Похожие презентации:

DFM-Star_10TMK+Star_20TMK

1.

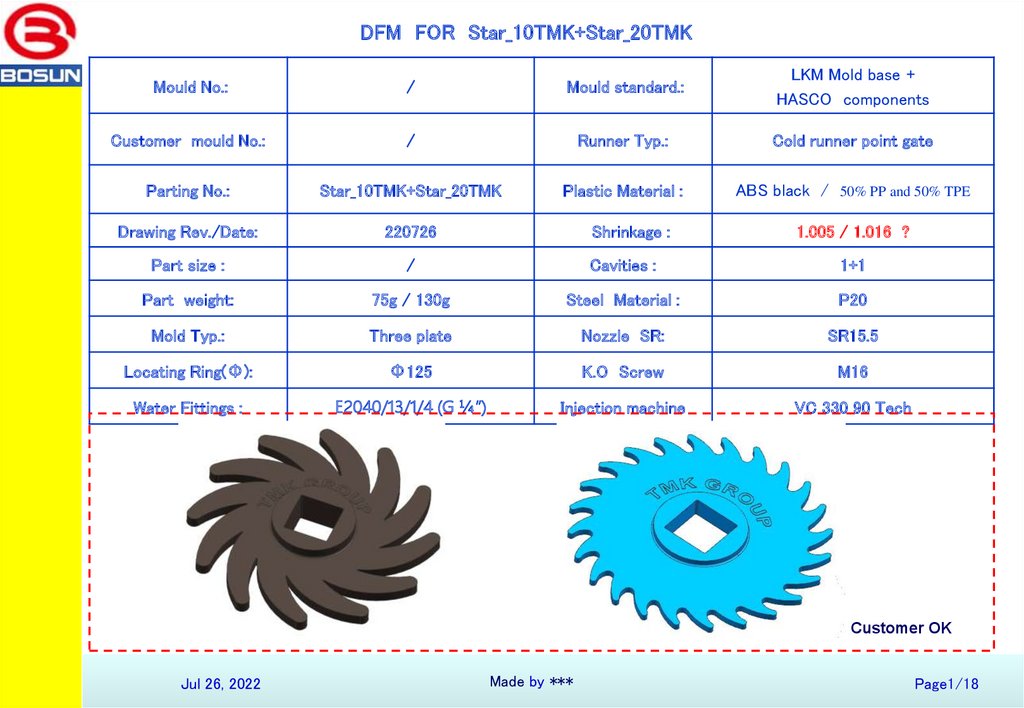

DFM FOR Star_10TMK+Star_20TMKMould No.:

/

Mould standard.:

LKM Mold base +

HASCO components

Customer mould No.:

/

Runner Typ.:

Cold runner point gate

Parting No.:

Star_10TMK+Star_20TMK

Plastic Material :

ABS black / 50% PP and 50% TPE

Drawing Rev./Date:

220726

Part size :

/

Cavities :

1+1

Part weight:

75g / 130g

Steel Material :

P20

Mold Typ.:

Three plate

Nozzle SR:

SR15.5

Locating Ring(Ф):

Ф125

K.O Screw

M16

Water Fittings :

E2040/13/1/4 (G ¼”)

Injection machine

VC 330 90 Tech

Shrinkage :

1.005 / 1.016 ?

Customer OK

Jul 26, 2022

Made by ***

Page1/18

2.

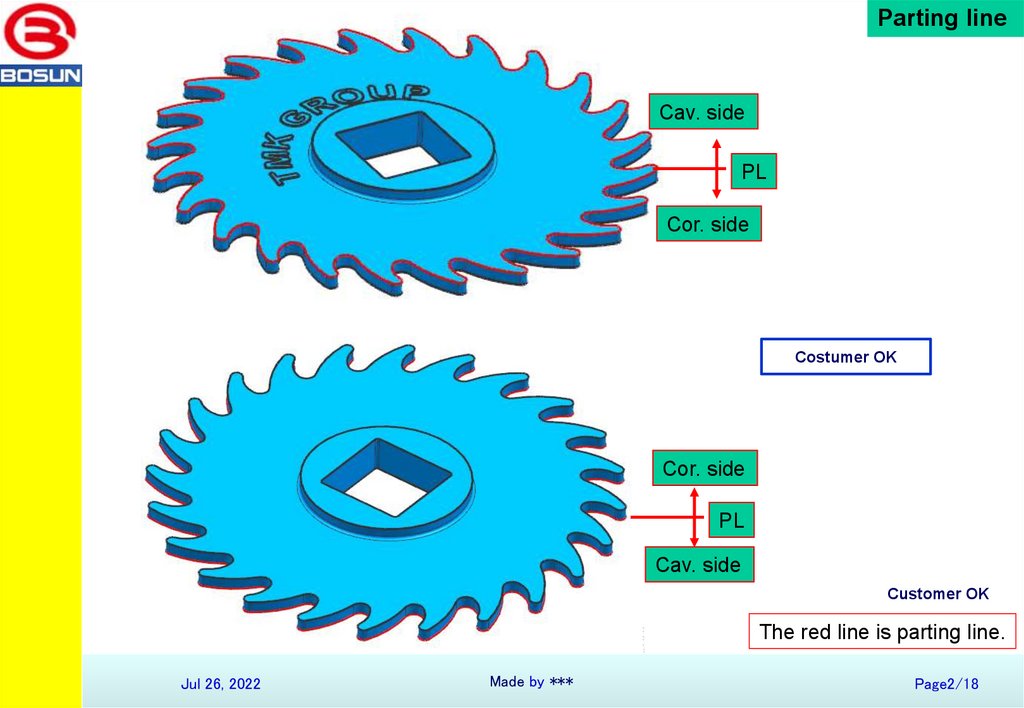

Parting lineCav. side

PL

Cor. side

Costumer OK

Cor. side

PL

Cav. side

Customer OK

The red line is parting line.

Jul 26, 2022

Made by ***

Page2/18

3.

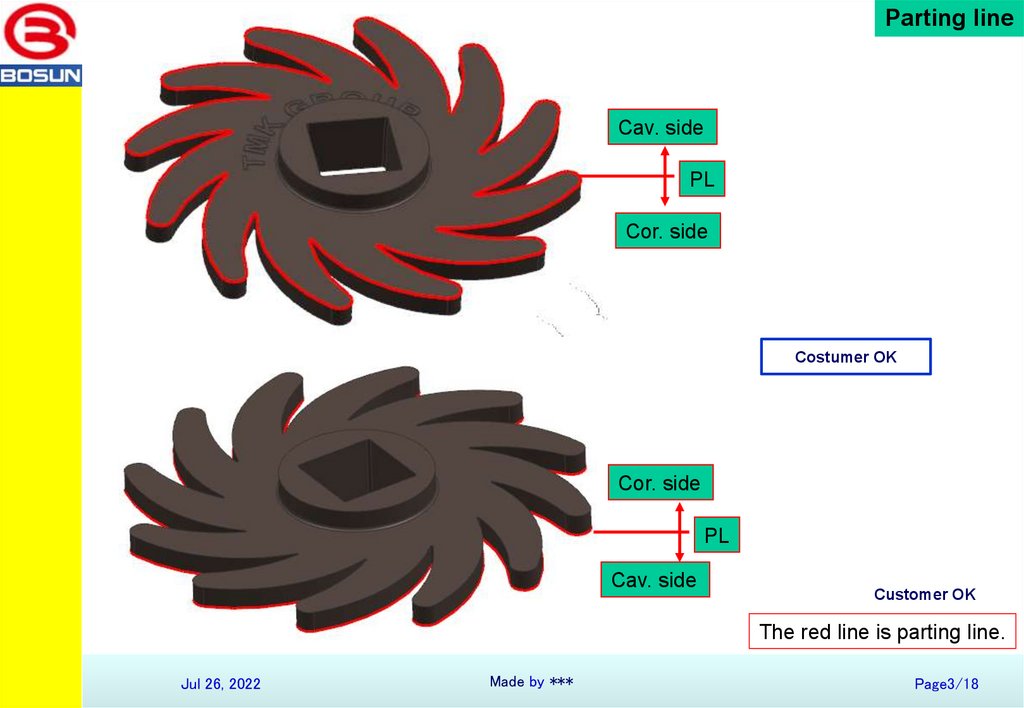

Parting lineCav. side

PL

Cor. side

Costumer OK

Cor. side

PL

Cav. side

Customer OK

The red line is parting line.

Jul 26, 2022

Made by ***

Page3/18

4.

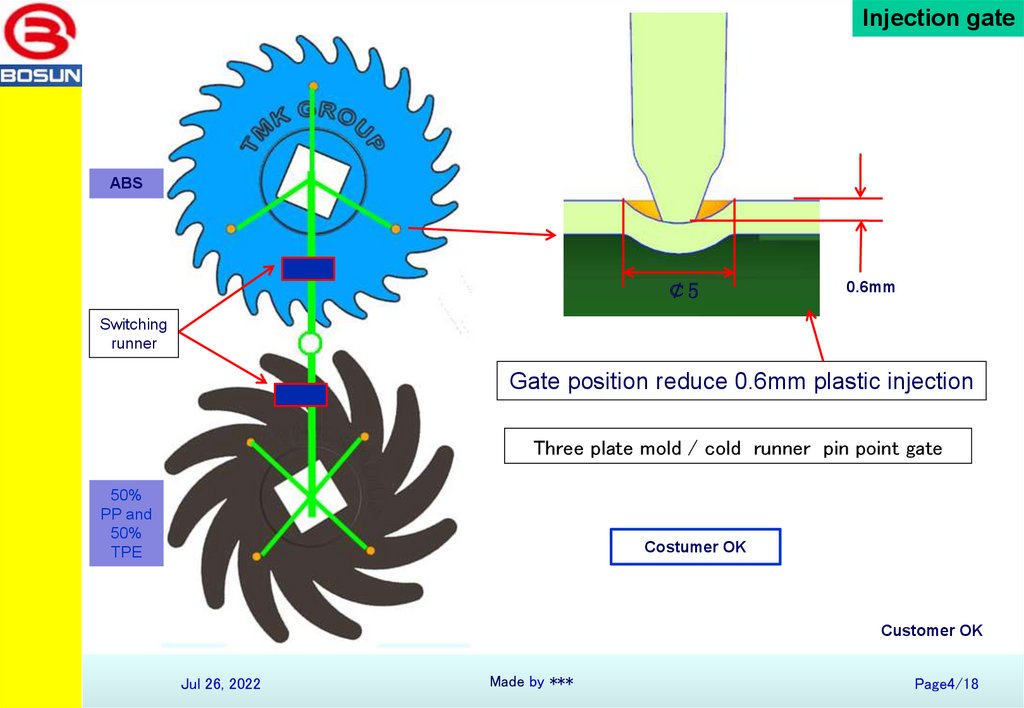

Injection gateABS

5

0.6mm

Switching

runner

Gate position reduce 0.6mm plastic injection

Three plate mold / cold runner pin point gate

50%

PP and

50%

TPE

Costumer OK

Customer OK

Jul 26, 2022

Made by ***

Page4/18

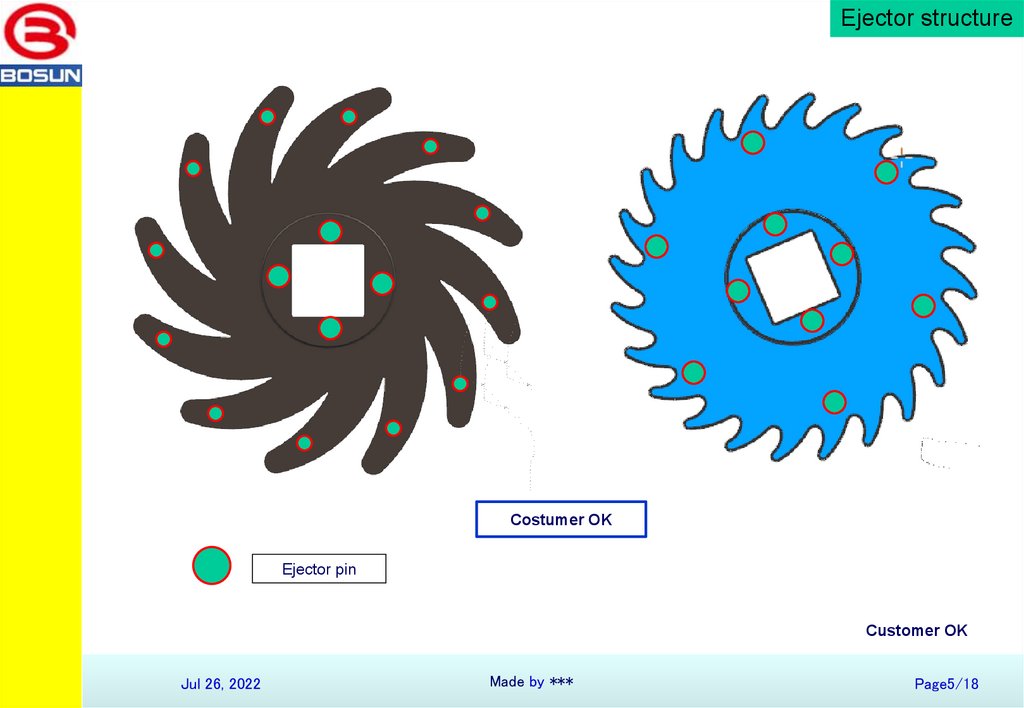

5.

Ejector structureCostumer OK

Ejector pin

Customer OK

Jul 26, 2022

Made by ***

Page5/18

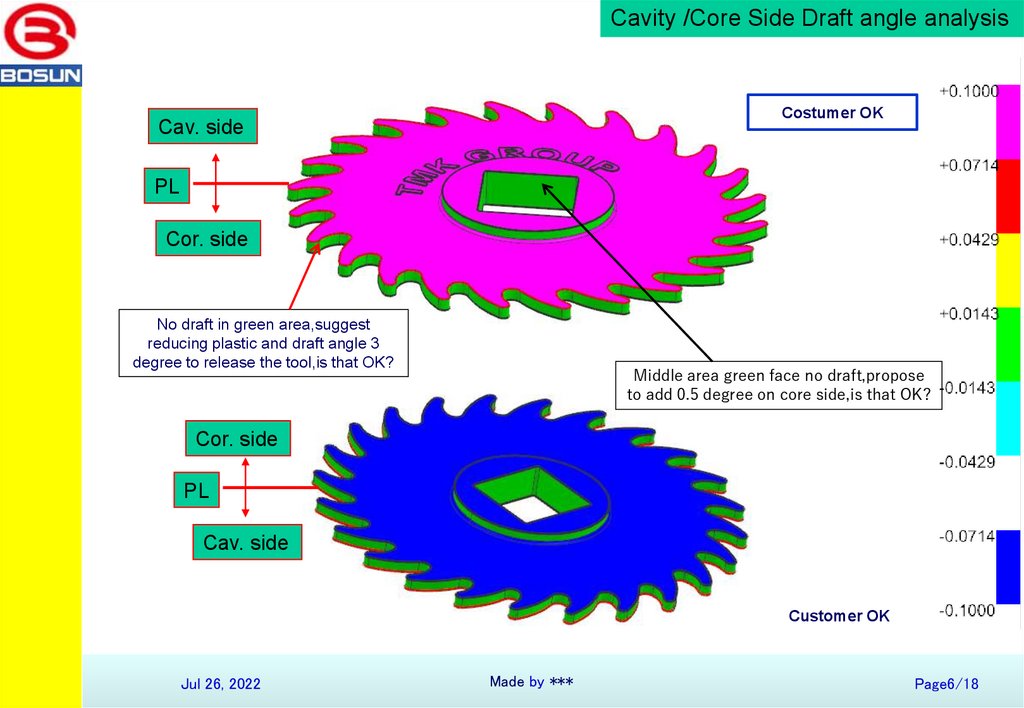

6.

Cavity /Core Side Draft angle analysisCostumer OK

Cav. side

PL

Cor. side

No draft in green area,suggest

reducing plastic and draft angle 3

degree to release the tool,is that OK?

Middle area green face no draft,propose

to add 0.5 degree on core side,is that OK?

Cor. side

PL

Cav. side

Customer OK

Jul 26, 2022

Made by ***

Page6/18

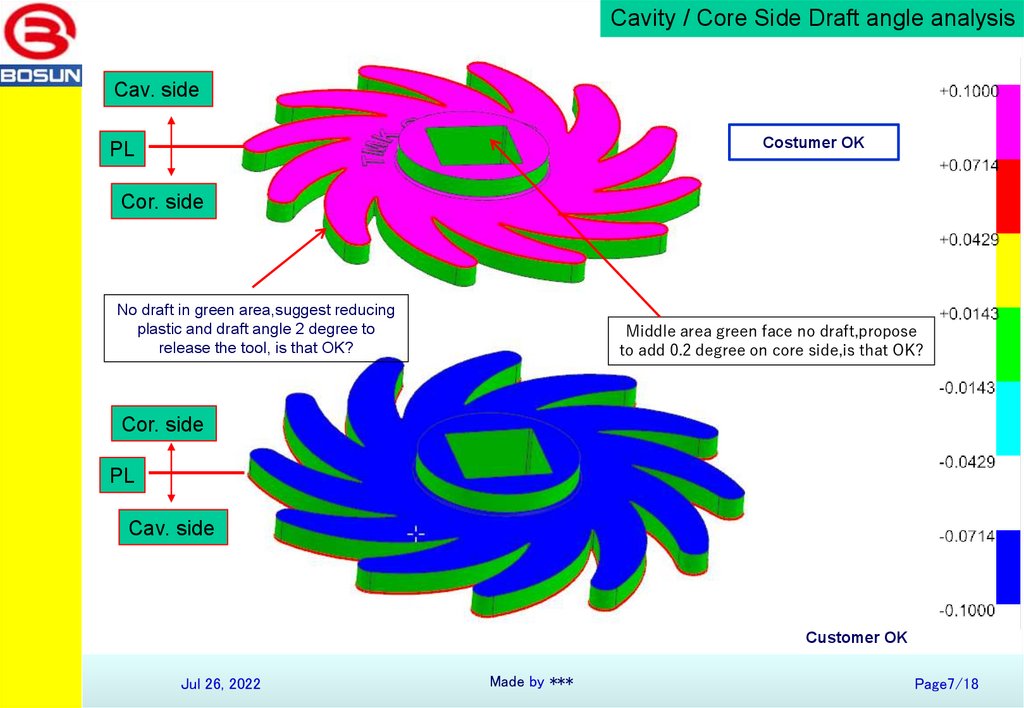

7.

Cavity / Core Side Draft angle analysisCav. side

Costumer OK

PL

Cor. side

No draft in green area,suggest reducing

plastic and draft angle 2 degree to

release the tool, is that OK?

Middle area green face no draft,propose

to add 0.2 degree on core side,is that OK?

Cor. side

PL

Cav. side

Customer OK

Jul 26, 2022

Made by ***

Page7/18

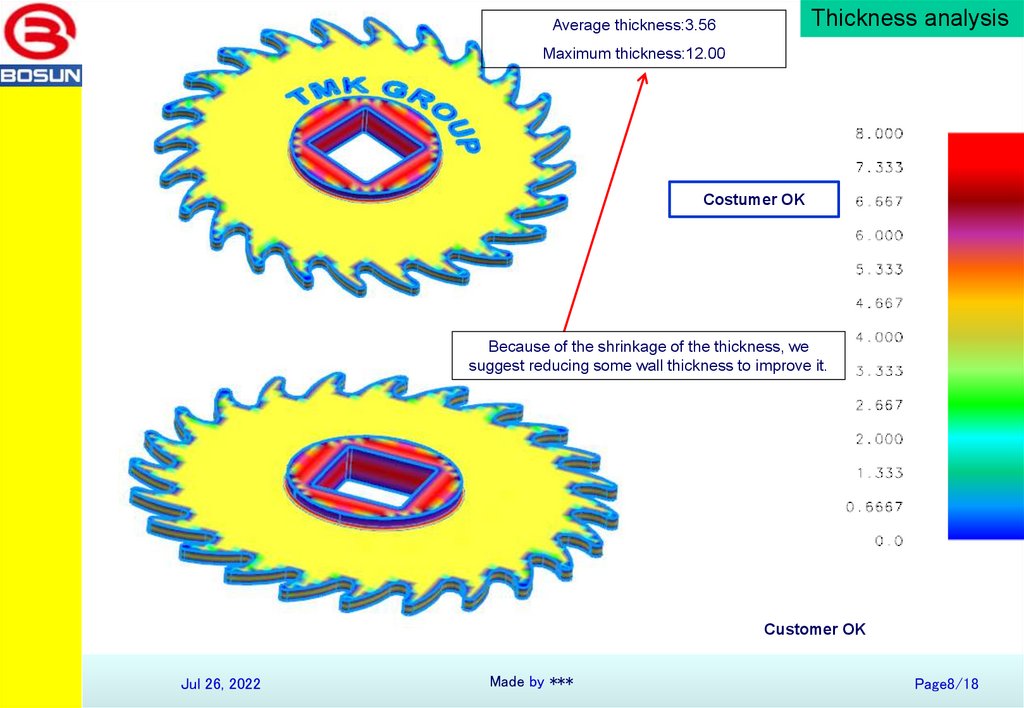

8.

Thickness analysisAverage thickness:3.56

Maximum thickness:12.00

Costumer OK

Because of the shrinkage of the thickness, we

suggest reducing some wall thickness to improve it.

Customer OK

Jul 26, 2022

Made by ***

Page8/18

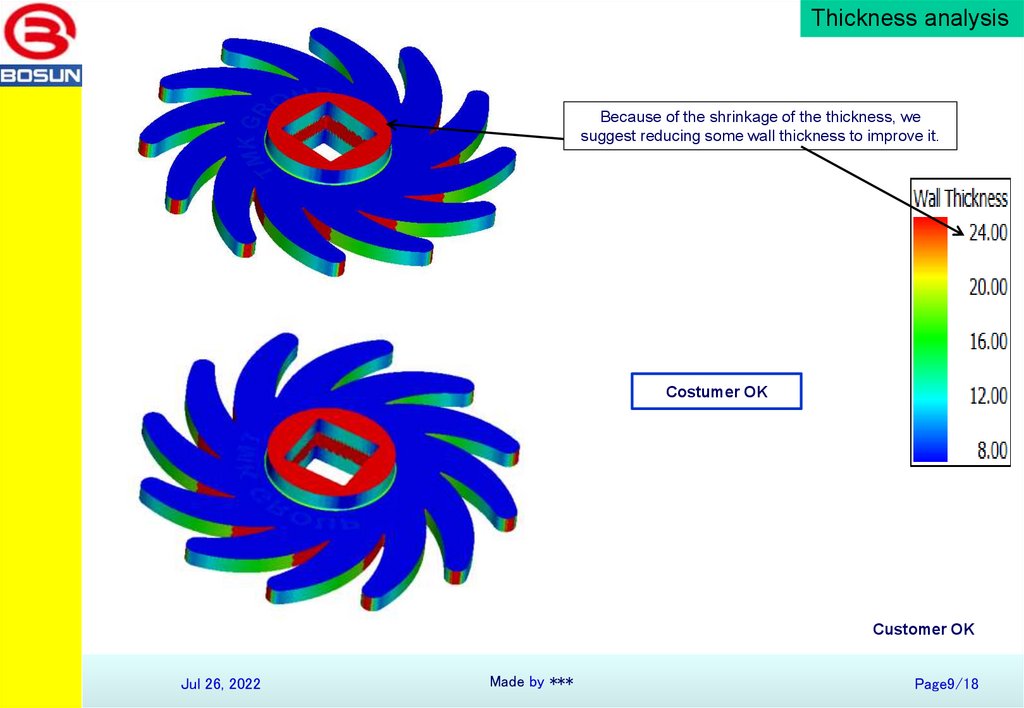

9.

Thickness analysisBecause of the shrinkage of the thickness, we

suggest reducing some wall thickness to improve it.

Costumer OK

Customer OK

Jul 26, 2022

Made by ***

Page9/18

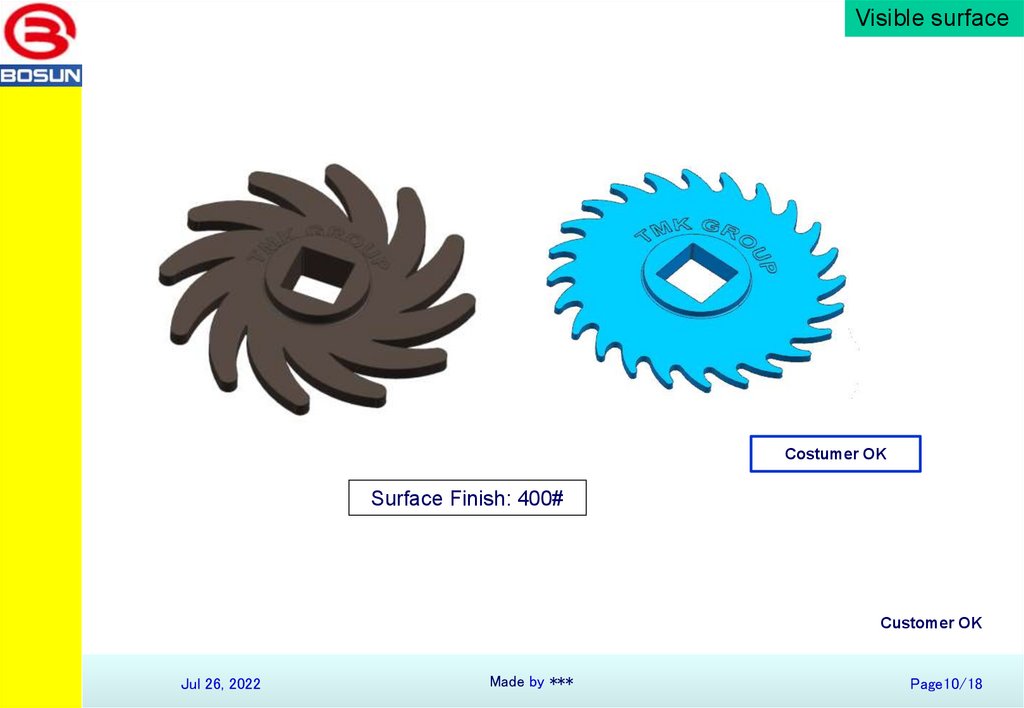

10.

Visible surfaceCostumer OK

Surface Finish: 400#

Customer OK

Jul 26, 2022

Made by ***

Page10/18

11.

—— THANK YOU ——Customer OK

Jul 26, 2022

Made by ***

Page11/18

Механика

Механика