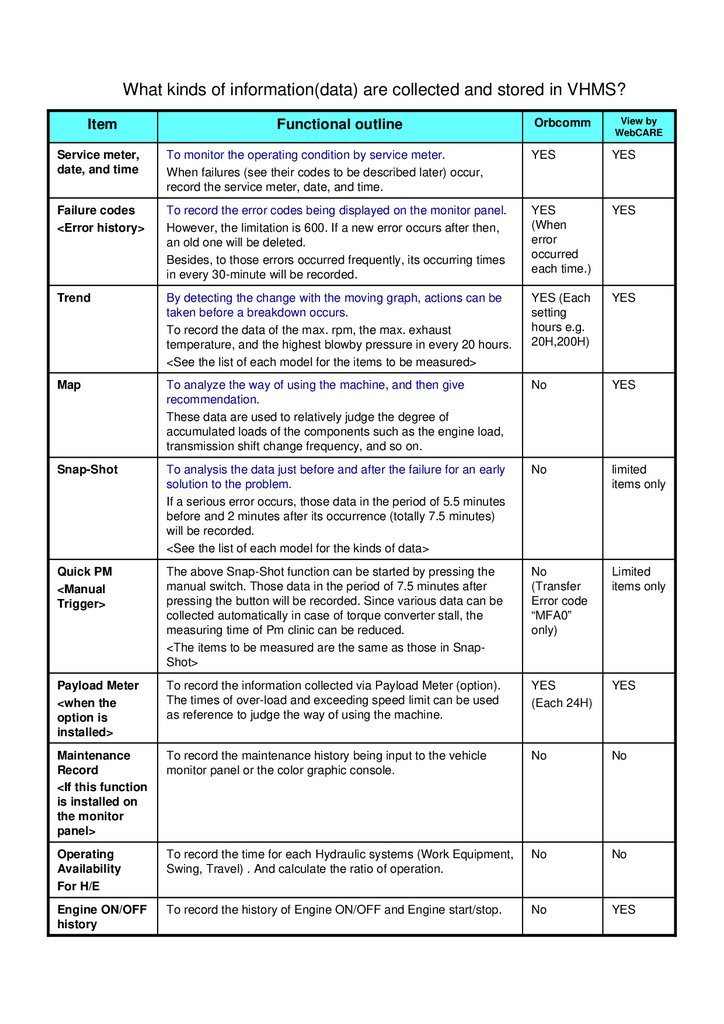

What kinds of information(data) are collected and stored in VHMS?Item

Functional outline

Orbcomm

View by

WebCARE

Service meter,

date, and time

To monitor the operating condition by service meter.

When failures (see their codes to be described later) occur,

record the service meter, date, and time.

YES

YES

Failure codes

<Error history>

To record the error codes being displayed on the monitor panel.

However, the limitation is 600. If a new error occurs after then,

an old one will be deleted.

Besides, to those errors occurred frequently, its occurring times

in every 30-minute will be recorded.

YES

(When

error

occurred

each time.)

YES

Trend

By detecting the change with the moving graph, actions can be

taken before a breakdown occurs.

To record the data of the max. rpm, the max. exhaust

temperature, and the highest blowby pressure in every 20 hours.

<See the list of each model for the items to be measured>

YES (Each

setting

hours e.g.

20H,200H)

YES

Map

To analyze the way of using the machine, and then give

recommendation.

These data are used to relatively judge the degree of

accumulated loads of the components such as the engine load,

transmission shift change frequency, and so on.

No

YES

Snap-Shot

To analysis the data just before and after the failure for an early

solution to the problem.

If a serious error occurs, those data in the period of 5.5 minutes

before and 2 minutes after its occurrence (totally 7.5 minutes)

will be recorded.

<See the list of each model for the kinds of data>

No

limited

items only

Quick PM

<Manual

Trigger>

The above Snap-Shot function can be started by pressing the

manual switch. Those data in the period of 7.5 minutes after

pressing the button will be recorded. Since various data can be

collected automatically in case of torque converter stall, the

measuring time of Pm clinic can be reduced.

<The items to be measured are the same as those in SnapShot>

No

(Transfer

Error code

“MFA0”

only)

Limited

items only

Payload Meter

<when the

option is

installed>

To record the information collected via Payload Meter (option).

The times of over-load and exceeding speed limit can be used

as reference to judge the way of using the machine.

YES

(Each 24H)

YES

Maintenance

Record

<If this function

is installed on

the monitor

panel>

To record the maintenance history being input to the vehicle

monitor panel or the color graphic console.

No

No

Operating

Availability

For H/E

To record the time for each Hydraulic systems (Work Equipment,

Swing, Travel) . And calculate the ratio of operation.

No

No

Engine ON/OFF

history

To record the history of Engine ON/OFF and Engine start/stop.

No

YES

17.

1. Failure CodesWhen a failure occurs in the vehicle, the error codes being displayed on the monitor panel will be

recorded. Moreover, the items not displayed on the monitor will also be recorded in the history.

(See the shop manual of each model for the items.)

However, the limitation is 400. If a new error occurs after then, an old one will be deleted.

Besides, to the errors occur frequently, those occurred within every 30-minute will be gathered and

recorded as one error.

Example) In case of inspecting the errors with an analysis tool.

Example) In case inspecting the errors on WebCARE

Error History

18.

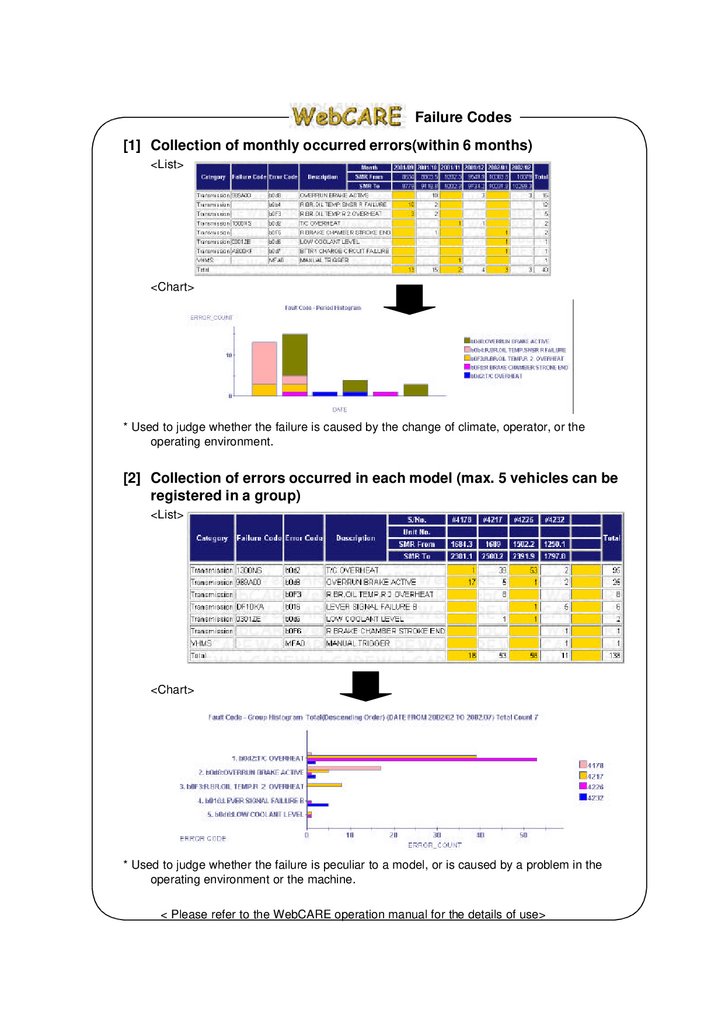

Failure Codes[1] Collection of monthly occurred errors(within 6 months)

<List>

<Chart>

* Used to judge whether the failure is caused by the change of climate, operator, or the

operating environment.

[2] Collection of errors occurred in each model (max. 5 vehicles can be

registered in a group)

<List>

<Chart>

* Used to judge whether the failure is peculiar to a model, or is caused by a problem in the

operating environment or the machine.

< Please refer to the WebCARE operation manual for the details of use>

19.

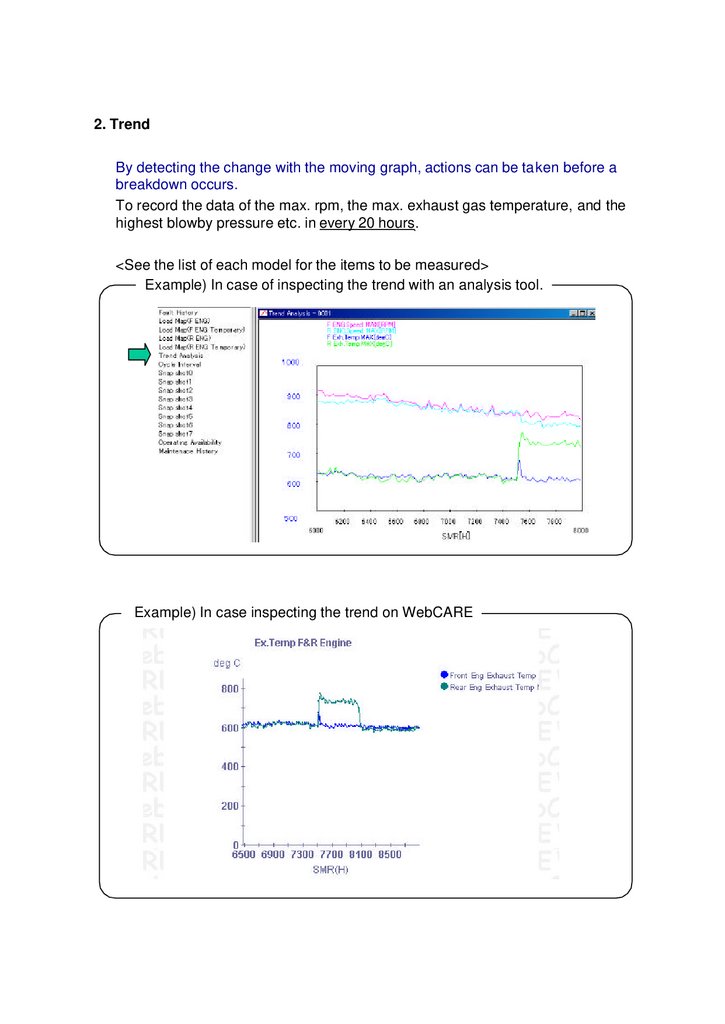

2. TrendBy detecting the change with the moving graph, actions can be taken before a

breakdown occurs.

To record the data of the max. rpm, the max. exhaust gas temperature, and the

highest blowby pressure etc. in every 20 hours.

<See the list of each model for the items to be measured>

Example) In case of inspecting the trend with an analysis tool.

Example) In case inspecting the trend on WebCARE

20.

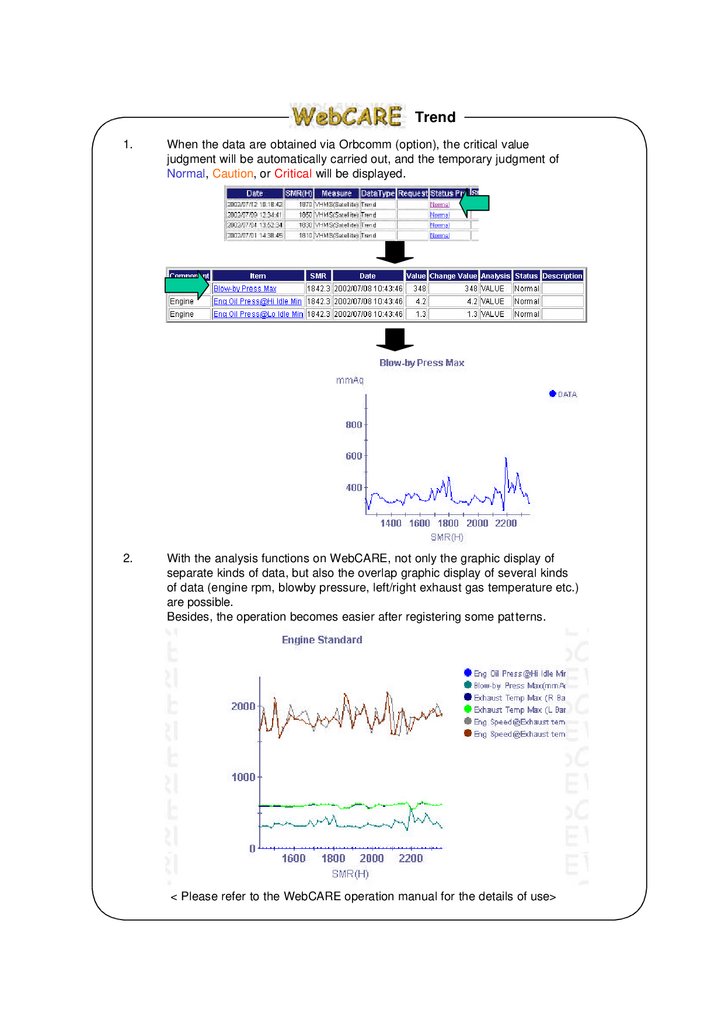

Trend1.

When the data are obtained via Orbcomm (option), the critical value

judgment will be automatically carried out, and the temporary judgment of

Normal, Caution, or Critical will be displayed.

2.

With the analysis functions on WebCARE, not only the graphic display of

separate kinds of data, but also the overlap graphic display of several kinds

of data (engine rpm, blowby pressure, left/right exhaust gas temperature etc.)

are possible.

Besides, the operation becomes easier after registering some patterns.

< Please refer to the WebCARE operation manual for the details of use>

21.

Key Points!!!In Pm clinic, when measuring the engine rpm, exhaust gas temperature, and blowby pressure,

the torque converter stall and oil pressure relief are taken as the load condition. While in

VHMS, the data are sampled continuously in 20 hours, and the maximum, the minimum, and

the mean can be obtained.

By inspecting the trend of the data, it is easy to judge whether the load is a continuous one or a

temporary one. Monitoring data in this way is helpful to estimate the life of the machine.

Particularly, the following 3 items (blowby pressure, exhaust gas temperature, and the fuel

consumption ) are important in inspecting the load.

[1] The blowby pressure, measured at the point of maximum horse power, is at its maximum

value. Therefore, the engine rpm at the point of the maximum blowby pressure can be handle

as the rated engine rpm.

≈ Means “Approximate Value”

The maximum blowby value ≈ the rated point (the maximum horse power)

<The engine rpm at the maximum blowby ≈ the rated engine rpm>

By the load conditions of torque converter stall and oil pressure relief being used in Pm clinic,

the data in real operation have high possibility to become the condition of rated rpm (the

maximum horse power).

Important

On the specification of blowby pressure

The conditions for carrying out the quick PM or PM clinic are torque stall, or torque stall +

operating machine relief. The specification at this time is described in the job manual.

However, when inspecting the maximum value in the real operation of 20 hours like the

trend of VHMS, the specification for judging OK/NG is also changed.

In the case of the maximum value of the real operation 20 hours obtained from the real

data, under the influences of being near to the maximum horse power, the over shoot, and

so on, a higher value than that in specified condition of quick PM or PM clinic can be

obtained.

Therefore, the specification used in judging abnormality on VHMS or inspecting the trend

on WebCARE is set to a higher value than that described in the shop manual.

22.

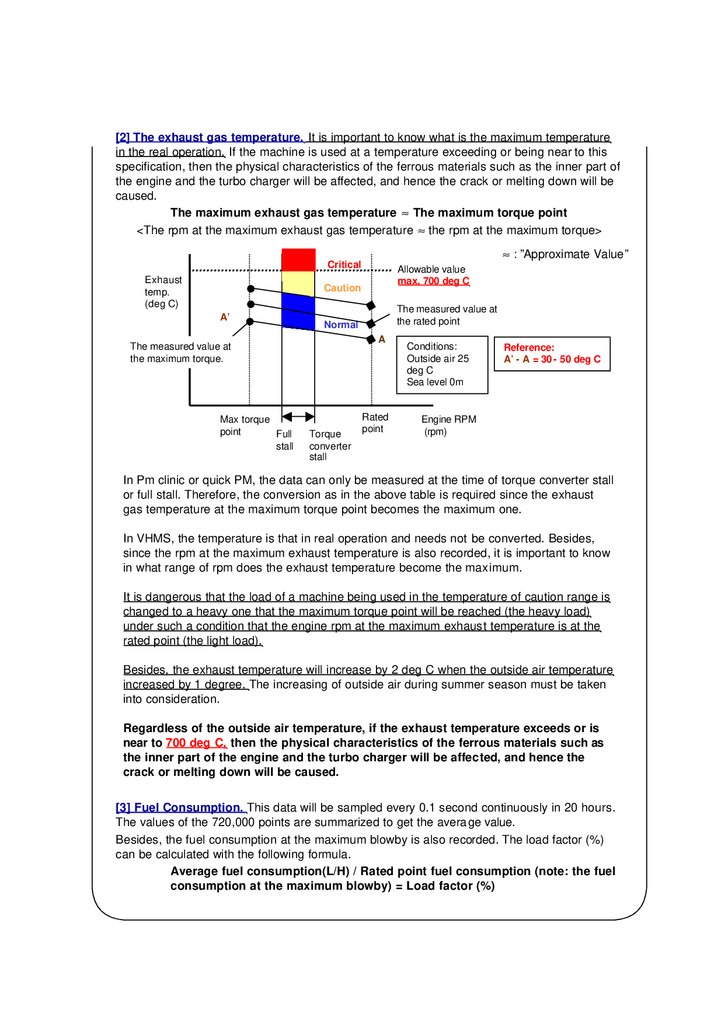

[2] The exhaust gas temperature. It is important to know what is the maximum temperaturein the real operation. If the machine is used at a temperature exceeding or being near to this

specification, then the physical characteristics of the ferrous materials such as the inner part of

the engine and the turbo charger will be affected, and hence the crack or melting down will be

caused.

The maximum exhaust gas temperature ≈ The maximum torque point

<The rpm at the maximum exhaust gas temperature ≈ the rpm at the maximum torque>

≈ : ”Approximate Value”

Critical

Exhaust

temp.

(deg C)

Allowable value

max. 700 deg C

Caution

A’

A

The measured value at

the maximum torque.

Max torque

point

Full

stall

The measured value at

the rated point

Normal

Torque

converter

stall

Rated

point

Conditions:

Outside air 25

deg C

Sea level 0m

Reference:

A’ - A = 30 - 50 deg C

Engine RPM

(rpm)

In Pm clinic or quick PM, the data can only be measured at the time of torque converter stall

or full stall. Therefore, the conversion as in the above table is required since the exhaust

gas temperature at the maximum torque point becomes the maximum one.

In VHMS, the temperature is that in real operation and needs not be converted. Besides,

since the rpm at the maximum exhaust temperature is also recorded, it is important to know

in what range of rpm does the exhaust temperature become the maximum.

It is dangerous that the load of a machine being used in the temperature of caution range is

changed to a heavy one that the maximum torque point will be reached (the heavy load)

under such a condition that the engine rpm at the maximum exhaust temperature is at the

rated point (the light load).

Besides, the exhaust temperature will increase by 2 deg C when the outside air temperature

increased by 1 degree. The increasing of outside air during summer season must be taken

into consideration.

Regardless of the outside air temperature, if the exhaust temperature exceeds or is

near to 700 deg C, then the physical characteristics of the ferrous materials such as

the inner part of the engine and the turbo charger will be affected, and hence the

crack or melting down will be caused.

[3] Fuel Consumption. This data will be sampled every 0.1 second continuously in 20 hours.

The values of the 720,000 points are summarized to get the average value.

Besides, the fuel consumption at the maximum blowby is also recorded. The load factor (%)

can be calculated with the following formula.

Average fuel consumption(L/H) / Rated point fuel consumption (note: the fuel

consumption at the maximum blowby) = Load factor (%)

23.

T/M Clutch Filling Time & Disc WearTrigger Time

V

Control

Press.

Time

Kg/cm2

Hydraulic

Control Valve

Clutch Unit

Clutch

Press.

ECMV

Time

V

Fill

Sensor

Voltage

Fill Sensor

Detect filling, and send

signal to controller

Time

Filling Time

HD465, 785

WA1200

Trigger

Time

Fixed

Change =

Disc Wear

Filling

Time

Change =

Disc Wear

Fixed

Change from

flow control to

Pressure

control. Then

increase

pressure.

24.

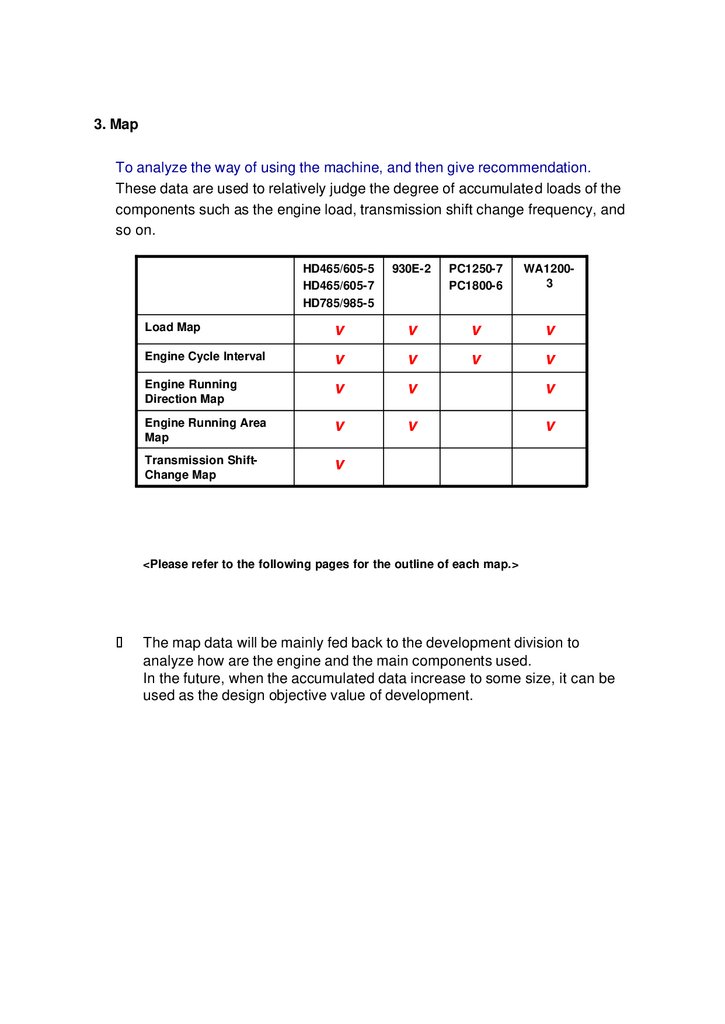

3. MapTo analyze the way of using the machine, and then give recommendation.

These data are used to relatively judge the degree of accumulated loads of the

components such as the engine load, transmission shift change frequency, and

so on.

HD465/605-5

HD465/605-7

HD785/985-5

930E-2

PC1250-7

PC1800-6

WA12003

Load Map

v

v

v

v

Engine Cycle Interval

v

v

v

v

Engine Running

Direction Map

v

v

v

Engine Running Area

Map

v

v

v

Transmission ShiftChange Map

v

<Please refer to the following pages for the outline of each map.>

à The map data will be mainly fed back to the development division to

analyze how are the engine and the main components used.

In the future, when the accumulated data increase to some size, it can be

used as the design objective value of development.

25.

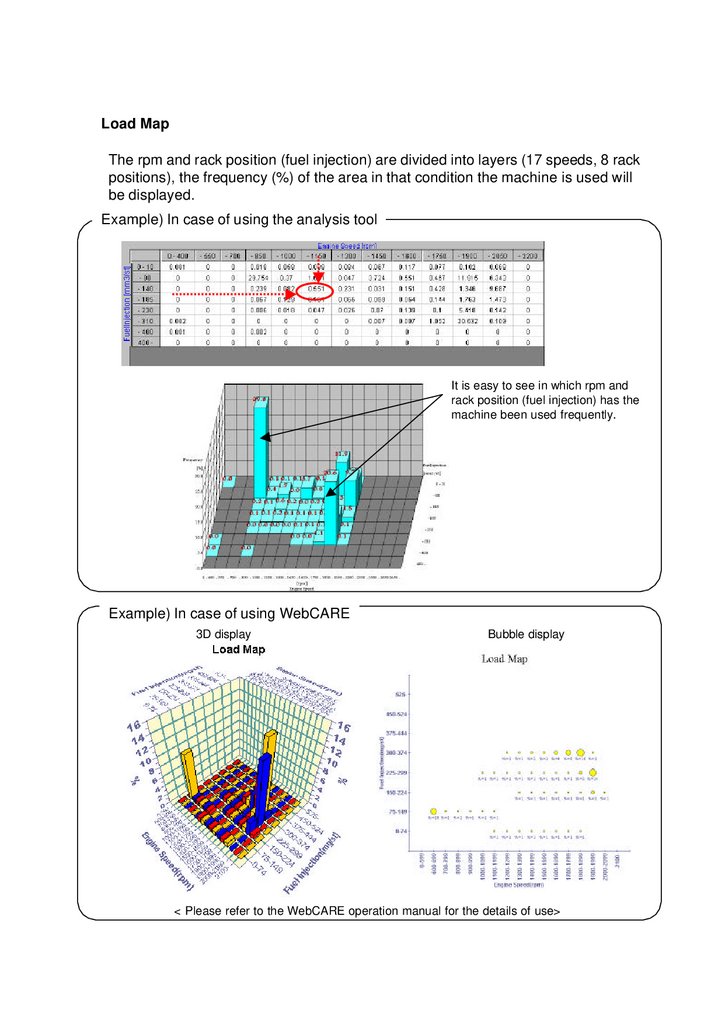

Load MapThe rpm and rack position (fuel injection) are divided into layers (17 speeds, 8 rack

positions), the frequency (%) of the area in that condition the machine is used will

be displayed.

Example) In case of using the analysis tool

It is easy to see in which rpm and

rack position (fuel injection) has the

machine been used frequently.

Example) In case of using WebCARE

3D display

Bubble display

< Please refer to the WebCARE operation manual for the details of use>

26.

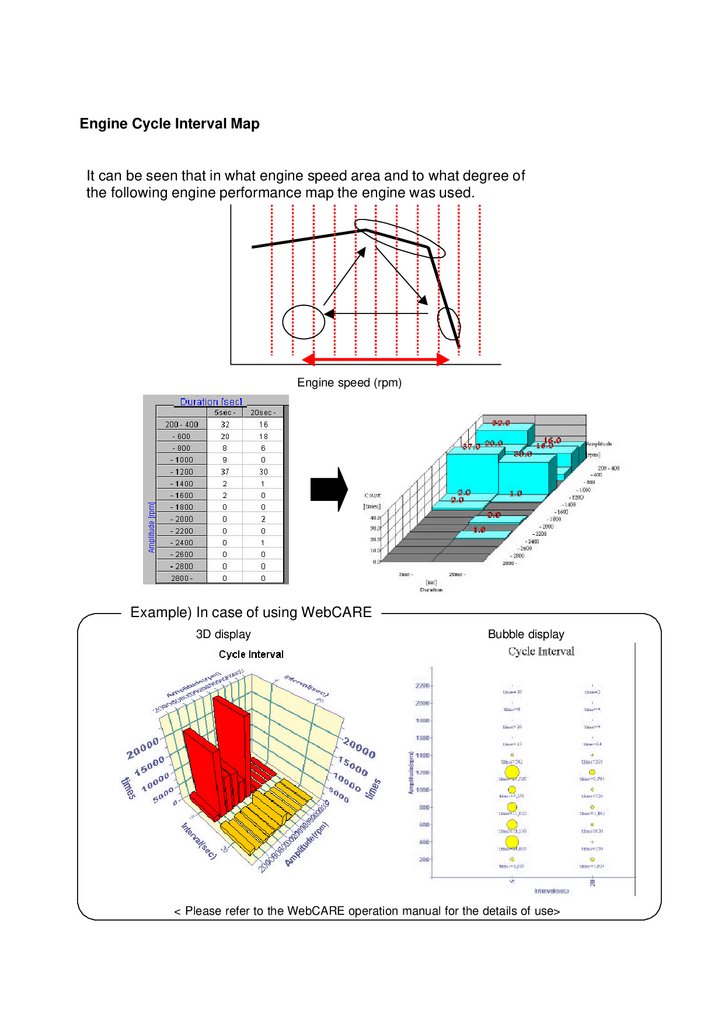

Engine Cycle Interval MapIt can be seen that in what engine speed area and to what degree of

the following engine performance map the engine was used.

Engine speed (rpm)

Example) In case of using WebCARE

3D display

Bubble display

< Please refer to the WebCARE operation manual for the details of use>

27.

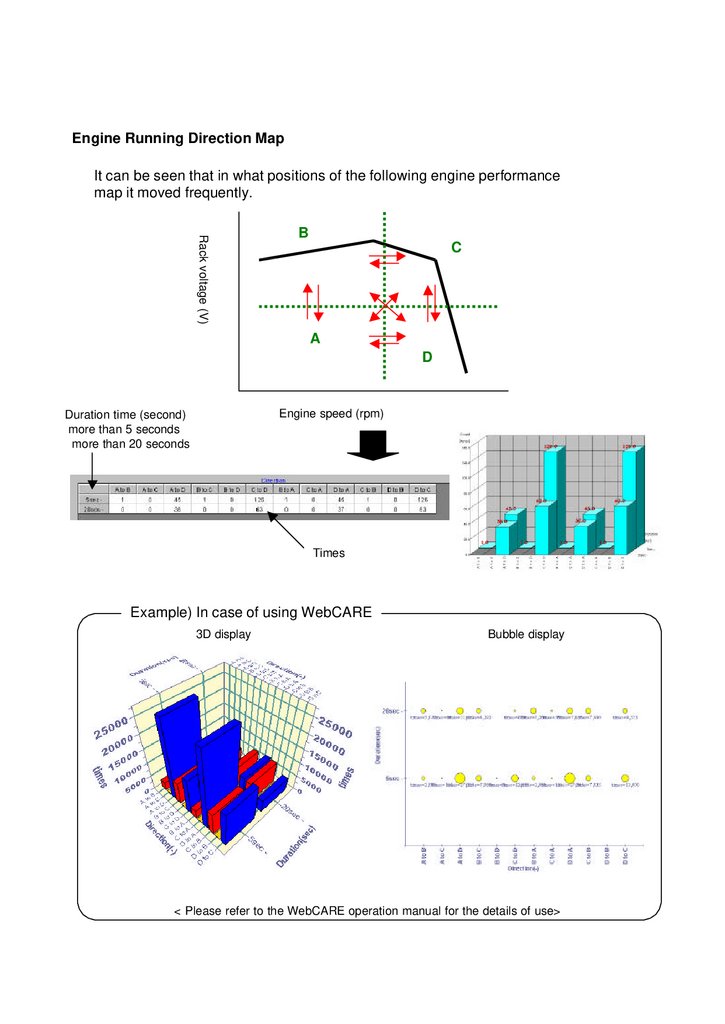

Engine Running Direction MapIt can be seen that in what positions of the following engine performance

map it moved frequently.

Rack voltage (V)

B

C

A

D

Engine speed (rpm)

Duration time (second)

more than 5 seconds

more than 20 seconds

Times

Example) In case of using WebCARE

3D display

Bubble display

< Please refer to the WebCARE operation manual for the details of use>

28.

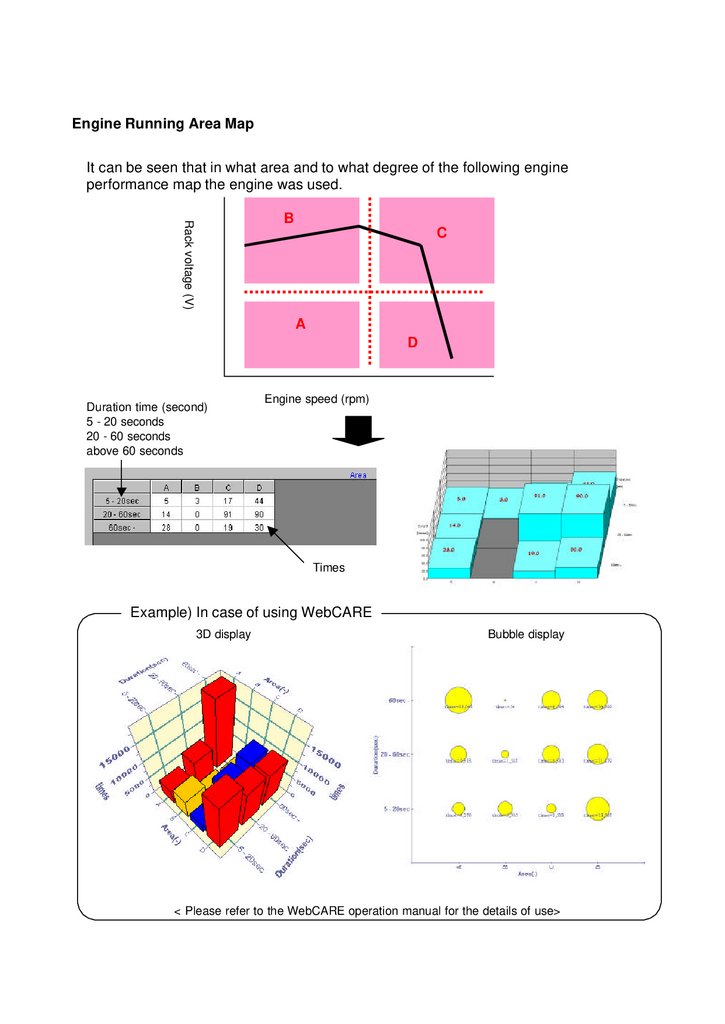

Engine Running Area MapIt can be seen that in what area and to what degree of the following engine

performance map the engine was used.

Rack voltage (V)

B

C

A

D

Duration time (second)

5 - 20 seconds

20 - 60 seconds

above 60 seconds

Engine speed (rpm)

Times

Example) In case of using WebCARE

3D display

Bubble display

< Please refer to the WebCARE operation manual for the details of use>

29.

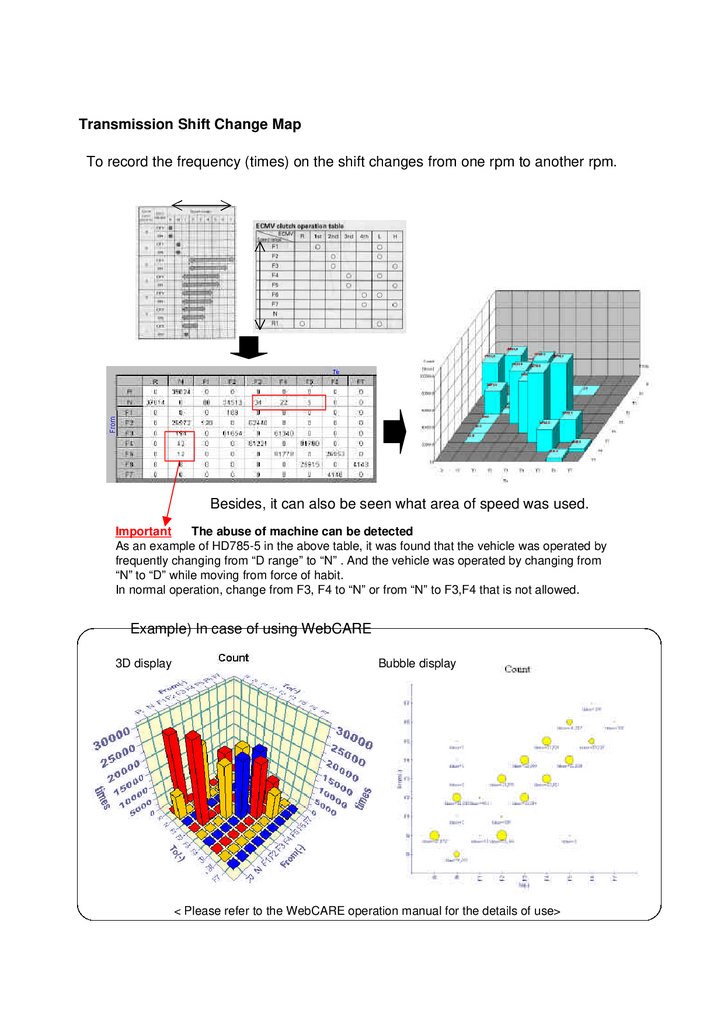

Transmission Shift Change MapTo record the frequency (times) on the shift changes from one rpm to another rpm.

Besides, it can also be seen what area of speed was used.

Important

The abuse of machine can be detected

As an example of HD785-5 in the above table, it was found that the vehicle was operated by

frequently changing from “D range” to “N” . And the vehicle was operated by changing from

“N” to “D” while moving from force of habit.

In normal operation, change from F3, F4 to “N” or from “N” to F3,F4 that is not allowed.

Example) In case of using WebCARE

3D display

Bubble display

< Please refer to the WebCARE operation manual for the details of use>

30.

4. Snap-ShotTo analysis the data just before and after the failure for an early solution to the problem.

If a serious error occurs, those data in the period of 5.5 minutes before and 2 minutes

after its occurrence (totally 7.5 minutes) will be recorded.

Within 7 minutes and 30 seconds, the data at 180 points in all can be sampled

automatically.

Data sampling of 1

time in each second.

(Total 150 points in

2.5 minutes)

Data sampling of 1 time

in every 10 seconds

(Total 30 points in 5

minutes)

3

3

3

3

3

3

3

5 minutes 30 seconds

before

3

3

3 30 30 30 30 30

The number if each frame

(representing 30 sec)

is the number of

sampling data.

2 minutes

Error occurs

The maximum number of snap-shot errors that can be kept in memory is 9 for all

models.

Note: In case of carrying out quick PM to be described next, the quick PM itself is

stored as one error. Therefore, the above number for the occurred errors becomes 8.

<Refer to the next page for the details of the serious errors which start the snap-shot.>

However, if an error occurs that the same error has occurred before and the snap-shot

data still remain there, then the snap-shot of the newly occurred one will not be kept.

Unless clearing the data, in case of a frequently occurred error, only the snap-shot data

of the oldest error will be remained.

Example) In case of using the analysis tool

31.

Code List of Serious Errors That Start Snap-Shot (1/2)HD465/605-7

HD465/605-5, HD785/985-5

No.

Error Code

Contents

No.

Error Code

Contents

1

M250

#123 high exhaust temp. (step 1)

1

F@BYNS

#123 high exhaust temp. (step 1)

2

M260

#456 high exhaust temp. (step 1)

2

F@BZNS

#456 high exhaust temp. (step 1)

High blowby pressure

3

M270

High blow by pressure

3

F@BBZL

4

MFA0

To do quick PM

4

MFA0

5

M680

#123 high exhaust temp. (step 2)

5

F@BYNR

#123 high exhaust temp. (step 2)

6

M690

#456 high exhaust temp. (step 2)

6

b005

Transmission clutch double mesh

F@BZNR

#456 high exhaust temp. (step 2)

7

7

b021

Lockup clutch failure

1500L0

Transmission clutch double mesh

8

b022

High clutch failure

8

1380MW

Lockup clutch f ailure

9

10

b023

Low clutch failure

To do quick PM

9

15H0MW

High clutch f ailure

10

15J0MW

Low clutch f ailure

11

15K0MW

No.1 clutch f ailure

11

b024

No.1 clutch failure

12

b025

No.2 clutch failure

13

b026

No.3 clutch failure

12

15L0MW

No.2 clutch f ailure

14

b027

No.4 clutch failure

13

15M0MW

No.3 clutch f ailure

15

b028

R clutch failure

14

15N0MW

No.4 clutch f ailure

16

b029

M clutch failure

15

C115KZ

Engine Speed Sensor f ailure

17

b082

Abnormal torque converter output signal

16

C151NS

Abnormal Coolant Temp. HIGH

18

b0d2

Torque converter overheat

17

C261NS

Abnormal Fuel Temp. HIGH

19

b0F3

Rear brake oil overheat

18

C234N1

Abnormal torque conv erter output signal

20

C022

Overrun

19

B@CENS

Torque conv erter ov erheat

21

C024

Engine oil pressure abnormally low

20

B@C7NS

Rear brake oil ov erheat

21

A000N1

Ov errun

22

C143ZG

Engine oil pressure abnormally low

PC1800-6

No.

Error Code

Contents

1

E108

Front engine water temperature is abnormal

2

E111

Rear engine water temperature is abnormal

3

E115

Operating oil temperature is abnormal

4

E883

Font engine oil pressure becomes low

5

E884

Rear engine oil pressure becomes low

6

E885

Front PTO oil temperature is high

7

E886

Rear PTO oil temperature is high

8

E887

Gear pump oil pressure is abnormal

9

E888

Front engine exhaust temperature is high

10

E891

F engine #1,2 pump relief pressure is high

11

E892

R engine #1,2 pump relief pressure is high

12

E893

F engine #3,4 pump relief pressure is high

13

E894

R engine #3,4 pump relief pressure is high

14

E895

Rotation pump relief oil pressure is high

15

E898

Rear engine exhaust temperature is high

16

E001

Front engine stop

17

E002

Rear engine stop

18

E007

To do quick PM

: When “key-on” only

Please refer to Shop manuals for the details of

the errors.

32.

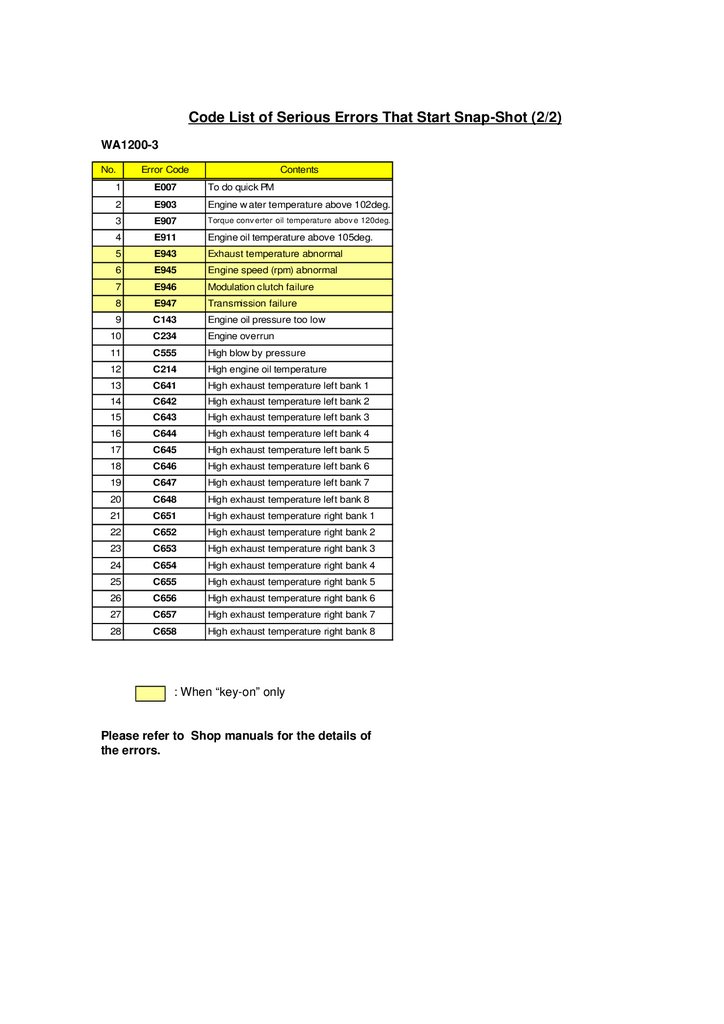

Code List of Serious Errors That Start Snap-Shot (2/2)WA1200-3

No.

Error Code

Contents

1

E007

To do quick PM

2

E903

Engine w ater temperature above 102deg.

3

E907

Torque conv erter oil temperature abov e 120deg.

4

E911

Engine oil temperature above 105deg.

5

E943

Exhaust temperature abnormal

6

E945

Engine speed (rpm) abnormal

7

E946

Modulation clutch failure

8

E947

Transmission failure

9

C143

Engine oil pressure too low

10

C234

Engine overrun

11

C555

High blow by pressure

12

C214

High engine oil temperature

13

C641

High exhaust temperature left bank 1

14

C642

High exhaust temperature left bank 2

15

C643

High exhaust temperature left bank 3

16

C644

High exhaust temperature left bank 4

17

C645

High exhaust temperature left bank 5

18

C646

High exhaust temperature left bank 6

19

C647

High exhaust temperature left bank 7

20

C648

High exhaust temperature left bank 8

21

C651

High exhaust temperature right bank 1

22

C652

High exhaust temperature right bank 2

23

C653

High exhaust temperature right bank 3

24

C654

High exhaust temperature right bank 4

25

C655

High exhaust temperature right bank 5

26

C656

High exhaust temperature right bank 6

27

C657

High exhaust temperature right bank 7

28

C658

High exhaust temperature right bank 8

: When “key-on” only

Please refer to Shop manuals for the details of

the errors.

33.

5. Quick PMThe snap-shot function describe above can be started by pressing the manual

switch. Those data in the period of 7.5 minutes after pressing the button will be

recorded.

Since various data can be collected automatically in case of torque converter

stall, the measuring time of Pm clinic can be reduced.

<The items to be measured are the same as those in Snap-Shot>

Data sampling of 1

time in each second.

(Total 150 points in

2.5 minutes)

Data sampling of 1 time

in every 10 seconds

(Total 30 points in 5

minutes)

3

3

3

3

3

3

3

3

3

3

30 30 30 30 30

7 minutes and 30 seconds

Pressing the

Snap-Shot switch

Example) In case using the analysis tool

< An example of quick PM>

Engine Speed

Heating air operation 5

minutes

1 time every 10

second, 5 minutes

Pressing the Snap-Shot

switch

1 cycle (about 60 sec)

1 time/sec., 2.5 minutes

End

The number if each

frame (representing

30 sec) is the number

of sampling data.

34.

For the the Snap shot (Quick PM function) in the following models, monitorpanel or CGC are added. It can be used as an aim of time during quick PM.

WA1200-3 CGC

PC1800-6 CGC

PC1250-7 Monitor panel

HD465/605-7 Monitor panel

35.

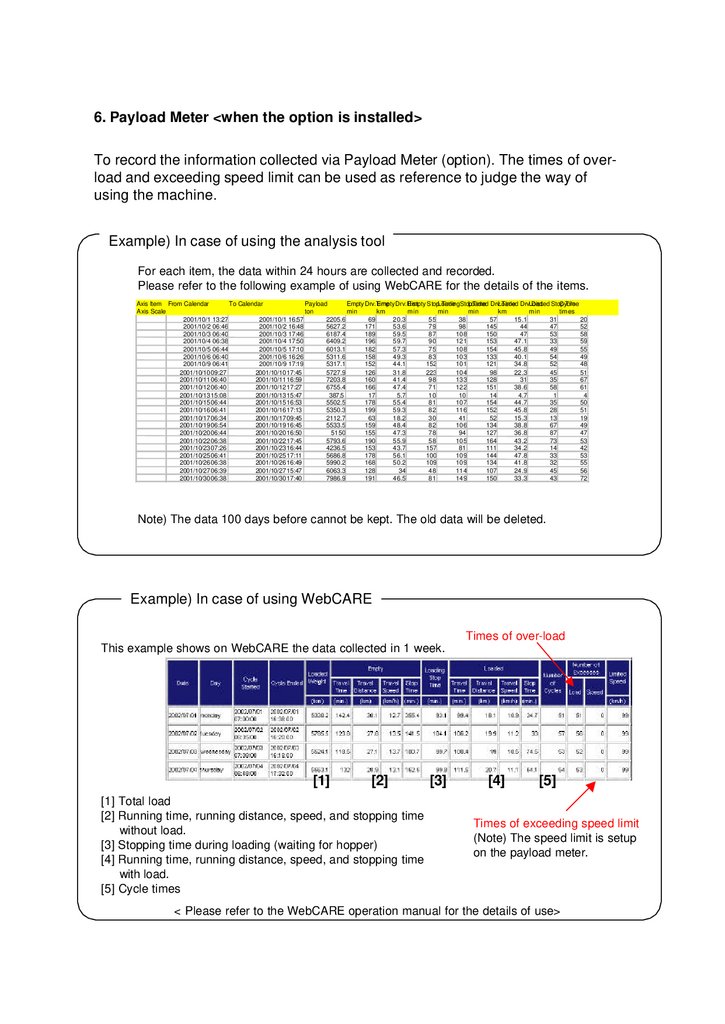

6. Payload Meter <when the option is installed>To record the information collected via Payload Meter (option). The times of overload and exceeding speed limit can be used as reference to judge the way of

using the machine.

Example) In case of using the analysis tool

For each item, the data within 24 hours are collected and recorded.

Please refer to the following example of using WebCARE for the details of the items.

Axis Item From Calendar

To Calendar

Payload

Empty Drv.Time

Empty Drv.Dist.

Empty StopLoadingStopTime

Time

Loaded Drv.Time

Loaded Drv.Dist.

Loaded Stop

Cycle

Time

Axis Scale

ton

min

km

min

min

min

km

min

times

2001/10/1 13:27

2001/10/1 16:57

2205.6

69

20.3

55

38

57

15.1

31

20

2001/10/2 06:46

2001/10/2 16:48

5627.2

171

53.6

79

98

145

44

47

52

2001/10/3 06:40

2001/10/3 17:46

6187.4

189

59.5

87

108

150

47

53

58

2001/10/4 06:38

2001/10/4 17:50

6409.2

196

59.7

90

121

153

47.1

33

59

2001/10/5 06:44

2001/10/5 17:10

6013.1

182

57.3

75

108

154

45.8

49

55

2001/10/6 06:40

2001/10/6 16:26

5311.6

158

49.3

83

103

133

40.1

54

49

2001/10/9 06:41

2001/10/9 17:19

5317.1

152

44.1

152

101

121

34.8

52

48

2001/10/10 09:27

2001/10/10 17:45

5727.9

126

31.8

223

104

98

22.3

45

51

2001/10/11 06:40

2001/10/11 16:59

7203.8

160

41.4

98

133

128

31

35

67

2001/10/12 06:40

2001/10/12 17:27

6755.4

166

47.4

71

122

151

38.6

58

61

2001/10/13 15:08

2001/10/13 15:47

387.5

17

5.7

10

10

14

4.7

1

4

2001/10/15 06:44

2001/10/15 16:53

5502.5

178

55.4

81

107

154

44.7

35

50

2001/10/16 06:41

2001/10/16 17:13

5350.3

199

59.3

82

116

152

45.8

28

51

2001/10/17 06:34

2001/10/17 09:45

2112.7

63

18.2

30

41

52

15.3

13

19

2001/10/19 06:54

2001/10/19 16:45

5533.5

159

48.4

82

106

134

38.8

67

49

2001/10/20 06:44

2001/10/20 16:50

5150

155

47.3

78

94

127

36.8

87

47

2001/10/22 06:38

2001/10/22 17:45

5793.6

190

55.9

58

105

164

43.2

73

53

2001/10/23 07:26

2001/10/23 16:44

4236.5

153

43.7

157

81

111

34.2

14

42

2001/10/25 06:41

2001/10/25 17:11

5686.8

178

56.1

100

109

144

47.8

33

53

2001/10/26 06:38

2001/10/26 16:49

5990.2

168

50.2

109

109

134

41.8

32

55

2001/10/27 06:39

2001/10/27 15:47

6063.3

128

34

48

114

107

24.9

45

56

2001/10/30 06:38

2001/10/30 17:40

7986.9

191

46.5

81

149

150

33.3

43

72

Note) The data 100 days before cannot be kept. The old data will be deleted.

Example) In case of using WebCARE

Times of over-load

This example shows on WebCARE the data collected in 1 week.

[1]

[2]

[1] Total load

[2] Running time, running distance, speed, and stopping time

without load.

[3] Stopping time during loading (waiting for hopper)

[4] Running time, running distance, speed, and stopping time

with load.

[5] Cycle times

[3]

[4]

[5]

Times of exceeding speed limit

(Note) The speed limit is setup

on the payload meter.

< Please refer to the WebCARE operation manual for the details of use>

36.

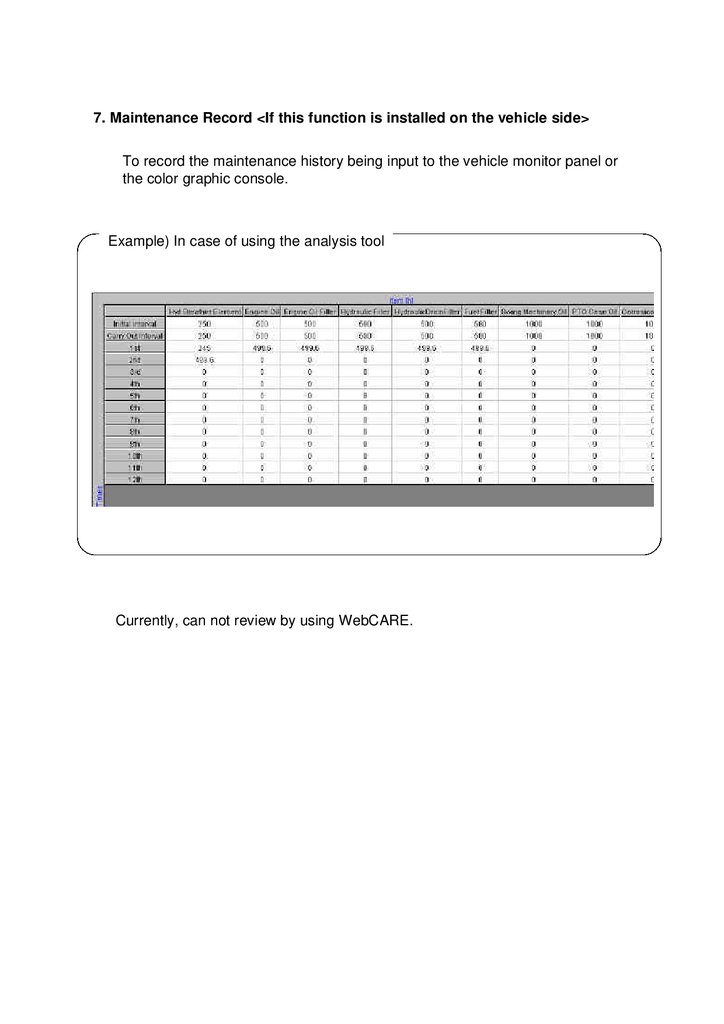

7. Maintenance Record <If this function is installed on the vehicle side>To record the maintenance history being input to the vehicle monitor panel or

the color graphic console.

Example) In case of using the analysis tool

Currently, can not review by using WebCARE.

37.

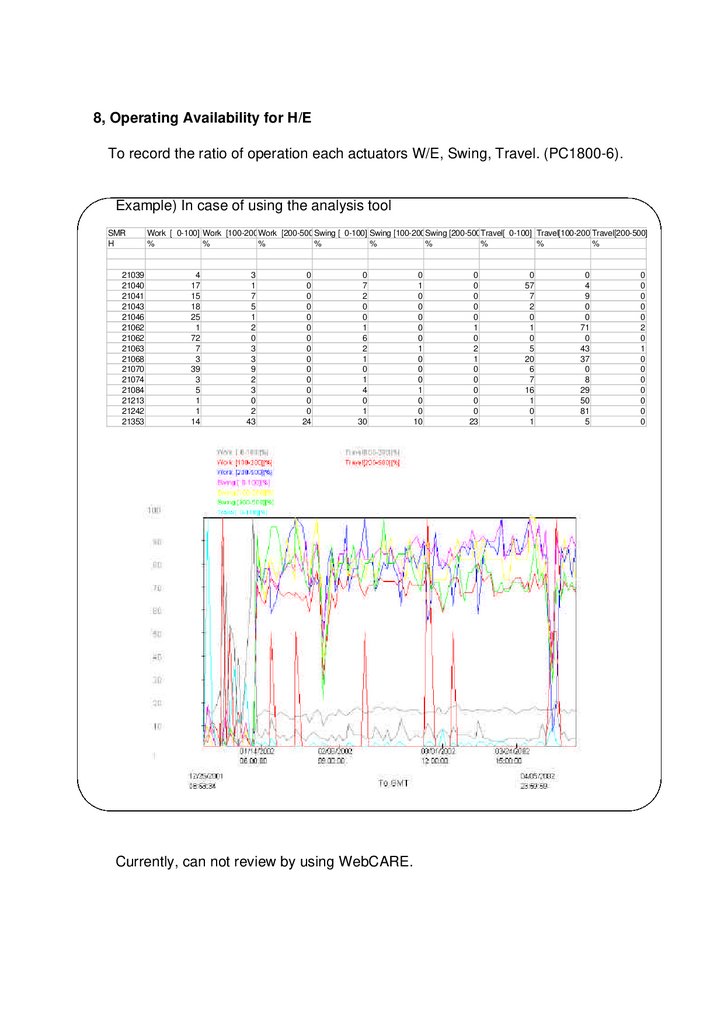

8, Operating Availability for H/ETo record the ratio of operation each actuators W/E, Swing, Travel. (PC1800-6).

Example) In case of using the analysis tool

SMR

H

21039

21040

21041

21043

21046

21062

21062

21063

21068

21070

21074

21084

21213

21242

21353

Work [ 0-100] Work [100-200]Work [200-500]Swing [ 0-100] Swing [100-200]Swing [200-500]Travel[ 0-100] Travel[100-200]Travel[200-500]

%

%

%

%

%

%

%

%

%

4

17

15

18

25

1

72

7

3

39

3

5

1

1

14

3

1

7

5

1

2

0

3

3

9

2

3

0

2

43

0

0

0

0

0

0

0

0

0

0

0

0

0

0

24

0

7

2

0

0

1

6

2

1

0

1

4

0

1

30

Currently, can not review by using WebCARE.

0

1

0

0

0

0

0

1

0

0

0

1

0

0

10

0

0

0

0

0

1

0

2

1

0

0

0

0

0

23

0

57

7

2

0

1

0

5

20

6

7

16

1

0

1

0

4

9

0

0

71

0

43

37

0

8

29

50

81

5

0

0

0

0

0

2

0

1

0

0

0

0

0

0

0

38.

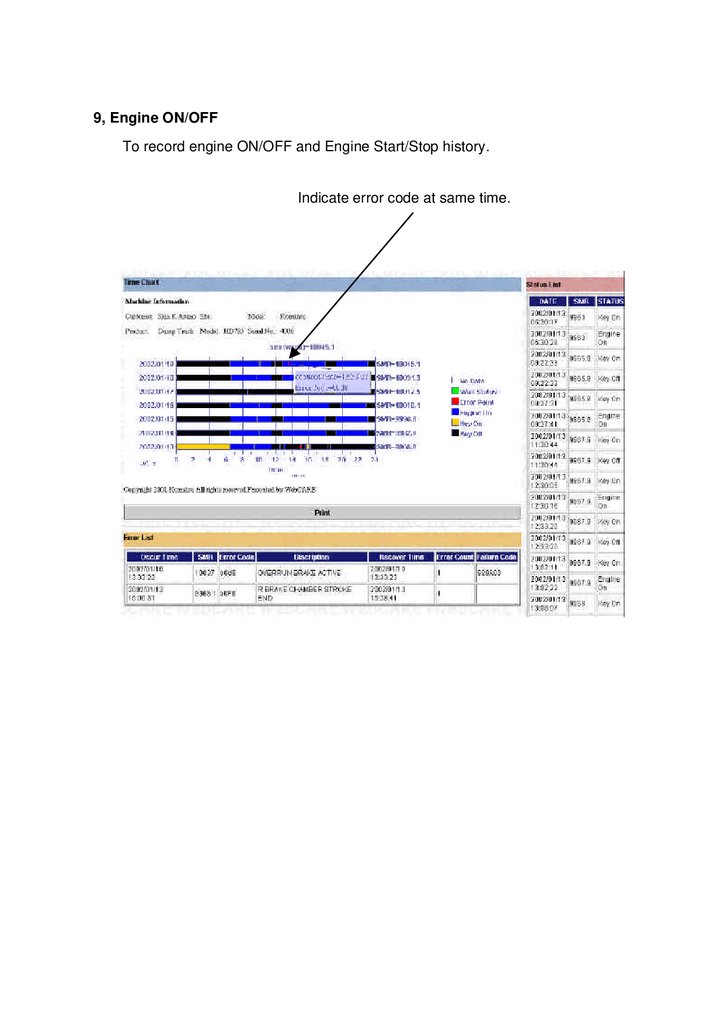

9, Engine ON/OFFTo record engine ON/OFF and Engine Start/Stop history.

Indicate error code at same time.

39.

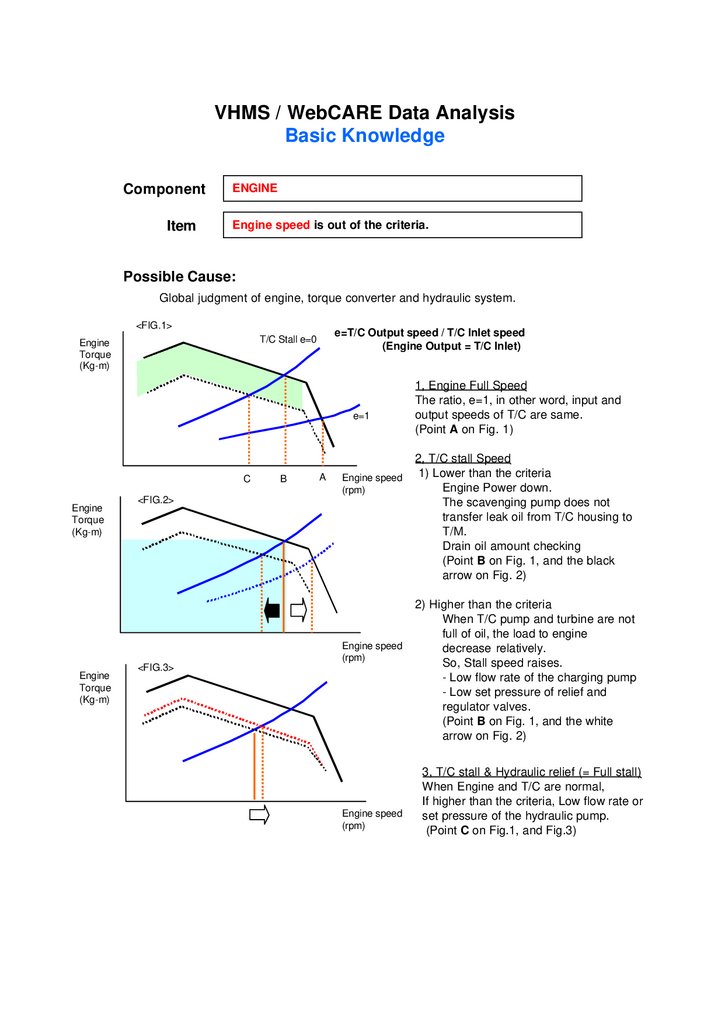

VHMS / WebCARE Data AnalysisBasic Knowledge

Component

Item

ENGINE

Engine speed is out of the criteria.

Possible Cause:

Global judgment of engine, torque converter and hydraulic system.

<FIG.1>

e=T/C Output speed / T/C Inlet speed

(Engine Output = T/C Inlet)

T/C Stall e=0

Engine

Torque

(Kg-m)

e=1

C

Engine

Torque

(Kg-m)

B

A

Engine speed

(rpm)

<FIG.2>

Engine speed

(rpm)

Engine

Torque

(Kg-m)

<FIG.3>

Engine speed

(rpm)

1, Engine Full Speed

The ratio, e=1, in other word, input and

output speeds of T/C are same.

(Point A on Fig. 1)

2, T/C stall Speed

1) Lower than the criteria

Engine Power down.

The scavenging pump does not

transfer leak oil from T/C housing to

T/M.

Drain oil amount checking

(Point B on Fig. 1, and the black

arrow on Fig. 2)

2) Higher than the criteria

When T/C pump and turbine are not

full of oil, the load to engine

decrease relatively.

So, Stall speed raises.

- Low flow rate of the charging pump

- Low set pressure of relief and

regulator valves.

(Point B on Fig. 1, and the white

arrow on Fig. 2)

3, T/C stall & Hydraulic relief (= Full stall)

When Engine and T/C are normal,

If higher than the criteria, Low flow rate or

set pressure of the hydraulic pump.

(Point C on Fig.1, and Fig.3)

40.

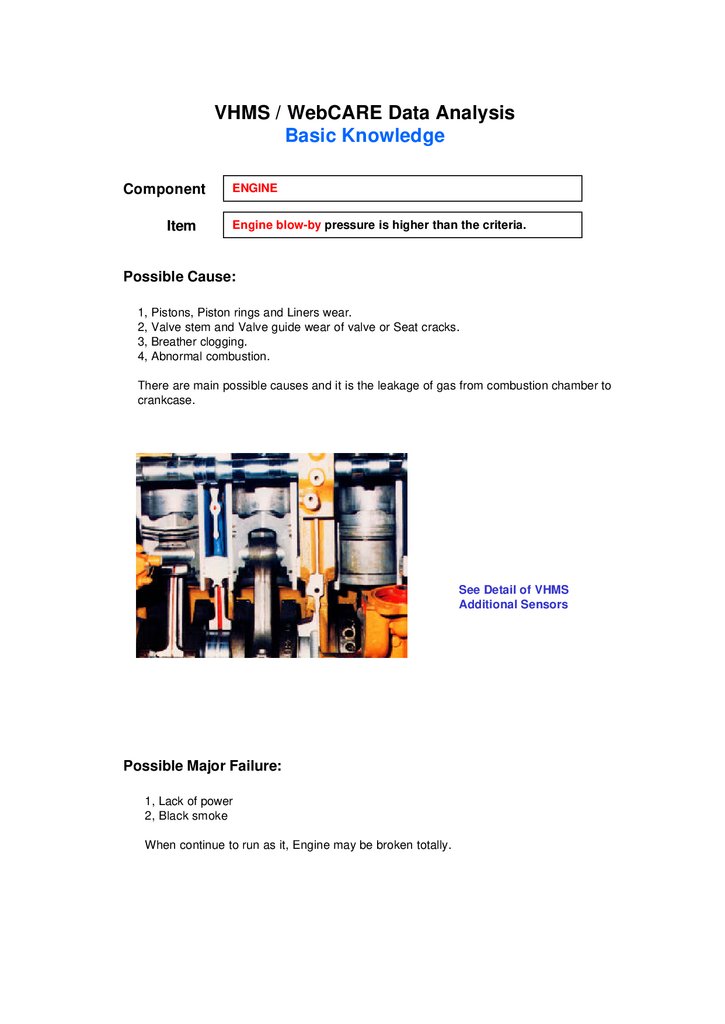

VHMS / WebCARE Data AnalysisBasic Knowledge

Component

Item

ENGINE

Engine blow-by pressure is higher than the criteria.

Possible Cause:

1, Pistons, Piston rings and Liners wear.

2, Valve stem and Valve guide wear of valve or Seat cracks.

3, Breather clogging.

4, Abnormal combustion.

There are main possible causes and it is the leakage of gas from combustion chamber to

crankcase.

See Detail of VHMS

Additional Sensors

Possible Major Failure:

1, Lack of power

2, Black smoke

When continue to run as it, Engine may be broken totally.

41.

VHMS / WebCARE Data AnalysisBasic Knowledge

Component

ENGINE

Item

Lubrication pressure is lower than the criteria.

Possible Cause:

b

Press.

Valve

operation

b'

a

a'

Low

High

Engine Speed

<Fig.1>

See Detail of VHMS

Additional Sensors

1, Low flow rate of pump

When the engine speed is low, lower pressure may occur more earlier than high speed.

(See fig.1 point a & a‘ )

2, Low set pressure of regulator valve

Lower pressure may be measured also when high engine speed.

(See Fig. 1 point b & b‘ )

3, Blockage of lubrication line

Possible Major Failure:

1, Seizure of main bearings.

2, Seizure of camshaft.

3, Turbocharger damage.

42.

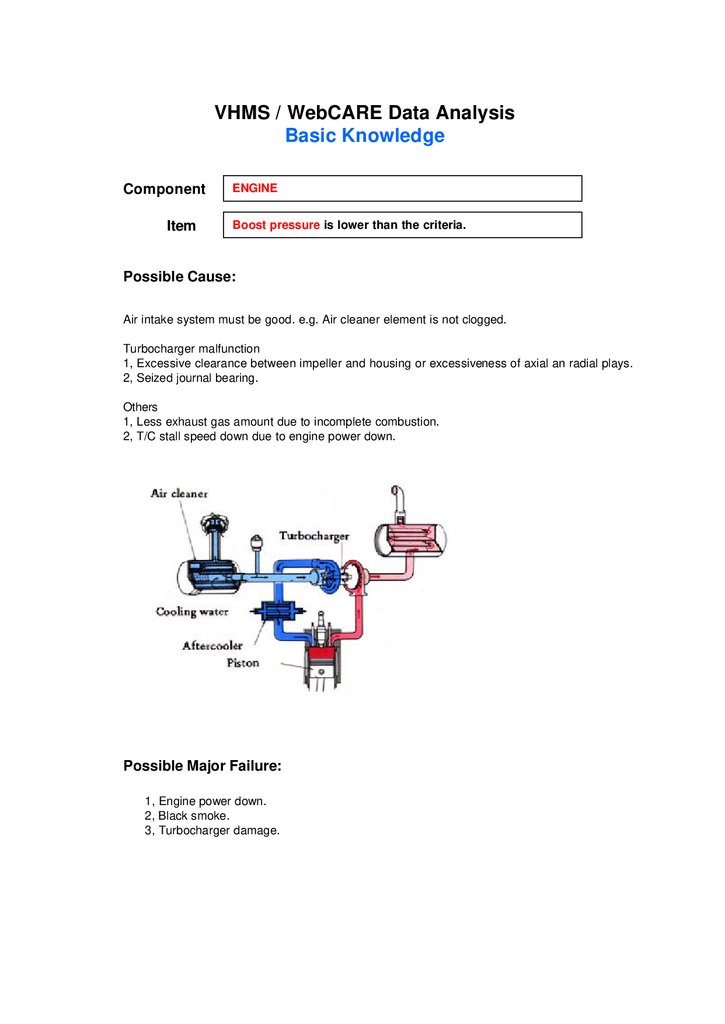

VHMS / WebCARE Data AnalysisBasic Knowledge

Component

Item

ENGINE

Boost pressure is lower than the criteria.

Possible Cause:

Air intake system must be good. e.g. Air cleaner element is not clogged.

Turbocharger malfunction

1, Excessive clearance between impeller and housing or excessiveness of axial an radial plays.

2, Seized journal bearing.

Others

1, Less exhaust gas amount due to incomplete combustion.

2, T/C stall speed down due to engine power down.

Possible Major Failure:

1, Engine power down.

2, Black smoke.

3, Turbocharger damage.

43.

VHMS / WebCARE Data AnalysisBasic Knowledge

Component

Item

ENGINE

Exhaust gas temp. is too high or increased sharply.

Possible Cause:

EXCESS AIR RATIO must be corrected and when Excess Air Ratio is low,

the exhaust gas temperature will goes up.

1, Intake air related (Lower air amount)

1) Air cleaner or piping clogging

2) Turbocharger malfunction

3) Leaking Boost Air

4) After-cooler malfunction (If equipped)

5) Low compression due to piston, piston ring and liner wear

6) Bad contact of valve and seat

2, Fuel related

1) Too much fuel injection due to pump governor inner parts wear

2) Incomplete fuel spraying from nozzle

3) RH & LH banks imbalance injection (V Engine only)

4) Incorrect injection timing (Advanced : Max. pressure is too high)

See Detail of VHMS

Additional Sensors

Possible Major Failure:

Excessive high temperature of exhaust gas (Over 700 deg C) may cause major

failure. In the worst case, it will sometimes cause cracks on the piston or cylinder

head.

44.

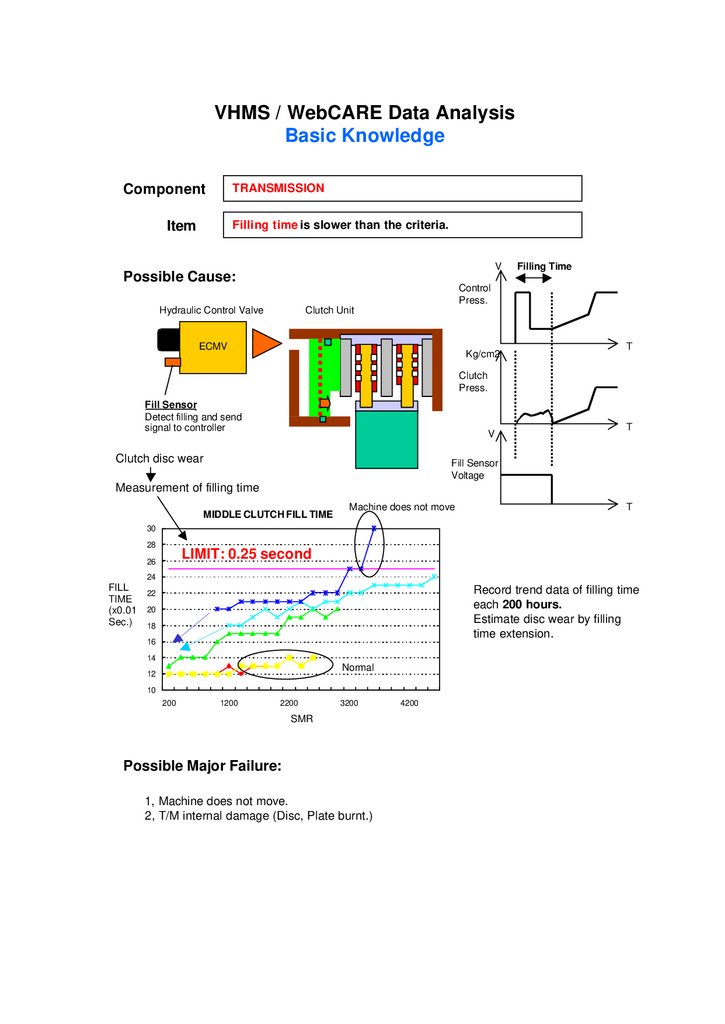

VHMS / WebCARE Data AnalysisBasic Knowledge

Component

TRANSMISSION

Item

Filling time is slower than the criteria.

V

Possible Cause:

Filling Time

Control

Press.

Hydraulic Control Valve

Clutch Unit

ECMV

Kg/cm2

T

Clutch

Press.

Fill Sensor

Detect filling and send

signal to controller

V

Clutch disc wear

T

Fill Sensor

Voltage

Measurement of filling time

MIDDLE CLUTCH FILL TIME

Machine does not move

T

30

28

LIMIT: 0.25 second

26

24

FILL

TIME

(x0.01

Sec.)

Record trend data of filling time

each 200 hours.

Estimate disc wear by filling

time extension.

22

20

18

16

14

Normal

12

10

200

1200

2200

3200

SMR

Possible Major Failure:

1, Machine does not move.

2, T/M internal damage (Disc, Plate burnt.)

4200

45.

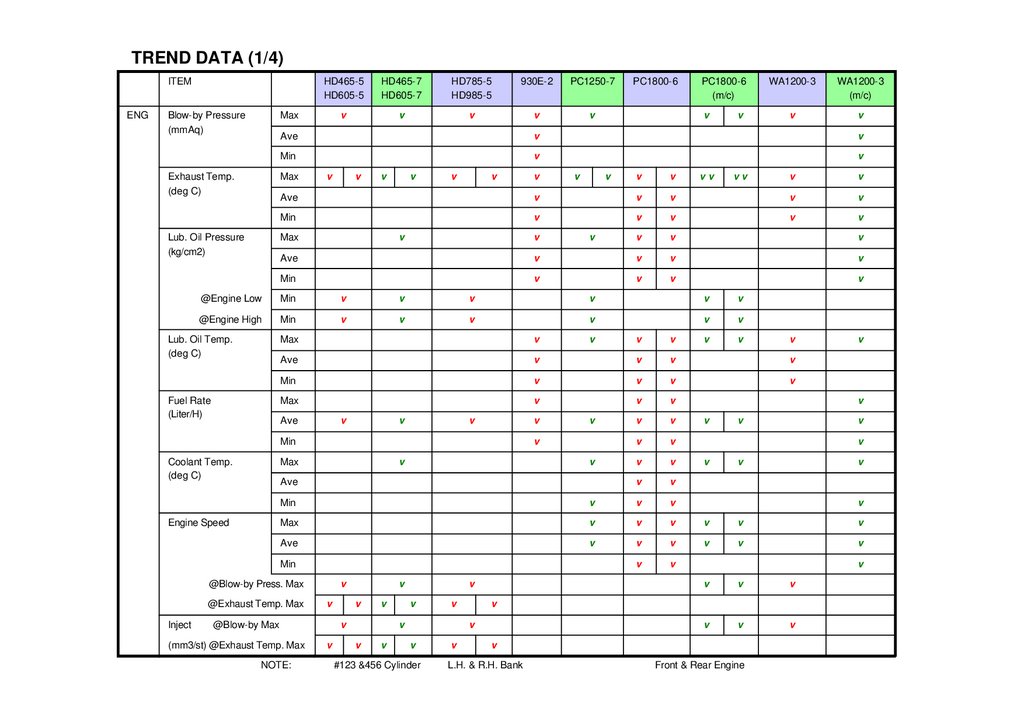

TREND DATA (1/4)ITEM

ENG

Blow-by Pressure

(mmAq)

HD465-5

HD605-5

HD465-7

HD605-7

HD785-5

HD985-5

930E-2

PC1250-7

v

v

v

v

v

Max

Exhaust Temp.

(deg C)

v

v

v

v

v

v

v

v

v

v

v

v

v

v

v

v

vv

vv

v

v

Ave

v

v

v

v

v

Min

v

v

v

v

v

v

v

v

v

v

v

Ave

v

v

v

v

Min

v

v

v

v

v

v

v

v

v

v

@Engine High

Min

v

v

v

v

v

v

v

v

Max

v

v

v

Ave

v

v

v

v

Min

v

v

v

v

Max

v

v

v

v

v

v

v

v

v

v

v

Ave

v

v

v

v

Min

v

v

v

Max

v

v

Ave

Engine Speed

v

Min

Min

Coolant Temp.

(deg C)

WA1200-3

(m/c)

v

@Engine Low

Fuel Rate

(Liter/H)

WA1200-3

v

Max

Lub. Oil Temp.

(deg C)

v

v

v

v

v

v

v

v

v

v

Min

v

v

v

Max

v

v

v

v

v

v

Ave

v

v

v

v

v

v

v

v

Min

@Blow-by Press. Max

@Exhaust Temp. Max

Inject

PC1800-6

(m/c)

Ave

Max

Lub. Oil Pressure

(kg/cm2)

PC1800-6

v

v

@Blow-by Max

(mm3/st) @Exhaust Temp. Max

NOTE:

v

v

v

v

v

v

v

v

v

v

v

#123 &456 Cylinder

v

v

v

v

v

v

v

v

v

v

v

v

v

L.H. & R.H. Bank

Front & Rear Engine

46.

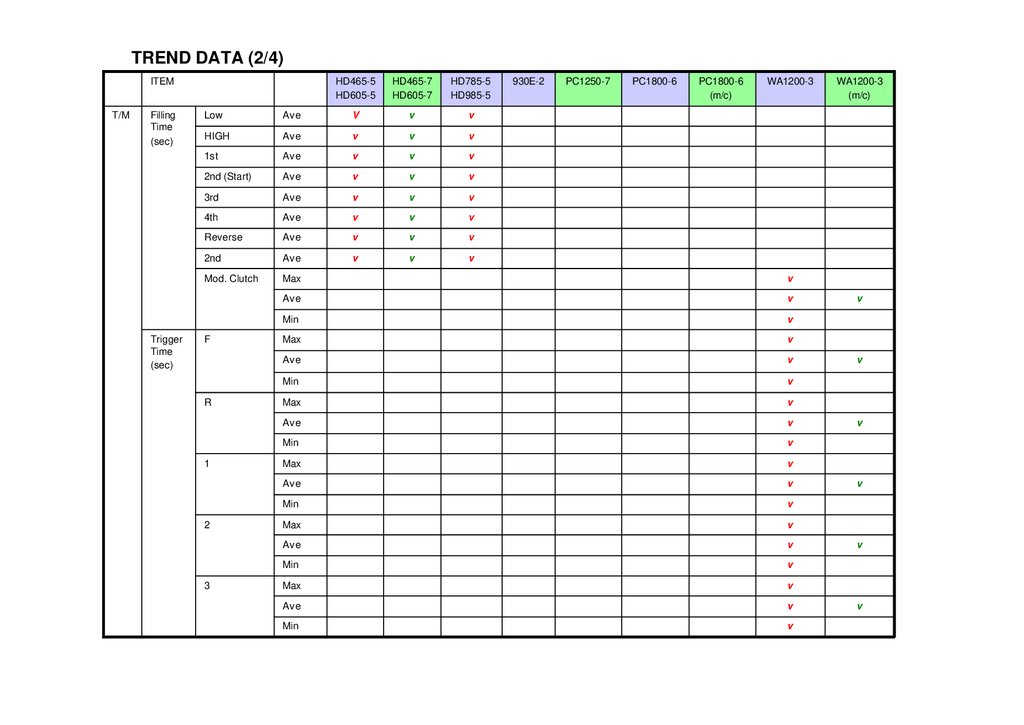

TREND DATA (2/4)ITEM

T/M

Filling

Time

(sec)

Trigger

Time

(sec)

HD465-5

HD605-5

HD465-7

HD605-7

HD785-5

HD985-5

930E-2

PC1250-7

PC1800-6

PC1800-6

(m/c)

WA1200-3

Low

Ave

V

v

v

HIGH

Ave

v

v

v

1st

Ave

v

v

v

2nd (Start)

Ave

v

v

v

3rd

Ave

v

v

v

4th

Ave

v

v

v

Reverse

Ave

v

v

v

2nd

Ave

v

v

v

Mod. Clutch

Max

v

Ave

v

Min

v

Max

v

Ave

v

Min

v

Max

v

Ave

v

Min

v

Max

v

Ave

v

Min

v

Max

v

Ave

v

Min

v

Max

v

Ave

v

Min

v

F

R

1

2

3

WA1200-3

(m/c)

v

v

v

v

v

v

47.

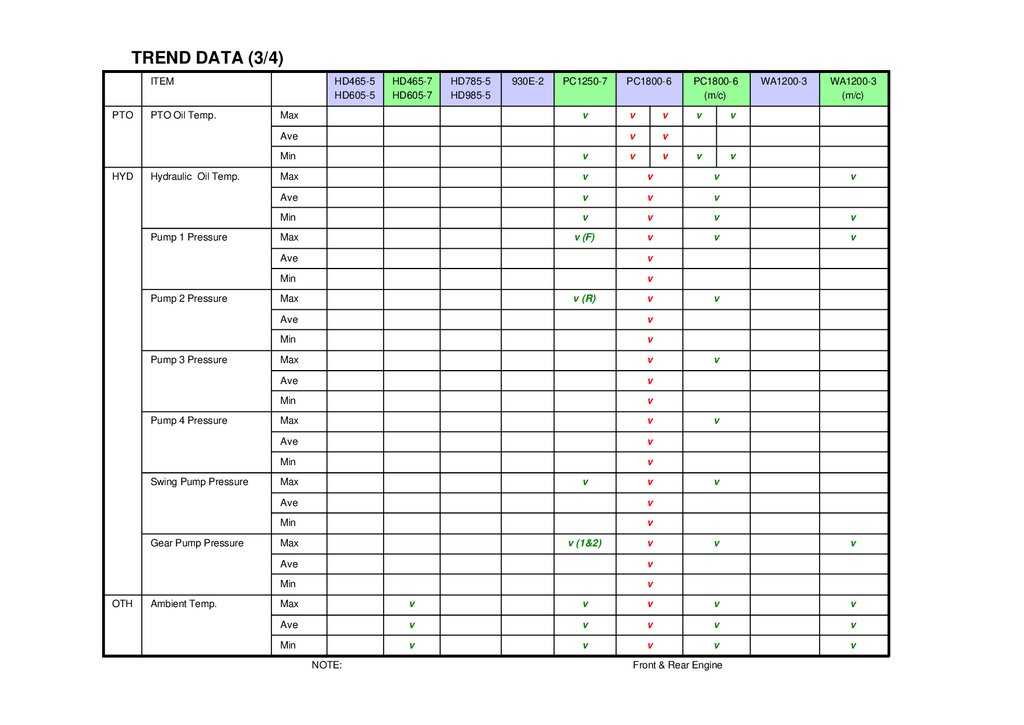

TREND DATA (3/4)ITEM

PTO

PTO Oil Temp.

HD465-5

HD605-5

HD465-7

HD605-7

Max

HD785-5

HD985-5

930E-2

PC1250-7

v

Ave

HYD

Hydraulic Oil Temp.

Pump 1 Pressure

Pump 2 Pressure

Pump 3 Pressure

Pump 4 Pressure

Swing Pump Pressure

Gear Pump Pressure

OTH

Ambient Temp.

PC1800-6

PC1800-6

(m/c)

v

v

v

v

v

v

v

v

v

v

WA1200-3

WA1200-3

(m/c)

Min

v

Max

v

v

v

Ave

v

v

v

Min

v

v

v

v

Max

v (F)

v

v

v

Ave

v

Min

v

Max

v (R)

v

Ave

v

Min

v

Max

v

Ave

v

Min

v

Max

v

Ave

v

Min

v

Max

v

v

Ave

v

Min

v

Max

v (1&2)

v

Ave

v

Min

v

v

v

v

v

v

v

v

Max

v

v

v

v

v

Ave

v

v

v

v

v

Min

v

v

v

v

v

NOTE:

Front & Rear Engine

48.

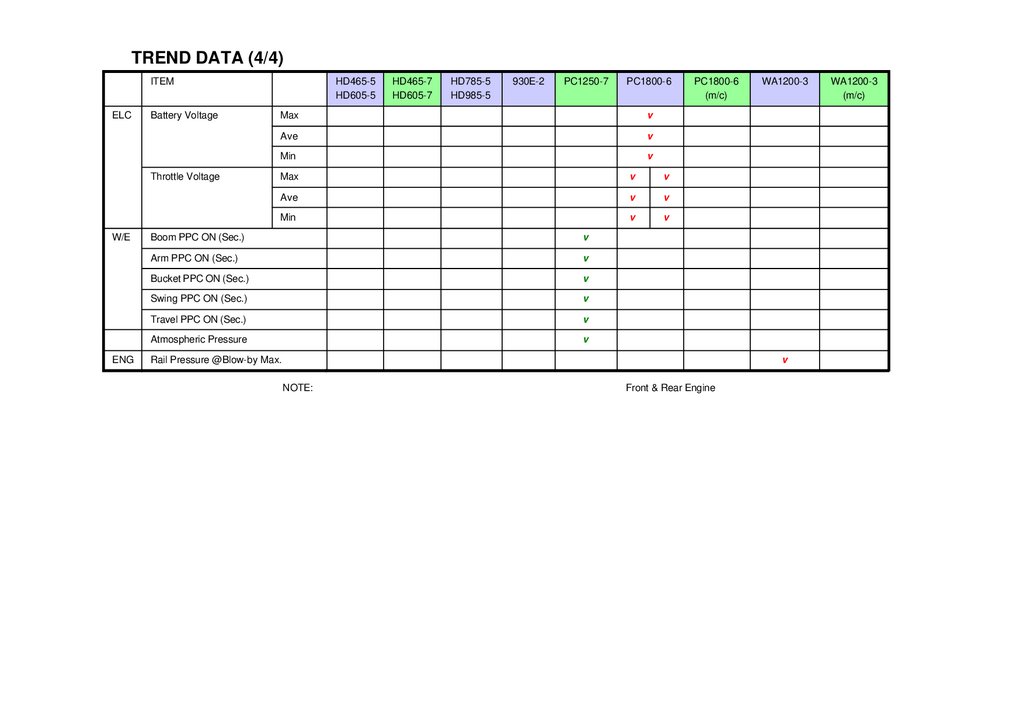

TREND DATA (4/4)ITEM

ELC

Battery Voltage

Throttle Voltage

W/E

ENG

HD465-5

HD605-5

HD465-7

HD605-7

HD785-5

HD985-5

930E-2

PC1250-7

PC1800-6

Max

v

Ave

v

Min

v

Max

v

v

Ave

v

v

Min

v

v

Boom PPC ON (Sec.)

v

Arm PPC ON (Sec.)

v

Bucket PPC ON (Sec.)

v

Swing PPC ON (Sec.)

v

Travel PPC ON (Sec.)

v

Atmospheric Pressure

v

PC1800-6

(m/c)

Rail Pressure @Blow-by Max.

WA1200-3

v

NOTE:

Front & Rear Engine

WA1200-3

(m/c)

49.

SNAP SHOT DATA (1/2)ITEM

ENG

HD465-5

HD605-5

HD465-7

HD605-7

HD785-5

HD985-5

930E-2

PC1250-7

v

v

v

v

v

Blow-by Pressure

Exhaust Temp.

v

v

v

v

v

v

v

v

v

PC1800-6

WA1200-3

WA1200-3

(m/c)

v

v

v

v

v

v

v

v

vv

vv

Lub. Oil Pressure

v

v

v

v

v

v

v

v

v

Lub. Oil Temp.

v

v

v

v

v

v

v

v

v

v

v

Lub. Oil Level

v

v

v

Coolant Temp.

v

v

v

v

v

v

v

v

v

v

v

Engine Speed

v

v

v

v

v

v

v

v

v

v

v

Fuel Injection

v

v

v

v

v

v

v

v

v

v

v

v

v

v

v

v

v

v

v

Boost Pressure

Governor Voltage

v

Rail Pressure

v

v

PCV Timing

PTO Temp.

T/C

T/M

BRK

PC1800-6

(m/c)

v

T/M Output Speed

v

v

v

Shift Position

v

v

v

Lock-up Signal

v

v

v

Retarder oil Temp

v

v

v

T/C Oil Temp.

v

v

v

Retarder SW

v

v

v

Rear Brake SW

v

v

v

v

v

v

v

v

Mod. Clutch Slip Rate

v

v

Mod. Output Speed

v

v

Mod. Clutch Solenoid

v

Mod. Clutch Fill Signal

v

Fill Signal (F,R,1st,2nd,3rd)

v

Solenoid (F,R,1st,2nd,3rd)

v

T/M Filter

v

Brake Pressure

v

50.

SNAP SHOT DATA (2/2)ITEM

HYD

HD465-5

HD605-5

HD465-7

HD605-7

HD785-5

HD985-5

930E-2

PC1250-7

PC1800-6

PC1800-6

(m/c)

Pump 1 Pressure

v

v

v

Pump 2 Pressure

v

v

v

Pump 3 Pressure

v

v

Pump 4 Pressure

v

v

Swing Pump Pressure

v

v

v

Gear Pump Pressure

v

v

v

Hydraulic Oil Temp.

v

v

v

TVC Ampere

v

PPC Boom Raise ON

v

v

v

PPC Boom Lower ON

v

v

v

PPC Arm In ON

v

v

v

PPC Arm Out ON

v

v

v

PPC Bucket Curl ON

v

v

v

PPC Bucket Dump ON

v

v

v

PPC RH Travel ON

v

v

v

PPC LH Travel ON

v

v

v

PPC Swing ON

v

v

v

v

v

v

PPC Service ON

v

v

v

v

Main Relief Valve

v

v

v

CO Cancel Valve

v

v

v

v (v)

v

v

Throttle Voltage

v

Pedal Signal

v

v

WA1200-3

(m/c)

v

v

v

v

v

Straight Travel Valve

Swing Brake Valve (PRI)

ELC

v

WA1200-3

v

v

v

Lo Idle SW Signal

v

Fuel Controller Output signal

v

v

v

v

Ambient Temp.

v

NOTE:

#123 &456 Cylinder

v

L.H. & R.H. Bank

v

Front & Rear Engine

v

Электроника

Электроника