Похожие презентации:

Regarding to the factory operation of 5 bay

1.

Regarding to the factory operation of 5 bay1. Layout of 5bay

2. 5 Bay operation details

3. Opertion analysis (1) _ main plate production platen

4. Opertion analysis (2) _ T-bar assembly production platen

5. Improvements point (1)~(3)

Production team by JVC

2.

▣ Regarding to the factory operation of 5 baydate:2019.03.15

1. Layout of 5bay

2. 5 Bay operation details

Section

Main working

Size( L x W )

Use for

A

main plate joint

320m X 24m

main plate production at line

B

assembly production

120m X 24m

T-bar joint assembly production

C

assembly production

120m X 12m

T-bar joint assembly production

D

assembly production

48m X 12m

T-bar joint assembly production

Remarks

*The early 5Bay is a specialized main

plate production zone and

now it is producing blocks together

(section B,C,D).

3.Production assembly of 5bay

A section

* main plate

B section

* T-bar structure block

C section

D section

3.

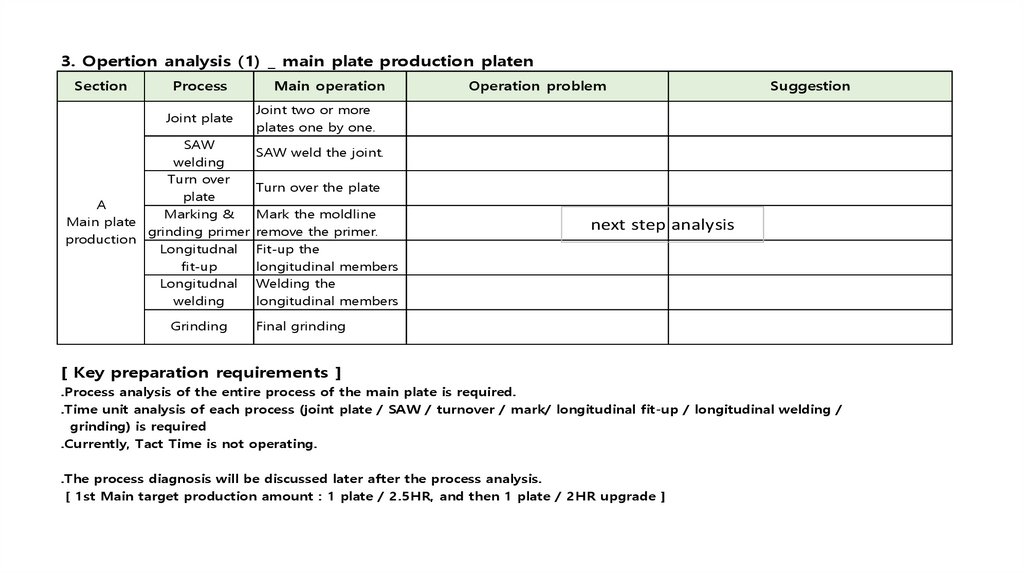

3. Opertion analysis (1) _ main plate production platenSection

Process

Joint plate

SAW

welding

Turn over

plate

A

Marking &

Main plate

grinding primer

production

Longitudnal

fit-up

Longitudnal

welding

Grinding

Main operation

Operation problem

Suggestion

Joint two or more

plates one by one.

SAW weld the joint.

Turn over the plate

Mark the moldline

remove the primer.

Fit-up the

longitudinal members

Welding the

longitudinal members

next step analysis

Final grinding

[ Key preparation requirements ]

.Process analysis of the entire process of the main plate is required.

.Time unit analysis of each process (joint plate / SAW / turnover / mark/ longitudinal fit-up / longitudinal welding /

grinding) is required

.Currently, Tact Time is not operating.

.The process diagnosis will be discussed later after the process analysis.

[ 1st Main target production amount : 1 plate / 2.5HR, and then 1 plate / 2HR upgrade ]

4.

4. Opertion analysis (2) _ T-bar assembly production platenSection

Main production

.T-bar structure

block

Operation problem

1.Located at the end of the main plate production

workspace to interfere with line flow

Suggestion

1.Restrict as much as possible the process of obstructing line flow.

If necessary, the line process should operate at the same speed.

2.It takes a lot of time to make the block, and

the process wait is severe.

3.Due to the nature of the equipment, it can

2.The process needs to be shortened.

(The maximum time shall not be exceeded by more than two hours.)

damage the base during assembly from the non-

B

Block

assembly

production

assembly workshop and shorten the life of

3.BIntegrated operation of B/C section is required.

the equipment in the future.

-Section B is simply producing T-BAR and maintaining the speed of

-maintain block accuracy also expected problems.

4.Because it is restrained directly on the surface,

the line speed

-Move back to section C and work that takes a lot of time to produce.

it is not maintained by the problem of restraint

and the surface is damaged.

5.By building blocks in the line platen,

4.However, some modifications of the platen are required for continued use.

-foundation fixed and work platen reinforcement etc.

the platen is not organized.

.T-bar structure

block

C

Block

assembly

production

.Sub-assemlby

It takes a long time to complete one block.

1.The Lead Time in the block production is excessive.

(Choose and focus required)

( It's more than a week by default )

2.to be in the production of sub-assembly/blocks

together. - space efficiency is poor due to

2.Shorten the block manufacturing time by receiving small parts

from the sub-assembly shop

the production of sub-assembly.

.T-bar structure

D

Block

assembly

production

1.It takes too much time to make a block.

block

3.The Tact Time is not being managed

3.Analyze the operability of the blocks in section C and keep the same time.

throughout section C.

It is going to start/finish one block per day and operate it as a goal.

1.have a long way to go since the production.

1.Let's close the D section.

2.Interference occurs with the making of the plate.

Make the block fabrication, which is needed within the con-fines c section.

3.It need to distinguish it from the main plate.

(The main plate working area is a machine tool

that needs to be protect from welding slag or dust.)

Causes major equipment failure.

4.If you use C section, D section is unnecessary.

2.Failure of equipment in section A affects the entire yard process

and ensures that class 1 equipment is maintained.

5.

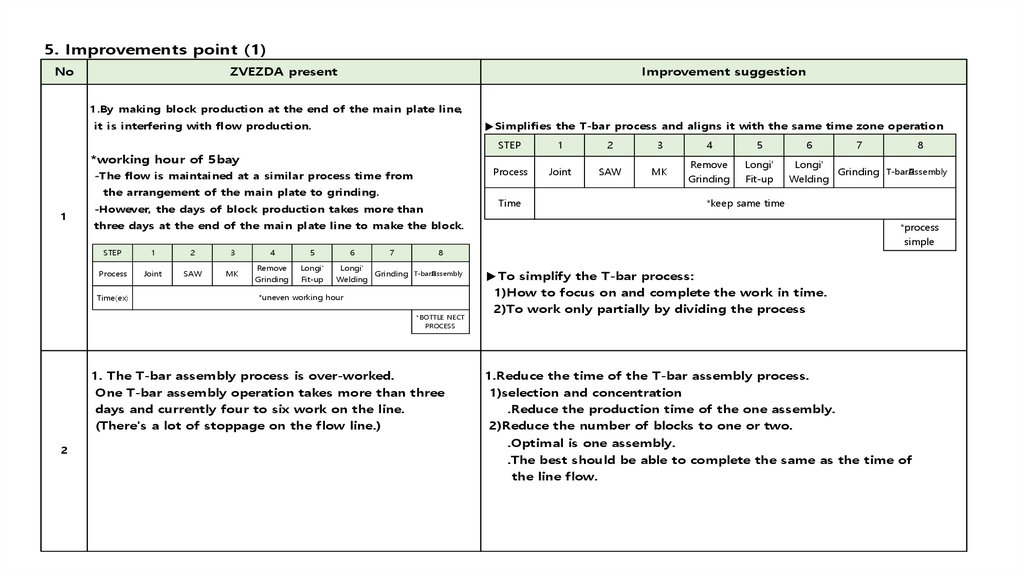

5. Improvements point (1)No

ZVEZDA present

Improvement suggestion

1.By making block production at the end of the main plate line,

it is interfering with flow production.

▶Simplifies the T-bar process and aligns it with the same time zone operation

*working hour of 5bay

-The flow is maintained at a similar process time from

the arrangement of the main plate to grinding.

1

1

2

3

4

5

Process

Joint

SAW

MK

Remove

Grinding

Longi'

Fit-up

Time

-However, the days of block production takes more than

6

Process

Time(ex)

1

Joint

2

SAW

3

4

5

MK

Remove

Grinding

Longi'

Fit-up

6

7

7

8

Longi'

Grinding T-barAssembly

Welding

*keep same time

three days at the end of the main plate line to make the block.

STEP

*process

simple

8

Longi'

Grinding T-barAssembly

Welding

*uneven working hour

*BOTTLE NECT

PROCESS

1. The T-bar assembly process is over-worked.

One T-bar assembly operation takes more than three

days and currently four to six work on the line.

(There's a lot of stoppage on the flow line.)

2

STEP

▶To simplify the T-bar process:

1)How to focus on and complete the work in time.

2)To work only partially by dividing the process

1.Reduce the time of the T-bar assembly process.

1)selection and concentration

.Reduce the production time of the one assembly.

2)Reduce the number of blocks to one or two.

.Optimal is one assembly.

.The best should be able to complete the same as the time of

the line flow.

6.

5. Improvements point (2)No

ZVEZDA present

Improvement suggestion

▶How to speed up T-bar block creation time is key

1.While making T-bar assembly in B&C section,

the process is getting pushed up too much.

=>T-bar blocks are divided into simple t-bar blocks and complex t-bar blocks

2.T-bar assembly in production B section : 4~6 EA

.Simple T-bar blocks are manufactured from section B, reducing quantity

3.T-bar assembly in production C section : 6 EA

.Complex T-bar blocks are manufactured in C section and reduced in quantity.

Production block

Amout/day

B

simple T-bar block

2ea

C

complex T-bar block

4ea

Section

*simple T-bar block

3

Section Production block Amout/day

B

t-bar block

4~6EA

C

t-bar block

6EA

remarks

*small ass'y at 3bay

*complex T-bar block

remarks

*include small assembly

▶Expected effect: Easier flow of B section

and less time to manufacture C section.

1.As C section is producing small parts and T-bar blocks together, ▶As the sub-assemblies are fully supplied and produced in 3bay,

process time is lengthened and space is overused

the space in C section is used as the entire block space,

thus effectively using space and reducing manufacturing time.

Section

4

C

Production block

supply

T-bar block

keep

small ass'y

3bay

remarks

▶Expected Effect : easy to flow of C section

and maximum use of block space.

7.

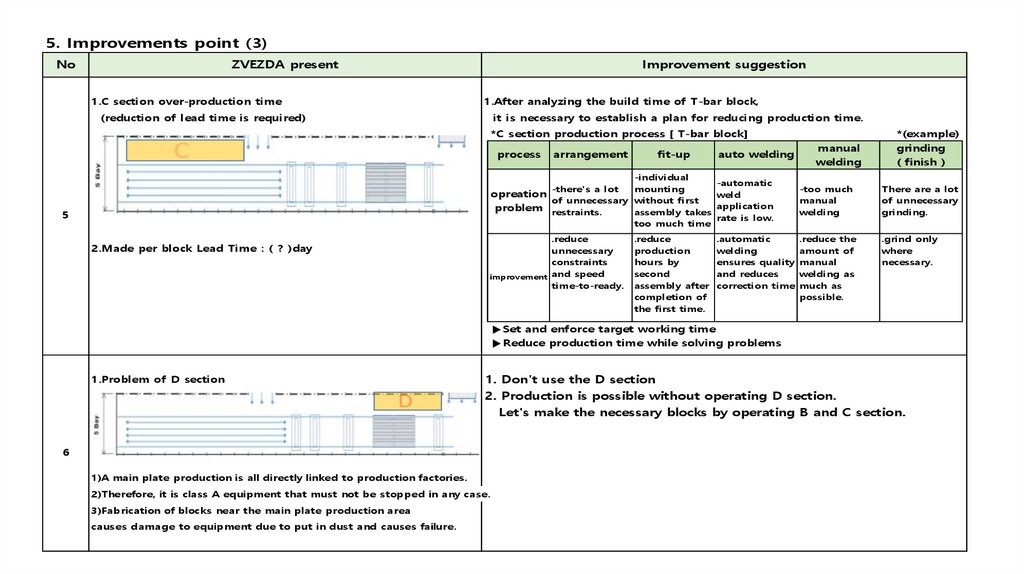

5. Improvements point (3)No

ZVEZDA present

1.C section over-production time

Improvement suggestion

1.After analyzing the build time of T-bar block,

(reduction of lead time is required)

it is necessary to establish a plan for reducing production time.

*C section production process [ T-bar block]

process

5

2.Made per block Lead Time : ( ? )day

arrangement

fit-up

auto welding

-individual

-there's a lot

mounting

opreation

of unnecessary without first

problem restraints.

assembly takes

too much time

-automatic

weld

application

rate is low.

.reduce

unnecessary

constraints

improvement and speed

time-to-ready.

.automatic

welding

ensures quality

and reduces

correction time

.reduce

production

hours by

second

assembly after

completion of

the first time.

manual

welding

*(example)

grinding

( finish )

-too much

manual

welding

There are a lot

of unnecessary

grinding.

.reduce the

amount of

manual

welding as

much as

possible.

.grind only

where

necessary.

▶Set and enforce target working time

▶Reduce production time while solving problems

1.Problem of D section

1. Don't use the D section

2. Production is possible without operating D section.

Let's make the necessary blocks by operating B and C section.

6

1)A main plate production is all directly linked to production factories.

2)Therefore, it is class A equipment that must not be stopped in any case.

3)Fabrication of blocks near the main plate production area

causes damage to equipment due to put in dust and causes failure.

Промышленность

Промышленность