Похожие презентации:

Some Basic Questions before starting …

1.

Some Basic Questions before starting …- Why is Refrigerated Transport needed?

- What commodities are transported under controlled

Temperature?

- What Temperature range can be offered?

- What other features can a Reefer Container

accomplish (other than Temperature?)

2. Refrigerated Containers are primarily used to maintain the cargo at a given Temperature

More than 5 working days are required todecrease the cargo temperature from 5°C to

-18°C inside Reefer container.

During this period the cargo continues to

develop bacteria down to -15°C.

As a comparison, a Cold storage can

decrease the temperature of 20 Tons of

meat from 3°C to -20°C in just a few hours.

Therefore the main function of a reefer

container is to maintain the temperature of

the cargo and not to decrease it.

3.

Reefer mission – Keep it cool !What a reefer container can do:

Maintain Temperature as required

Regulate Air Exchange up to 240 m3/h

Monitor Humidity level

Control Atmosphere

What we have to do:

PTI (Pre - Trip Inspection)

Follow handling procedures, stuffing etc.

Ensure proper routing, trans-shipments, plugging and

monitoring, repair malfunctions etc

Once temperature deviations have occurred, they cannot be

reversed! Maintain the cold chain from packing to

ultimate consumer.

4. What is carried in reefers ?

Meat, fish, seafoodMainly Perishable

Fruit, vegetables

Dairy products, candy, confectionary

Flowers, bulbs and other horticultural products

But also Chemicals, biological products,

pharmaceuticals

Or Photographic supplies, electronic components

5.

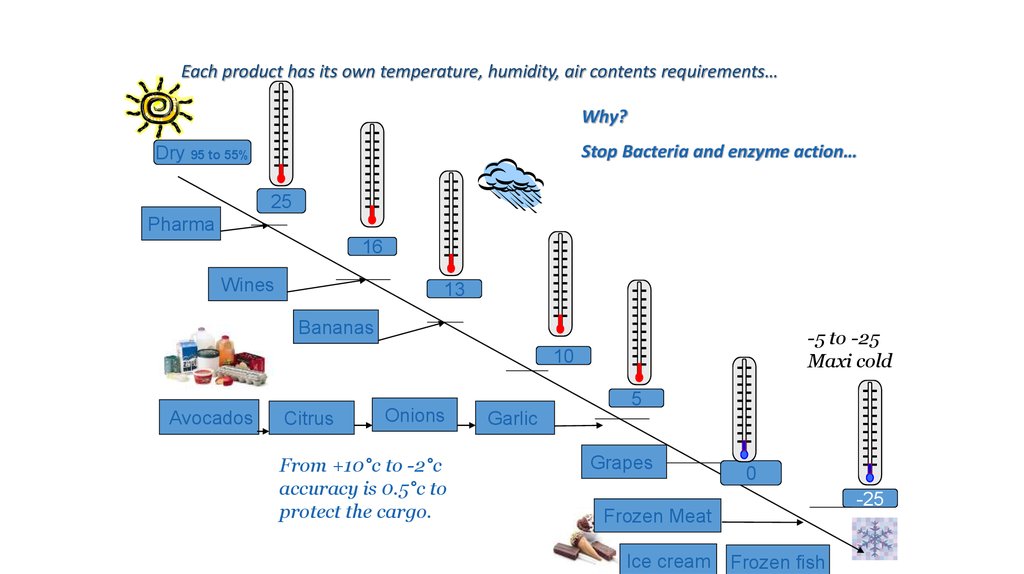

Each product has its own temperature, humidity, air contents requirements…Why?

Stop Bacteria and enzyme action…

Dry 95 to 55%

25

Pharma

16

Wines

13

Bananas

-5 to -25

Maxi cold

10

Avocados

Citrus

Onions

From +10°c to -2°c

accuracy is 0.5°c to

protect the cargo.

5

Garlic

Grapes

0

-25

Frozen Meat

Ice cream

Frozen fish

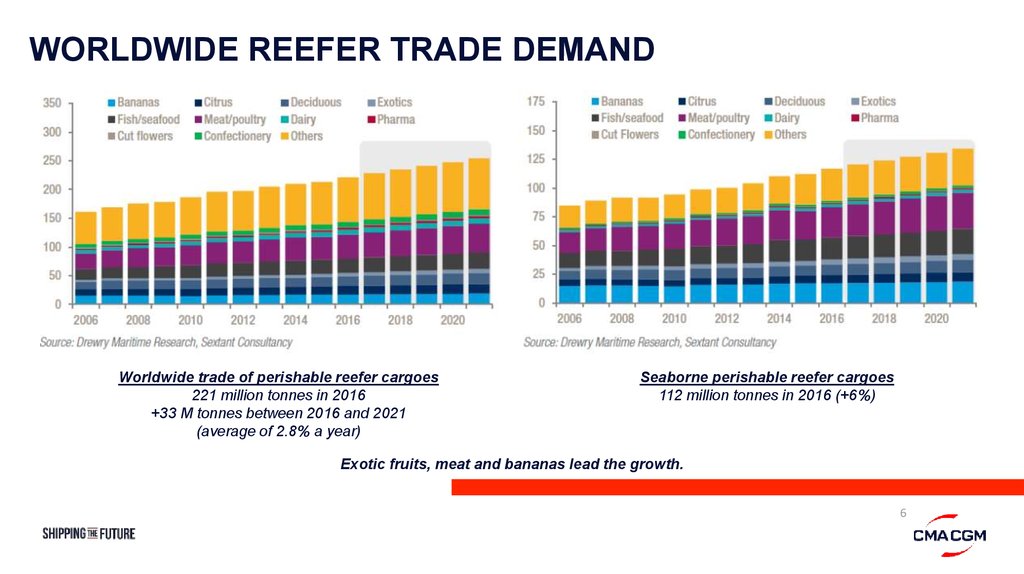

6. WORLDWIDE REEFER TRADE DEMAND

Worldwide trade of perishable reefer cargoes221 million tonnes in 2016

+33 M tonnes between 2016 and 2021

(average of 2.8% a year)

Seaborne perishable reefer cargoes

112 million tonnes in 2016 (+6%)

Exotic fruits, meat and bananas lead the growth.

6

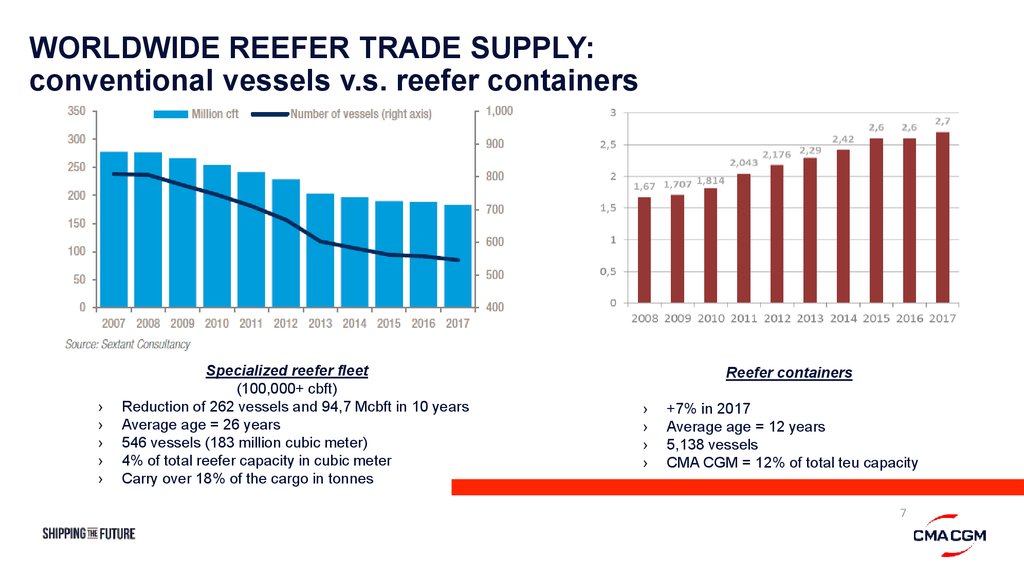

7. WORLDWIDE REEFER TRADE SUPPLY: conventional vessels v.s. reefer containers

››

›

›

›

Specialized reefer fleet

(100,000+ cbft)

Reduction of 262 vessels and 94,7 Mcbft in 10 years

Average age = 26 years

546 vessels (183 million cubic meter)

4% of total reefer capacity in cubic meter

Carry over 18% of the cargo in tonnes

Reefer containers

›

›

›

›

+7% in 2017

Average age = 12 years

5,138 vessels

CMA CGM = 12% of total teu capacity

7

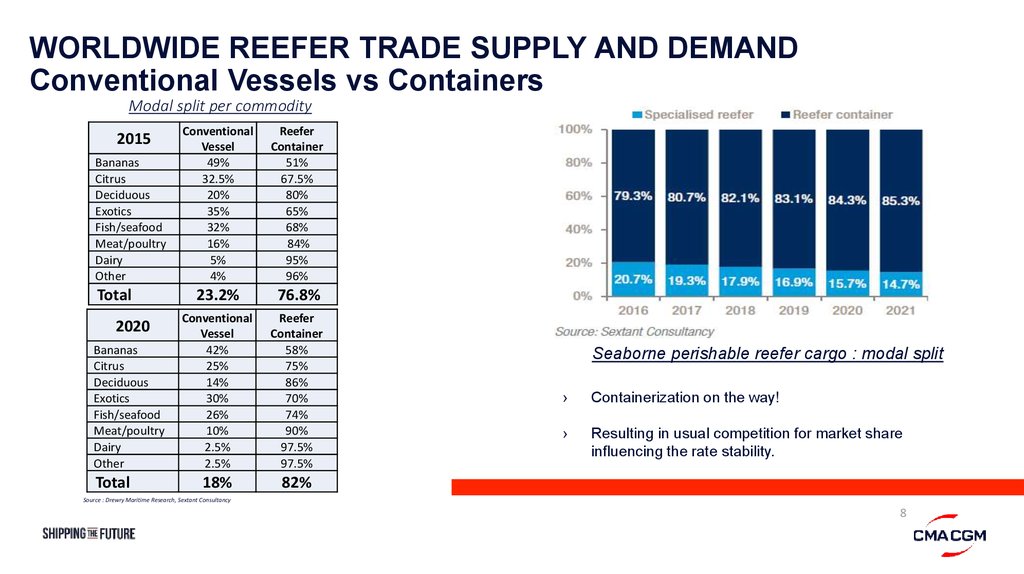

8. WORLDWIDE REEFER TRADE SUPPLY AND DEMAND Conventional Vessels vs Containers

Modal split per commodity2015

Bananas

Citrus

Deciduous

Exotics

Fish/seafood

Meat/poultry

Dairy

Other

Total

2020

Bananas

Citrus

Deciduous

Exotics

Fish/seafood

Meat/poultry

Dairy

Other

Total

Conventional

Vessel

49%

32.5%

20%

35%

32%

16%

5%

4%

Reefer

Container

51%

67.5%

80%

65%

68%

84%

95%

96%

23.2%

76.8%

Conventional

Vessel

42%

25%

14%

30%

26%

10%

2.5%

2.5%

Reefer

Container

58%

75%

86%

70%

74%

90%

97.5%

97.5%

18%

82%

Seaborne perishable reefer cargo : modal split

›

Containerization on the way!

›

Resulting in usual competition for market share

influencing the rate stability.

Source : Drewry Maritime Research, Sextant Consultancy

8

9. Global Reefer Seaborne Market

1. Perishables transported worldwide2015: 192 million tons

2020: 250 million tons

2. Perishables transported by sea (55%)

2016: 106 million tons

2020: 130 million tons

3. Reefer Containers (81% and increasing)

2015: 84.75 million tons

2020: 109 million tons

4. Reefer Conventional vessels (19% and decreasing)

2015: 27 million tons

2020: 21 million tons

Source : Drewry Maritime Research, Sextant Consultancy

9

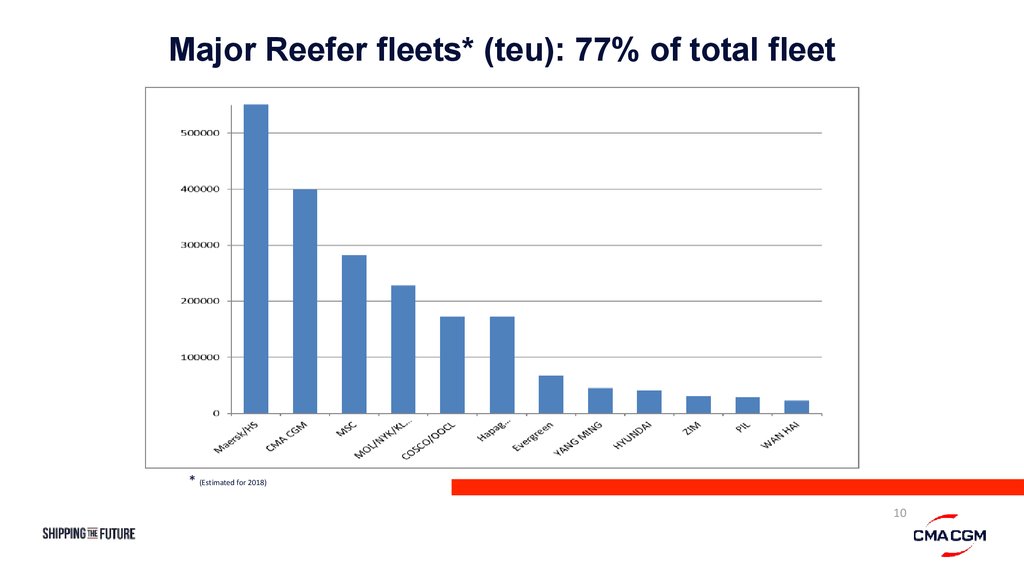

10. Major Reefer fleets* (teu): 77% of total fleet

* (Estimated for 2018)10

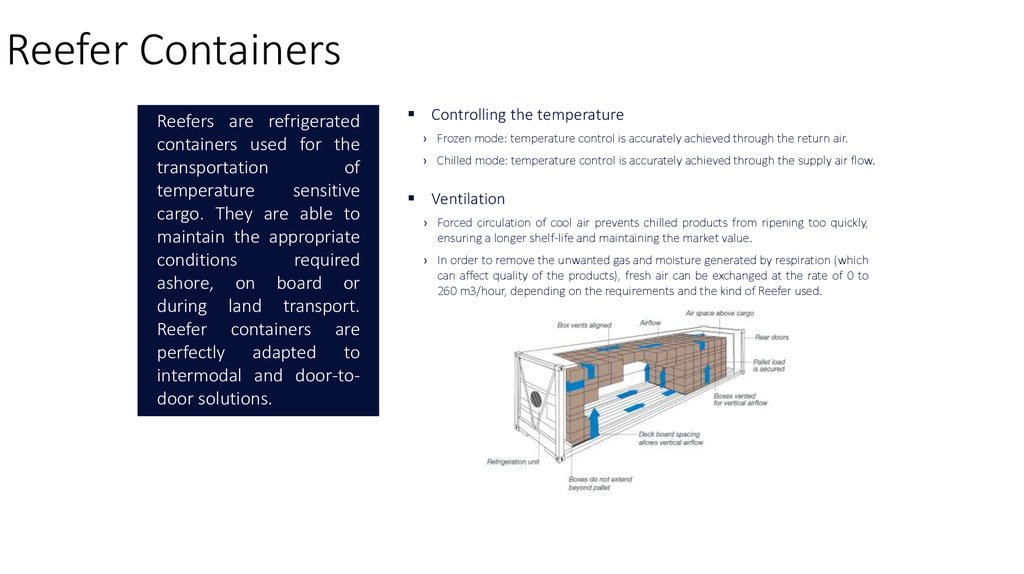

11. Reefer Containers

Reefers are refrigeratedcontainers used for the

transportation

of

temperature

sensitive

cargo. They are able to

maintain the appropriate

conditions

required

ashore, on board or

during land transport.

Reefer containers are

perfectly adapted to

intermodal and door-todoor solutions.

Controlling the temperature

› Frozen mode: temperature control is accurately achieved through the return air.

› Chilled mode: temperature control is accurately achieved through the supply air flow.

Ventilation

› Forced circulation of cool air prevents chilled products from ripening too quickly,

ensuring a longer shelf-life and maintaining the market value.

› In order to remove the unwanted gas and moisture generated by respiration (which

can affect quality of the products), fresh air can be exchanged at the rate of 0 to

260 m3/hour, depending on the requirements and the kind of Reefer used.

12.

13.

Diversified Reefer fleet: an option for everyrequirement

45’ Pallet Wide Reefer Containers were

specifically designed with the “Europallet” in

mind, allowing a largest number of pallets to

be loaded (33). The equipment ensures

optimum utilization of space. Shippers

benefit by being able to load more

Europallets than they would in a standard

ISO container.

40’ High Cube Containers

20’ Containers

45’ Pallet Wide Containers

Super Freezer Containers

Some products have to be transported

at ultra-low temperatures.

The Super Freezer Container can

maintain temperatures as low as -60

°C thanks to a double-compressor

unit. They are equipped with a

GPS/GSM tracking system that

transmits information in real time

(temperature/alarm status, etc.).

13

14. Controlled Atmosphere Fleet

• CMA CGM Group is able to offer a large anddiverse fleet of Controlled Atmosphere Containers,

meeting various green products storage and

transportation needs.

• Advantages of the proposed CMA CGM CA fleet:

• Integrated with the Reefer, uses the main power to

operate

• Transparency assured by built in sensors

• Scrubbing CO2 without using atmosphere air

• Lower dependency on Container’s age

BENEFITS

ENSURE PRODUCT QUALITY

• Controlled atmosphere technology controls the atmosphere

inside containers.

• Enhanced functionality to help slow down the ripening process

of fruits and vegetables by removing ethylene.

EXTENDED TIME FOR DISTRIBUTION AT DESTINATION, AND REACHING

MARKETS WITH LONGER TRANSIT TIMES

• By accurately controlling the temperature and the atmosphere

surrounding the cargo, shelf life of fruits can now be extended.

• Delivery to remote markets and new destinations made

possible.

TECHNOLOGY TO MANAGE

THE WAY YOUR FRUIT CARGO

BREATHES AND INCREASE SHELF-LIFE

14

15.

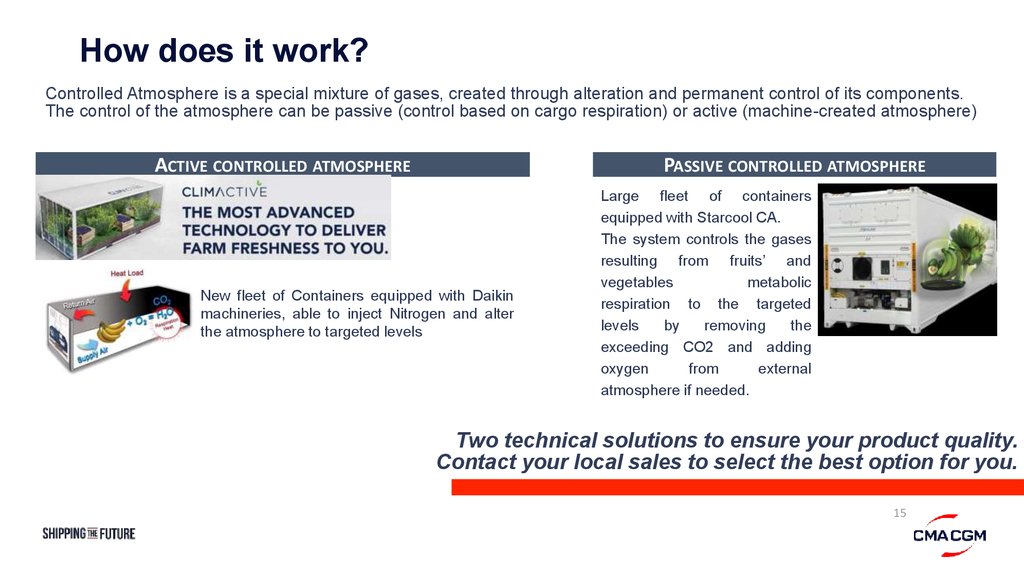

How does it work?Controlled Atmosphere is a special mixture of gases, created through alteration and permanent control of its components.

The control of the atmosphere can be passive (control based on cargo respiration) or active (machine-created atmosphere)

ACTIVE CONTROLLED ATMOSPHERE

PASSIVE CONTROLLED ATMOSPHERE

New fleet of Containers equipped with Daikin

machineries, able to inject Nitrogen and alter

the atmosphere to targeted levels

Large fleet of containers

equipped with Starcool CA.

The system controls the gases

resulting from fruits’ and

vegetables

metabolic

respiration to the targeted

levels

by

removing

the

exceeding CO2 and adding

oxygen

from

external

atmosphere if needed.

Two technical solutions to ensure your product quality.

Contact your local sales to select the best option for you.

15

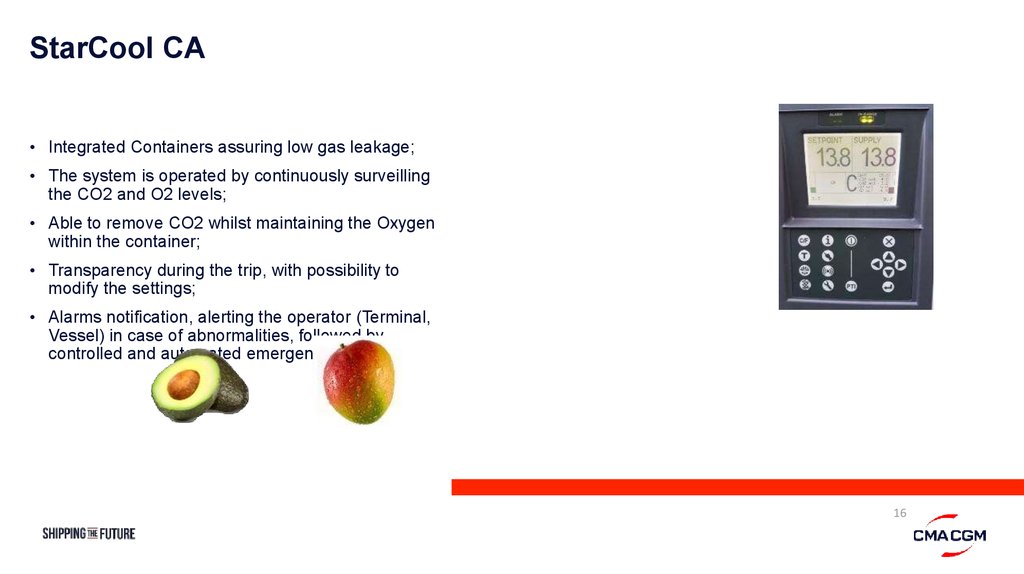

16. StarCool CA

• Integrated Containers assuring low gas leakage;• The system is operated by continuously surveilling

the CO2 and O2 levels;

• Able to remove CO2 whilst maintaining the Oxygen

within the container;

• Transparency during the trip, with possibility to

modify the settings;

• Alarms notification, alerting the operator (Terminal,

Vessel) in case of abnormalities, followed by

controlled and automated emergency action.

16

17. CMA CGM presents CLIMACTIVE, The most advanced technology in active controlled atmosphere for refrigerated containers

CLIMACTIVE is the latest and most advanced solution to maintain sensitivecommodities’ freshness to destination, by faster reducing the level of oxygen

inside the container equipped with DAIKIN Active CA.

CLIMACTIVE is created for highly sensitive commodities that require special

attention, such as fresh fruits and vegetables due to their biological

specificities and maturation time. It specifically targets:

high added value products (Blueberries, asparagus …),

long transit time products (Snow peas, melons …),

organic products (Grapes, bananas …).

17

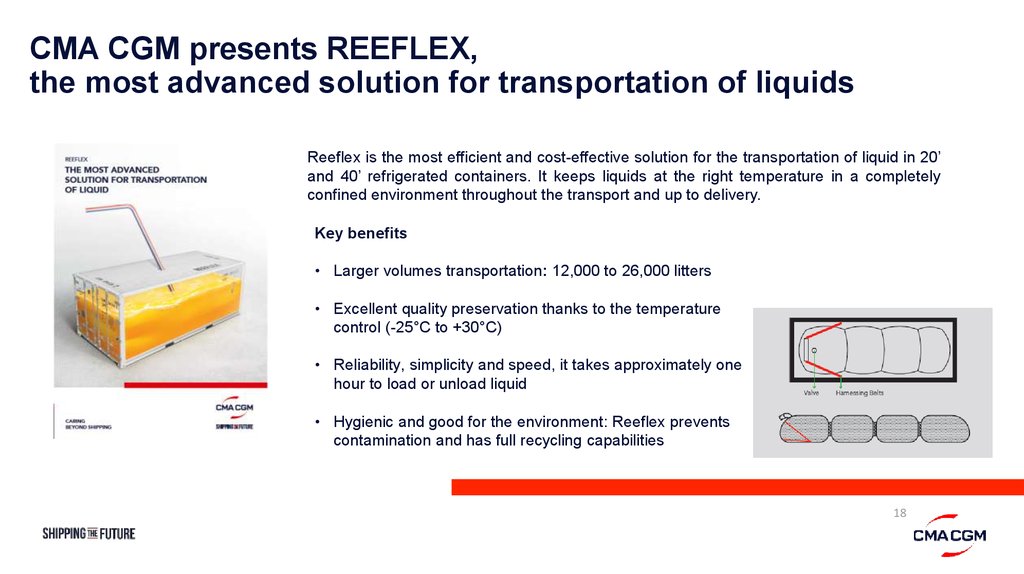

18. CMA CGM presents REEFLEX, the most advanced solution for transportation of liquids

Reeflex is the most efficient and cost-effective solution for the transportation of liquid in 20’and 40’ refrigerated containers. It keeps liquids at the right temperature in a completely

confined environment throughout the transport and up to delivery.

Key benefits

• Larger volumes transportation: 12,000 to 26,000 litters

• Excellent quality preservation thanks to the temperature

control (-25°C to +30°C)

• Reliability, simplicity and speed, it takes approximately one

hour to load or unload liquid

• Hygienic and good for the environment: Reeflex prevents

contamination and has full recycling capabilities

18

19. CMA CGM develops AQUAVIVA, a new generation of containers

AQUAVIVA is a new generation of containers which allows the safetransport of live lobsters in their original water while maintaining their

natural habitat. The development of this global innovation relies on the

strong CMA CGM’s Reefer expertise and the unique INNOPURE®

technology developed by EMYG Environment & Aquaculture.

›Replicates lobsters’ natural living conditions

›Preserves the water’s oxygen level and quality

›Guarantees the water’s optimum temperature during transportation

›The slogan: LIVE SEAFOOD NOW TRAVELS ABOVE WATER

›The signature - AQUAVIVA: INNOVATION AND CARE FOR LIVE SEAFOOD

›Combine innovation, expertise, respect for the environment and

technological progress.

19

20.

MAGNUM Container -35°C1 Used to obtain lower temperatures down to -35 ° C

2 To preserve some goods as ice cream or frozen fish

3 Possibility to do hot stuffing (can lower temp quicker)

4 To stuff certain goods as grapes directly on the Field

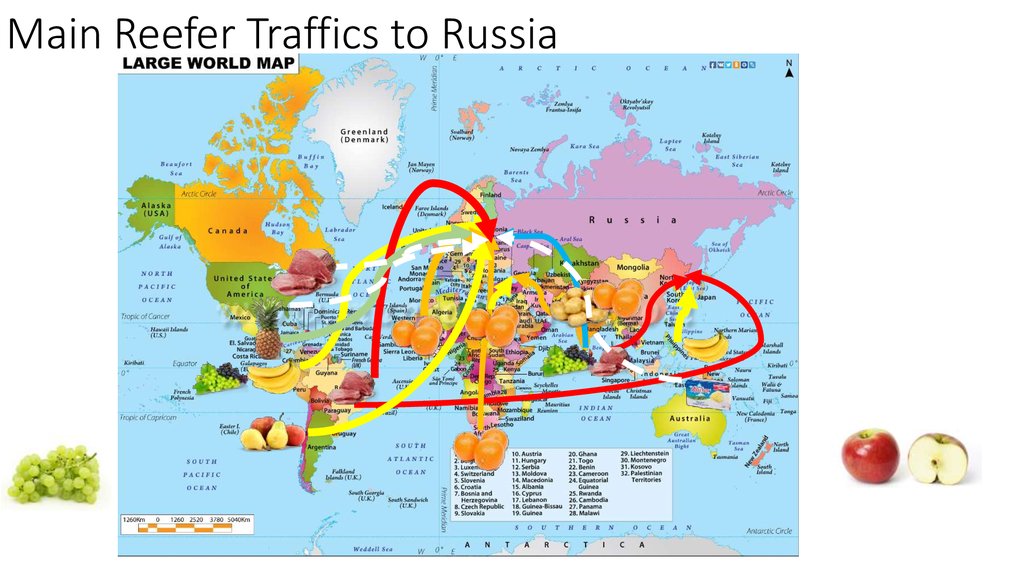

21. Main Reefer Traffics to Russia

22. Heat comes through the walls

The Sun’s Radiant Heat.In case of unplugging, the temperature increases

High Ambient Temperature

1 to 2 degree lost per day at 30 degree outside if frozen cargo .

23.

Super Freezer Container -60°CUsed to obtain ultra- low

temperatures down to -60 ° C

To preserve goods as sashimigrade frozen fish (mainly tuna),

but also sea urchins, some types of

ice-cream etc.

Turn-time : 3 bookings / year, rates

$750/ ton with 20 tons minimum,

contributions at $5000/teu !!

24.

• Melons• Live plants

• Potatoes in bags

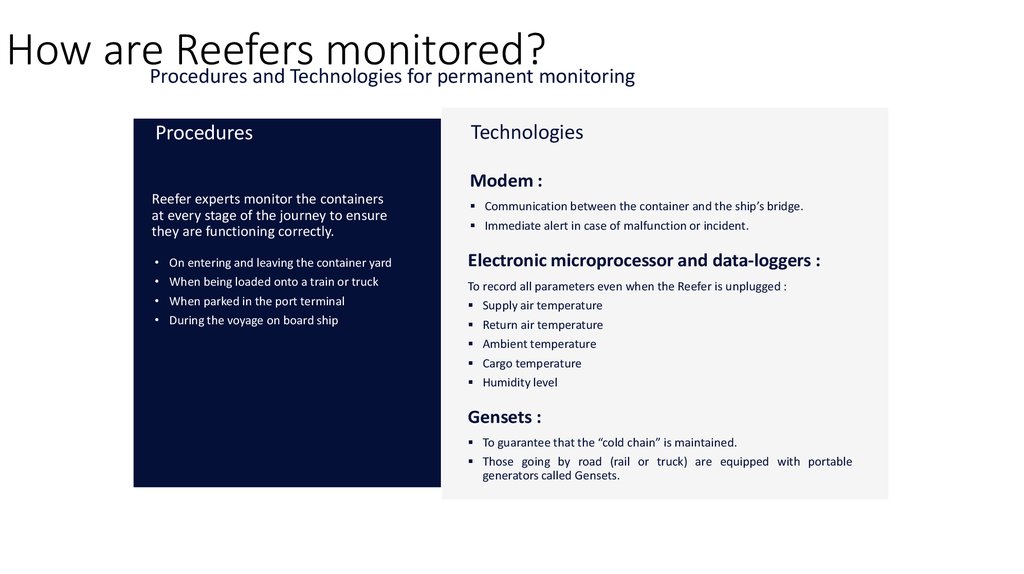

25. How are Reefers monitored?

How areProceduresReefers

monitored?

and Technologies for permanent monitoring

Procedures

Technologies

Modem :

Reefer experts monitor the containers

at every stage of the journey to ensure

they are functioning correctly.

Communication between the container and the ship’s bridge.

Immediate alert in case of malfunction or incident.

• On entering and leaving the container yard

• When being loaded onto a train or truck

Electronic microprocessor and data-loggers :

• When parked in the port terminal

• During the voyage on board ship

To record all parameters even when the Reefer is unplugged :

Supply air temperature

Return air temperature

Ambient temperature

Cargo temperature

Humidity level

Gensets :

To guarantee that the “cold chain” is maintained.

Those going by road (rail or truck) are equipped with portable

generators called Gensets.

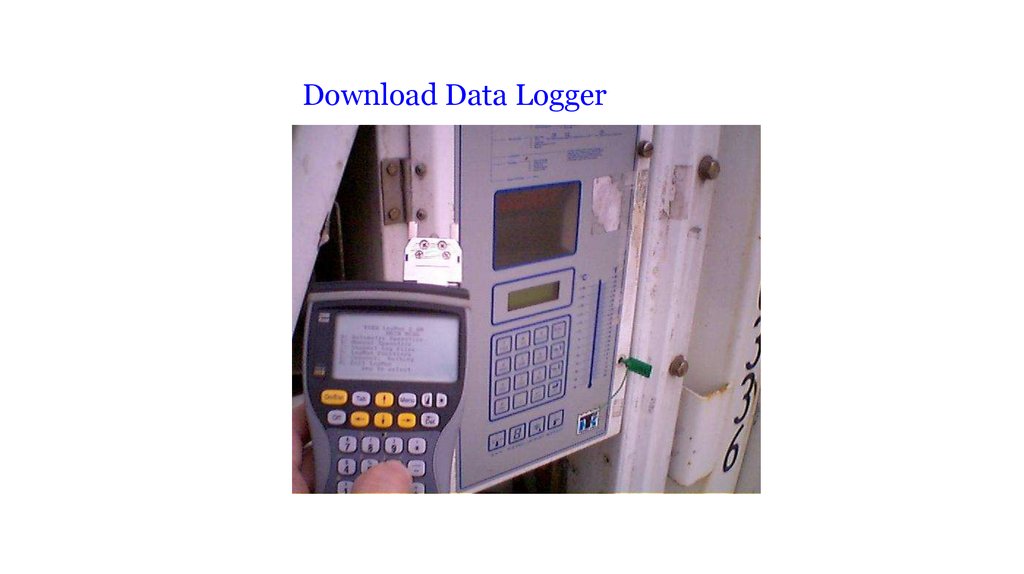

26. Download Data Logger

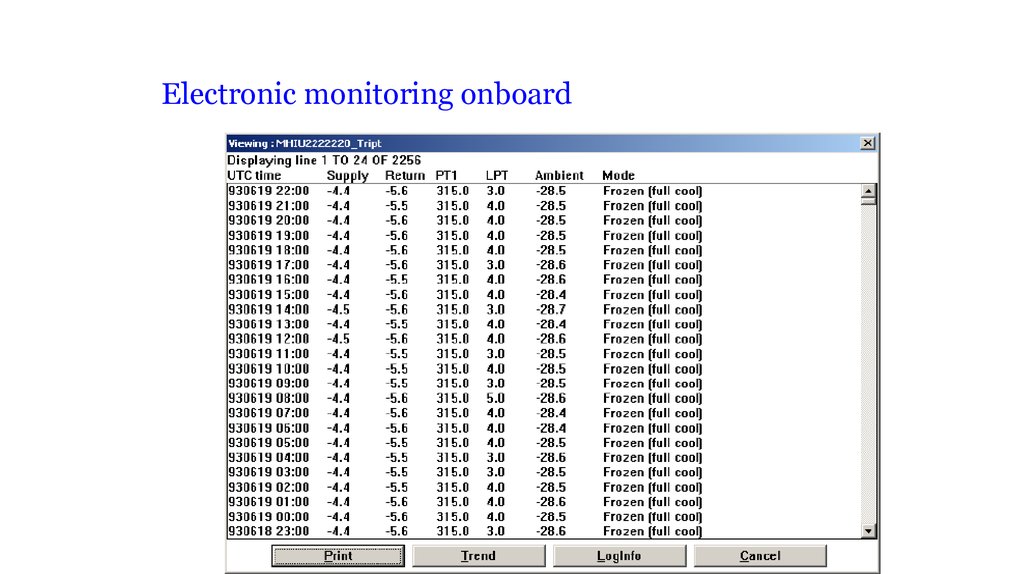

27. Electronic monitoring onboard

28. Gen set - Why do we use it ?

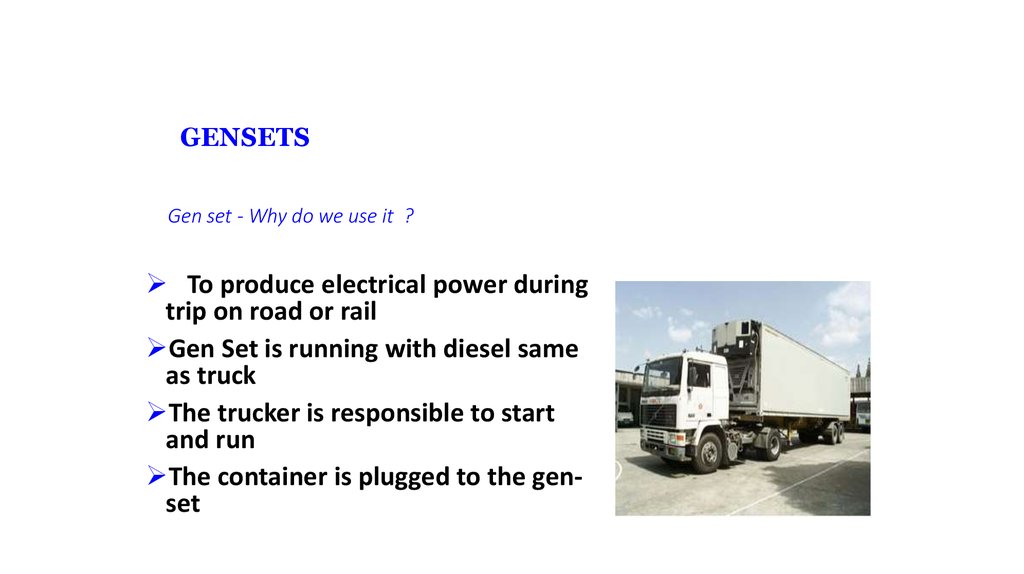

GENSETSGen set - Why do we use it ?

To produce electrical power during

trip on road or rail

Gen Set is running with diesel same

as truck

The trucker is responsible to start

and run

The container is plugged to the genset

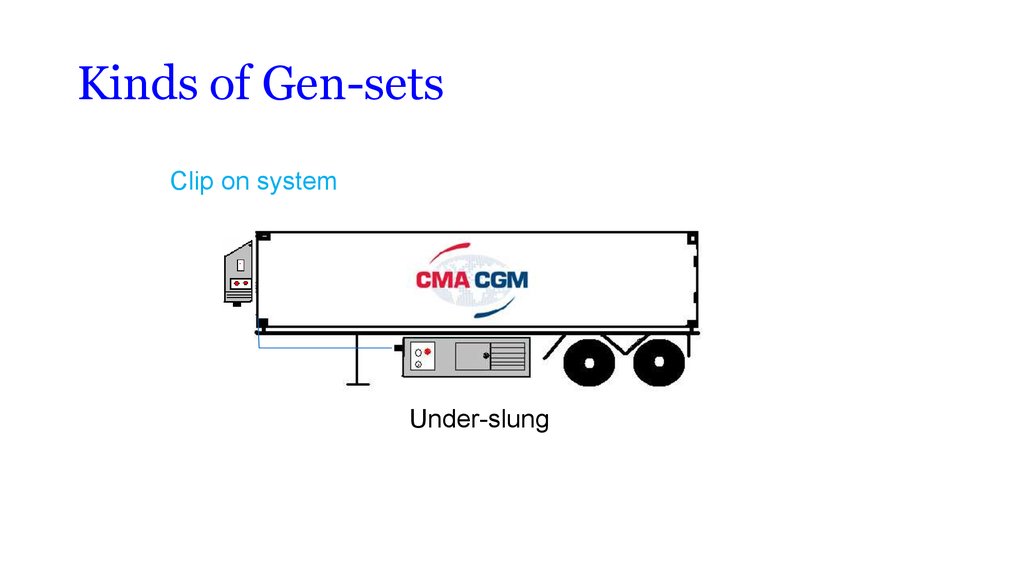

29. Kinds of Gen-sets

Clip on systemUnder-slung

30. Under-slung

Clip-on31. CMA CGM presents TRAXENS, End to end visibility and supply chain operational excellence

The Group presents TRAXENS, a solution allowing our customers todirect their Supply Chain in real-time and to optimize it through an

advanced analysis.

TRAXENS is a permanent electronic high-tech device designed to

generate near real-time data and notifications about cargo’s

movement and condition at any given point in time, be it:

• Geographic position

• Status in the shipping process

• External and internal* temperature variation

• Humidity variation*

• Shocks

• Door opening

31

Промышленность

Промышленность