Похожие презентации:

BP560X System Application Notes

1.

BP560X System ApplicationNotes

1

www.bpsemi.com

2.

ContentsPatent

Effect

Typical Applications / Overview

Examples of Design

Considerations of Design

2

www.bpsemi.com

3.

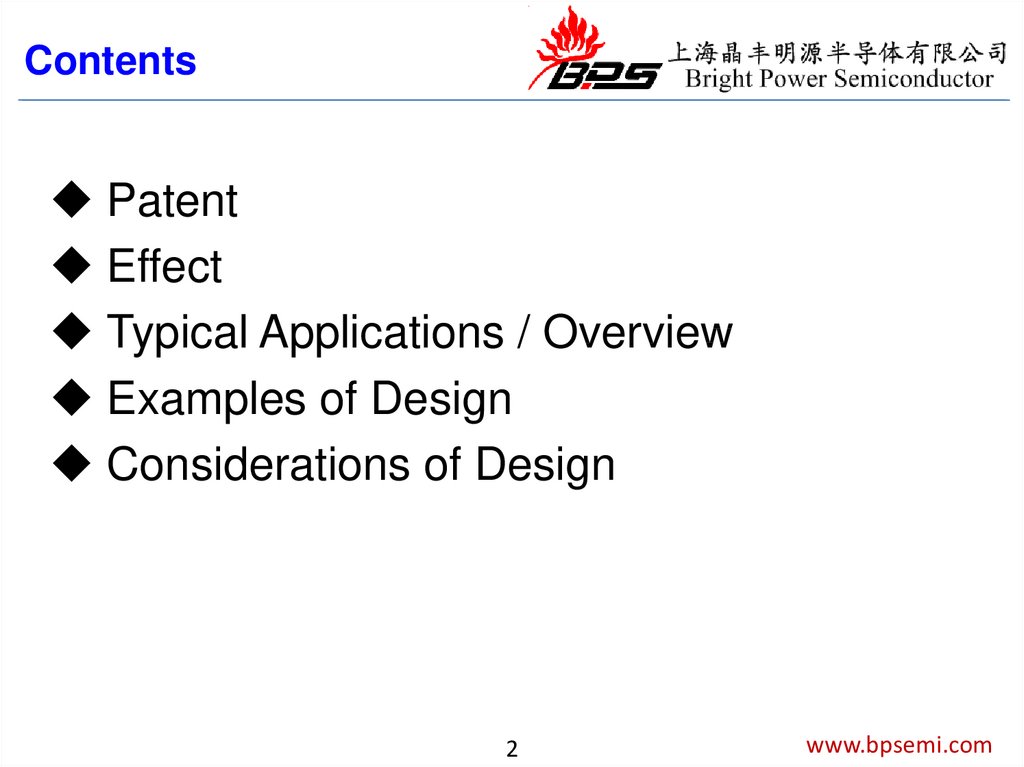

PatentBP560X Patent

Capacitor Voltage

LED

C1

T

10

Voltage of power MOS drain

T

voltage of LED load

D

G

S

40

30

50

T

current of LED load

20

S1

M1

CS

T

C2

R2

V1

R1

ref

Voltage of power MOS gate

GND

T

Patent application number in China CN201310218482

Patent application number in America 14-039072

3

www.bpsemi.com

4.

EffectBP3316D+BP5609 (36V/430mA)

The Ripple is

decreased

No strobe

Io

Vo

+5609

After the current loop is closed, the current and voltage on the LED are

DC

The voltage ripple will be superimposed on the MOSFET

4

www.bpsemi.com

5.

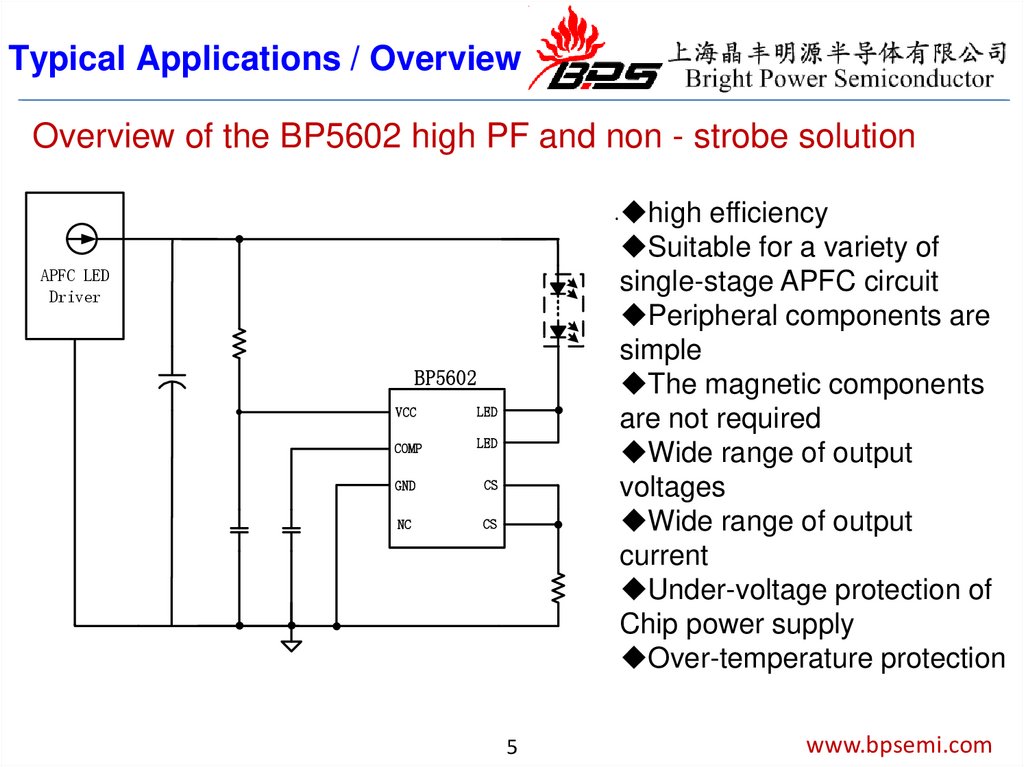

Typical Applications / OverviewOverview of the BP5602 high PF and non - strobe solution

high efficiency

Suitable for a variety of

single-stage APFC circuit

Peripheral components are

simple

The magnetic components

are not required

Wide range of output

voltages

Wide range of output

current

Under-voltage protection of

Chip power supply

Over-temperature protection

APFC LED

Driver

BP5602

VCC

LED

COMP

LED

GND

CS

NC

CS

5

www.bpsemi.com

6.

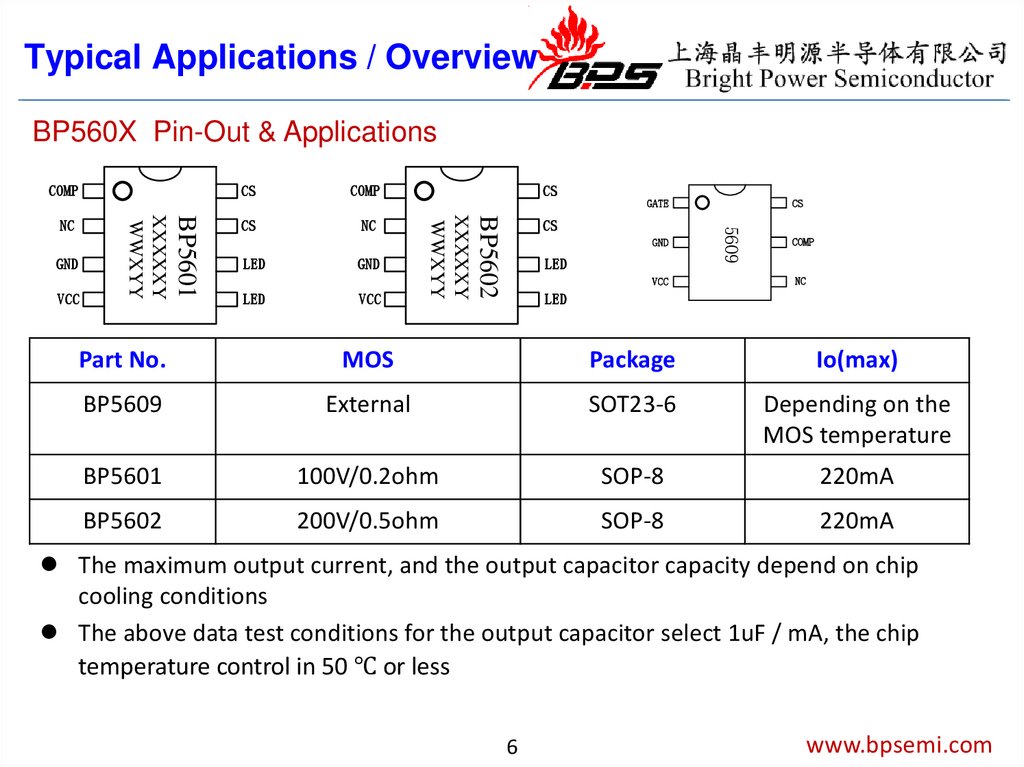

Typical Applications / OverviewBP560X Pin-Out & Applications

COMP

NC

LED

GND

LED

VCC

GATE

CS

GND

LED

VCC

CS

5609

CS

CS

BP5602

COMP

XXXXXY

WWXYY

VCC

BP5601

GND

XXXXXY

WWXYY

NC

CS

COMP

NC

LED

Part No.

MOS

Package

Io(max)

BP5609

External

SOT23-6

Depending on the

MOS temperature

BP5601

100V/0.2ohm

SOP-8

220mA

BP5602

200V/0.5ohm

SOP-8

220mA

The maximum output current, and the output capacitor capacity depend on chip

cooling conditions

The above data test conditions for the output capacitor select 1uF / mA, the chip

temperature control in 50 ℃ or less

6

www.bpsemi.com

7.

Typical Applications / OverviewLED+

BP5609 Typical Applications (Vo=36V;Io=440mA)

L

N

LED-

LED

R1

27K

V in +

BP3316D

Q1

C1

V in -

U2

+

1

GATE CS

6

BP5609

C2

4.7uF/25V

7

2

GND COMP 5

3

VCC

NC

4

Rs1

1.0R

Rs2

1.0R

C3

4.7uF/16V

www.bpsemi.com

8.

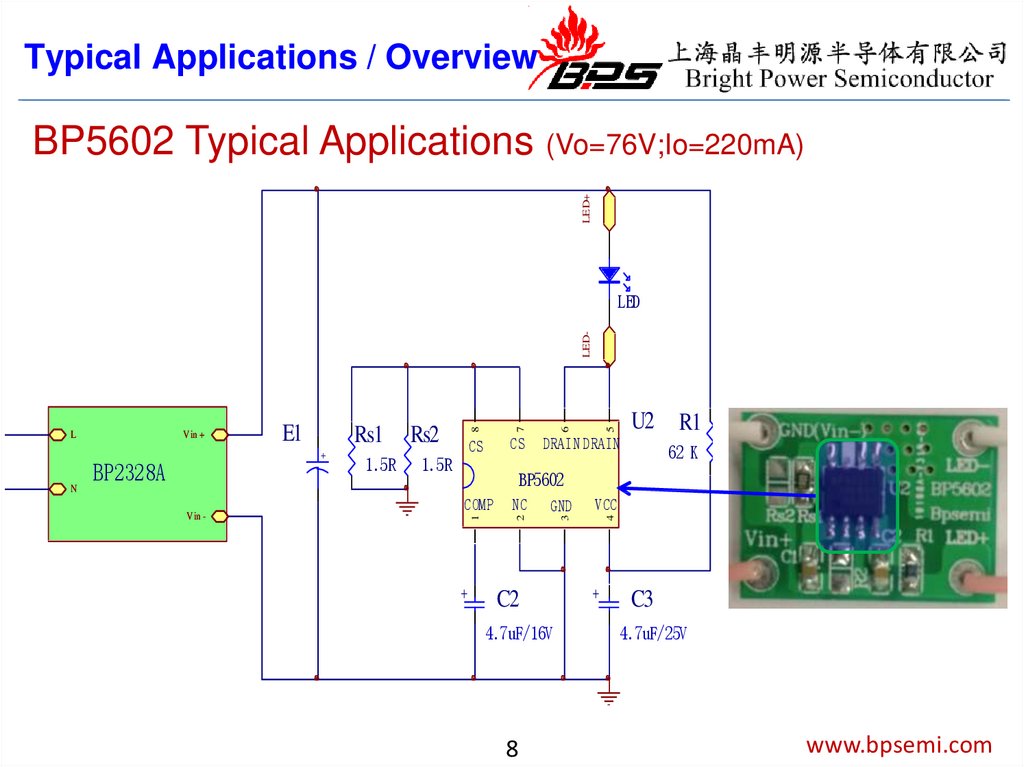

Typical Applications / OverviewLED+

BP5602 Typical Applications (Vo=76V;Io=220mA)

+

BP2328A

1.5R

Rs2

CS

CS

1.5R

U2

DRAIN DRAIN

R1

62 K

BP5602

+

NC

GND

3

1

COMP

2

N

V in -

5

Rs1

C2

4.7uF/16V

8

VCC

4

E1

6

V in +

7

L

8

LED-

LED

+

C3

4.7uF/25V

www.bpsemi.com

9.

Examples of DesignBP3316D+BP5609 36V/430mA

Load regulation in 220Vac

424

Output current mA

Output current mA

Linear adjustment rate of Full load

422

420

418

416

414

80

120

160

200

240

280

422

421

420

419

418

417

20

Input voltage V

28

32

36

40

output voltage V

PF

efficiency of Full load

1

84

83

0,98

82

0,96

PF

effectiveness %

24

0,94

81

BP5609AA

80

79

0,92

0,9

80

120

160

200

Input voltage V

240

280

80

120

160

200

240

280

Input voltage V

no-affect to the linear load regulation,and PF / THD; efficiency decreased by about 2

percentage points 。

www.bpsemi.com

9

10.

Examples of DesignSelection of pre-output capacitor

According to the output current, it is recommended to select the preoutput capacitor of 1uF / mA

Capacitance is too large,when from open or normal work to short-circuit it

is more likely to burn, and it is not helpful to the system efficiency

The pre-output capacitor is larger, the ripple amplitude is lower, the

temperature of chip is lower

The per-input capacitance is larger, the efficiency of the system loss

with the BP560X is lower

10

www.bpsemi.com

11.

Examples of DesignPower Loss VS Output Cap

1,4

Input power loss W

1,2

1

0,8

0,6

0,4

0,2

0

0

220

440

660

880

1100

1320

The output capacitor(uF)

BP3316D + BP5609 36V / 430mA, the output capacitor 440uF, the loss of

about 2 to 3% efficiency

11

www.bpsemi.com

12.

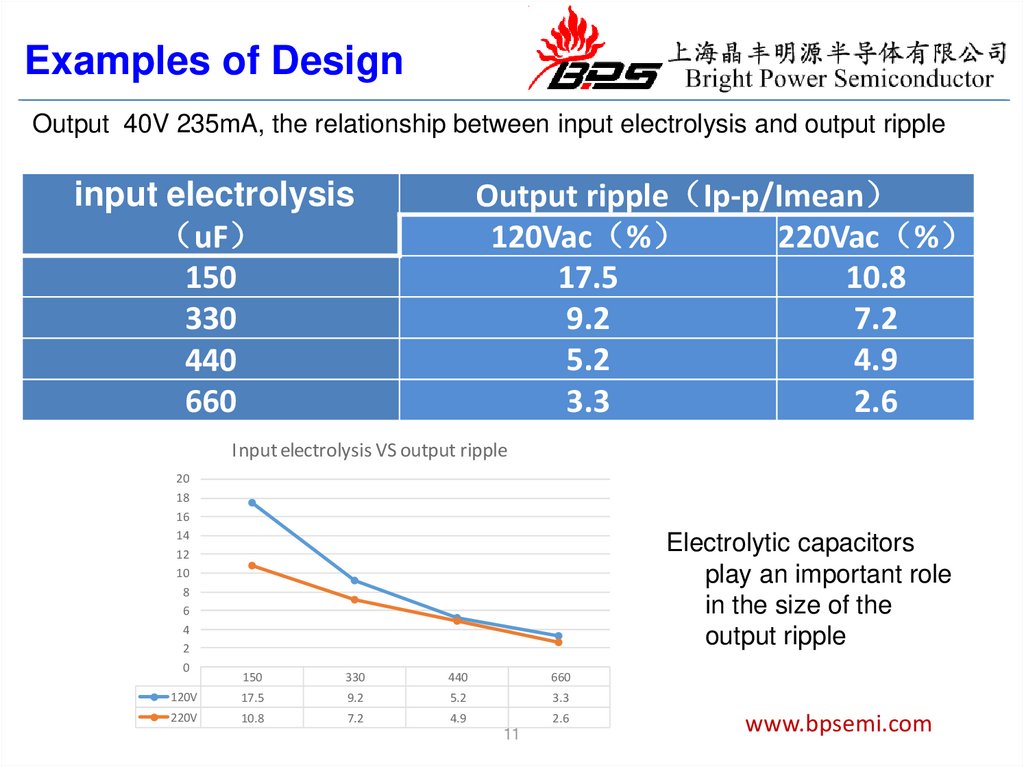

Examples of DesignOutput 40V 235mA, the relationship between input electrolysis and output ripple

Output ripple Ip-p/Imean

120Vac %

220Vac %

17.5

10.8

9.2

7.2

5.2

4.9

3.3

2.6

input electrolysis

uF

150

330

440

660

Input electrolysis VS output ripple

20

18

16

14

12

10

8

6

4

2

0

Electrolytic capacitors

play an important role

in the size of the

output ripple

150

330

440

660

120V

17.5

9.2

5.2

3.3

220V

10.8

7.2

4.9

2.6

11

www.bpsemi.com

13.

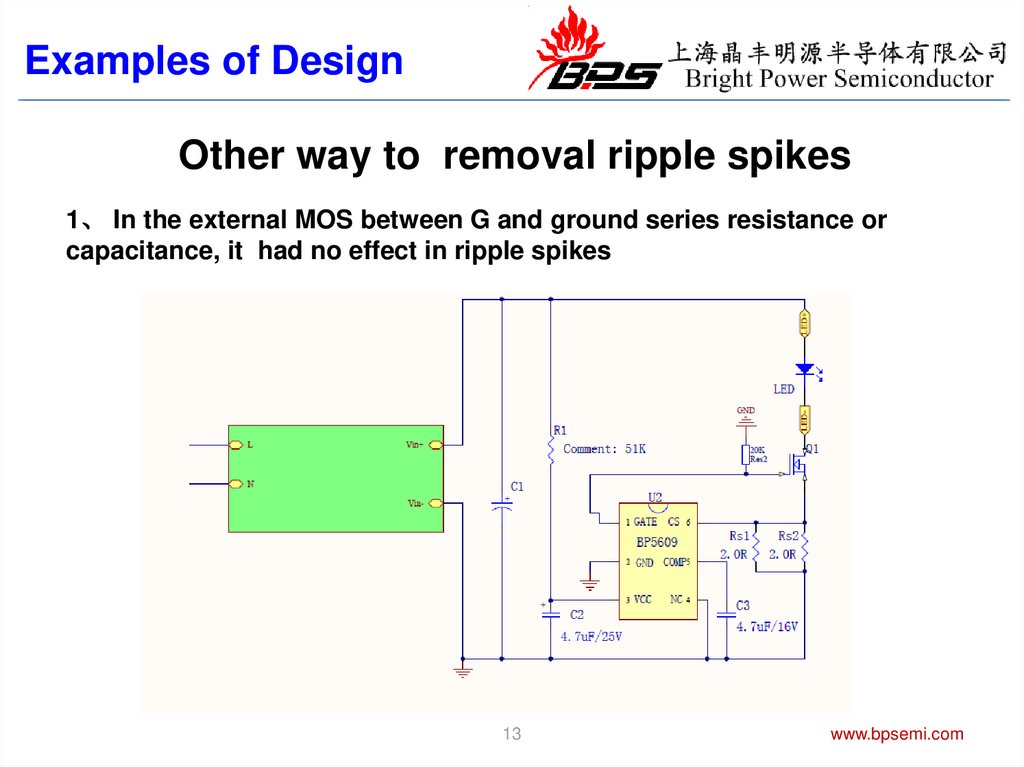

Examples of DesignOther way to removal ripple spikes

1、 In the external MOS between G and ground series resistance or

capacitance, it had no effect in ripple spikes

13

www.bpsemi.com

14.

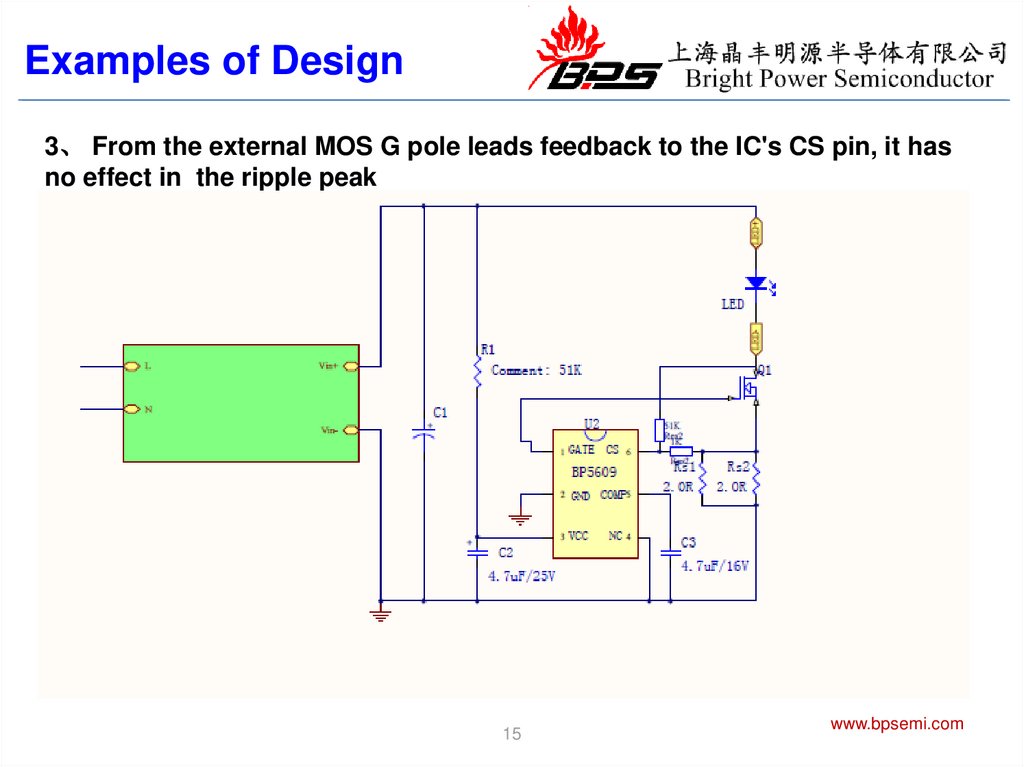

Examples of Design3、 From the external MOS G pole leads feedback to the IC's CS pin, it has

no effect in the ripple peak

15

www.bpsemi.com

15.

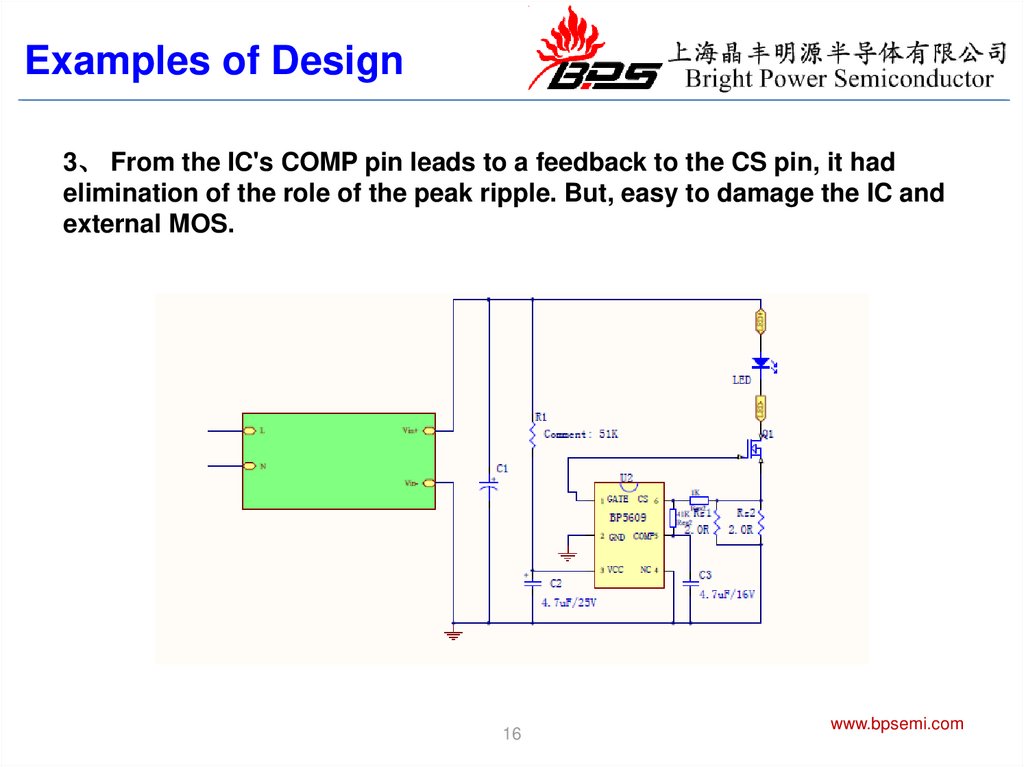

Examples of Design3、 From the IC's COMP pin leads to a feedback to the CS pin, it had

elimination of the role of the peak ripple. But, easy to damage the IC and

external MOS.

16

www.bpsemi.com

16.

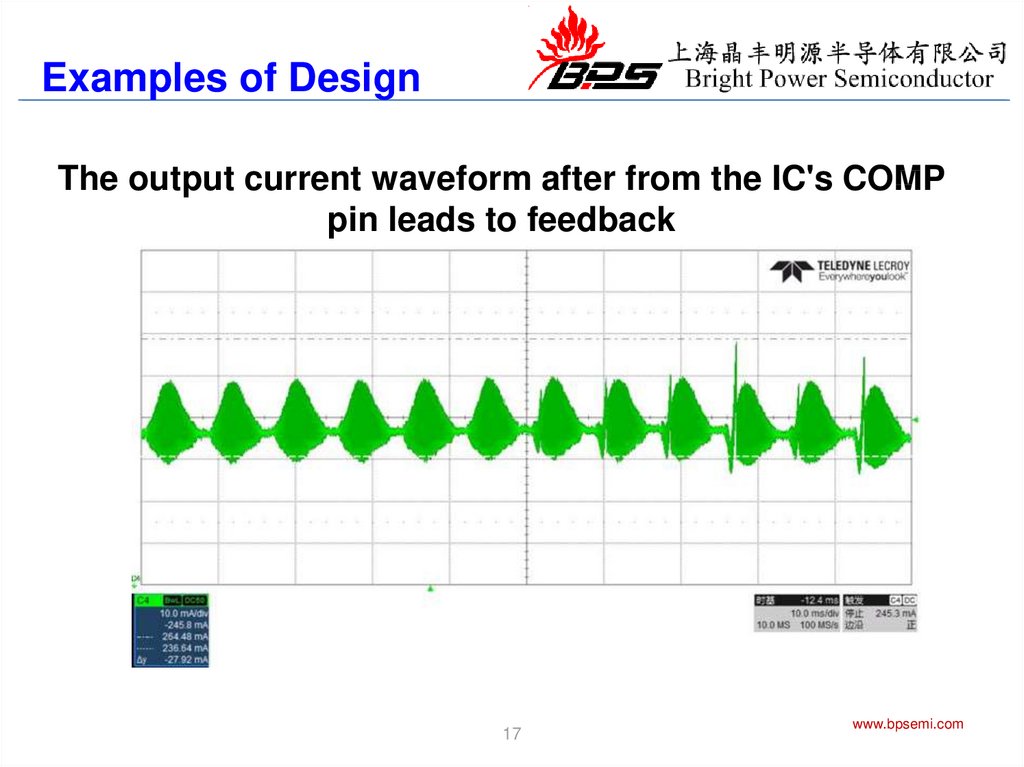

Examples of DesignThe output current waveform after from the IC's COMP

pin leads to feedback

17

www.bpsemi.com

17.

Examples of DesignPre-APFC'S capacitor parameters requirements

Pre-APFC'S COMP capacitor capacitance should not be greater than 1uF,

otherwise the LED will flash

17

www.bpsemi.com

18.

Considerations of DesignStart resistor and VCC capacitor selection

The starting resistor is selected according to the output LED voltage and

should be calculated with the minimum LED voltage

RSTART (VLED 16V ) *1000

VCC capacitor is recommended to select 4.7uF / 25V;

Due to the voltage coefficient of the chip capacitors, electrolytic capacitors

are recommended

COMP capacitor selection

COMP capacitor is recommended to select 4.7uF / 16V (0805)

18

www.bpsemi.com

19.

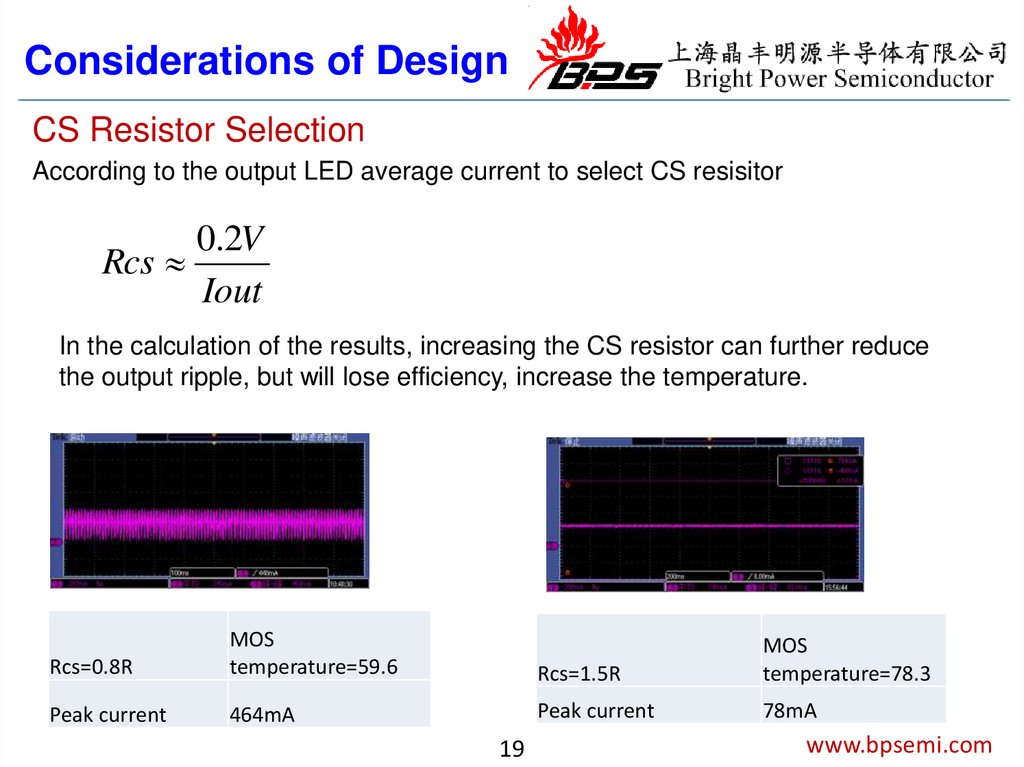

Considerations of DesignCS Resistor Selection

According to the output LED average current to select CS resisitor

0.2V

Rcs

Iout

In the calculation of the results, increasing the CS resistor can further reduce

the output ripple, but will lose efficiency, increase the temperature.

Rcs=0.8R

MOS

temperature=59.6

Rcs=1.5R

MOS

temperature=78.3

Peak current

464mA

Peak current

78mA

19

www.bpsemi.com

20.

Considerations of DesignRepeated switch

Repeated switch does not appear repeatedly start phenomenon

Vds

Vcc

Vo

Io

20

www.bpsemi.com

21.

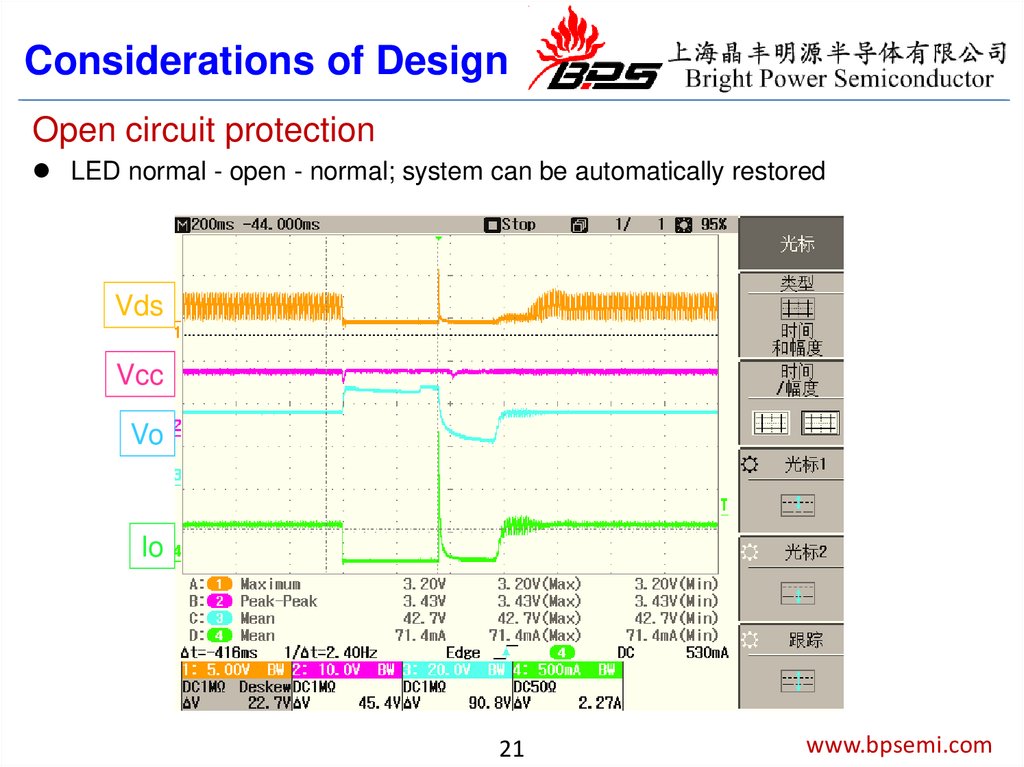

Considerations of DesignOpen circuit protection

LED normal - open - normal; system can be automatically restored

Vds

Vcc

Vo

Io

21

www.bpsemi.com

22.

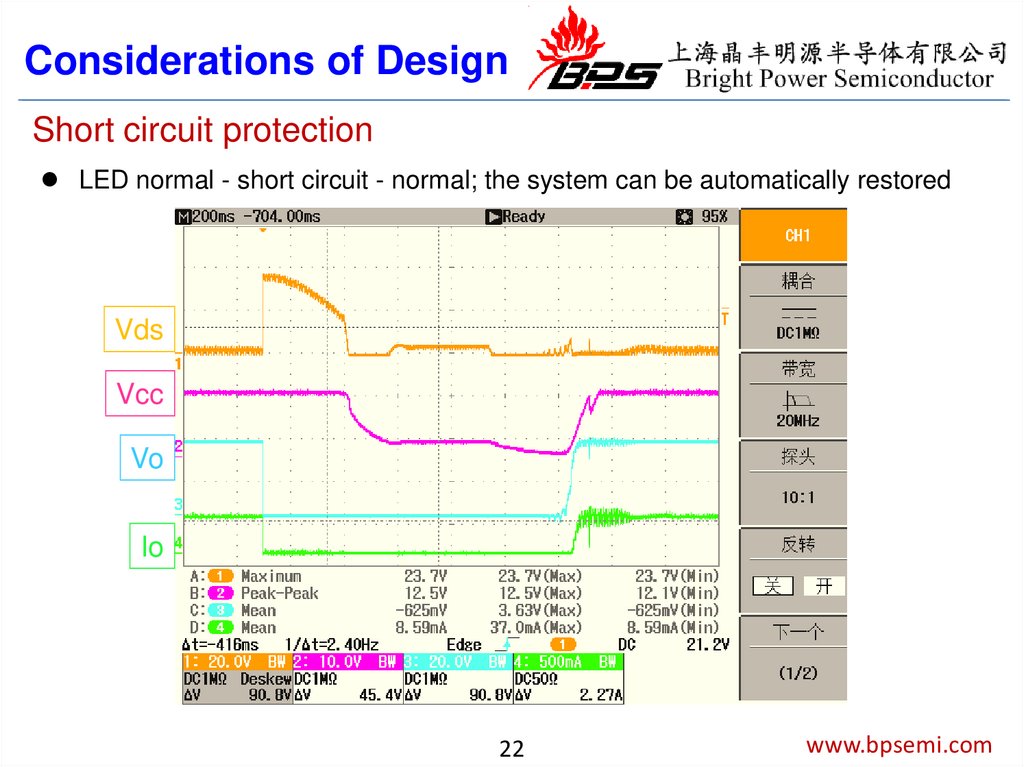

Considerations of DesignShort circuit protection

LED normal - short circuit - normal; the system can be automatically restored

Vds

Vcc

Vo

Io

22

www.bpsemi.com

23.

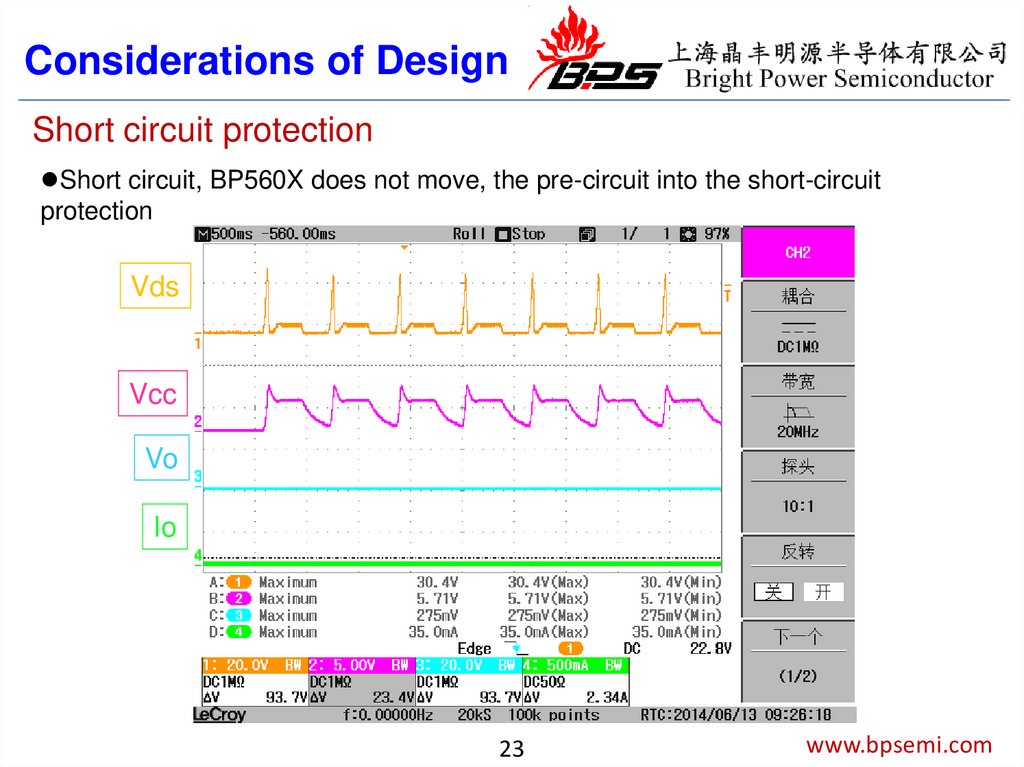

Considerations of DesignShort circuit protection

Short circuit, BP560X does not move, the pre-circuit into the short-circuit

protection

Vds

Vcc

Vo

Io

23

www.bpsemi.com

24.

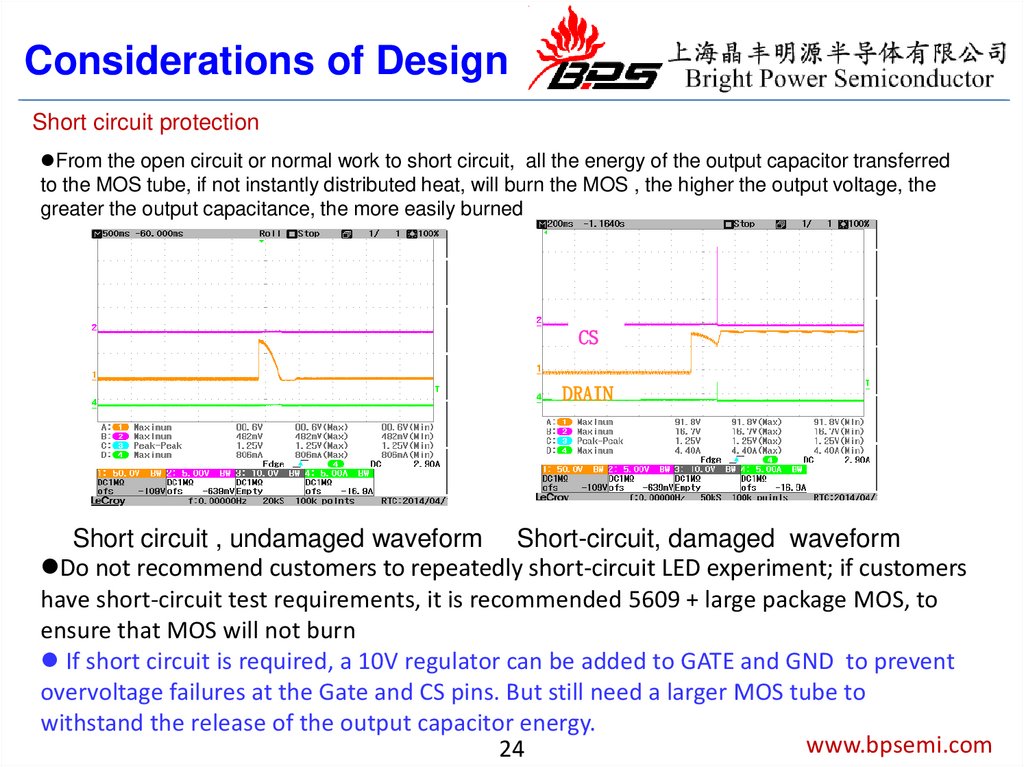

Considerations of DesignShort circuit protection

From the open circuit or normal work to short circuit, all the energy of the output capacitor transferred

to the MOS tube, if not instantly distributed heat, will burn the MOS , the higher the output voltage, the

greater the output capacitance, the more easily burned

CS

DRAIN

Short circuit , undamaged waveform Short-circuit, damaged waveform

Do not recommend customers to repeatedly short-circuit LED experiment; if customers

have short-circuit test requirements, it is recommended 5609 + large package MOS, to

ensure that MOS will not burn

If short circuit is required, a 10V regulator can be added to GATE and GND to prevent

overvoltage failures at the Gate and CS pins. But still need a larger MOS tube to

withstand the release of the output capacitor energy.

www.bpsemi.com

24

25.

Considerations of DesignLayout

Increase Drain's

copper area,

improve cooling

capacity

GND

GND Leakage copper to

prevent leakage of high

voltage on the COMP

COMP

capacitance

25

www.bpsemi.com

Электроника

Электроника