Похожие презентации:

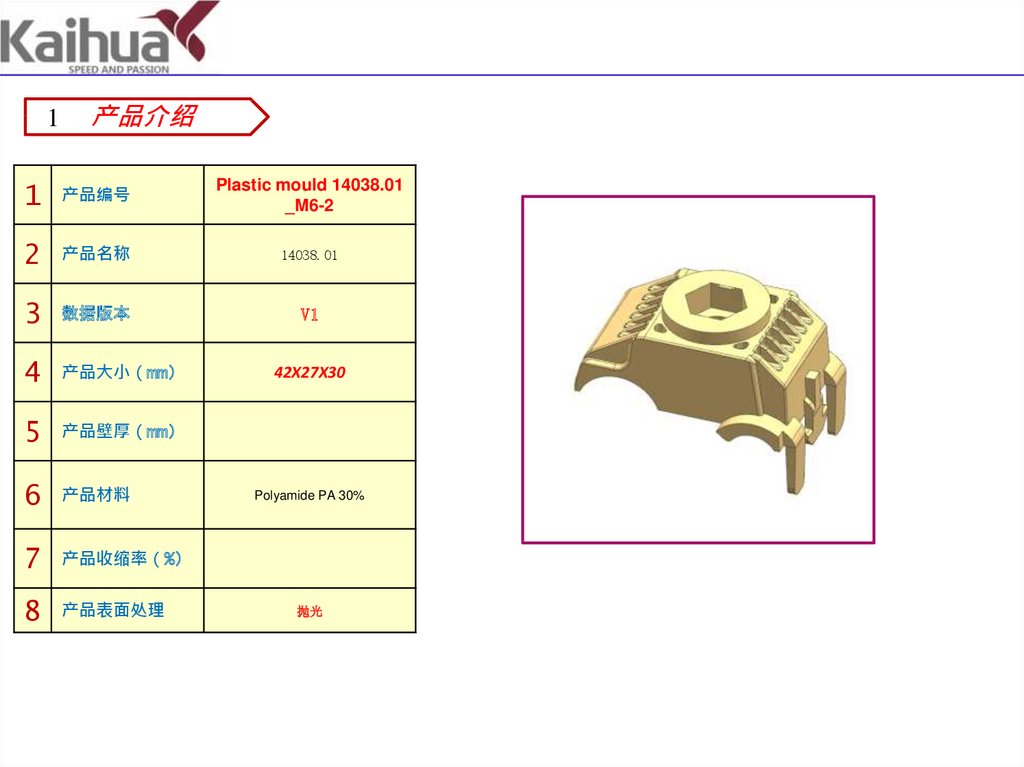

产品介绍. 产品编号

1.

1产品介绍

1

产品编号

Plastic mould 14038.01

_M6-2

2

产品名称

14038.01

3

数据版本

V1

4

产品大小 mm

5

产品壁厚 mm

6

产品材料

7

产品收缩率 %

8

产品表面处理

42X27X30

Polyamide PA 30%

抛光

2.

2P.L确认

Cav.

PL

Cor.

问题描述 issue

红色线为产品分型线 请确认。

The red line is parting line, please check it.

客户回复customer reply

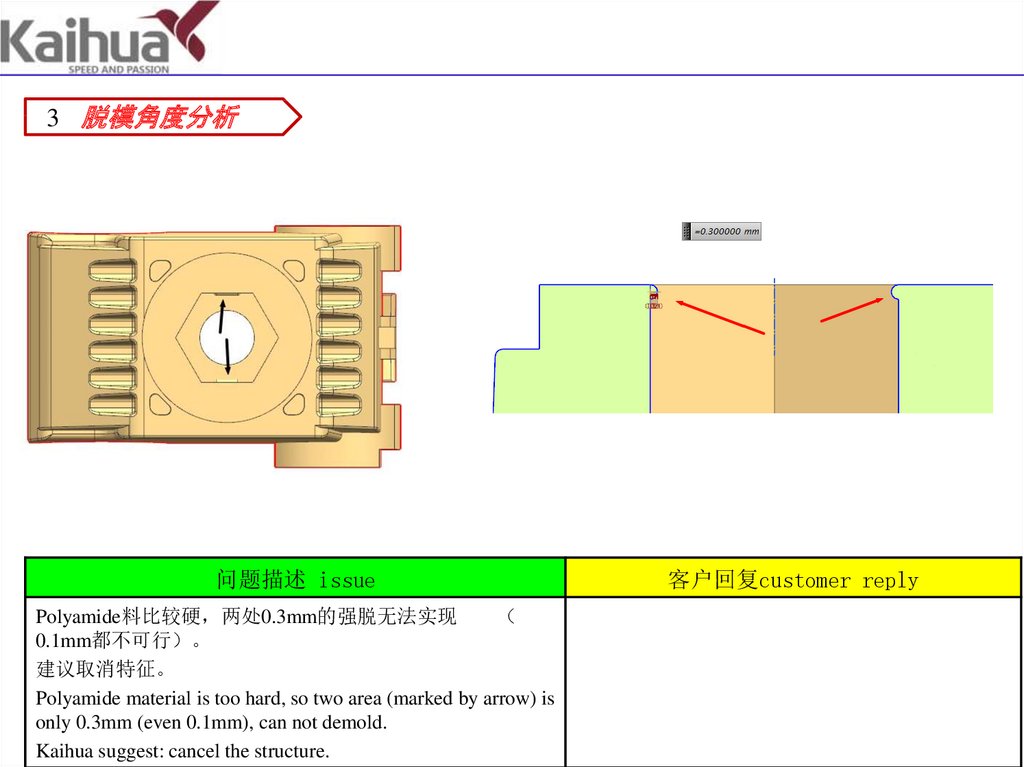

3.

3 脱模角度分析问题描述 issue

Polyamide料比较硬 两处0.3mm的强脱无法实现

0.1mm都不可行 。

建议取消特征。

Polyamide material is too hard, so two area (marked by arrow) is

only 0.3mm (even 0.1mm), can not demold.

Kaihua suggest: cancel the structure.

客户回复customer reply

4.

4 脱模角度分析定模侧

问题描述 issue

指示绿色面均无斜度 产品牢模风险。

确认能否增加0.5°脱模斜度。

There are no draft angle at green surface, so will have risk of

sticking mold.

Kaihua suggest: please check whether we can add 0.5°draft

angle.

客户回复customer reply

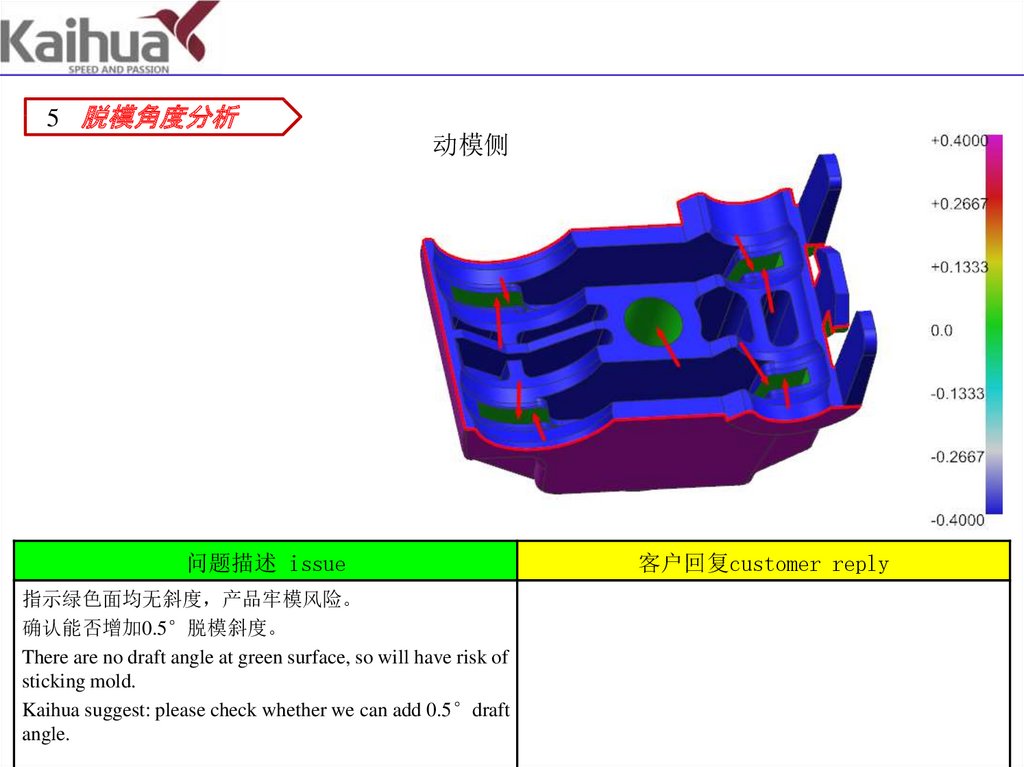

5.

5 脱模角度分析动模侧

问题描述 issue

指示绿色面均无斜度 产品牢模风险。

确认能否增加0.5°脱模斜度。

There are no draft angle at green surface, so will have risk of

sticking mold.

Kaihua suggest: please check whether we can add 0.5°draft

angle.

客户回复customer reply

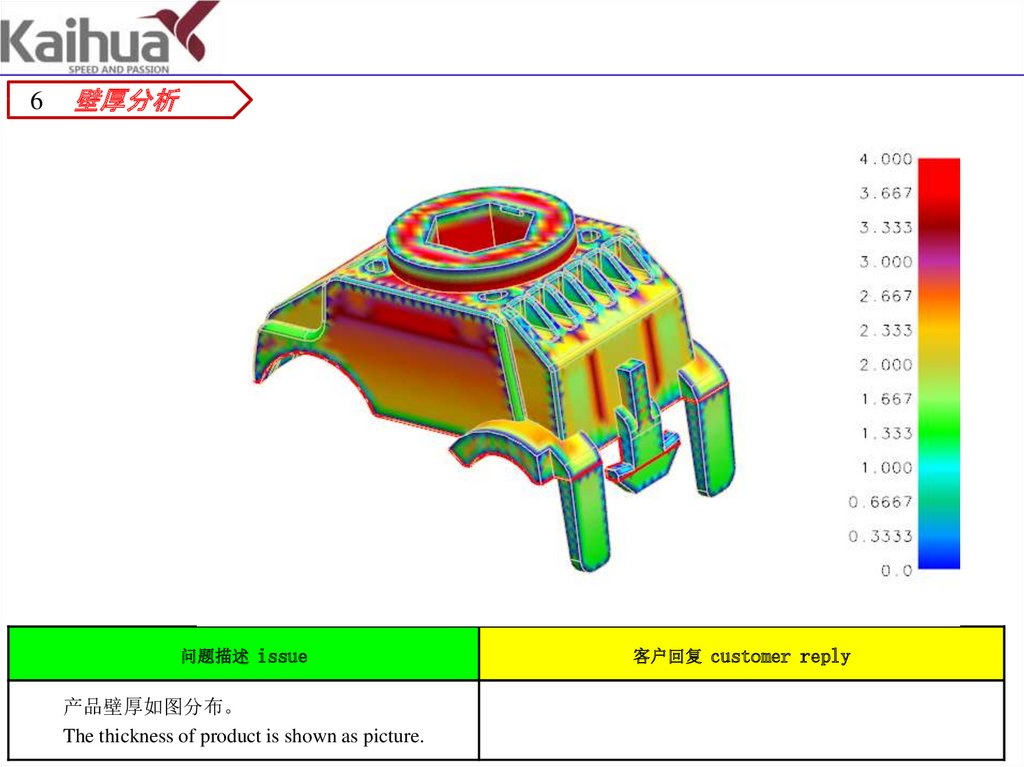

6.

6壁厚分析

问题描述 issue

产品壁厚如图分布。

The thickness of product is shown as picture.

客户回复 customer reply

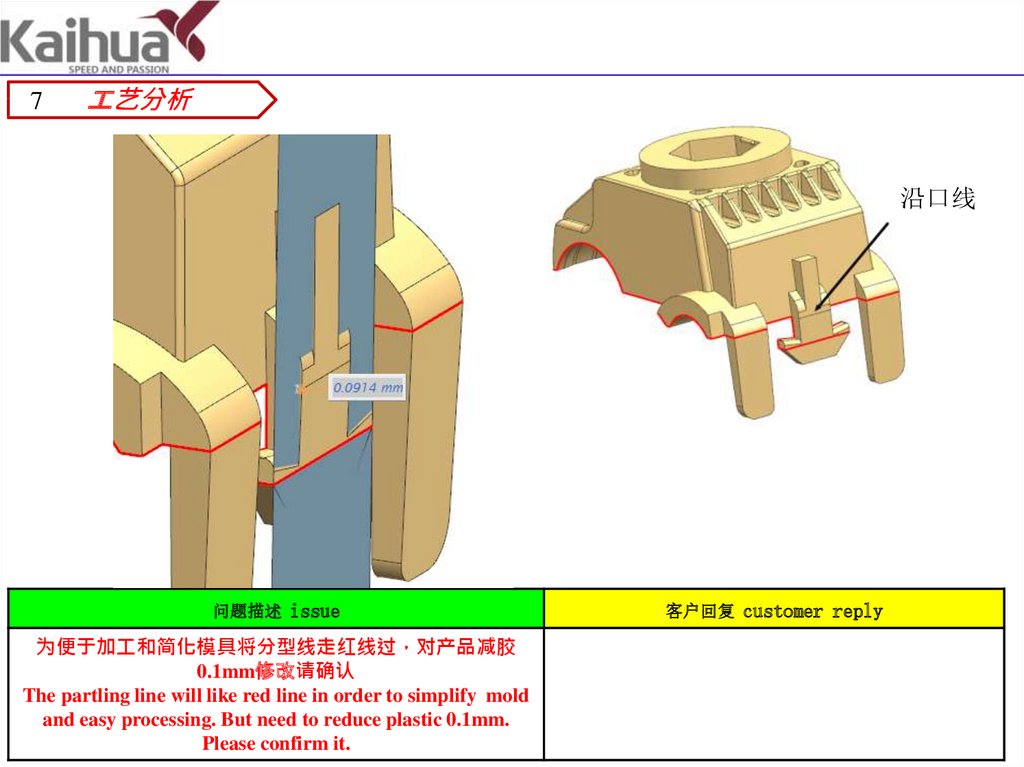

7.

7工艺分析

沿口线

问题描述 issue

为便于加工和简化模具将分型线走红线过 对产品减胶

0.1mm修改请确认

The partling line will like red line in order to simplify mold

and easy processing. But need to reduce plastic 0.1mm.

Please confirm it.

客户回复 customer reply

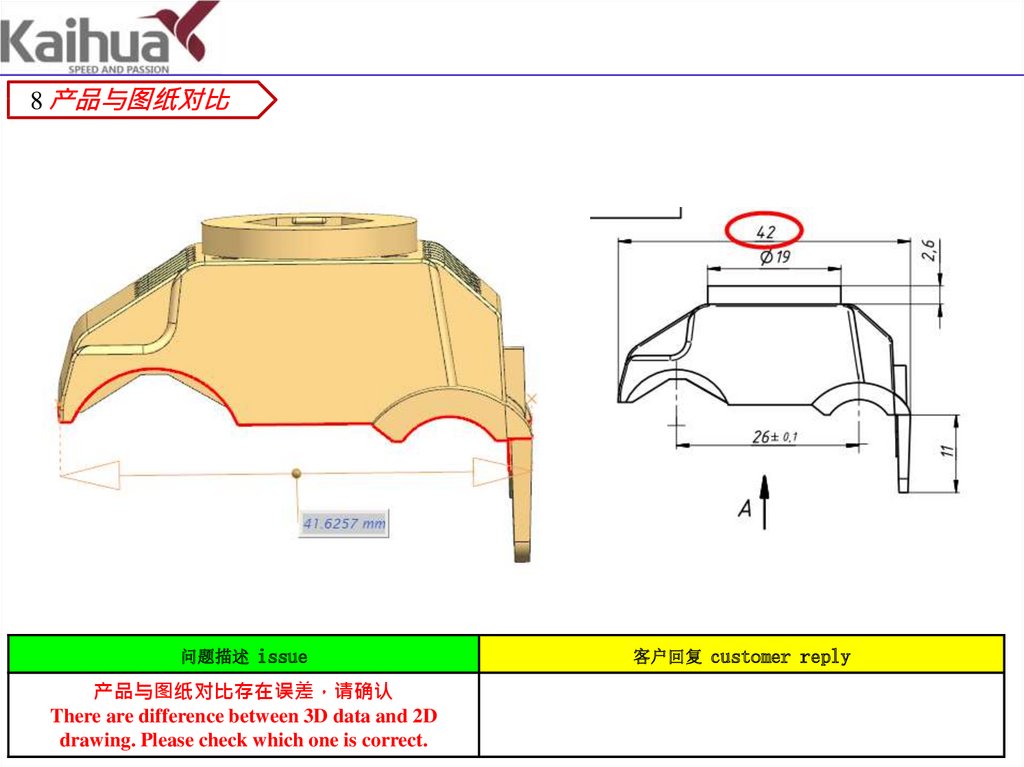

8.

8 产品与图纸对比问题描述 issue

产品与图纸对比存在误差 请确认

There are difference between 3D data and 2D

drawing. Please check which one is correct.

客户回复 customer reply

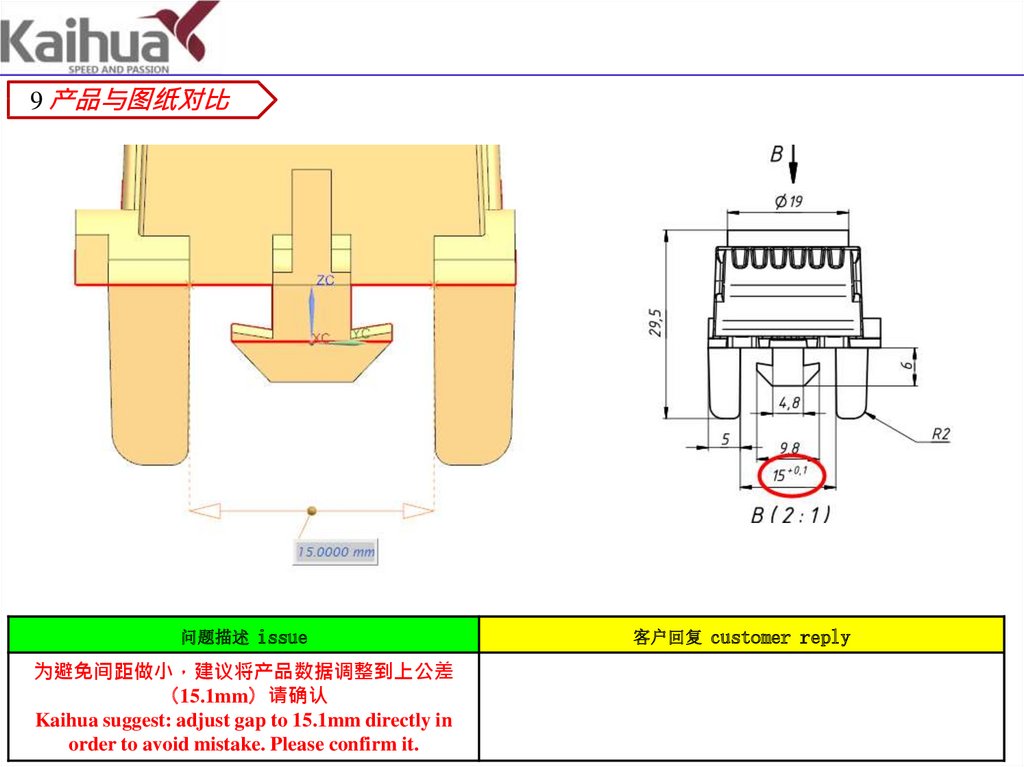

9.

9 产品与图纸对比问题描述 issue

为避免间距做小 建议将产品数据调整到上公差

15.1mm 请确认

Kaihua suggest: adjust gap to 15.1mm directly in

order to avoid mistake. Please confirm it.

客户回复 customer reply

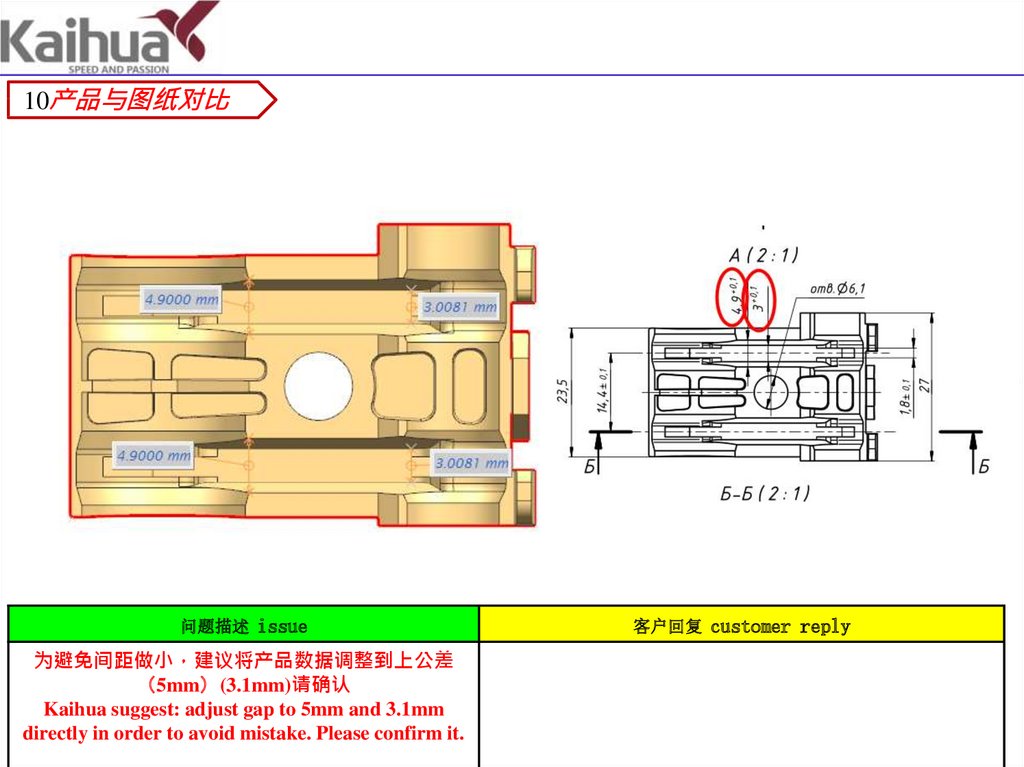

10.

10产品与图纸对比问题描述 issue

为避免间距做小 建议将产品数据调整到上公差

5mm (3.1mm)请确认

Kaihua suggest: adjust gap to 5mm and 3.1mm

directly in order to avoid mistake. Please confirm it.

客户回复 customer reply

11.

WE ARE JUST ON THEWAY

THANK YOU.

Промышленность

Промышленность