Похожие презентации:

International Journal of Civil Engineering and Technology (IJCIET)

1.

International Journal of Civil Engineering and Technology (IJCIET)Volume 8, Issue 2, February 2017, pp. 289–299 Article ID: IJCIET_08_02_031

Available online at http://www.iaeme.com/IJCIET/issues.asp?JType=IJCIET&VType=8&IType=2

ISSN Print: 0976-6308 and ISSN Online: 0976-6316

© IAEME Publication

Scopus Indexed

SEISMIC PROTECTION OF RC FRAMES USING

FRICTION DAMPERS

A.K. Sinha

Professor and Centre Director, Earthquake Safety Clinic and Centre, Department of Civil Engineering,

National Institute of Technology Patna, Patna, Bihar, India

Sharad Singh

Research Scholar, Structural Engineering, Department of Civil Engineering, National Institute of

Technology Patna, Patna, Bihar, India

ABSTRACT

The increasing infrastructural growth incurs large investments and large section of society

being served by them, it is necessary to make them safer against earthquakes and let people

feel confident in their structures. The need for structural response control has gained pace in

application around the globe. This paper discusses the use and effectiveness of one such

device, friction dampers, for response control of structures. In this paper a non-linear time

history analysis has been carried out on a 3D model of a 12 story RCC MRF building using 3directional synthetic accelerogram. Two different cases of building models with and without

friction dampers have been analyzed using ETABS. The response of the structure to seismic

excitation in terms of absolute maximum displacement and story drift has been compared.

Time history response plots have also been compared for various responses viz. roof

displacement and acceleration, base shear and story shear forces, along with the various

energy components and damping behavior. The results of the time history analysis are in close

conformation with previous investigations and represent the effectiveness of dampers in

improving the structural response as well as damping demand on structural systems.

Key words: Structural response control, Non-linear time history analysis, Friction dampers,

supplemental damping.

Cite this Article: A.K. Sinha and Sharad Singh, Seismic Protection of RC Frames Using

Friction Dampers. International Journal of Civil Engineering and Technology, 8(2), 2017, pp.

289–299.

http://www.iaeme.com/IJCIET/issues.asp?JType=IJCIET&VType=8&IType=2

1. INTRODUCTION

The dynamic behavior of structure reveals the manner in which the structure responds to external

excitation. The concept of structural response control has been active for more than a century and in

last few decades notable advancement has been done in the field to make it a practical solution. The

reduction of structural response caused by dynamic effects has become a subject of intensive research.

Several concepts have evolved in this advancement but with only a few implementations in practice.

Numerous motivation have conducted towards this research like reduction of undesirable vibrational

http://www.iaeme.com/IJCIET/index.asp

289

[email protected]

2.

Seismic Protection of RC Frames Using Friction Damperslevels, retrofitting existing structures, protecting equipment and important secondary systems and

eventually to provide new concepts of design of structures. The concept of response control dates long

back into history but the first known formal concept was introduced by James T.P. Yao in 1972 [11].

Until than several experimentations by individual investigators had already been carried out as early as

1890s.The structural control using energy dissipation which is based on modification of energy

absorption can be achieved in many ways [15]. For any structural system under dynamic loading the

entrant energy is dissipated naturally by various damping mechanisms acting simultaneously [3, 15].

A comprehensive review of PED concepts and application available in published literature [21] shows

that addition of PED devices to structural system reduces the excessive deformation and ductility

demands and at the same time enhances its energy dissipation capacity. The application to structural

systems to resist wind and earthquake induced vibration has only been known for a couple of decades

only after pioneering investigations of Housner in 1956 [11], on energy balance approach for design

procedure. The dynamic behavior of the structure installed with Friction Damper (FD) can be

represented by equation (1).

M ̈ + C ̇ + {Ku+ ∆ ℎ( )} =−M ̈ g

(1)

Where M is the mass matrix, C is the damping coefficient matrix, K is stiffness matrix, k0 is the

stiffness of damper brace system, ∆ is the displacement of the damper brace system, h(t) is hysteretic

variable for the friction damper, ̈ is acceleration, ̇ is velocity, u is displacement, and ̈ g is ground

acceleration.

The mass and stiffness contribution of damper brace system to the dynamic behavior of structures,

even though very small as compared to those of structural members, should be incorporated in

analysis. Investigations have been carried out to use FD in RC buildings for dynamic response control.

Various devices utilizing friction for energy dissipation have been developed and tested. Various

forms of friction have been used to reduce vibrations and the most popular type being solid friction

[21]. Friction devices do not change the inherent properties of the structure, their cost is relatively low,

and their installation and maintenance are simple [14]. Pall et.al developed friction joints (Pall

Friction dampers) for concrete walls and framed structures [16]. A series of static and dynamic tests

have been performed on passive friction dampers using various combinations of sliding materials and

surface treatments to identify one that provides a consistent and predictable response [16]. Various

modifications have been suggested in the friction damped bracing systems are the tension-only and

tension-compression bracing systems [18]. Investigations on proposals of Pall and Marsh [16] have

reaffirmed the practicality of FDs [6, 7, 10]. A superior performance of friction damped braced frames

(FDBFs) has been shown compared to traditional earthquake resisting systems [2, 6]. Furthermore

energy dissipation is concentrated in the dampers rather than due to the inelastic behavior of the

structural members. Translational FD depends on ground motion and hence for small excitation they

do not slip and dissipate energy. Research and applications around the globe demonstrate that friction

dampers represent an inexpensive and effective way to reduce seismic response parameters without

hampering the integrity of the structural elements [19]. Pall friction dampers also add stiffness to the

structure and a large amount of energy is dissipated through friction rather than any other mode where

a damping of 20 to 50% of critical is achieved. No external energy source is needed to operate and no

maintenance or replacement of device after earthquakes is needed [20]. Recent research on friction

dampers focuses mainly on their utilization as a (semi) active control system.

2. MATHEMATICAL MODEL FOR FRICTION DAMPER

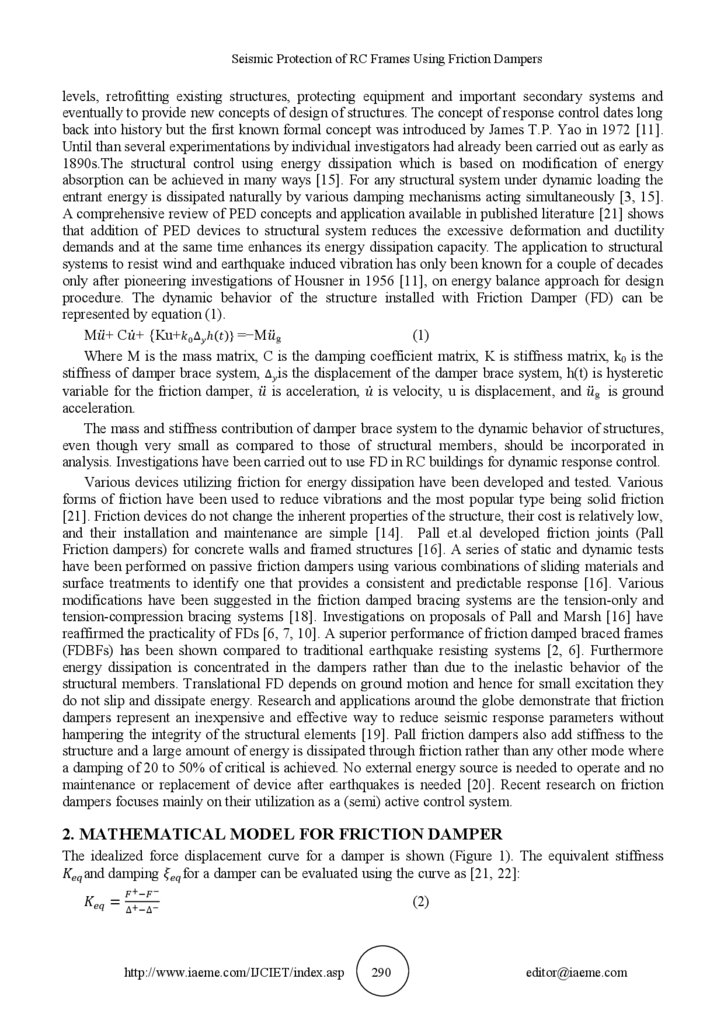

The idealized force displacement curve for a damper is shown (Figure 1). The equivalent stiffness

and damping

for a damper can be evaluated using the curve as [21, 22]:

=

∆

(2)

∆

http://www.iaeme.com/IJCIET/index.asp

290

[email protected]

3.

A.K. Sinha and Sharad Singh=

(3)

∆

Figure 1 A generalized force displacement curve for dampers to represent formulation of equation (2) and (3)

for linear dampers (dashed straight line) and for non-linear dampers (solid bilinear curve)

Where F is the force and Δ is the displacement and empirical expressions for

and

depends

upon material properties and characteristics. A damper is termed linear damper if equivalent stiffness

envelope is straight line, as shown in the Figure 1. For a non-linear damper, equivalent stiffness

envelope is not straight line, but can be bi-linear or tri-linear. The equivalent stiffness (or secant

stiffness) varies with the displacement, and can be obtained for any displacement as shown in the

Figure 1. Similarly, equivalent damping of nonlinear dampers also varies with the deformation level.

A damper is designed to give desired equivalent stiffness and damping characteristics. Empirical

expressions for

and

depending upon material properties and characteristics have been

presented. The basic force displacement and stiffness relationship is as same but with the difference in

their mechanism to dissipate energy. The formulation of this mechanism has been explained below [8,

9].

Cyclic force-deformation response of FD is characterized by rectangular hysteresis loop. The

behavior is represented in practice by rigid-perfectly-plastic models. The threshold force at which

device starts to deform continuously is called slip-load. The value of this parameter, denoted as ,

provides a complete definition of idealized model of device. The above description is sufficient to

display behavior of friction damper where the elements used to support and connect device to main

structural members is considered as rigid. The flexibility of bracings can be introduced in analysis.

This is accomplished by considering SR ratio between stiffness

of device-brace assembly and

structural stiffness . The relationship is given as [21, 22]:

=

;

(4)

=

For a friction element, stiffness of device is considered as infinitely large, i.e., ≈ ∞ and

stiffness

of friction assemblage becomes the same as stiffness of supporting bracing. That is,

=

;

(5)

=

The slip-load is then related to deformation ∆y experienced by device-brace assembly as

=

∆ = ∆

(6)

For design purposes, this equation is expressed in terms of stiffness parameter SR as

=

∆

(7)

This is the basic expression that relates mechanical parameters of friction element. From the

equation, it is observed that behavior of friction element is governed by slip load P s, stiffness ratio SR,

and displacement of bracing ∆ at which device starts to slip. However, only two of the variables are

http://www.iaeme.com/IJCIET/index.asp

291

[email protected]

4.

Seismic Protection of RC Frames Using Friction Dampersindependent since the third one can be determined from above expression. The hysteretic behavior of

friction element is also characterized using continuous Bouc-Wen’s model. Recognizing the absence

of any post-yielding or strain hardening effect, force P(t) developed in friction element is obtained as

( ) = ∆ ℎ( )

(8)

∆ ℎ( ̇ ) − ∆( ̇ ) + ∆( ̇ ) ℎ( )|ℎ( )|

+ ∆( ̇ )|ℎ( )| = 0

(9)

The model parameters H, Y, β and n can be adjusted to approximate the shape of hysteresis loop.

A value of n = 2, with H = 1 and Y+β = 1 (β = 0.1, Y = 0.9) have been proposed in the literature to

produce loops of frictional forces versus sliding displacements that are in good agreement with

experimental results. If flexibility of bracing is included in analysis, hysteretic loop of friction

assemblage is better approximated by use of a suitable value of exponent coefficient n. The remaining

model parameters, and ,is related to the mechanical properties of friction element. This is done by

considering that at slipping condition, hysteretic variable h(t) takes values of ±1, and friction element

force P(t) is equal to slip-load . Thus, it is easily shown that

=

(10)

;∆ =

3. PARAMETERIC CONSIDERATIONS

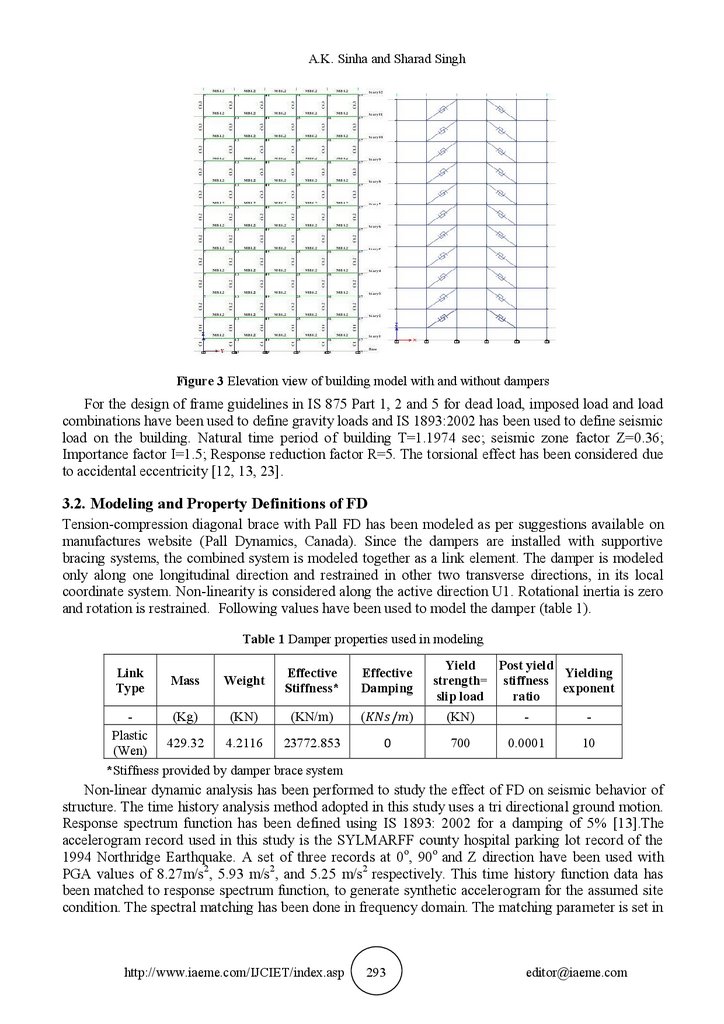

3.1. Structural Modeling

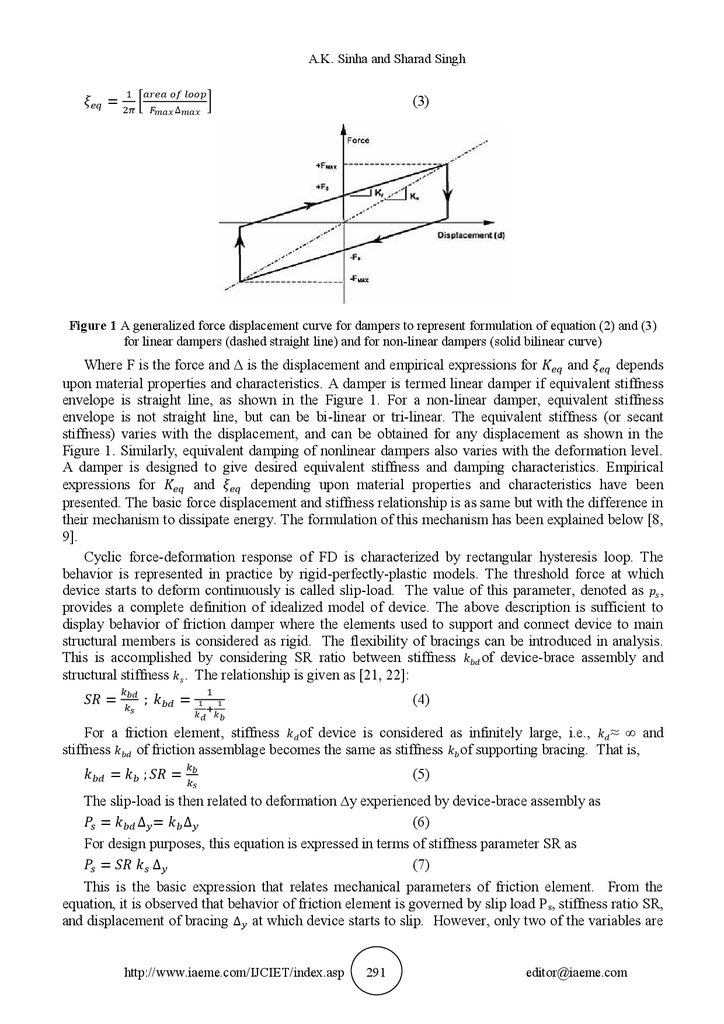

ETABS 2015 has been used to carry out this study. The building under consideration in this study is a

12 storey RCC special moment resistant frame. The schematics of building plan and elevation are

shown in figure 2 and 3. The plan is regular in shape and measures 21x21 m2. The total height of the

building is 40.2 m. The height of 1 st floor from ground floor is 3.2 m and the foundation is at 2 m

below the ground floor. All other storey heights above the 1st floor are 3.5 m. The base is fixed to

restrain in all 6 DOFs. A rigid diaphragm action has been considered for all the floors. A panel zone

has been considered for beam column connectivity with local axes along column, with inbuilt auto

inelastic properties. Non-linear hinges have been considered for frame elements [1, 23].

Figure 2 Plan view of building model

http://www.iaeme.com/IJCIET/index.asp

292

[email protected]

5.

A.K. Sinha and Sharad SinghFigure 3 Elevation view of building model with and without dampers

For the design of frame guidelines in IS 875 Part 1, 2 and 5 for dead load, imposed load and load

combinations have been used to define gravity loads and IS 1893:2002 has been used to define seismic

load on the building. Natural time period of building T=1.1974 sec; seismic zone factor Z=0.36;

Importance factor I=1.5; Response reduction factor R=5. The torsional effect has been considered due

to accidental eccentricity [12, 13, 23].

3.2. Modeling and Property Definitions of FD

Tension-compression diagonal brace with Pall FD has been modeled as per suggestions available on

manufactures website (Pall Dynamics, Canada). Since the dampers are installed with supportive

bracing systems, the combined system is modeled together as a link element. The damper is modeled

only along one longitudinal direction and restrained in other two transverse directions, in its local

coordinate system. Non-linearity is considered along the active direction U1. Rotational inertia is zero

and rotation is restrained. Following values have been used to model the damper (table 1).

Table 1 Damper properties used in modeling

Link

Type

Mass

Weight

Effective

Stiffness*

(Kg)

(KN)

(KN/m)

Plastic

429.32

4.2116

23772.853

(Wen)

*Stiffness provided by damper brace system

Effective

Damping

(

/ )

0

Yield

Post yield

Yielding

strength= stiffness

exponent

ratio

slip load

(KN)

-

-

700

0.0001

10

Non-linear dynamic analysis has been performed to study the effect of FD on seismic behavior of

structure. The time history analysis method adopted in this study uses a tri directional ground motion.

Response spectrum function has been defined using IS 1893: 2002 for a damping of 5% [13].The

accelerogram record used in this study is the SYLMARFF county hospital parking lot record of the

1994 Northridge Earthquake. A set of three records at 0o, 90o and Z direction have been used with

PGA values of 8.27m/s2, 5.93 m/s2, and 5.25 m/s2 respectively. This time history function data has

been matched to response spectrum function, to generate synthetic accelerogram for the assumed site

condition. The spectral matching has been done in frequency domain. The matching parameter is set in

http://www.iaeme.com/IJCIET/index.asp

293

[email protected]

6.

Seismic Protection of RC Frames Using Friction Dampersa frequency range of 0.01 cycles/sec to 100 cycles/sec. The 3 synthetic accelerogram in 3 directions

(U1, U2 and U3) are applied simultaneously, to create realistic ground motion condition [22, 23].

4. RESULTS AND DISCUSSION

For the modal analysis carried out for 12 modes following time periods have been noted down (tables

2) in each case for frame with and without supplemental damping. From the table for time period it

can be easily seen that the time period of the oscillation of the structure has shifted to lower values on

addition of dampers to the system to as much as 35% reduction in time period. The variation along the

modes is considerable [3, 4, 5].

Table 2 Time period for buildings with and without supplemental damping for various modes

Mode No.

1

2

3

4

5

6

7

8

9

10

11

12

Without FD

1.246

1.246

0.422

0.422

0.235

0.235

0.171

0.159

0.14

0.107

0.07

0.053

Time Period is in sec.

with FD

1.075

1.075

0.363

0.363

0.199

0.199

0.135

0.135

0.091

0.091

0.045

0.045

4.1. Results of Non-Linear Time History Analysis

The results of non-linear time history analysis (THA) have been studied for both storey responses in

terms of storey v/s storey response as well as time history functions of the responses. The storey

responses considered here are absolute maximum storey displacement (AMSD) and absolute

maximum storey drift (AMSd).

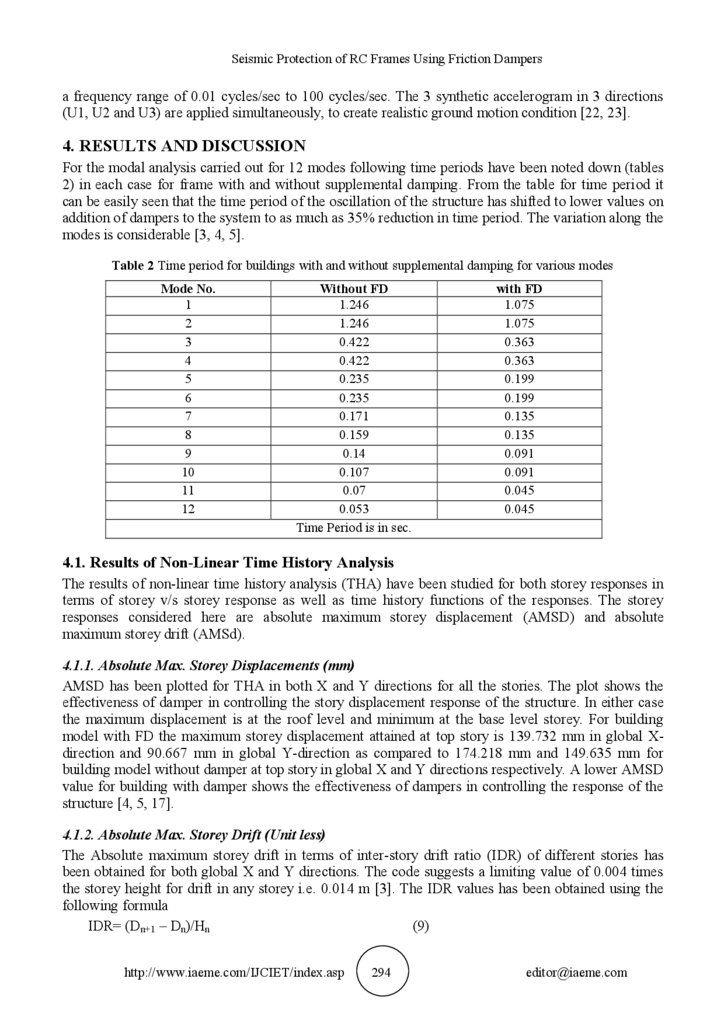

4.1.1. Absolute Max. Storey Displacements (mm)

AMSD has been plotted for THA in both X and Y directions for all the stories. The plot shows the

effectiveness of damper in controlling the story displacement response of the structure. In either case

the maximum displacement is at the roof level and minimum at the base level storey. For building

model with FD the maximum storey displacement attained at top story is 139.732 mm in global Xdirection and 90.667 mm in global Y-direction as compared to 174.218 mm and 149.635 mm for

building model without damper at top story in global X and Y directions respectively. A lower AMSD

value for building with damper shows the effectiveness of dampers in controlling the response of the

structure [4, 5, 17].

4.1.2. Absolute Max. Storey Drift (Unit less)

The Absolute maximum storey drift in terms of inter-story drift ratio (IDR) of different stories has

been obtained for both global X and Y directions. The code suggests a limiting value of 0.004 times

the storey height for drift in any storey i.e. 0.014 m [3]. The IDR values has been obtained using the

following formula

IDR= (Dn+1 – Dn)/Hn

(9)

http://www.iaeme.com/IJCIET/index.asp

294

[email protected]

7.

A.K. Sinha and Sharad SinghWhere, Dn+1 is the displacement of upper floor or n+1th floor, Dn is the displacement of lower floor

or nth floor and Hn is the storey height or floor separation for the given storey.

Figure 4 AMSD for building with and without supplemental damping in Global X and Y directions

Figure 5 IDR v/s storey plot for building with and without supplemental damping in Global X and Y Directions

The IDR plot shows that this value is exceeded in both the cases. The maximum value of IDR for

building without damper is 0.0068 and 0.0055 in global X and Y directions respectively at story 4.

Whereas the maximum value for building with damper is 0.0051 at story 4 in global X-direction and

0.0033 at story 5 in global Y-direction. The value of IDR has been controlled within the limiting value

of 0.004 in the case of building with FD except for stories 3,4 and 5 where it has exceeded the limiting

value in global X-direction. Even though the drift exceeds the limiting value for building with dampers

at storey 4 it is comparatively lower than the drift for building without damper.

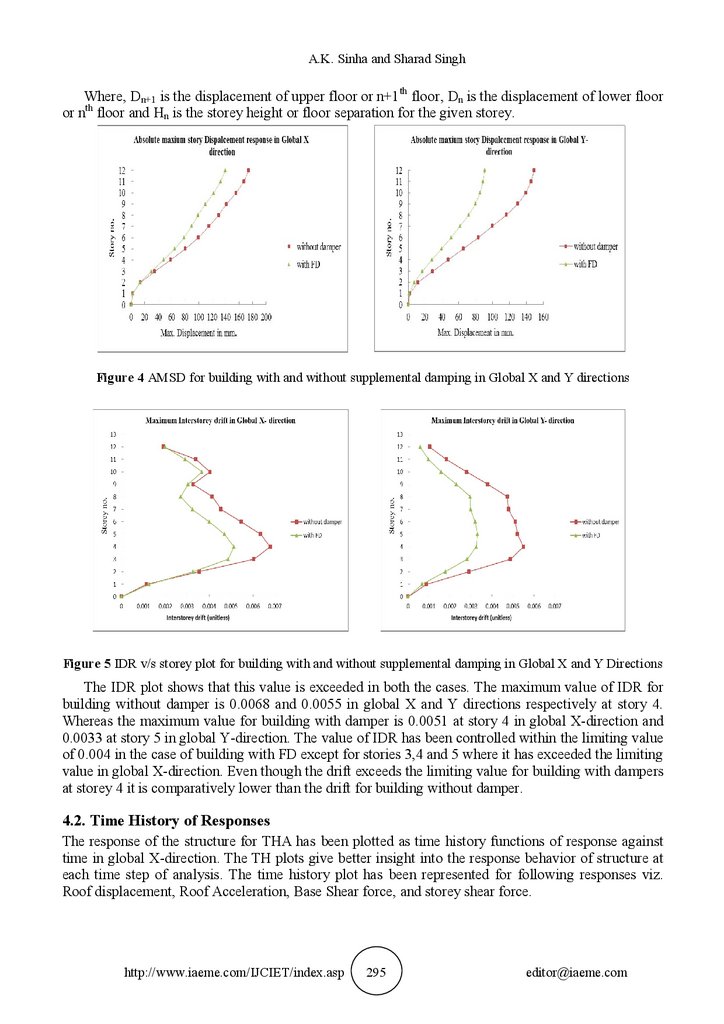

4.2. Time History of Responses

The response of the structure for THA has been plotted as time history functions of response against

time in global X-direction. The TH plots give better insight into the response behavior of structure at

each time step of analysis. The time history plot has been represented for following responses viz.

Roof displacement, Roof Acceleration, Base Shear force, and storey shear force.

http://www.iaeme.com/IJCIET/index.asp

295

[email protected]

8.

Seismic Protection of RC Frames Using Friction DampersFigure 6 Roof displacement and acceleration v/s time plots in global X-direction for building with and without

supplemental damping

4.2.1. Roof Displacement and Roof Acceleration

Roof displacement and acceleration are important parameters to analyze the response of structure

under dynamic loading and gives a better insight into performance of the structure as a whole. Plots of

roof displacement v/s time period and roof acceleration v/s time period for two building models with

and without supplemental damping under seismic loading have been generated. The displacement

plots reveal that displacement values for building without dampers is as high as 174.218 mm which is

subsequently lower for building model with FD with maximum displacement as high as 139.732 mm.

The use of dampers has successfully reduced the displacement values at all-time instances in

comparison to building without dampers and has managed to keep the overall displacement of building

within a limited range with smooth transitions preventing sudden reversal of displacement load.

Similar interpretation can be made for roof acceleration time history response. The roof acceleration

for building with damper is as high as 8.72 m/sec2 which is even higher than the maximum roof

acceleration of 5.99 m/sce2 for building without dampers.

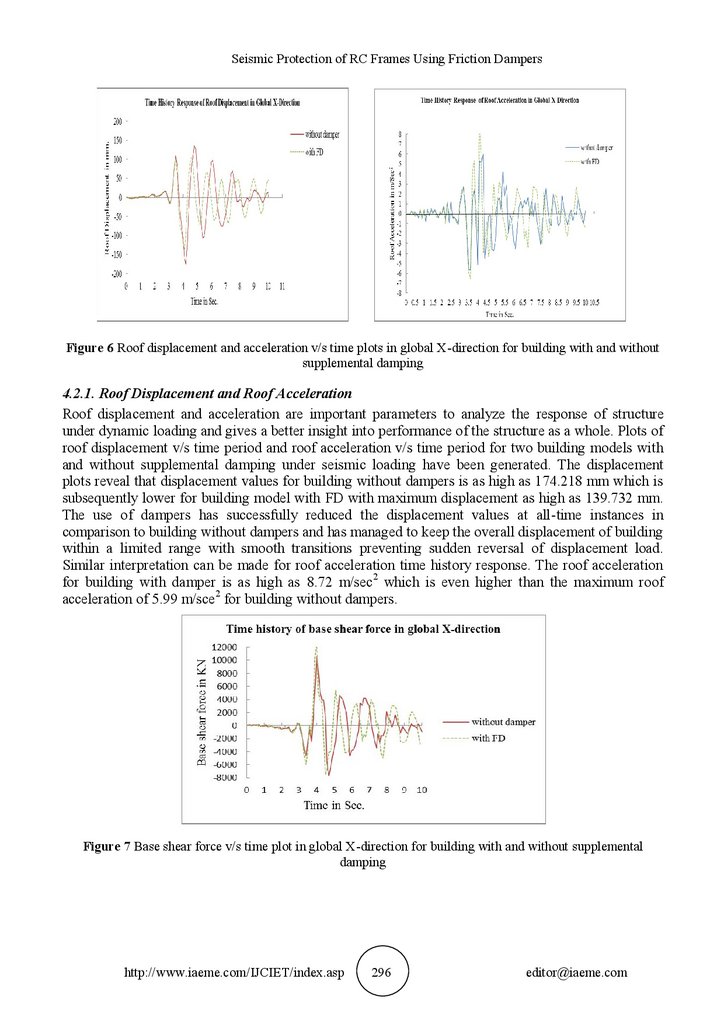

Figure 7 Base shear force v/s time plot in global X-direction for building with and without supplemental

damping

http://www.iaeme.com/IJCIET/index.asp

296

[email protected]

9.

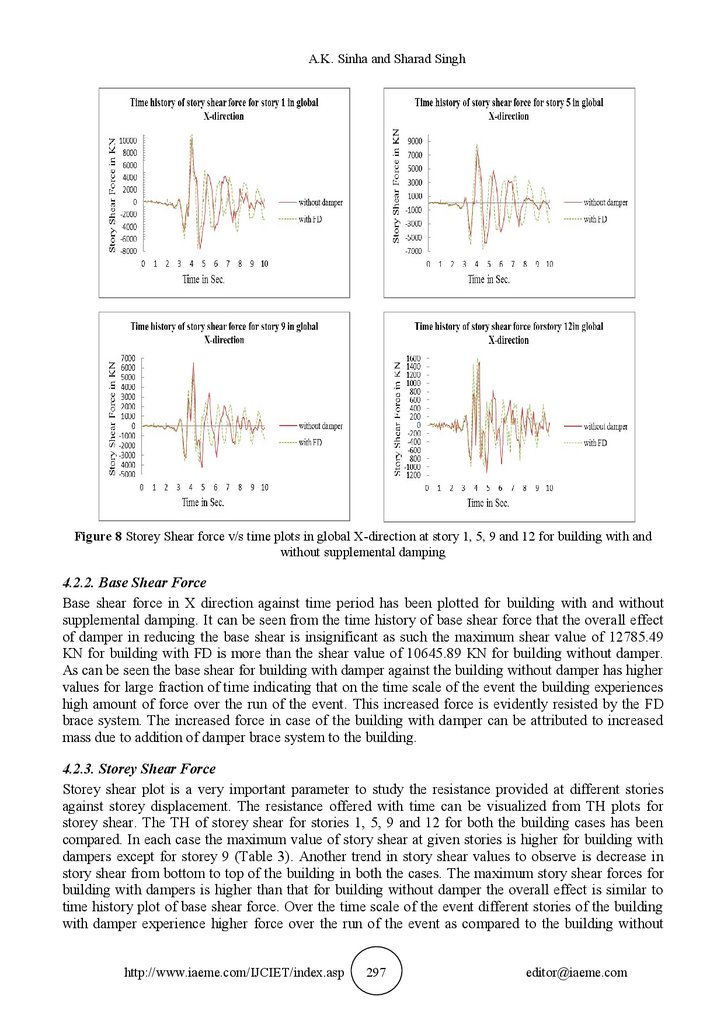

A.K. Sinha and Sharad SinghFigure 8 Storey Shear force v/s time plots in global X-direction at story 1, 5, 9 and 12 for building with and

without supplemental damping

4.2.2. Base Shear Force

Base shear force in X direction against time period has been plotted for building with and without

supplemental damping. It can be seen from the time history of base shear force that the overall effect

of damper in reducing the base shear is insignificant as such the maximum shear value of 12785.49

KN for building with FD is more than the shear value of 10645.89 KN for building without damper.

As can be seen the base shear for building with damper against the building without damper has higher

values for large fraction of time indicating that on the time scale of the event the building experiences

high amount of force over the run of the event. This increased force is evidently resisted by the FD

brace system. The increased force in case of the building with damper can be attributed to increased

mass due to addition of damper brace system to the building.

4.2.3. Storey Shear Force

Storey shear plot is a very important parameter to study the resistance provided at different stories

against storey displacement. The resistance offered with time can be visualized from TH plots for

storey shear. The TH of storey shear for stories 1, 5, 9 and 12 for both the building cases has been

compared. In each case the maximum value of story shear at given stories is higher for building with

dampers except for storey 9 (Table 3). Another trend in story shear values to observe is decrease in

story shear from bottom to top of the building in both the cases. The maximum story shear forces for

building with dampers is higher than that for building without damper the overall effect is similar to

time history plot of base shear force. Over the time scale of the event different stories of the building

with damper experience higher force over the run of the event as compared to the building without

http://www.iaeme.com/IJCIET/index.asp

297

[email protected]

10.

Seismic Protection of RC Frames Using Friction Dampersdamper. Again as stated for base shear force the higher value of story shear in case of building with

damper can be attributed to the increased mass by addition of damper brace systemat each story level.

Table 3 Maximum storey shear force for building with and without FD

Storey

Without FD

With FD

Storey 1

Storey 5

Storey 9

Storey 12

(KN)

10503.66361

12647.54961

(KN)

7689.719927

8602.891748

(KN)

6532.578515

4866.847959

(KN)

1512.290501

1631.295419

5. CONCLUSION

The results of the non-linear modal time history analysis conducted on a 12 story RC frame structure

with and without FD, represented using story responses and time history plots for various parameters,

demonstrate that the story response of the structure in form of AMSD and AMSd have been reduced

considerably by use of dampers. The time history plot of roof displacement shows considerable

reduction by use of dampers against the building without supplemental damping. The effectiveness of

dampers is evident in form of reduced storey responses and stress demands on structural elements and

indicates the nature of the FD which is a displacement based damper. The time history plot of roof

acceleration, base shear and storey shear reveals that by use of dampers there is an overall increase in

the value of these parameters which implies the ineffectiveness of FD in reducing the value of these

parameters. The increase forces in case of building with dampers has lower damaging effects on the

structural members as these forces are considerably shared by the damper brace system. The damping

demand on structural members is reduced due to frictional damping and hysteretic damping by damper

brace system. This indicates a lower hysteretic damping by structural members. A lower hysteretic

damping by structural members indicates that the structure shows less inelastic behaviour and remains

within elastic limit preventing damage to structural members. Even though the FDs have significantly

reduced the responses, the damping demand of structure can be further reduced by optimum selection

and installation of FDs at various critical locations.

REFERENCES

[1]

Austin, M. A. and Pister, K. S., (1985). "Design of Seismic-Resistant Friction-Braced Frames,"

Journal of Structural Engineering, 111, pp. 2751-2769.

[2]

Aiken I.D., Kelly J.M., Pall A.S., 1988, “Seismic Response of A Nine Storey Steel Frame with

Friction Damped Cross Bracing”, Report No. UCB/EERC-88/17, Earthquake Engineering Research

Centre of the University Of California, Berkeley, pp. 1-7.

[3]

Chopra A.K., 2007, “Dynamics of Structure- Theory and application to earthquake engineering”,

2nd edition. Prentice Hall of India Pvt Ltd, New Delhi.

[4]

Cherry, S. and Filiatrault, A., (1993). "Seismic Response Control of Buildings Using Friction

Dampers," Earthquake Spectra, 9, pp. 447-466.

[5]

Colajanni, P. and Papia, M., (1995). "Seismic Response of Braced Frames with and Without

Friction Dampers," Engineering Structures, 17, pp. 129-140.

[6]

Filiatrault, A. and Cherry, S., (1987). "Performance Evaluation of Friction Damped Braced Steel

Frames Under Simulated Earthquake Loads," Earthquake Spectra, 3, pp. 57-78.

[7]

Filiatrault, A. and Cherry, S., (1988). "Comparative Performance of Friction Damped Systems and

Base Isolation Systems for Earthquake Retrofit Systems for Earthquake Retrofit and Aseismic

Design," Earthquake Engineering and Structural Dynamics, 16, pp. 389-416.

[8]

Filiatrault, A. and Cherry, S., (1989a). "Efficient Numerical Modeling for the Design of Friction

Damped Braced Steel Plane Frames," Canadian Journal of Civil Engineering, 16, pp. 211-218.

http://www.iaeme.com/IJCIET/index.asp

298

[email protected]

11.

A.K. Sinha and Sharad Singh[9]

Filiatrault, A. and Cherry, S., (1989b). "Parameters Influencing the Design of Friction Damped

Structures," Canadian Journal of Civil Engineering, 16, pp. 753-766.

[10]

Filiatrault, A. and Cherry, S., (1990). "Seismic Design Spectra for Friction-Damped Structures,"

Journal of Structural Engineering, 116, pp. 1334-1355.

[11]

Housner, G. W., Bergman, L. A., Caughey, T. K., Chassiakos, A. G., Claus, R. O., Masri, S. F.,

Skelton, R. E., Soong, T. T., Spencer, B. F., and Yao, J. T. P., (1997). "Structural Control: Past,

Present, and Future," Journal of Engineering Mechanics, 123(9), pp. 897-971.

[12]

IS: 456 -2000, Code of Practice for Plain and Reinforced Concrete.

[13]

IS: 1893(Part-I)-2002, Criteria for Earthquake Resistant Design of Structures, Fifth Revision.

[14]

Mualla I.H., Belev B., 2002, “performance of steel frames with a new friction damper device under

earthquake excitation”, Engineering Structures, 24, pp. 365-371.

[15]

PankajAggarwal& Manish Shrikhande, “Earthquake resistant design of structures”, ISBN-81-2032892-2, Prentice Hall of India Pvt Ltd, M-97, Connaught Circus, New Delhi (India) 110001.

[16]

Pall, A. S., Marsh, C., and Fazio, P., (1980). "Friction Joints for Seismic Control of Large Panel

Structures," Journal of the Prestressed Concrete Institute, 25(6), pp. 38-61.

[17]

Pall, A. S. and Marsh, C., (1982). "Response of Friction Damped Braced Frames," Journal of

Structural Engineering, 108(ST6), pp. 1313-1323.

[18]

Pall A.S., 1983, “friction devices for aseismic design of buildings”, proceedings of IV Canadian

conference on earthquake engineering, pp. 475-484.

[19]

Pall, A. S. and Pall, R., (1993). "Friction-Dampers Used for Seismic Control of New and Existing

Buildings in Canada," ATC-17-1 Seminar on Seismic Isolation, Passive Energy Dissipation, and

Active Control, San Francisco, CA, pp. 675-686.

[20]

Pall A.S., Pall T., 2004, “performance based design using pall friction dampers-an economical

design solution”, proceedings of 13th world conference on earthquake engineering, Vancouver,

B.C., Canada, Paper no 1955.

[21]

Soong T.T., Dargush G.F., “Passive Energy Dissipation Systems In Structural Engineering”, ISBN

978-0-471-96821-4, John Wiley &Sons (Asia) Pte Ltd, 2 Clementi Loop, # 02-01, Singapore

129809, 1997.

[22]

T. K. Datta, Indian Institute Of Technology Delhi, India, “Seismic Analysis Of Structures”, ISBN

978-0-470-82461-0 (HB), John Wiley & Sons (Asia) Pte Ltd, 2 Clementi Loop, # 02-01, Singapore

129809, 2010.

[23]

A.K. Sinha and Sharad Singh, Structural Response Control of RCC Moment Resisting Frame Using

Fluid Viscous Dampers. International Journal of Civil Engineering and Technology, 8(1), 2017, pp.

900–910

[24]

M.E. Ephraim and T.C. Nwofor, Experimental Modeling of in Filled RC Frames with Opening,

International Journal of Civil Engineering and Technology, 7(2), 2016, pp. 95–106.

[25]

A.K. Sinha and Sharad Singh, Structural Response Control of RCC Moment Resisting Frame Using

Fluid Viscous Dampers. International Journal of Civil Engineering and Technology, 8(1), 2017,

pp. 900–910

http://www.iaeme.com/IJCIET/index.asp

299

[email protected]

Строительство

Строительство