Похожие презентации:

Shanghai WTL Welding Equipment

1.

MAGIC AC GTIG-200PShanghai WTL Welding Equipment

Manufacture Co.Ltd

March.2018

2.

Catalogue1、Introduction of working principle

2、Introduction of main circuit

3、Introduction of control circuit

4、Introduction of panel circuit

5、Troubleshooting

6、Component test

3.

1、Introduction ofworking principle

4.

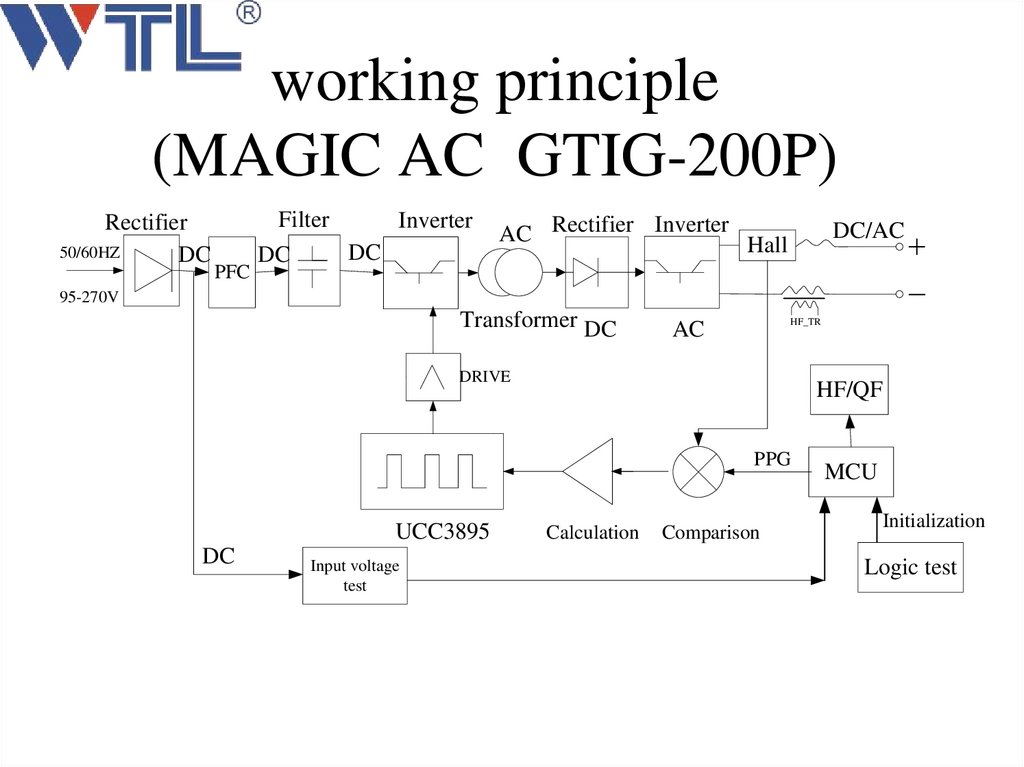

working principle(MAGIC AC GTIG-200P)

Rectifier

50/60HZ

DC

PFC

Filter

Inverter

DC

DC

AC Rectifier Inverter Hall

DC/AC

95-270V

Transformer DC

HF_TR

AC

DRIVE

HF/QF

PPG

UCC3895

DC

Input voltage

test

Calculation

Comparison

MCU

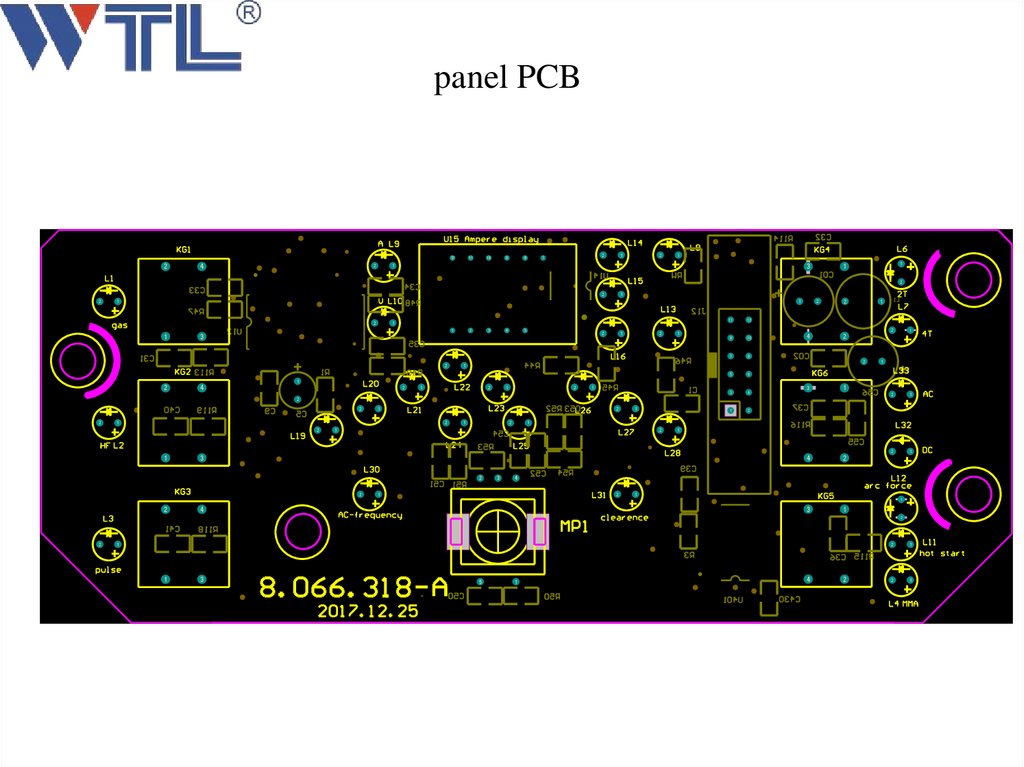

Initialization

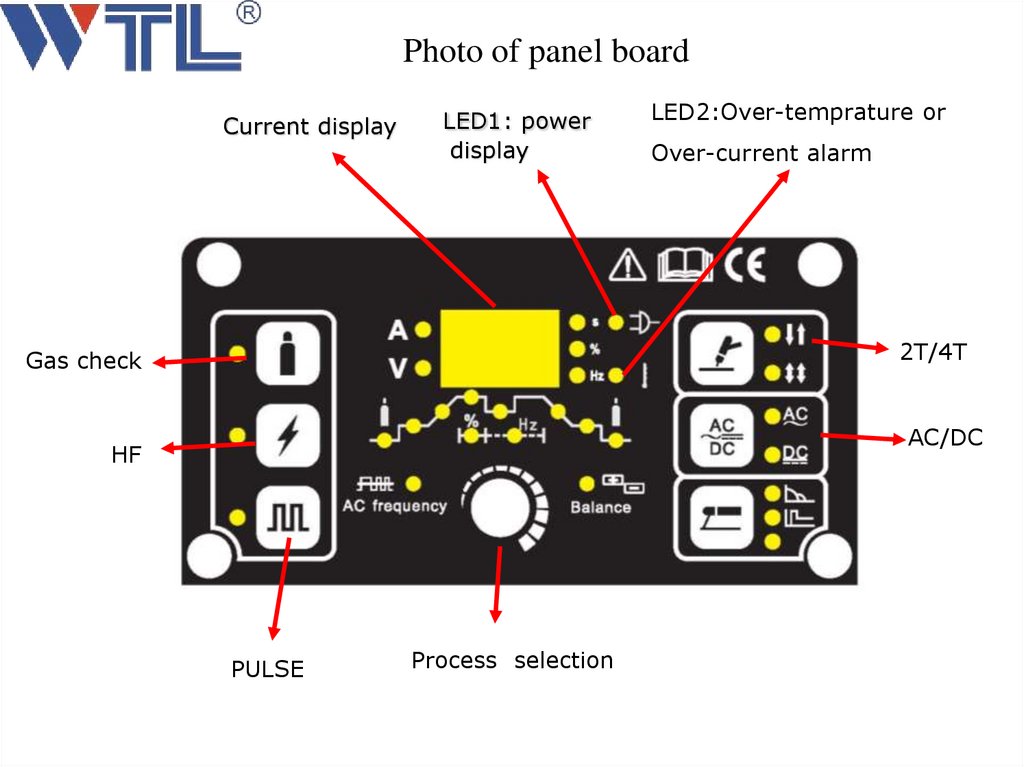

Logic test

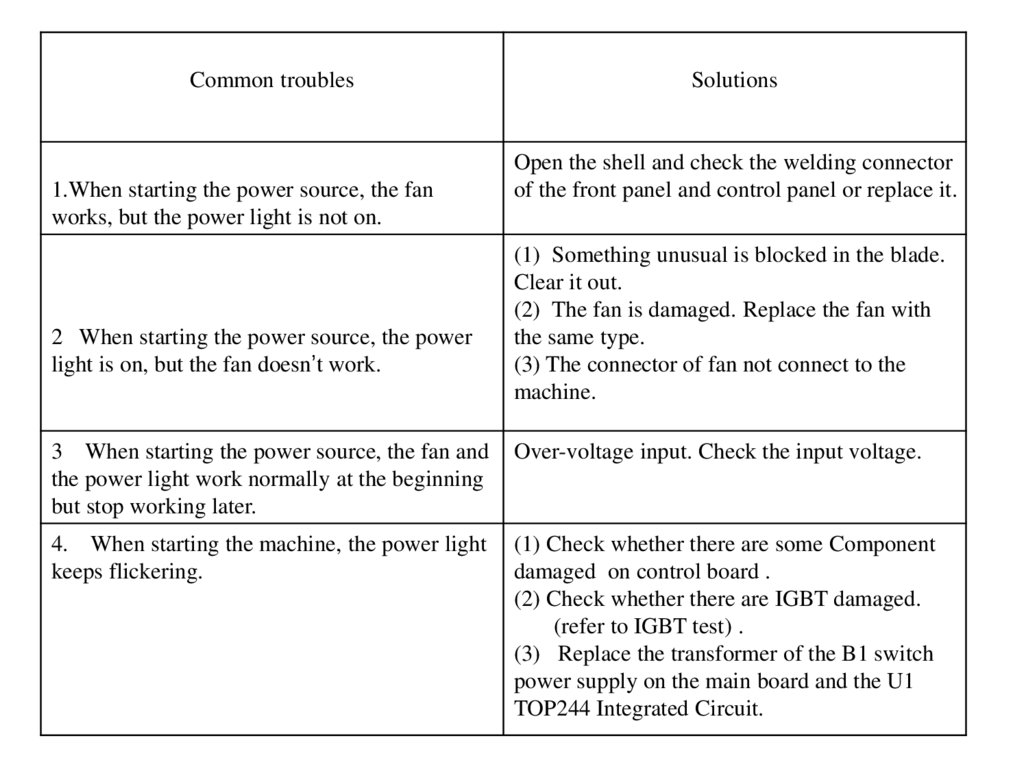

5.

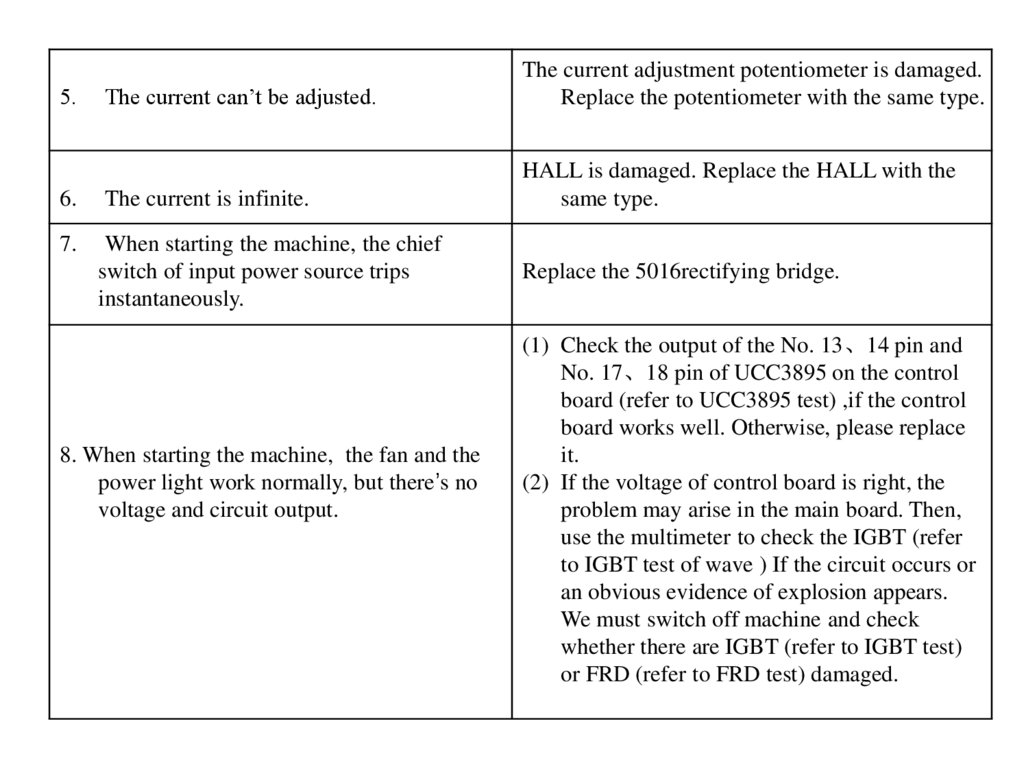

C10R187

Q1

AC 95-270V

SOFT

START

SW1

1

AC

V+

4

D3

LT

1

V8

A

EMC

2

B

1

E

2

AC

V-

AC

V+

AC

V-

1

3

8.066.337-D

8.066.336-C

2

AK

D4

2

AK

D1

R1

4

T5

C11 C12

T7

C26

B1

T3

TR1

C2 R2

3

C10

D4

C6

C5

R12

JP1

HALL

POSITIVE

C61/62

V8-1

80A

R3

Q2

TH1

R4

3uF

T6

C7

C15

C27

D3

T8

D2

C8

T4

PFC drive circuit

TR2

85A

JP2

R28

TH3

85A

L

TH2

SOU1

DRIVE

NEGATIVE

FD1

POWER

JC

HF

AC

L1

DC

7.731.146

FD2

T1

JP3

Solenoid Valve

SOU

8

DRIVE

2

3

POWER

OT1

110/220

2

QF/HF

MAIN CONTROL BOARD

W

A

WVIN

8.066.824-B

OT2

P1

F

Display Board

12

3

2

J8

DC24V FAN

J1

12-lead socket

2

ACPOUT

2

12-lead socket

GUN/REMOTE

4

2

5

B2

8 PIN SOCKET

9.066.318-A

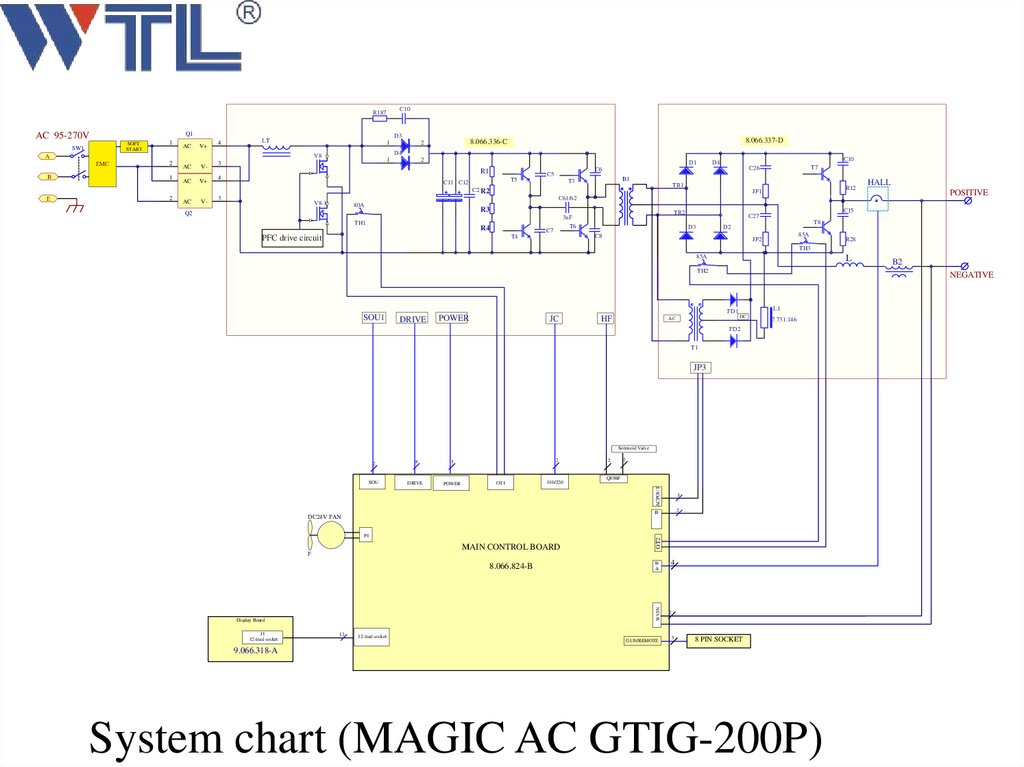

System chart (MAGIC AC GTIG-200P)

6.

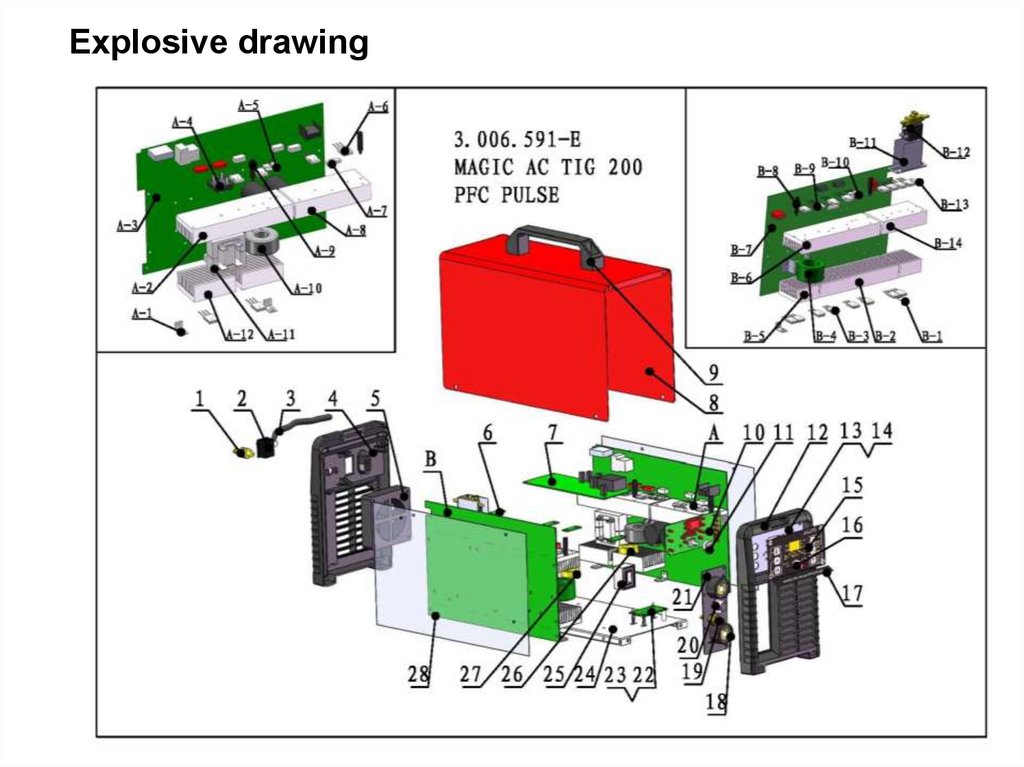

Explosive drawing7.

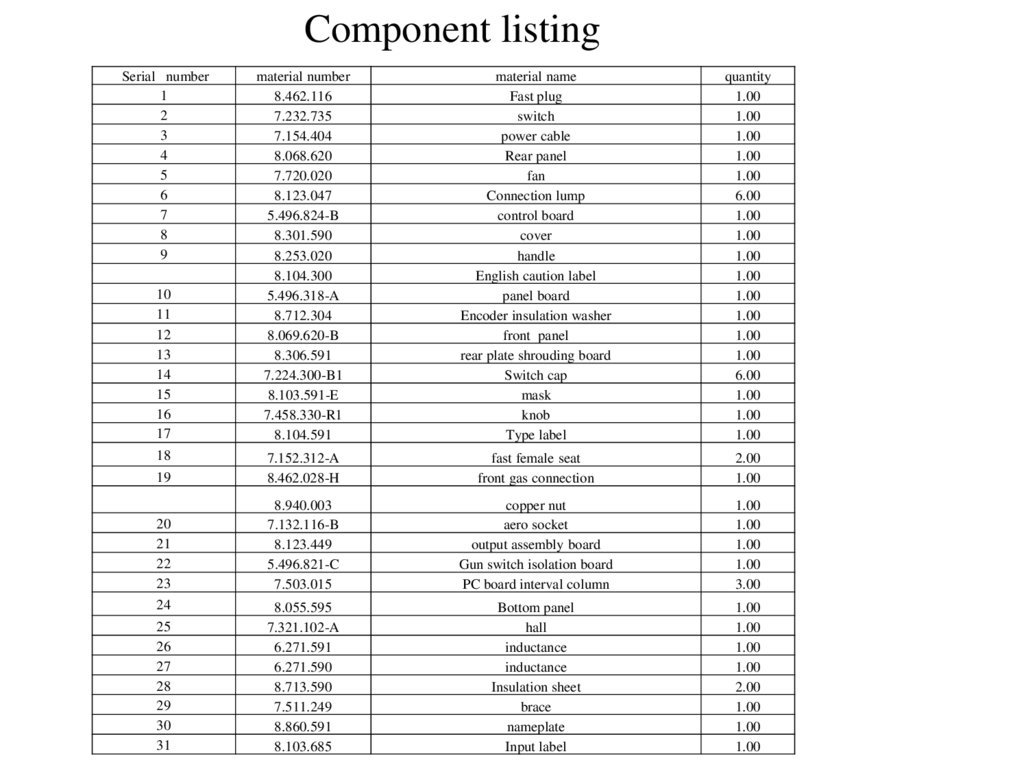

Component listingSerial number

1

2

3

4

5

6

7

8

9

material number

8.462.116

7.232.735

7.154.404

8.068.620

7.720.020

8.123.047

5.496.824-B

8.301.590

8.253.020

8.104.300

5.496.318-A

8.712.304

8.069.620-B

8.306.591

7.224.300-B1

8.103.591-E

7.458.330-R1

8.104.591

material name

Fast plug

switch

power cable

Rear panel

fan

Connection lump

control board

cover

handle

English caution label

panel board

Encoder insulation washer

front panel

rear plate shrouding board

Switch cap

mask

knob

Type label

quantity

1.00

1.00

1.00

1.00

1.00

6.00

1.00

1.00

1.00

1.00

1.00

1.00

1.00

1.00

6.00

1.00

1.00

1.00

19

7.152.312-A

8.462.028-H

fast female seat

front gas connection

2.00

1.00

20

21

22

23

8.940.003

7.132.116-B

8.123.449

5.496.821-C

7.503.015

copper nut

aero socket

output assembly board

Gun switch isolation board

PC board interval column

1.00

1.00

1.00

1.00

3.00

8.055.595

7.321.102-A

6.271.591

6.271.590

8.713.590

7.511.249

8.860.591

8.103.685

Bottom panel

hall

inductance

inductance

Insulation sheet

brace

nameplate

Input label

1.00

1.00

1.00

1.00

2.00

1.00

1.00

1.00

10

11

12

13

14

15

16

17

18

24

25

26

27

28

29

30

31

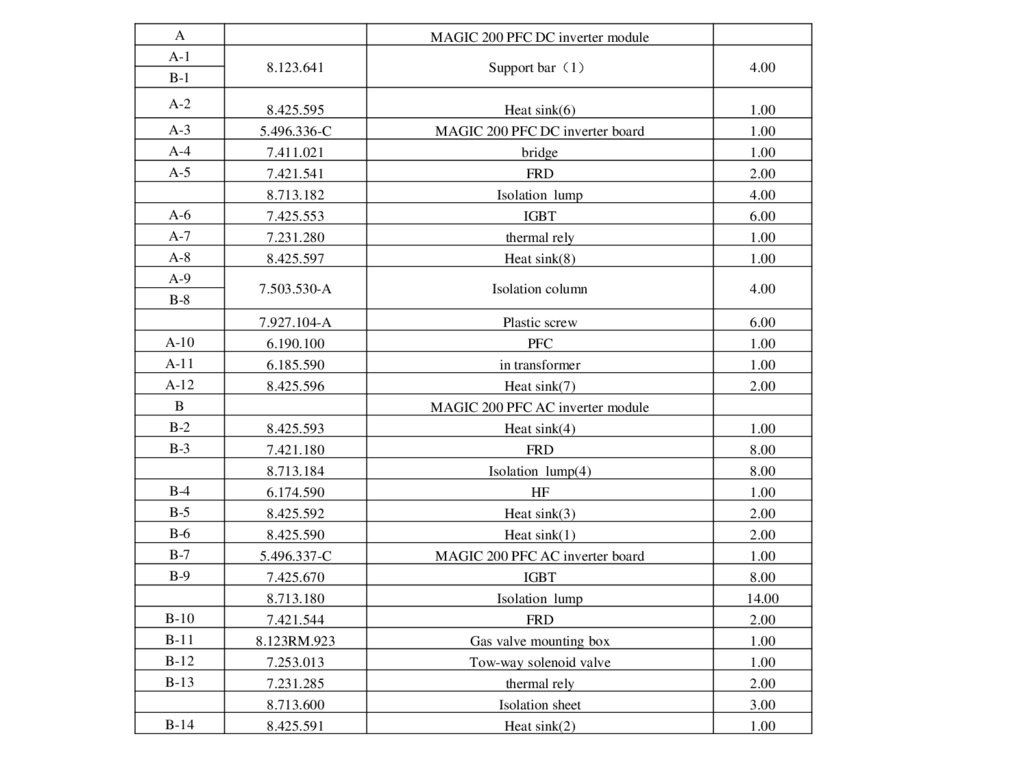

8.

AA-1

B-1

A-2

A-3

A-4

A-5

A-6

A-7

A-8

A-9

B-8

A-10

A-11

A-12

B

B-2

B-3

B-4

B-5

B-6

B-7

B-9

B-10

B-11

B-12

B-13

B-14

MAGIC 200 PFC DC inverter module

8.123.641

Support bar 1

4.00

8.425.595

5.496.336-C

7.411.021

7.421.541

8.713.182

7.425.553

7.231.280

8.425.597

Heat sink(6)

MAGIC 200 PFC DC inverter board

bridge

FRD

Isolation lump

IGBT

thermal rely

Heat sink(8)

1.00

1.00

1.00

2.00

4.00

6.00

1.00

1.00

7.503.530-A

Isolation column

4.00

7.927.104-A

6.190.100

6.185.590

8.425.596

Plastic screw

PFC

in transformer

Heat sink(7)

MAGIC 200 PFC AC inverter module

Heat sink(4)

FRD

Isolation lump(4)

HF

Heat sink(3)

Heat sink(1)

MAGIC 200 PFC AC inverter board

IGBT

Isolation lump

FRD

Gas valve mounting box

Tow-way solenoid valve

thermal rely

Isolation sheet

Heat sink(2)

6.00

1.00

1.00

2.00

8.425.593

7.421.180

8.713.184

6.174.590

8.425.592

8.425.590

5.496.337-C

7.425.670

8.713.180

7.421.544

8.123RM.923

7.253.013

7.231.285

8.713.600

8.425.591

1.00

8.00

8.00

1.00

2.00

2.00

1.00

8.00

14.00

2.00

1.00

1.00

2.00

3.00

1.00

9.

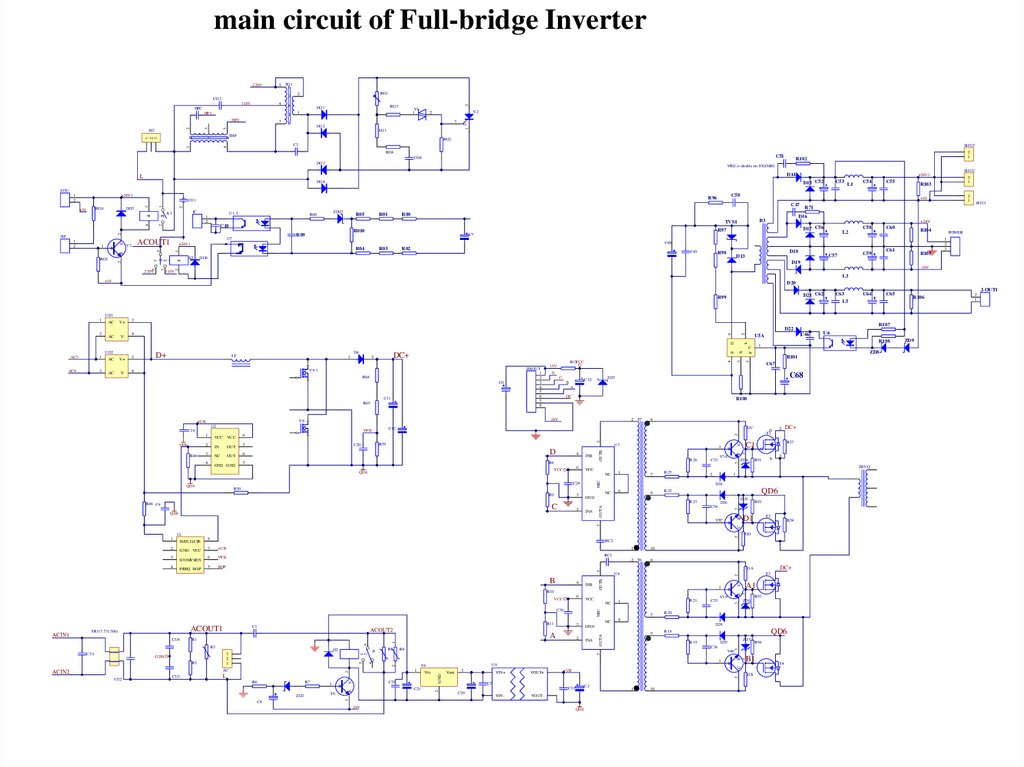

2、Introduction of main circuit10.

main circuit of Full-bridge Inverter5 TG1

5

HF1

1

RG3

V1

1

1

2

3

3

DG2

5

3

3

DG1

V2

G

LG1

45

THF

RG2

C3

4

1

1

2

3

12

KG

3

2

HF2

RG1

2

4

2

4

HFC

1 2

2

110V

1

220V

CG2

SOU3

RG4

C51

CG4

DG3

2

1

R102

VRD is disable on TIG/MIG

SOU2

D14

L

+24V1

D15 C52

DG4

1

2

U1-2

1

2

R08

2

220V

R00

1

K2

21

110V

D17 C56

C58

C60

R104

L2

R02

C49

D18

R98

C61

C59

C57

D13

DG6

SOU1

POWER

1

2

3

C48

R03

2

1

R71

C7

R04

2

1

R103

+24V

R97

R010

R09

C55

D16

B3

TVS1

U7

C54

R105

D19

-24V

2

7

3

RG5

R01

+24V1

7

5

3

E

B

R05

C18

ACOUT1

V3

5

1

3

1

2

C

HF

ZD02

L1

+01

C47

JC

C53

C50

R96

CG1

K1

2

4

43

DG5

3

RG6

+01

1 2

+24V1

21

1

2

1

SOU

L3

+01

D20

D21 C62

R99

C63

L5

C64

C65

J-OUT1

R106

UD1

1

AC

V+

AC

V-

2

R107

R108

D

R64

C6

C11

R65

V8

+UB

U2

INB

R8

5

6

VCC

R26

VCC

NC

C28

R50

R9

R46 C4

3

1

7

R25

C33

2

2

QD6

NC

8

9

C

2

4

6

ACOUT2

INB

D2

J1

R5

MIC

2

NC

7

R20

9

R18

C35

V39

R19

V40

B

C21

VIN+

VOUT+

VIN-

VOUT-

+UB

-24V

B

2

GND

2

2

2

T6

C

1

E

R7

ZD2

C8

3

C5

C2

C19

C29

3

R6

Vout

QD6

1

10

R94

B1

C

4

5

1

Vin

QD6

ZD3

D29

C36

U9

V4

1

C25

R93

ZD6

D28

R4

L

A1

B

8

GND

INA

T3

2

R21

1

7

3

2

1

AC

CU3

A

DC+

GA

1

VCC

6

R3

CU2

3

1

R1

R2

8

OUTA

R11

C1

ACOUT1

GDN

10

2 T8

U4

NC

CU1

1

C

BOP

E

2

5

C30

ACIN2

R24

GD

RC1

3

VFB

VCC

CU4

T2

1

+UB

6

R10

TR1(7.731.506)

R92

RC2

7

B

ACIN1

3

ZBYQ

1

FREQ BOP

R91

D1

E

2

ICOMVSEN

F

C

B

7

GND VCC

5

4

ISEN GATE

R27

S

QD6

ZD5

D26

C34

OUTB

3

DC+

G

R22

U1

8

2

D24

V37

1

2

ZD4

1

GND

INA

C11

B

V38

2 1

R23

C

1

D

T1

2

4

1

E

2

D

6

U3

3

R59

C20

AK

7

QD6

QD6

5

GC

8

1

GND GND

8

1

OUT

R100

2 T7

3

4

NC

A

OC

KA

3

OUT

C68

ZD7

C32

B

E

2

R48

IN

C

AK

2

D

5

VCC VCC

C67

15V

C12

VFB

1

QD6

IMOUT

1

2

3

4

5

6

7

8

-24V

C14

ZD8

R101

R12VCC

V8-1

4

X

S

DC+

2

AK

4

1

3

D4

LT

3

V-

D+

KA

AC

2

OUTB

3

V+

MIC

AC4

AC

OUTA

1

U6

1

C

UD2

AC3

C66

U5A

L

6

4

2

D22

3

GB

T4

ZD9

2

1

11.

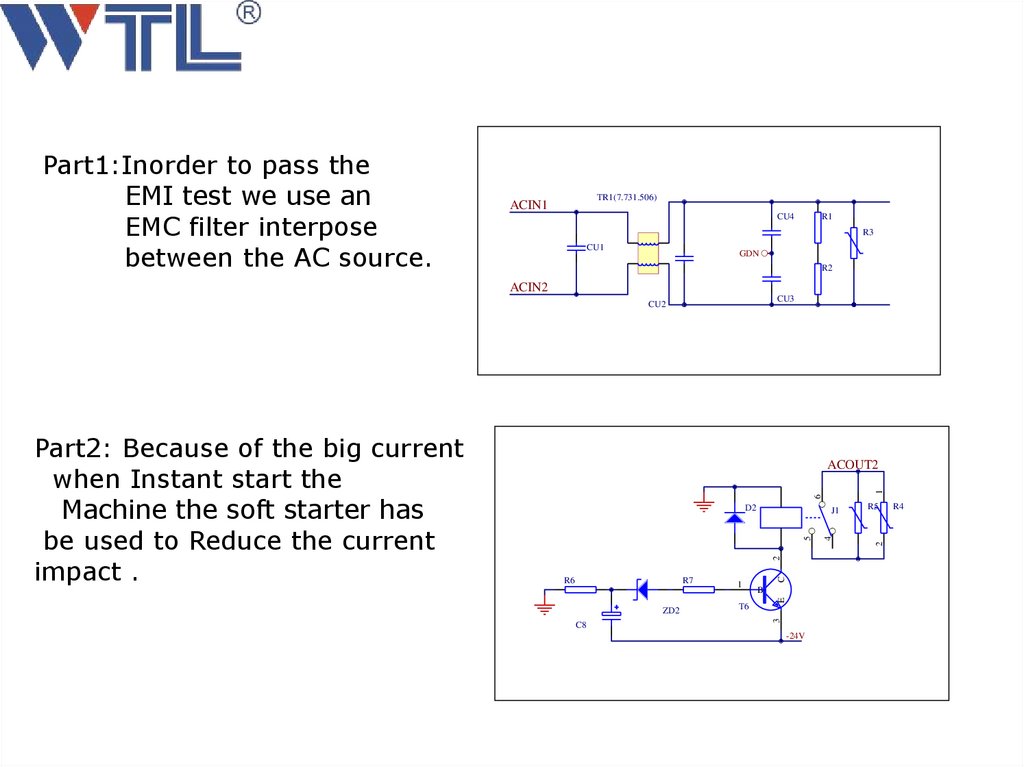

Part1:Inorder to pass theEMI test we use an

EMC filter interpose

between the AC source.

TR1(7.731.506)

ACIN1

CU4

R1

R3

CU1

GDN

R2

ACIN2

CU3

CU2

6

1

ACOUT2

D2

R5

R7

ZD2

C8

1

T6

B

E

R6

C

2

2

4

5

J1

3

Part2: Because of the big current

when Instant start the

Machine the soft starter has

be used to Reduce the current

impact .

-24V

R4

12.

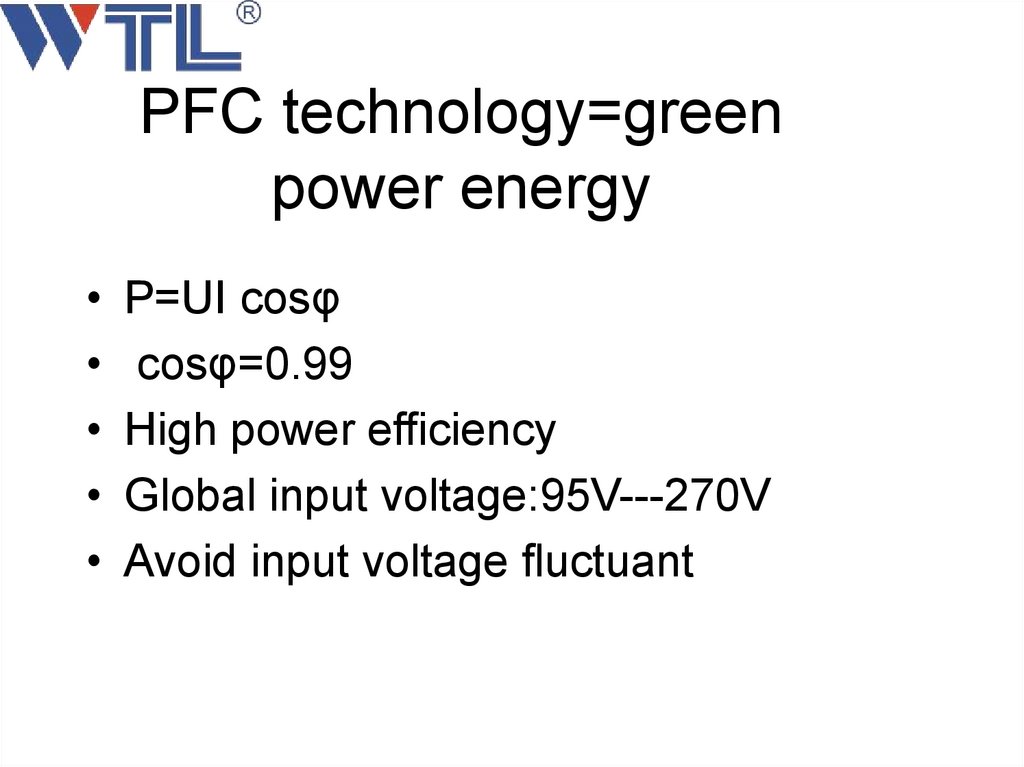

PFC technology=greenpower energy

P=UI cosφ

cosφ=0.99

High power efficiency

Global input voltage:95V---270V

Avoid input voltage fluctuant

13.

PFC chip and theory• ICE3PCS03G(see the PDF document)

• Power input : 95V 270VAC

• PFC output: 360(working) 385(open circuit)

VDC

14.

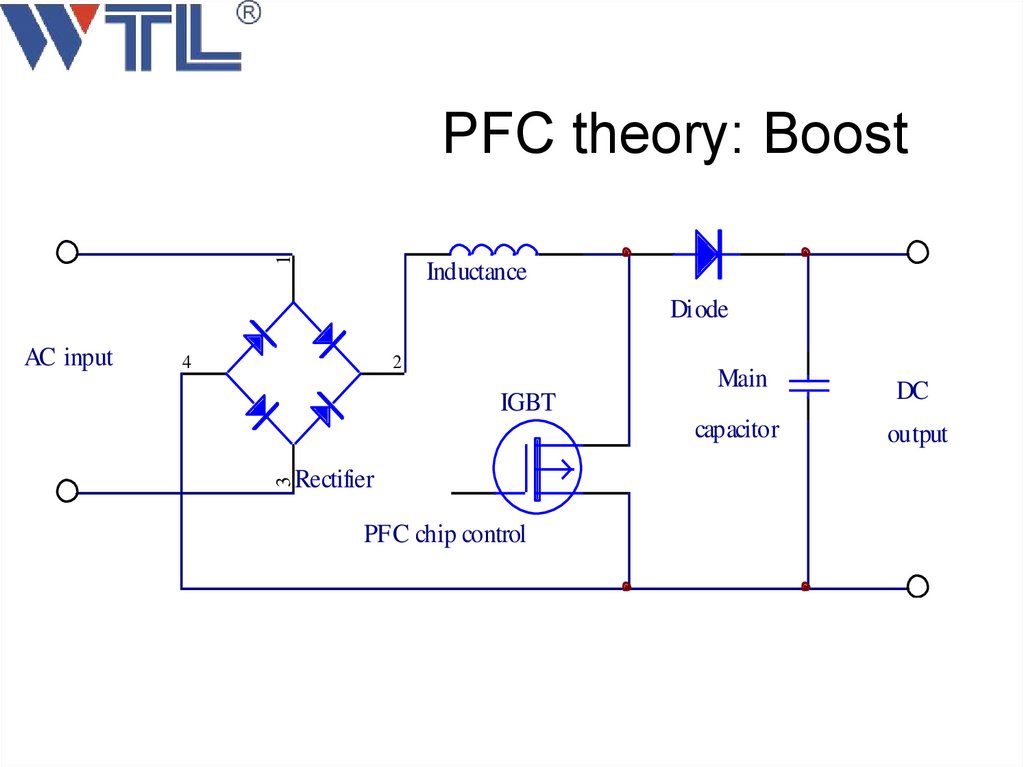

1PFC theory: Boost

Inductance

Diode

4

2

Main

DC

capacitor

output

IGBT

3

AC input

Rectifier

PFC chip control

15.

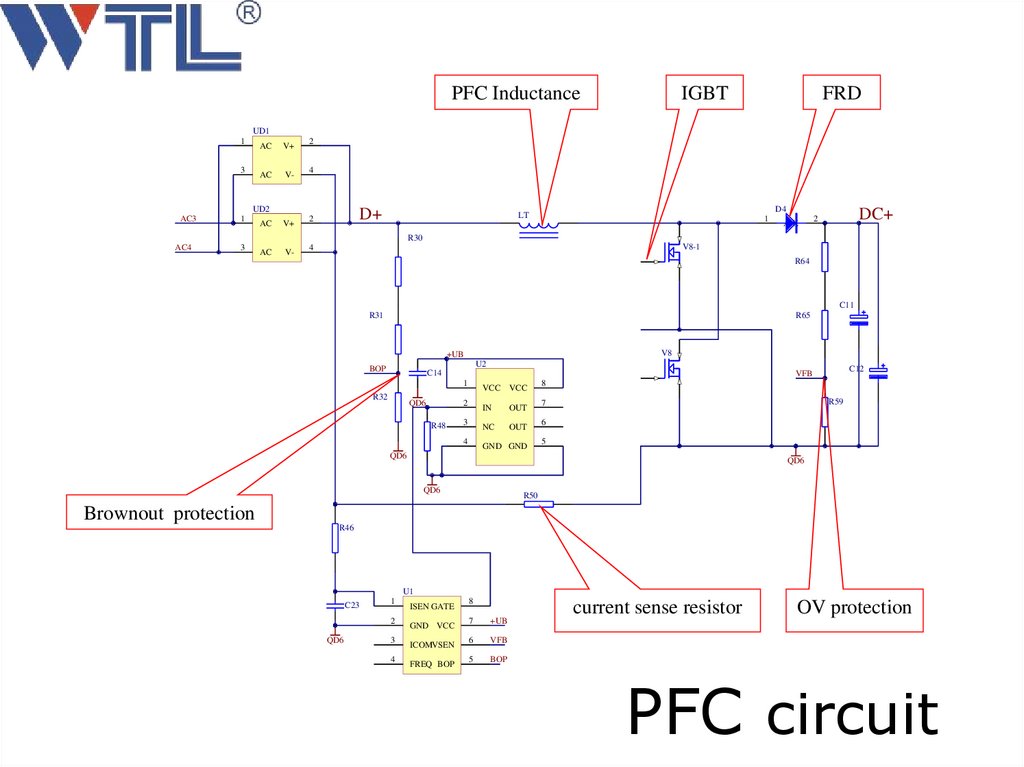

PFC InductanceIGBT

FRD

UD1

1

3

AC

V+

AC

V-

2

4

UD2

AC3

1

AC

V+

AC

V-

D+

2

D4

LT

1

AK

DC+

2

R30

AC4

3

V8-1

4

R64

C11

R31

R65

V8

+UB

U2

BOP

C14

R32

QD6

VCC VCC

2

R48

C12

VFB

1

IN

3

NC

4

OUT

OUT

GND GND

8

R59

7

6

5

QD6

QD6

QD6

R50

Brownout protection

R46

U1

C23

1

2

QD6

3

4

ISEN GATE

GND VCC

ICOMVSEN

FREQ BOP

8

7

+UB

6

VFB

5

BOP

current sense resistor

OV protection

PFC circuit

16.

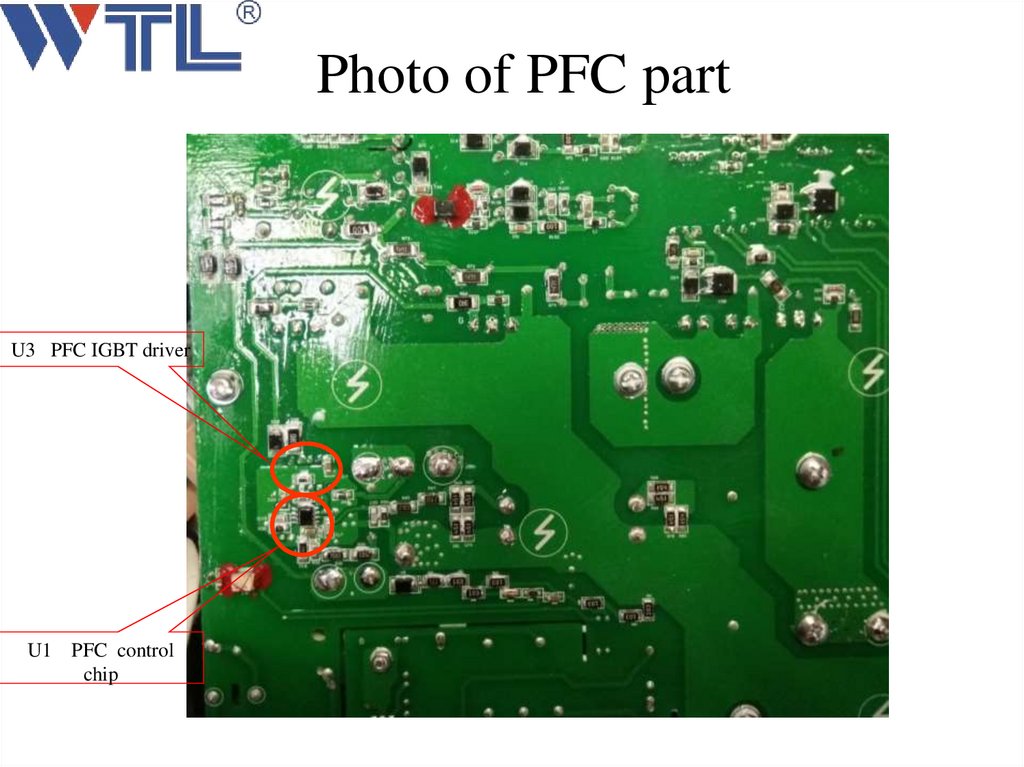

Photo of PFC partU3 PFC IGBT driver

U1 PFC control

chip

17.

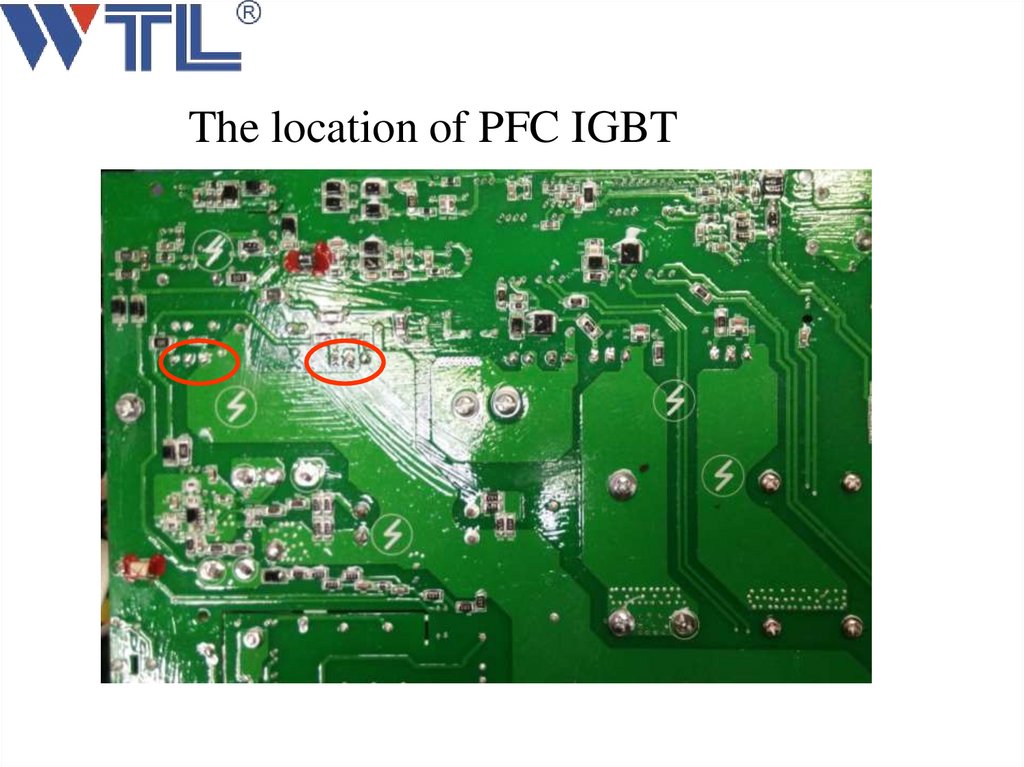

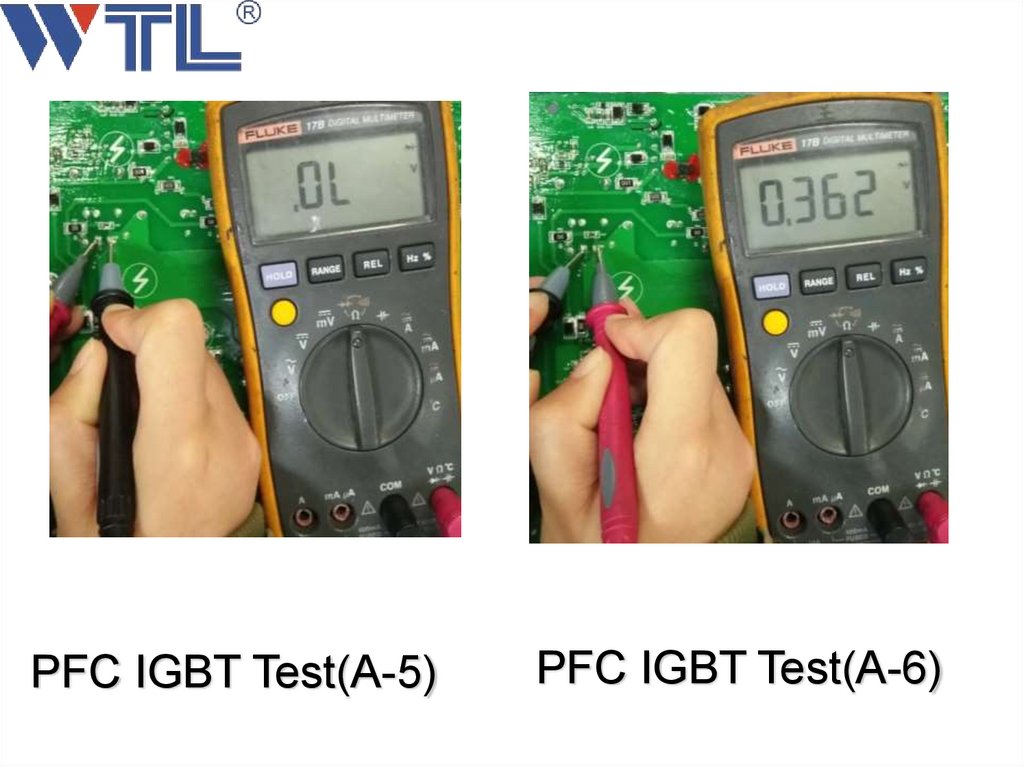

The location of PFC IGBT18.

Preparation of test PFC IGBT1、We must Switch off the machine

2、After 5 minutes we can test .

3、Turn the rotary switch to test diode.

4、keep 3 seconds when we test every step.

5、If the result we test as similar as the following

picture .we can say the IGBT is good. Otherwise

there are some IGBT damaged.

19.

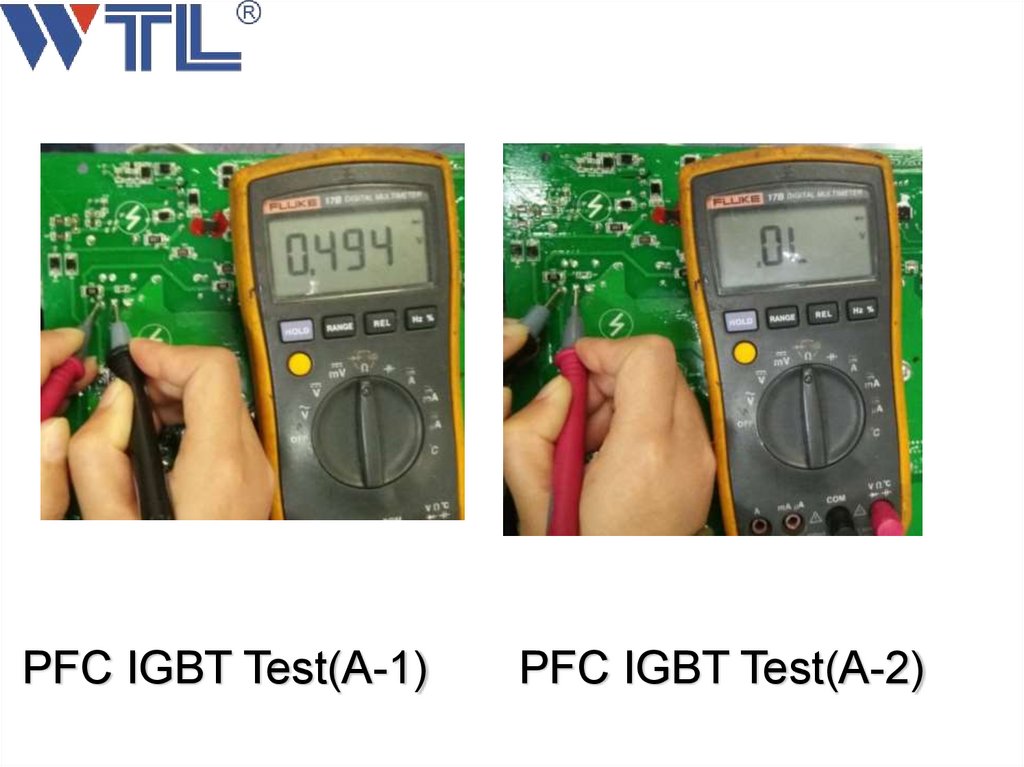

PFC IGBT Test(A-1)PFC IGBT Test(A-2)

20.

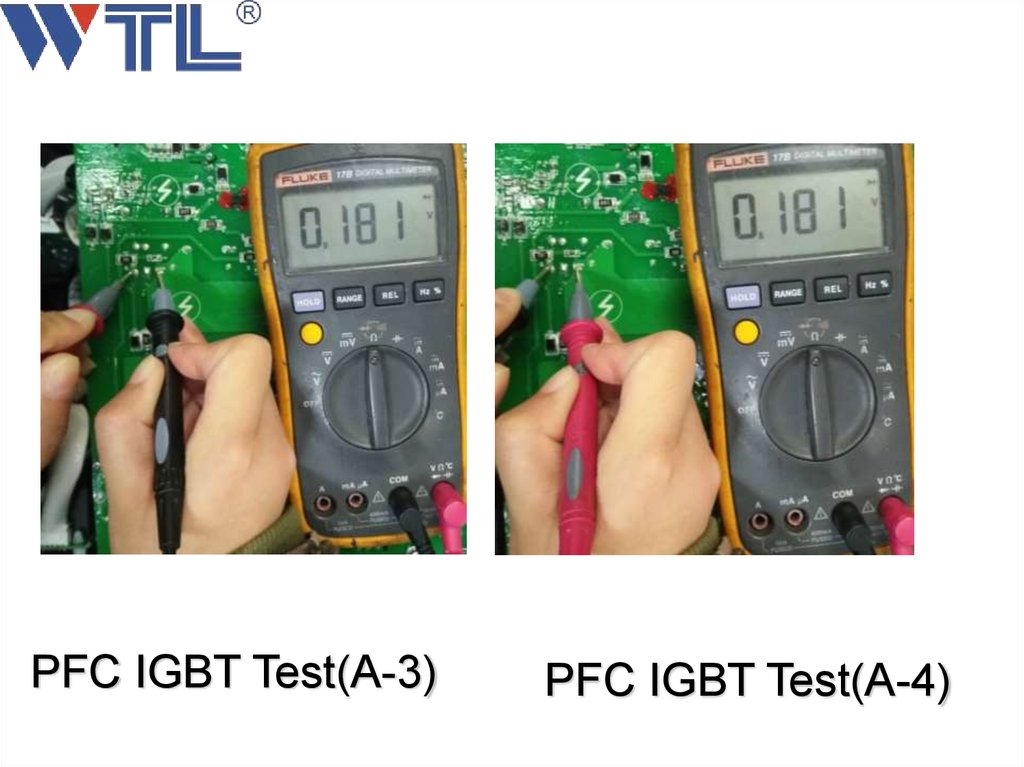

PFC IGBT Test(A-3)PFC IGBT Test(A-4)

21.

PFC IGBT Test(A-5)PFC IGBT Test(A-6)

22.

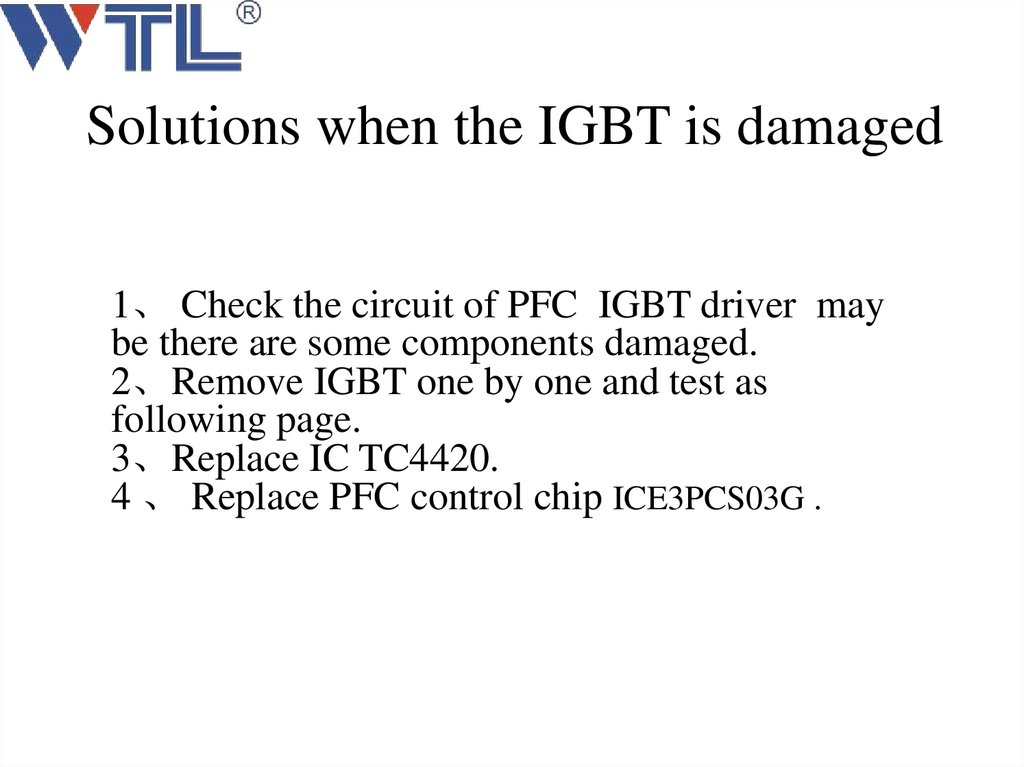

Solutions when the IGBT is damaged1、 Check the circuit of PFC IGBT driver may

be there are some components damaged.

2、Remove IGBT one by one and test as

following page.

3、Replace IC TC4420.

4 、 Replace PFC control chip ICE3PCS03G .

23.

2 T78

GC

C28

3

C

7

R25

2

C

E

2

3

1

2 1

NC

8

9

INA

R91

S

3

ZBYQ

QD6

R22

GND

R23

2

R27

D24

ZD5

D26

C34

OUTA

R9

1

MIC

NC

ZD4

AK

VCC

V38

DC+

G

1

6

C33

3

VCC

R26

KA

INB

R8

C11

B

E

2

4

1

OUTB

D

U3

2

1

5

2

D

T1

V37

1

T2

D1

R24

2

C

7

B

R92

GD

RC2

1

10

2 T8

8

RC1

2

NC

2

R20

9

R18

C

E

2

R93

AK

ZD6

D28

GND

INA

V39

R19

QD6

ZD3

D29

C36

V40

7

A

3

7

C35

8

OUTA

R11

MIC

C30

R21

1

B

R94

B1

T4

2

C

1

KA

NC

3

VCC

A1

B

1

6

1

1

VCC

T3

E

2

INB

R10

3

5

4

OUTB

B

DC+

GA

U4

1

10

GB

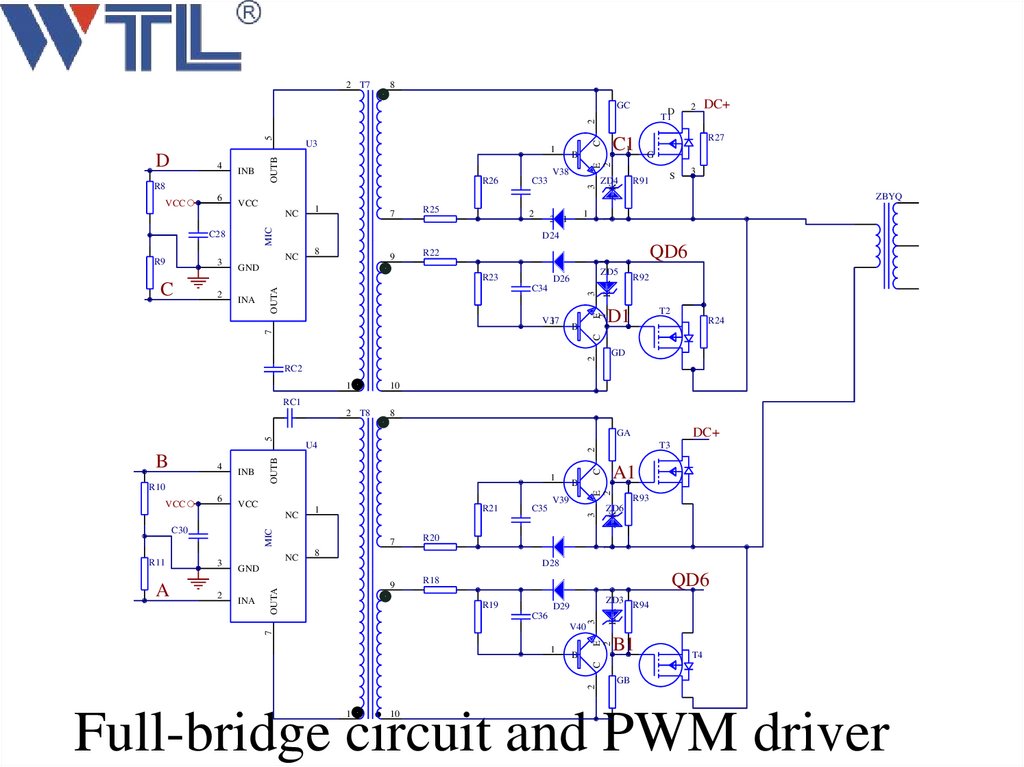

Full-bridge circuit and PWM driver

24.

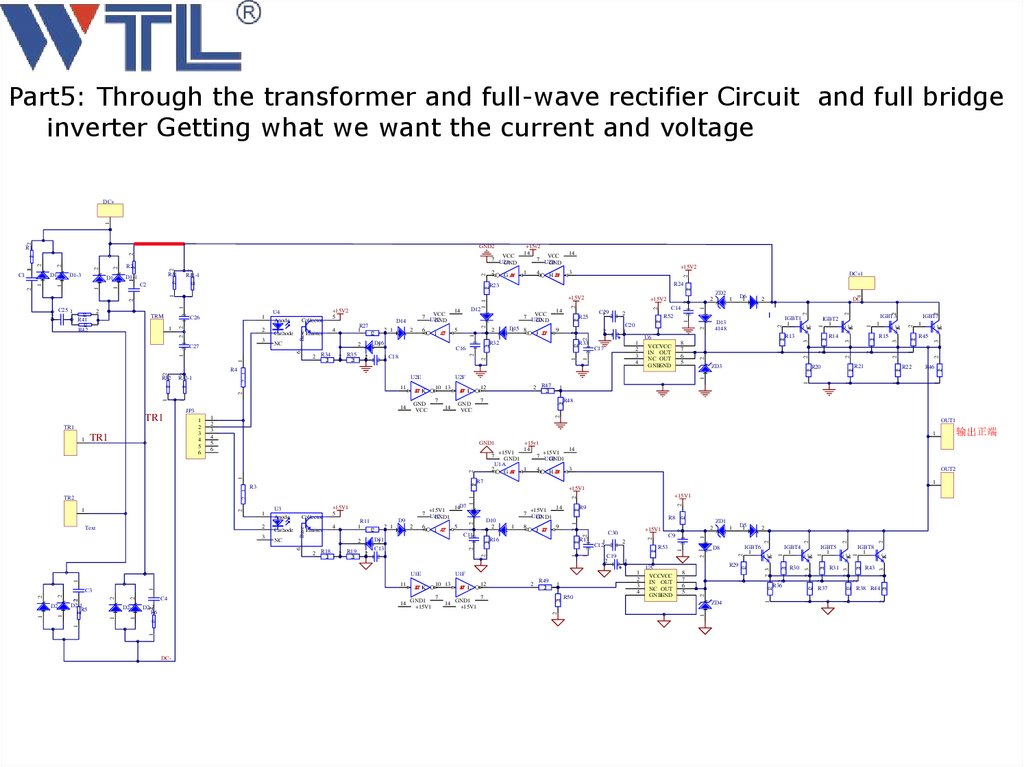

Part5: Through the transformer and full-wave rectifier Circuit and full bridgeinverter Getting what we want the current and voltage

2

E K

GND

VCC

10 13

2

1

1

12

2

2

EC

3

2

EC

G

R45

1

2

1

R22

R46

12

2

2

R21

1

1

1

1

12

12

R20

IGBT7

12

G

R15

2

2

ZD3

1

3

1

21

R14

3

21

3

IGBT3

2

1

8

7

6

5

12

R13

U6

VCCVCC

IN OUT

NC OUT

GNDGND

G

EC

IGBT2

1

1

EC

2

2

1

2

D13

4148

2

1

12

A K

2

2

12

2

DC+

IGBT1

1

G

1

2

+15v1

14

14

+15V1

+15V1

7

7 U1B

GND1

GND1

U1A

2

1

4

3

GA

HB

1

OUT2

R7

12

1

12

1 3

G

EC

2

2

R43

R38 R44

21

2

12

R37

21

EC

1

IGBT8

1

2 3

1

R31

G

2

12

R36

IGBT5

1

21

2 3

EC

2

2

1

EC

21

2 3

2

12

2

A K

ZD4

2

2 1

2

1

R30

G

1

R50

IGBT4

1

1

1

G

2

R49

21

8

7

6

5

2

12

2

U5

VCCVCC

IN OUT

NC OUT

GNDGND

K A

IGBT6

1

1

7

D8

1

12

1

2

3

4

D5

1

1

R29

K A

F L

GND1

14

+15V1

R53

A K

2

7

2

GND1

14

+15V1

U1F

10 13

C19

2

1

1 2

ZD1

2

1

E K

1

2

C12 2 1

12

R17

C9

1

R16

+15V1

C30

12

12

R9

R8

9

2

J D

14

2 1

A K

8

1

C11

+15V1

7 U1D

GND1

1

2

2

D10

2

12

D11

1

A K

C13

21

1

1 2

+15V1

2 1

A K

1 2

5

1

I C

14D7

1

21 R19

21

K A

6

1

2 R18

21

12

2

21

2

+15V1

7 U1C

GND1

D9

2 1

1 2

R11

1

4

21

NC

Emitter

+15V1

5

2

Cathode

Collector

2

U3

Anode

Base

1

+15V1

1 1

R3

6

2

12

1

DC-

2

R48

2

1

1

2

K A

1

2

K A

1

12

12

1

2 R47

21

7

GND

VCC

14

K A

GND1

2 1

1

2

2

K A

1

D2-3

R6

1

2

K A

1

D2-2

1

2

3

4

C17

D6

1

1

OUT1

11

D2-1

R5

R33

12

F L

7

U1E

D2

12

1 1

A K

1 2

R32

A K

1

3

C4

1 2

C20

1

U2F

1

2

3

4

5

6

2

Text

2

2 1

2

1

U2E

14

2

1

J D

9

C14

R52

2

K A

1 C18

JP3

A K

D15

1

8

R25

2 1

C16

2

+15V2

C29

1

1

1 2

5

14

1

21

11

1

2

3

4

5

6

I C

D16

1

A K

1

1

6

1

2

+15V2

VCC

7 U2D

GND

ZD2

21

21 R35

21

K A

2 1

1

1

2 R34

21

12

2 1

D12

14

DC+1

12

12

2

D14

12

2

12

2

R4

R27

1

4

VCC

7 U2C

GND

21

NC

Emitter

+15V2

5

1 2

C27

RJ2-1

TR1

C3

+15V2

R24

2

3

Cathode

Collector

6

2 1

2

RJ2

TR2

1

HB

2

1

C26

U4

Anode

Base

1

1

TR1

1

3

4

1

2

12

1

2

TR1

1

1

GA

1

1

1 2

TRM

2 2

2

2

R23

2

C25 1

12

2

1

1 R41

12

R42

14

1

2

2

RJ1-1

12

C2

+15v2

14

VCC

7 U2B

GND

2 1

2

12

RJ1

D1-1

1

2

1

D1

K A

2

K A

K A

1

D1-3

1

2

12

2

1

K A

D1-2

2

1

C1

R2

VCC

7 U2A

GND

12

GND2

R1

2

2

1

1

DC+

1

输出正端

25.

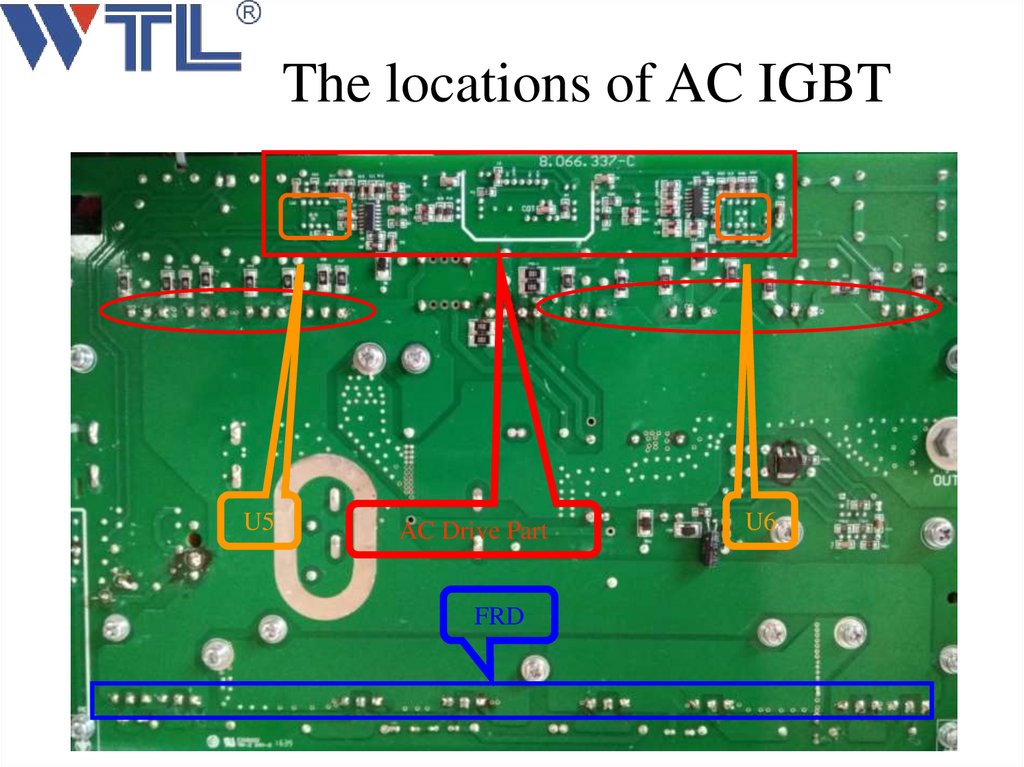

The locations of AC IGBTU5

AC Drive Part

FRD

U6

26.

Solutions when the IGBT is damaged1、 Check the circuit of AC IGBT driver may

be there are some components damaged.

2、Remove IGBT one by one and test as

following page.

3、Replace IC TC4420 and CD4066.

4 、Replace CNY17-4.

27.

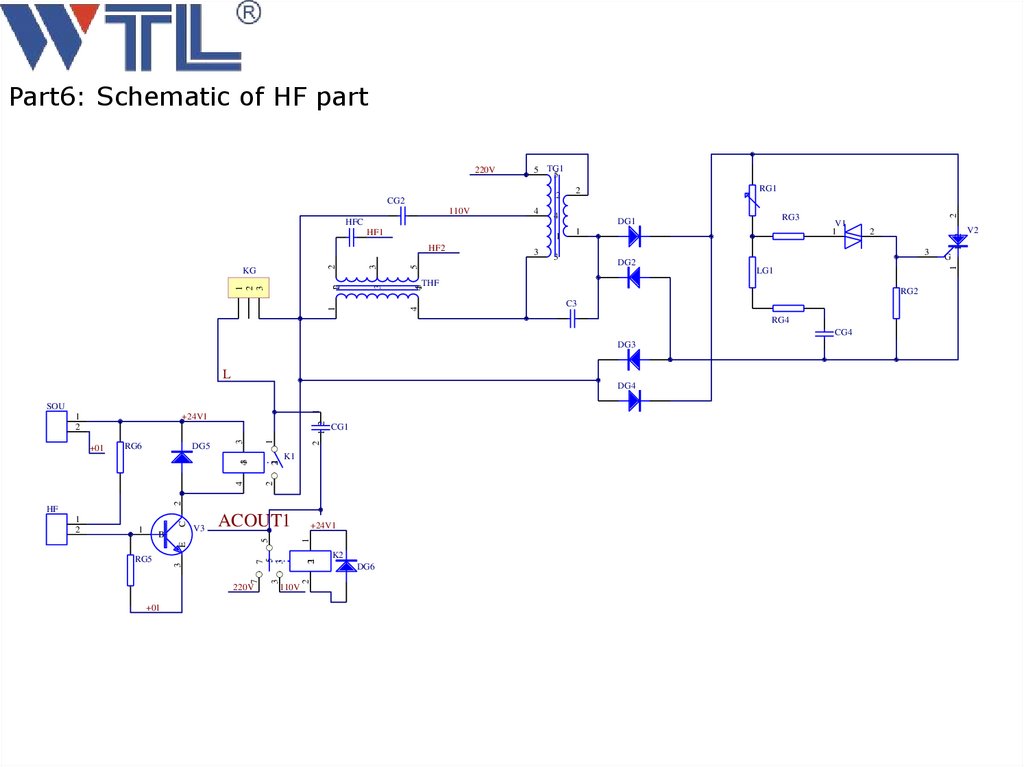

Part6: Schematic of HF part5 TG1

5

4

HF1

1

V1

1

3

5

DG2

LG1

RG2

C3

RG4

CG4

DG3

L

DG4

2

K1

2

4

CG1

2

1

DG5

21

RG6

43

+01

1 2

+24V1

3

1

2

1

SOU

ACOUT1

220V

+01

1

110V

21

7

5

3

7

RG5

+24V1

2

5

V3

E

B

3

1

3

1

2

C

HF

K2

DG6

2

3

45

3

3

RG3

DG1

1

THF

4

12

1

1

2

3

3

2

HF2

KG

4

2

110V

HFC

RG1

2

1 2

2

CG2

G

1

220V

V2

28.

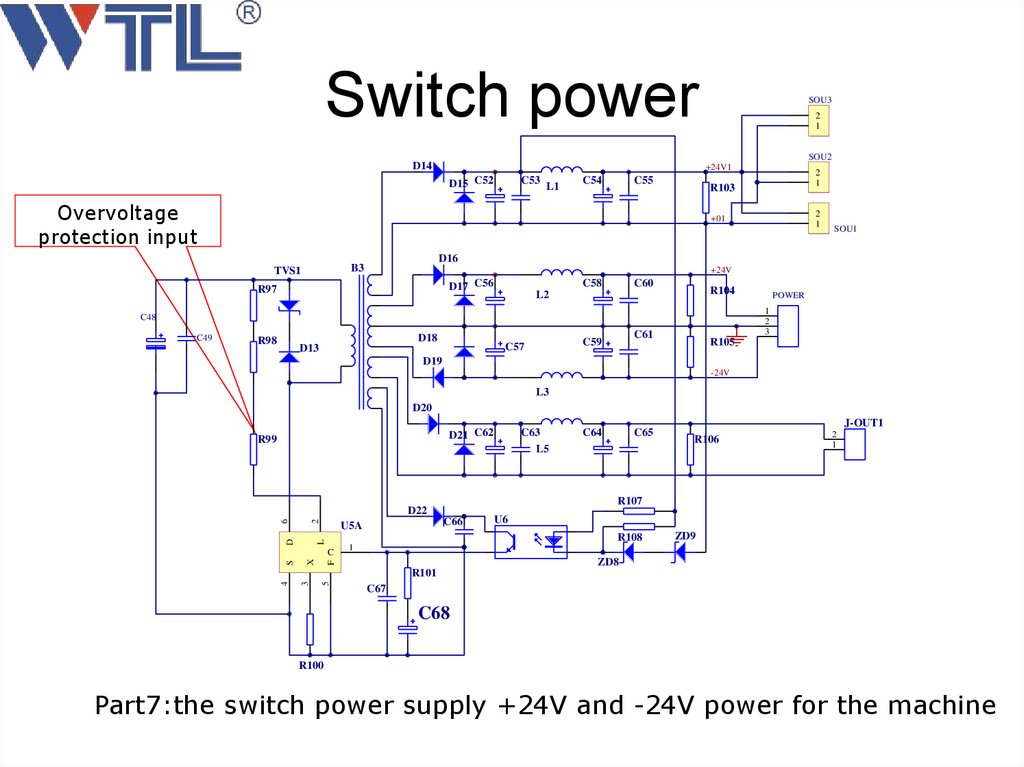

Switch powerSOU3

2

1

SOU2

D14

+24V1

D15 C52

C53

L1

C54

C55

Overvoltage

protection input

2

1

+01

+24V

D17 C56

R97

C58

C60

R104

L2

D18

C61

C59

C57

D13

POWER

1

2

3

C48

R98

SOU1

D16

B3

TVS1

C49

2

1

R103

R105

D19

-24V

L3

D20

D21 C62

R99

2

L

6

D

C66

J-OUT1

R106

2

1

U6

ZD9

1

ZD8

F

X

C65

R108

C

S

C64

R107

D22

U5A

C63

L5

5

3

4

R101

C67

C68

R100

Part7:the switch power supply +24V and -24V power for the machine

29.

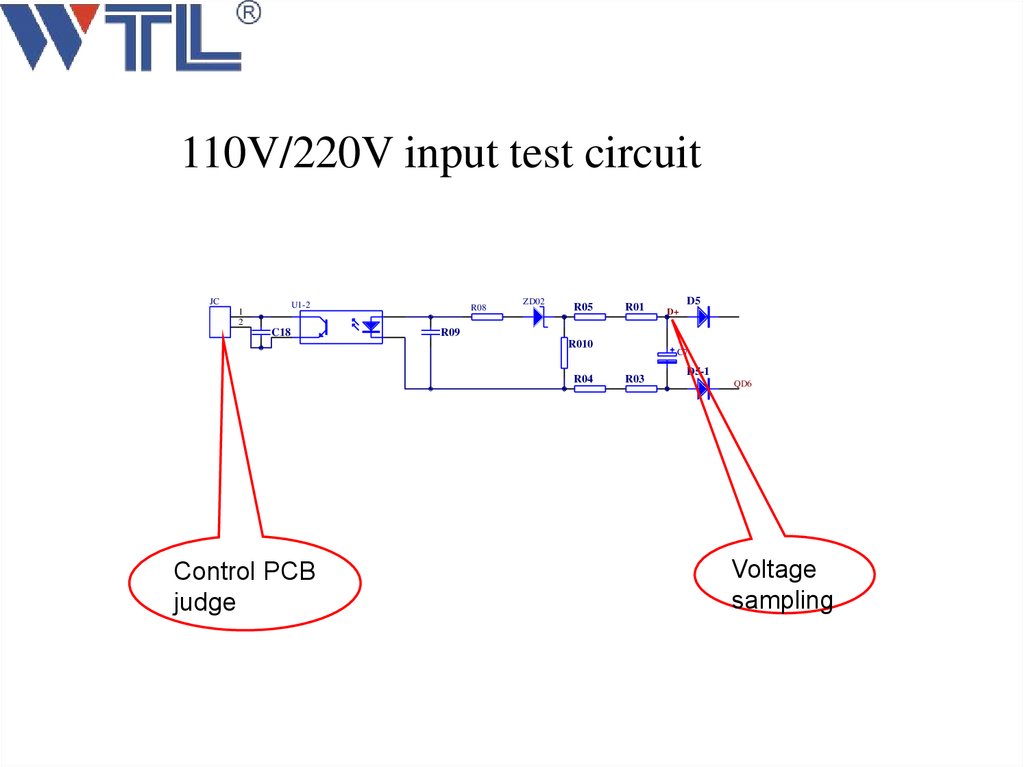

110V/220V input test circuitJC

U1-2

1

2

C18

R08

ZD02

R05

R01

R09

R010

R04

Control PCB

judge

D5

D+

C7

R03

D5-1

QD6

Voltage

sampling

30.

3、Introduction ofcontrol circuit

31.

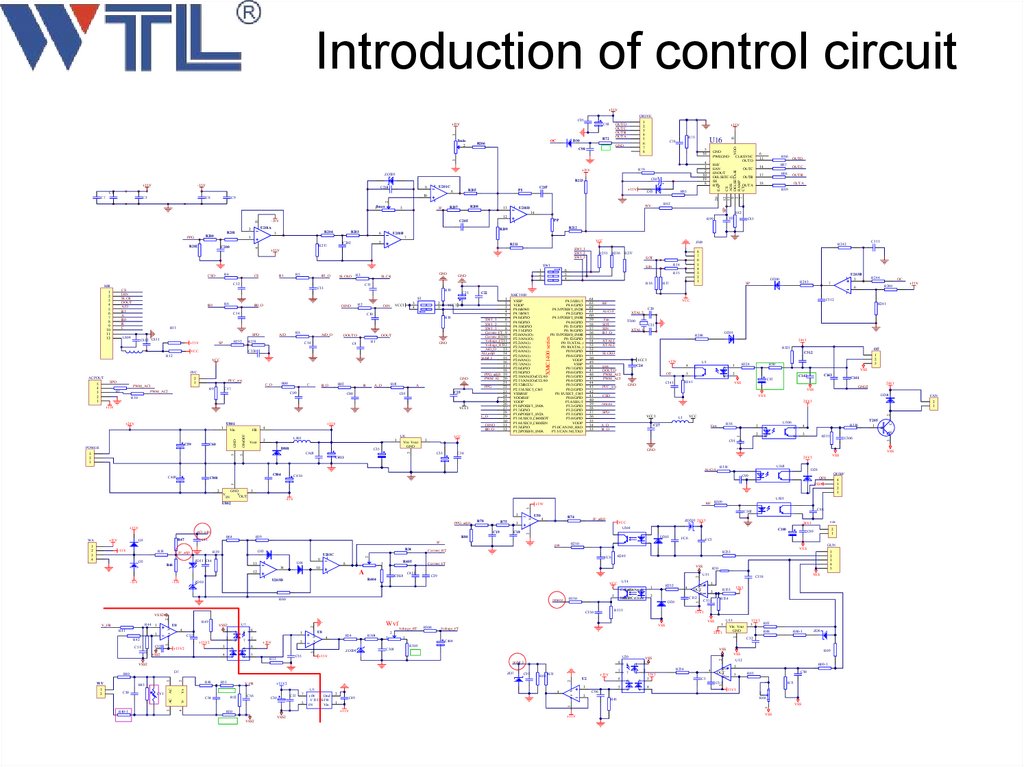

Introduction of control circuit+15V

DRIVE

OC

R206

R72

D30

GND

U16

C78

5

16

GND

PWRGND

4

1

2

10

19

8

C204

U201C

9

R205

8

C1

R85

C9

3

R208

R207

IF

13

14

12

3

R202

7

VCC

5

C202

R217

4

C200

J300

R211

SW1_1

SW1_2

SW1_3

+15V

R235

R236

SOT

B1_D

R3

SLCKD

C12

MB

R6

B0_D

R2

DIND

3

4

VCC1

DIN

C14

2

1

VCC1

C10

SPD

C812 C811

+15V

R232

SP

R8

A/D

A/D_D

R231

R18

DOUTD

C16

DOUT

R1

C4

GND

C220

VCC

R12

VCC

PFC

ACPOUT

2

1

SPD

5

4

3

2

1

PWM_AC1

PWM_AC2

R7

GND

PFC_test

R00

C_D

R9

C

R02

B_D

C17

C09

B

R01

A_D

C00

A

C25

C01

R10

+15V

VCC1

U801

C60

3

3

2

1

4

FB

ON/OFF

GND

C59

POWER

+15V

Vin

Vout

U6

L801

2

1

D801

Vin Vout

GND

C35

C803

C22

D200

VSSP

VDDP

P4.6/HW0

P4.7/HW1

P4.8/GPIO

P4.9/GPIO

P4.10/GPIO

P4.11/GPIO

P2.0/AN(IO)

P2.1/AN(IO)

P2.2/AN(I)

P2.3/AN(I)

P2.4/AN(I)

P2.5/AN(I)

P2.6/AN(I)

P2.7/AN(I)

P2.8/GPIO

P2.9/GPIO

P2.10/AN(IO)/CCU40

P2.11/AN(IO)/CCU40

P2.12/BCCU

P2.13/USIC1_CH1

VSS/REF

VDD/REF

VDDP

P1.8/POSIF1_IN0A

P1.7/GPIO

P1.6/POSIF1_IN2A

P1.5/USIC0_CH0/SOT

P1.4/USIC0_CH0/SIN

P1.3/GPIO

P1.2/POSIF0_IN0A

64

63

62

61

60

59

58

57

56

55

54

53

52

51

50

49

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

P4.5/ERU1

P4.4/GPIO

P4.3/POSIF1_IN2B

P4.2/GPIO

P4.1/POSIF1_IN0B

P4.0/GPIO

P0.15/GPIO

P0.14/GPIO

P0.13/POSIF0_IN0B

P0.12/GPIO

P0.11(XTAL)

P0.10(XTAL)

P0.9/GPIO

P0.8/GPIO

VDDP

VSSP

P0.7/GPIO

P0.6/GPIO

P0.5/GPIO

P0.4/GPIO

P0.3/GPIO

P0.2/GPIO

P0.1/USIC1_CH1

P0.0/GPIO

P3.4/ERU1

P3.3/GPIO

P3.2/GPIO

P3.1/GPIO

P3.0/GPIO

VDDP

P1.0CAN.N0_RXD

P1.1/CAN.N0_TXD

C804

C20

AirCtrl

XTAL2

Fan

SOT

SIN

B1_D

T300

C23

XTAL1

D201

R248

24V1

XTAL1

XTAL2

R325

OT

C312

SLCKD

VCC1

+15V

C24

gun

DOUTD

PWM_AC2

PWM_AC1

4

OT

3

C

A

E

K

R324

1

1

2

3

R90

VSS

2

R141

C141

GND

PFC_test

U1

C143

C142

D204

24V1

remote

VCC1

A_D

B_D

VCC

L1

C27

R58

Fan

U306

1

2

A

C

K

E

GND

R316

4

3

R315

C410

QF/HF

C99

-15V

QF0

5

1

U50

R74

4

IF_adj0

ZD201 24V1

VCC

3

10

C313

VSS

C29

U14

VCC

4

R60

remote

R150

R252

1

Collector

LED Anode

3

4

2

Emitter

LED Cathode

D20

R151

C150

U15

7

3

6

4

5

1

7

3

+15V

Voltage_RT

U8

R54

4

VSS2

4

C55

R53

ZD204

R305

V_FB

C54

7

C97

R63 R31

+15V

R52

C56

C37

C30

7

5

+0V

Dnd

F1515S-1W

0V

Vin

4

2

C49

1

+15V

R50

VSS2

VSS2

U2

6

+15V2

U5

R67

R66

R66-1

+15V

1

5

C96

3

R45

8

7

ZD8

R69

VSS

U20

8

2

R51

15V1

3

C32

VSS

5

2

1

R48

V+

AC

AC

V4

CY1

3

R40-1

C301

ZD7

R43

Vin Vout

GND

24V1

pedal_I

D7

R40

C50

1

VSS

Voltage_FT

3

+15V

VSS2

1

2

R306

2

1

C404

6

5

R304

U13

VSS

Wvf

2

8

2

8

2

R154

VSS

1

1

R254

2

2

6

3

5

4

15V1

3

4

U12

C5

IN+

OUT

IN-

3

C5-1

4

R69-1

1

C90

R65

1

3

+15V2

1

15V1

15V1

2

+15V2

5

C52

2

V+ V-

C53

5

C51

U7

VSS2

1

4

VSS

C158

R153

V+ V-

R49

U0

R42

V+ V-

3

V+ V-

R44 1

R41

R70

1

IN+

OUT

3

INC152

C153

2

VSS2

V_FB

1

2

3

4

5

R253

R249

R404

U203D

ZD10

-15V

Current_FT

C413

5

-15V

Current_RT

R405

FC8

1

A

15V1

R71

1

8

14

12

GUN

VSS

2

2

R68

3

D14

13

2

1

FC5

R250

VSS

3

U203C

9

ZD11 C44

FC6

2

D13

R39

IF_adj0

gun

R34

C89

2

IF

R46

C100

D203

V+ V-

R38

D5

C18

R80

5

-15V

C45

R59

2

R47

D3

C19

R64

sou

24V1

U304

AD_adj0

WV

C88

C302

V- V+

PPG_adj0

R75

+15V

+15V

4

3

2

1

U301

HF R309

+15V

R78

T205

1

B

VSS

VSS

D28

3

3

1

2

3

4

C306

24V1

U303

R314

VSS

FAN

2

1

SPD

VSS

GND

V

V

OUT

IN

24V1

GND2

VSS

VSS

C34

U802

WA

C101

C87

VSS

CSD

1

2

+15V

R241

C411

C801

OC

R240

C112

VCC

HF

AirCtrl

C409

R244

7

XMC1400

1

2

3

4

5

SW1_1

6

SW1_2

7

SW1_3

8

Current_FT 9

Current_RT10

Voltage_FT11

Voltage_RT12

A/D_D

13

AD_adj0

14

pedal_I

15

16

17

18

PPG_adj0 19

PWM AL 20

21

PPG

22

23

24

25

26

27

28

C_D

29

30

DIND

31

B0_D

32

C91

C33

U203B

5

R243

SP

VCC

3

2

1

5

+24V

R15

R17

6

C21

R11

L804

R14

SIN

6

5

4

R16

R19

S1

B0

1

2

3

GND

C11

C13

CS

DIN

SLCK

DOUT

A/D

B1

A

B0

B

C

1

2

3

4

5

6

7

8

9

10

11

12

GND

SLCK

1

R5

B1

XMC1400 series

CS

C111

R242

8

7

6

5

4

3

2

1

R237

SW1

R4

CSD

C81

U201B

2

6

C

R203

R82

C02

R212

R209

E

PPG

R204

1

OUTA

2

11

R201

R200

U201A

2

R99

PP

C205

OUTB

R89

R83

WV

U201D

SP

1Imax

-15V

OUTC

17

R88

18

OUTA

OUTD

R87

3

C8

D15

20

C3

+15V

2

C7

C207

PI

10

OUTB

R86

14

1 2

-15V

+

R213

+15V

OUTC

CS

ADS

DELSETA-B

RAMP

CT

C80

EAP

ZD203

REF

EAN

ENOUT

DELSETC-D

SS

RT

12

11

9

3

7

R79

+15V

6

13

CLKSYNC

OUTD

3

C98

+15V

R73

15

Imin

2

1

2

3

4

5

6

7

8

OUTD

OUTC

OUTB

OUTA

1

C93

VDD

C95

+15V

32.

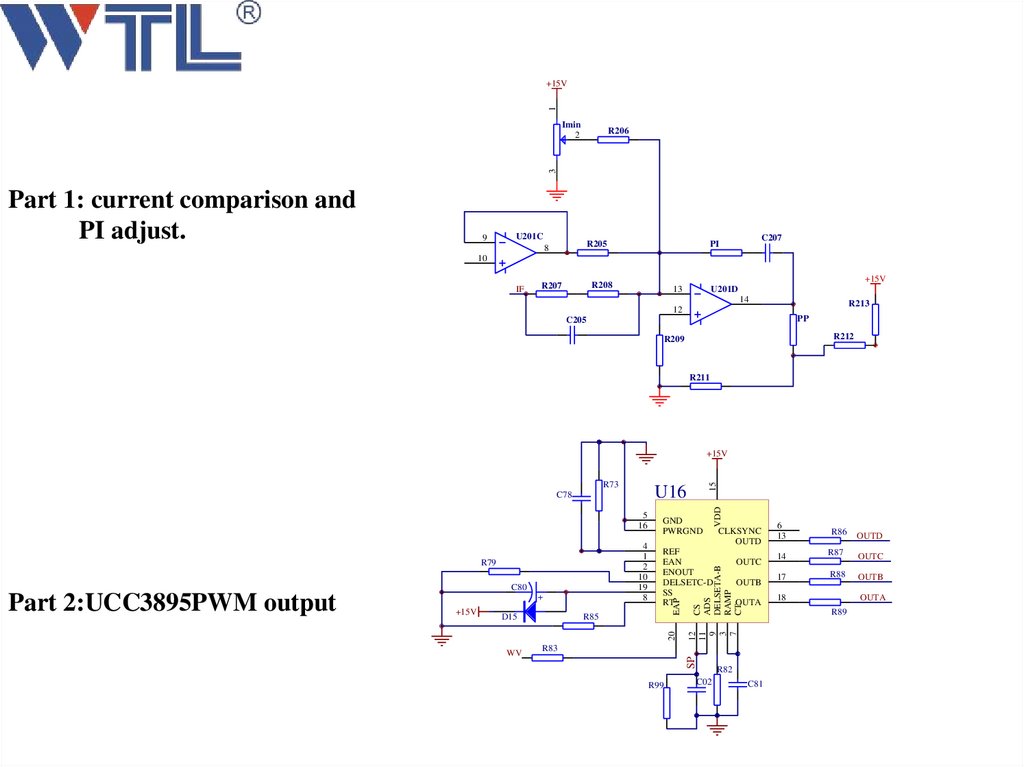

1+15V

Imin

2

3

R206

Part 1: current comparison and

PI adjust.

9

U201C

R205

8

C207

PI

10

IF

+15V

R208

R207

13

U201D

14

R213

12

PP

C205

R212

R209

R211

U16

R79

C80

+

D15

R85

20

+15V

REF

EAN

ENOUT

DELSETC-D

SS

RT

WV

OUTC

OUTB

OUTA

R99

C02

6

13

R86

R82

C81

OUTD

14

R87

OUTC

17

R88

OUTB

18

OUTA

R89

R83

SP

Part 2:UCC3895PWM output

CLKSYNC

OUTD

CS

ADS

DELSETA-B

RAMP

CT

4

1

2

10

19

8

GND

PWRGND

EAP

5

16

12

11

9

3

7

C78

VDD

R73

15

+15V

33.

C111R242

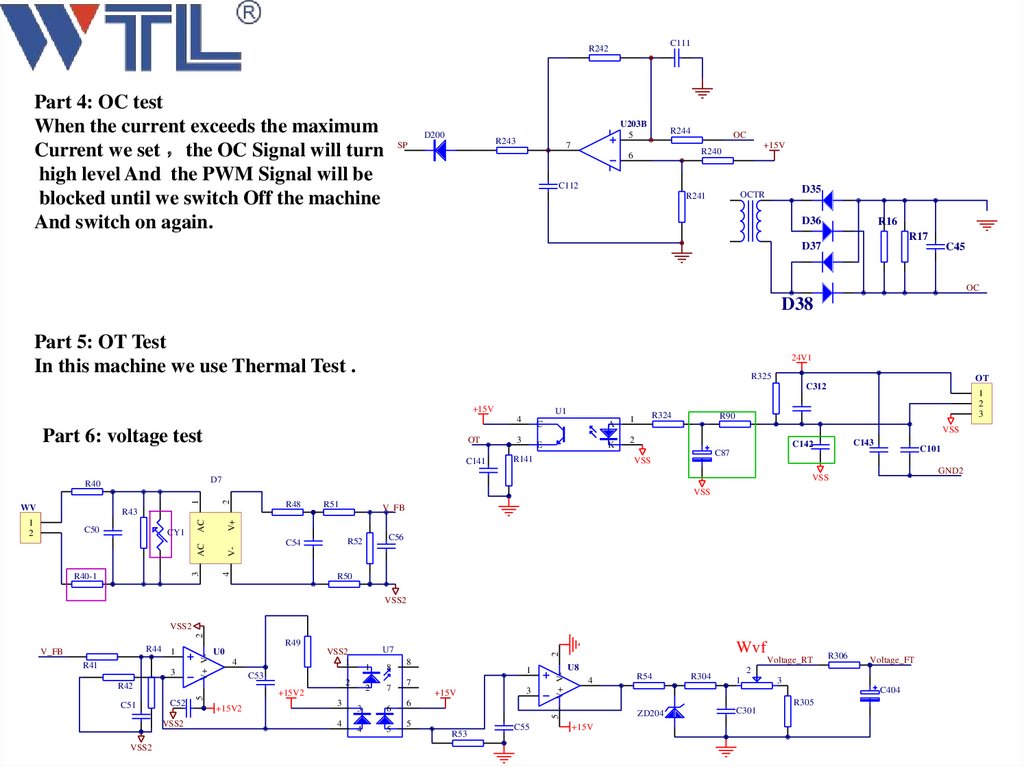

Part 4: OC test

When the current exceeds the maximum

Current we set the OC Signal will turn

high level And the PWM Signal will be

blocked until we switch Off the machine

And switch on again.

D200

U203B

5

R243

SP

R244

7

OC

+15V

R240

6

C112

D35

OCTR

R241

D36

R16

R17

D37

C45

OC

D38

Part 5: OT Test

In this machine we use Thermal Test .

24V1

R325

OT

C312

+15V

U1

4

Part 6: voltage test

OT

C141

3

C

A

E

K

R141

R324

1

R90

VSS

2

C143

C142

C101

C87

VSS

GND2

VSS

D7

R40

1

2

3

2

1

VSS

WV

R48

C50

R40-1

V_FB

V-

C56

R52

C54

4

3

AC

CY1

R51

V+

1

2

AC

R43

R50

VSS2

2

VSS2

3

C53

R42

2

2

+15V2

5

C52

1

+15V2

3

8

7

3

6

4

5

8

Wvf

1

7

+15V

3

Voltage_RT

U8

4

VSS2

VSS2

4

R54

5

R53

C55

R304

R306

Voltage_FT

2

1

3

C404

6

ZD204

5

C51

U7

VSS2

1

4

2

U0

V+ V-

R41

R49

V+ V-

R44 1

V_FB

+15V

C301

R305

34.

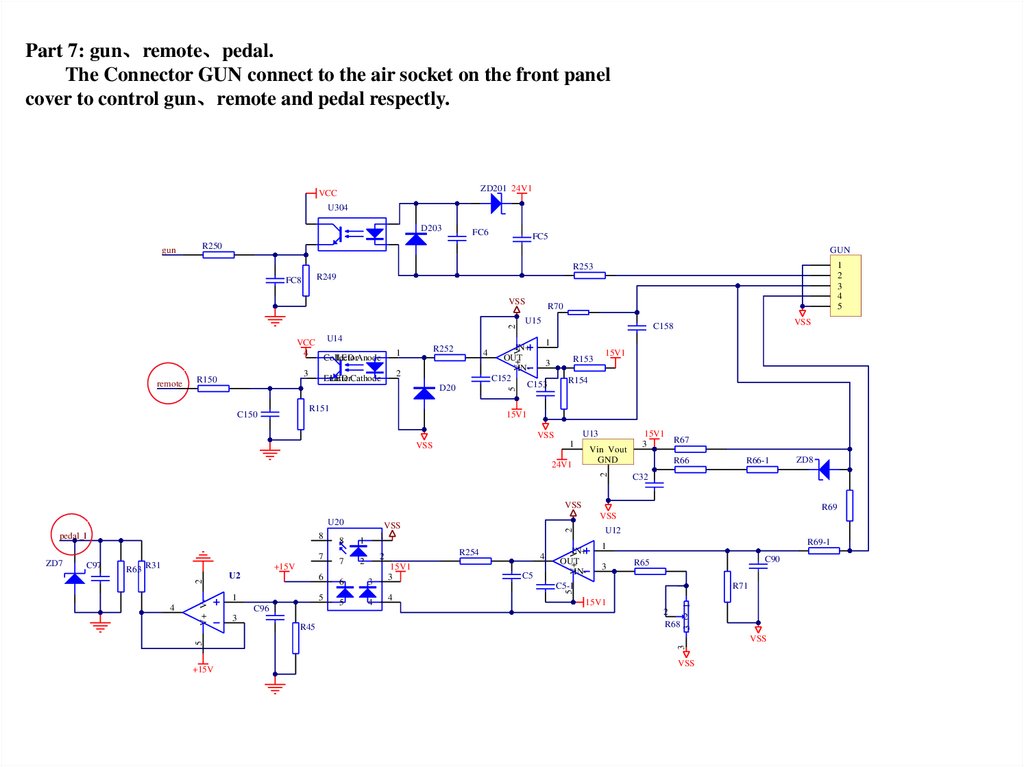

Part 7: gun、remote、pedal.The Connector GUN connect to the air socket on the front panel

cover to control gun、remote and pedal respectly.

ZD201 24V1

VCC

U304

D203

gun

FC6

FC5

R250

GUN

1

2

3

4

5

R253

R249

FC8

2

VSS

U14

3

R150

R252

1

Collector

LED Anode

4

2

Emitter

LED Cathode

R151

C150

IN+

OUT

3

INC152

C153

R153

15V1

R154

5

D20

VSS

C158

1

V+ V-

VCC

4

remote

R70

U15

15V1

U13

VSS

1

VSS

Vin Vout

GND

2

24V1

15V1

3

R67

R66

R66-1

VSS

+15V

C96

3

R45

3

5

4

15V1

3

2

C5

3

C5-1

4

R69-1

C90

R65

1

5

2

6

IN+

OUT

IN-

15V1

R71

1

1

7

4

2

2

R68

3

4

6

R254

2

U12

1

VSS

3

2

+15V

U2

1

V+ V-

R63 R31

V+ V-

C97

8

VSS

1

5

7

5

ZD7

8

R69

VSS

U20

pedal_I

ZD8

C32

VSS

35.

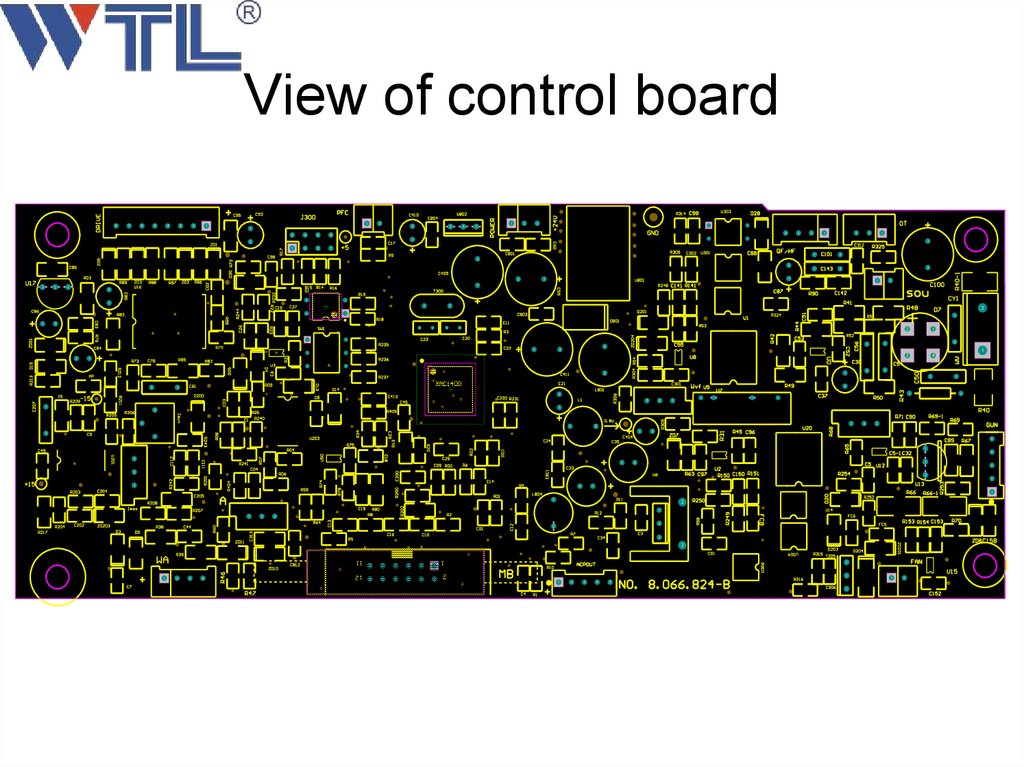

View of control board8

7

6

5

4

3

2

1

1

2

2

1

2

4

6

3

2

1

1

2

3

3

5

4

2

3

4

1

1

1

8

2

3

2

1

3

2

1

1

7

1

2

1

2

2

2

2

3

2

1

2

2

1

1

2

1

1

1

1

3

2

4

1

1

2

2

1

2

1

2

1

1

2

1

2

2

5

3

4

2

4

2

1

2

1

2

1

1

3

2

1

1

2

5

2

7

1

3

2

1

1

2

1

2

3

2

2

1

2

1

1

1

1

1

2

1

2

2

6

2

3

2

1

5

1

3

1

2

2

2

3

1

2

4

3

2

1

1

1

2

1

1

2

3

2

2

3

2

1

2

3

4

11

9

7

5

3

1

12

10

8

6

4

2

3

2

1

2

3

4

5

1

1

2

36.

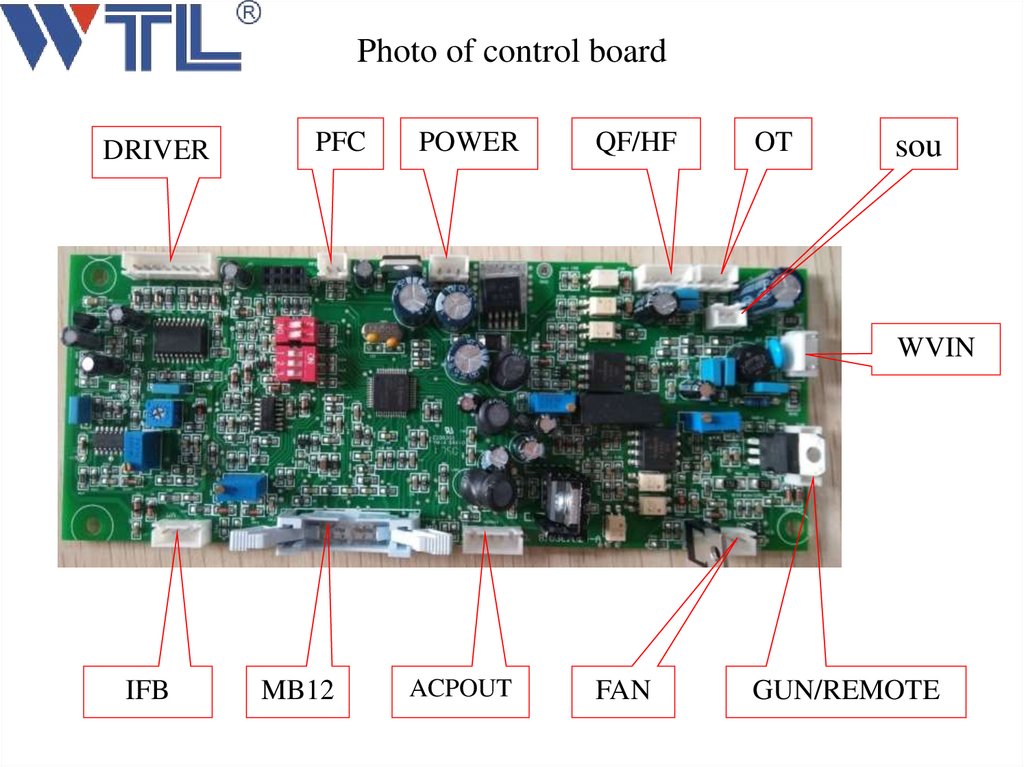

Photo of control boardDRIVER

PFC

POWER

QF/HF

OT

sou

WVIN

IFB

MB12

ACPOUT

FAN

GUN/REMOTE

37.

• FAN ---- Connected with the FAN of the machine. 1_-24V 2_ GND• OT ---- Connected with the temperature sensor to provide over-temperature

signal. 1_NTC-GND 2_OT 3_NTC.

• PFC ---- Connected with the main board to judge the input voltage.

• IF ---- Connected with HALL sensor to sample current signal.

1_+15V 2_-15V 3_Iist-In 4_GND.

• DRIVER ---- Connected with DC main board to provide PWM signal and

control board power. 1_+15V 2_out-D 3_out-C,4_out-B 5_out-A

6_OC 7_GND 8_-24V.

• WVIN----Connected with the output to sample voltage signal.1_+ 2_-.

• SOU---- Connected with main board. 1_VSS 2_24V1.

38.

GUN/REMOTE ---- Connected with the gun and remote to provide signal

POWER ---- Connected with main board. 1_+24V 2_GND 3_-24V.

MB12---- Connected with panel board .

QF/HF---- Connected with gas valve and main board to provide signal.

DRIVER ---- Connected with AC main board to provide PWM signal and

control board power. 1_+15V 2_GND 3_AC1,4_AC2.

39.

4、Introduction of panel circuit40.

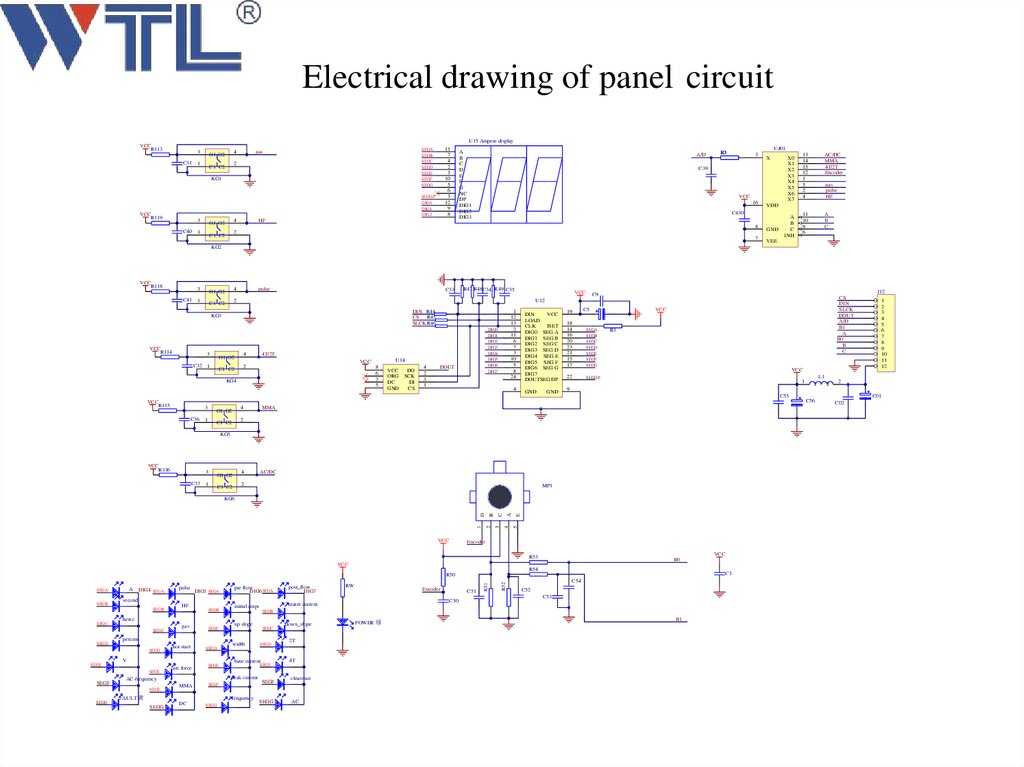

Electrical drawing of panel circuitU15 Ampere display

VCC

R113

3

C31

4

O1 O2

1

2

C1 C2

11

7

4

2

1

10

5

6

3

12

9

8

SEGA

SEGB

SEGC

SEGD

SEGE

SEGF

SEGG

gas

KG1

SEGDP

DIG0

DIG1

DIG2

VCC

R119

3

C40

4

O1 O2

1

HF

A

B

C

D

E

F

G

NC

DP

DIG1

DIG2

DIG3

A/D

U401

R3

3

C39

VCC

16

8

7

X0

X1

X2

X3

X4

X5

X6

X7

13

14

15

12

1

5

2

4

AC/DC

MMA

4T/2T

Encoder

11

10

9

6

A

B

C

gas

pulse

HF

VDD

C430

2

C1 C2

X

GND

A

B

C

INH

VEE

KG2

VCC

R118

3

C41

4

O1 O2

1

pulse

C33

3

DIN R44

CS

R45

SLCK R46

4

O1 O2

C32 1

3

8

6

7

5

C36

4

O1 O2

1

U14

VCC

VCC

DO

ORG SCK

DC

DI

GND

CS

4

2

3

1

1

12

13

2

11

6

7

3

10

5

8

24

DIG0

DIG1

DIG2

DIG3

DIG4

DIG5

DIG6

DIG7

4T/2T

2

C1 C2

KG4

VCC

R115

VCC

J12

C9

CS

DIN

SLCK

DOUT

A/D

B1

A

B0

B

C

U12

KG3

VCC

R114

R47 R48C34 R49 C35

2

C1 C2

DOUT

4

DIN

VCC

LOAD

CLK

ISET

DIG0 SEG A

DIG1 SEG B

DIG2 SEG C

DIG3 SEG D

DIG4 SEG E

DIG5 SEG F

DIG6 SEG G

DIG7

DOUTSEG DP

GND

GND

19

C5

18

14

16

20

23

21

15

17

SEGA

SEGB

SEGC

SEGD

SEGE

SEGF

SEGG

22

SEGDP

VCC

R1

VCC

1

9

C55

MMA

2

C1 C2

KG5

VCC

R116

3

C37 1

4

O1 O2

AC/DC

2

C1 C2

MP1

VCC

A

C

B

E

5

4

3

2

1

D

KG6

Encoder

VCC

R53

VCC

B0

R54

C1

SEGB

SEGC

hot start

SEGD

arc force

SEGE

pre flow

DIG6 SEGA

post_flow

DIG7

initial amps

crater current

MMA

up slope

width

DC

SEGG

SEGD

SEGE

frequency

SEGG

SEGC

base current

SEGF

FAULT 黄

RW

Encoder

C51

C50

C54

C52

C53

SEGB

peak current

AC-frequency

SEGF

SEGG

gas

V

SEGE

SEGF

SEGB

percent

SEGD

SEGE

HF

hertz

SEGC

SEGD

DIG5 SEGA

second

SEGB

SEGC

pulse

R52

DIG4 SEGA

R51

R50

A

SEGA

SEGF

SEGG

down_slope

2T

4T

clearence

AC

POWER 绿

B1

L1

1

C56

2

1

2

3

4

5

6

7

8

9

10

11

12

2

C01

C02

41.

panel PCB12

2

4

2

11

10

9

8

2

7

1

2

1

3

1

1

1

2

2

2

1

1

1

2

1

1

1

3

2

2

4

2

3

4

5

2

1

2

1

11

12

9

10

7

8

5

6

3

4

1

2

2

4

2

1

2

1

2

1

3

1

2

2

2

1

1

2

2

2

1

1

2

3

3

2

1

2

1

2

1

1

1

2

2

2

1

1

2

1

2

1

1

2

2

1

4

2

3

1

4

1

2

4

1

1

2

2

1

1

3

5

1

4

2

2

1

2

1

42.

Photo of panel boardCurrent display

LED1: power

display

LED2:Over-temprature or

Over-current alarm

2T/4T

Gas check

AC/DC

HF

PULSE

Process selection

43.

Common troubles1.When starting the power source, the fan

works, but the power light is not on.

2 When starting the power source, the power

light is on, but the fan doesn’t work.

Solutions

Open the shell and check the welding connector

of the front panel and control panel or replace it.

(1) Something unusual is blocked in the blade.

Clear it out.

(2) The fan is damaged. Replace the fan with

the same type.

(3) The connector of fan not connect to the

machine.

3 When starting the power source, the fan and

the power light work normally at the beginning

but stop working later.

Over-voltage input. Check the input voltage.

4. When starting the machine, the power light

keeps flickering.

(1) Check whether there are some Component

damaged on control board .

(2) Check whether there are IGBT damaged.

(refer to IGBT test) .

(3) Replace the transformer of the B1 switch

power supply on the main board and the U1

TOP244 Integrated Circuit.

44.

The current can’t be adjusted.The current adjustment potentiometer is damaged.

Replace the potentiometer with the same type.

6.

The current is infinite.

HALL is damaged. Replace the HALL with the

same type.

7.

When starting the machine, the chief

switch of input power source trips

instantaneously.

5.

8. When starting the machine, the fan and the

power light work normally, but there’s no

voltage and circuit output.

Replace the 5016rectifying bridge.

(1) Check the output of the No. 13、14 pin and

No. 17、18 pin of UCC3895 on the control

board (refer to UCC3895 test) ,if the control

board works well. Otherwise, please replace

it.

(2) If the voltage of control board is right, the

problem may arise in the main board. Then,

use the multimeter to check the IGBT (refer

to IGBT test of wave ) If the circuit occurs or

an obvious evidence of explosion appears.

We must switch off machine and check

whether there are IGBT (refer to IGBT test)

or FRD (refer to FRD test) damaged.

45.

5、Troubleshooting46.

A-1:When the machine is turned on , the powerLED is not on.

Resolution:

1.There is no input voltage , check whether there is

input voltage of the connection box on the rear panel;

2.The power LED is damaged or there is a poor

contact , repair the inside circuit of the power LED;

3.There is something wrong with the main board ,

repair it.

A-2:The digital display is not intact.

Resolution:

The nixie tube on the digital display is damaged ,

change it or change the front panel.

47.

A-3:The max/min welding current is not agree with the outfactory set value.Resolution:

1.If the min welding current is not agree with the out-factory set

value , adjust the Imin potentiometer on the control board;

2. If the max welding current is not agree with the out-factory set

value , adjust the Imax potentiometer on the control board.

48.

A-4:The display welding current is not agree with theactual current.

Resolution:

1.The min display welding current is not agree with the

actual current, value , adjust the A potentiometer on the

control board;

2. 1.The max display welding current is not agree with the

actual current, value, adjust the A potentiometer on the

control board.

A-5:The welding current can not be adjusted.

Resolution:

1.The welding current potentiometer on the panel is

damaged or has a poor contact , repair or change it;

2.The control board is damaged , repair or change it.

49.

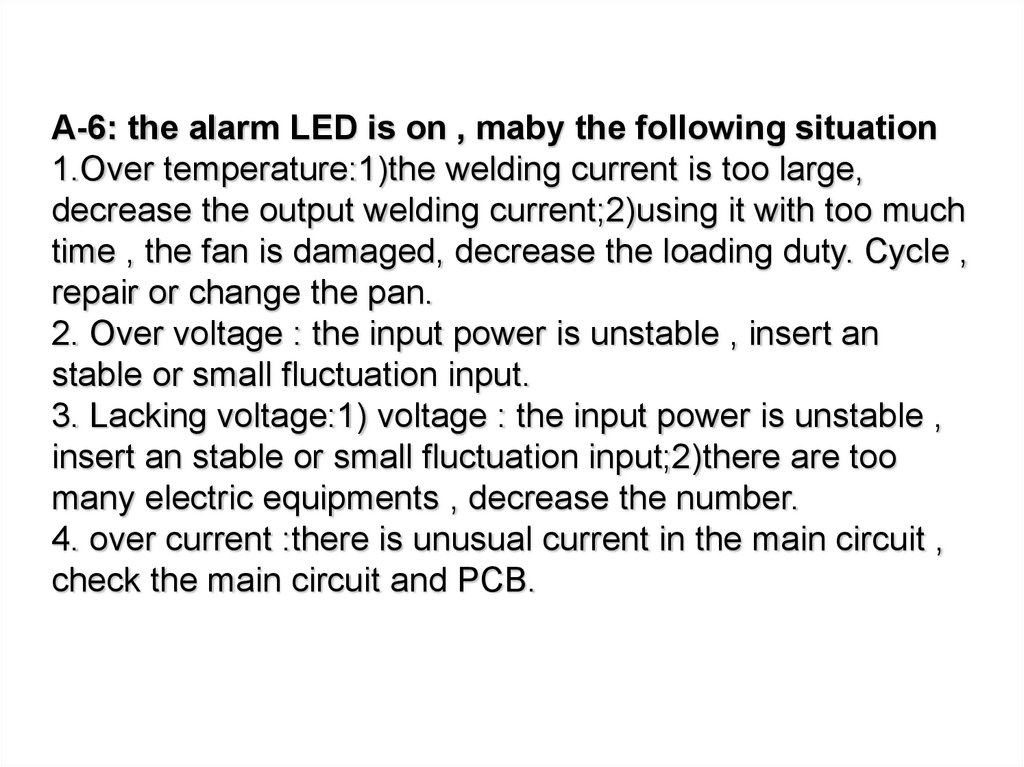

A-6: the alarm LED is on , maby the following situation1.Over temperature:1)the welding current is too large,

decrease the output welding current;2)using it with too much

time , the fan is damaged, decrease the loading duty. Cycle ,

repair or change the pan.

2. Over voltage : the input power is unstable , insert an

stable or small fluctuation input.

3. Lacking voltage:1) voltage : the input power is unstable ,

insert an stable or small fluctuation input;2)there are too

many electric equipments , decrease the number.

4. over current :there is unusual current in the main circuit ,

check the main circuit and PCB.

50.

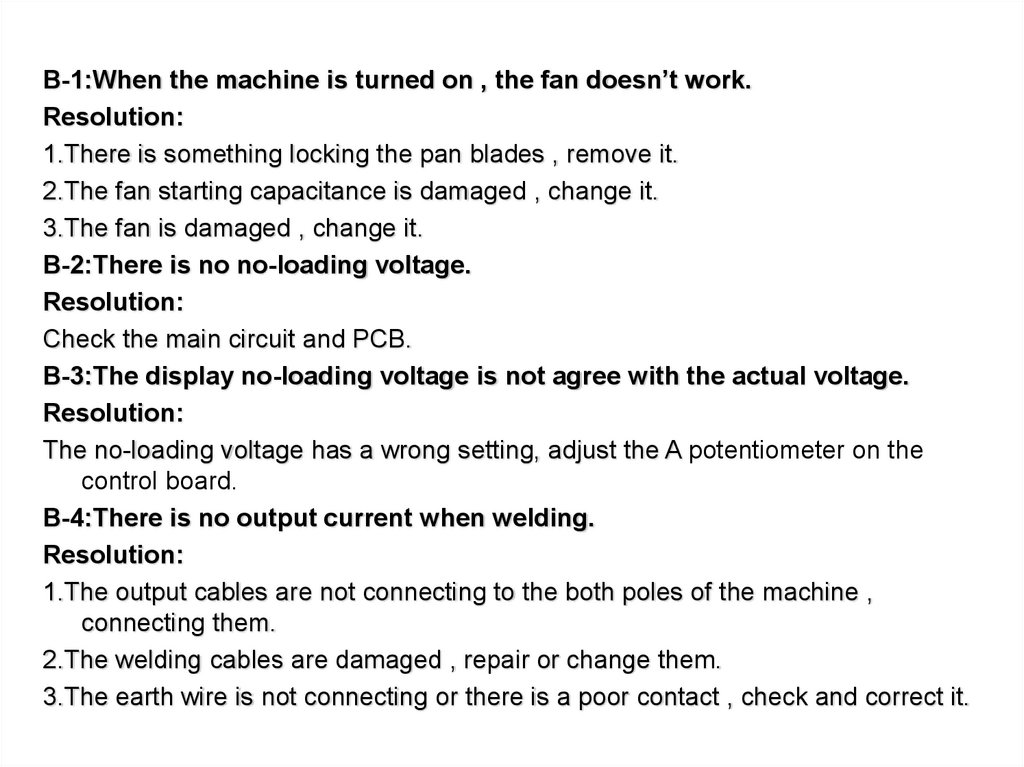

B-1:When the machine is turned on , the fan doesn’t work.Resolution:

1.There is something locking the pan blades , remove it.

2.The fan starting capacitance is damaged , change it.

3.The fan is damaged , change it.

B-2:There is no no-loading voltage.

Resolution:

Check the main circuit and PCB.

B-3:The display no-loading voltage is not agree with the actual voltage.

Resolution:

The no-loading voltage has a wrong setting, adjust the A potentiometer on the

control board.

B-4:There is no output current when welding.

Resolution:

1.The output cables are not connecting to the both poles of the machine ,

connecting them.

2.The welding cables are damaged , repair or change them.

3.The earth wire is not connecting or there is a poor contact , check and correct it.

51.

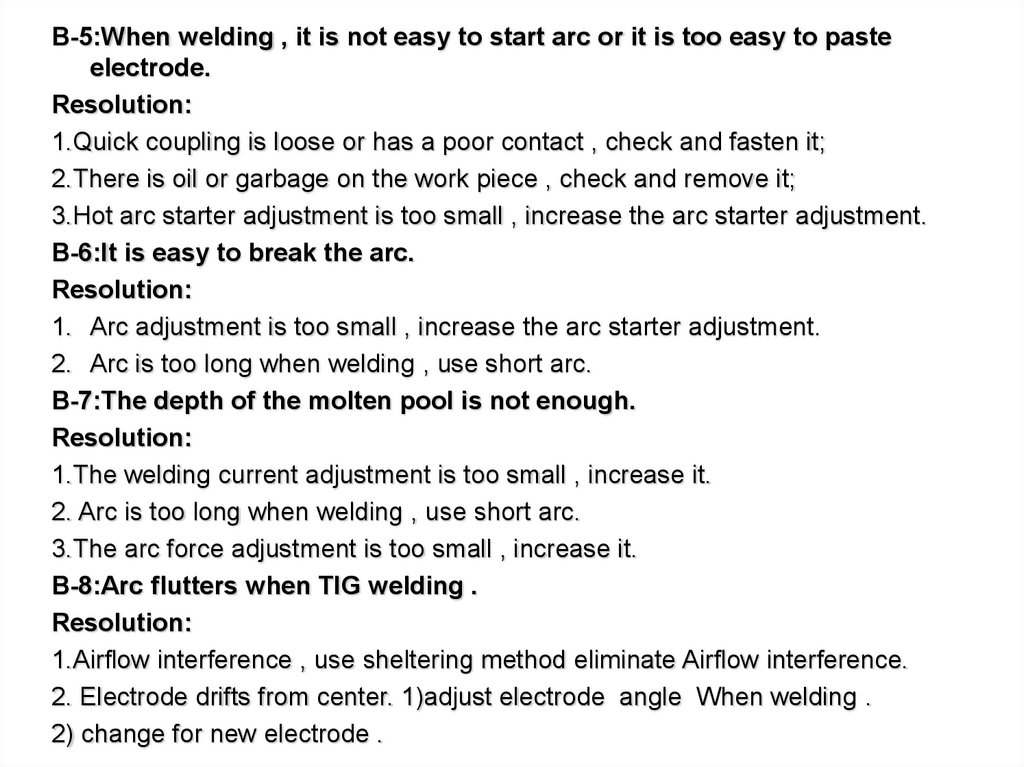

B-5:When welding , it is not easy to start arc or it is too easy to pasteelectrode.

Resolution:

1.Quick coupling is loose or has a poor contact , check and fasten it;

2.There is oil or garbage on the work piece , check and remove it;

3.Hot arc starter adjustment is too small , increase the arc starter adjustment.

B-6:It is easy to break the arc.

Resolution:

1. Arc adjustment is too small , increase the arc starter adjustment.

2. Arc is too long when welding , use short arc.

B-7:The depth of the molten pool is not enough.

Resolution:

1.The welding current adjustment is too small , increase it.

2. Arc is too long when welding , use short arc.

3.The arc force adjustment is too small , increase it.

B-8:Arc flutters when TIG welding .

Resolution:

1.Airflow interference , use sheltering method eliminate Airflow interference.

2. Electrode drifts from center. 1)adjust electrode angle When welding .

2) change for new electrode .

52.

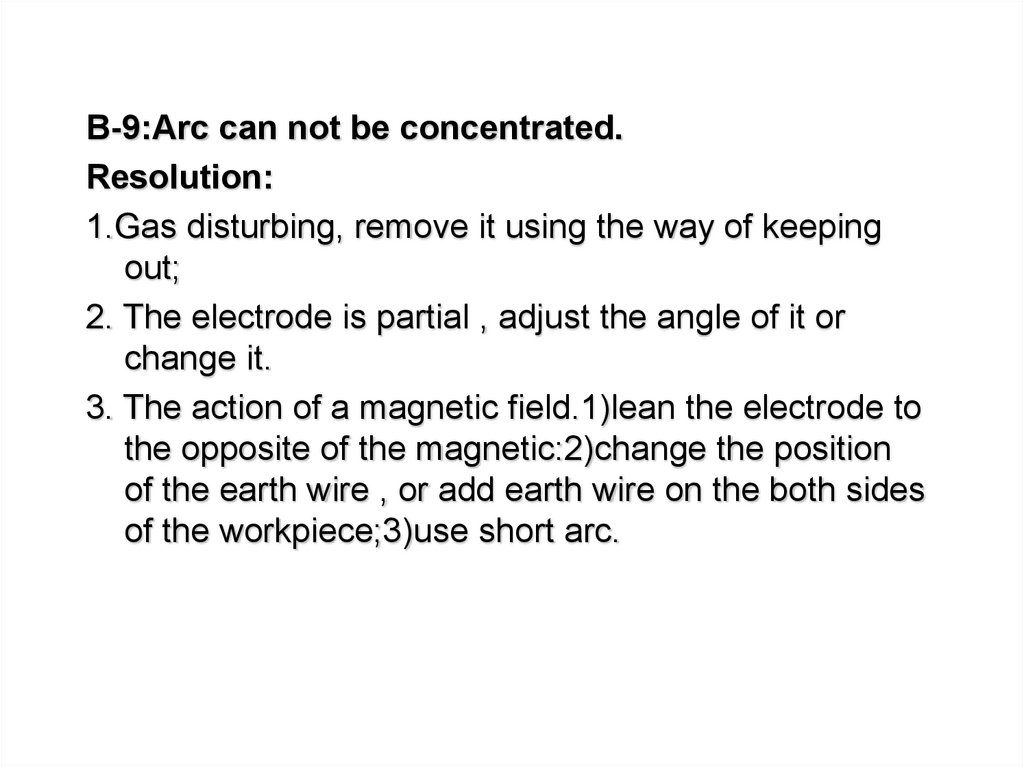

B-9:Arc can not be concentrated.Resolution:

1.Gas disturbing, remove it using the way of keeping

out;

2. The electrode is partial , adjust the angle of it or

change it.

3. The action of a magnetic field.1)lean the electrode to

the opposite of the magnetic:2)change the position

of the earth wire , or add earth wire on the both sides

of the workpiece;3)use short arc.

53.

6.Component test1、 UC3895 Test

2、IGBT Test

3、FRD Test

54.

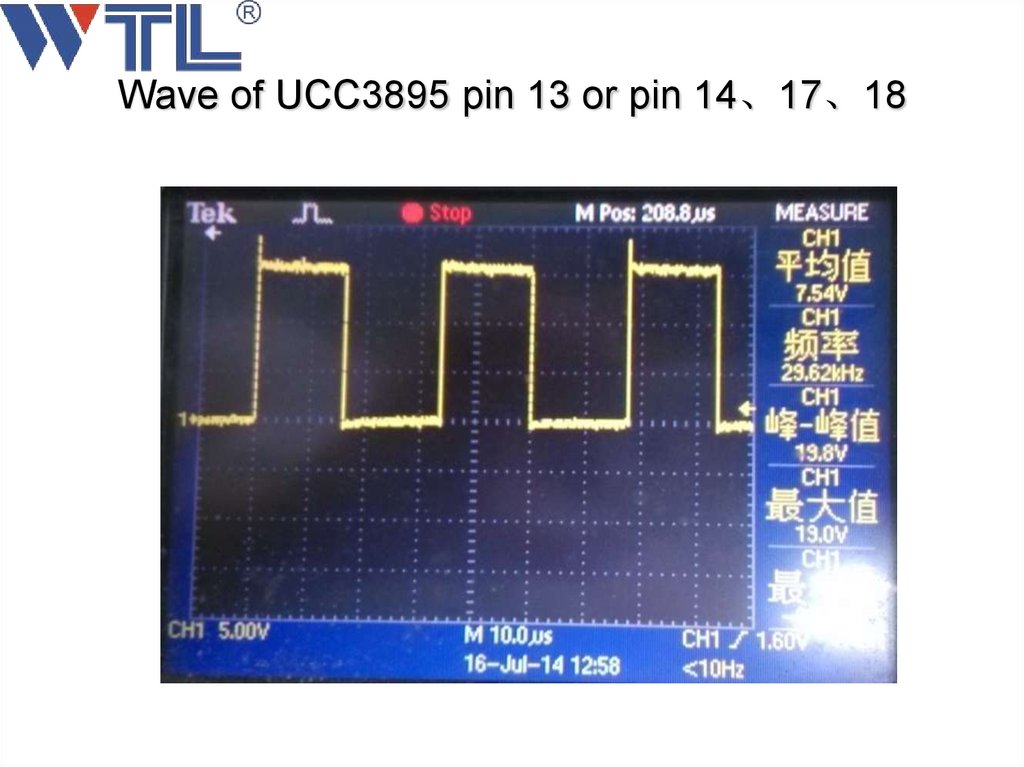

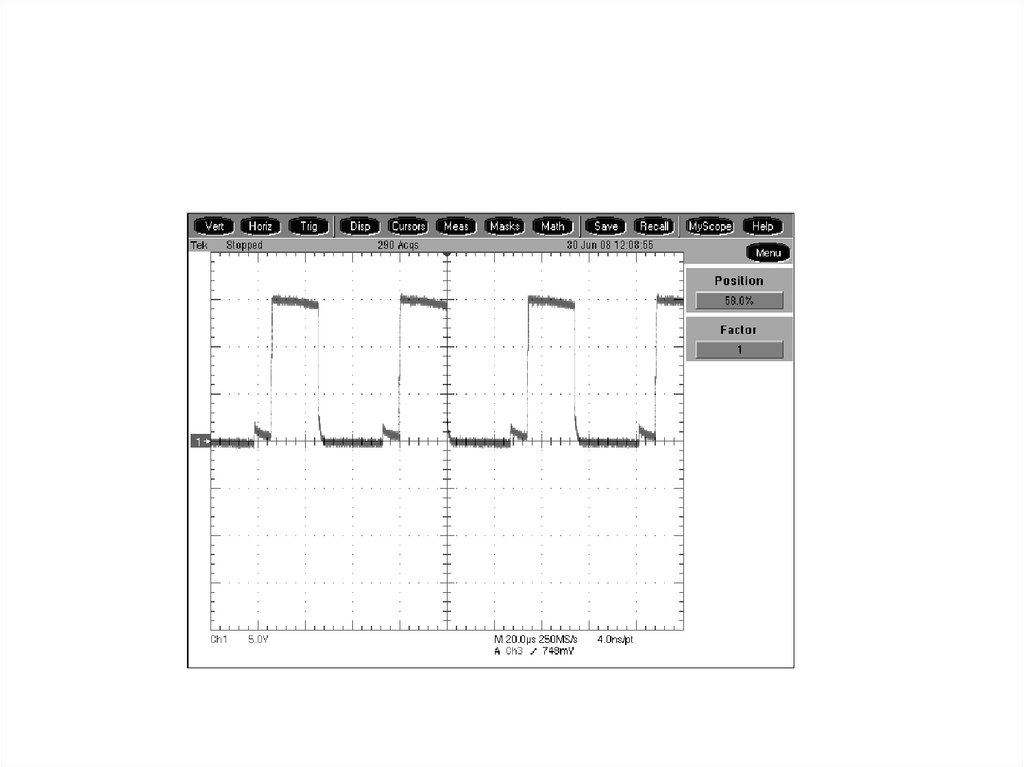

UC3895 TestingWe can use the

oscilloscope test pin

13、14 and pin 17、

18 if the wave as

good as the following

figure, then

the control board

works well .

55.

Wave of UCC3895 pin 13 or pin 14、17、1856.

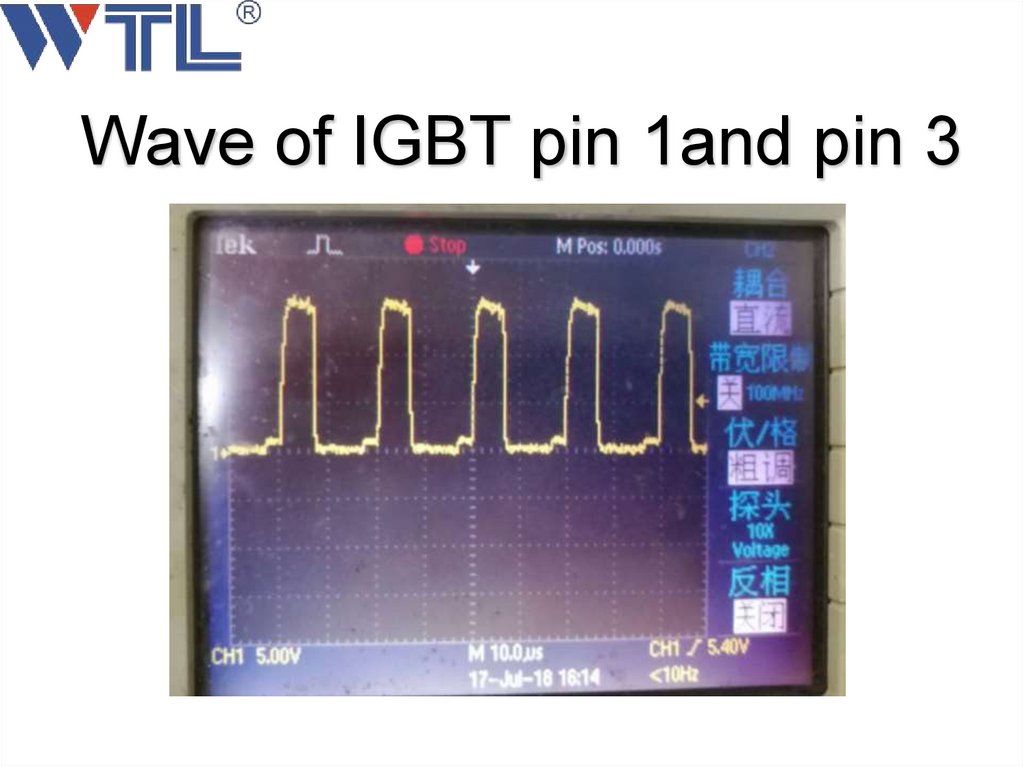

Wave of IGBT pin 1and pin 357.

The location of IGBTG C E

EC G

G C E

E CG

58.

Preparation of test IGBT1、We must Switch off the machine

2、After 5 minutes we can test .

3、Turn the rotary switch to test diode.

4、keep 3 seconds when we test every step.

5、If the result we test as similar as the following

picture .we can say the IGBT is good. Otherwise

there are some IGBT damaged.

59.

IGBT Test(A-1)IGBT Test(A-2)

60.

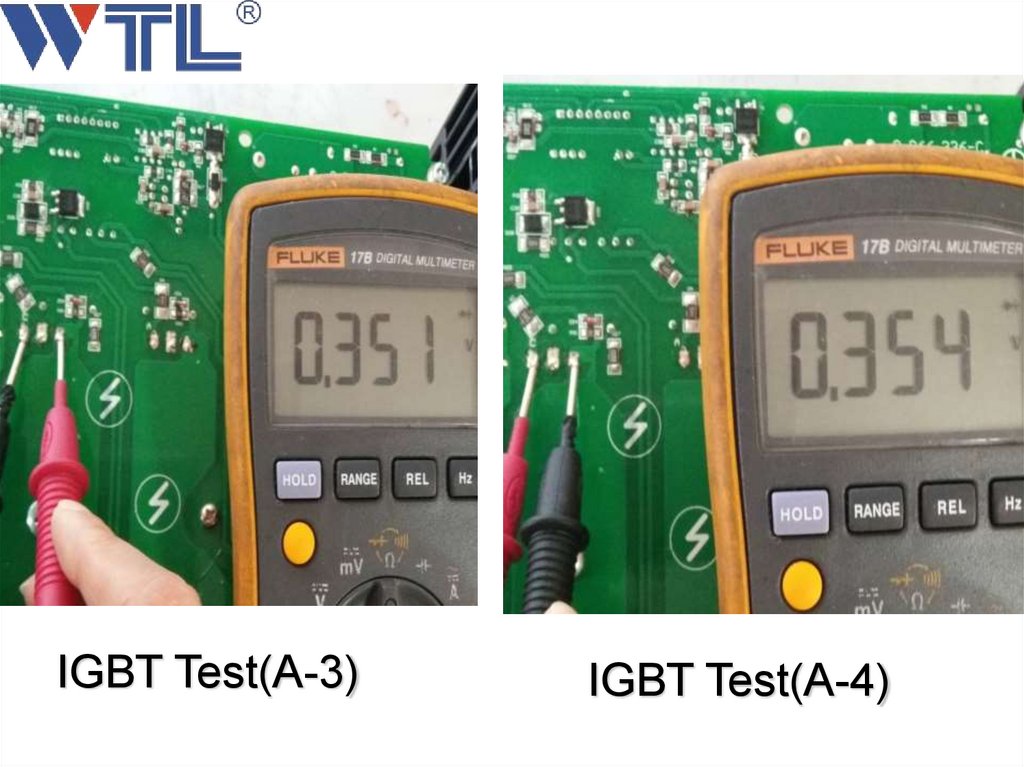

IGBT Test(A-3)IGBT Test(A-4)

61.

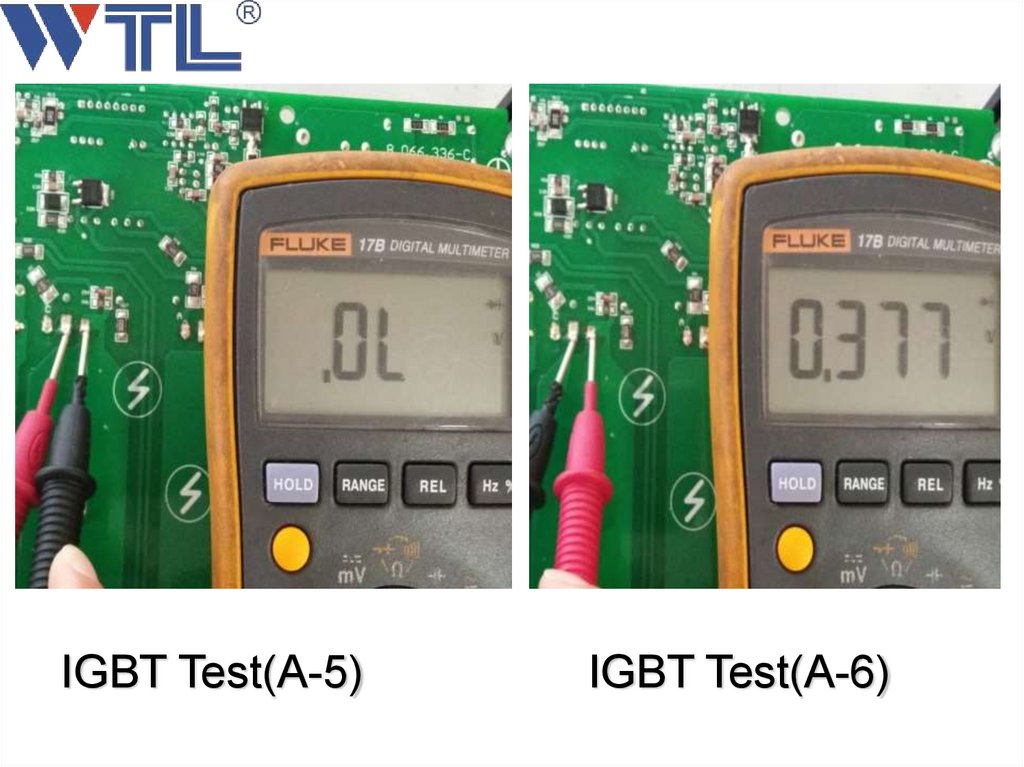

IGBT Test(A-5)IGBT Test(A-6)

62.

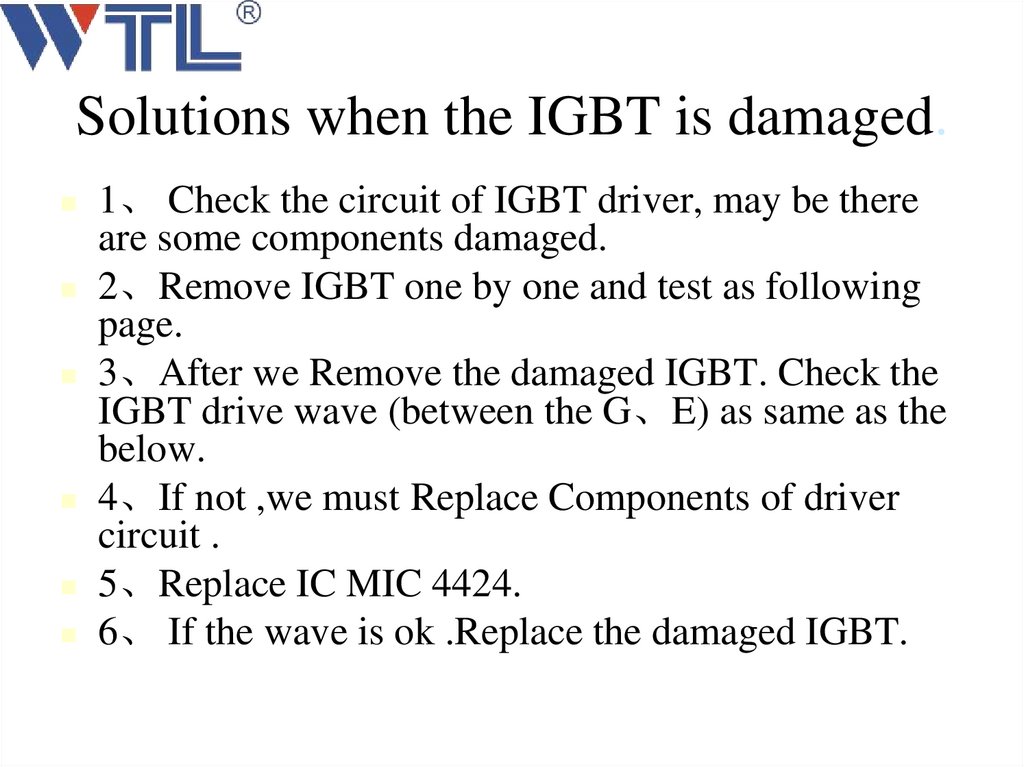

Solutions when the IGBT is damaged.1、 Check the circuit of IGBT driver, may be there

are some components damaged.

2、Remove IGBT one by one and test as following

page.

3、After we Remove the damaged IGBT. Check the

IGBT drive wave (between the G、E) as same as the

below.

4、If not ,we must Replace Components of driver

circuit .

5、Replace IC MIC 4424.

6、 If the wave is ok .Replace the damaged IGBT.

63.

64.

IGBT Test(B-1)IGBT Test(B-2)

65.

IGBT Test(B-3)IGBT Test(B-4)

66.

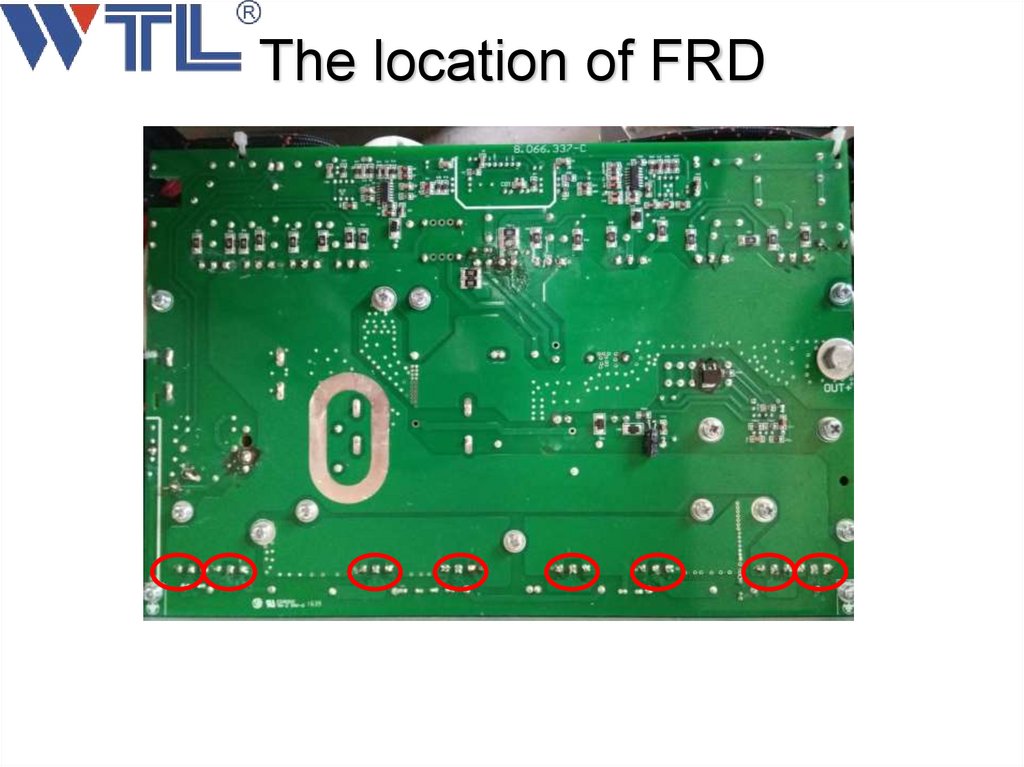

The location of FRD67.

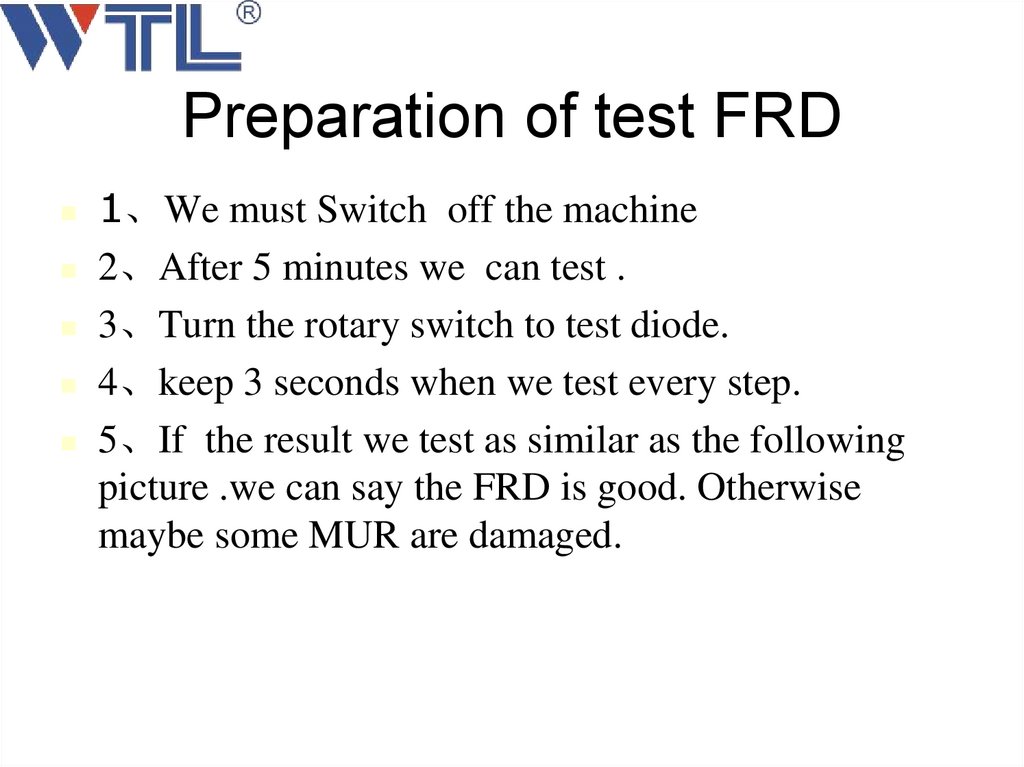

Preparation of test FRD1、We must Switch off the machine

2、After 5 minutes we can test .

3、Turn the rotary switch to test diode.

4、keep 3 seconds when we test every step.

5、If the result we test as similar as the following

picture .we can say the FRD is good. Otherwise

maybe some MUR are damaged.

68.

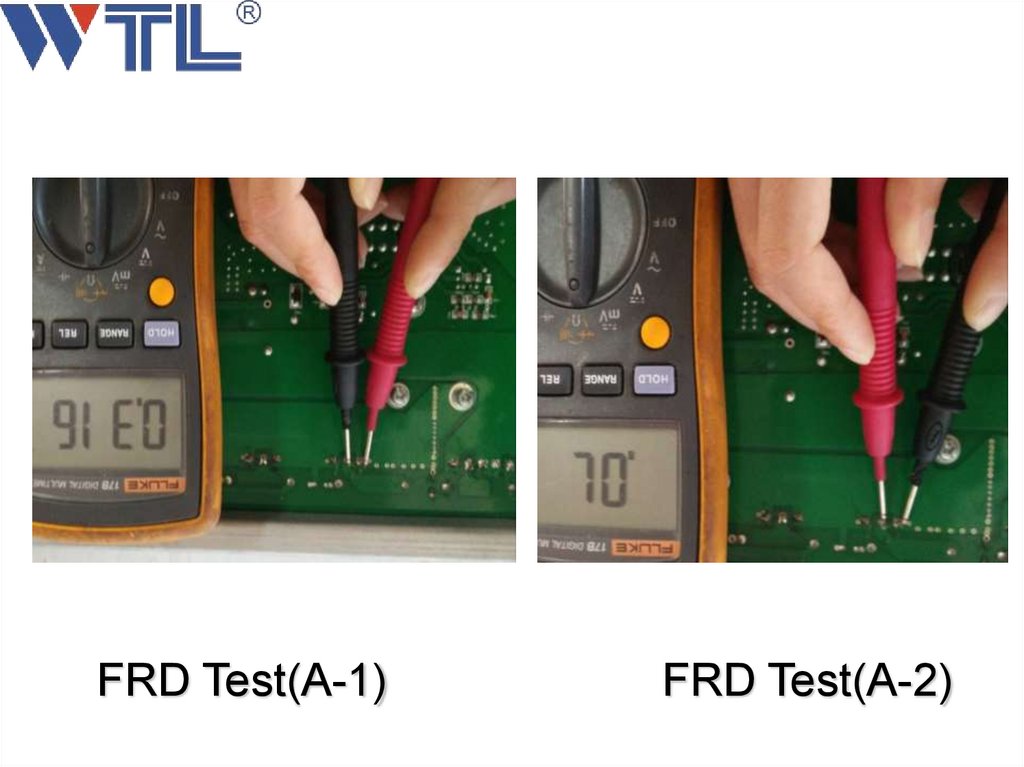

FRD Test(A-1)FRD Test(A-2)

69.

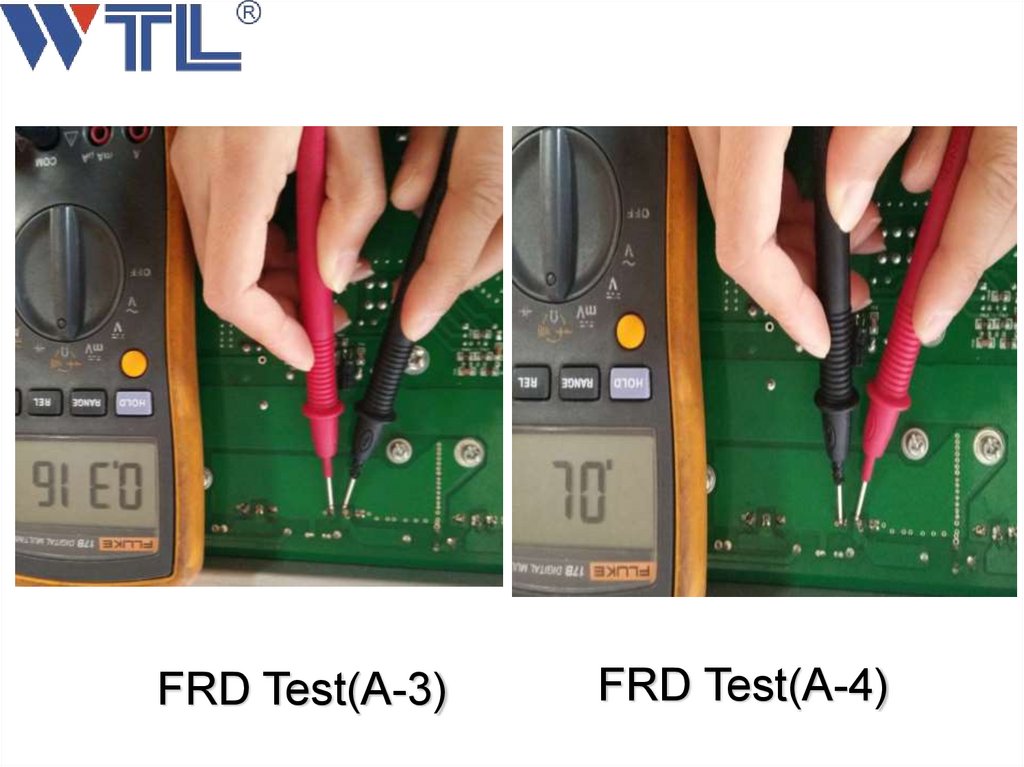

FRD Test(A-3)FRD Test(A-4)

70.

Solutions when the FRD is damaged1、 Remove FRD one by one and test as following

page.

2、 Replace the damaged FRD.

71.

FRD Test(B-1)FRD Test(B-2)

72.

FRD Test(B-3)FRD Test(B-3)

FRD Test(B-4)

73.

Q&A74.

Thanks for yourattention!!!

Электроника

Электроника Промышленность

Промышленность