Похожие презентации:

Classifying. Why a separator?

1. CLASSIFYING

Key Separator RelationsCirculating Load

Tromp Curve

2. Why a separator?

ClassifyingWhy a separator?

• Open circuit grinding is not very efficient:

• Overgrinding of fines

• Useless for quality

• Coating

• No way to be sure of coarse rejects

• Limitation of mill ventilation

• Solution = separator

• Quick grinding is followed by extraction of the fines

already produced, rejects going back to mill inlet

• Retention time in the mill is reduced (20 to 5 min)

• Direct actuator on finish product fineness

KUJ - July 2012 – Grinding I - 2

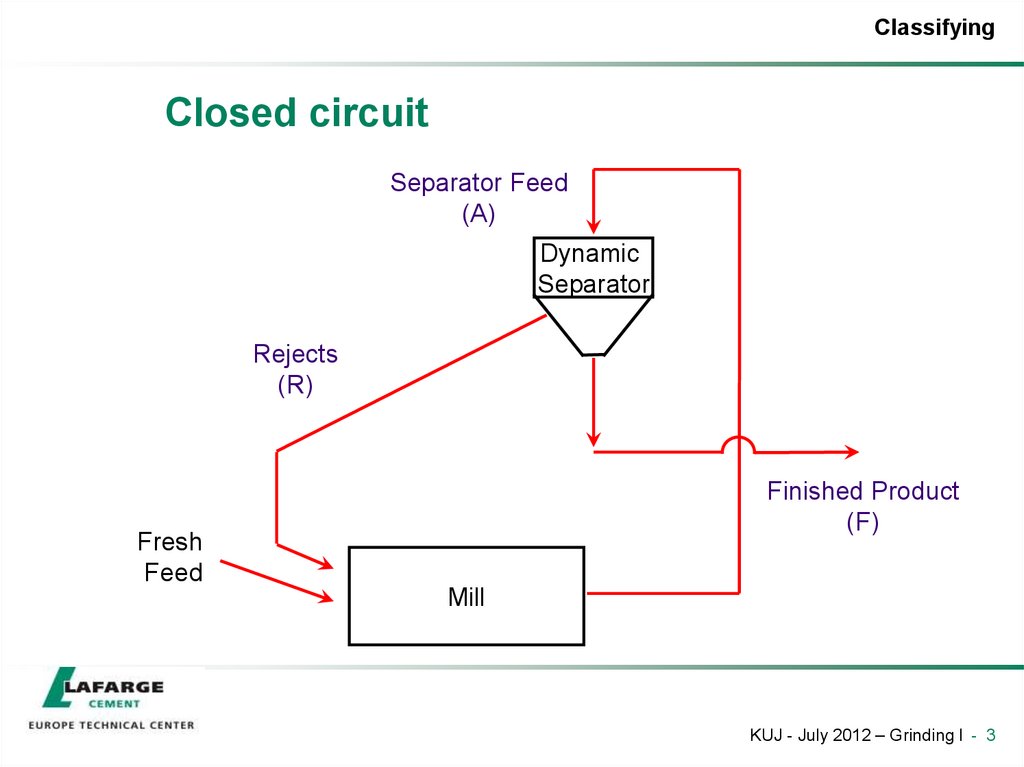

3. Closed circuit

ClassifyingClosed circuit

Separator Feed

(A)

Dynamic

Separator

Rejects

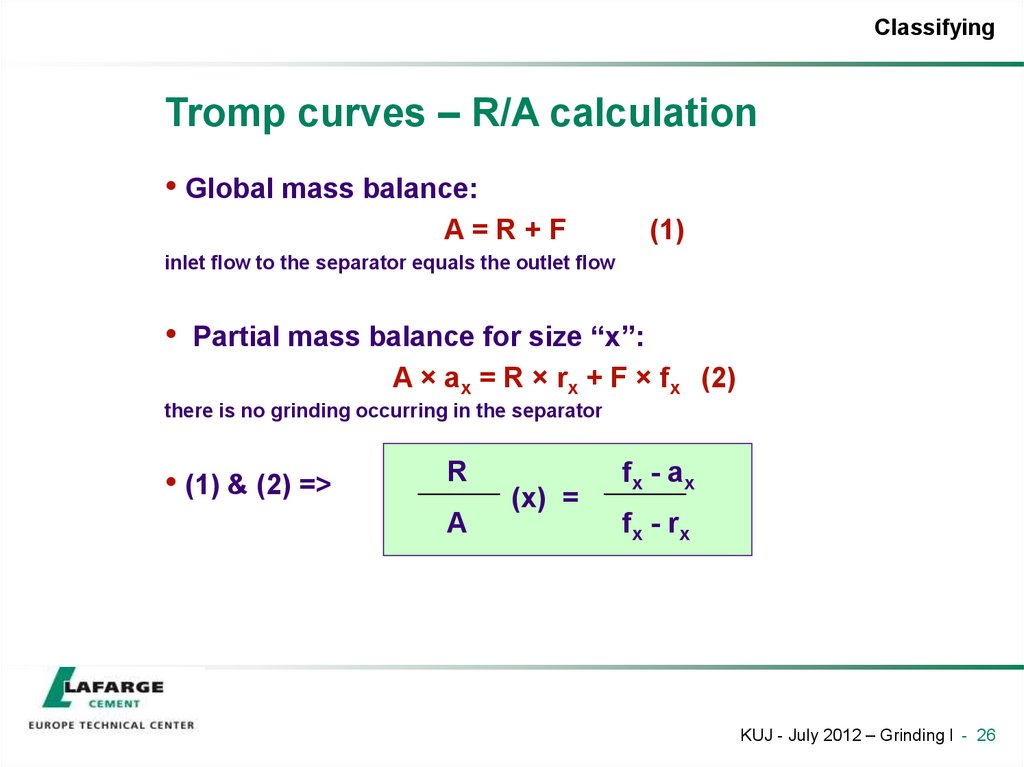

(R)

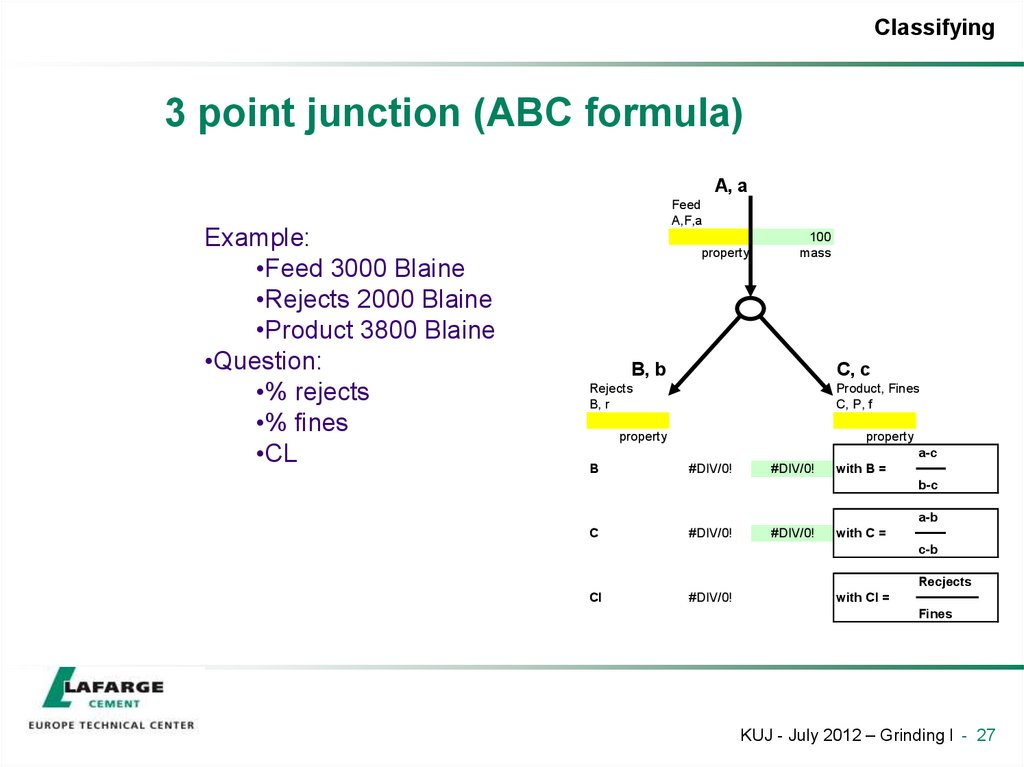

Finished Product

(F)

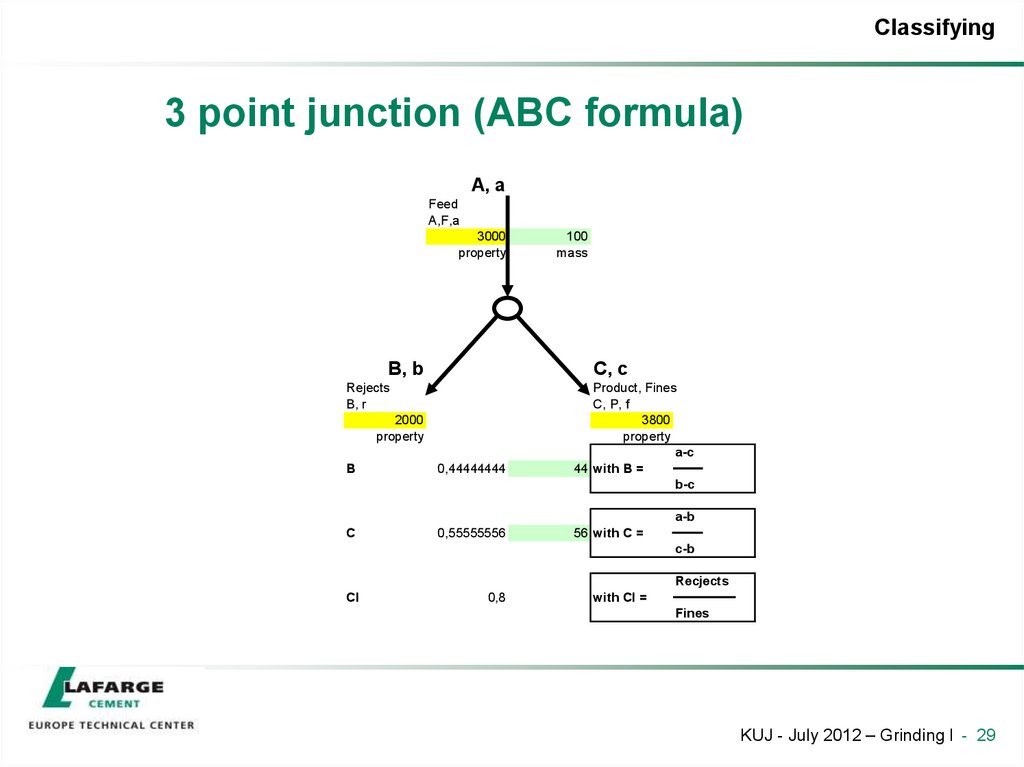

Fresh

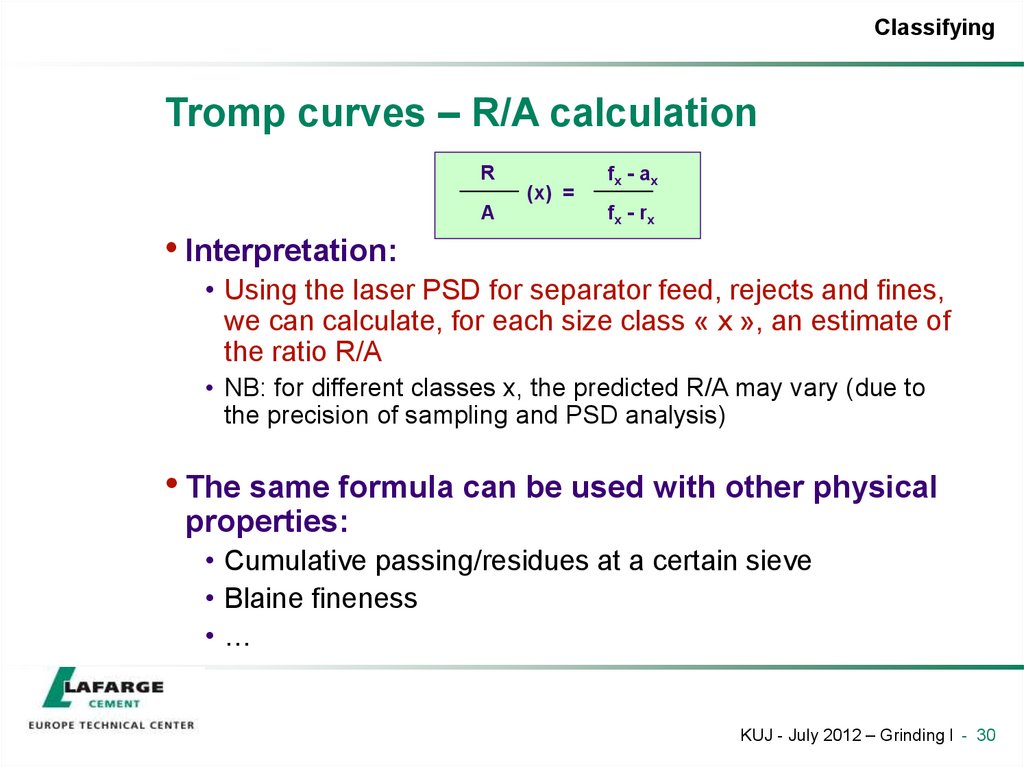

Feed

Mill

KUJ - July 2012 – Grinding I - 3

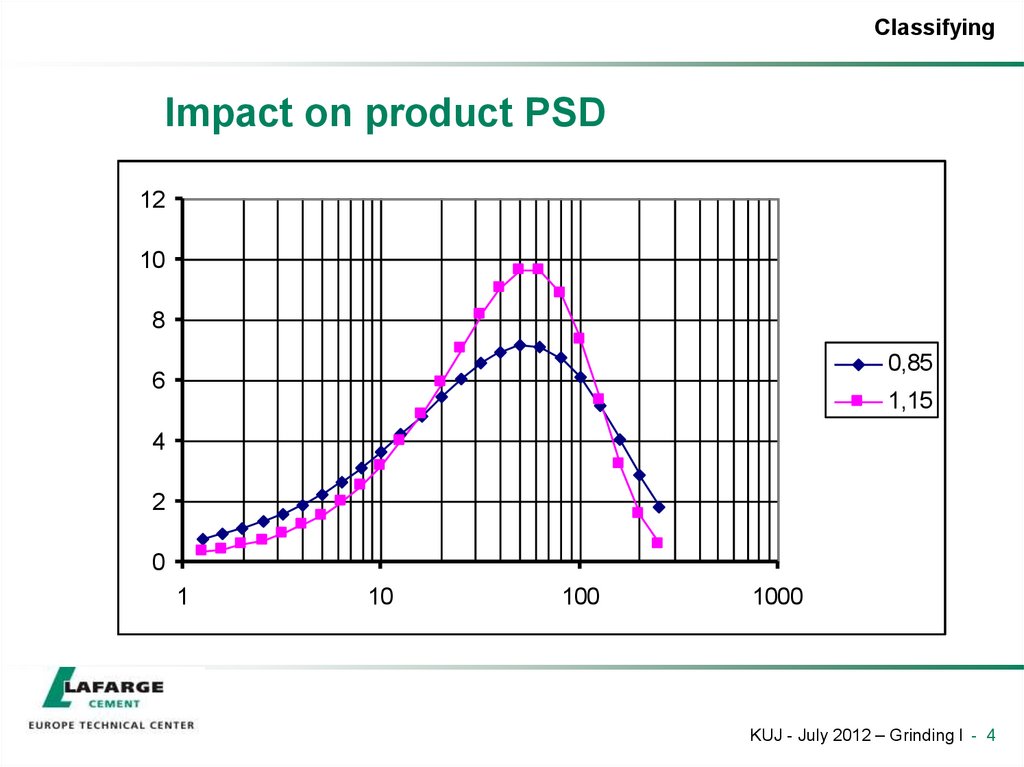

4. Impact on product PSD

ClassifyingImpact on product PSD

12

10

8

0,85

0,85

1,15

6

4

2

0

1

10

100

1000

KUJ - July 2012 – Grinding I - 4

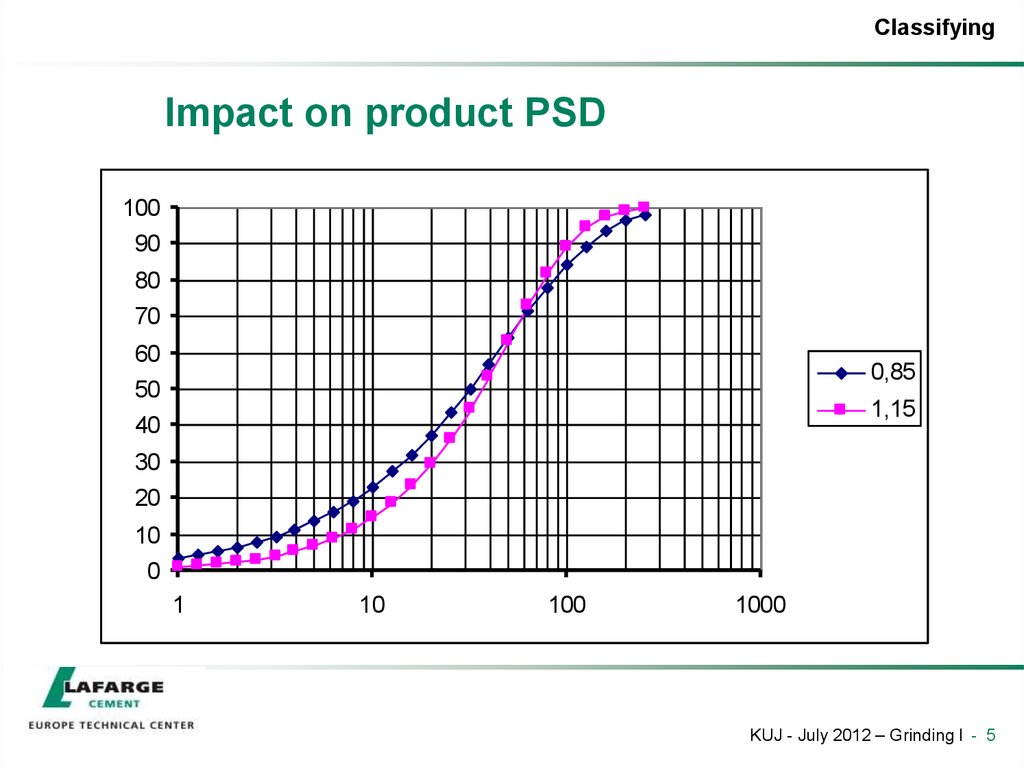

5. Impact on product PSD

ClassifyingImpact on product PSD

100

90

80

70

60

0,85

50

1,15

40

30

20

10

0

1

10

100

1000

KUJ - July 2012 – Grinding I - 5

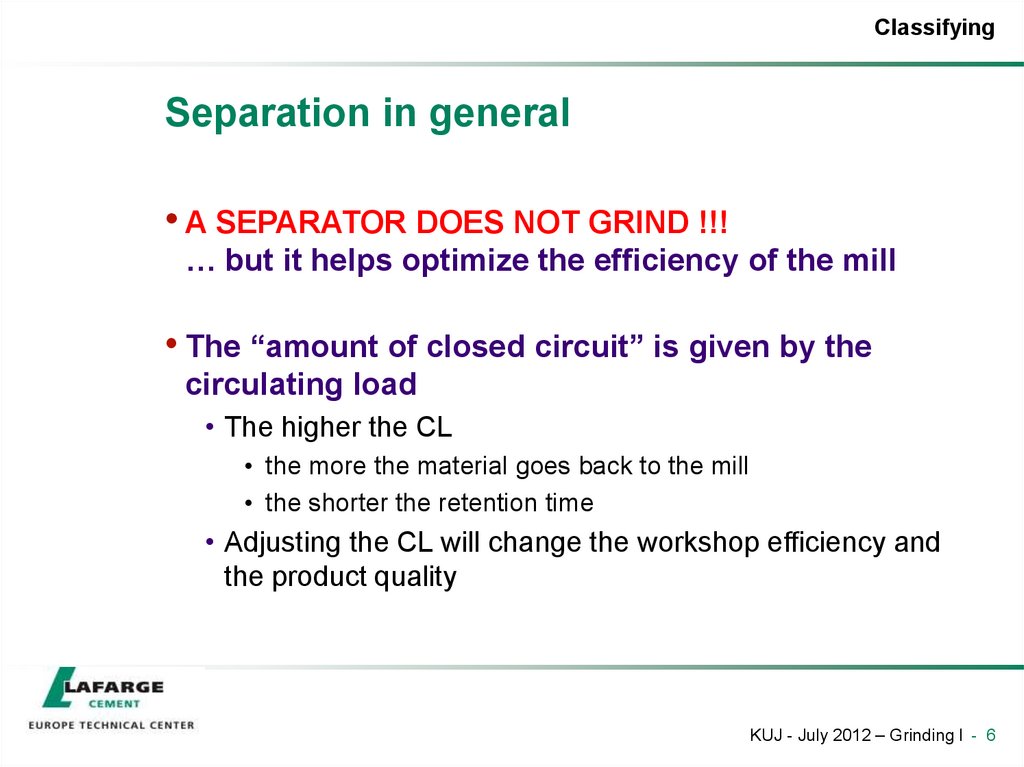

6. Separation in general

ClassifyingSeparation in general

• A SEPARATOR DOES NOT GRIND !!!

… but it helps optimize the efficiency of the mill

• The “amount of closed circuit” is given by the

circulating load

• The higher the CL

• the more the material goes back to the mill

• the shorter the retention time

• Adjusting the CL will change the workshop efficiency and

the product quality

KUJ - July 2012 – Grinding I - 6

7. Circulating Load (CL)

ClassifyingCirculating Load (CL)

• How can we determine it?

A: Separator Feed

• C.L. = R/F (used by Lafarge)

• Others define it as C.L. = A/F

• Or A/F = 1+ R/F

• Meaning?

• Number of material passages

through the mill, in addition to the

first one

• What is the best CL?

The best is unique to each

circuit and can only be found

by experimentation

R: Rejects

(or Tails)

F: Fines

KUJ - July 2012 – Grinding I - 7

8. Separation efficiency

ClassifyingSeparation efficiency

• How do we assess the efficiency of separation?

• The tool is the separation curve, or TROMP CURVE

• First, what do we expect of a separator?

•…

KUJ - July 2012 – Grinding I - 8

9. Separation efficiency

ClassifyingSeparation efficiency

• What do we expect of a separator?

100%

9

90%

8

80%

7

70%

6

60%

5

50%

4

40%

3

30%

2

20%

1

10%

0

0%

Feed PSD

Feed

Feed Feed

Rejects

Feed

Rejects

Ideal

Rejects

Fines

FinesFines

Ideal

P(x)

Ideal separation

Real separation

Tromp curve

1,

0

1,

3

1,

6

2,

0

2,

5

3,

2

4,

0

5,

0

6,

3

8,

0

110

0,,0

0

112

2,,0

0

116

6,,0

0

220

0,,0

0

225

5,,0

0

332

2,,0

0

440

0,,0

0

5500,

,00

6633,

,00

8800

,,00

10

KUJ - July 2012 – Grinding I - 9

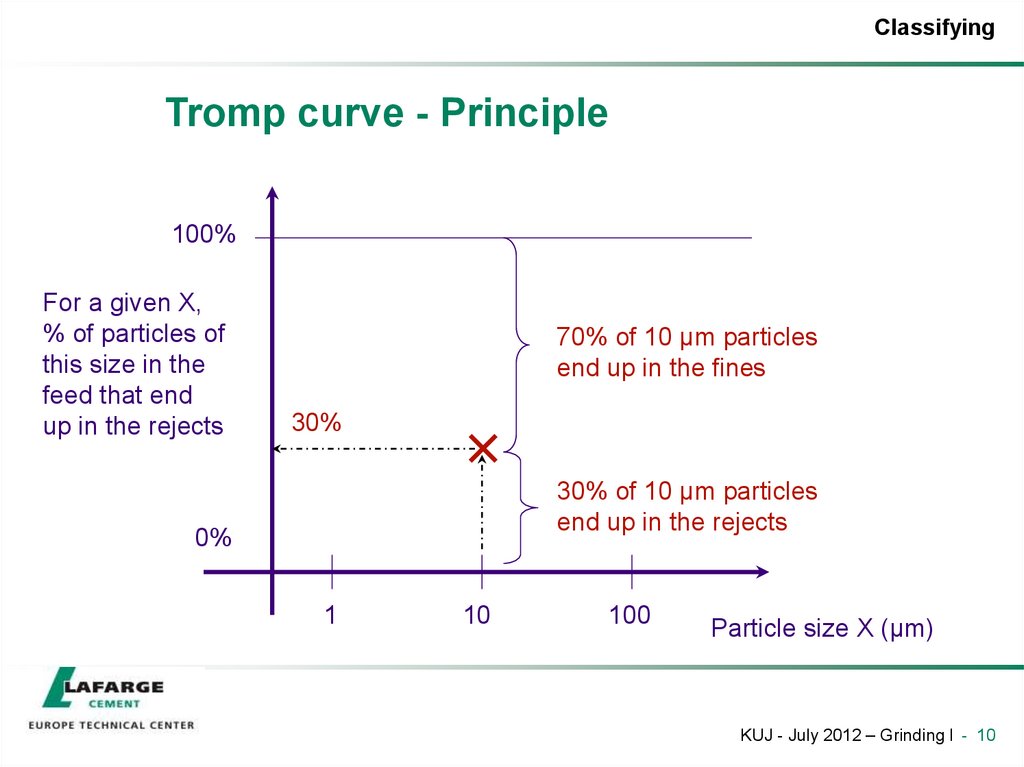

10. Tromp curve - Principle

ClassifyingTromp curve - Principle

100%

For a given X,

% of particles of

this size in the

feed that end

up in the rejects

70% of 10 µm particles

end up in the fines

30%

30% of 10 µm particles

end up in the rejects

0%

1

10

100

Particle size X (µm)

KUJ - July 2012 – Grinding I - 10

11. Tromp curve – example

ClassifyingTromp curve – example

• Let’s take the example of a sieve:

KUJ - July 2012 – Grinding I - 11

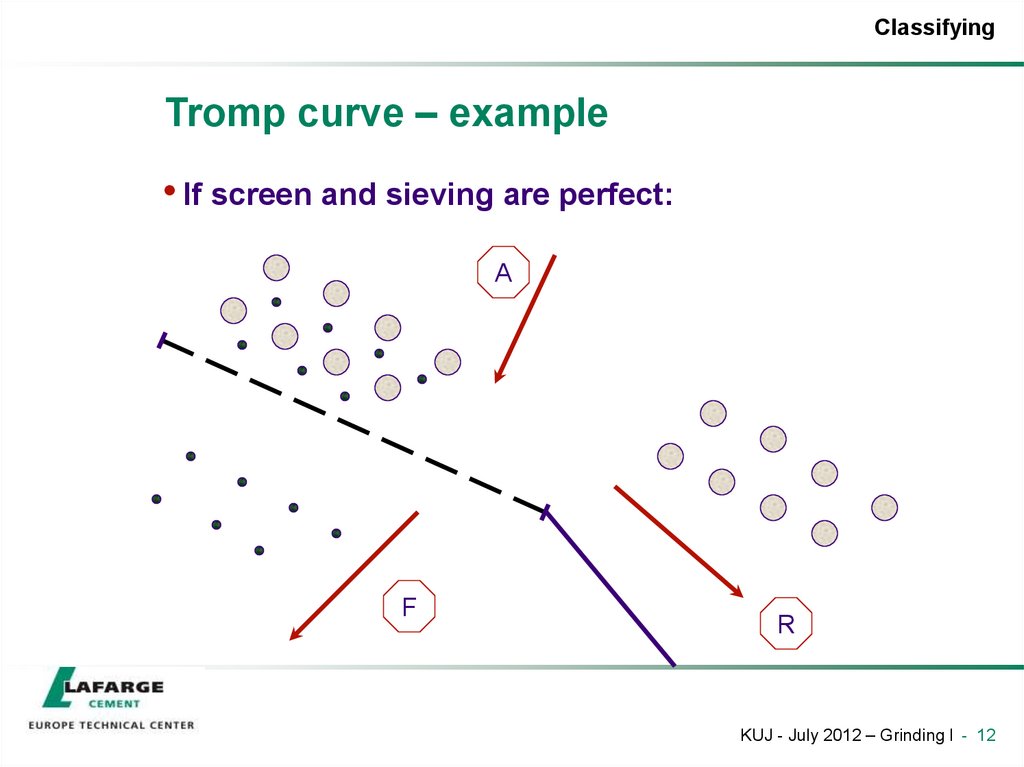

12. Tromp curve – example

ClassifyingTromp curve – example

• If screen and sieving are perfect:

A

F

R

KUJ - July 2012 – Grinding I - 12

13. Tromp curve – Perfect screen

ClassifyingTromp curve – Perfect screen

100%

For a given X,

% of particles of

this size in the

feed that end

up in the rejects

Below 50 µm, all

particles end up in

the fines

Above 50 µm, all

particles end up in

the rejects

0%

1

10

50µm 100

Particle size X (µm)

KUJ - July 2012 – Grinding I - 13

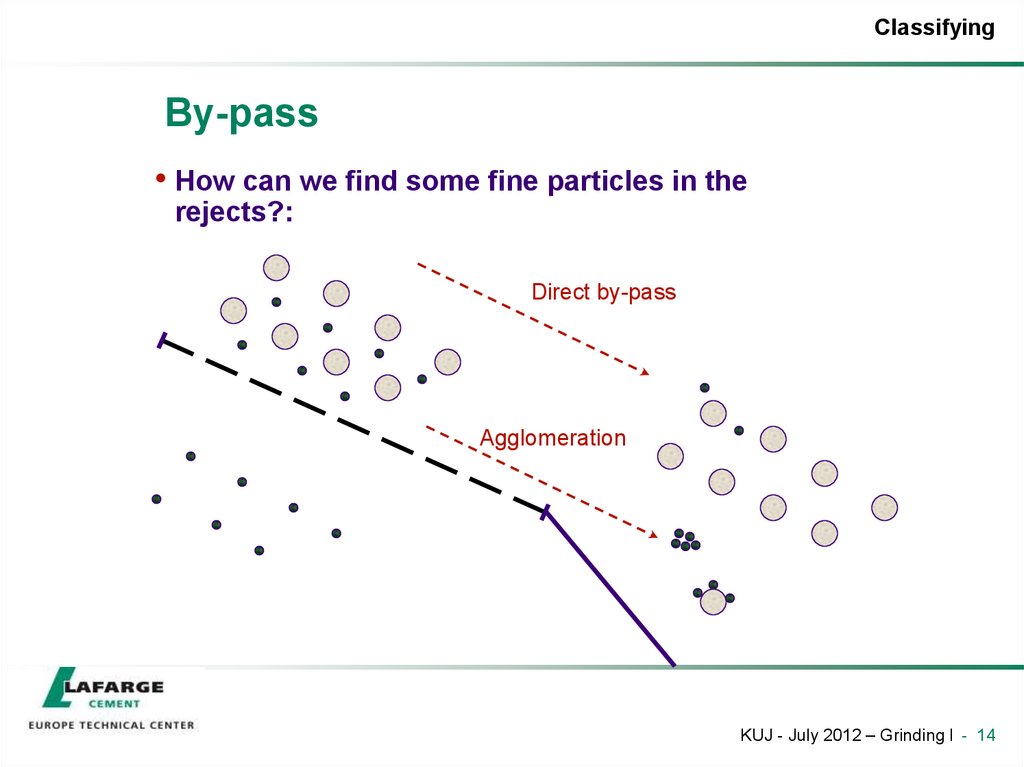

14. By-pass

ClassifyingBy-pass

• How can we find some fine particles in the

rejects?:

Direct by-pass

Agglomeration

KUJ - July 2012 – Grinding I - 14

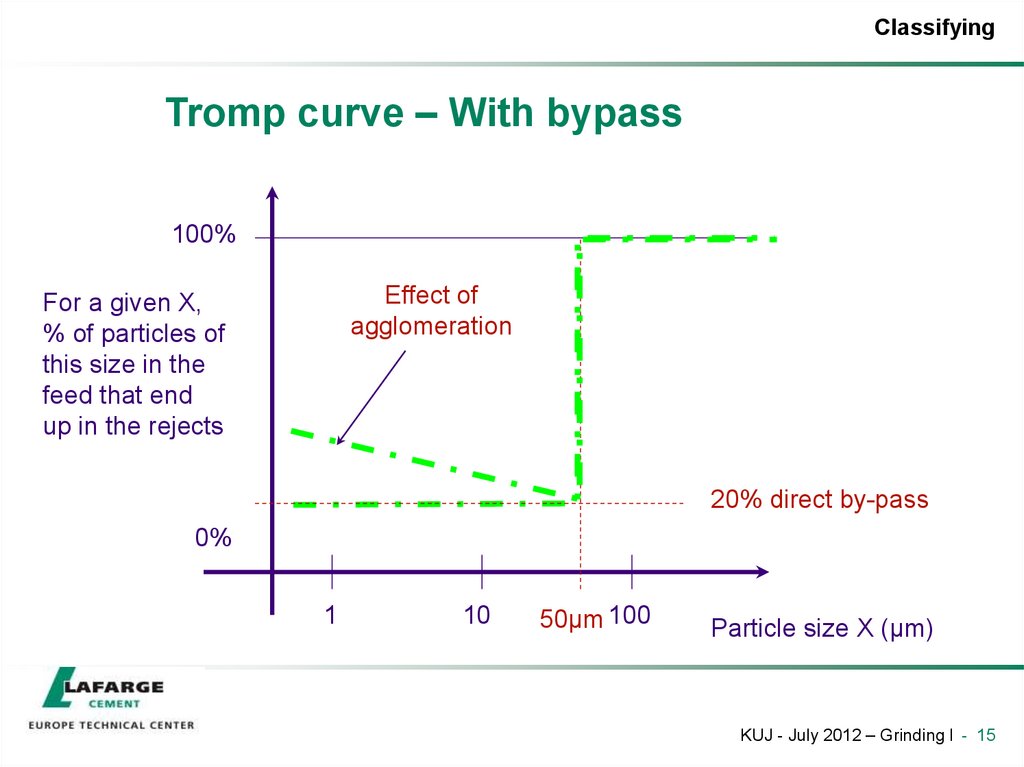

15. Tromp curve – With bypass

ClassifyingTromp curve – With bypass

100%

Effect of

agglomeration

For a given X,

% of particles of

this size in the

feed that end

up in the rejects

20% direct by-pass

0%

1

10

50µm 100

Particle size X (µm)

KUJ - July 2012 – Grinding I - 15

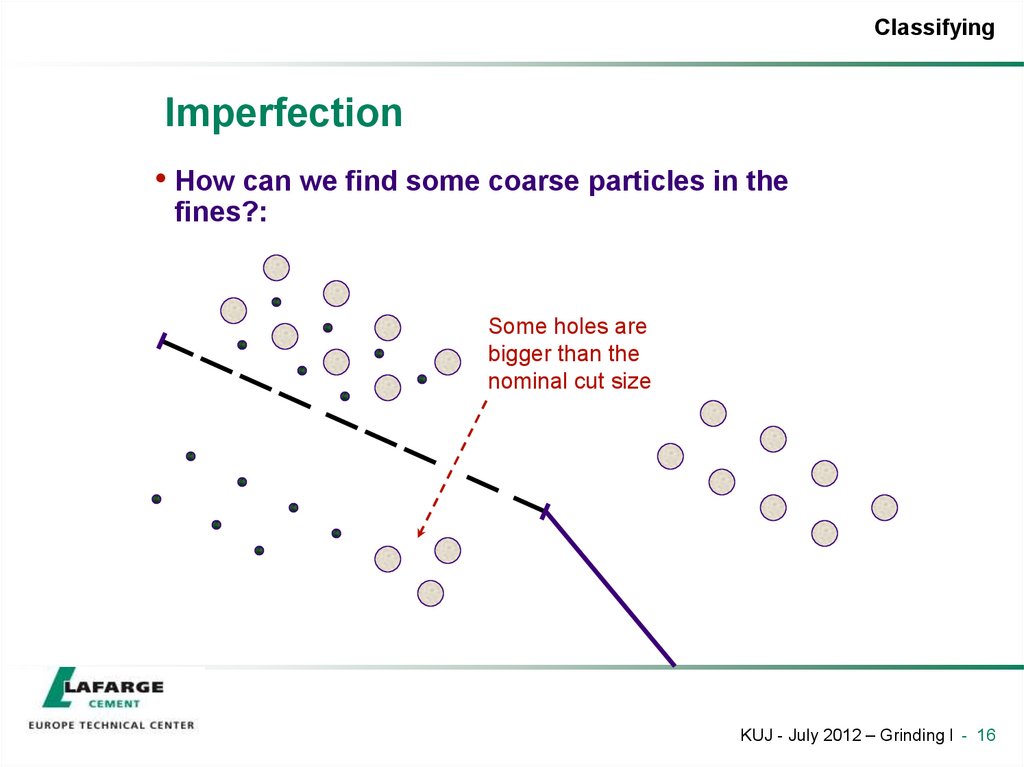

16. Imperfection

ClassifyingImperfection

• How can we find some coarse particles in the

fines?:

Some holes are

bigger than the

nominal cut size

KUJ - July 2012 – Grinding I - 16

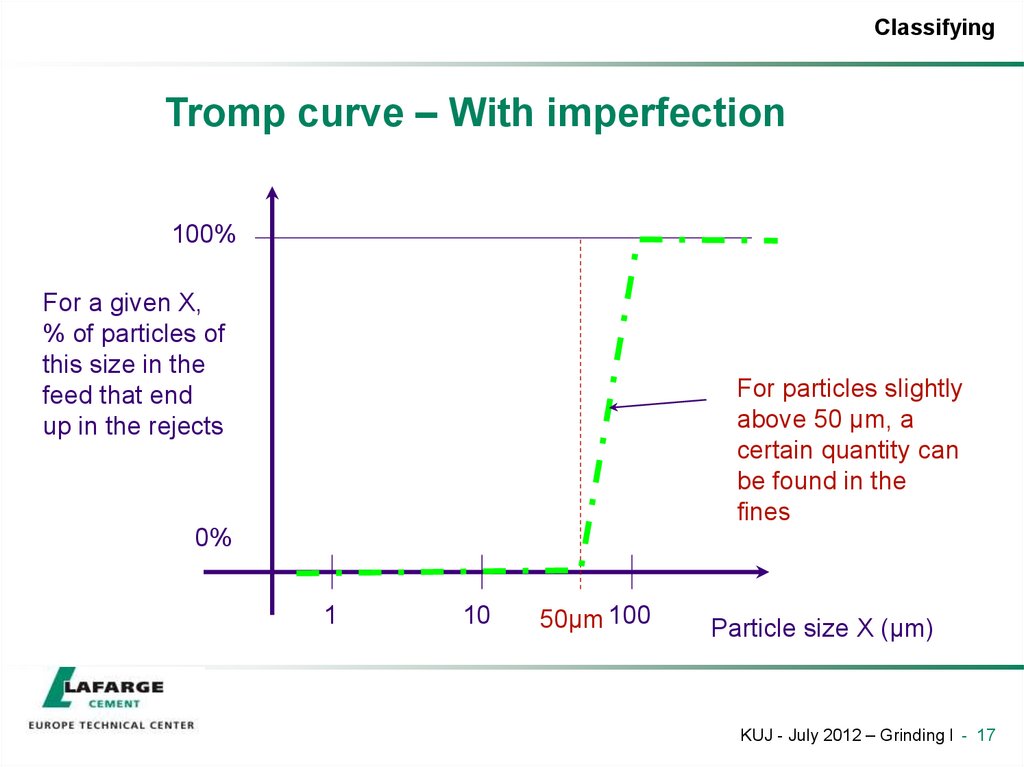

17. Tromp curve – With imperfection

ClassifyingTromp curve – With imperfection

100%

For a given X,

% of particles of

this size in the

feed that end

up in the rejects

For particles slightly

above 50 µm, a

certain quantity can

be found in the

fines

0%

1

10

50µm 100

Particle size X (µm)

KUJ - July 2012 – Grinding I - 17

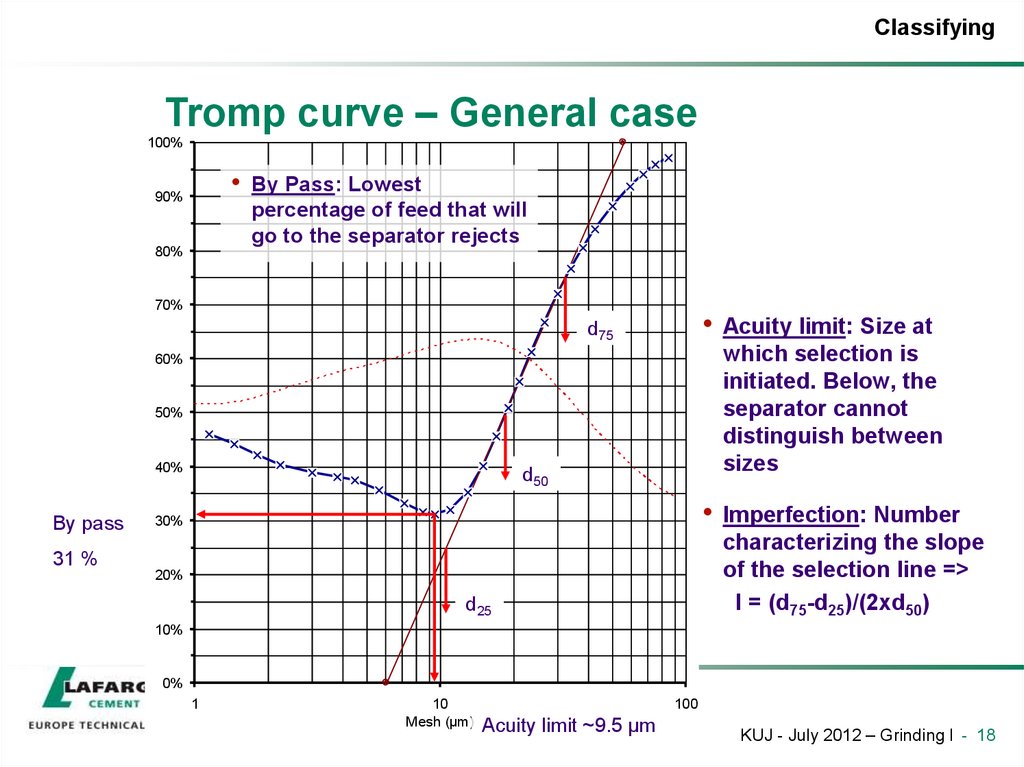

18. Tromp curve – General case

ClassifyingTromp curve – General case

100%

90%

80%

By Pass: Lowest

percentage of feed that will

go to the separator rejects

70%

d75

Acuity limit: Size at

which selection is

initiated. Below, the

separator cannot

distinguish between

sizes

Imperfection: Number

characterizing the slope

of the selection line =>

I = (d75-d25)/(2xd50)

60%

50%

40%

By pass

31 %

d50

30%

20%

d25

10%

0%

1

10

Mesh (µm)

100

Acuity limit ~9.5 µm

KUJ - July 2012 – Grinding I - 18

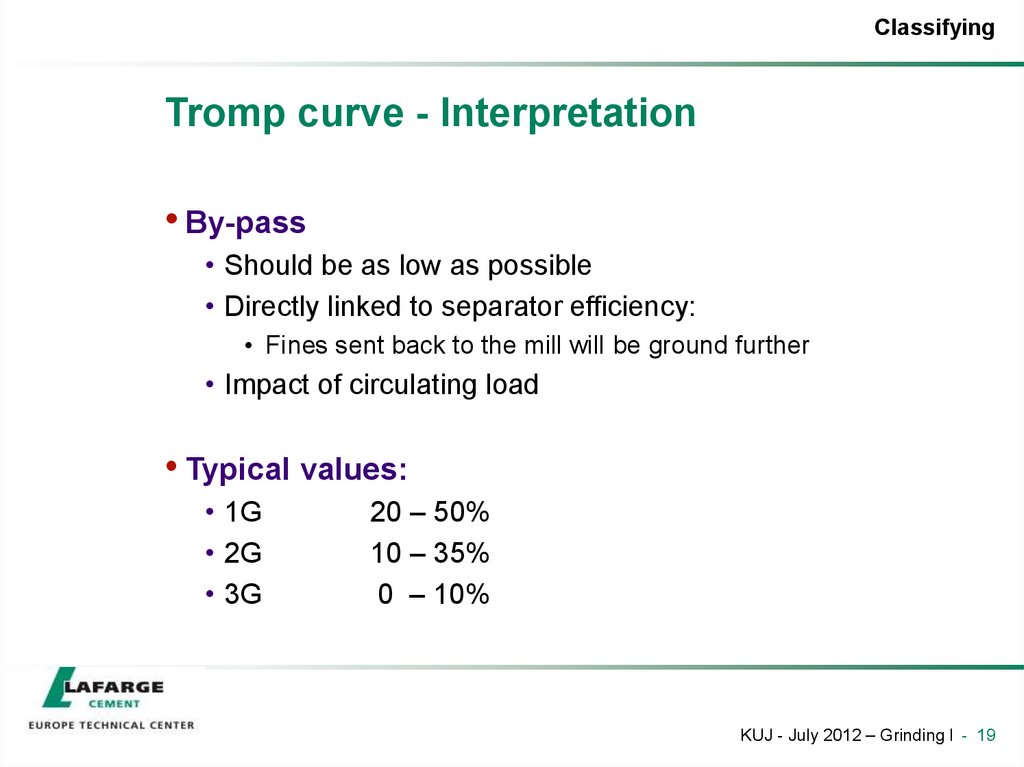

19. Tromp curve - Interpretation

ClassifyingTromp curve - Interpretation

• By-pass

• Should be as low as possible

• Directly linked to separator efficiency:

• Fines sent back to the mill will be ground further

• Impact of circulating load

• Typical values:

• 1G

• 2G

• 3G

20 – 50%

10 – 35%

0 – 10%

KUJ - July 2012 – Grinding I - 19

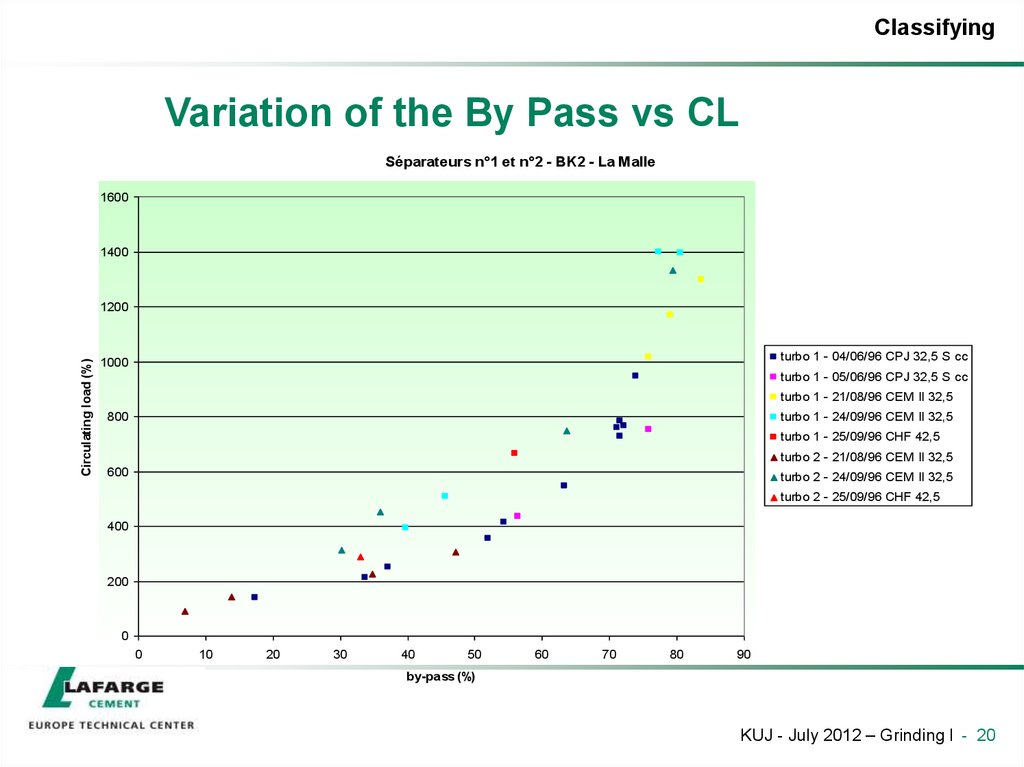

20. Variation of the By Pass vs CL

ClassifyingVariation of the By Pass vs CL

Séparateurs n°1 et n°2 - BK2 - La Malle

1600

1400

Circulating load (%)

1200

turbo 1 - 04/06/96 CPJ 32,5 S cc

1000

turbo 1 - 05/06/96 CPJ 32,5 S cc

turbo 1 - 21/08/96 CEM II 32,5

800

turbo 1 - 24/09/96 CEM II 32,5

turbo 1 - 25/09/96 CHF 42,5

turbo 2 - 21/08/96 CEM II 32,5

600

turbo 2 - 24/09/96 CEM II 32,5

turbo 2 - 25/09/96 CHF 42,5

400

200

0

0

10

20

30

40

50

60

70

80

90

by-pass (%)

KUJ - July 2012 – Grinding I - 20

21. Tromp curve - Interpretation

ClassifyingTromp curve - Interpretation

• Acuity limit

• Mainly depends on the fineness of final product

• Imperfection

• Should be as low as possible

• When high, presence of very coarse particles in the final

product (for the same global fineness)

KUJ - July 2012 – Grinding I - 21

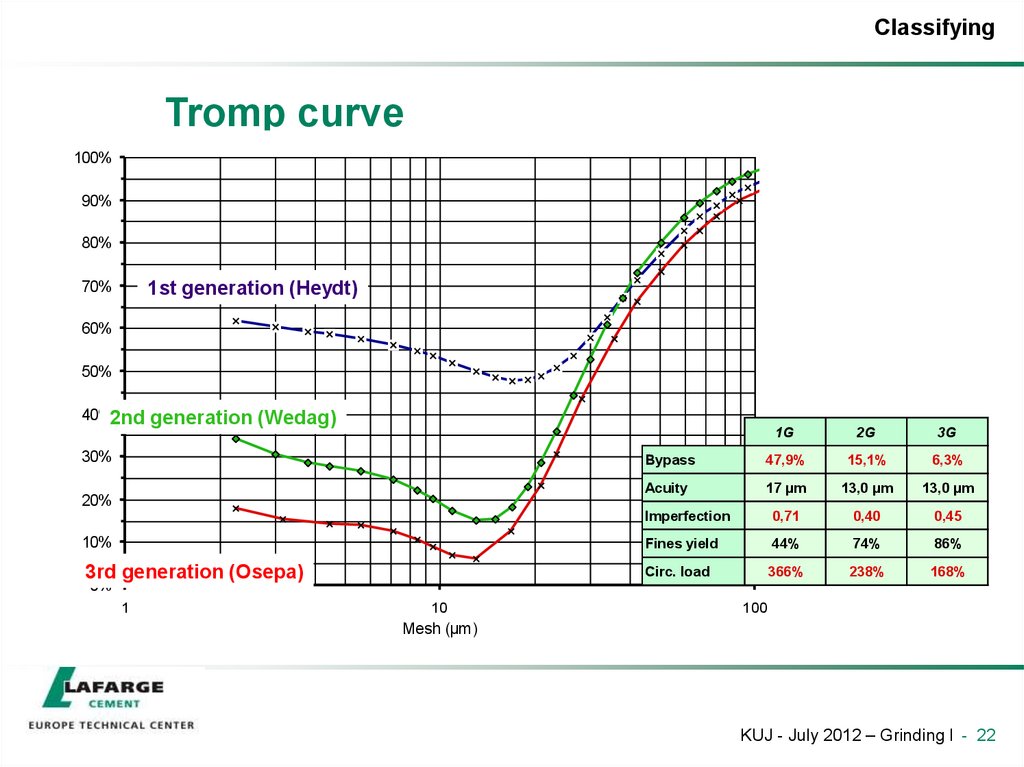

22. Tromp curve

ClassifyingTromp curve

100%

90%

80%

1st generation (Heydt)

70%

60%

50%

40%2nd

generation (Wedag)

1G

2G

3G

Bypass

47,9%

15,1%

6,3%

Acuity

17 µm

13,0 µm

13,0 µm

Imperfection

0,71

0,40

0,45

10%

Fines yield

44%

74%

86%

3rd generation (Osepa)

Circ. load

366%

238%

168%

30%

20%

0%

1

10

100

Mesh (µm)

KUJ - July 2012 – Grinding I - 22

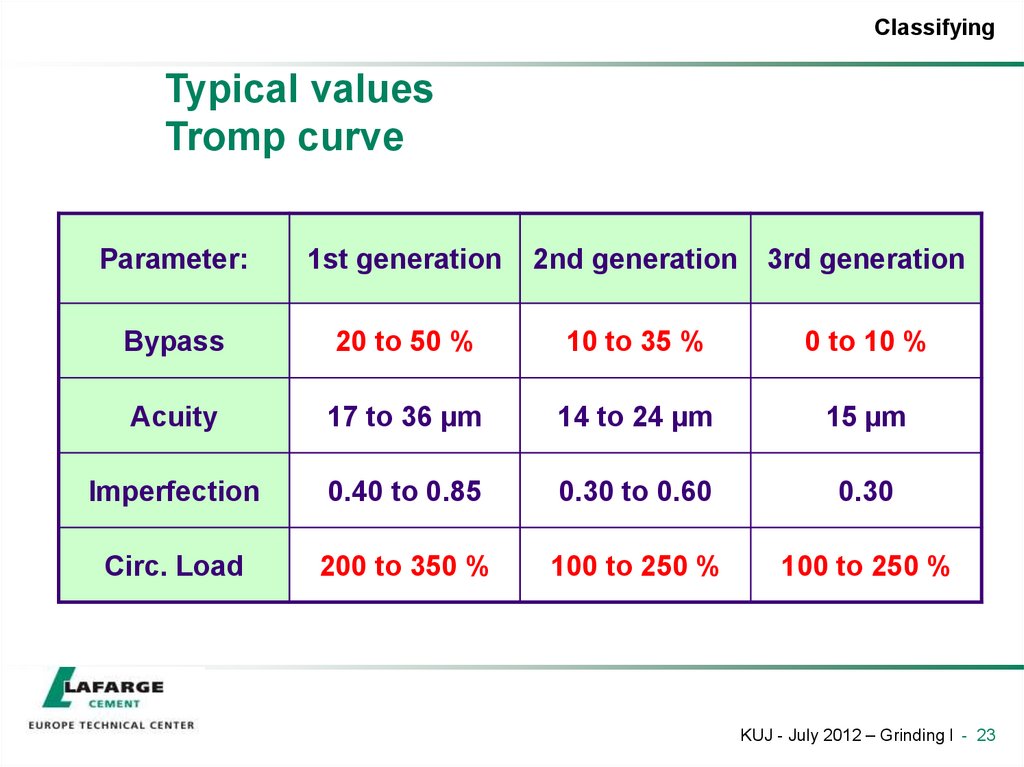

23. Typical values Tromp curve

ClassifyingTypical values

Tromp curve

Parameter:

1st generation

2nd generation

3rd generation

Bypass

20 to 50 %

10 to 35 %

0 to 10 %

Acuity

17 to 36 µm

14 to 24 µm

15 µm

Imperfection

0.40 to 0.85

0.30 to 0.60

0.30

Circ. Load

200 to 350 %

100 to 250 %

100 to 250 %

KUJ - July 2012 – Grinding I - 23

24. Building a Tromp curve

ClassifyingBuilding a Tromp curve

• Mass balance

• Knowledge of a physical property of 3 flows gives

access to R/A ratio

• Let’s apply to powders, using laser PSD

KUJ - July 2012 – Grinding I - 24

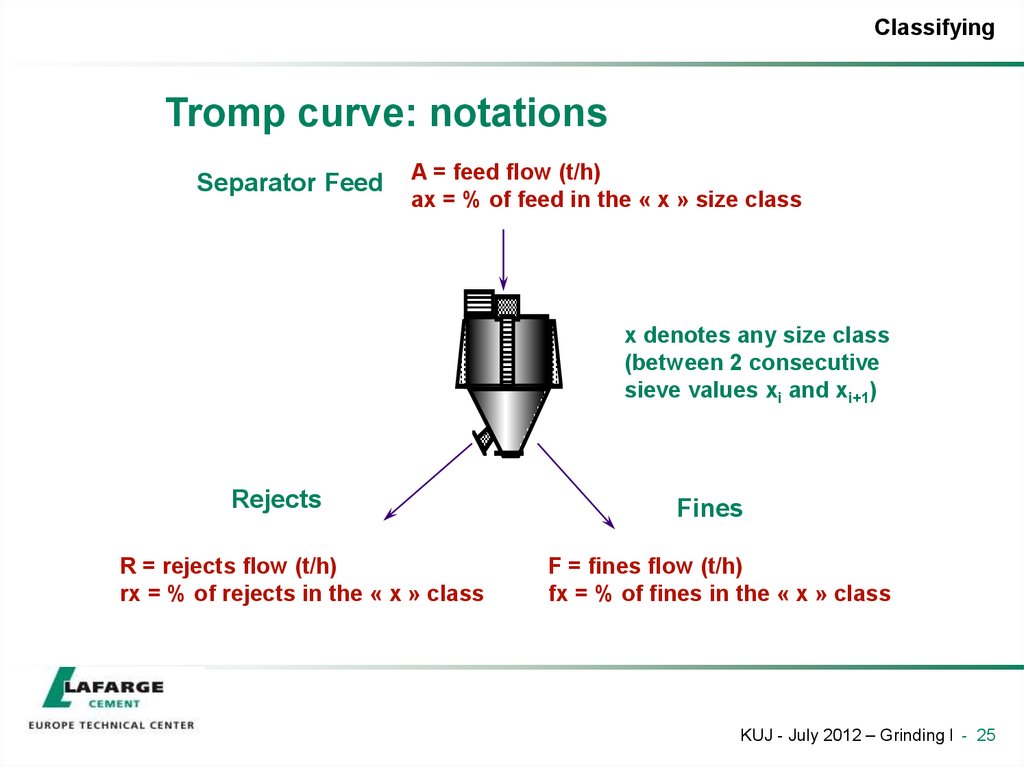

25. Tromp curve: notations

ClassifyingTromp curve: notations

Separator Feed

A = feed flow (t/h)

ax = % of feed in the « x » size class

x denotes any size class

(between 2 consecutive

sieve values xi and xi+1)

Rejects

R = rejects flow (t/h)

rx = % of rejects in the « x » class

Fines

F = fines flow (t/h)

fx = % of fines in the « x » class

KUJ - July 2012 – Grinding I - 25

26. Tromp curves – R/A calculation

ClassifyingTromp curves – R/A calculation

• Global mass balance:

A=R+F

(1)

inlet flow to the separator equals the outlet flow

Partial mass balance for size “x”:

A × ax = R × rx + F × fx (2)

there is no grinding occurring in the separator

• (1) & (2) =>

R

A

(x) =

f x - ax

f x - rx

KUJ - July 2012 – Grinding I - 26

27. 3 point junction (ABC formula)

Classifying3 point junction (ABC formula)

A, a

Example:

•Feed 3000 Blaine

•Rejects 2000 Blaine

•Product 3800 Blaine

•Question:

•% rejects

•% fines

•CL

Feed

A,F,a

property

100

mass

B, b

C, c

Rejects

B, r

Product, Fines

C, P, f

property

property

a-c

B

#DIV/0!

#DIV/0!

with B =

b-c

a-b

C

#DIV/0!

#DIV/0!

with C =

c-b

Recjects

Cl

#DIV/0!

with Cl =

Fines

KUJ - July 2012 – Grinding I - 27

28. 3 point junction (ABC formula)

Classifying3 point junction (ABC formula)

Example:

•Feed 3000 Blaine

•Rejects 2000 Blaine

•Product 3800 Blaine

•Question:

•% rejects

•% fines

•CL

KUJ - July 2012 – Grinding I - 28

29. 3 point junction (ABC formula)

Classifying3 point junction (ABC formula)

A, a

Feed

A,F,a

3000

property

B, b

100

mass

C, c

Rejects

B, r

2000

property

B

0,44444444

C

0,55555556

Product, Fines

C, P, f

3800

property

a-c

44 with B =

b-c

a-b

56 with C =

c-b

Recjects

Cl

0,8

with Cl =

Fines

KUJ - July 2012 – Grinding I - 29

30. Tromp curves – R/A calculation

ClassifyingTromp curves – R/A calculation

R

(x) =

A

• Interpretation:

fx - ax

fx - r x

• Using the laser PSD for separator feed, rejects and fines,

we can calculate, for each size class « x », an estimate of

the ratio R/A

• NB: for different classes x, the predicted R/A may vary (due to

the precision of sampling and PSD analysis)

• The same formula can be used with other physical

properties:

• Cumulative passing/residues at a certain sieve

• Blaine fineness

•…

KUJ - July 2012 – Grinding I - 30

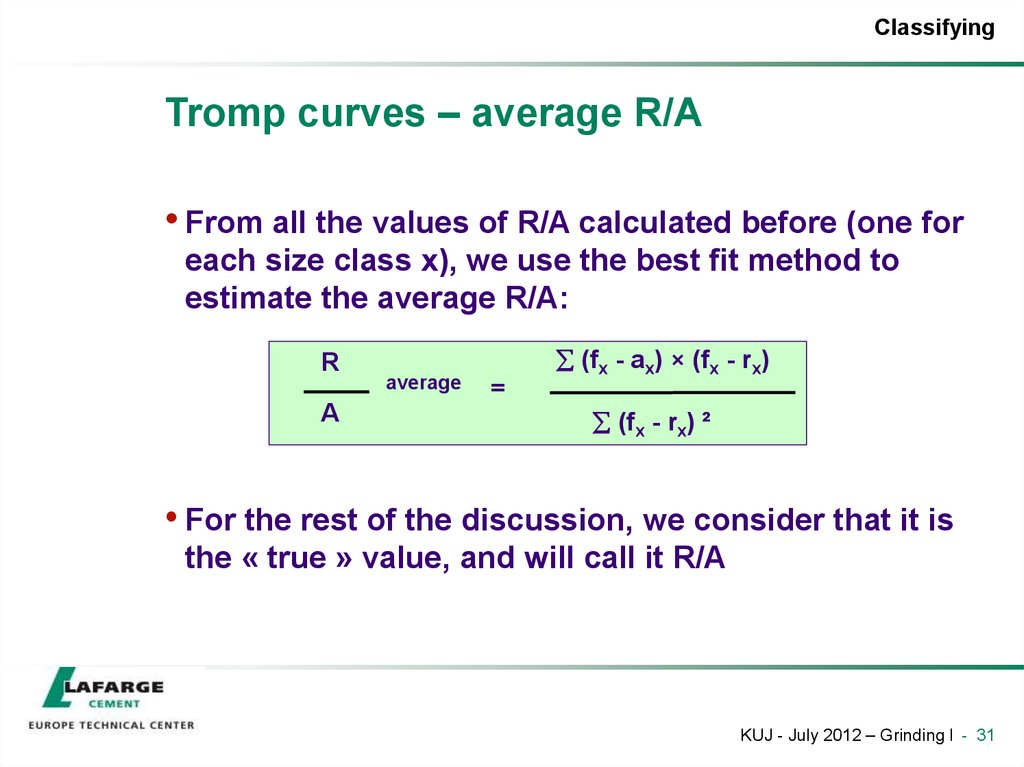

31. Tromp curves – average R/A

ClassifyingTromp curves – average R/A

• From all the values of R/A calculated before (one for

each size class x), we use the best fit method to

estimate the average R/A:

R

A

average

(fx - ax) × (fx - rx)

=

(fx - rx) ²

• For the rest of the discussion, we consider that it is

the « true » value, and will call it R/A

KUJ - July 2012 – Grinding I - 31

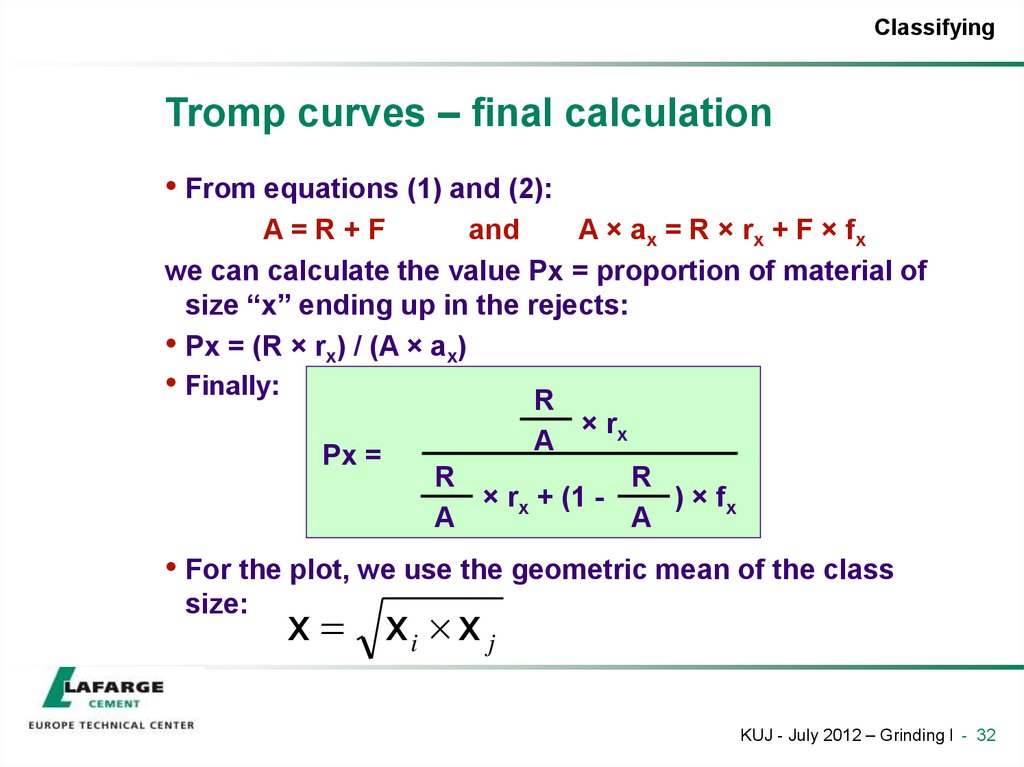

32. Tromp curves – final calculation

ClassifyingTromp curves – final calculation

• From equations (1) and (2):

A=R+F

and

A × ax = R × rx + F × fx

we can calculate the value Px = proportion of material of

size “x” ending up in the rejects:

• Px = (R × rx) / (A × ax)

• Finally:

Px =

R

× rx

A

R

R

× rx + (1 ) × fx

A

A

• For the plot, we use the geometric mean of the class

size:

x xi x j

KUJ - July 2012 – Grinding I - 32

33. Tromp curves - How to build?

ClassifyingTromp curves - How to build?

• Evaluate and interprete the tromp curve for a given laser

analysis

KUJ - July 2012 – Grinding I - 33

Промышленность

Промышленность