Похожие презентации:

For classroom G5951 DC fundamentals

1.

PRESENTATION FOR CLASSROOM G5951DC fundamentals

3ADW000547R0201 DC FUNDAMENTALS EN B

2.

ContentDC motor:

Introduction

Design

Physical way a DC motor works and equations

Characteristics of a DC drives

DC drive:

General Layout

Armature converter and commutation chokes

Converter current, calculations and discontinuous current

Operating mode and control structure

August 25, 2020

Slide 2

3.

DC motorIntroduction

DC motor highlights

DC motors are well known for

– Full torque from zero speed

– Wide field weakening range

– Excellent control behavior

Correlation for motor control

– Torque: Field current and Armature current

– Power: Armature voltage and current

DC motors have half size compared

to Standard AC motors

August 25, 2020

Slide 3

4.

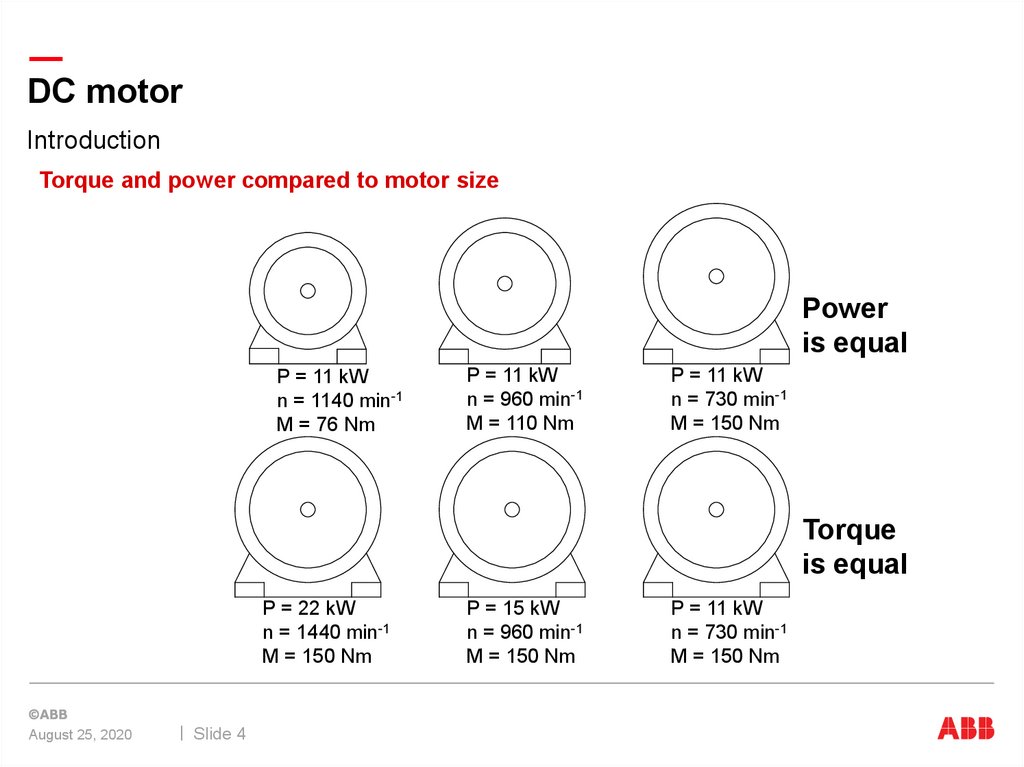

DC motorIntroduction

Torque and power compared to motor size

Power

is equal

P = 11 kW

n = 1140 min-1

M = 76 Nm

P = 11 kW

n = 960 min-1

M = 110 Nm

P = 11 kW

n = 730 min-1

M = 150 Nm

Torque

is equal

P = 22 kW

n = 1440 min-1

M = 150 Nm

August 25, 2020

Slide 4

P = 15 kW

n = 960 min-1

M = 150 Nm

P = 11 kW

n = 730 min-1

M = 150 Nm

5.

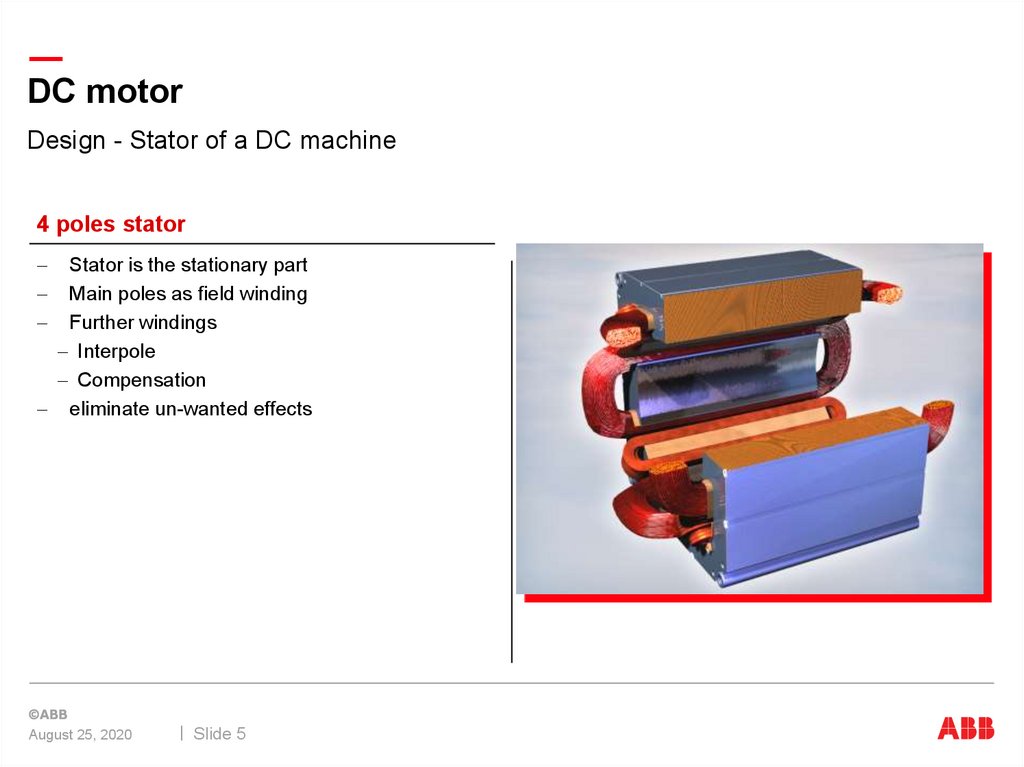

DC motorDesign - Stator of a DC machine

4 poles stator

Stator is the stationary part

Main poles as field winding

Further windings

Interpole

Compensation

eliminate un-wanted effects

August 25, 2020

Slide 5

6.

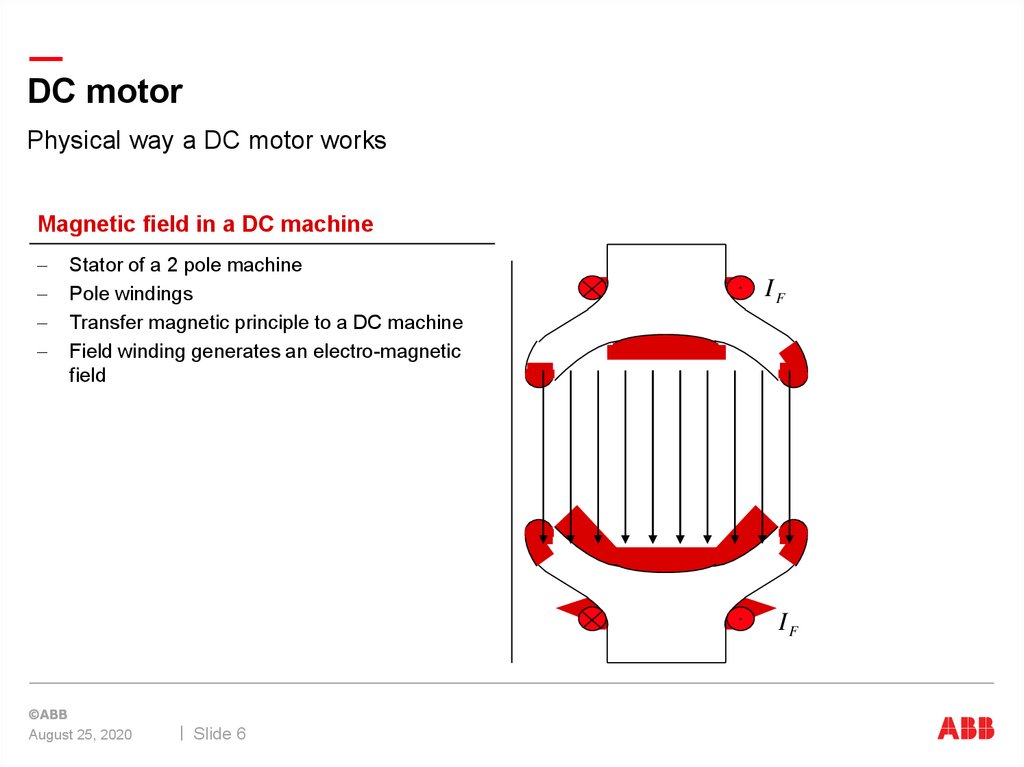

DC motorPhysical way a DC motor works

Magnetic field in a DC machine

Stator of a 2 pole machine

Pole windings

Transfer magnetic principle to a DC machine

Field winding generates an electro-magnetic

field

IF

IF

August 25, 2020

Slide 6

7.

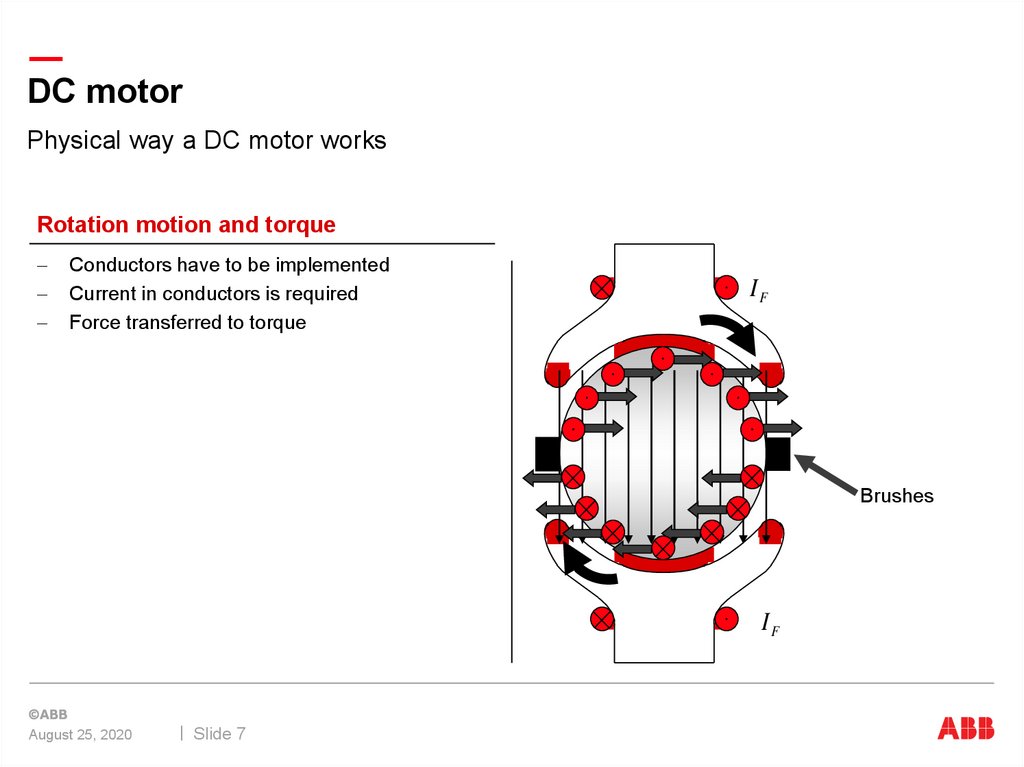

DC motorPhysical way a DC motor works

Rotation motion and torque

Conductors have to be implemented

Current in conductors is required

Force transferred to torque

IF

Brushes

IF

August 25, 2020

Slide 7

8.

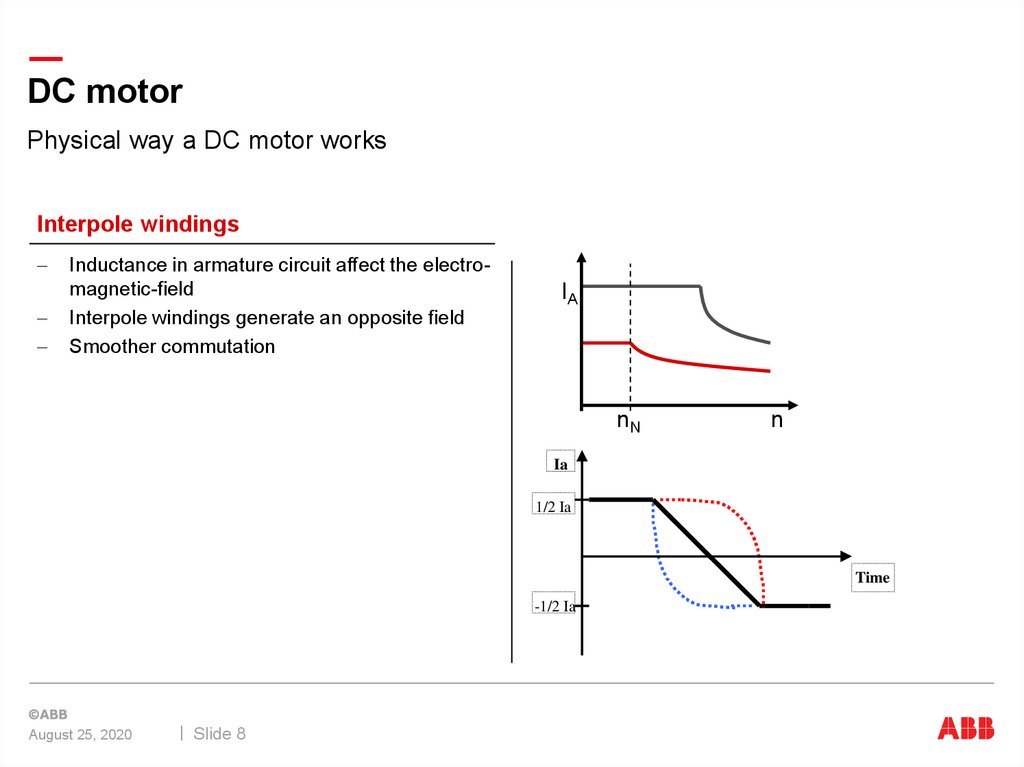

DC motorPhysical way a DC motor works

Interpole windings

Inductance in armature circuit affect the electromagnetic-field

Interpole windings generate an opposite field

Smoother commutation

IA

nN

n

Ia

1/2 Ia

Time

-1/2 Ia

August 25, 2020

Slide 8

9.

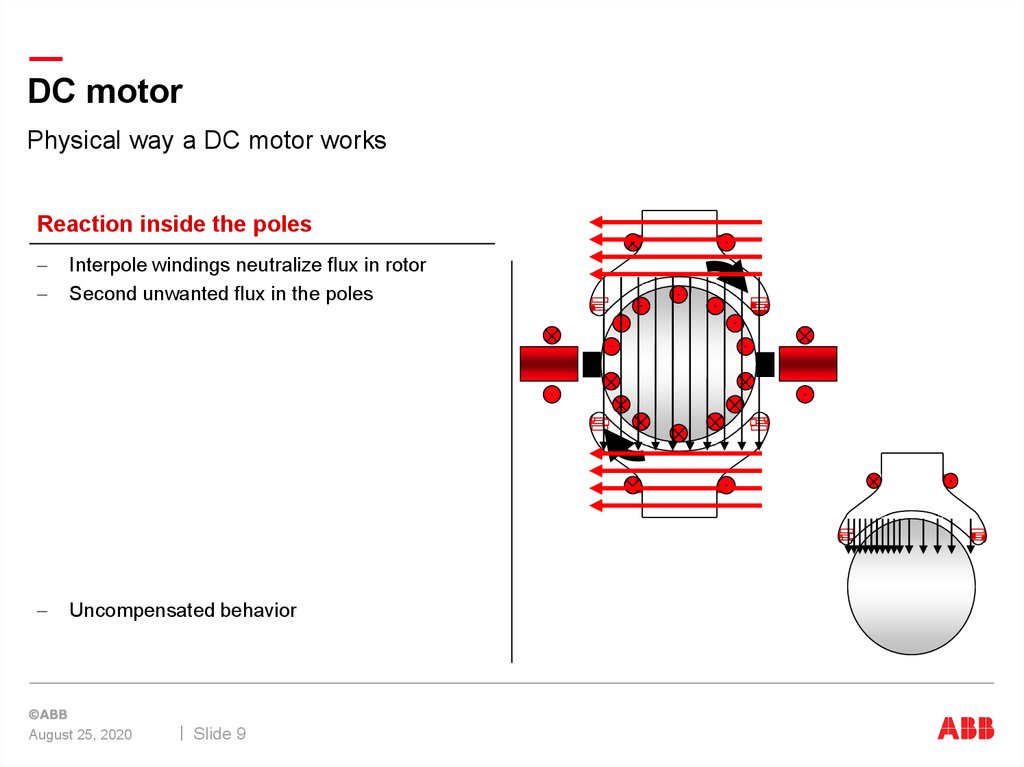

DC motorPhysical way a DC motor works

Reaction inside the poles

Interpole windings neutralize flux in rotor

Second unwanted flux in the poles

Uncompensated behavior

August 25, 2020

Slide 9

10.

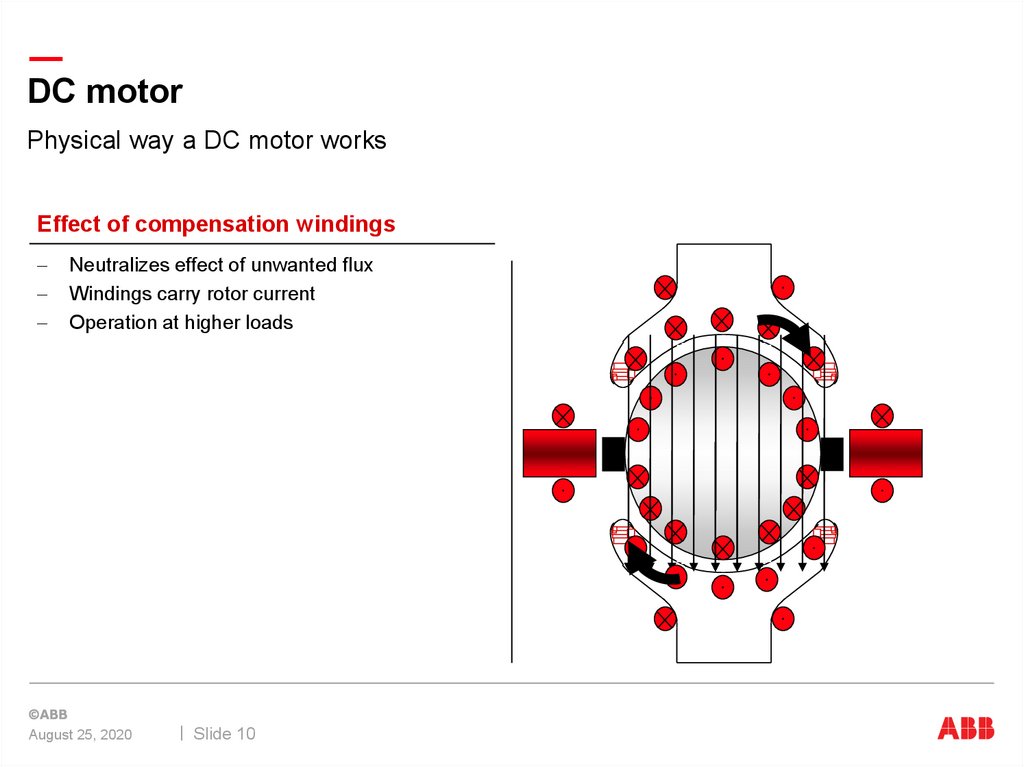

DC motorPhysical way a DC motor works

Effect of compensation windings

Neutralizes effect of unwanted flux

Windings carry rotor current

Operation at higher loads

August 25, 2020

Slide 10

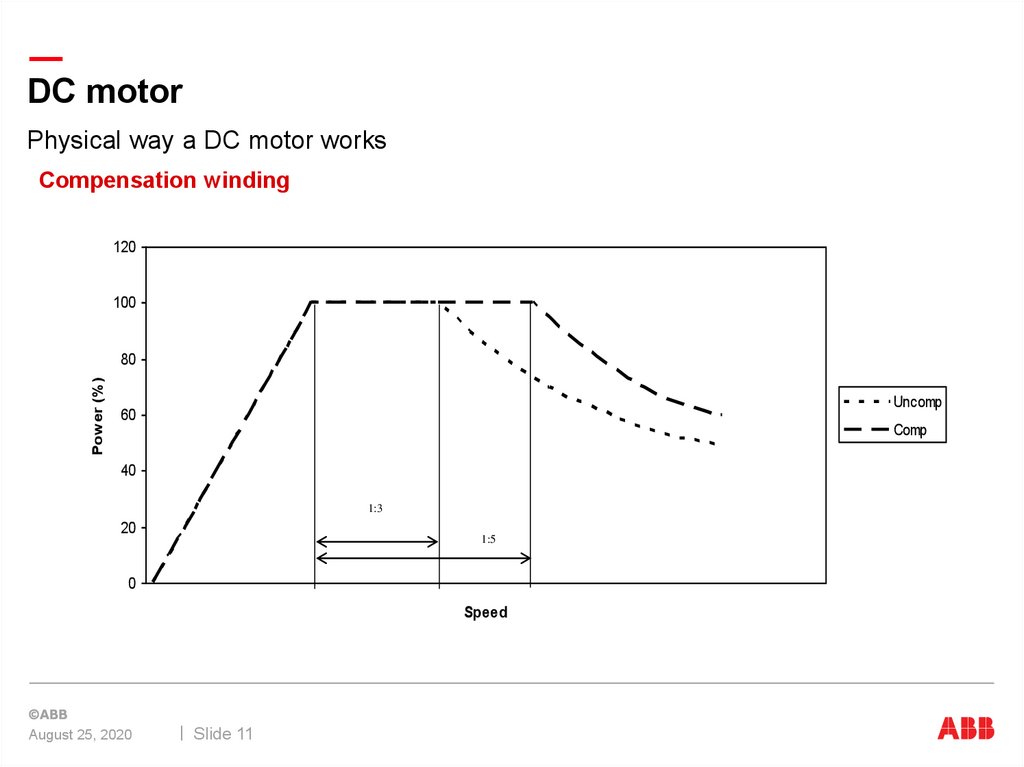

11.

DC motorPhysical way a DC motor works

Compensation winding

120

100

Power (%)

80

Uncomp

60

Comp

40

1:3

20

1:5

0

Speed

August 25, 2020

Slide 11

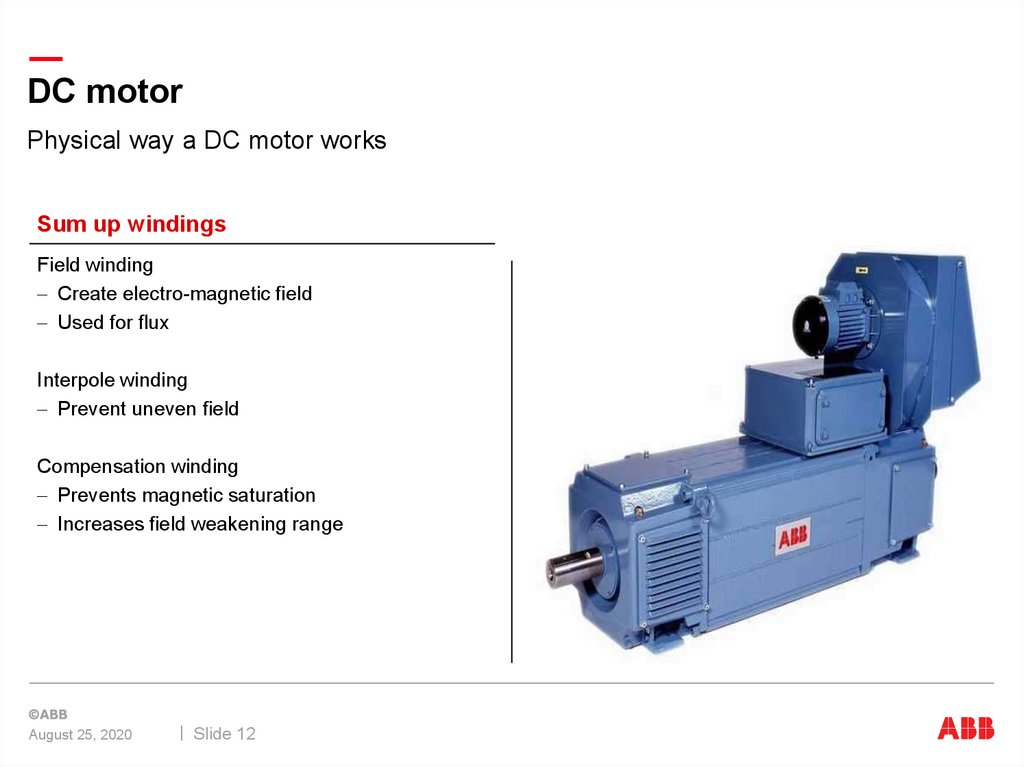

12.

DC motorPhysical way a DC motor works

Sum up windings

Field winding

Create electro-magnetic field

Used for flux

Interpole winding

Prevent uneven field

Compensation winding

Prevents magnetic saturation

Increases field weakening range

August 25, 2020

Slide 12

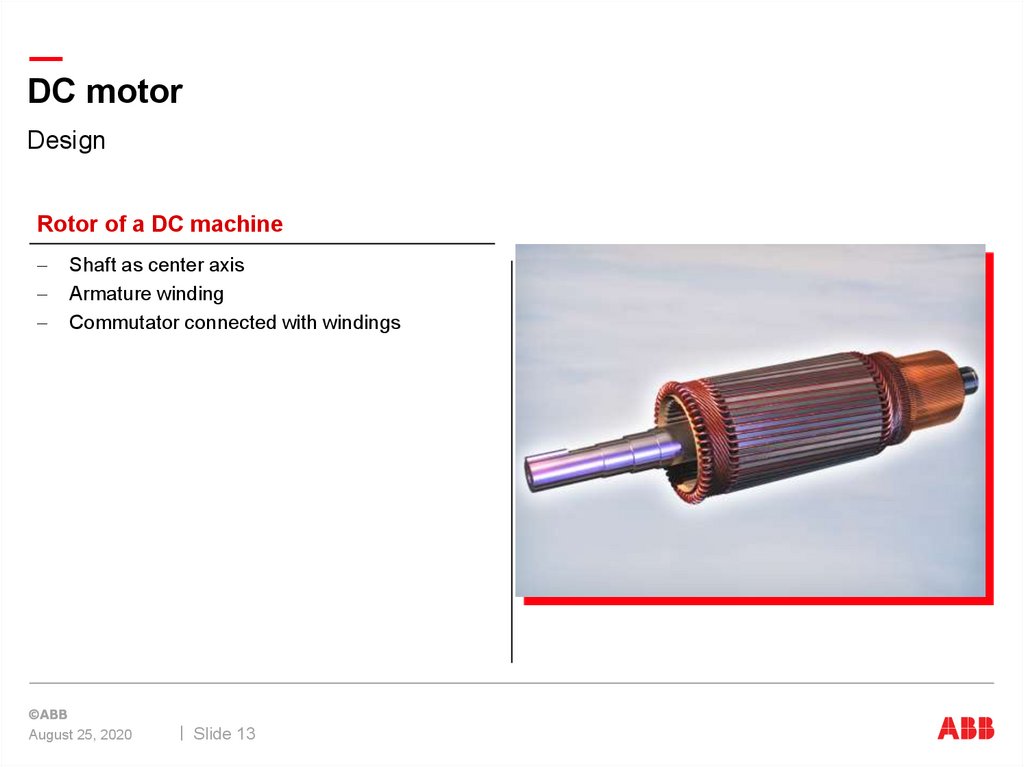

13.

DC motorDesign

Rotor of a DC machine

Shaft as center axis

Armature winding

Commutator connected with windings

August 25, 2020

Slide 13

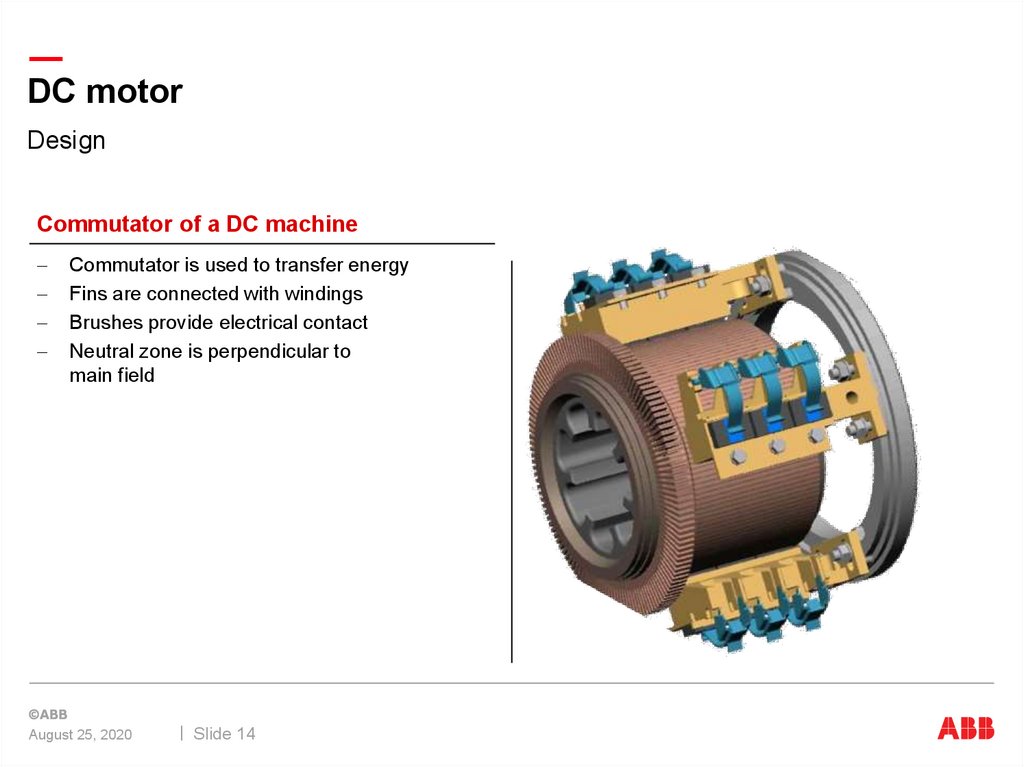

14.

DC motorDesign

Commutator of a DC machine

Commutator is used to transfer energy

Fins are connected with windings

Brushes provide electrical contact

Neutral zone is perpendicular to

main field

August 25, 2020

Slide 14

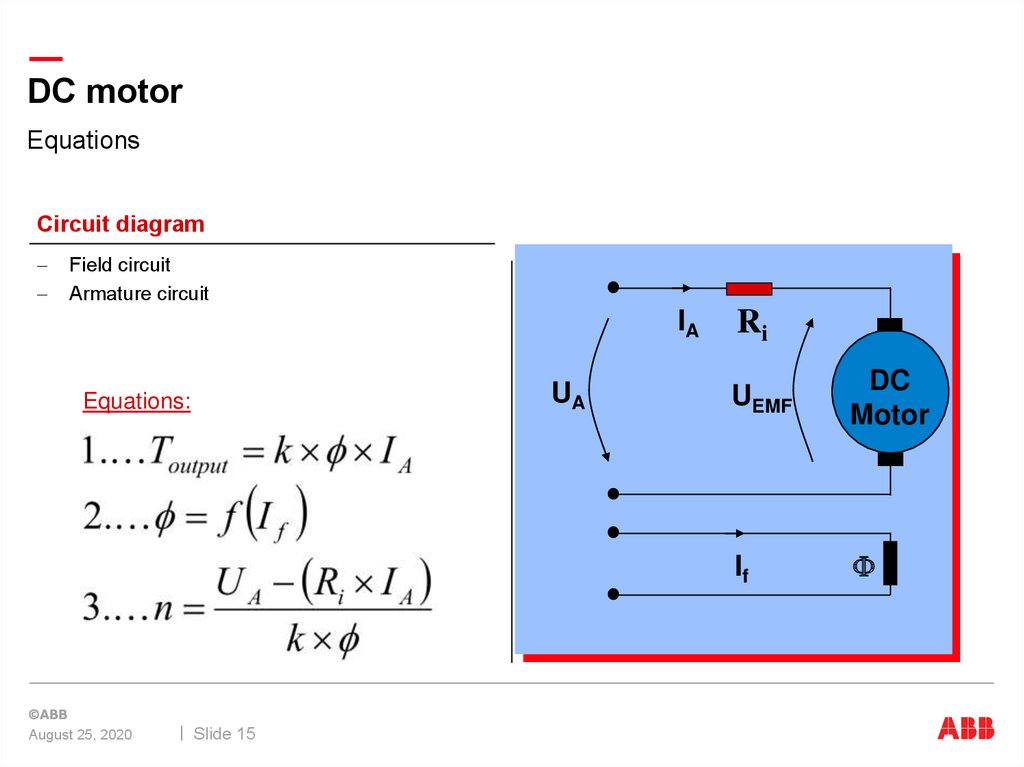

15.

DC motorEquations

Circuit diagram

Field circuit

Armature circuit

IA

UA

Equations:

August 25, 2020

Slide 15

Ri

UEMF

DC

Motor

If

F

16.

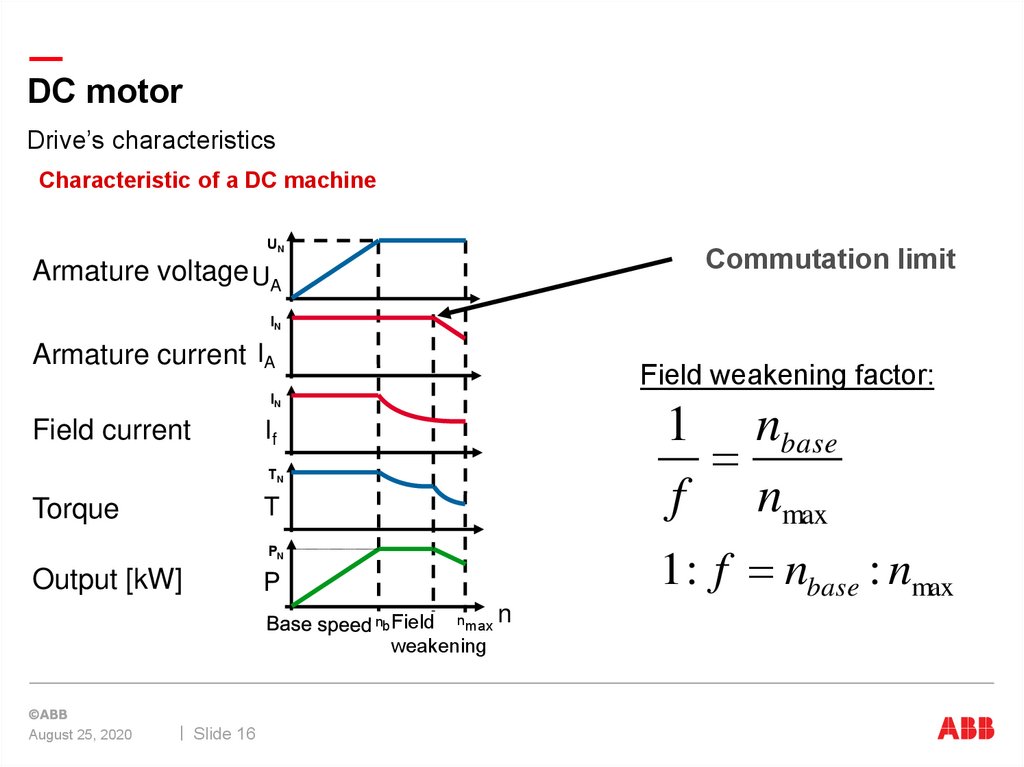

DC motorDrive’s characteristics

Characteristic of a DC machine

UN

Commutation limit

Armature voltage UA

IN

Armature current IA

Field weakening factor:

IN

Field current

1 nbase

f nmax

If

TN

T

Torque

1 : f nbase : nmax

PN

Output [kW]

P

nb Field

n max

weakening

August 25, 2020

Slide 16

n

17.

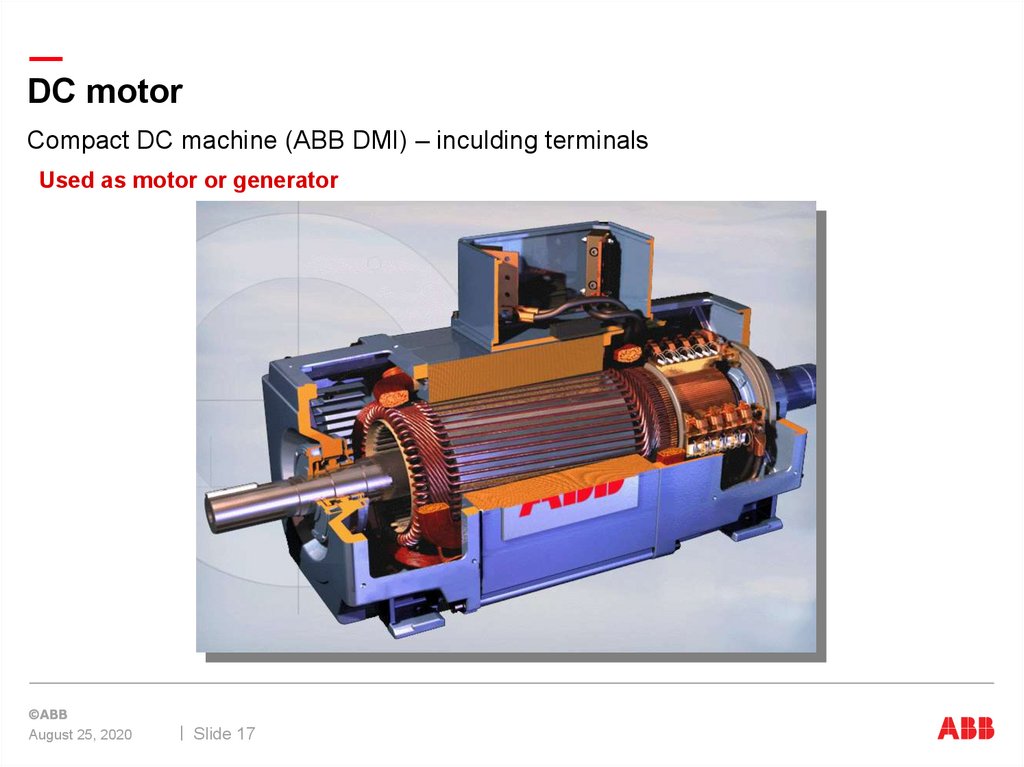

DC motorCompact DC machine (ABB DMI) – inculding terminals

Used as motor or generator

August 25, 2020

Slide 17

18.

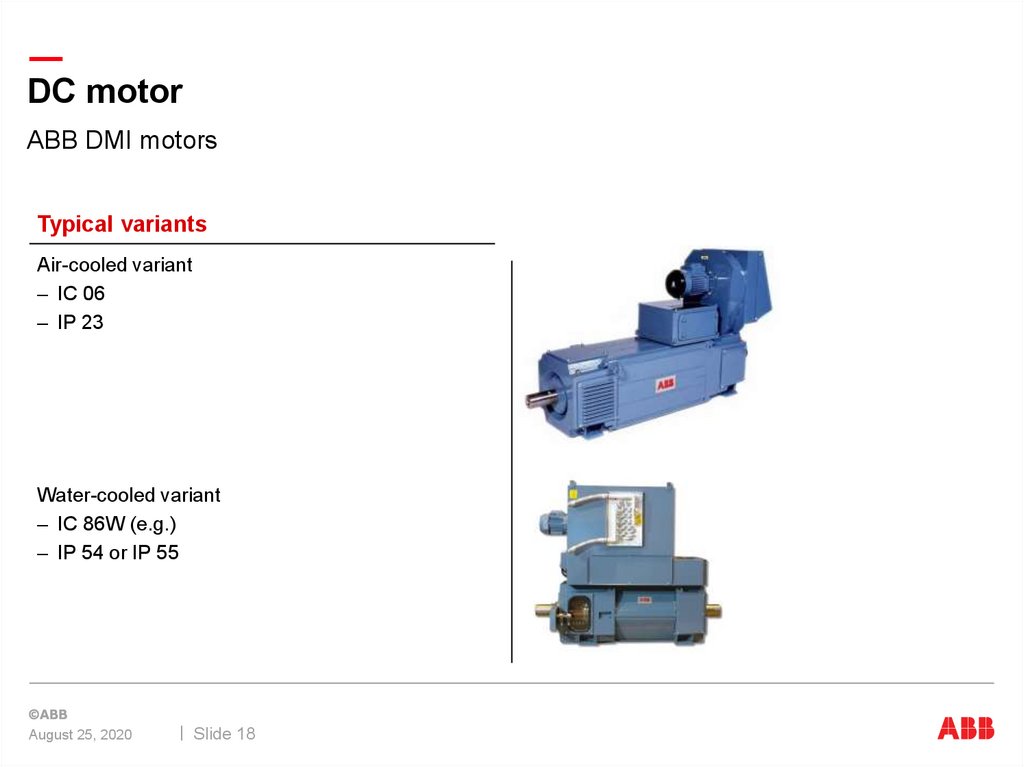

DC motorABB DMI motors

Typical variants

Air-cooled variant

– IC 06

– IP 23

Water-cooled variant

– IC 86W (e.g.)

– IP 54 or IP 55

August 25, 2020

Slide 18

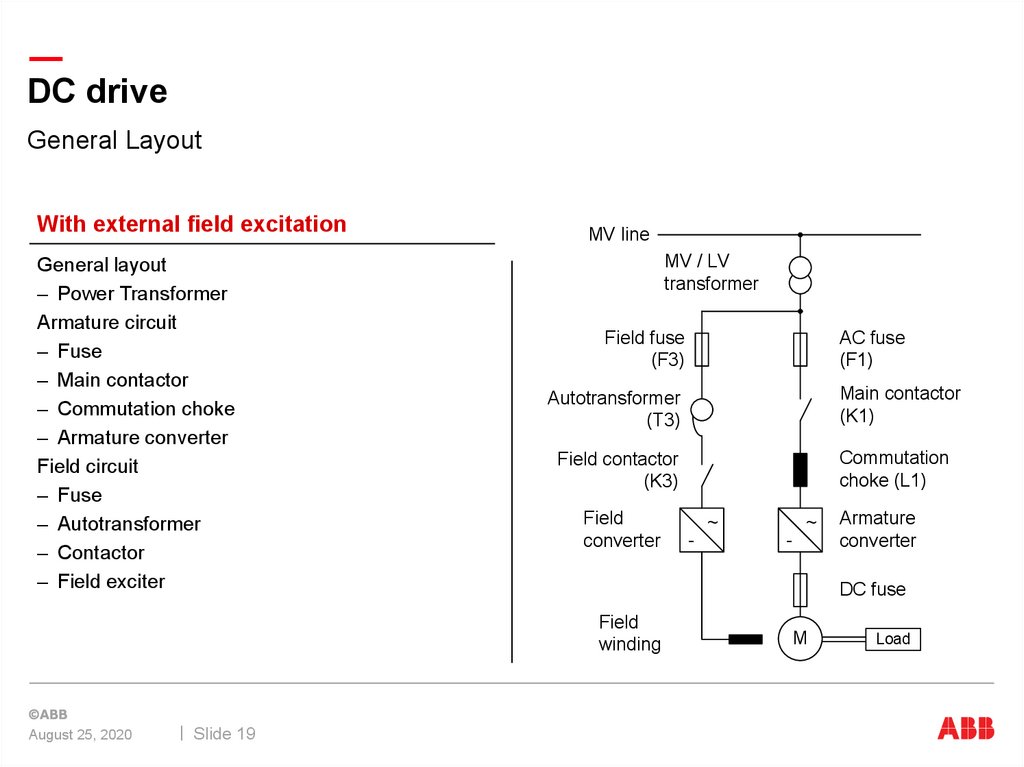

19.

DC driveGeneral Layout

With external field excitation

General layout

– Power Transformer

Armature circuit

– Fuse

– Main contactor

– Commutation choke

– Armature converter

Field circuit

– Fuse

– Autotransformer

– Contactor

– Field exciter

MV line

MV / LV

transformer

Field fuse

(F3)

Slide 19

Main contactor

(K1)

Autotransformer

(T3)

Commutation

choke (L1)

Field contactor

(K3)

Field

converter

~

~

-

-

Armature

converter

DC fuse

Field

winding

August 25, 2020

AC fuse

(F1)

M

Load

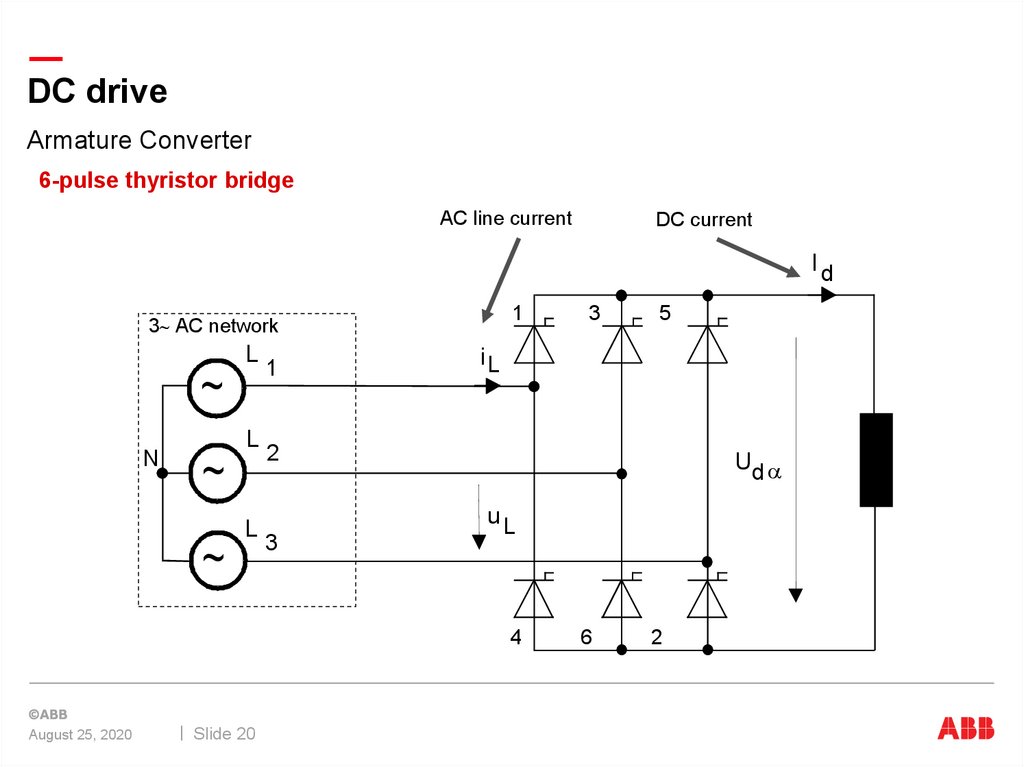

20.

DC driveArmature Converter

6-pulse thyristor bridge

AC line current

DC current

Id

1

3 AC network

L

~

N

L

~

L

~

1

Slide 20

5

iL

2

3

Ud a

uL

4

August 25, 2020

3

6

2

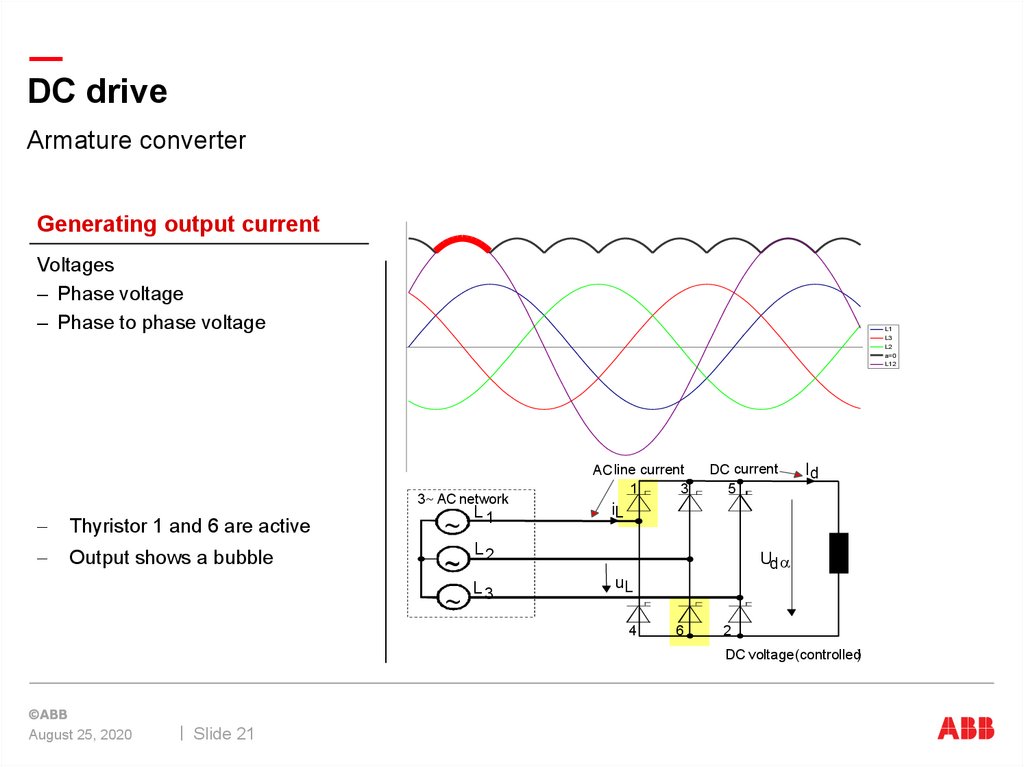

21.

DC driveArmature converter

Generating output current

Voltages

– Phase voltage

– Phase to phase voltage

L1

L3

L1

L2

L3

a=0

L2

a=0

L12

3 AC network

Thyristor 1 and 6 are active

Output shows a bubble

~

~

~

L1

ACline current

1

3

DC current

5

iL

L2

L3

Id

Ud a

uL

4

6

2

DC voltage(controlled)

August 25, 2020

Slide 21

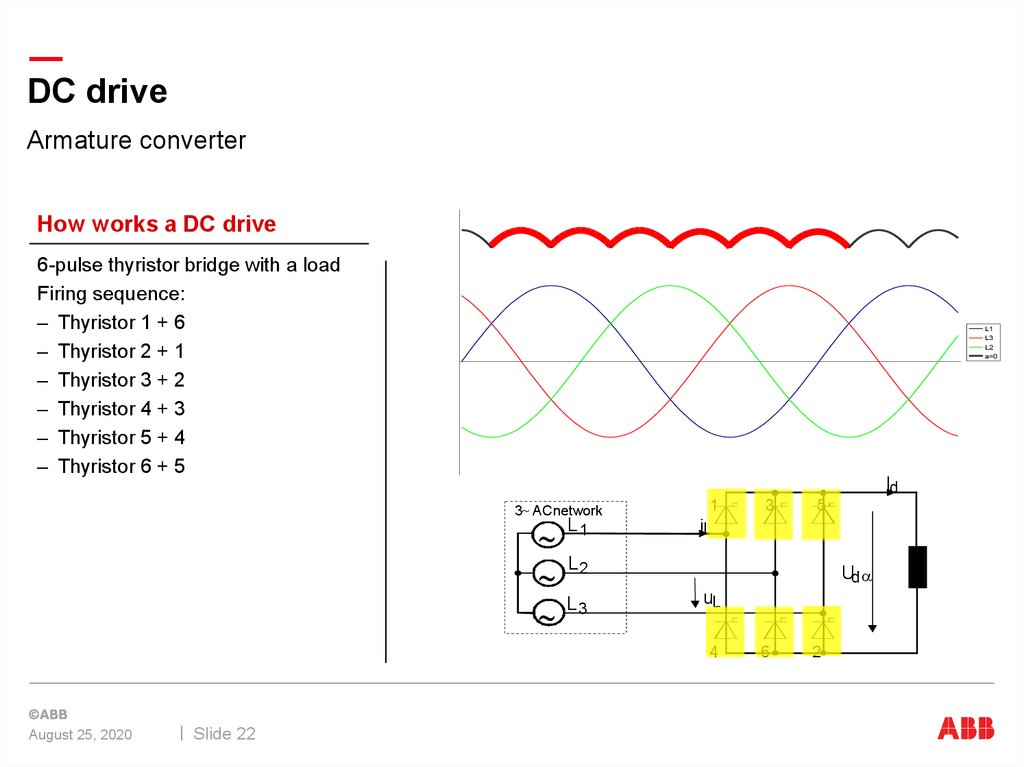

22.

DC driveArmature converter

How works a DC drive

6-pulse thyristor bridge with a load

Firing sequence:

– Thyristor 1 + 6

– Thyristor 2 + 1

– Thyristor 3 + 2

– Thyristor 4 + 3

– Thyristor 5 + 4

– Thyristor 6 + 5

L1

L3

L2

a=0

Id

3 ACnetwork

~

~

~

L1

1

iL

Slide 22

5

L2

L3

Ud a

uL

4

August 25, 2020

3

6

2

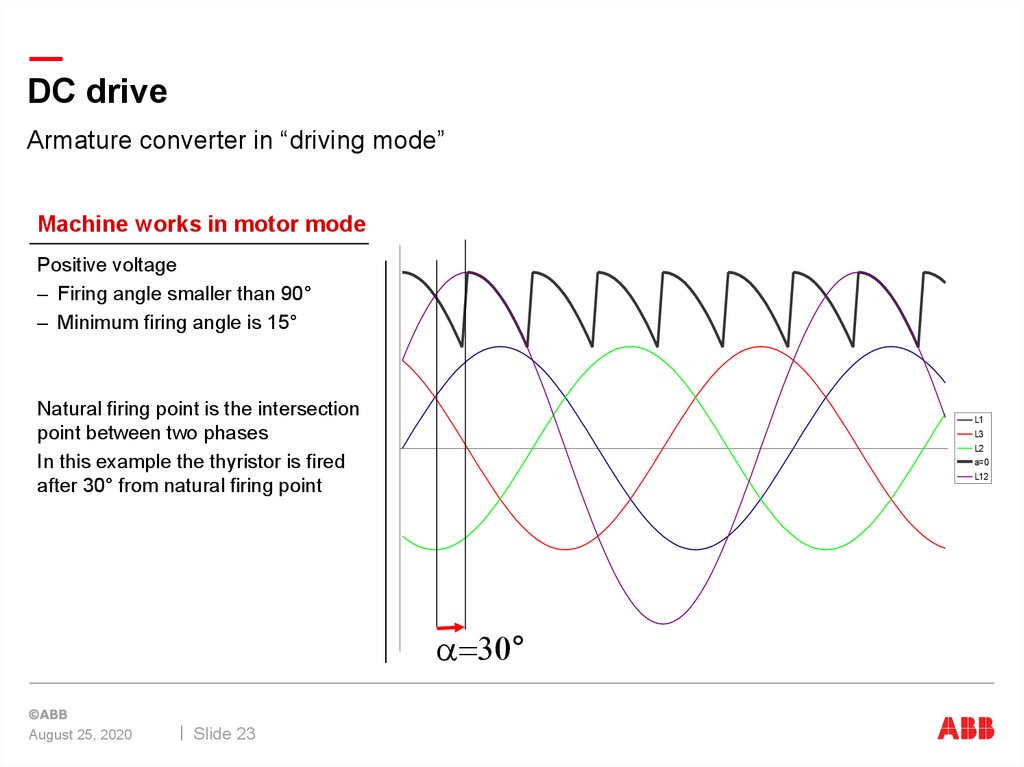

23.

DC driveArmature converter in “driving mode”

Machine works in motor mode

Positive voltage

– Firing angle smaller than 90°

– Minimum firing angle is 15°

Natural firing point is the intersection

point between two phases

In this example the thyristor is fired

after 30° from natural firing point

L1

L3

L2

a=0

L12

a 30°

August 25, 2020

Slide 23

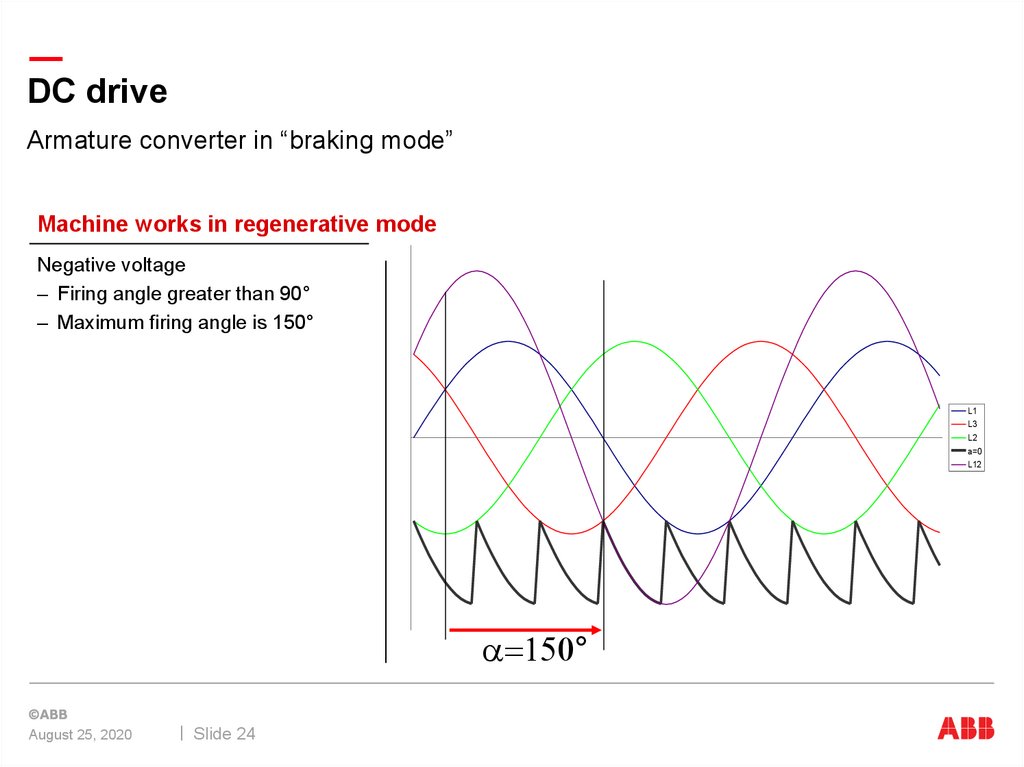

24.

DC driveArmature converter in “braking mode”

Machine works in regenerative mode

Negative voltage

– Firing angle greater than 90°

– Maximum firing angle is 150°

L1

L3

L2

a=0

L12

a 150°

August 25, 2020

Slide 24

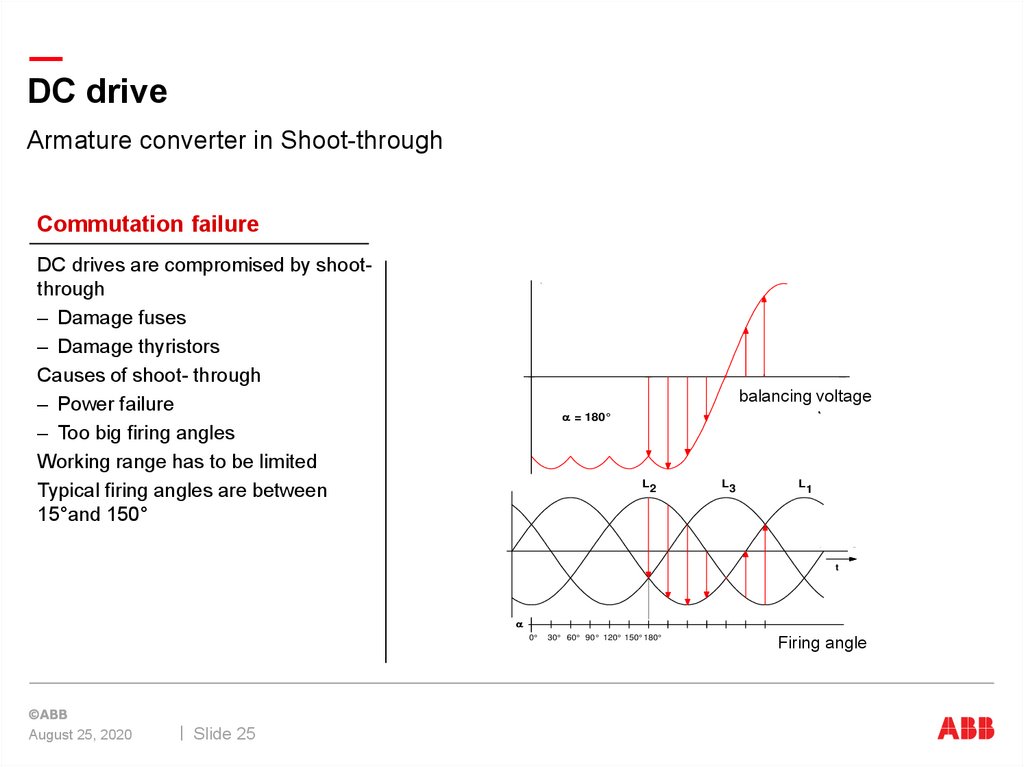

25.

DC driveArmature converter in Shoot-through

Commutation failure

DC drives are compromised by shootthrough

– Damage fuses

– Damage thyristors

Causes of shoot- through

– Power failure

– Too big firing angles

Working range has to be limited

Typical firing angles are between

15°and 150°

GDCZ142

WECHSELRICHTERKIPPEN

Ausgangsgleichspannung

balancing voltage

t

a = 180°

L2

L3

L1

Netzspannung

t

a

0°

Zündwinkel

30° 60° 90° 120° 150° 180°

Firing angle

1

2

3

4

5

6

Zündimpulsreihenfolge an den Thyristoren

August 25, 2020

Slide 25

3

1

5

4

6

Stromführungsdauer der Thyristoren

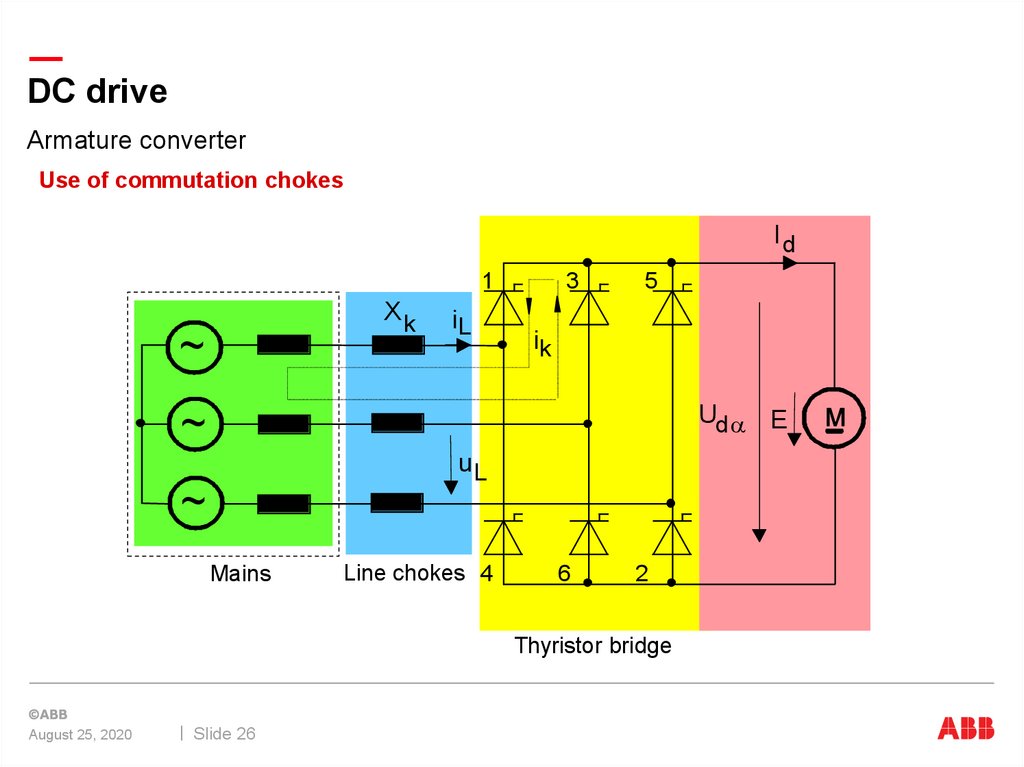

26.

DC driveArmature converter

Use of commutation chokes

Id

1

Xk

~

iL

3

5

ik

Ud a E

~

uL

~

Mains

Line chokes 4

6

2

Thyristor bridge

August 25, 2020

Slide 26

27.

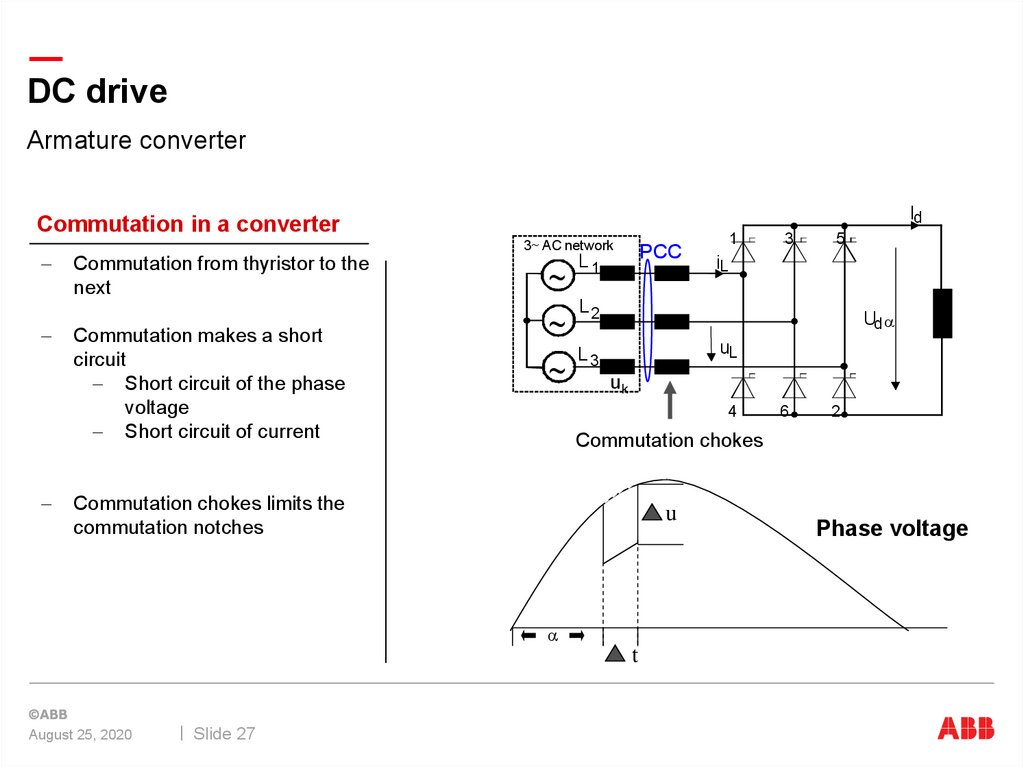

DC driveArmature converter

Commutation in a converter

Commutation from thyristor to the

next

Commutation makes a short

circuit

Short circuit of the phase

voltage

Short circuit of current

Id

3 AC network

~

~

~

PCC

L1

5

iL

Ud a

uL

L3

uk

4

6

2

Commutation chokes

u

a

t

Slide 27

3

L2

Commutation chokes limits the

commutation notches

August 25, 2020

1

Phase voltage

28.

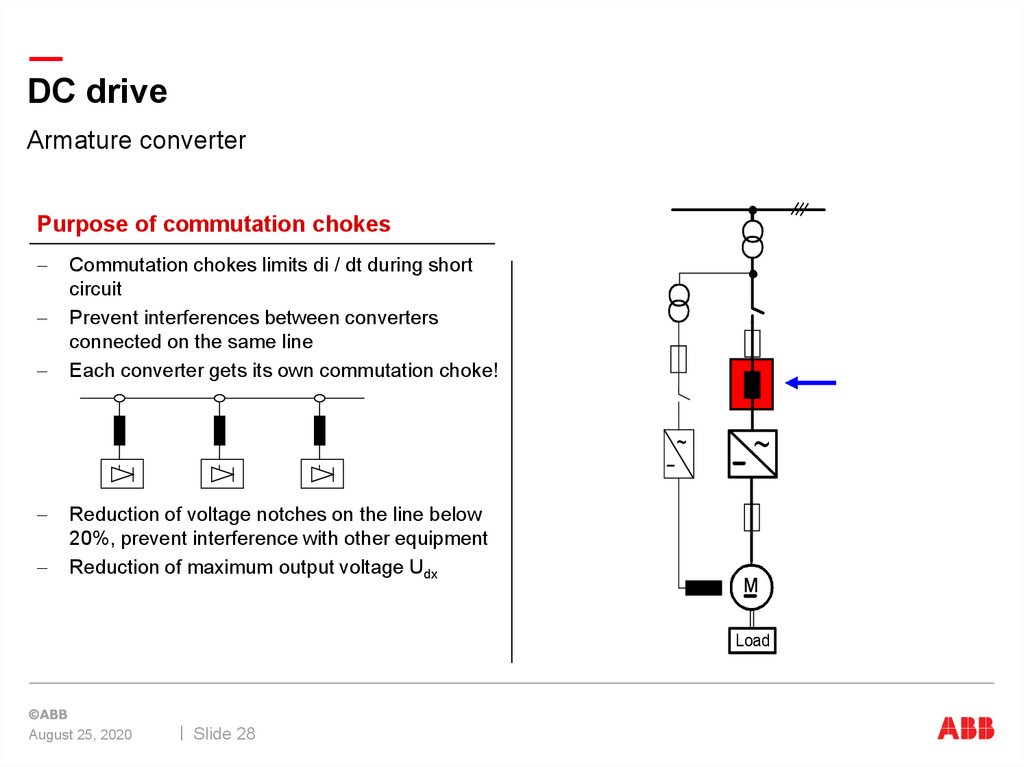

DC driveArmature converter

Purpose of commutation chokes

Commutation chokes limits di / dt during short

circuit

Prevent interferences between converters

connected on the same line

Each converter gets its own commutation choke!

~

~

Reduction of voltage notches on the line below

20%, prevent interference with other equipment

Reduction of maximum output voltage Udx

Load

August 25, 2020

Slide 28

29.

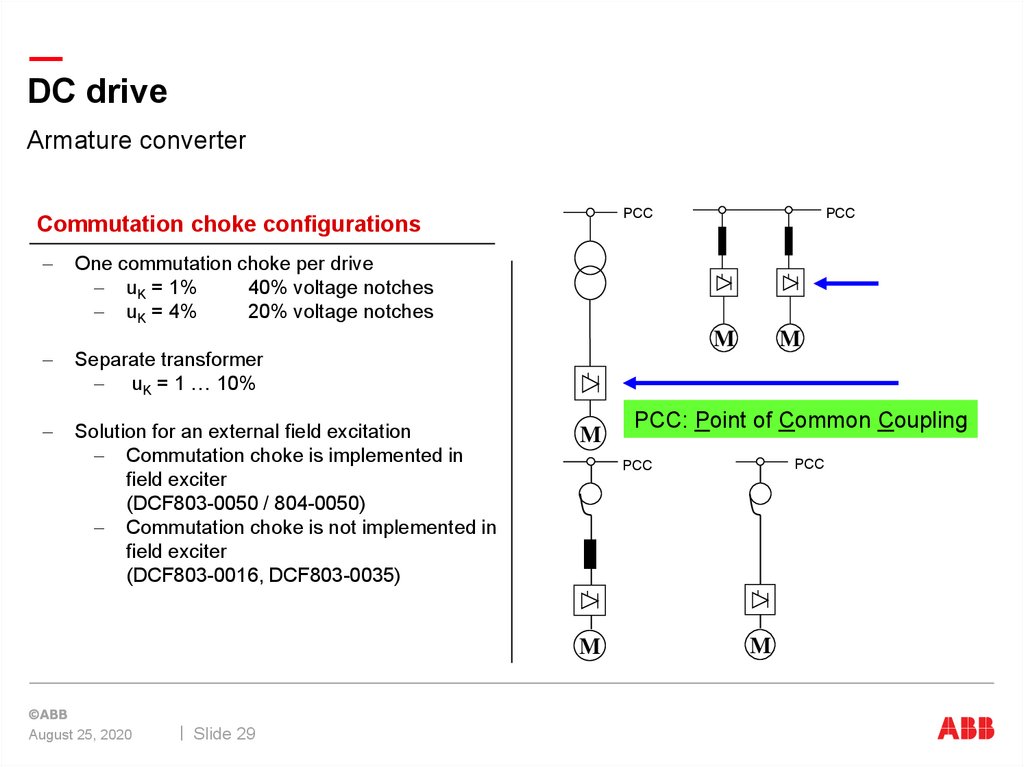

DC driveArmature converter

PCC

Commutation choke configurations

PCC

One commutation choke per drive

uK = 1%

40% voltage notches

uK = 4%

20% voltage notches

M

Separate transformer

uK = 1 … 10%

Solution for an external field excitation

Commutation choke is implemented in

field exciter

(DCF803-0050 / 804-0050)

Commutation choke is not implemented in

field exciter

(DCF803-0016, DCF803-0035)

M

Slide 29

PCC: Point of Common Coupling

PCC

PCC

M

August 25, 2020

M

M

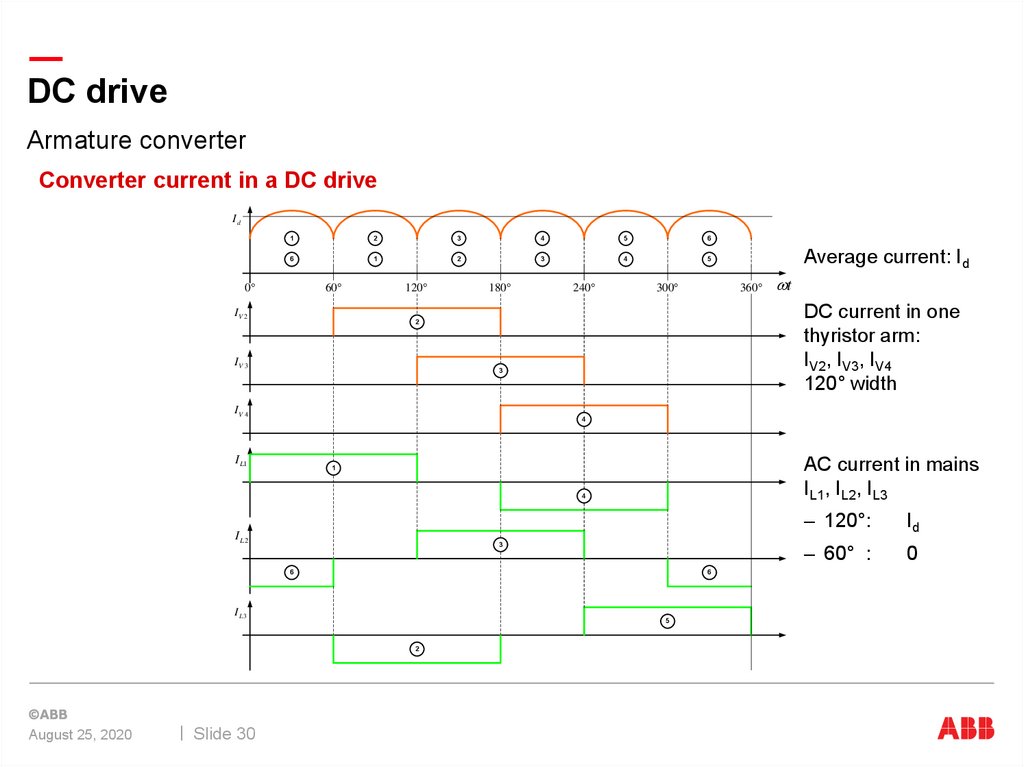

30.

DC driveArmature converter

Converter current in a DC drive

Id

1

2

3

4

5

6

6

1

2

3

4

5

60

0

IV 2

120

180

240

360

300

3

IV 4

4

I L1

AC current in mains

IL1, IL2, IL3

1

4

I L2

3

6

6

I L3

5

2

August 25, 2020

Slide 30

t

DC current in one

thyristor arm:

IV2, IV3, IV4

120° width

2

IV 3

Average current: Id

– 120°:

Id

– 60° :

0

31.

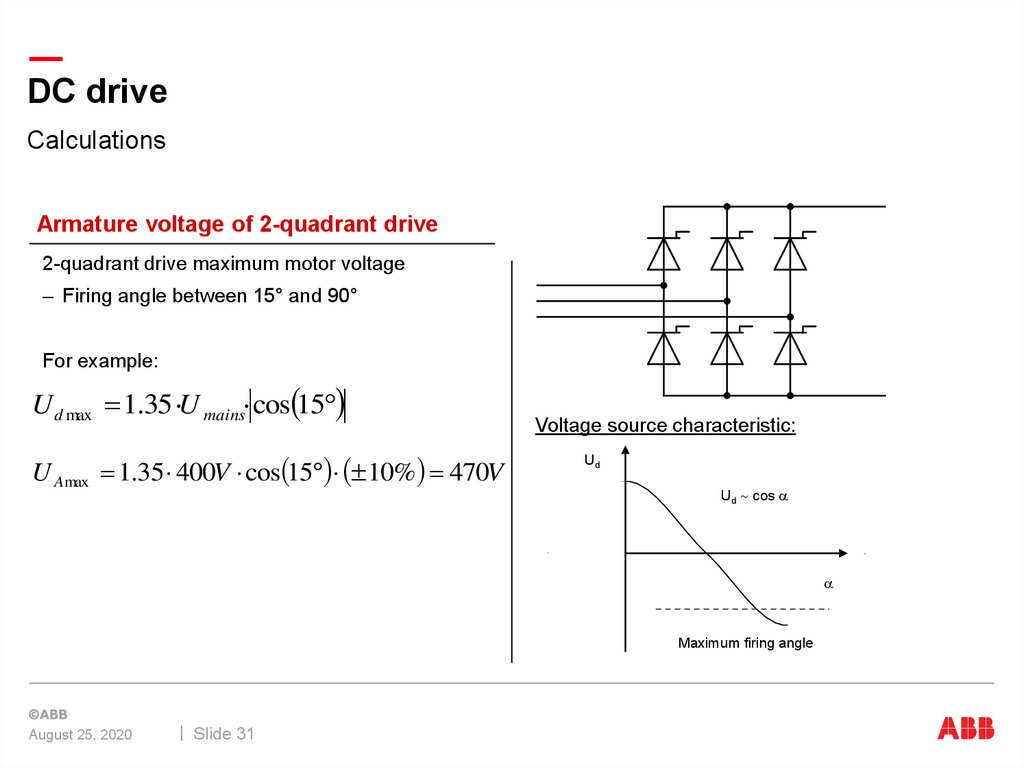

DC driveCalculations

Armature voltage of 2-quadrant drive

2-quadrant drive maximum motor voltage

– Firing angle between 15° and 90°

For example:

U d max 1.35 U mains cos 15

U A max 1.35 400V cos 15 10% 470V

Voltage source characteristic:

Ud

Ud cos a

a

Maximum firing angle

August 25, 2020

Slide 31

32.

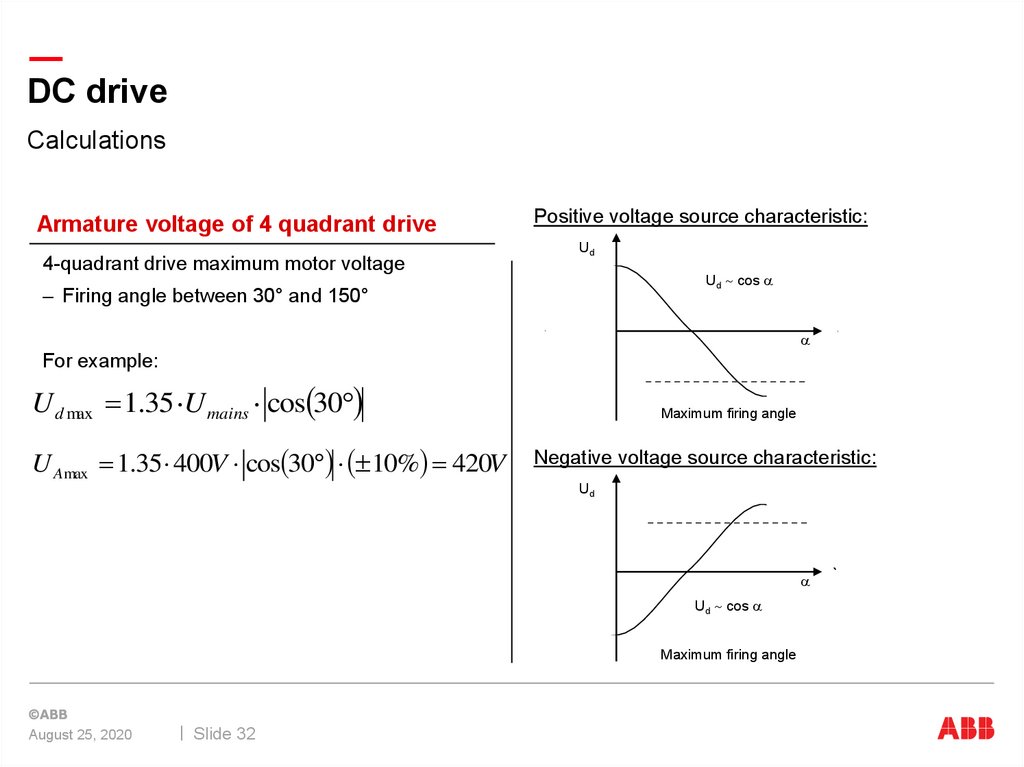

DC driveCalculations

Armature voltage of 4 quadrant drive

4-quadrant drive maximum motor voltage

Positive voltage source characteristic:

Ud

Ud cos a

– Firing angle between 30° and 150°

a

For example:

U d max 1.35 U mains cos 30

U Amax 1.35 400V cos 30 10% 420V

Maximum firing angle

Negative voltage source characteristic:

Ud

a

Ud cos a

Maximum firing angle

August 25, 2020

Slide 32

33.

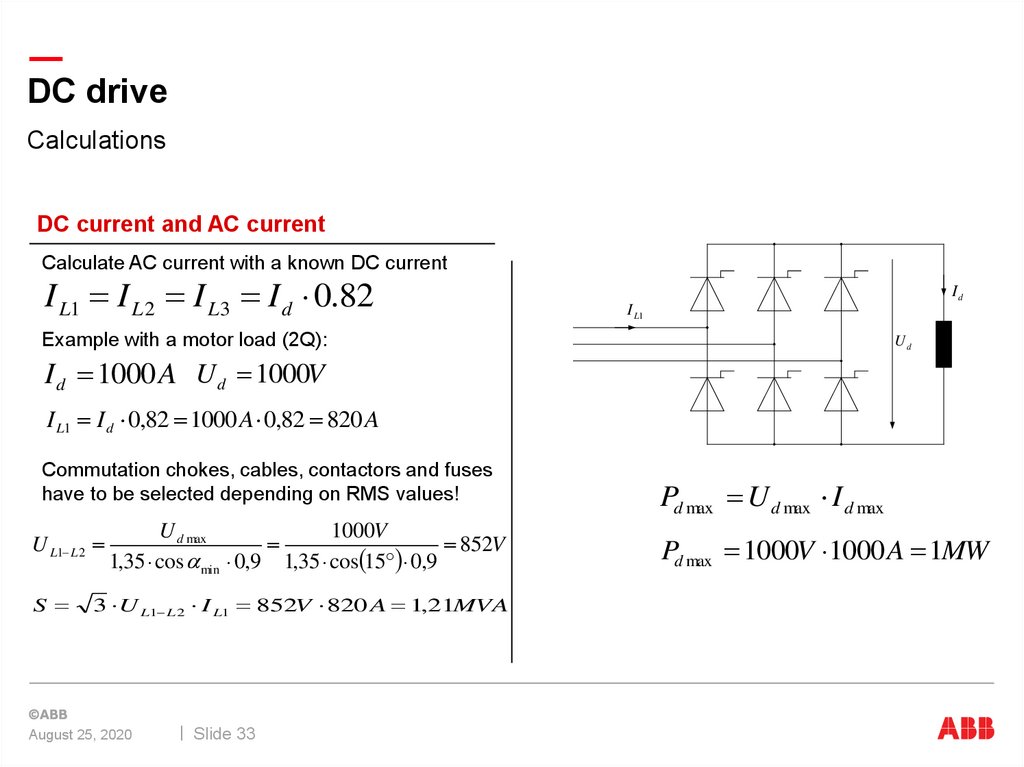

DC driveCalculations

DC current and AC current

Calculate AC current with a known DC current

I L1 I L 2 I L3 I d 0.82

Id

I L1

Example with a motor load (2Q):

Ud

I d 1000 A U d 1000V

I L1 I d 0,82 1000 A 0,82 820 A

Commutation chokes, cables, contactors and fuses

have to be selected depending on RMS values!

U L1 L 2

S

U d max

1000V

852V

1,35 cos a min 0,9 1,35 cos 15 0,9

3 U L1 L 2 I L1 852V 820 A 1,21MVA

August 25, 2020

Slide 33

Pd max U d max I d max

Pd max 1000V 1000 A 1MW

34.

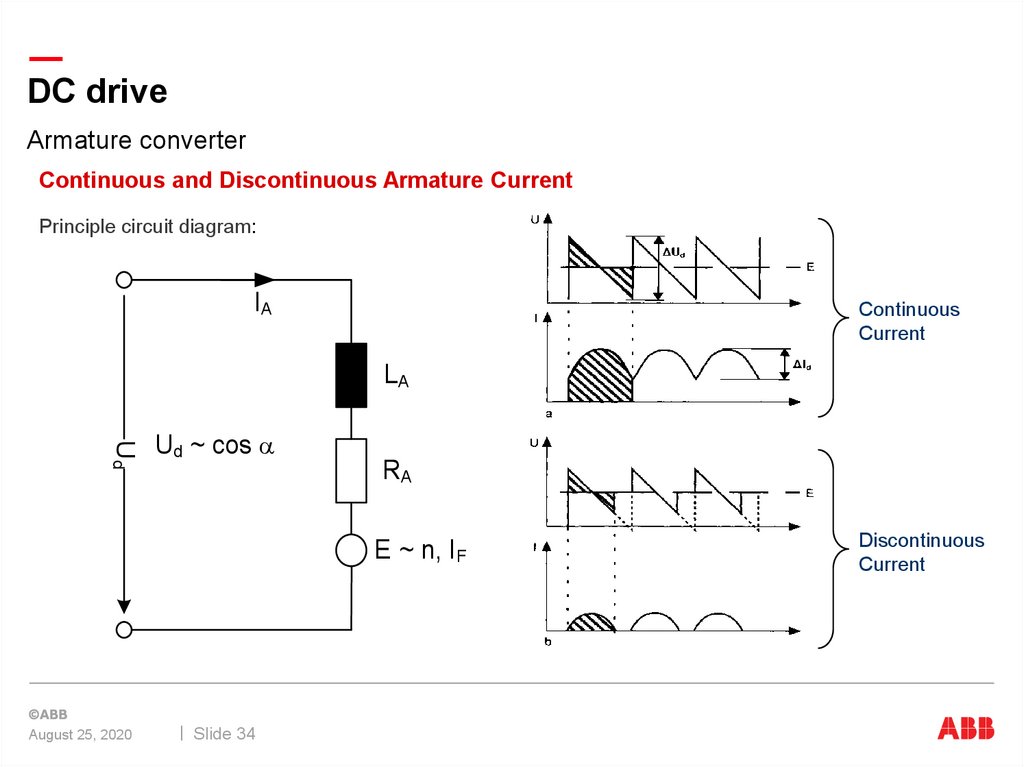

DC driveArmature converter

Continuous and Discontinuous Armature Current

Principle circuit diagram:

IA

Continuous

Current

LA

Ud

Ud ~ cos a

RA

E ~ n, IF

August 25, 2020

Slide 34

Discontinuous

Current

35.

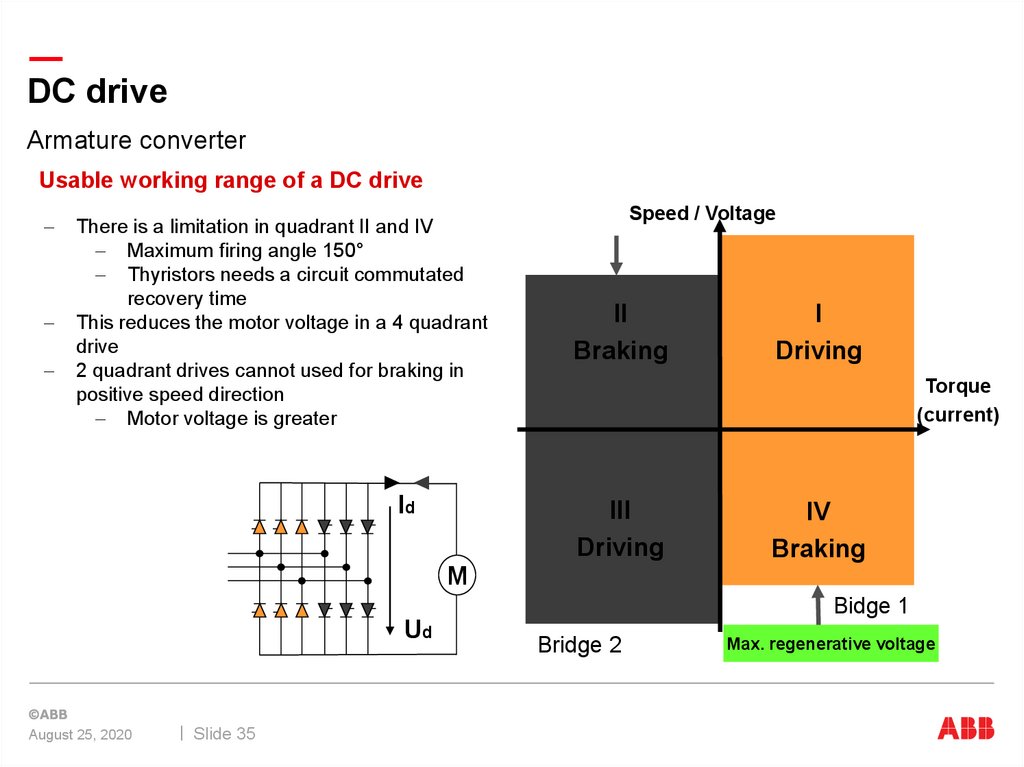

DC driveArmature converter

Usable working range of a DC drive

There is a limitation in quadrant II and IV

Maximum firing angle 150°

Thyristors needs a circuit commutated

recovery time

This reduces the motor voltage in a 4 quadrant

drive

2 quadrant drives cannot used for braking in

positive speed direction

Motor voltage is greater

Id

Speed / Voltage

II

Braking

I

Driving

Torque

(current)

III

Driving

IV

Braking

M

Bidge 1

Ud

August 25, 2020

Slide 35

Bridge 2

Max. regenerative voltage

36.

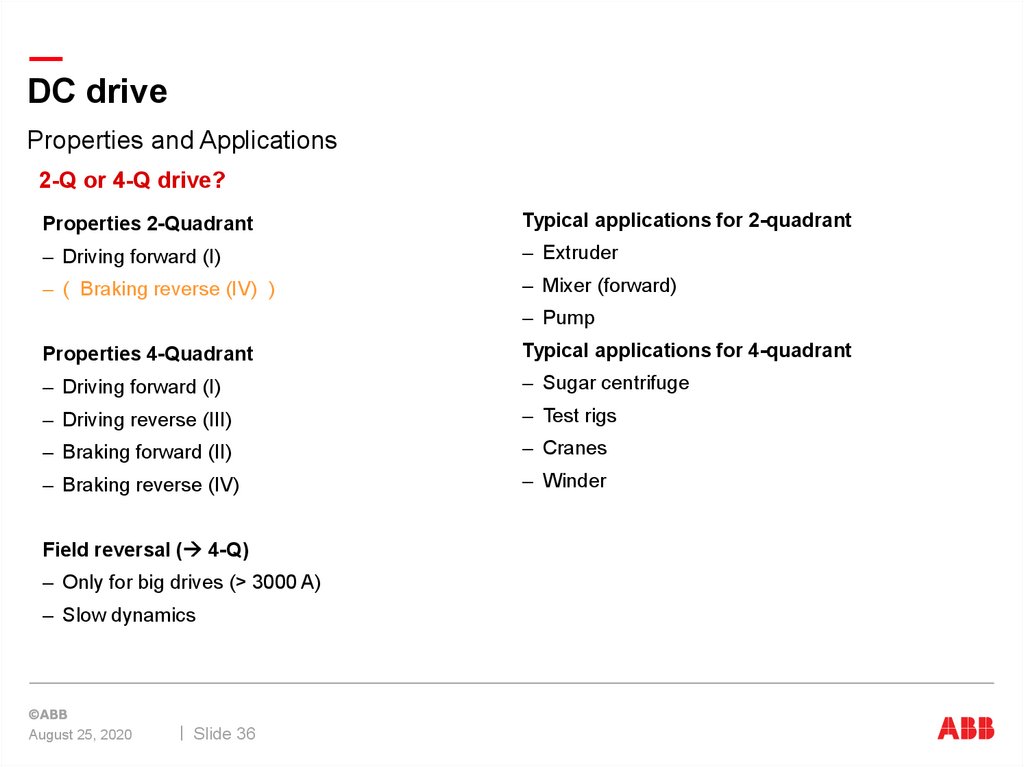

DC driveProperties and Applications

2-Q or 4-Q drive?

Properties 2-Quadrant

Typical applications for 2-quadrant

– Driving forward (I)

– Extruder

– ( Braking reverse (IV) )

– Mixer (forward)

– Pump

Properties 4-Quadrant

Typical applications for 4-quadrant

– Driving forward (I)

– Sugar centrifuge

– Driving reverse (III)

– Test rigs

– Braking forward (II)

– Cranes

– Braking reverse (IV)

– Winder

Field reversal ( 4-Q)

– Only for big drives (> 3000 A)

– Slow dynamics

August 25, 2020

Slide 36

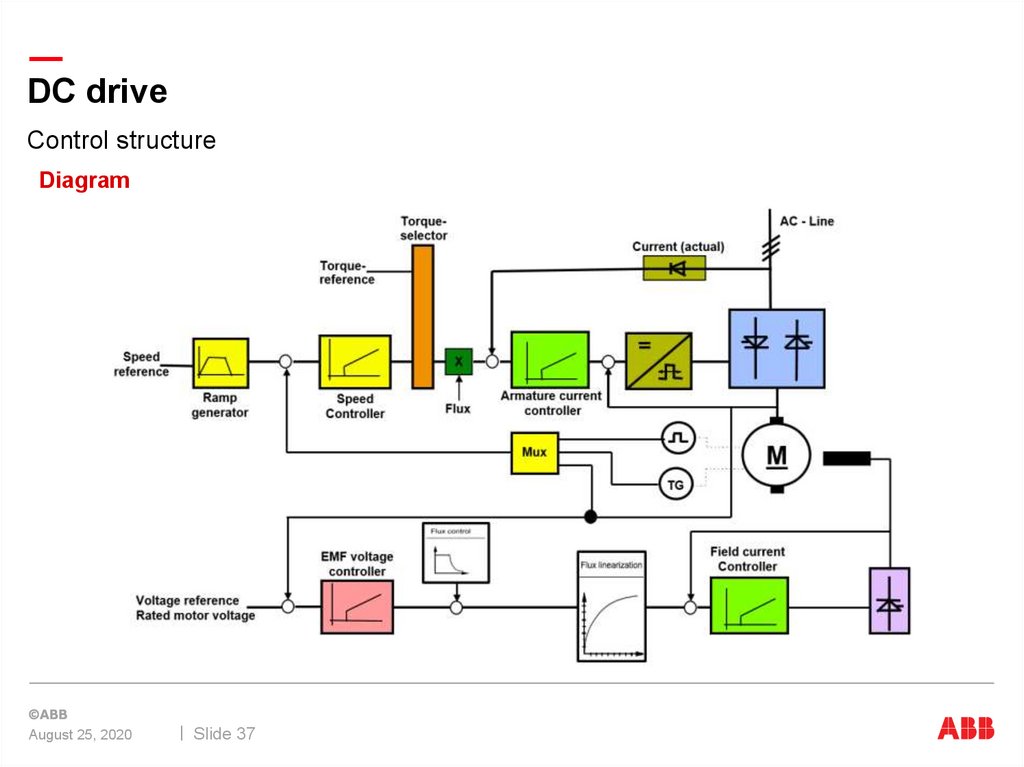

37.

DC driveControl structure

Diagram

August 25, 2020

Slide 37

Электроника

Электроника