Похожие презентации:

NW Rapid Site Installation

1. NW Rapid Site Installation

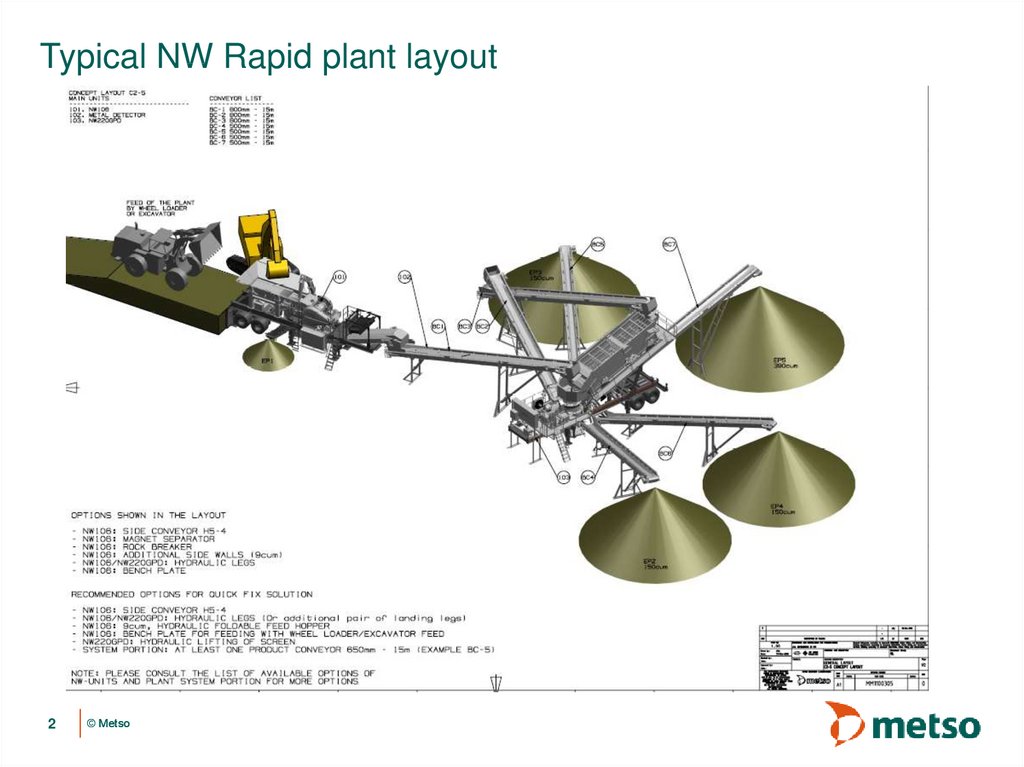

NW220GPD2. Typical NW Rapid plant layout

2© Metso

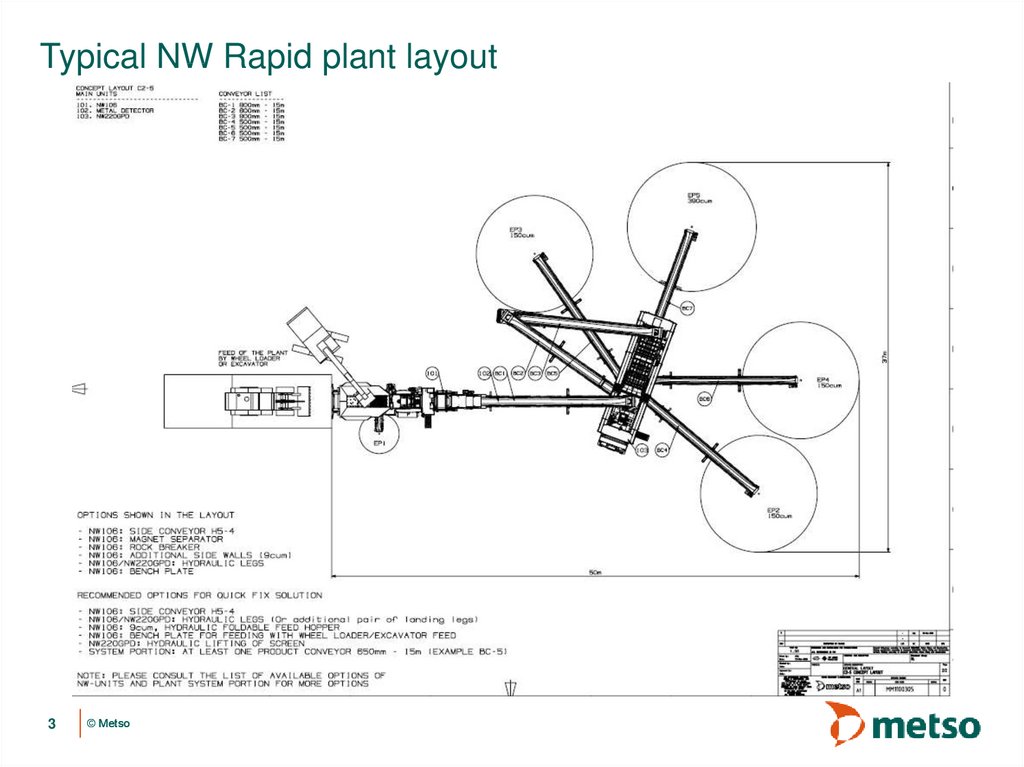

3. Typical NW Rapid plant layout

3© Metso

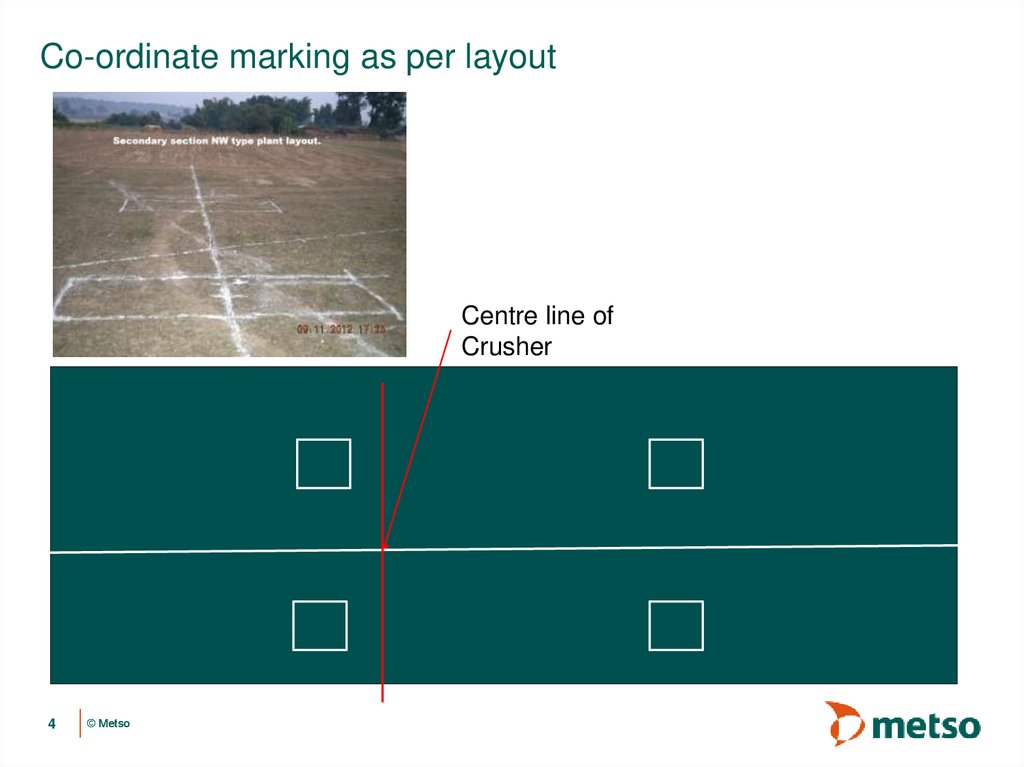

4. Co-ordinate marking as per layout

Centre line ofCrusher

4

© Metso

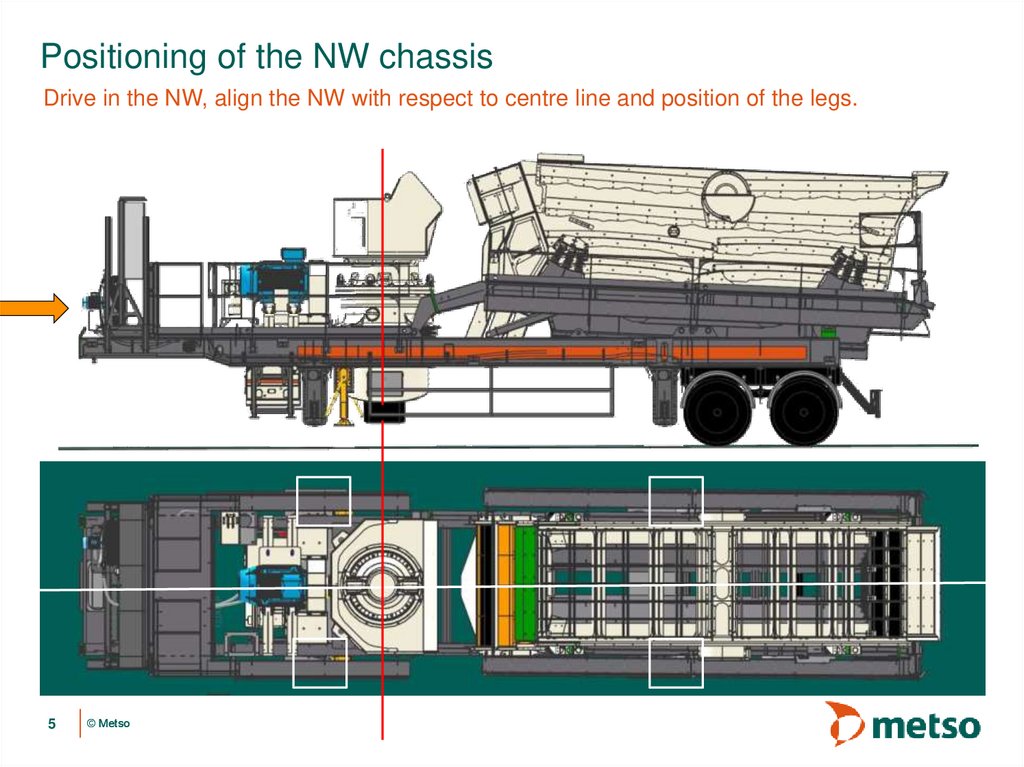

5. Positioning of the NW chassis

Drive in the NW, align the NW with respect to centre line and position of the legs.5

© Metso

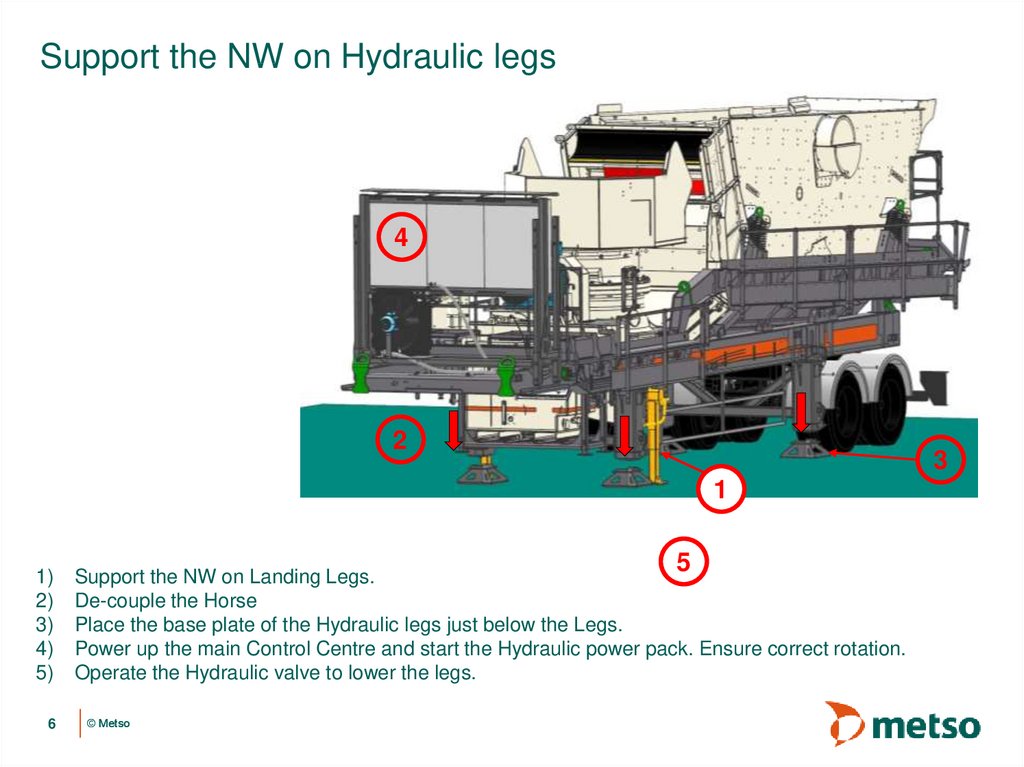

6. Support the NW on Hydraulic legs

42

3

1

1)

2)

3)

4)

5)

6

5

Support the NW on Landing Legs.

De-couple the Horse

Place the base plate of the Hydraulic legs just below the Legs.

Power up the main Control Centre and start the Hydraulic power pack. Ensure correct rotation.

Operate the Hydraulic valve to lower the legs.

© Metso

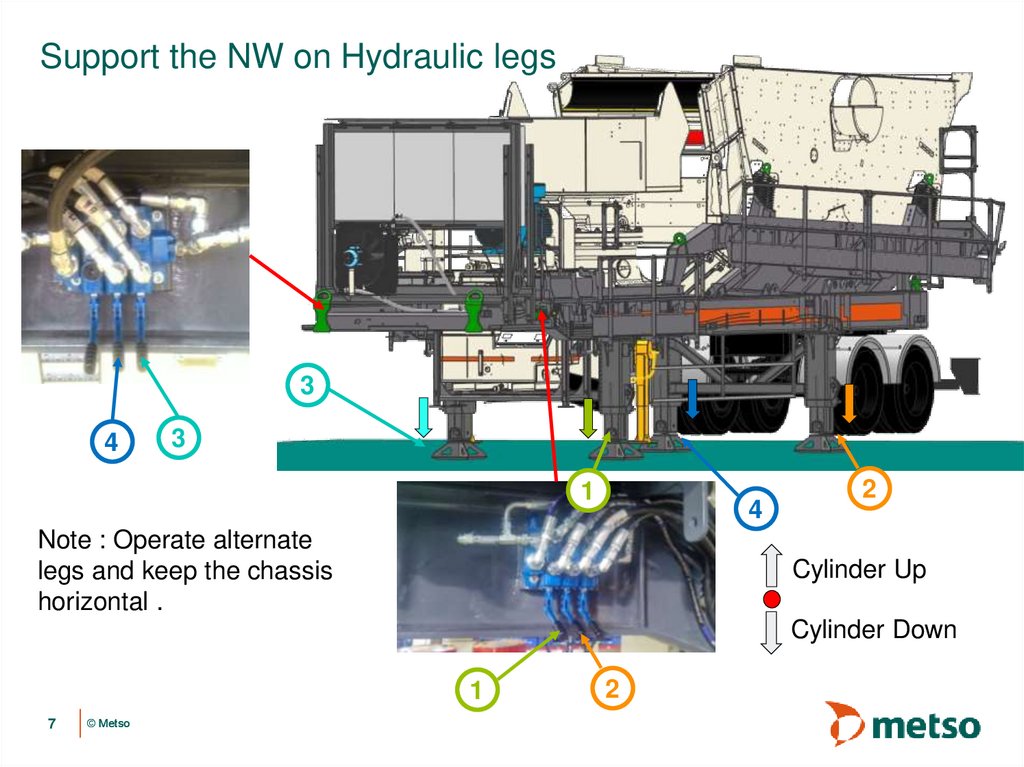

7. Support the NW on Hydraulic legs

34

3

1

4

Note : Operate alternate

legs and keep the chassis

horizontal .

2

Cylinder Up

Cylinder Down

1

7

© Metso

2

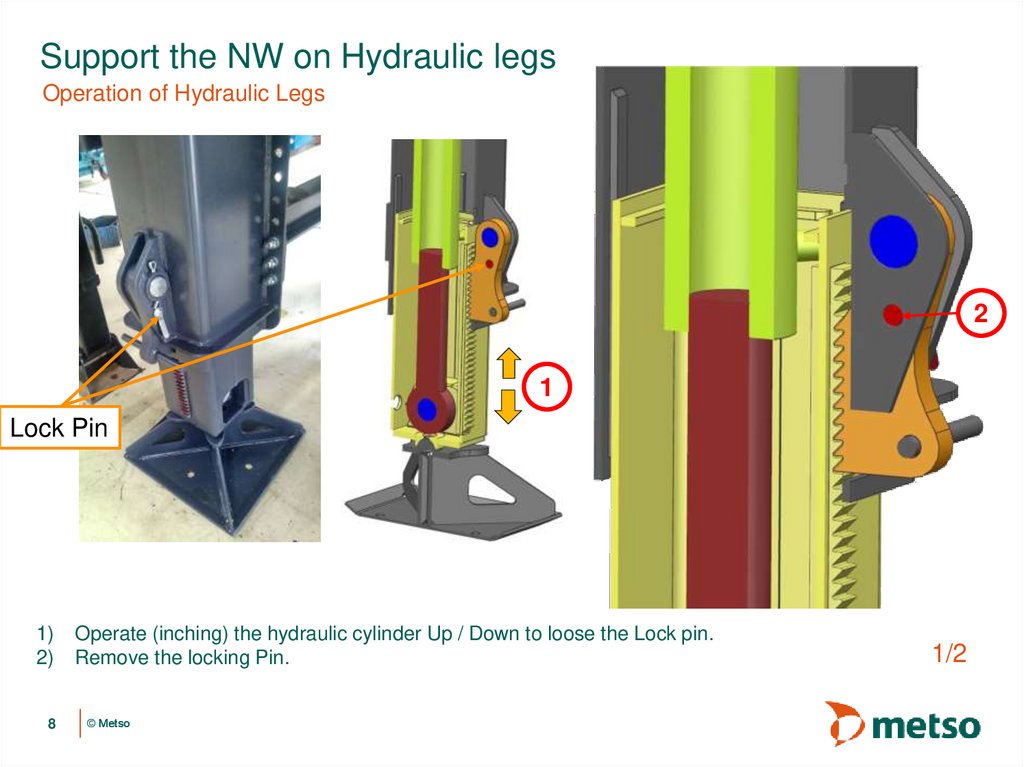

8. Support the NW on Hydraulic legs

Operation of Hydraulic Legs2

1

Lock Pin

1)

2)

8

Operate (inching) the hydraulic cylinder Up / Down to loose the Lock pin.

Remove the locking Pin.

© Metso

1/2

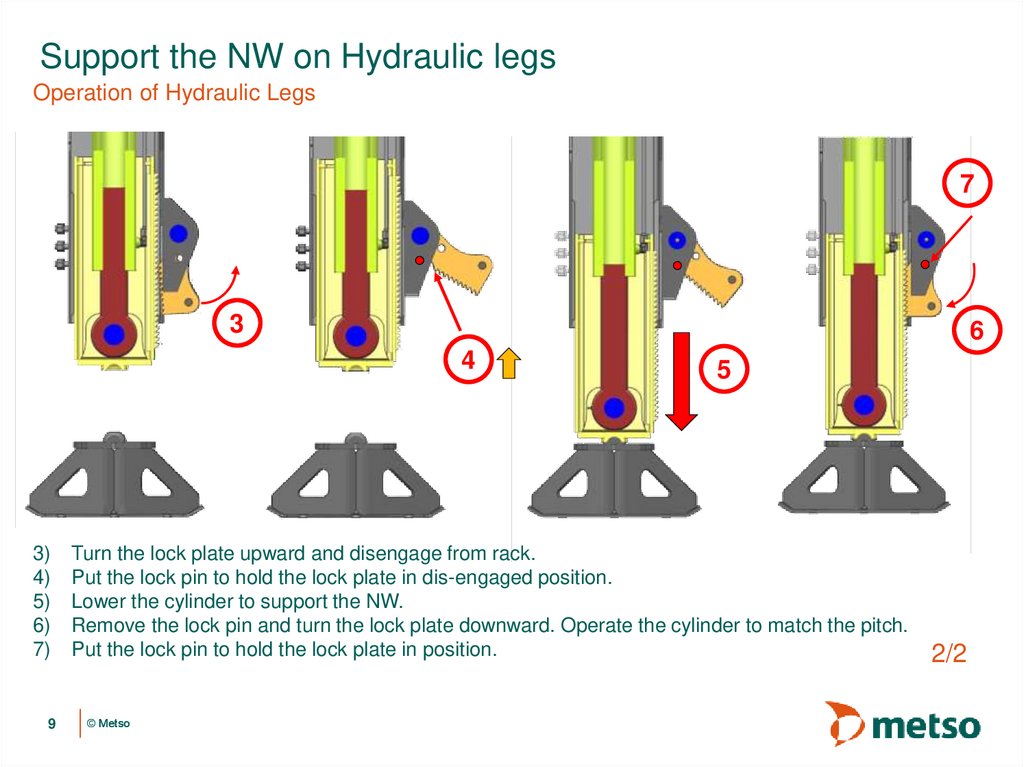

9. Support the NW on Hydraulic legs

Operation of Hydraulic Legs7

3

6

4

3)

4)

5)

6)

7)

9

5

Turn the lock plate upward and disengage from rack.

Put the lock pin to hold the lock plate in dis-engaged position.

Lower the cylinder to support the NW.

Remove the lock pin and turn the lock plate downward. Operate the cylinder to match the pitch.

Put the lock pin to hold the lock plate in position.

© Metso

2/2

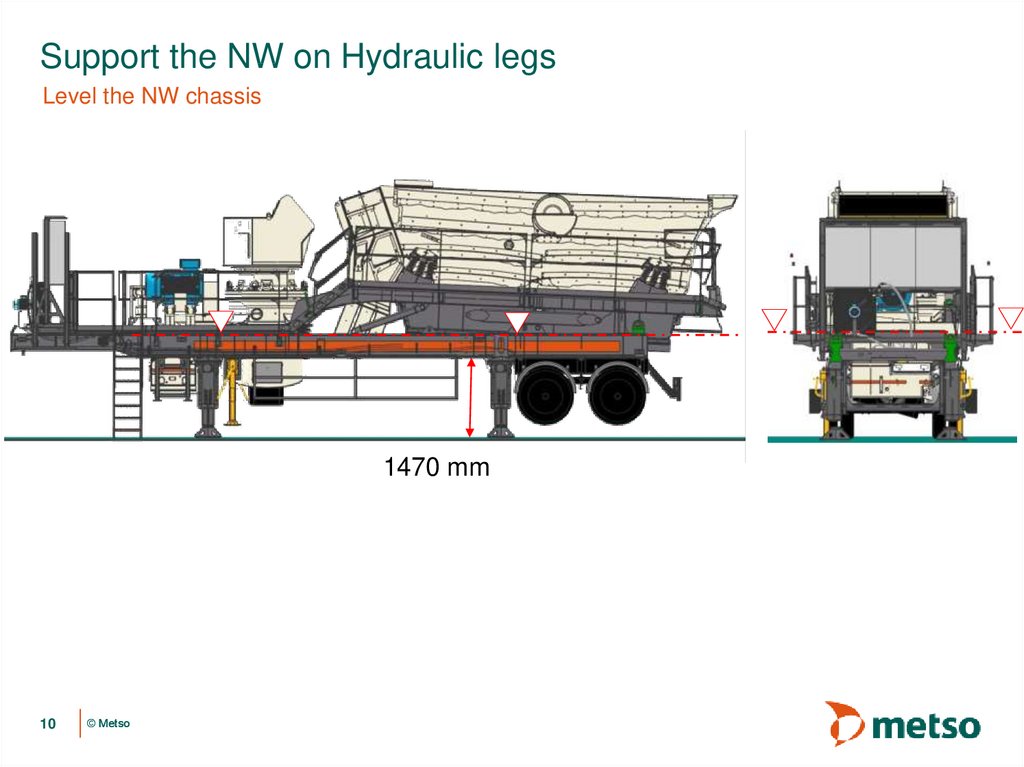

10. Support the NW on Hydraulic legs

Level the NW chassis1470 mm

10

© Metso

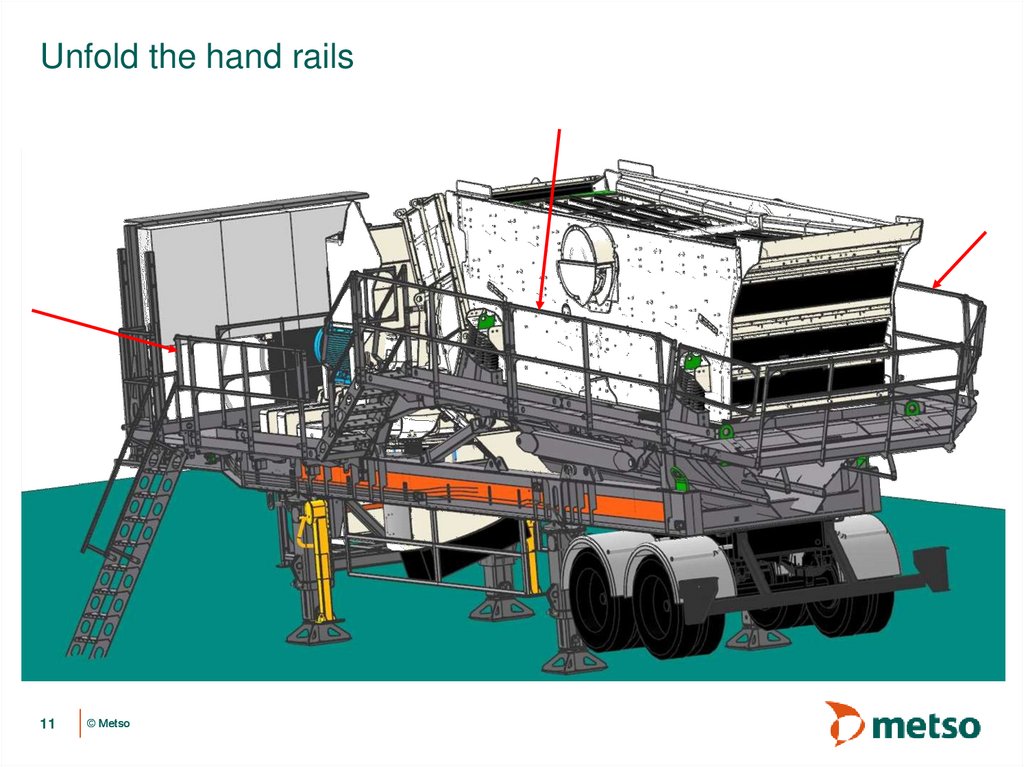

11. Unfold the hand rails

11© Metso

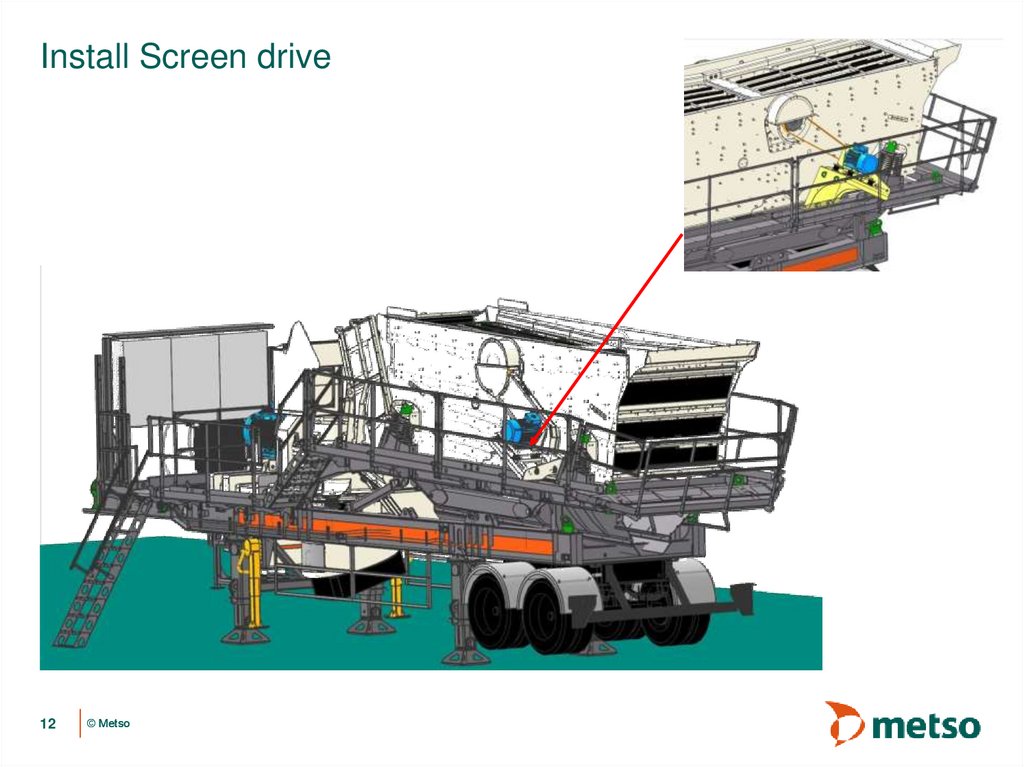

12. Install Screen drive

12© Metso

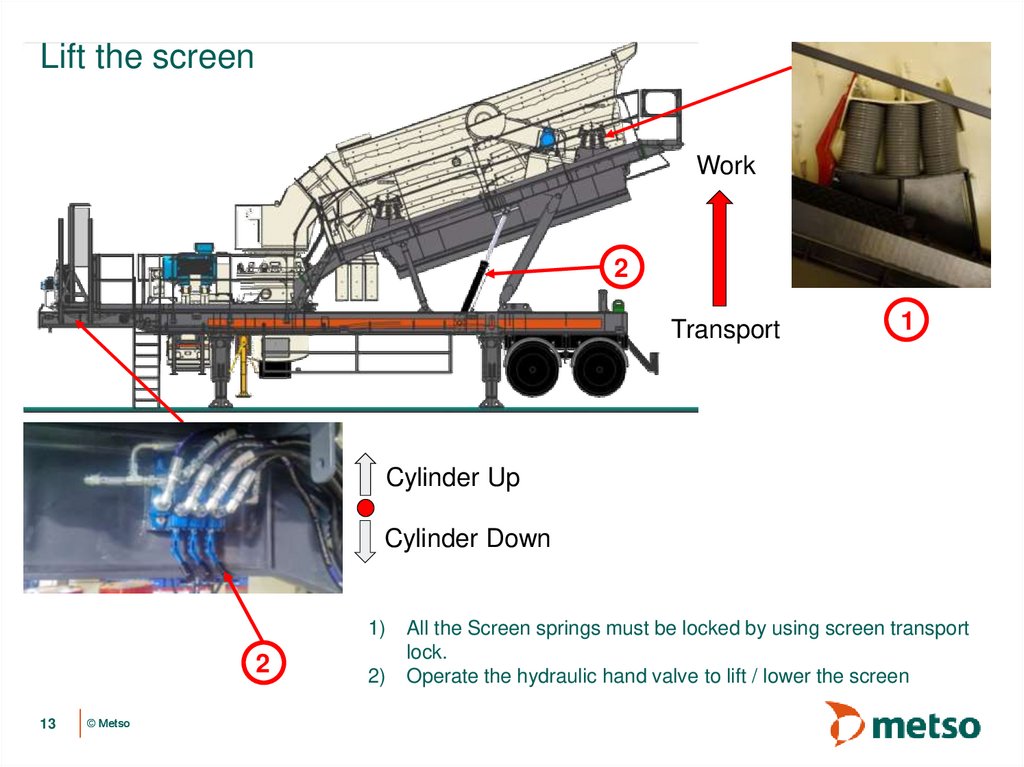

13. Lift the screen

Work2

Transport

1

Cylinder Up

Cylinder Down

1)

2

13

© Metso

2)

All the Screen springs must be locked by using screen transport

lock.

Operate the hydraulic hand valve to lift / lower the screen

14. Lift the screen

11)

2)

14

2

Install the smaller support levers first.

Lift the screen and install bigger support levers.

© Metso

1

2

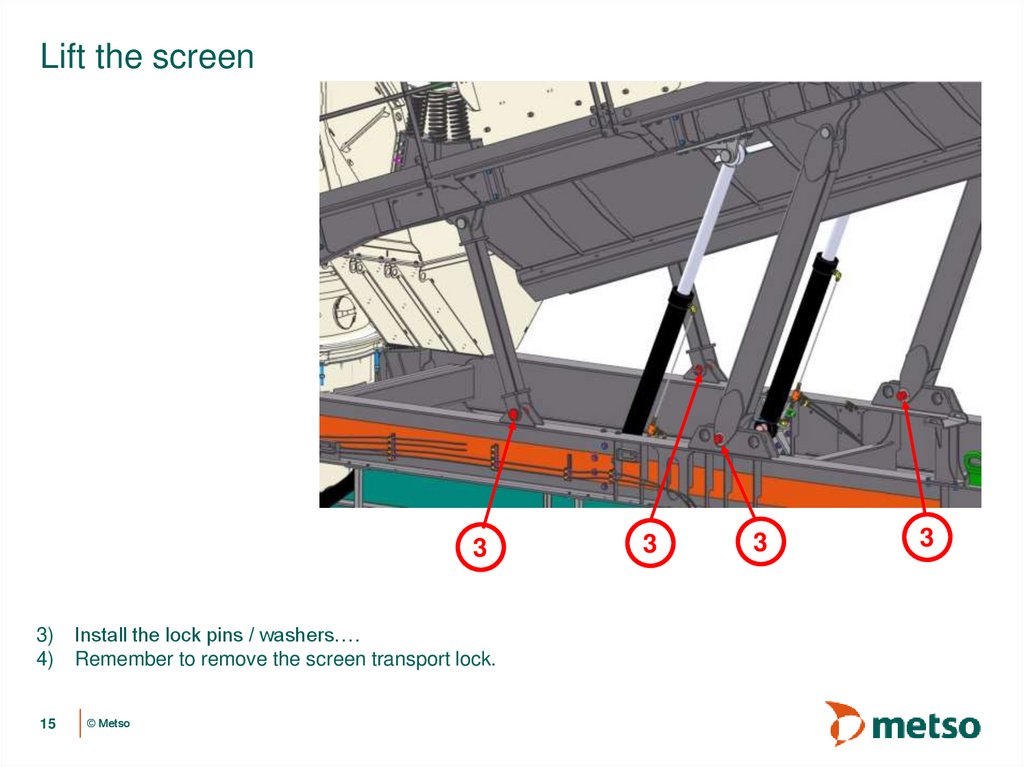

15. Lift the screen

33)

4)

15

Install the lock pins / washers….

Remember to remove the screen transport lock.

© Metso

3

3

3

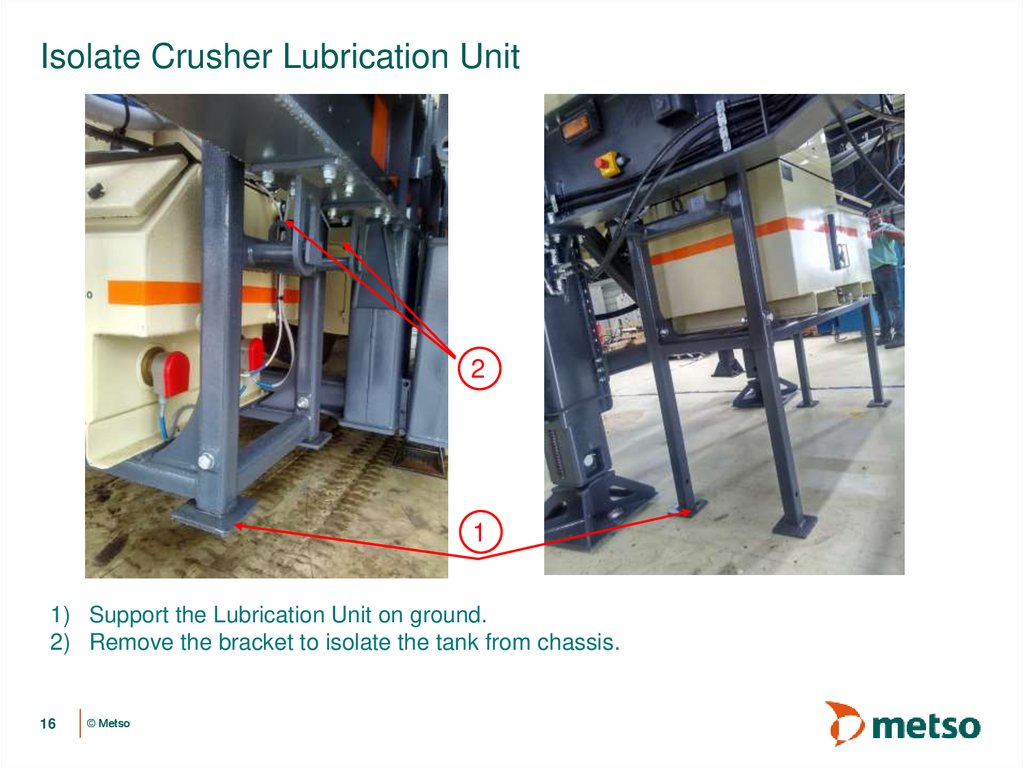

16. Isolate Crusher Lubrication Unit

21

1) Support the Lubrication Unit on ground.

2) Remove the bracket to isolate the tank from chassis.

16

© Metso

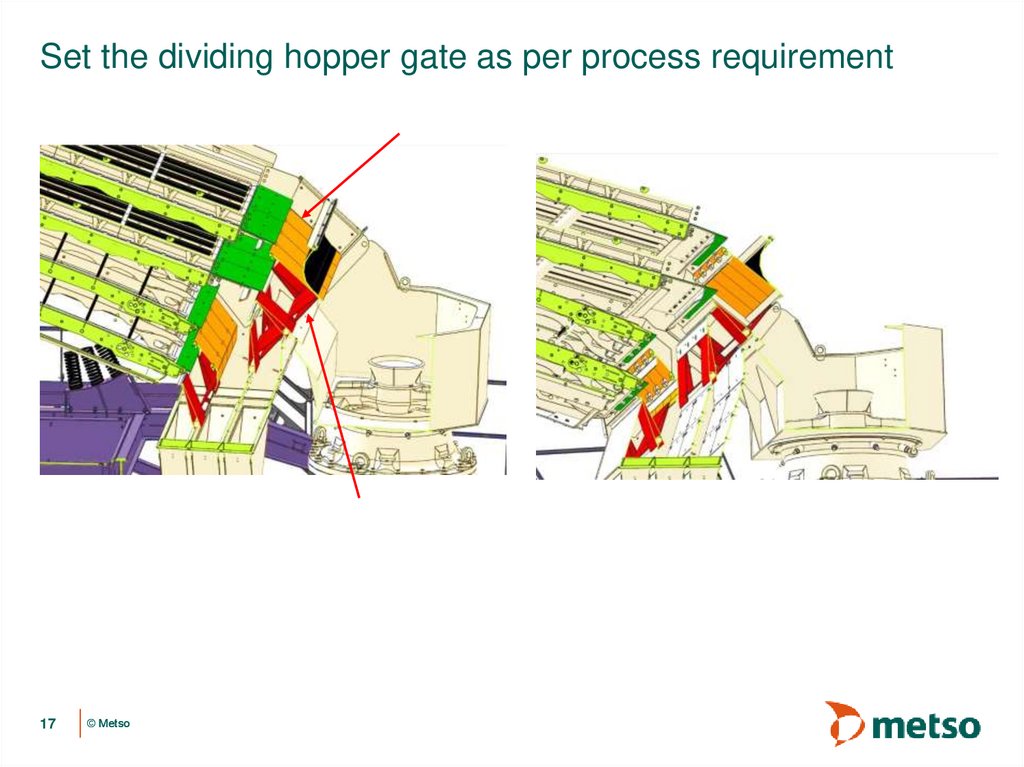

17. Set the dividing hopper gate as per process requirement

217

© Metso

18. Set Up Cavity Level Sensor

18© Metso

Date Author Title

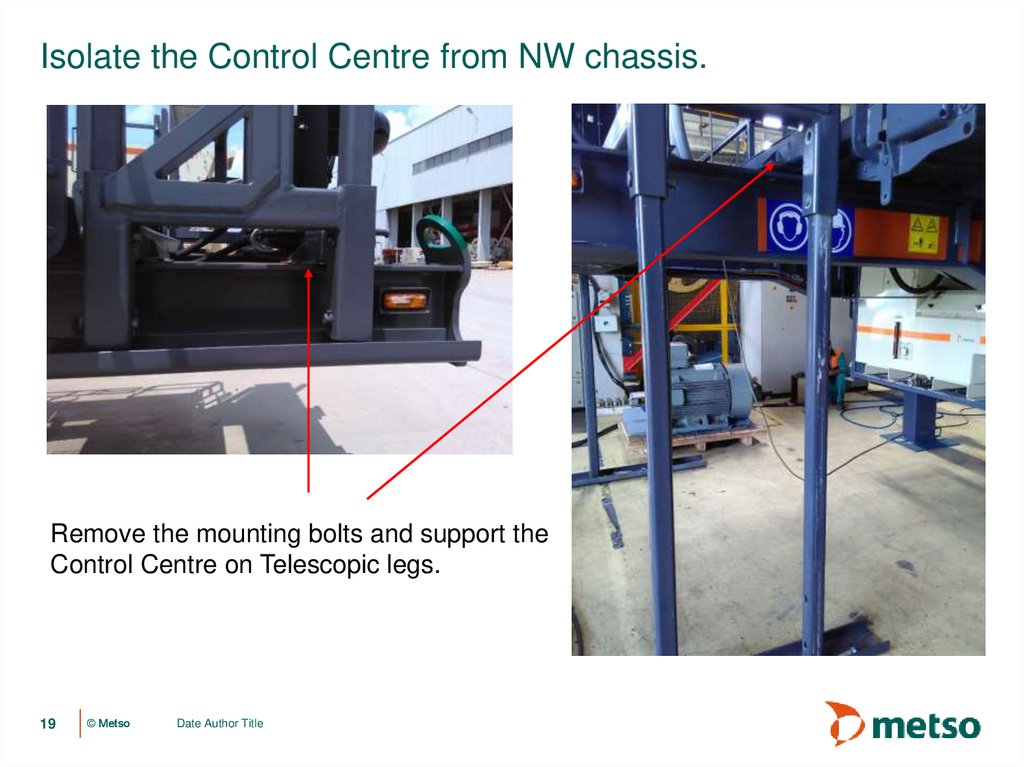

19. Isolate the Control Centre from NW chassis.

Remove the mounting bolts and support theControl Centre on Telescopic legs.

19

© Metso

Date Author Title

20. Electrical Installation

2021. Electrical Installation

Connect Screen motor power cable.21

© Metso

Date Author Title

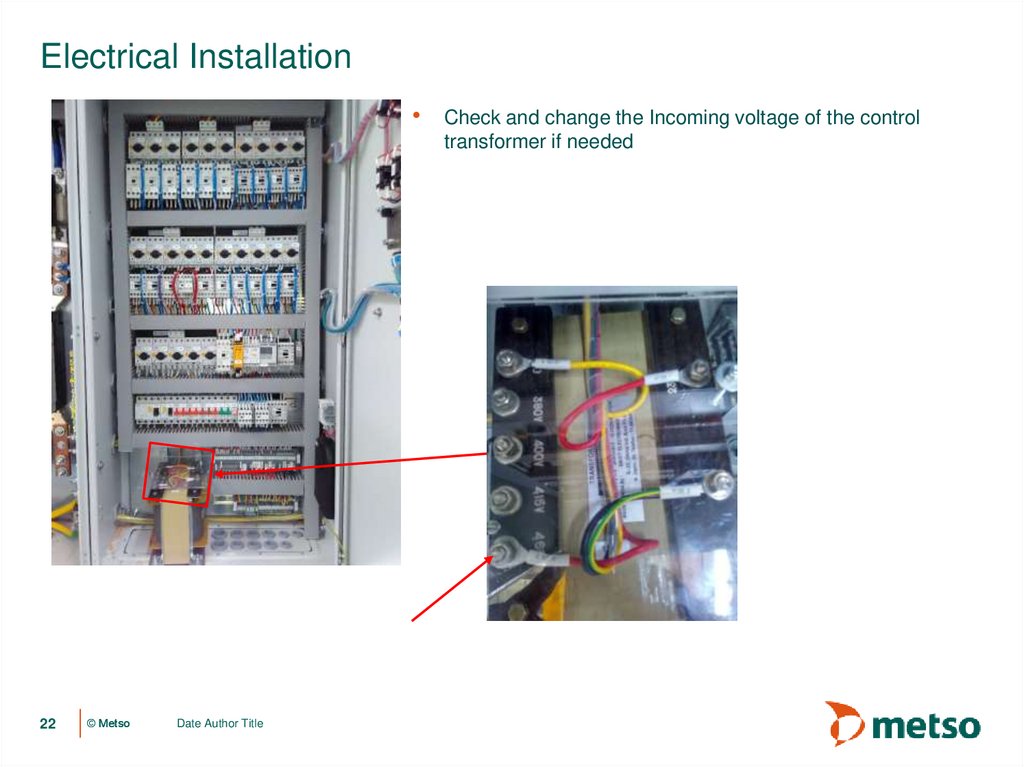

22. Electrical Installation

22

© Metso

Date Author Title

Check and change the Incoming voltage of the control

transformer if needed

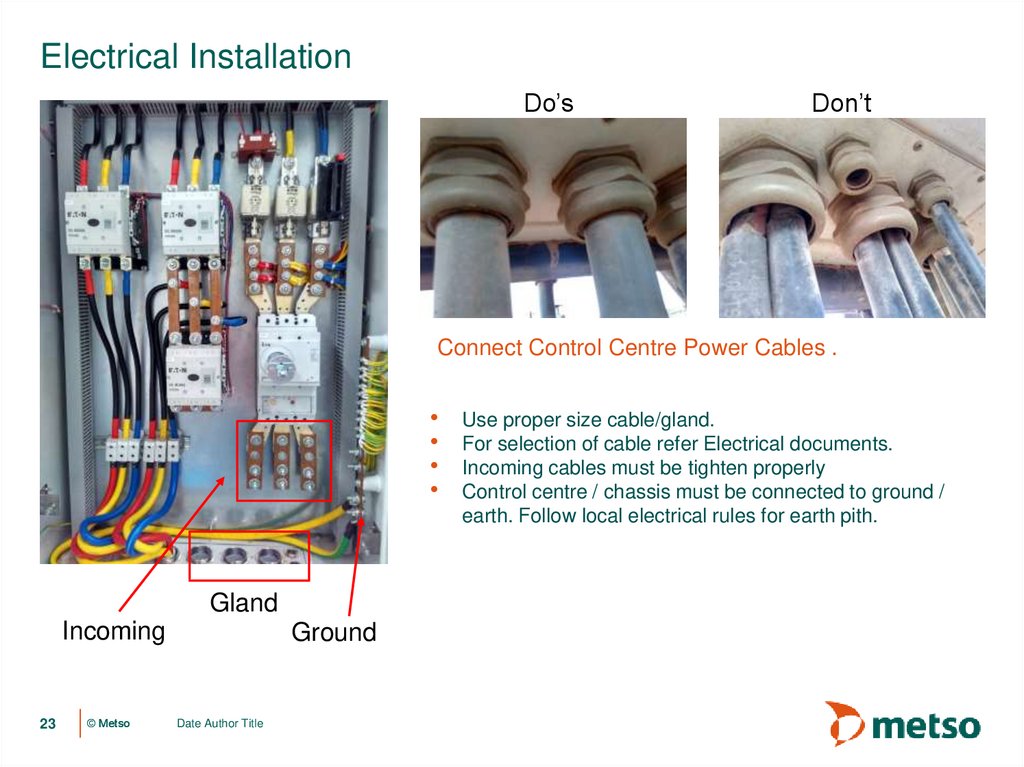

23. Connect Control Centre Power Cables .

Electrical InstallationDo’s

Don’t

Connect Control Centre Power Cables .

Gland

Incoming

23

© Metso

Ground

Date Author Title

Use proper size cable/gland.

For selection of cable refer Electrical documents.

Incoming cables must be tighten properly

Control centre / chassis must be connected to ground /

earth. Follow local electrical rules for earth pith.

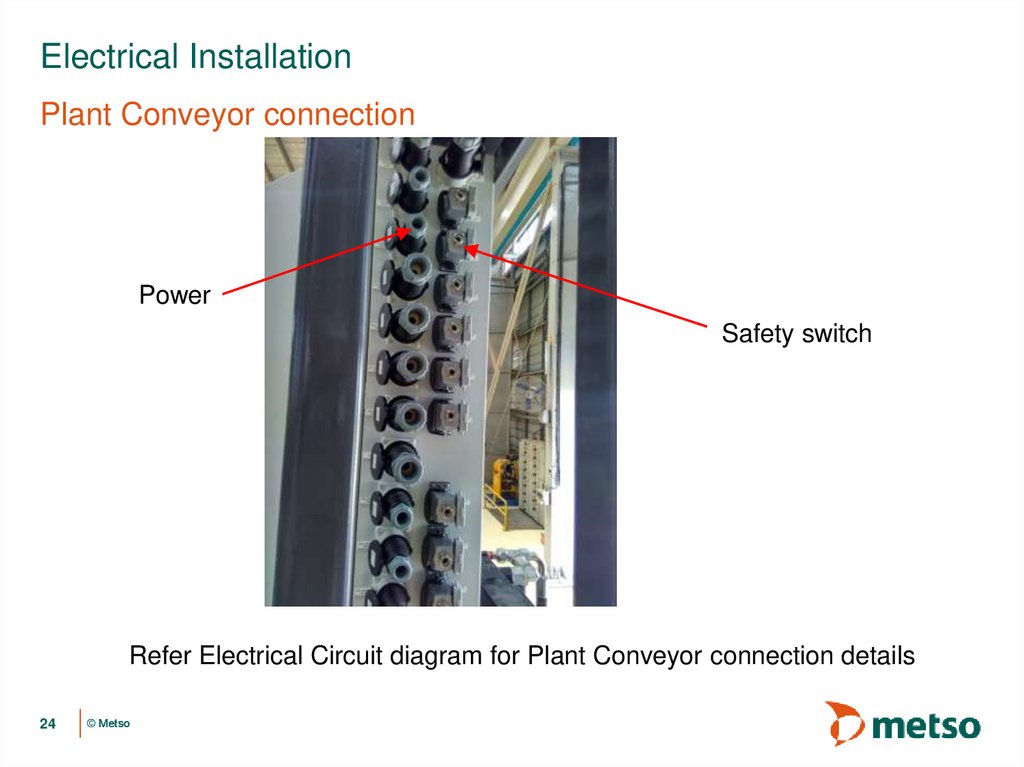

24.

Electrical InstallationPlant Conveyor connection

Power

Safety switch

Refer Electrical Circuit diagram for Plant Conveyor connection details

24

© Metso

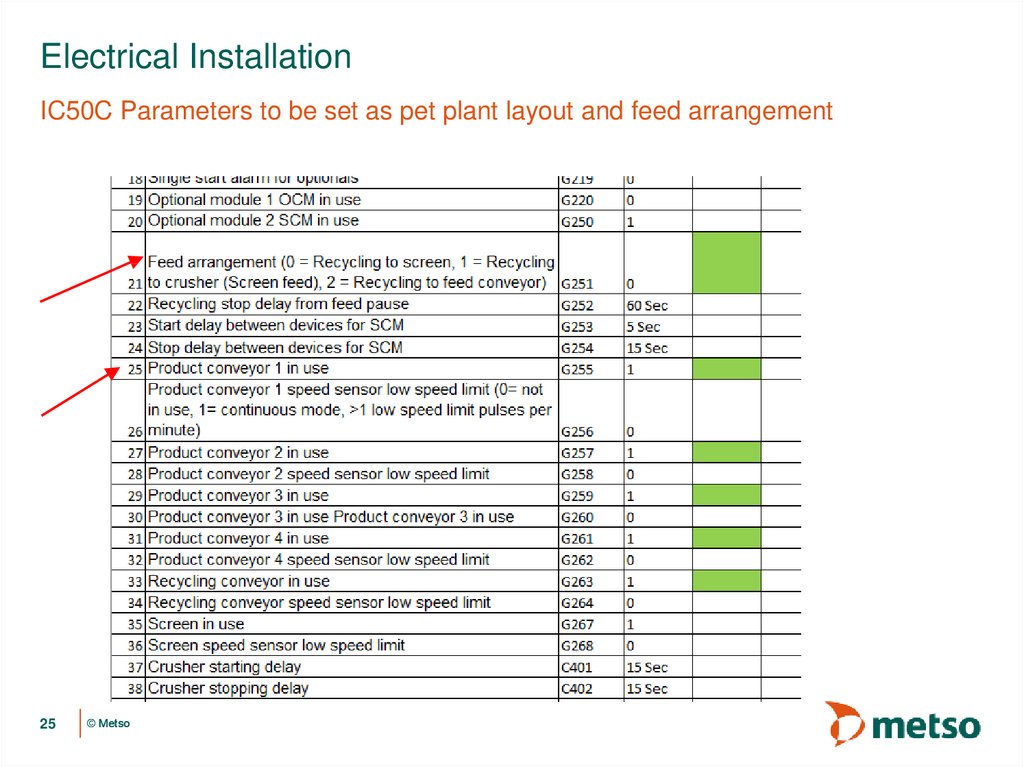

25.

Electrical InstallationIC50C Parameters to be set as pet plant layout and feed arrangement

25

© Metso

26.

www.metso.comcompany/metso

metsoworld

metsogroup

metsoworld

metsogroup

Механика

Механика