Похожие презентации:

Summary of effective use 6

1.

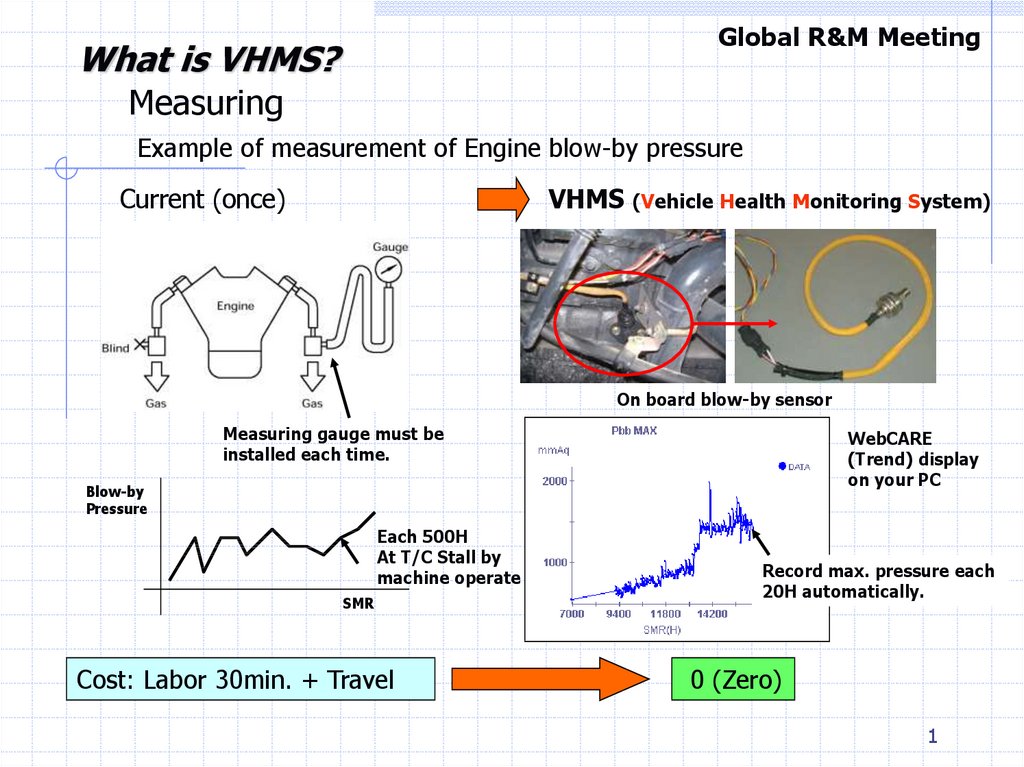

Global R&M MeetingWhat is VHMS?

Measuring

Example of measurement of Engine blow-by pressure

Current (once)

VHMS (Vehicle Health Monitoring System)

On board blow-by sensor

Measuring gauge must be

installed each time.

WebCARE

(Trend) display

on your PC

Blow-by

Pressure

Each 500H

At T/C Stall by

machine operate

SMR

Cost: Labor 30min. + Travel

Record max. pressure each

20H automatically.

0 (Zero)

1

2.

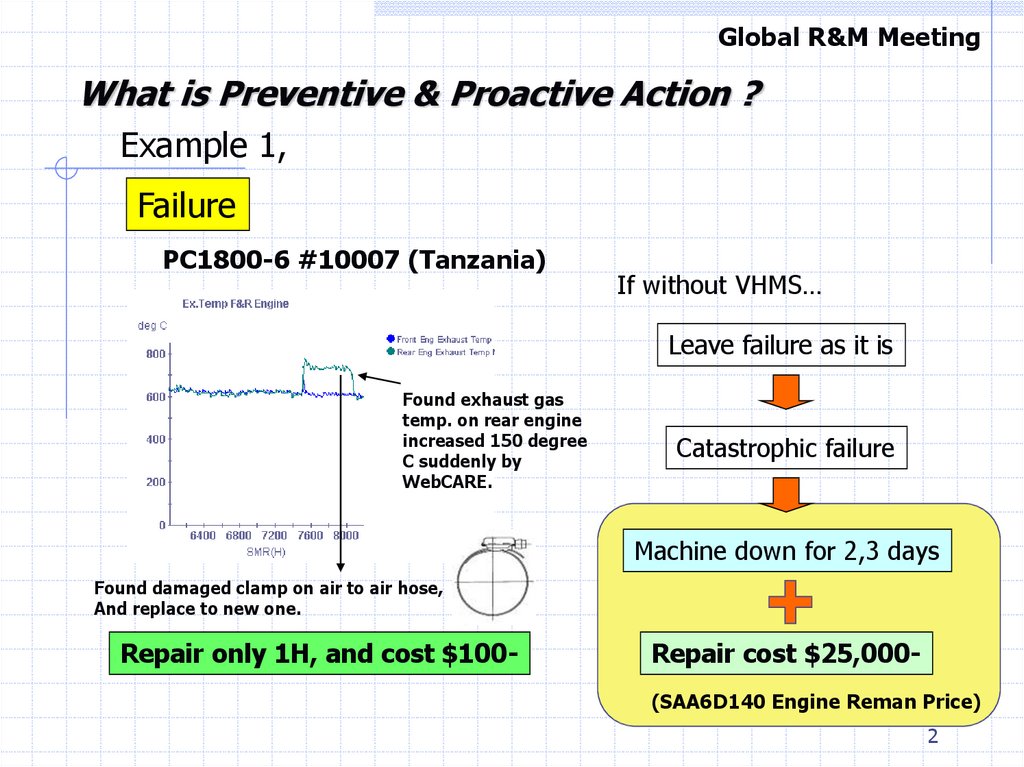

Global R&M MeetingWhat is Preventive & Proactive Action ?

Example 1,

Failure

PC1800-6 #10007 (Tanzania)

If without VHMS…

Leave failure as it is

Found exhaust gas

temp. on rear engine

increased 150 degree

C suddenly by

WebCARE.

Catastrophic failure

Machine down for 2,3 days

Found damaged clamp on air to air hose,

And replace to new one.

Repair only 1H, and cost $100-

Repair cost $25,000(SAA6D140 Engine Reman Price)

2

3.

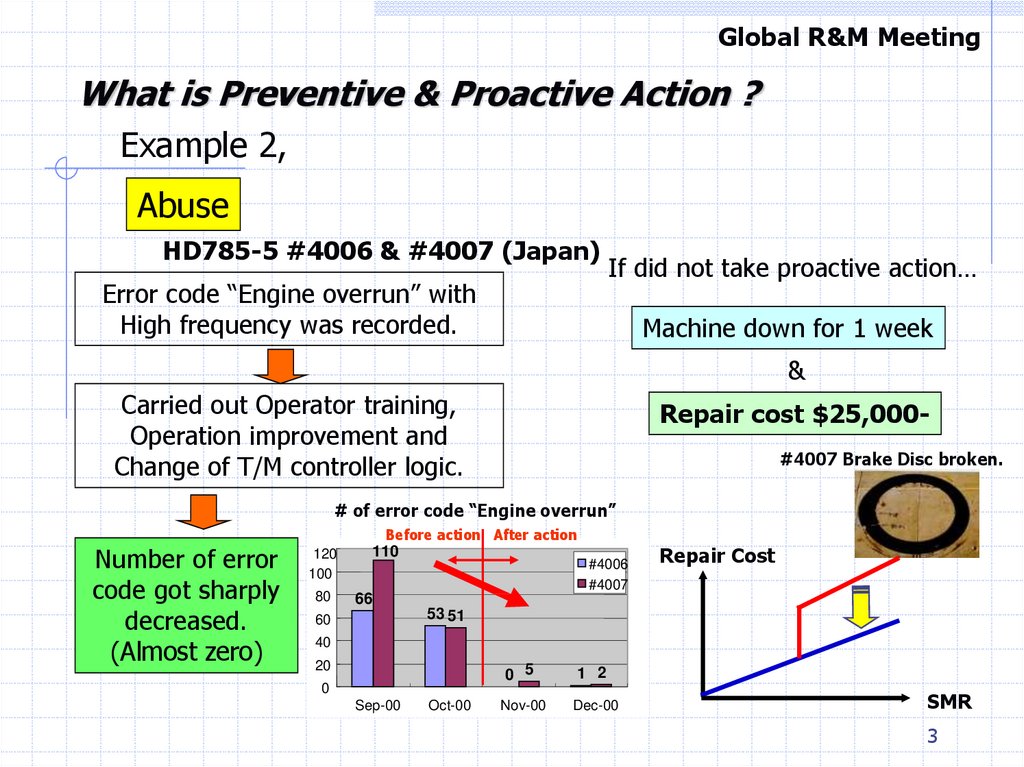

Global R&M MeetingWhat is Preventive & Proactive Action ?

Example 2,

Abuse

HD785-5 #4006 & #4007 (Japan)

Error code “Engine overrun” with

High frequency was recorded.

If did not take proactive action…

Machine down for 1 week

&

Carried out Operator training,

Operation improvement and

Change of T/M controller logic.

Repair cost $25,000#4007 Brake Disc broken.

# of error code “Engine overrun”

Number of error

code got sharply

decreased.

(Almost zero)

Before action After action

120

100

80

110

#4006

#4007

Repair Cost

66

53 51

60

40

20

0

Sep-00

Oct-00

0 5

1 2

Nov-00

Dec-00

SMR

3

4.

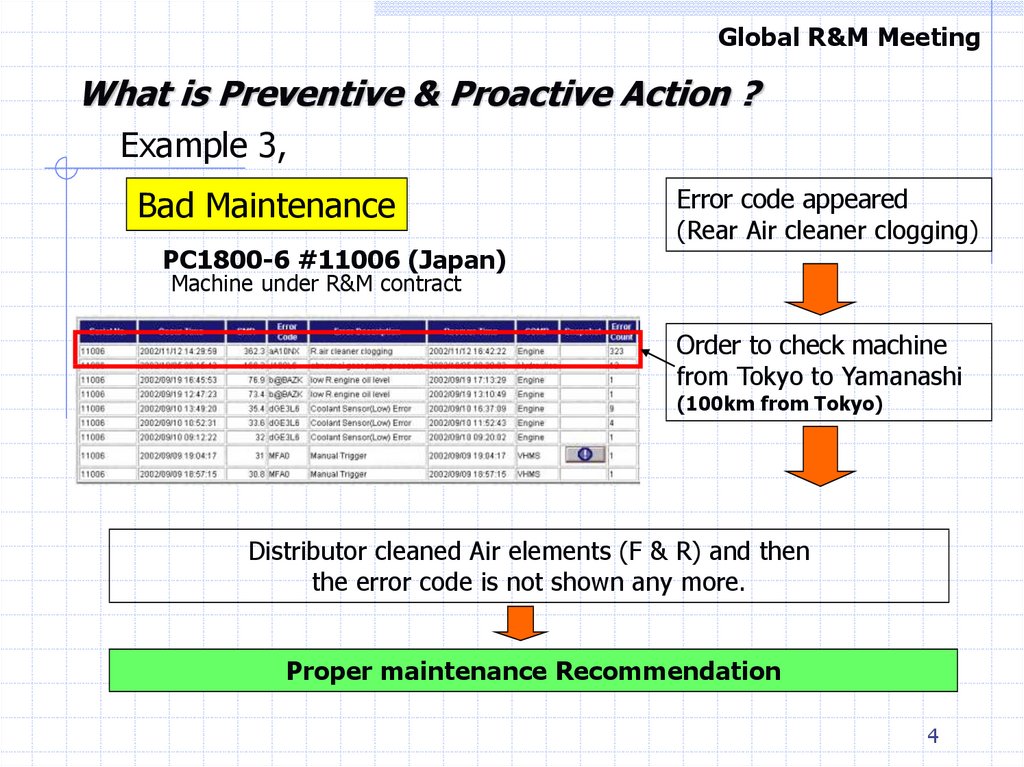

Global R&M MeetingWhat is Preventive & Proactive Action ?

Example 3,

Bad Maintenance

PC1800-6 #11006 (Japan)

Error code appeared

(Rear Air cleaner clogging)

Machine under R&M contract

Order to check machine

from Tokyo to Yamanashi

(100km from Tokyo)

Distributor cleaned Air elements (F & R) and then

the error code is not shown any more.

Proper maintenance Recommendation

4

5.

Global R&M MeetingWhat is Preventive & Proactive Action ?

Example 4,

Recommend O/H commodity judgment & Timing

PC1800-6 #10002 (Canada)

SMR 14,060 hours

1. Operation Frequency

(mmAq)

HD465-5 17000hrs

Spain Mineti

Blow-by Press.

2000

1500

100

1000

Frequency(%)

80

500

9,000

60

44

34

40

20

6

0

Work

Swing

Trav

2. Pressure Range distribution

- Swing

KG/cm2 range

100

Freq. (%)

80

60

47

38

40

15

20

0

[ 0-100]

[100-200]

[200-500]

11,000

13,000

15,000

O/H

Recommended

Final Recommendation

1) O/H for Travel motor and Final Drive

may not be necessary in this time.

2) Swing motor hoses should be

replaced at proper interval.

Due to swing safety relieved oil with the relief pressure energy

is converted directly to oil temperature and around swing

motor becomes high temperature much different from tank.

5

Механика

Механика