Похожие презентации:

Solid waste biotreatment. Ethanol production from lignocellulosic materials. Lecture 5

1.

BIOPROCESS TECHNOLOGYDr. TERESA FERNANDEZ ALDAMA

“SAMARA UNIVERSITY”

1

2.

LECTURE No. 5. SOLID WASTEBIOTREATMENT. Ethanol production

from lignocellulosic materials (II)

2

3.

IntroductionStructure of lignocellulosic materials

Hydrolysis

Acidic

Enzymatic

Pretreatment

Formation of inhibitors

3

4.

ObjectivesTo identify the inhibitors formed during

pretreatment of lignocellulosic materials.

To describe the most important strategies to

overcome the inhibition problems.

To discuss the choice of microorganisms to be

used in the fermentation of lignocellulosic

hydrolysates.

4

5.

OutlineFormation of inhibitors

Strategies to overcome the inhibition problems

Preventing formation of inhibitors

Reduction of amounts of formed inhibitors

(Detoxification)

Adaptation of strains to inhibitors

Fermentation of lignocellulosic hydrolyzates

Lignocellulosic hydrolyzates

Microorganisms

5

6.

Formation of inhibitorsCellulose

Hemicellulose

Glucose Mannose Galactose

Hydroxymethyl furfural (HMF)

Xylose Arabinose

Lignin

Extractives

Phenols

Furfural

Acetic acid

Levulinic acid Formic acid

6

7.

Formation of inhibitorsCellulose

Hemicellulose

Glucose Mannose Galactose

Xylose Arabinose

Hydroxymethyl furfural (HMF)

Lignin

Extractives

Phenols

Furfural

Acetic acid

1. Furan aldehydes

Levulinic acid Formic acid

7

8.

Formation of inhibitorsCellulose

Hemicellulose

Glucose Mannose Galactose

Hydroxymethyl furfural (HMF)

Lignin

Xylose Arabinose

Extractives

Phenols

Furfural

Acetic acid

Levulinic acid Formic acid

2. Aliphatic acids

8

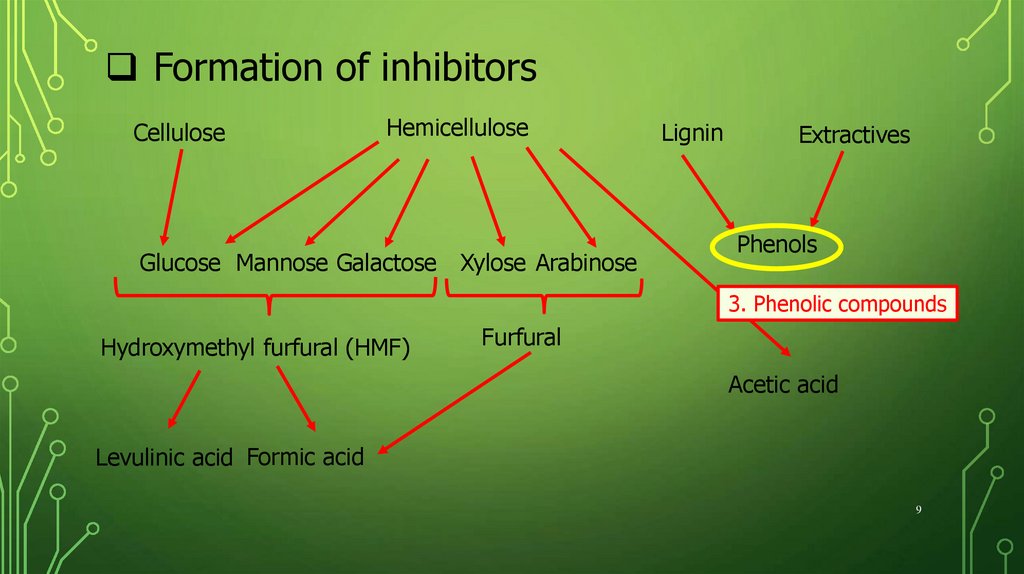

9.

Formation of inhibitorsCellulose

Hemicellulose

Glucose Mannose Galactose

Xylose Arabinose

Lignin

Extractives

Phenols

3. Phenolic compounds

Hydroxymethyl furfural (HMF)

Furfural

Acetic acid

Levulinic acid Formic acid

9

10.

Formation of inhibitorsHemicellulose

Cellulose

Glucose Mannose Galactose

Hydroxymethyl furfural (HMF)

Xylose

Lignin

Extractives

Phenols

Arabinose

Furfural

Acetic acid

Levulinic acid Formic acid

☹ Cell physiology (decrease viability)

☹ Low ethanol yield and productivity

10

11.

Flowchart for ethanol production from LCMLignocellulosic Materials

Pretreatment

Hydrolysis

Physical

Biological

Chemical

Physico-chemical

???

Fermentation

Distillation

Ethanol

11

12.

Strategies to overcome inhibition problems1. Preventing formation of inhibitors

To select less recalcitrant feedstock and to

utilize mild pretreatment conditions

Simultaneous saccharification and fermentation

(SSF)

12

13.

Simultaneous saccharification and fermentation (SSF)13

14.

Strategies to overcome inhibition problems2. Reduction of amounts of formed inhibitors (Detoxification)

Biological: involve the use of microorganism that

convert toxic compounds by changing their chemical

structure.

Physical: promote the removal of toxic compounds

from the medium without changing their chemical

structures.

Chemical: based on the use of chemical additives

(overliming, reducing agents, polymers) and pH

modifications.

14

15.

Strategies to overcome inhibition problems2. Reduction of amounts of formed inhibitors (Detoxification)

☺ Improve fermentability and

saccharification

of cellulose.

enzymatic

☹ A separate step is required.

15

16.

Strategies to overcome inhibition problems3. Adaptation of strains to inhibitors: ability of

microorganism

to

grow

in

lignocellulosic

hydrolysates.

☺ They can increase the tolerance to:

phenolic compounds,furaldehydes and aliphatic acids.

high temperature.

16

17.

Screening0%

25 %

50 %

75 %

100 %

Agar plates with

hydrolyzate

Liquid culture medium with

Hidrolyzates

Resistant

strain

50%

65%

80%

90%

95%

17

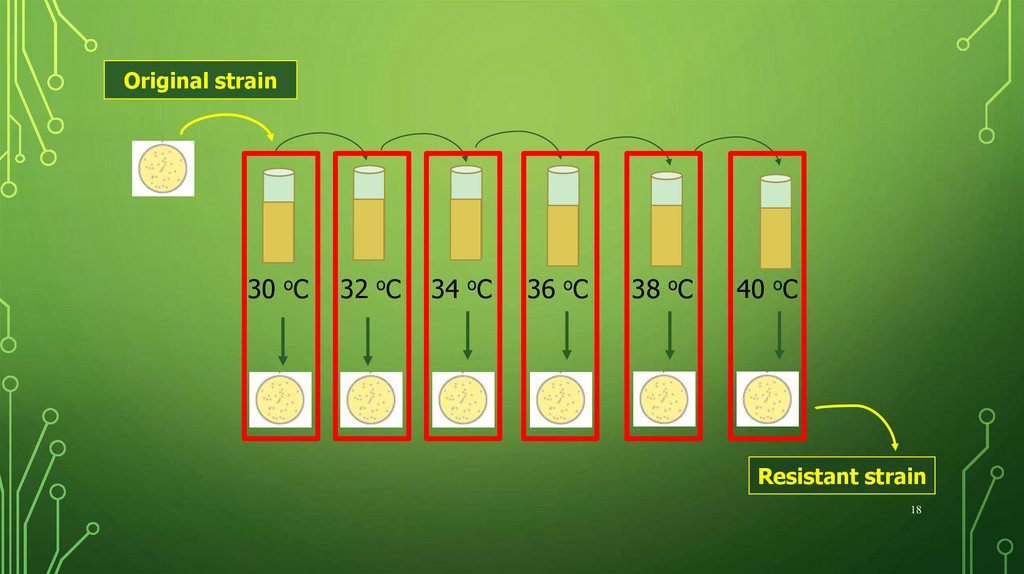

18.

Original strain30 oC

32 oC

34 oC

36 oC

38 oC

40 oC

Resistant strain

18

19.

Fermentation of lignocellulosic hydrolysates1. Particularities of LC hydrolysates

Low glucose concentration

High content of pentoses (xylose: ~33%

of the total sugar in bagasse)

Inhibitors

19

20.

2. Microorganisms used in ethanol production2.1. Essential requirements

High ethanol yield and productivity

Conversion of all the sugars

Low by-product formation

Ethanol tolerance

Tolerance to inhibitors

20

21.

2.2. Desirable requirements• Simultaneous consumption of different sugars

• Degradation of cellulose and hemicellulose

• GRAS status (General Regarded As Save)

• High cell size

• Ability to ferment at low pH

• Ability to ferment anaerobically

• Thermal tolerance

21

22.

2.3. The use of S cerevisiae in fermentation oflignocellulosic hydrolyzates

Manose

Galactose

Glucose

Xylose

Arabinose

Ethanol

Theoretical yield

0,51 g ethanol/g sugar

22

23.

2.4. Natural xylose-utilising microorganismsYeasts

Fungi

Pichia stipitis,

Pachysolen tannophilus,

Candida shehatae

Fusarium

☹ Controlled aeration is required,

sensible to inhibitors, xylitol

production

☹ Low productivity

Bacteria

Bacillus,

Clostridium,

Thermoanaerobacter

☹ Mixtures of acids, pHopt ~7,

pathogenicity

23

24.

2.5. Recombinant xylose-utilising S. cerevisiaeExpression of bacterial xyl A (XI) gene

Expression of yeast XYL1 (XR) and XYL2

(XDH) genes

Xylose

XI

Xylulose

Yeast

Ethanol

XDH

XR

Xylitol

XI: xylose isomerase

XR: xylose reductase

XDH: xylitol deshidrogenase

24

25.

2.5. Recombinant xylose-utilising S. cerevisiaeExpression of bacterial xyl A (XI) gene

Expression of yeast XYL1 (XR) and XYL2

(XDH) genes

Xylose

XI

Xylulose

Yeast

Ethanol

XDH

XR

Xylitol

XI: xylose isomerase

XR: xylose reductase

XDH: xylitol deshidrogenase

25

26.

2.5. Recombinant xylose-utilising S. cerevisiaeUtilize xylose

Produce ethanol

Ethanol tolerance

Inhibitors tolerance

26

27.

Ethanol production from LCMLignocellulosic

Materials

Ethanol

27

28.

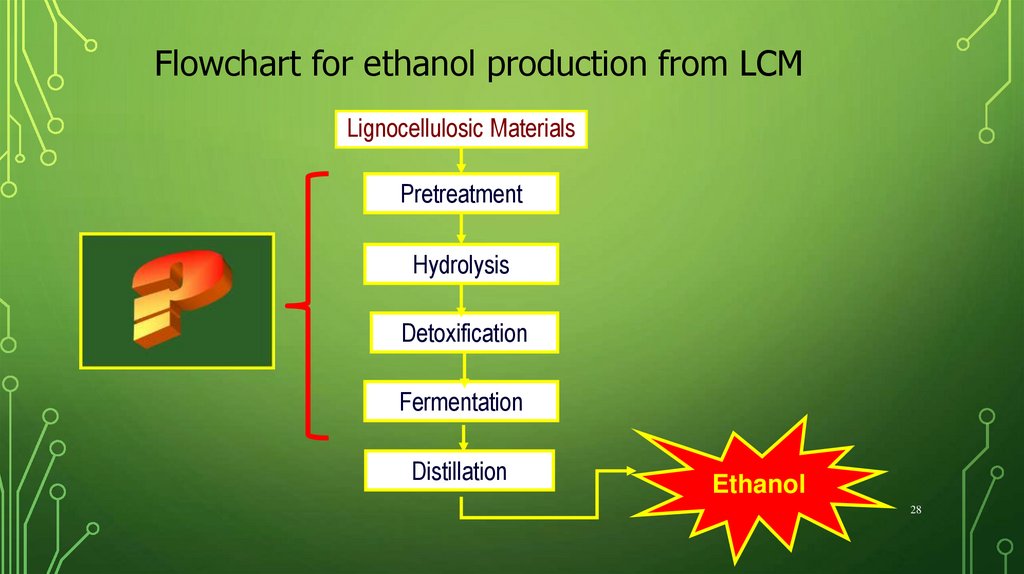

Flowchart for ethanol production from LCMLignocellulosic Materials

Pretreatment

Hydrolysis

Detoxification

Fermentation

Distillation

Ethanol

28

29.

Whole cycle of ethanol productionSugar

cane

Rice

Peanut

Ethanol

H2SO4

Hydrolysis

Destillation

Sugar solution

Fermentation

29

30.

Control questions1. Describe inhibitory formation during pretreatment

and explain its effect in the fermentation process?

2. Describe some of strategies to overcome the

inhibition problem.

3. According to the composition of lignocellulosic

hydrolyzates, analyze the choice of the appropriate

microorganism.

30

31.

Suggested literature-

Harmsen P., Huijgen W., Bermudez L., Bakker R. Literature

review of physical and chemical pretreatment processes for

lignocellulosic biomass. Biosynergy, 2010, Report 1184. ISBN

978-90-8585-757-0.

-

Kim D. Physico-Chemical Conversion of Lignocellulose:

Inhibitor Effects and Detoxification Strategies: A Mini Review.

Molecules, 2018, 23, 309.

-

Mohammad J.T., Keikhosro K. Acid-based hydrolysis processes

for ethanol from lignocellulosic materials: A review.

BioResources, 2007, 2 (3), 472-499.

31

32.

THANK YOU FOR YOURATTENTION!

32

Химия

Химия Промышленность

Промышленность