Похожие презентации:

How to use tables of tolerances and fundamental deviations (Seminar 3)

1. Seminar 3: How to use tables of tolerances and fundamental deviations

Standardization and measurementassurance of engineering production

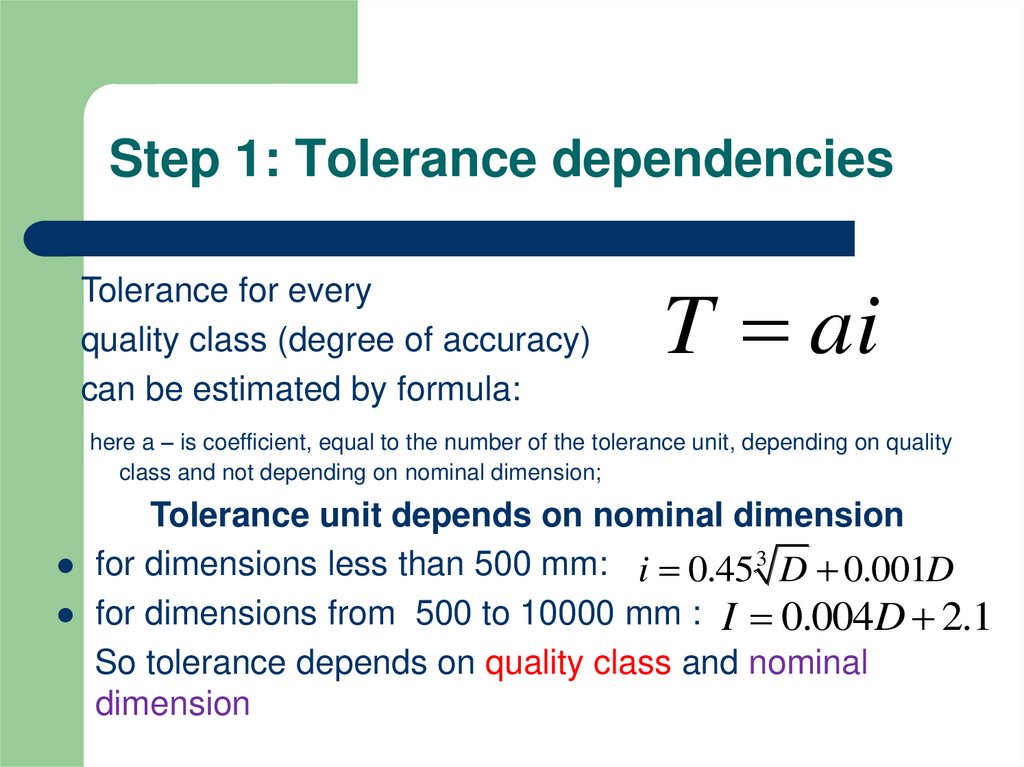

2. Step 1: Tolerance dependencies

Tolerance for everyquality class (degree of accuracy)

can be estimated by formula:

T ai

here a – is coefficient, equal to the number of the tolerance unit, depending on quality

class and not depending on nominal dimension;

Tolerance unit depends on nominal dimension

for dimensions less than 500 mm: i 0.45 3 D 0.001D

for dimensions from 500 to 10000 mm : I 0.004D 2.1

So tolerance depends on quality class and nominal

dimension

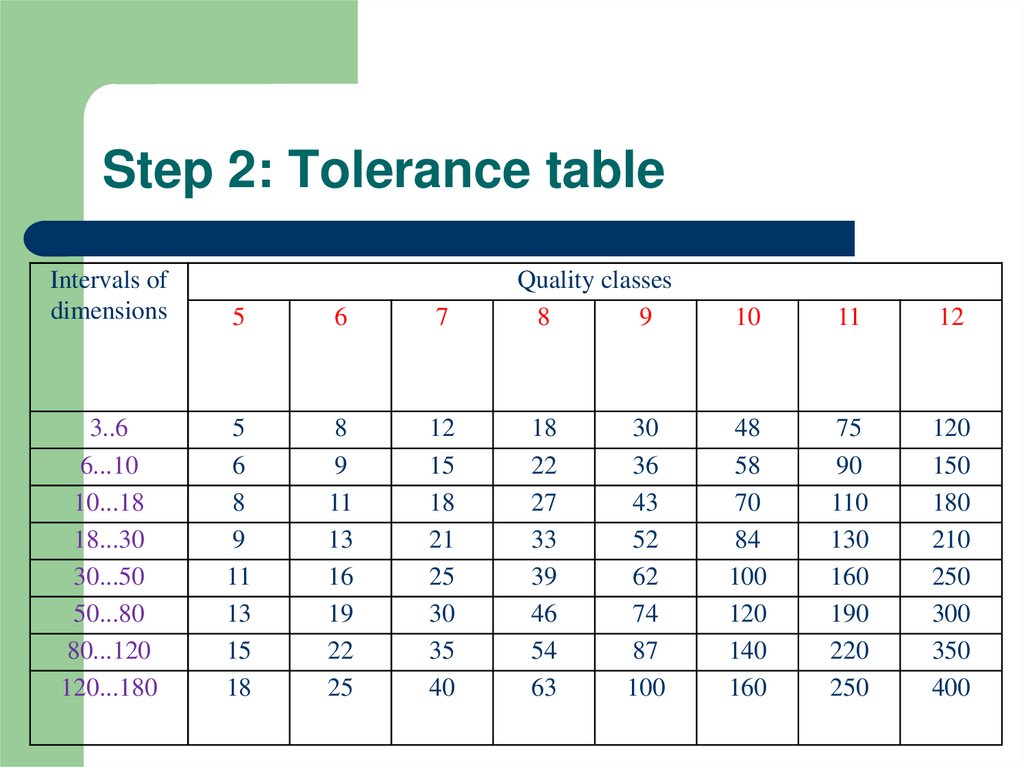

3. Step 2: Tolerance table

Intervals ofdimensions

5

6

7

3..6

6...10

10...18

18...30

30...50

50...80

80...120

120...180

5

6

8

9

11

13

15

18

8

9

11

13

16

19

22

25

12

15

18

21

25

30

35

40

Quality classes

8

9

18

22

27

33

39

46

54

63

30

36

43

52

62

74

87

100

10

11

12

48

58

70

84

100

120

140

160

75

90

110

130

160

190

220

250

120

150

180

210

250

300

350

400

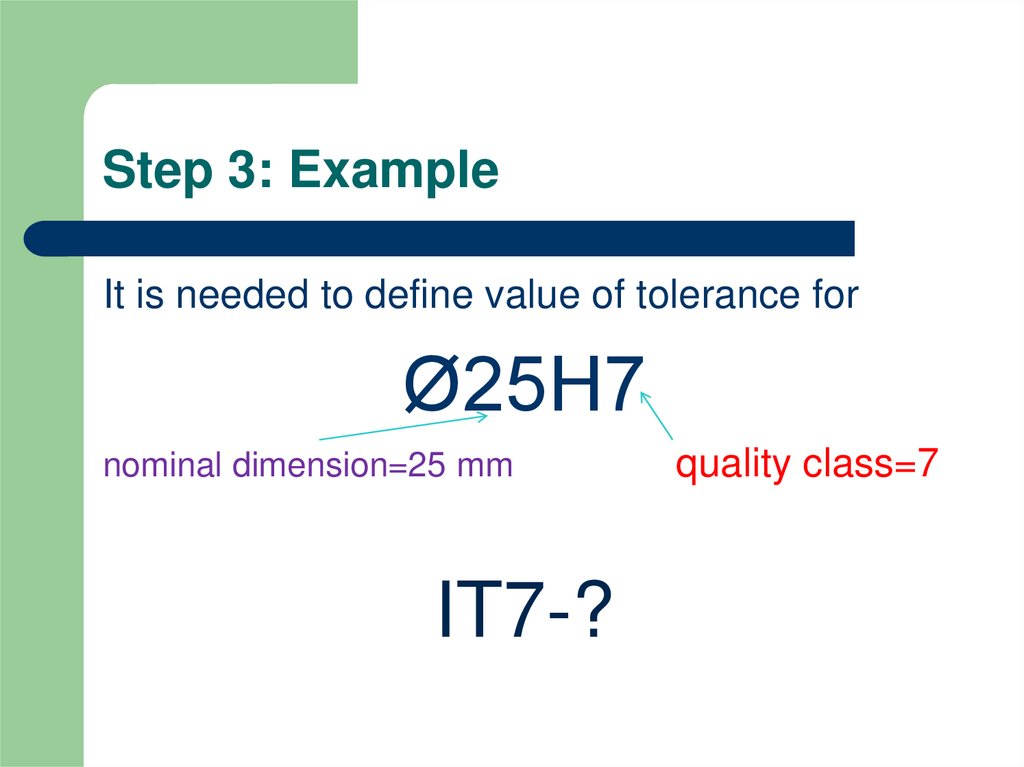

4. Step 3: Example

It is needed to define value of tolerance forØ25H7

nominal dimension=25 mm

IT7-?

quality class=7

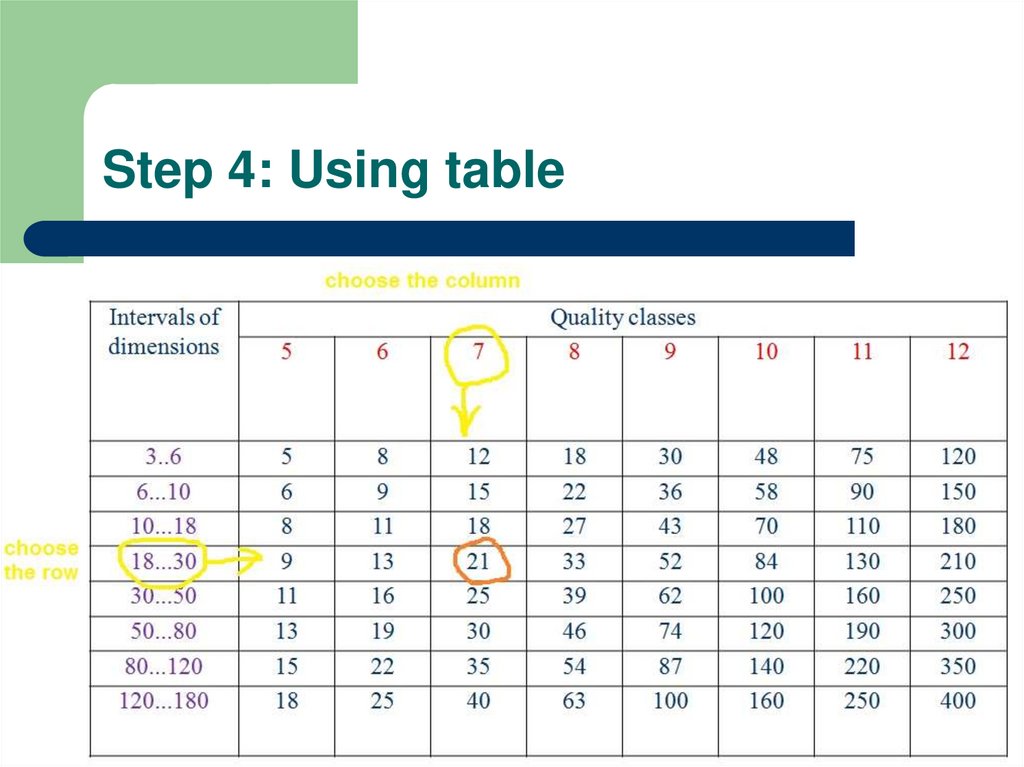

5. Step 4: Using table

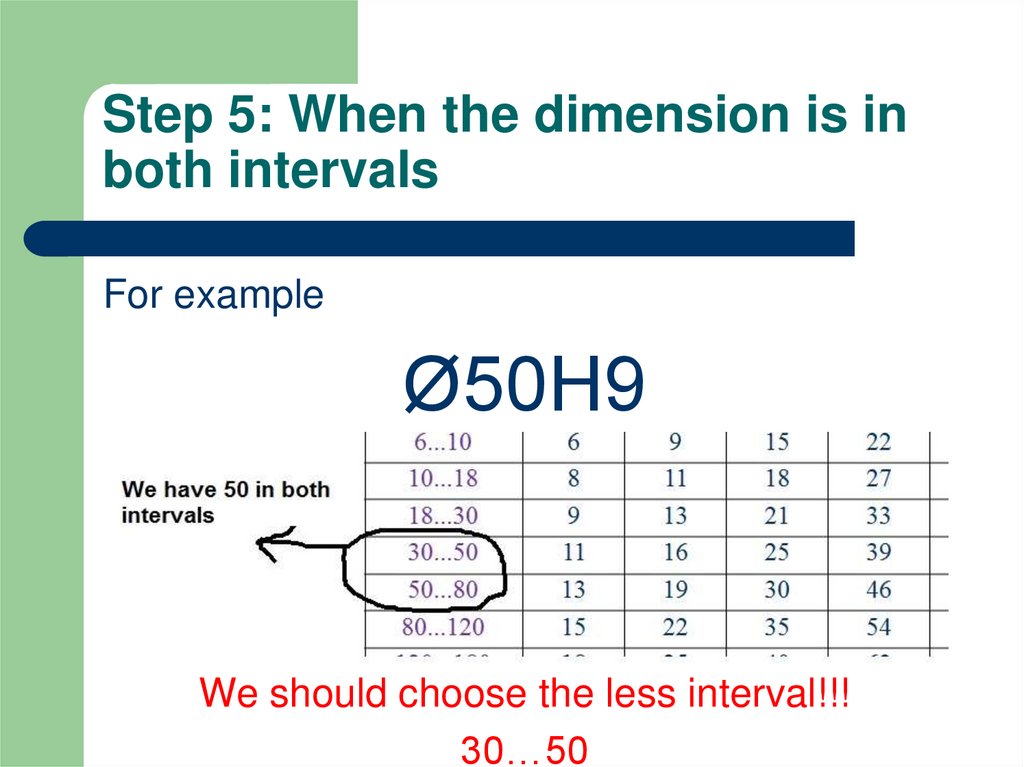

6. Step 5: When the dimension is in both intervals

For exampleØ50H9

We should choose the less interval!!!

30…50

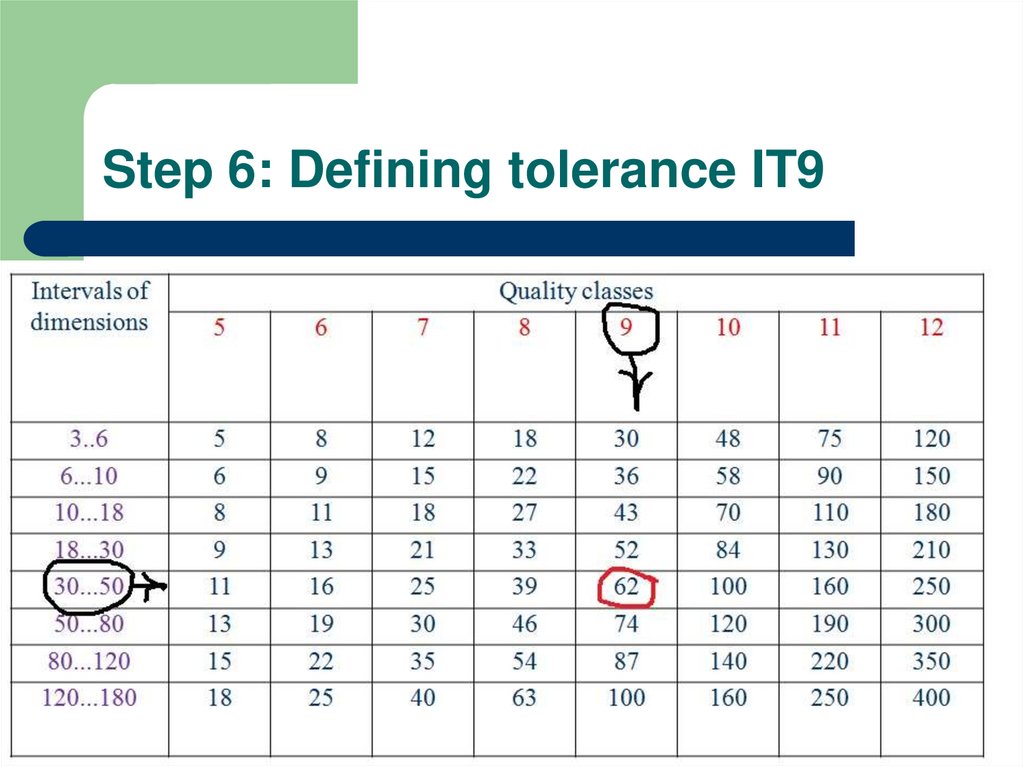

7. Step 6: Defining tolerance IT9

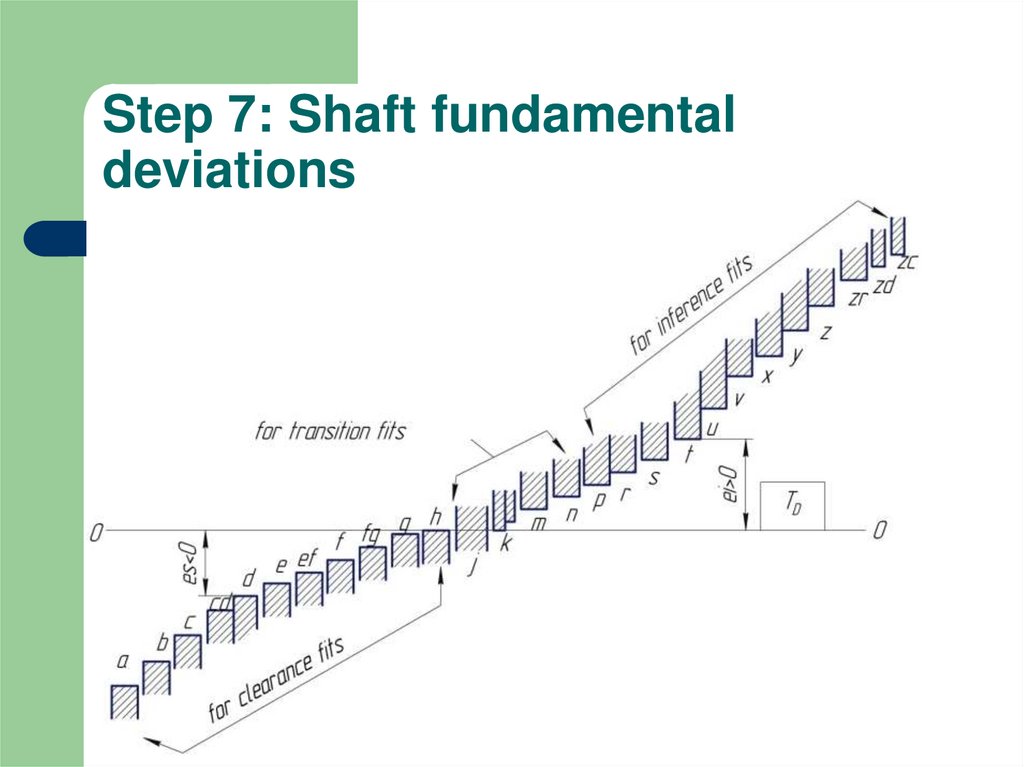

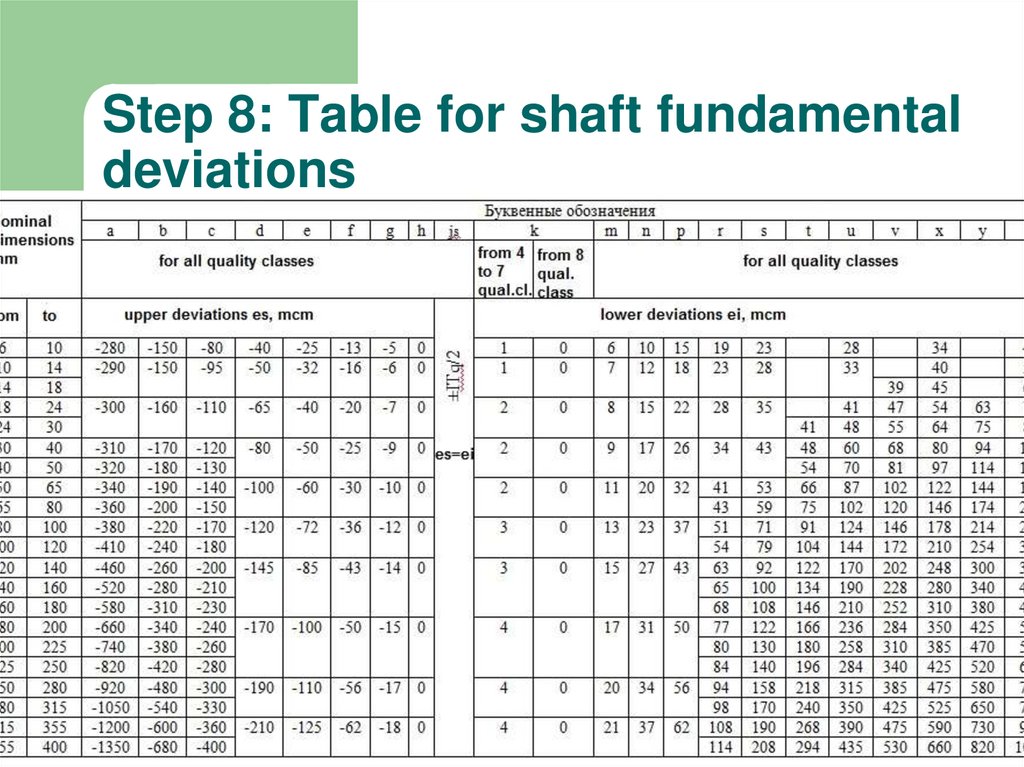

8. Step 7: Shaft fundamental deviations

9. Step 8: Table for shaft fundamental deviations

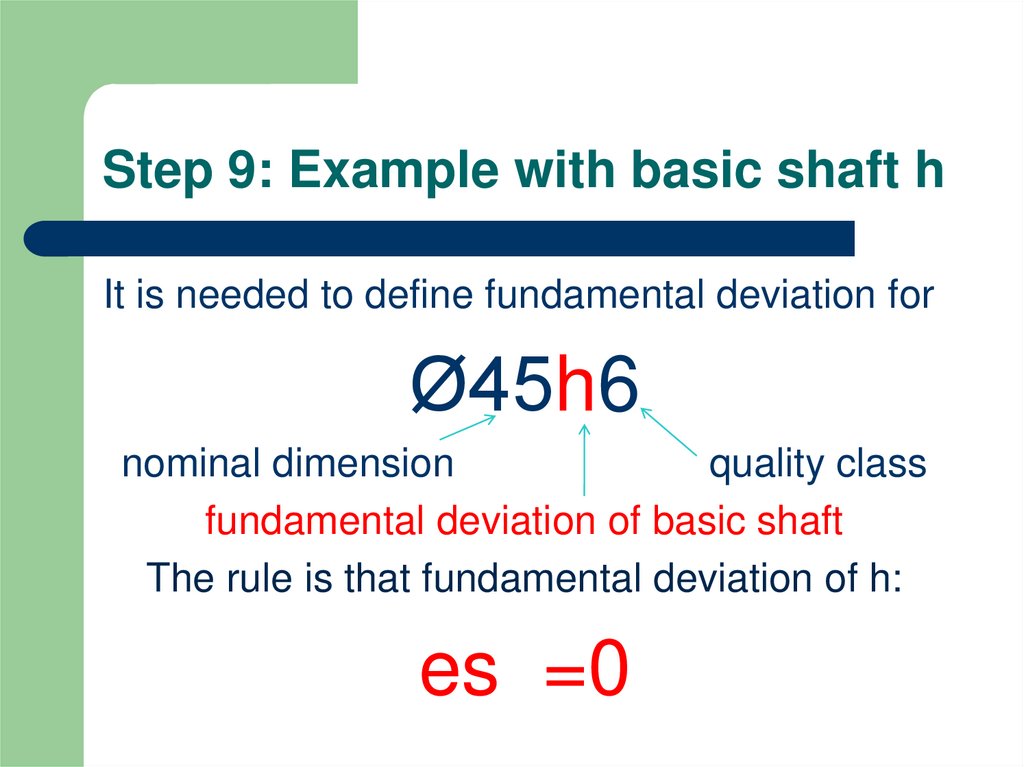

10. Step 9: Example with basic shaft h

It is needed to define fundamental deviation forØ45h6

nominal dimension

quality class

fundamental deviation of basic shaft

The rule is that fundamental deviation of h:

es =0

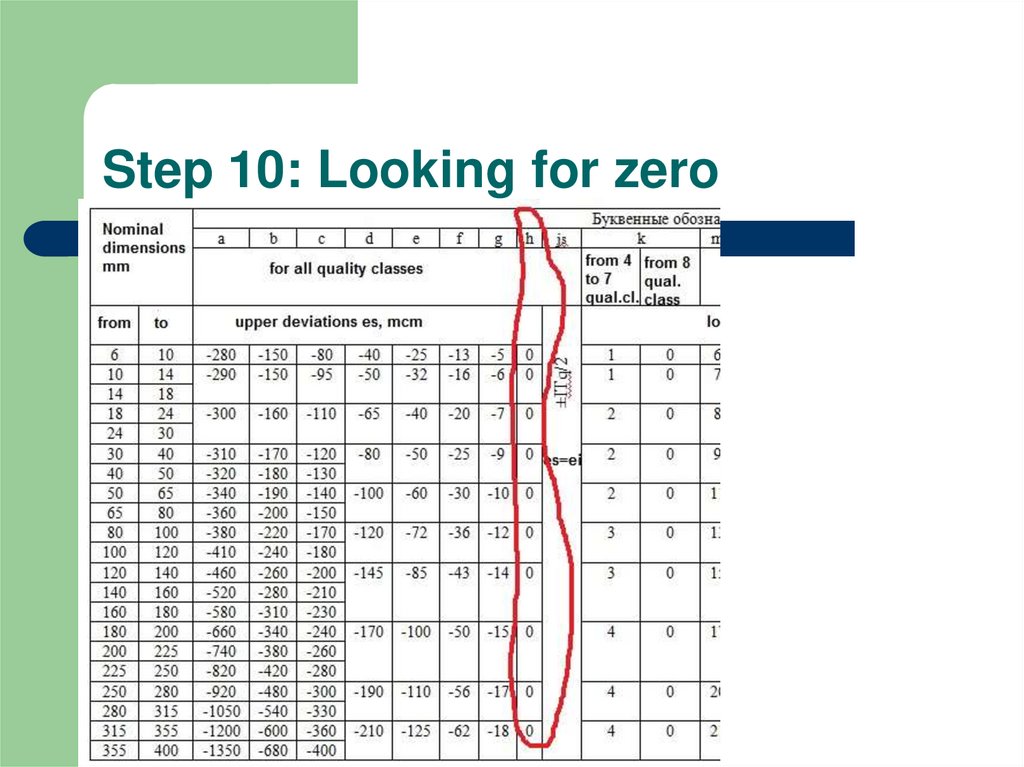

11. Step 10: Looking for zero

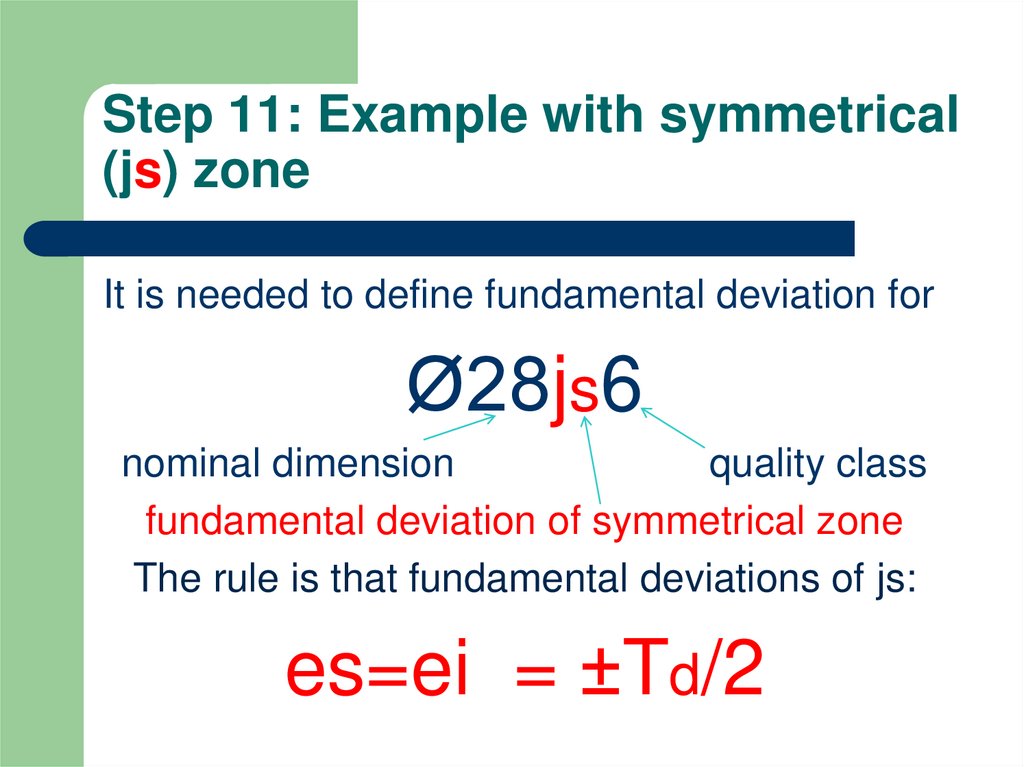

12. Step 11: Example with symmetrical (js) zone

It is needed to define fundamental deviation forØ28js6

nominal dimension

quality class

fundamental deviation of symmetrical zone

The rule is that fundamental deviations of js:

es=ei = ±Td/2

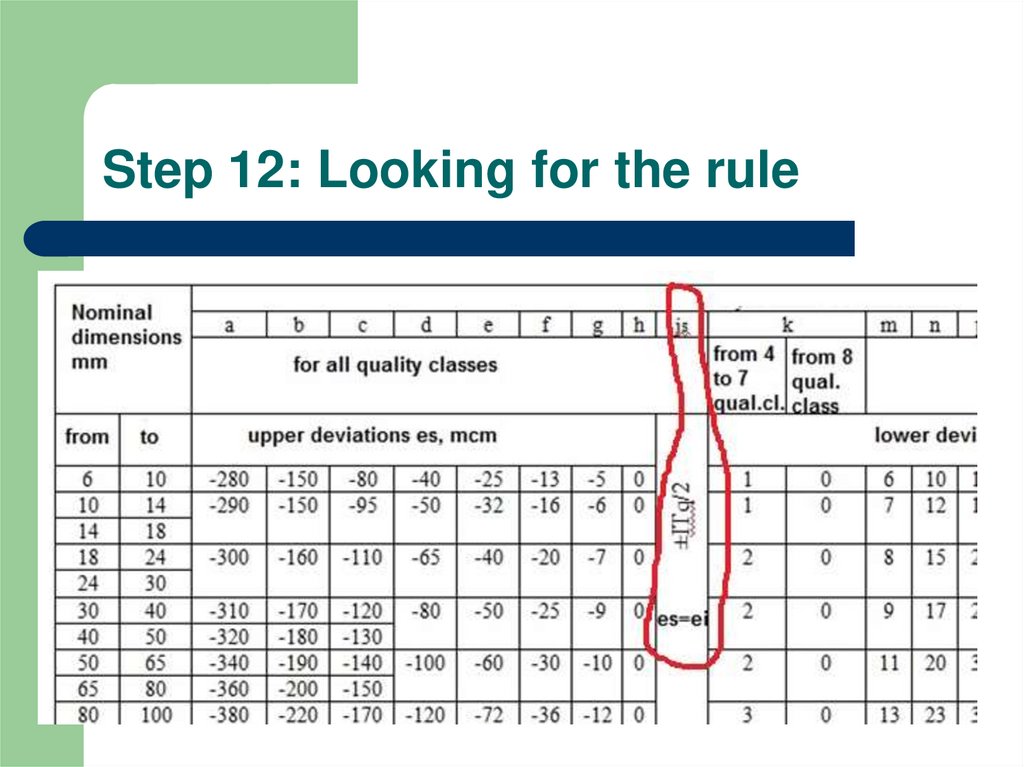

13. Step 12: Looking for the rule

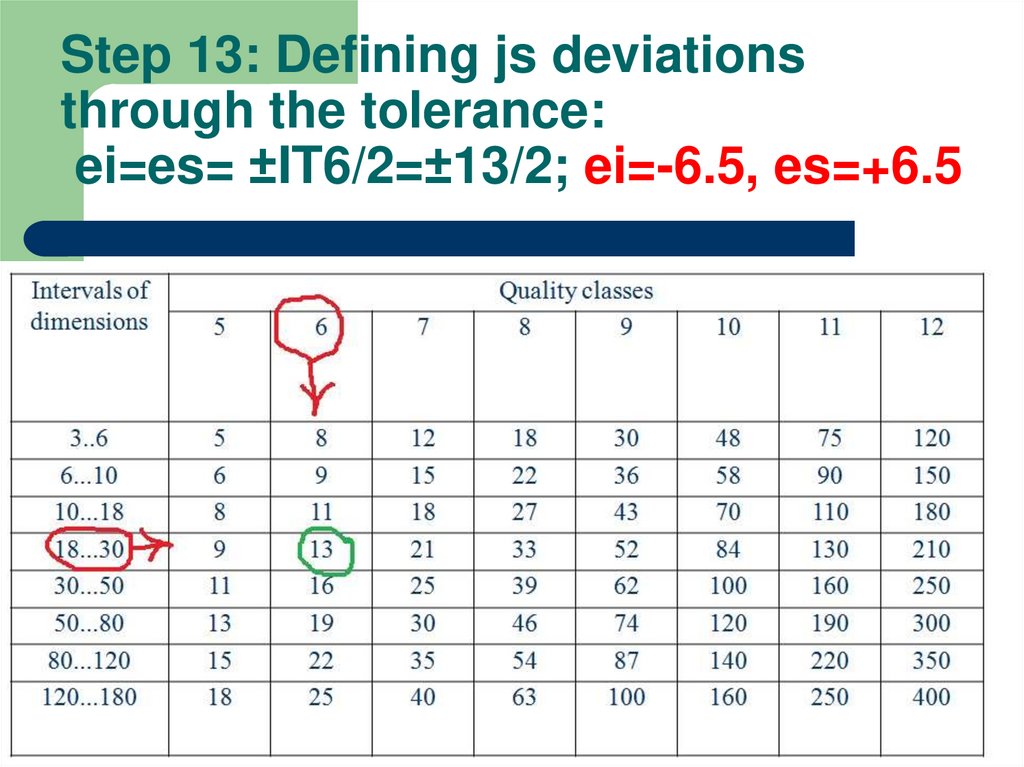

14. Step 13: Defining js deviations through the tolerance: ei=es= ±IT6/2=±13/2; ei=-6.5, es=+6.5

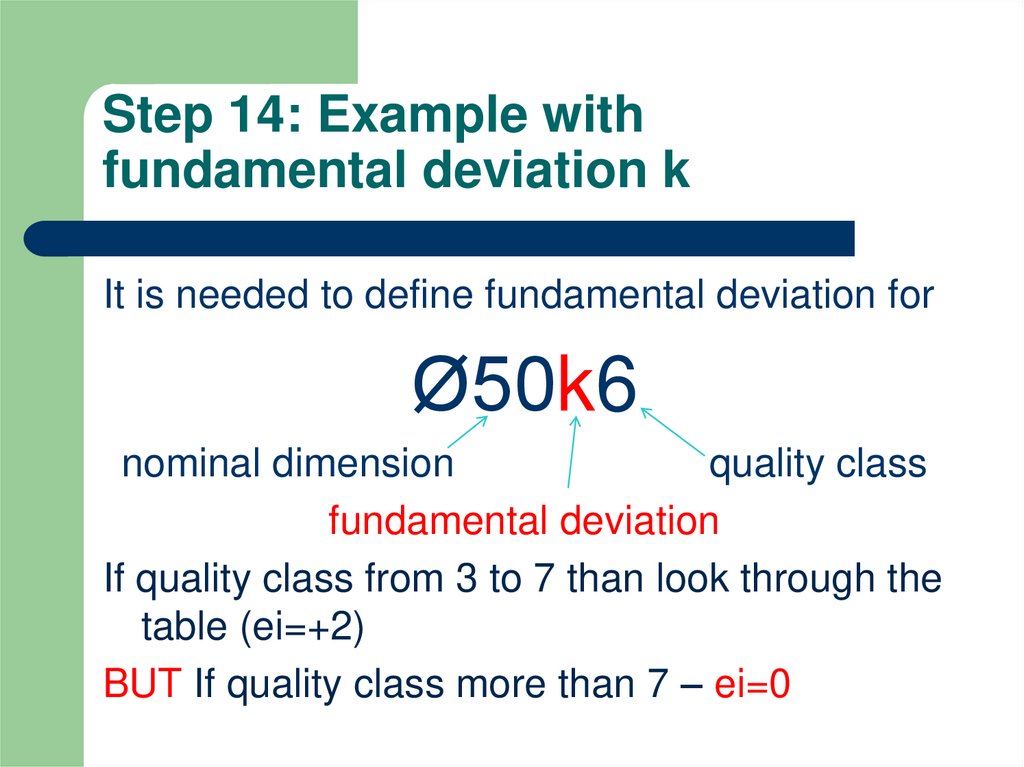

15. Step 14: Example with fundamental deviation k

It is needed to define fundamental deviation forØ50k6

nominal dimension

quality class

fundamental deviation

If quality class from 3 to 7 than look through the

table (ei=+2)

BUT If quality class more than 7 – ei=0

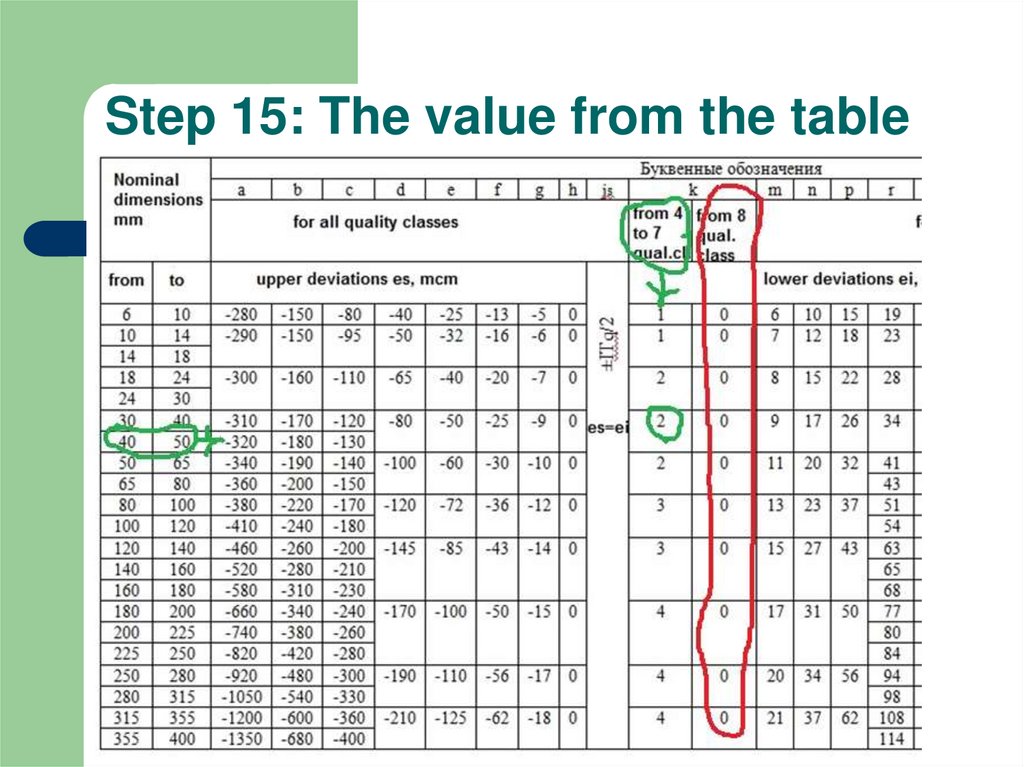

16. Step 15: The value from the table

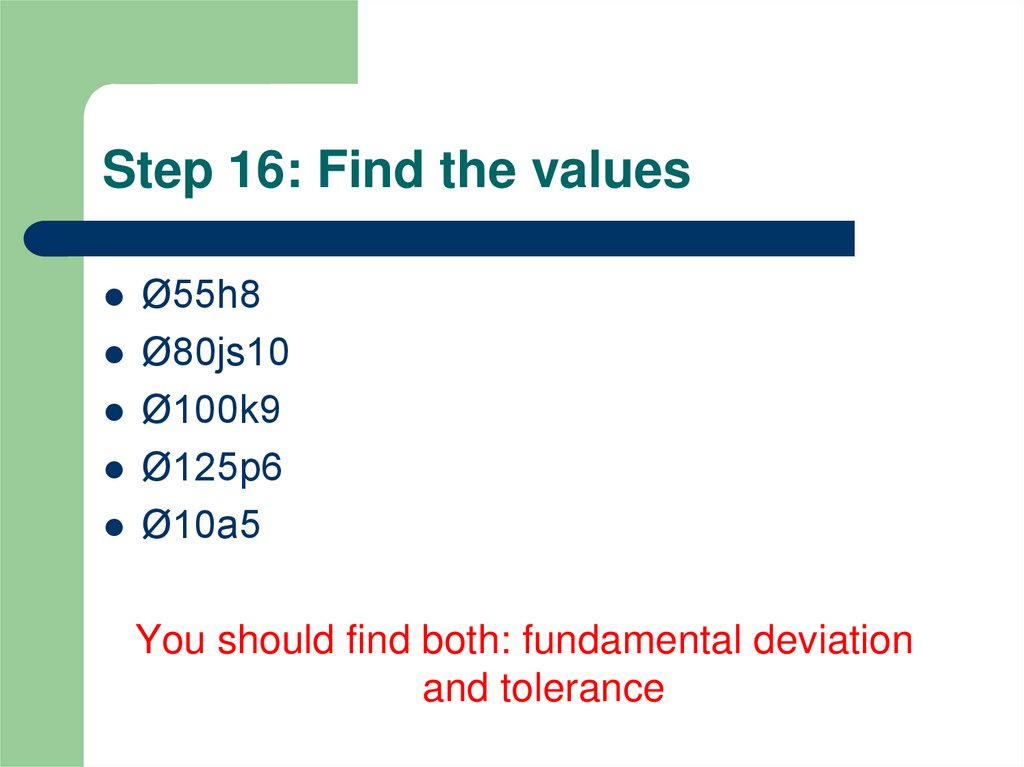

17. Step 16: Find the values

Ø55h8Ø80js10

Ø100k9

Ø125p6

Ø10a5

You should find both: fundamental deviation

and tolerance