Похожие презентации:

Fundamentals on grinding workshops

1. Fundamentals on Grinding Workshops

GRINDING I – Training Session2. Content

Fundamentals on Grinding WorkshopsContent

• Fundamentals on grinding

• Different types of ball mills

• Vertical mills

• Roller press

• Horomill

KUJ - July 2012 – Grinding I 2

3. Content

Fundamentals on Grinding WorkshopsContent

• Fundamentals on grinding

• Different types of ball mills

• Vertical mills

• Roller press

• Horomill

KUJ - July 2012 – Grinding I 3

4. Why do we grind in the cement business?

Fundamentals on Grinding WorkshopsWhy do we grind in the cement business?

• To create surface area for good chemical reactions

to occur

• Combination in the kiln (Raw grinding)

• Hydraulic reactions in the concrete (Cement grinding)

• Good combustion in the kiln flame (Coal grinding)

KUJ - July 2012 – Grinding I 4

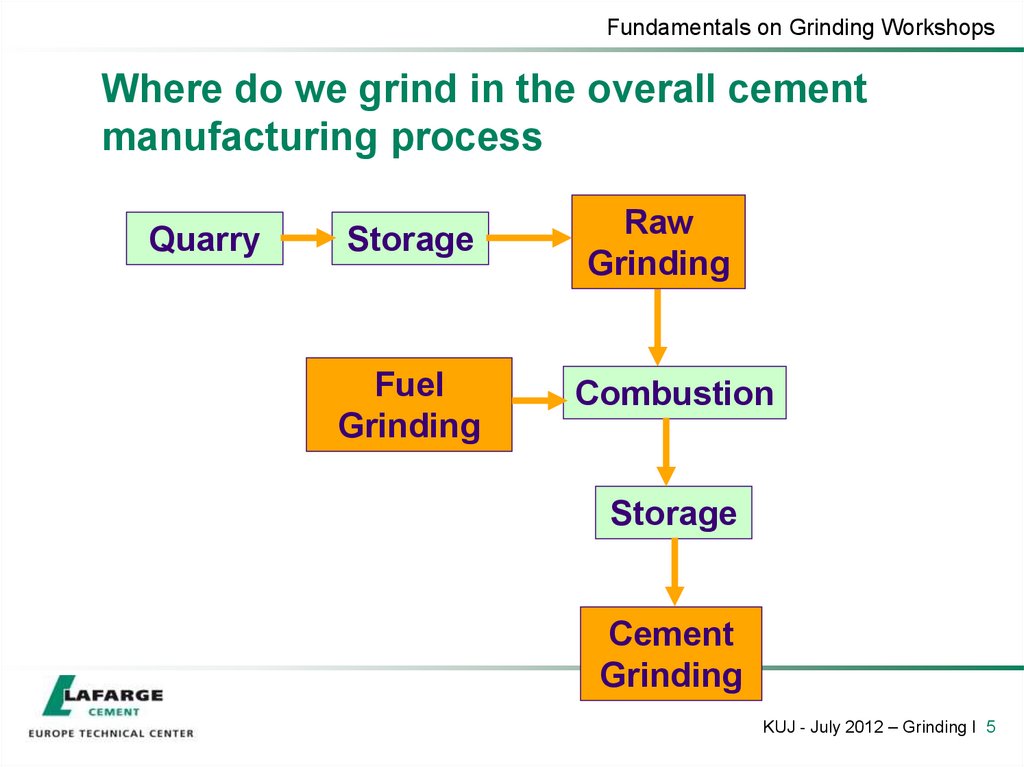

5. Where do we grind in the overall cement manufacturing process

Fundamentals on Grinding WorkshopsWhere do we grind in the overall cement

manufacturing process

Quarry

Storage

Fuel

Grinding

Raw

Grinding

Combustion

Storage

Cement

Grinding

KUJ - July 2012 – Grinding I 5

6. What are the main challenges for cement production

Fundamentals on Grinding WorkshopsWhat are the main challenges for cement

production

• Reduce power consumption

• Maximize production

• Optimize and improve product regularity

• Control maintenance costs

KUJ - July 2012 – Grinding I 6

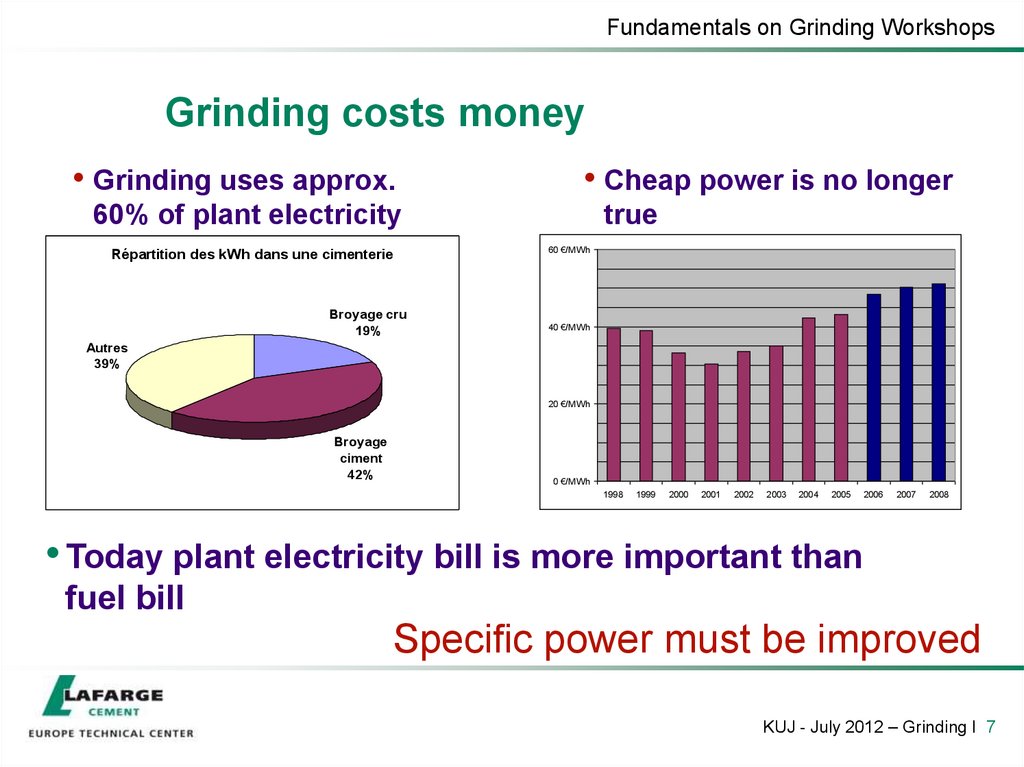

7. Grinding costs money

Fundamentals on Grinding WorkshopsGrinding costs money

• Grinding uses approx.

• Cheap power is no longer

60% of plant electricity

Répartition des kWh dans une cimenterie

Broyage cru

19%

true

60 €/MWh

40 €/MWh

Autres

39%

20 €/MWh

Broyage

ciment

42%

0 €/MWh

1998

1999

2000

2001

2002

2003

2004

2005

2006

2007

2008

• Today plant electricity bill is more important than

fuel bill

Specific power must be improved

KUJ - July 2012 – Grinding I 7

8.

Fundamentals on Grinding WorkshopsKUJ - July 2012 – Grinding I 8

9. Grinding costs money

Fundamentals on Grinding WorkshopsGrinding costs money

• Costs of wear parts increasing

• Joint visits between process and maintenance

departments upgrade the efficiency: wear takes place in

the process

PLN raw mill example:

• Change of iron source

• Wear before and after use

of this new raw material

• Material stays in the reject

TOTAL WEAR FROM 1998 TO 01-2004

TOTAL WEAR FROM 02-2004 TO 04-2004

KUJ - July 2012 – Grinding I 9

10. The different types of mill

Fundamentals on Grinding WorkshopsThe different types of mill

• Three different mill types with specific purposes

• Raw mills (for slag, shale, limestone…)

• Size reduction (targeted rejects at 90 and 200µm)

• Drying the materials

• Cement mills (pure or compound cements)

• Size reduction (objectives in SSB)

• Management of gypsum dehydration

• Fuel mills (coal and pet coke)

• Size reduction (targeted rejects at 90µm)

• Drying the materials

KUJ - July 2012 – Grinding I 10

11. Technologies and arrangements

Fundamentals on Grinding WorkshopsTechnologies and arrangements

• Different mill technologies

• Ball mills

• Air swept mill = materials released by ventilation air

• Compound mill = with end discharge

• Bi rotator mill = with central discharge

• Vertical mill

• Roller press

• Horomill

• Different architectures

• In open circuit

• In closed circuit

• With pre-grinding, hybrid grinding…

KUJ - July 2012 – Grinding I 11

12. Origin of a current workshop

Fundamentals on Grinding WorkshopsOrigin of a current workshop

• Existing workshop design depends on

• Material feed specifications

• Feed size

• Moisture

• Outlet product specifications

• Flow rate

• Fineness target

• History of the plant and workshop

KUJ - July 2012 – Grinding I 12

13. Content

Fundamentals on Grinding WorkshopsContent

• Fundamentals on grinding

• Different types of ball mills

• Vertical mills

• Roller press

• Horomill

KUJ - July 2012 – Grinding I 13

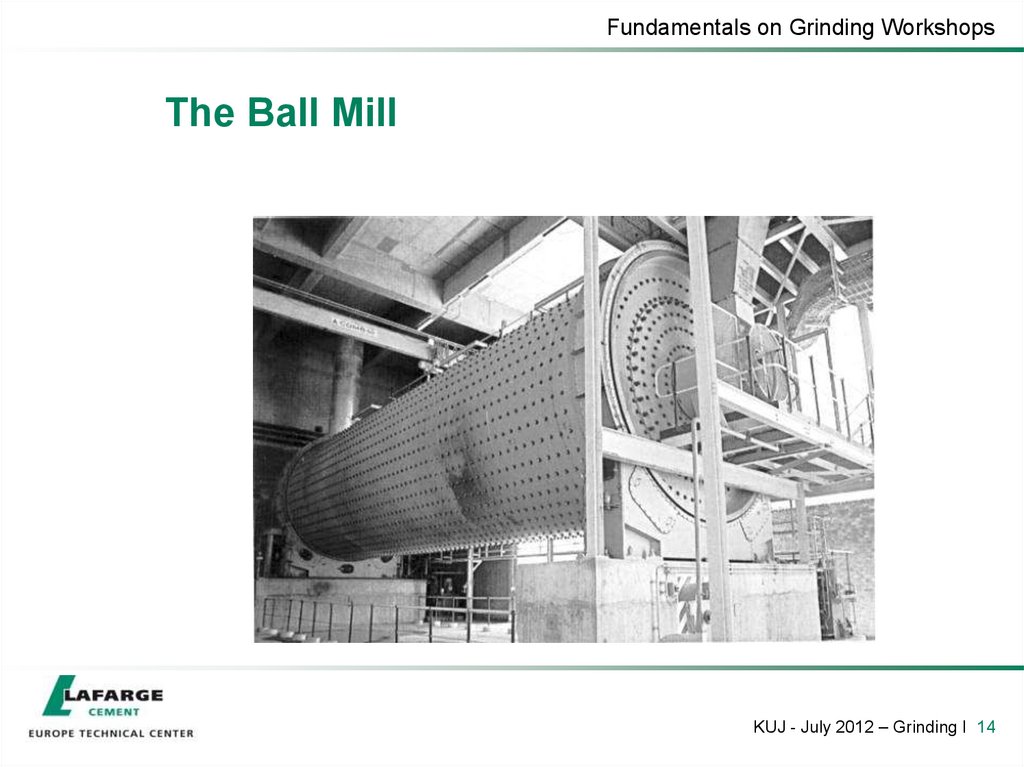

14. The Ball Mill

Fundamentals on Grinding WorkshopsThe Ball Mill

KUJ - July 2012 – Grinding I 14

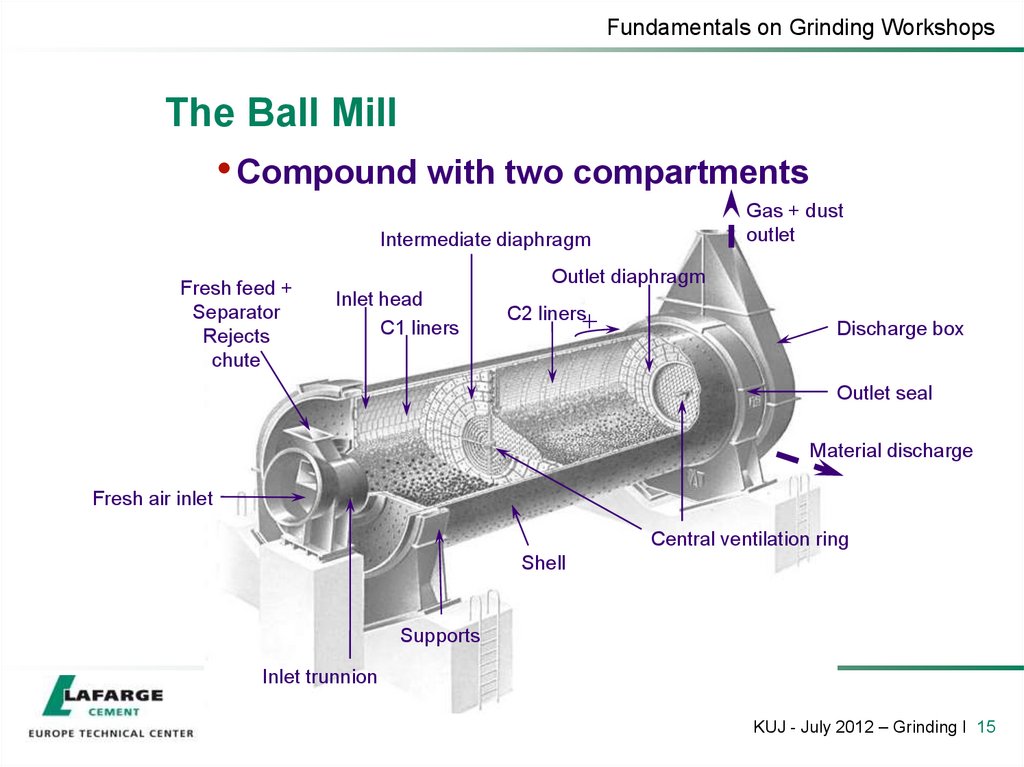

15. The Ball Mill

Fundamentals on Grinding WorkshopsThe Ball Mill

• Compound with two compartments

Gas + dust

outlet

Intermediate diaphragm

Fresh feed +

Separator

Rejects

chute

Outlet diaphragm

Inlet head

C1 liners

C2 liners

Discharge box

Outlet seal

Material discharge

Fresh air inlet

Central ventilation ring

Shell

Supports

Inlet trunnion

KUJ - July 2012 – Grinding I 15

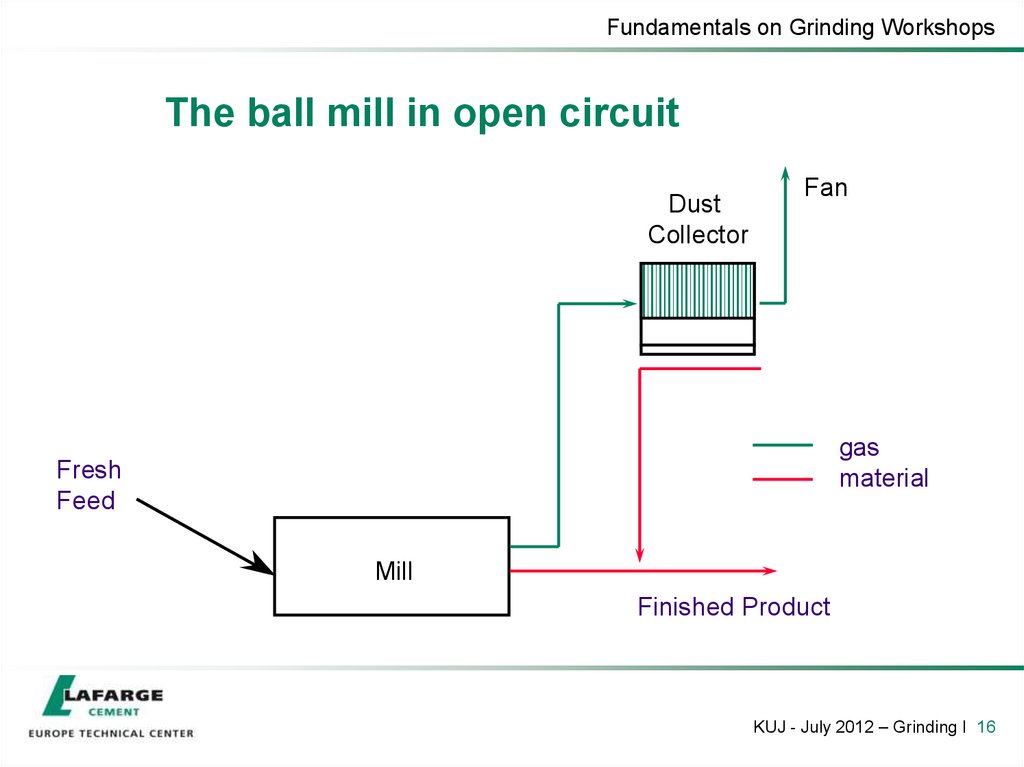

16. The ball mill in open circuit

Fundamentals on Grinding WorkshopsThe ball mill in open circuit

Dust

Collector

Fan

gas

material

Fresh

Feed

Mill

Finished Product

KUJ - July 2012 – Grinding I 16

17. The ball mill in open circuit

Fundamentals on Grinding WorkshopsThe ball mill in open circuit

• Advantages

Moderate investment costs

Simple operation

Simple maintenance

Highest reliability

• Disadvantages

little or no control of fineness

not adapted to high fineness (possibility of overgrinding)

broad particles size distribution

higher temperature of products

Limited drying capacity

KUJ - July 2012 – Grinding I 17

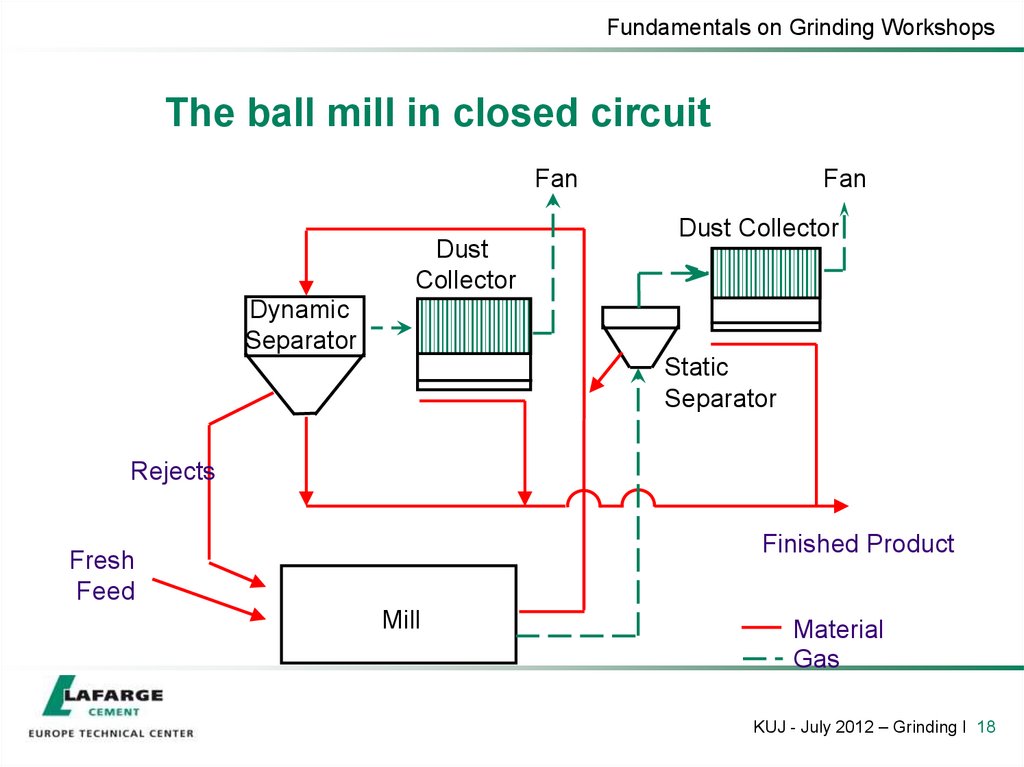

18. The ball mill in closed circuit

Fundamentals on Grinding WorkshopsThe ball mill in closed circuit

Fan

Dust

Collector

Fan

Dust Collector

Dynamic

Separator

Static

Separator

Rejects

Finished Product

Fresh

Feed

Mill

Material

Gas

KUJ - July 2012 – Grinding I 18

19. The ball mill in closed circuit

Fundamentals on Grinding WorkshopsThe ball mill in closed circuit

• General description

Better regularity thanks to a real control of the fineness

High fineness is possible

Higher flexibility and possibility of optimisation by product

Higher output, better efficiency

Possibility of higher mill ventilation

Better temperature control

• High mill ventilation

• Possibility to have a separated ventilation in the separator

• Narrow particle size distribution

• Higher investment costs

KUJ - July 2012 – Grinding I 19

20. The Bi-rotator Mill

Fundamentals on Grinding WorkshopsThe Bi-rotator Mill

KUJ - July 2012 – Grinding I 20

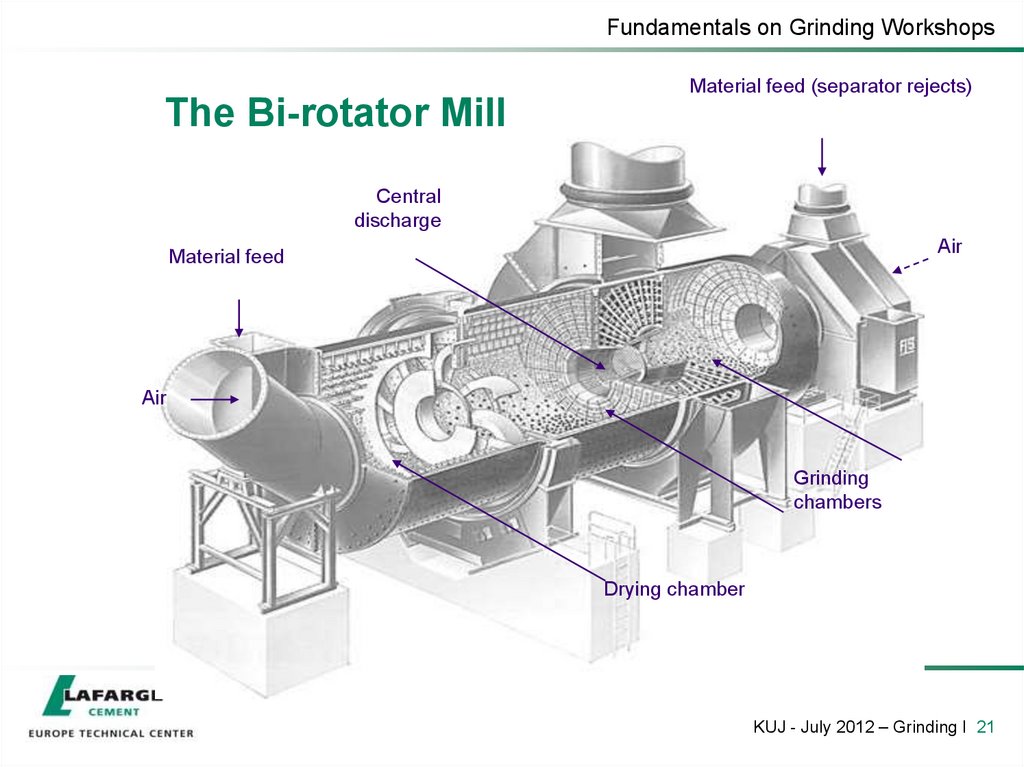

21. The Bi-rotator Mill

Fundamentals on Grinding WorkshopsMaterial feed (separator rejects)

The Bi-rotator Mill

Central

discharge

Air

Material feed

Air

Grinding

chambers

Drying chamber

KUJ - July 2012 – Grinding I 21

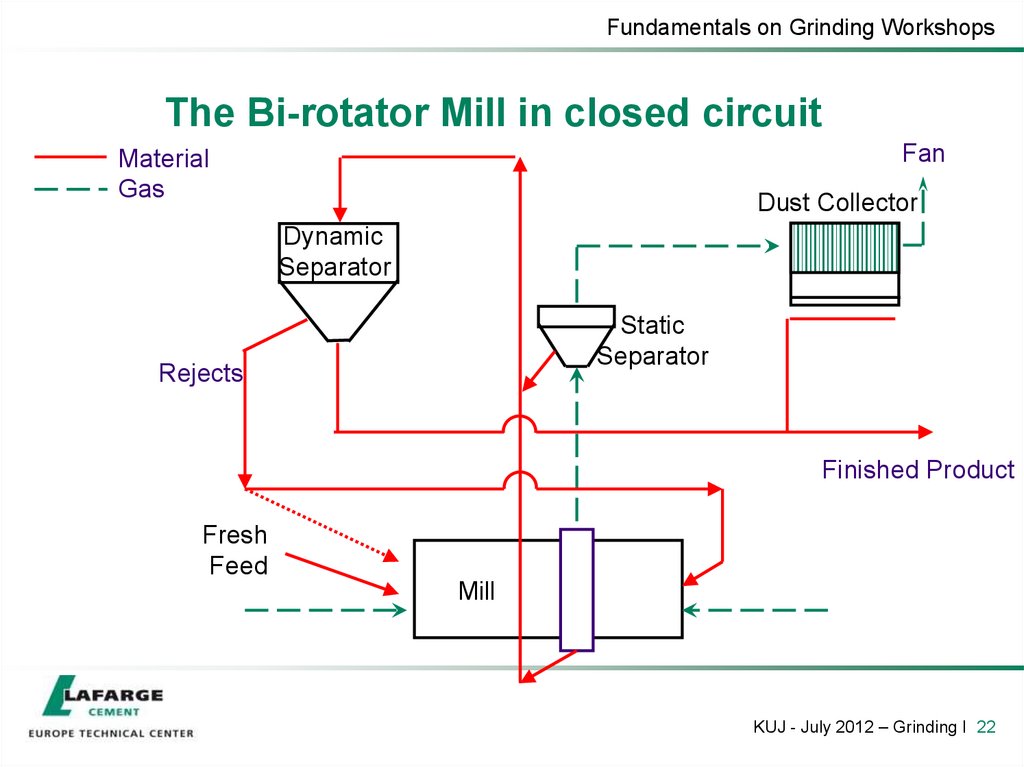

22. The Bi-rotator Mill in closed circuit

Fundamentals on Grinding WorkshopsThe Bi-rotator Mill in closed circuit

Fan

Material

Gas

Dust Collector

Dynamic

Separator

Static

Separator

Rejects

Finished Product

Fresh

Feed

Mill

KUJ - July 2012 – Grinding I 22

23. The Bi-rotator Mill

Fundamentals on Grinding WorkshopsThe Bi-rotator Mill

• Advantages

• High ventilation capacity for drying materials

• Disadvantages

• False air

KUJ - July 2012 – Grinding I 23

24. The Air-Swept Mill

Fundamentals on Grinding WorkshopsThe Air-Swept Mill

Material

Air + material

Intermediate

diaphragm

Air

Grinding

chamber

Drying

chamber

KUJ - July 2012 – Grinding I 24

25. The Air-Swept Mill in closed circuit

Fundamentals on Grinding WorkshopsThe Air-Swept Mill in closed circuit

Fan

Dust Collector

Material

Gas

Dynamic

Separator

Rejects

Finished Product

Fresh

Feed

Mill

KUJ - July 2012 – Grinding I 25

26. The Air-Swept Mill

Fundamentals on Grinding WorkshopsThe Air-Swept Mill

• Advantages

• High ventilation capacity to dry materials

• Disadvantages

• High specific power consumption due to swept solution

KUJ - July 2012 – Grinding I 26

27. Content

Fundamentals on Grinding WorkshopsContent

• Fundamentals on grinding

• Different types of ball mills

• Vertical mills

• Roller press

• Horomill

KUJ - July 2012 – Grinding I 27

28. The Vertical Mill

Fundamentals on Grinding WorkshopsThe Vertical Mill

Fine Product

Separator

Drive

Feed Material

HE Separator

Rejects Cone

Grinding Roller

Pressure

frame

Grinding Table

Port ring

Hydraulic

tensioning

cylinder

Air or Hot Gases

Mill Drive

KUJ - July 2012 – Grinding I 28

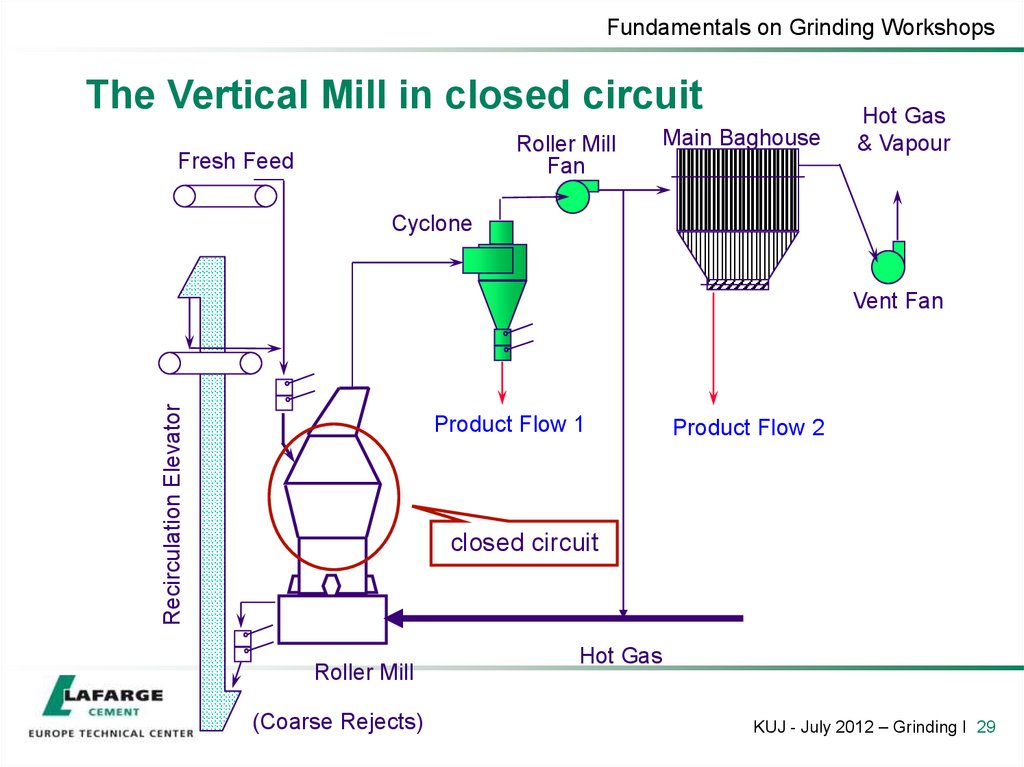

29. The Vertical Mill in closed circuit

Fundamentals on Grinding WorkshopsThe Vertical Mill in closed circuit

Roller Mill

Fan

Fresh Feed

Main Baghouse

Hot Gas

& Vapour

Cyclone

Recirculation Elevator

Vent Fan

Product Flow 1

Product Flow 2

closed circuit

Roller Mill

(Coarse Rejects)

Hot Gas

KUJ - July 2012 – Grinding I 29

30. The Vertical Mill

Fundamentals on Grinding WorkshopsThe Vertical Mill

• Advantages

Good efficiency factor

High drying capacity

Combined grinder, separator and dryer in one unit

Popular for coal and raw material grinding with high

moisture content

• Disadvantages

Complex operation

Reliability – maintenance costs

Vibrations

Management of gypsum dehydration in cement grinding

KUJ - July 2012 – Grinding I 30

31. Content

Fundamentals on Grinding WorkshopsContent

• Fundamentals on grinding

• Different types of ball mills

• Vertical mills

• Roller press

• Horomill

KUJ - July 2012 – Grinding I 31

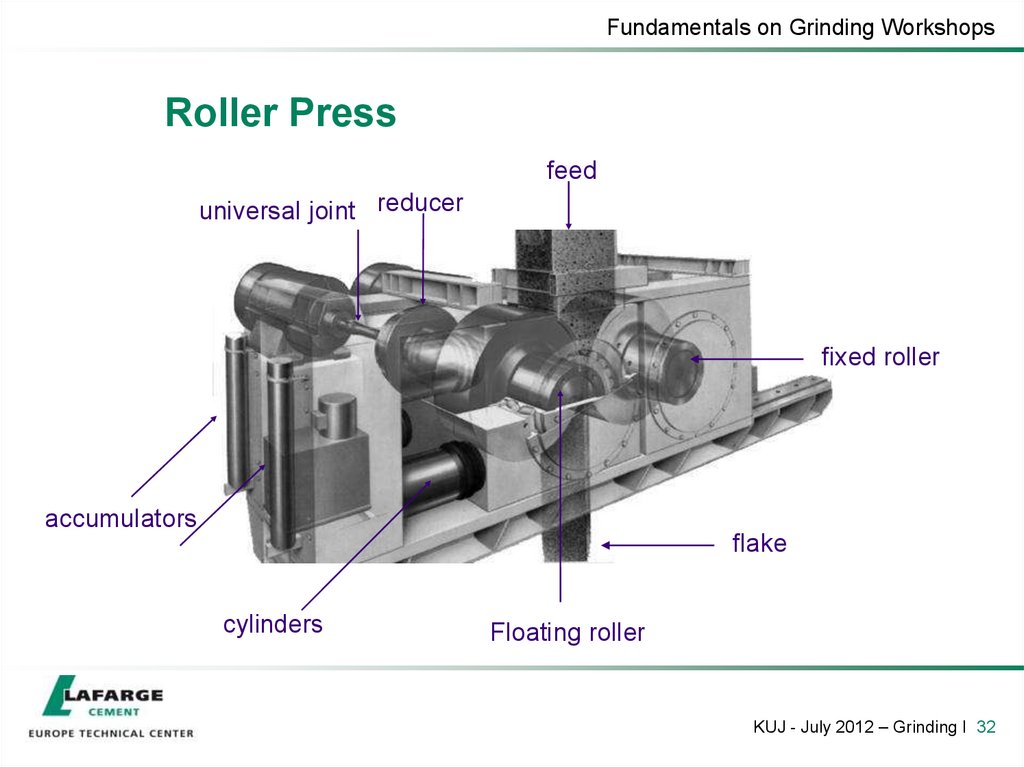

32. Roller Press

Fundamentals on Grinding WorkshopsRoller Press

feed

universal joint reducer

fixed roller

accumulators

flake

cylinders

Floating roller

KUJ - July 2012 – Grinding I 32

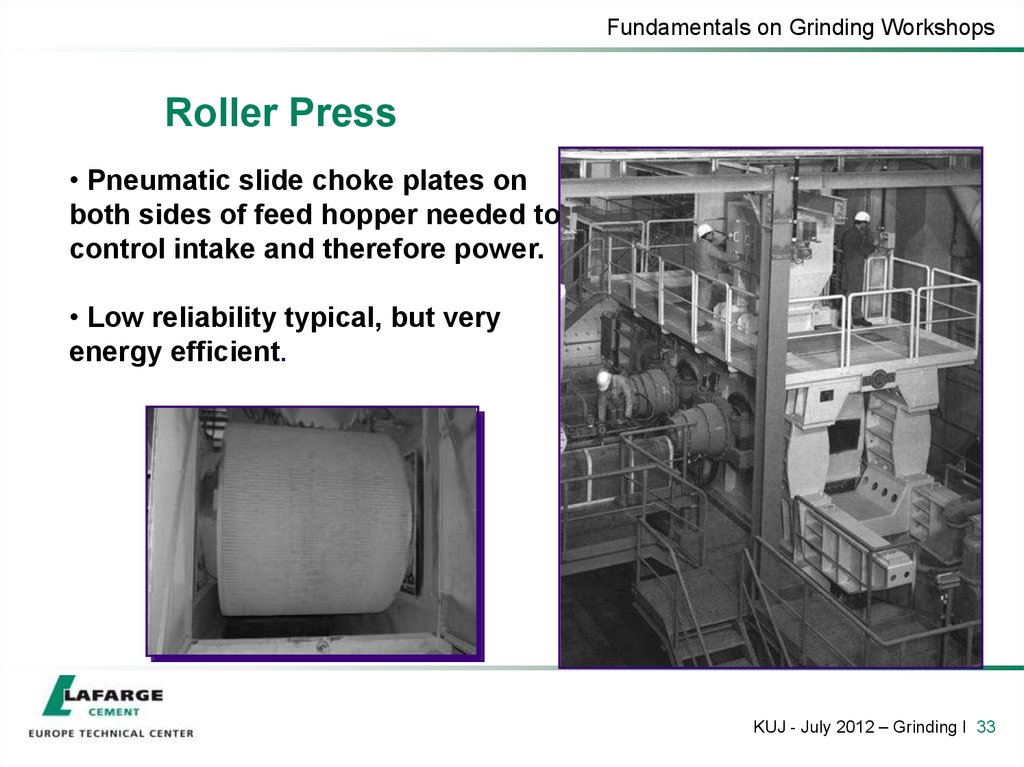

33. Roller Press

Fundamentals on Grinding WorkshopsRoller Press

• Pneumatic slide choke plates on

both sides of feed hopper needed to

control intake and therefore power.

• Low reliability typical, but very

energy efficient.

KUJ - July 2012 – Grinding I 33

34. Roller Press

Fundamentals on Grinding WorkshopsRoller Press

• Advantages

• High efficiency factor

• Compact installation

• High production increase when used as pregrinding

• Disadvantages

High investment costs

Complex operation

Reliabilty

Limited drying capacity

KUJ - July 2012 – Grinding I 34

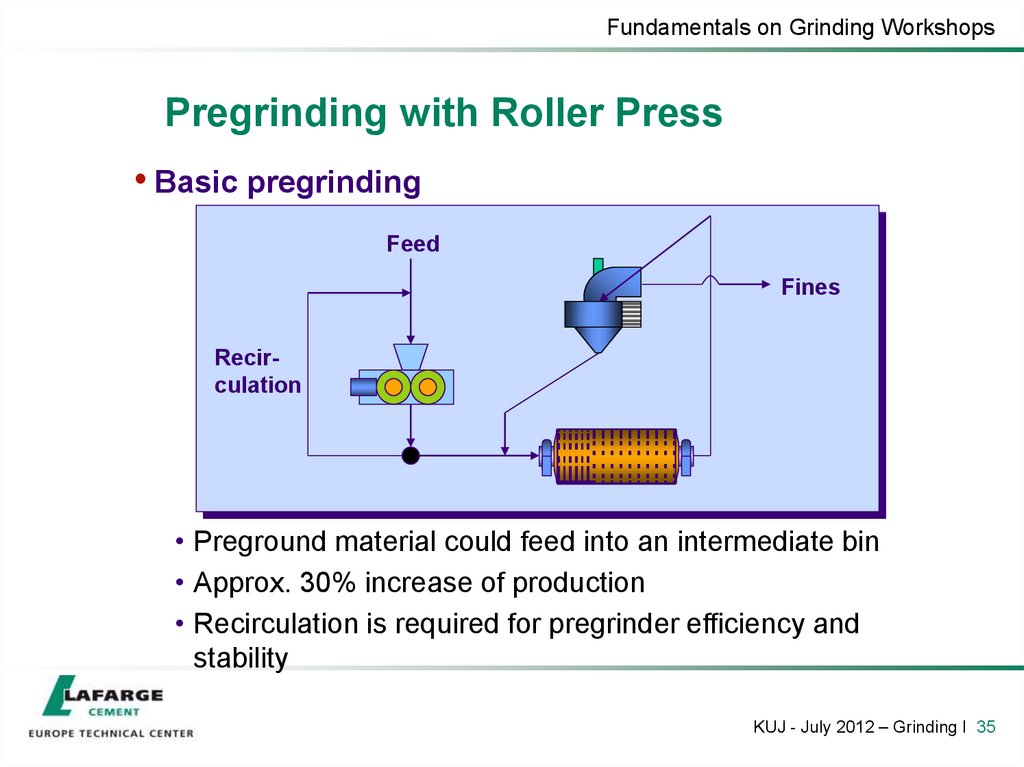

35. Pregrinding with Roller Press

Fundamentals on Grinding WorkshopsPregrinding with Roller Press

• Basic pregrinding

Feed

Fines

Recirculation

• Preground material could feed into an intermediate bin

• Approx. 30% increase of production

• Recirculation is required for pregrinder efficiency and

stability

KUJ - July 2012 – Grinding I 35

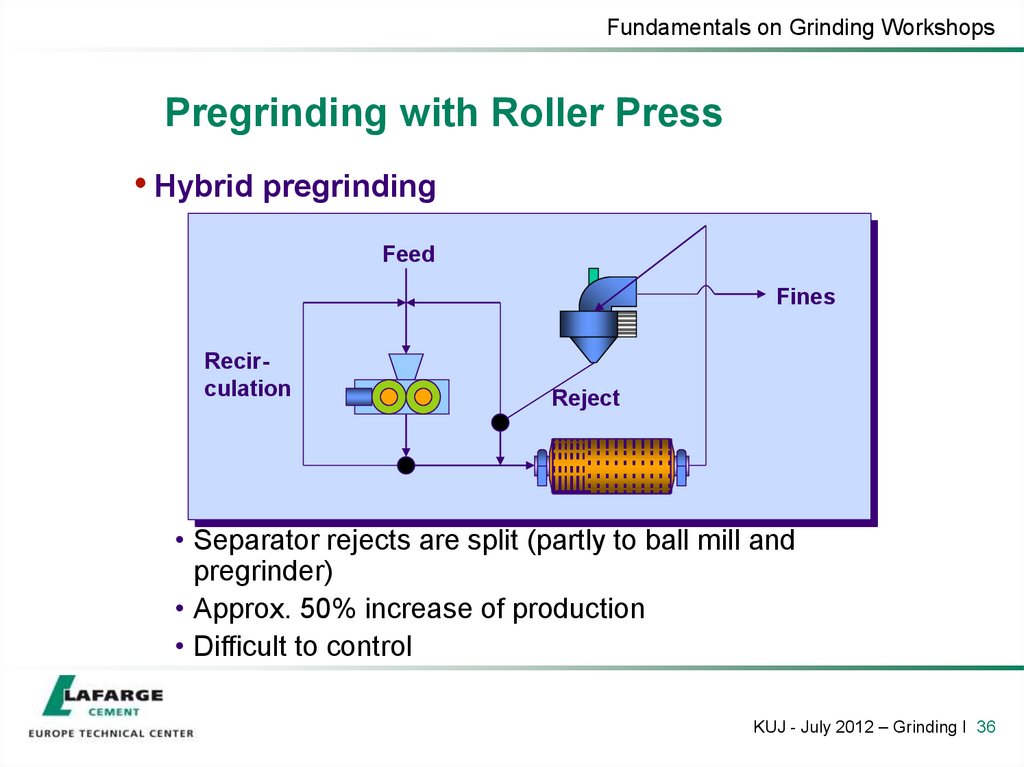

36. Pregrinding with Roller Press

Fundamentals on Grinding WorkshopsPregrinding with Roller Press

• Hybrid pregrinding

Feed

Fines

Recirculation

Reject

• Separator rejects are split (partly to ball mill and

pregrinder)

• Approx. 50% increase of production

• Difficult to control

KUJ - July 2012 – Grinding I 36

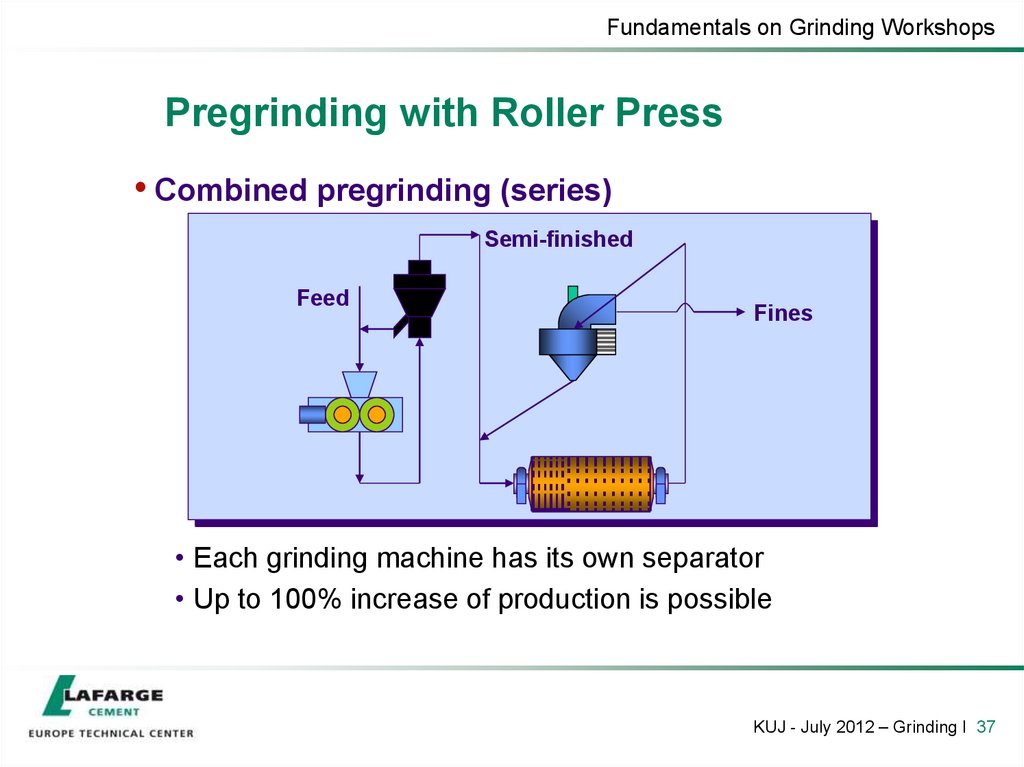

37. Pregrinding with Roller Press

Fundamentals on Grinding WorkshopsPregrinding with Roller Press

• Combined pregrinding (series)

Semi-finished

Feed

Fines

• Each grinding machine has its own separator

• Up to 100% increase of production is possible

KUJ - July 2012 – Grinding I 37

38. Content

Fundamentals on Grinding WorkshopsContent

• Fundamentals on grinding

• Different types of ball mills

• Vertical mills

• Roller press

• Horomill

KUJ - July 2012 – Grinding I 38

39. Horomill

Fundamentals on Grinding WorkshopsHoromill

• General description

Horizontal mill

Single roller inside a motorized tube shell

Slide shoe (thrust pad) bearings

Girth gear and pinion drive

Designed by FCB

KUJ - July 2012 – Grinding I 39

40. Horomill

Fundamentals on Grinding WorkshopsHoromill

Scraper and feed

forward plate

roller

pinion shaft

cylinder

KUJ - July 2012 – Grinding I 40

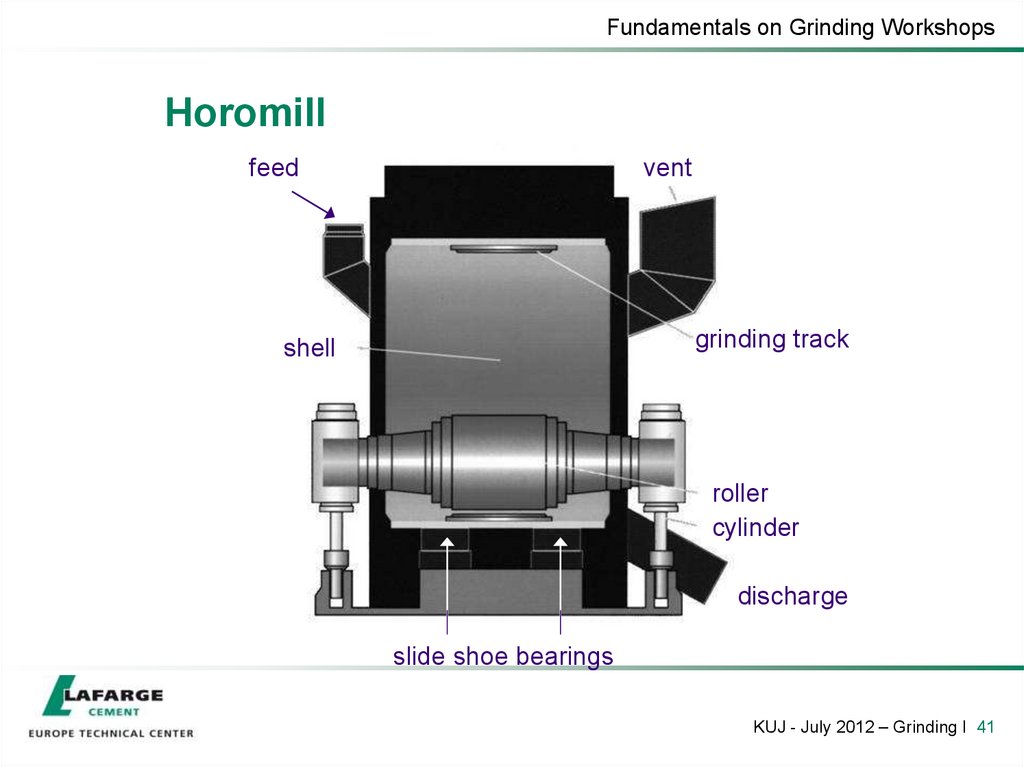

41. Horomill

Fundamentals on Grinding WorkshopsHoromill

feed

vent

grinding track

shell

roller

cylinder

discharge

slide shoe bearings

KUJ - July 2012 – Grinding I 41

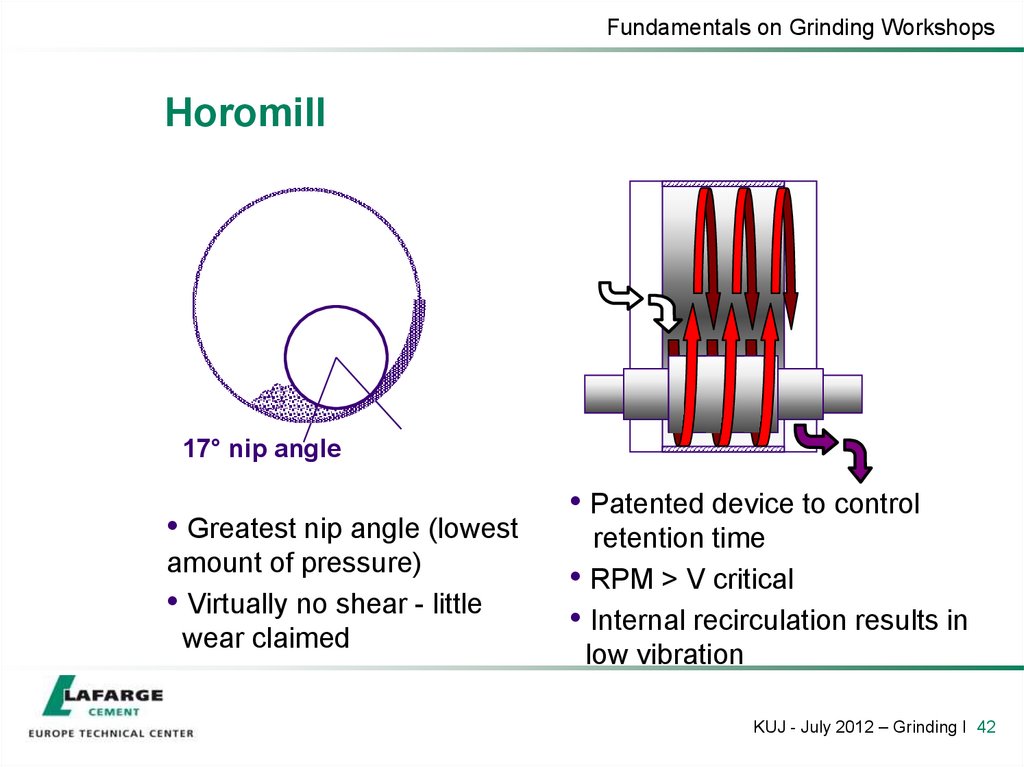

42. Horomill

Fundamentals on Grinding WorkshopsHoromill

17° nip angle

• Greatest nip angle (lowest

amount of pressure)

• Virtually no shear - little

wear claimed

• Patented device to control

retention time

• RPM > V critical

• Internal recirculation results in

low vibration

KUJ - July 2012 – Grinding I 42

43. Ways to upgrade a workshop

Fundamentals on Grinding WorkshopsWays to upgrade a workshop

• Optimisation of workshop operations

Ball charge design

Ventilation balance

Circulating load

Increase of the ball mill speed (target of 75% Vcrit)

• Replacement of the workshop separator with a third

generation one

KUJ - July 2012 – Grinding I 43

Промышленность

Промышленность