Похожие презентации:

NIR Systems

1.

CEMTREX, INC.MODCON SYSTEMS LTD

NIR Systems

July 2010

2.

NIR Spectroscopy PrincipleBeer–Lambert law

Logarithmic dependence between the transmission T, of light

through a substance and the product of the absorption A

coefficient of the substance, α, and the distance the light travels

through the material (i.e. the path length), ℓ.

3.

NIR Analyzers Advantage• Low Cost of Ownership

• Optimized production processes by real

time monitoring

• Improved process knowledge

• Expensive and time consuming

laboratory analyses are no longer

necessary

• Improved quality assurance

• Minimal maintenance required

• Easy to calibrate - automatic calibration

model updating

• Powerful communication system

4.

Beacon 3000 NIR Analyzer Advantage• Connection to up to 8 process

stream sensors

• No longer location-specific can be

situated up to 2 miles (3,2km)

away from main analyzer

• Use of standard

telecommunication fiber optics

• Contains no moving parts

• No electricity required

5.

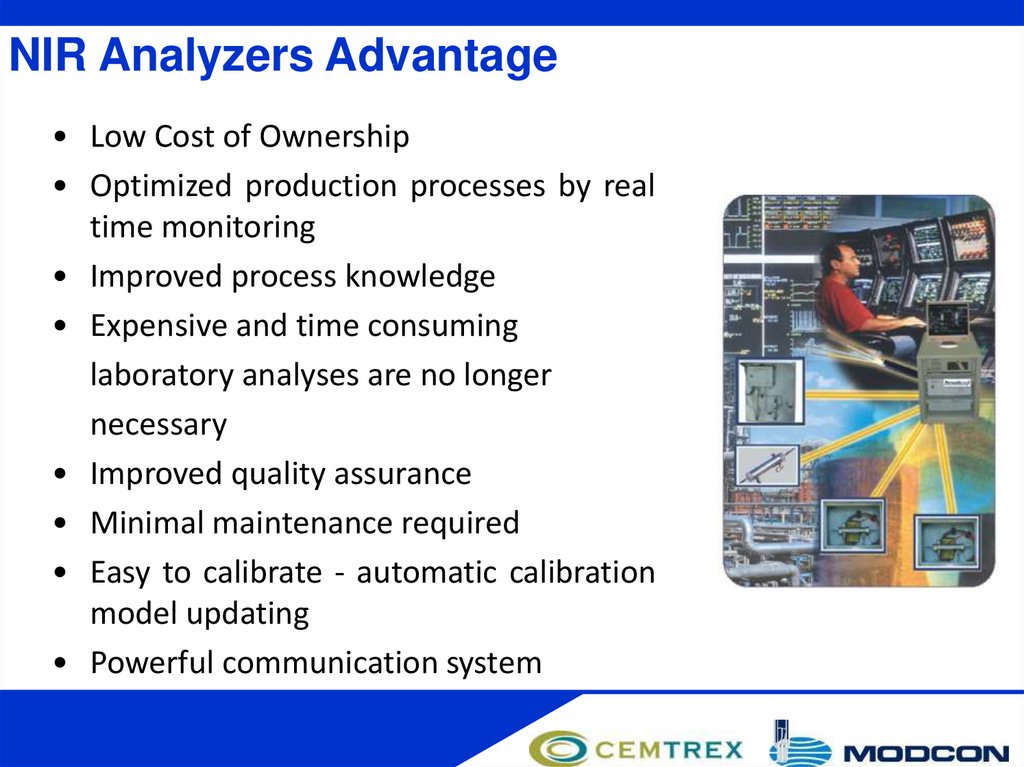

Block DiagramDCS

Analyzer

Processor

Controller

Fiber Optic

Cable

Field Units installed throughout the plant

6.

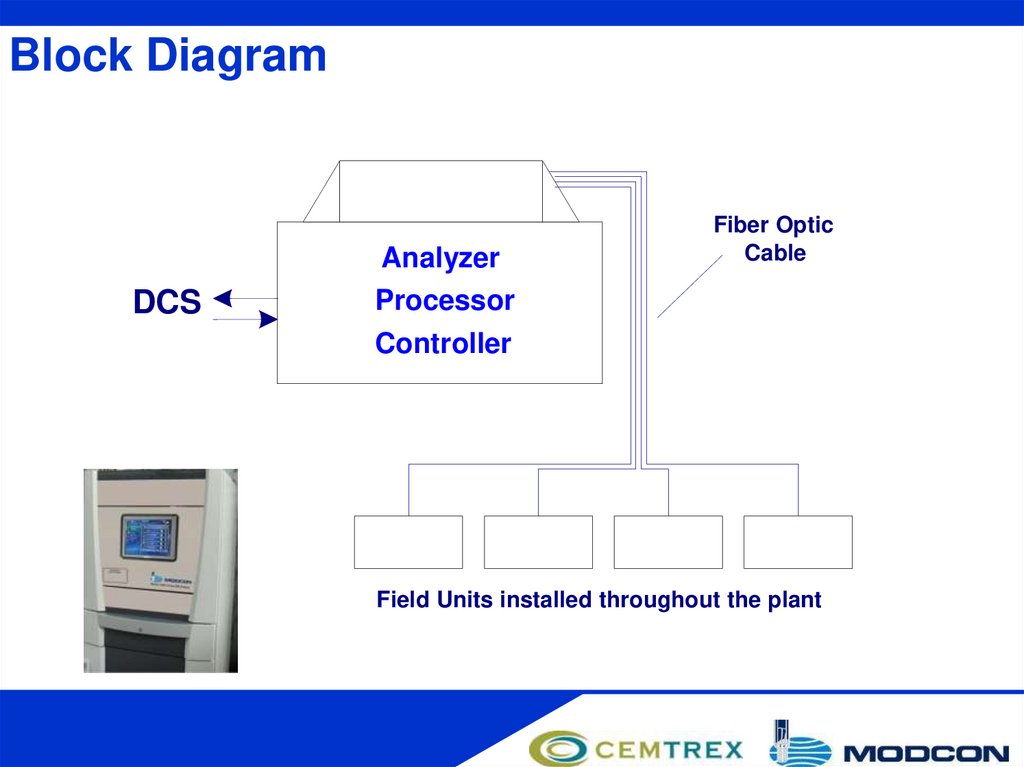

Field Unit Operation ConditionsHaze free

Max. Pressure

Flow rate

Temperature

Field Unit

- 550 psi (40 bar)

- 1 l/min to 3 l/min

- Above Cloud point to +160°C (300°F)

Sample Cell

Probe

7.

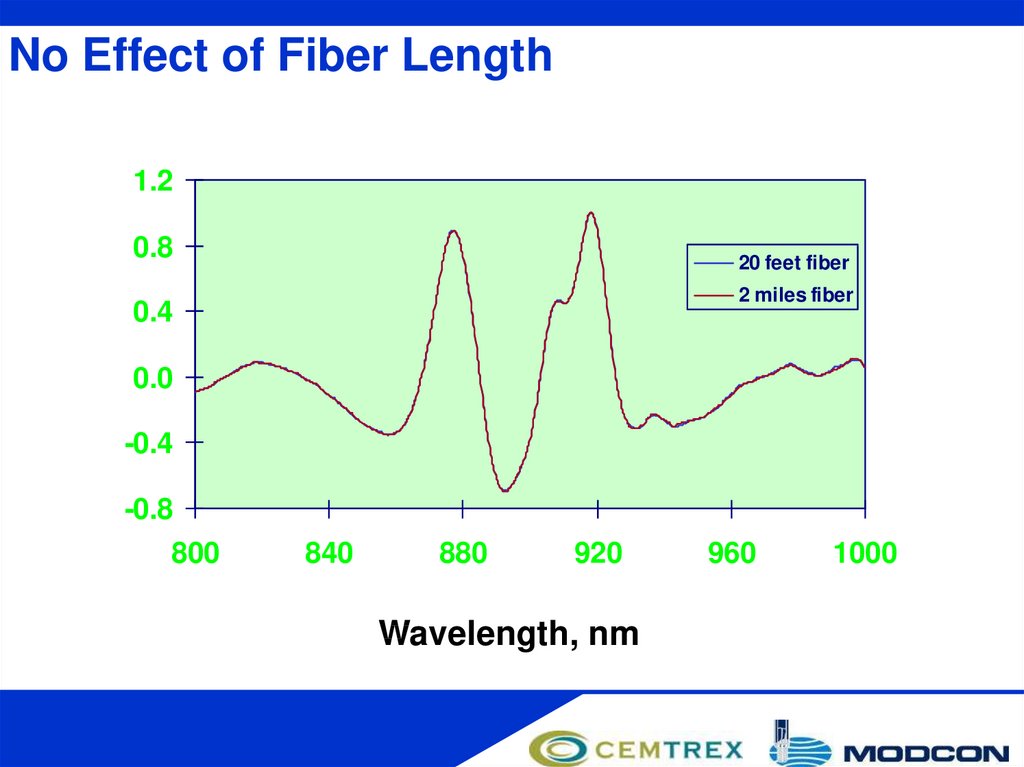

No Effect of Fiber Length1.2

0.8

20 feet fiber

2 miles fiber

0.4

0.0

-0.4

-0.8

800

840

880

920

Wavelength, nm

960

1000

8.

From Spectral Information to Electronic DataLight

Source

Field Unit

Reports

Detector

Module

Measured Spectra

Measured Spectra

3.00

Properties

Calculation

2.00

Processor

1.00

0.00

-1.00

-2.00

800

850

900

950

1000

9.

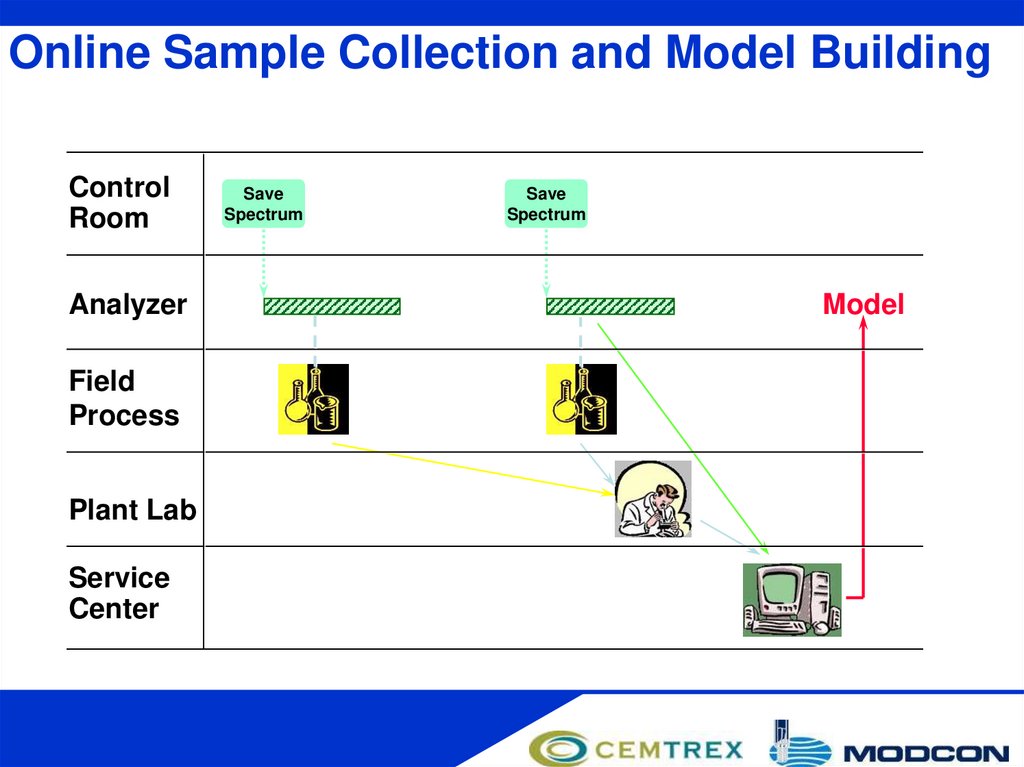

Online Sample Collection and Model BuildingControl

Room

Analyzer

Field

Process

Plant Lab

Service

Center

Save

Spectrum

Save

Spectrum

Model

10.

Principles of Chemo-metricsCalibration Phase

Reference Spectra

Reference Measurements

mix#

0.25

0.2

0.15

0.25

0.1

0.2

0.05

0.15

0

0.1

0.2

-0.05

810 0.05

0.15

860

0.1

0.2

-0.1

0

-0.05

810 0.05

0.15

860

-0.15

0.25

0.25

910

-0.1

0

0.1

-0.15

-0.05

810 0.05

-0.1

0

-0.15

-0.05

960

1010

910

860

810

960

910

860

+

1060

1010

960

910

1060

1010

960

1060

1010

1060

HCl

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

0

1.178964

0.790395

1.090314

1.06258

0.852719

0.99566

0.873404

0.988138

0.849897

1.000474

1.102819

1.135659

0.799425

0.950737

Calibration Model

HF

0

0.39912

0.442637

0.496751

0.543865

0.593886

0.634382

0.669103

0.721126

0.778561

0.81478

0.853354

0.893109

1.009638

0.958367

-0.1

-0.15

Measurement Phase

Unknown Spectra

Real Time Results

Calibration Model

0.25

0.2

+

0.15

0.1

0.05

A1(t)

A2(t)

tote changeover

new lot changeover

0.04

0.03

0.02

0.01

0.05

0

0

-0.05

-0.01

-0.1

-0.02

-0.15

-0.03

-0.04

-0.2

-0.05

-0.25

Wed

07/7

Fri

09/7

Sun

11/7

Tue

13/7

Thu

15/7

Sat

17/7

Mon

19/7

Wed

21/7

Fri

23/7

Sun

25/7

Tue

27/7

Thu

29/7

Sat

31/7

Mon

02/8

Wed

04/8

Fri

06/8

11.

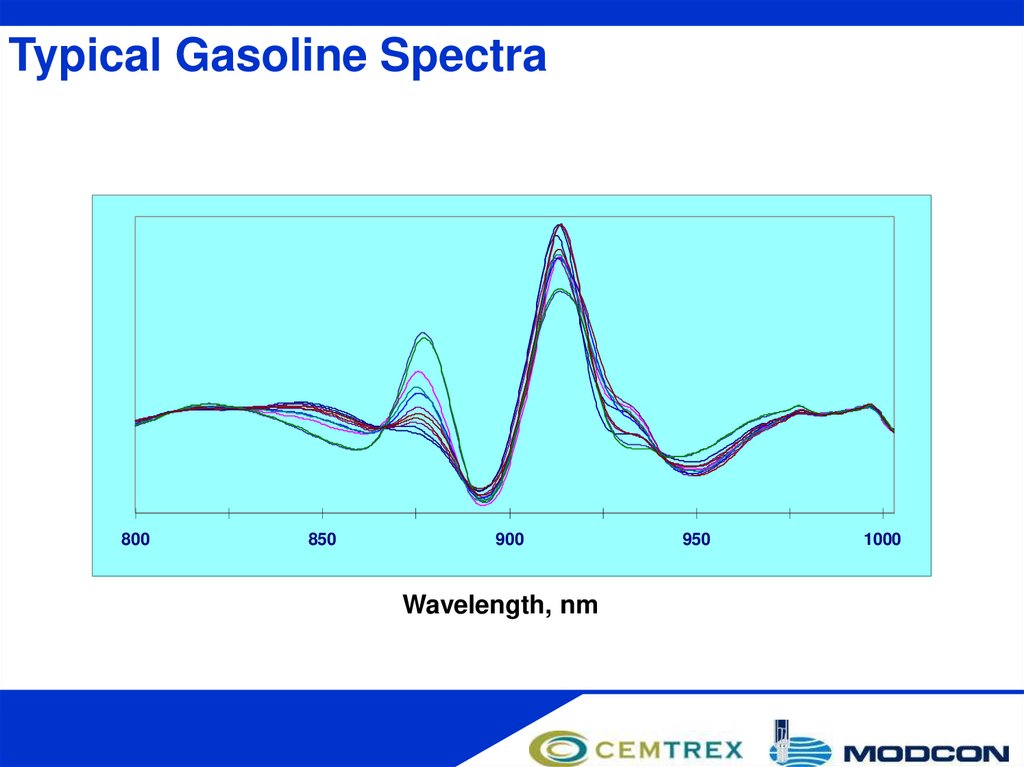

Typical Gasoline Spectra800

850

900

Wavelength, nm

950

1000

12.

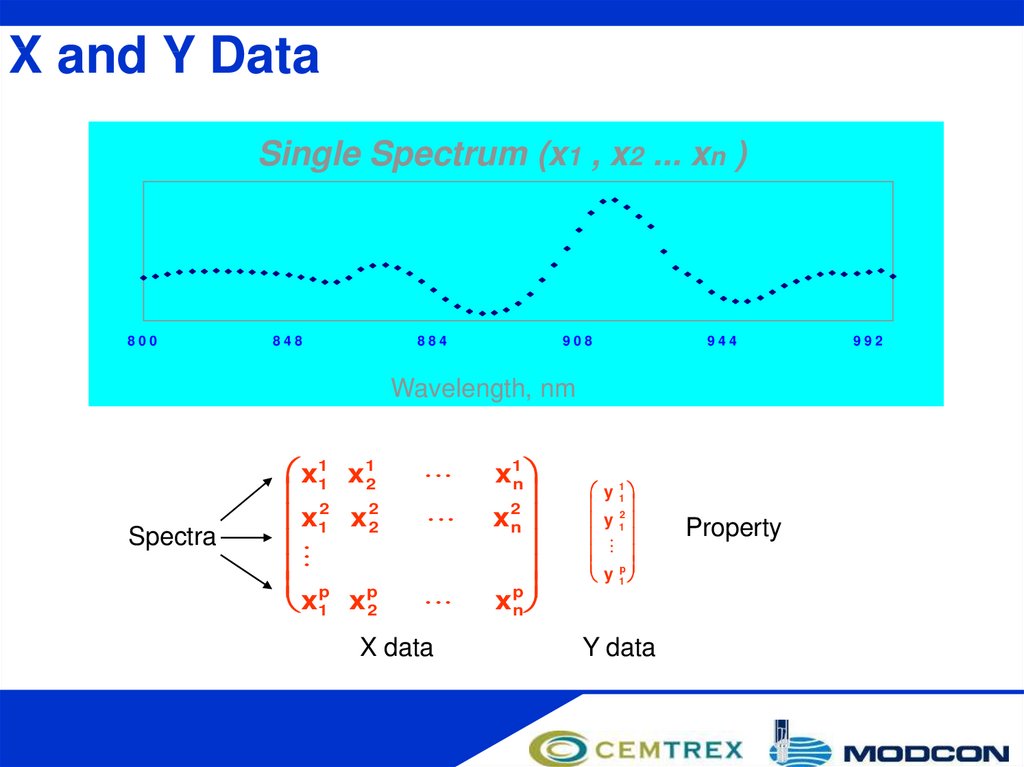

X and Y DataSingle Spectrum (x1 , x2 ... xn )

x11 x12

2 2

x1 x 2

p p

x1 x 2

800

848

884

908

944

Wavelength, nm

Spectra

x11 x12

2

x1 x 22

p p

x1 x 2

X data

x1n

2

xn

p

xn

y 11

y 12

y 1p

Y data

Property

x1n

x n2

x pn

992

13.

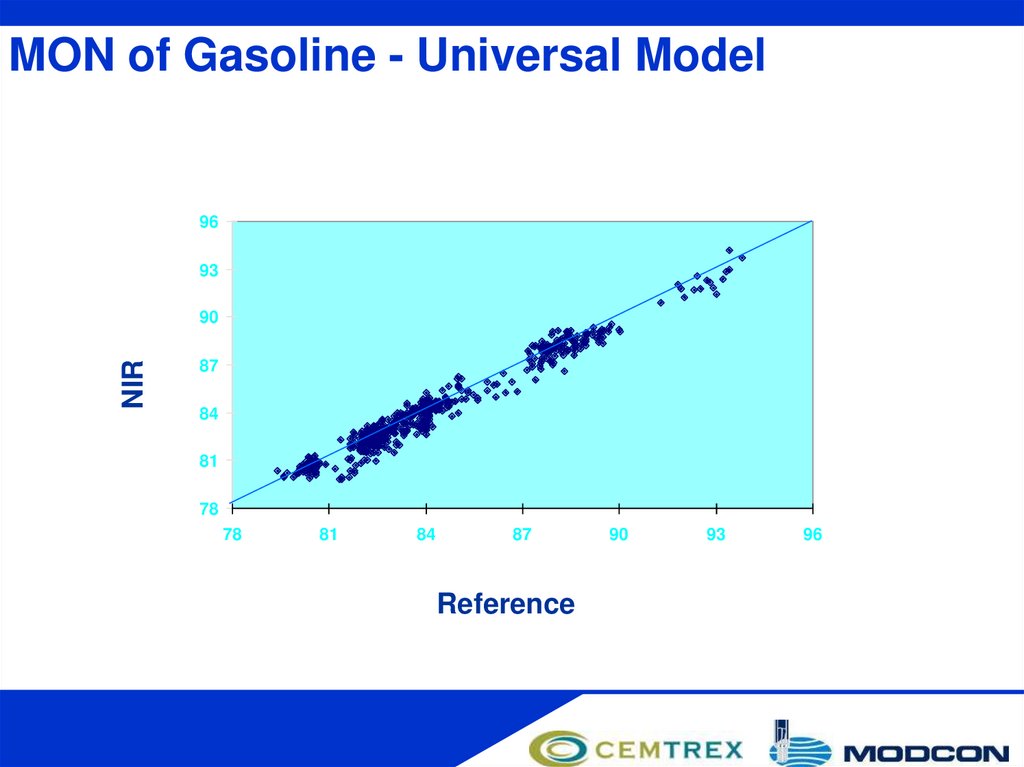

MON of Gasoline - Universal Model96

93

NIR

90

87

84

81

78

78

81

84

87

Reference

90

93

96

14.

Note on Lab ResultsGood Model

Good Lab data

and on Time

Bad Lab data

Good NIR

Results

GIGO

Bad Model

Bad NIR

Results

15.

Statistic NomenclatureRoot Mean Square Error of Prediction

n

2

(

ŷ

y

)

i i

RMSEP

i 1

n

ŷ - laboratory reference

y - calculated value

Standard Error of Prediction

n

2

(

ŷ

y

Bias)

i i

SEP

i =1

n -1

Average Difference between ŷ and

n

Bias

i 1

( yˆ i yi )

n

y in Prediction Set

16.

Modcon SolutionFree-tune Software

This software program is composed of two sequential blocks:

I. PLS regression is used to build a localized sensitive model (LSM) based on

just a small number of samples. One of the characteristics of this model is its

sensitivity to short term (hours) process variations. Since it is localized, the

model can be quickly built and validated. This procedure takes up to one week

and can be performed prior to startup.

II. A proprietary software program processes the model, together with the

specified plant data, to accurately quantify the properties. This part deals with

predicting the long-term product variability.

Monitored Variable

NIR Spectra

PreProcessing

Laboratory Data

LSM

Advanced

Processing

Validity Flag

17.

Model UpdatingModel updating during the crude switching

18.

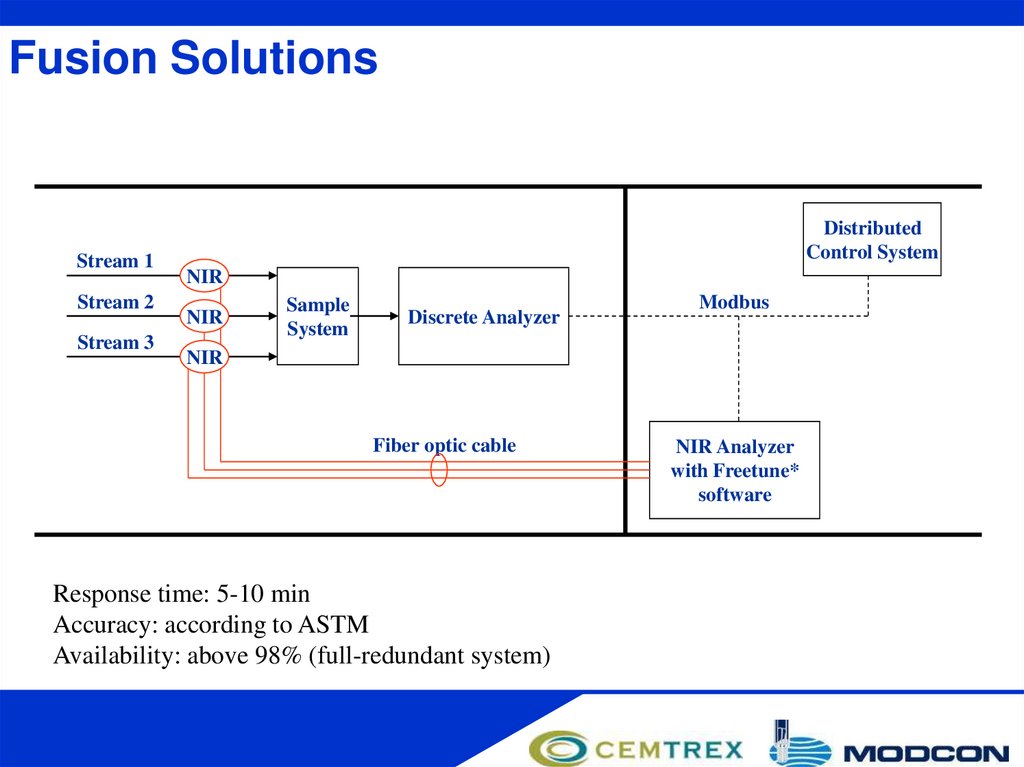

Fusion SolutionsStream 1

Stream 2

Stream 3

Distributed

Control System

NIR

NIR

Sample

System

Discrete Analyzer

Modbus

NIR

Fiber optic cable

Response time: 5-10 min

Accuracy: according to ASTM

Availability: above 98% (full-redundant system)

NIR Analyzer

with Freetune*

software

Промышленность

Промышленность