Похожие презентации:

STP Specific Training Packages. Sakhalin Energy LNG/OET/TLU

1.

STPSpecific Training Packages

7000-S-62-90-T-0001-00

Specific Training Package

1

2.

Sakhalin Energy LNG/OET/TLUSTP

Unit 6200

Specific Training Package

2

3.

The purpose of STP Training is that the operatorwill have understanding and awareness of the following topics.

1.

Process Introduction

2.

Purpose of the Unit

3.

Process description

4.

Equipment

5.

Health, Safety and Environment

6.

Routine checks

Specific Training Package

3

4. Introduction to the unit

To collect and dispose vapour and liquid in a safe manner:Types of gas and systems:

Emergency operational system for cold, light, dry streams,

liquid and vapour.

Emergency operational system for warm, heavy, streams,

liquid and vapour.

Emergency operational system for LNG storage and loading,

vapour.

Operational flare system, vapour.

LNG disposal system liquid and vapour (start-up).

Spare flare can be used for cold and warm service.

Liquid disposal burners.

Specific Training Package

4

5. Purpose of the unit

Purpose:The purpose of the unit is to safely collect and dispose

vapor or liquid hydrocarbons that result from upsets and

emergencies.

The unit can also handle streams as a result of operational

conditions such as start-up, shutdown, venting, draining

and purging. Also warm up and cool down of equipment or

piping is accommodated.

Specific Training Package

5

6. Unit 6400 position on the Plant overview

pigU/S

3600

6400

ETP

3300

0300

F4101

4000

EDG

A4420

K4701AB

U/S

U1100

1500

1400

4100

4200 4400

U1300

4000

GTG

U4100

K1440

U4200

K4401

Train 1

K4711

U1100

4300

4600

9000

K1420/30

Train 2

A1911

A4720AB

K1450

4200

1100

4800

1500

1400

4100

4200 4400

6400

CDF

U1300

U4100

U4200

K1440

K1450

K1420/30

6200

3400

K3401

pig

1000

1600

3100

3400

6000

4100

4900

Specific Training Package

6

7. Process description

Warm Flare System (FWW)All the warm vapours are collected into a single 48” header

which slopes to the liquid knock-out drum V-6201.

The header is continuously purged with LP fuel gas at sufficient

flow rate to keep velocity at the tip of flare stack. Nitrogen

connection is also given as back-up purge source.

Vapours from V-6201 are routed and burned to warm flare

6201 via 56” line.

A-

Specific Training Package

7

8. Process description

Warm Liquid Disposal System (DHC)The warm liquids from manual drains are collected in a

4” header and routed to V-6201.

Light components are flashed-off and burned in A-6201 (FWW).

The accumulated liquid in V-6201 is pumped and transferred to

warm liquid burner A-6204 by P-6201A/B via 6” line.

Specific Training Package

8

9. Process description

Cold Flare System (FCD)Cold dry and light hydrocarbon vapours from unit 1400, 1500

and 1600 are collected into a 48” header which slopes to the

cold flare KO drum V-6202.

The header is continuously purged with LP fuel gas. Nitrogen

connection is also given as back-up purge source.

Vapour from the cold flare KO drum is directed to the cold flare

(A-6202) through a 56” line.

HP fuel gas is used as atomising gas to flare stack A-6202.

Specific Training Package

9

10. Process description

Cold Liquid Disposal System (DLH)All the cold liquids are collected into two 12” headers that are

routed to the cold flare KO Drum (V-6202). flashed vapours are

removed and burned in A-6202.

Liquid from V-6202 is drained by gravity to the blow cases

(V-6207A/B) via an 8” line which transfers the liquid to the cold

liquid burners A-6205A/B. HP fuel gas is used as motive or

pressuring gas.

Specific Training Package

10

11. Process description

Operational Flare System (FOP)Operationally initiated release is vented

to separate 16” FOP header.

The vented gas is routed to V-6203 and

burned in operational flare, A-6211.

Picture not SEIC specific

Specific Training Package

11

12. Process description

Warm Flare System – FWWVapour collection point from

Unit 1000,1100,1300,1350,1400,

1500,1900,4000,4100 and 4400

Liquid disposal point – DHC

Collects liquids from

Unit 1000,1100,4400,1400 and unit

1500

Specific Training Package

12

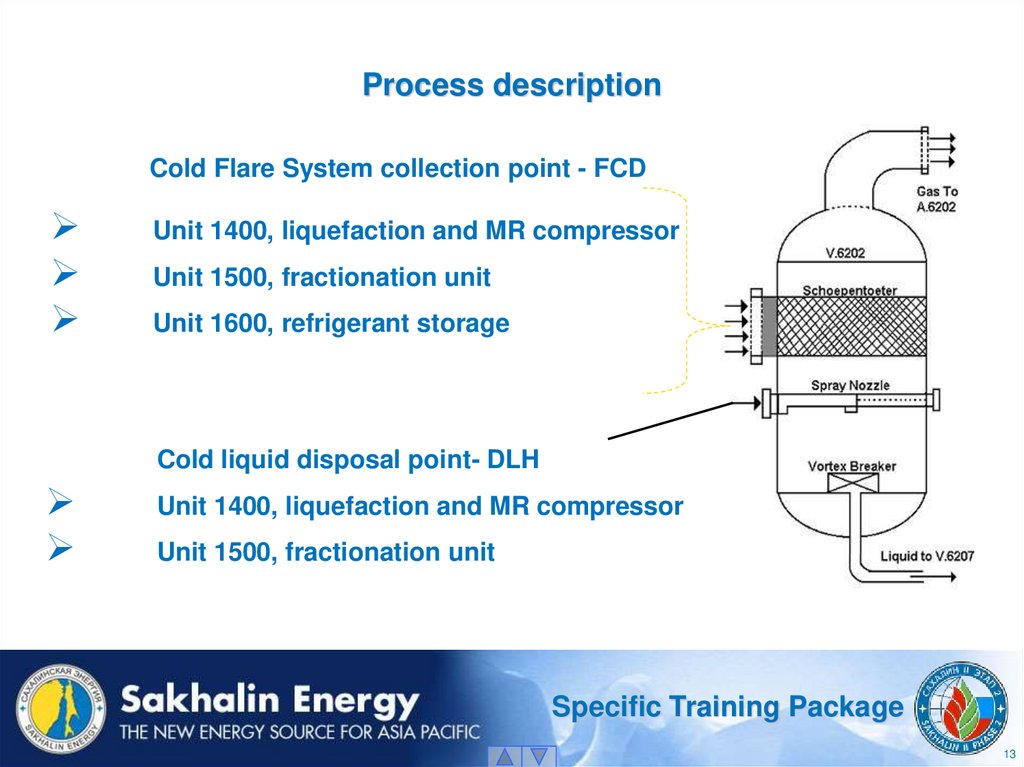

13. Process description

Cold Flare System collection point - FCDUnit 1400, liquefaction and MR compressor

Unit 1500, fractionation unit

Unit 1600, refrigerant storage

Cold liquid disposal point- DLH

Unit 1400, liquefaction and MR compressor

Unit 1500, fractionation unit

Specific Training Package

13

14. Process description

LNG Storage and Loading Flare – FLPUnit 3400, LNG storage and loading

Boil-off gas compressors dry gas seal, relief valves

Operational Flare System – FOP

Unit 1400, liquefaction and MR compressor

Specific Training Package

14

15. Process description

Fuel Gas:High pressure fuel gas is used for:

Motive gas in the blow cases V-6207A/B.

Atomising gas.

Fuel gas pilot burners.

Fuel gas for the flame front generators.

Low pressure fuel gas is used for:

Purging.

Specific Training Package

15

16. Process description

Blow case:Liquid from the cold flare KO

drums is drained by gravity to

one of the two blow case vessels.

HP fuel gas is used to pressurise

the blow case before displacing

the liquid to the cold liquid burner.

Specific Training Package

16

17.

Flare OverviewF-WW

D-HC

F-CD

D-LH

Start

up

F-LP

F-OP

HP Fuel Gas

Specific Training Package

17

18. Major equipment

3 flare KO drumsOne blow case (two vessels)

Two warm liquid disposal pumps

One warm flare

One cold flare

One storage and loading flare

One spare flare

One warm liquid burner

Two cold liquid burners

Two flame front generators

Specific Training Package

18

19. Health, Safety and Environment

Health, Safety:Noise when the flare is operating.

Radiated heat from the flare.

Nitrogen can be asphyxiating in high

concentration.

Cryogenic temperatures.

High pressures.

Specific Training Package

19

20. Environment

Controlled releases to atmosphere fromthe flares and liquid disposal burners pose no

harm to the environment.

Uncontrolled releases can occur as a result of a plant

emergencies, and short term air pollution from the

unburnt gases.

Specific Training Package

20

21. Routine checks

Routine checks:Check for leaks.

Check running equipment for any abnormal noise.

Fill in log sheet.

Check on night shift if the pilot burners are on.

Specific Training Package

21

Промышленность

Промышленность